Fuel Pelletization of Digestate: A Pathway to Renewable and Sustainable Energy Sources

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

- —combustion calorific of the analysed fuel (GCV) (MJ/kg),

- C—calorimeter heat capacity (J/°C),

- Dt—the overall temperature rise of the main period (°C),

- k—correction for environmental heat exchange (°C),

- c—correction sum for the additional heat effects (J),

- m—fuel sample mass (g).

- —calorific value of the analysed fuel in the analytical state (NCV) (MJ/kg),

- —combustion calorific of the analysed fuel (GCV) (MJ/kg),

- Wa—moisture content of test sample (%),

- Ha—hydrogen content of test sample (%).

- do = 6—diameter of matrix holes (mm);

- Qm = 50—consumption of mixture (kg/h);

- nr = 150—rotational frequency of the compaction roller systems (rpm);

- hr = 0.2—gap between the rollers and the matrix (mm).

3. Results

3.1. Qualitative Parameters of Produced Pellets

3.2. Calorific Value of Pellets

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ignatowicz, K.; Filipczak, G.; Dybek, B.; Wałowski, G. Biogas Production Depending on the Substrate Used: A Review and Evaluation Study—European Examples. Energies 2023, 16, 798. [Google Scholar] [CrossRef]

- Kupryaniuk, K.; Witaszek, K.; Vaskina, I.; Filipek-Kaźmierczak, S.; Kupryaniuk, J.; Sołowiej, P.; Dach, J. The Effect of Corn Ensiling Methods on Digestibility and Biogas Yield. Energies 2025, 18, 188. [Google Scholar] [CrossRef]

- Lisiak-Zielińska, M.; Jałoszyńska, S.; Borowiak, K.; Budka, A.; Dach, J. Perception of Biogas Plants: A Public Awareness and Preference—A Case Study for the Agricultural Landscape. Renew. Energy 2023, 217, 119212. [Google Scholar] [CrossRef]

- Vaskina, I.; Hopkalo, D.; Vaskin, R.; Pochwatka, P. Potential of Landfill Gas Extraction in North-East Ukraine. J. Ecol. Eng. 2024, 25, 258–270. [Google Scholar] [CrossRef]

- Skrzypczak, D.; Trzaska, K.; Mikula, K.; Gil, F.; Izydorczyk, G.; Mironiuk, M.; Polomska, X.; Moustakas, K.; Witek-Krowiak, A.; Chojnacka, K. Conversion of Anaerobic Digestates from Biogas Plants: Laboratory Fertilizer Formulation, Scale-up and Demonstration of Applicative Properties on Plants. Renew. Energy 2023, 203, 506–517. [Google Scholar] [CrossRef]

- Czubaszek, R.; Wysocka-Czubaszek, A.; Banaszuk, P. Importance of Feedstock in a Small-Scale Agricultural Biogas Plant. Energies 2022, 15, 7749. [Google Scholar] [CrossRef]

- Ablieieva, I.; Geletukha, G.; Kucheruk, P.; Enrich-Prast, A.; Carraro, G.; Berezhna, I.; Berezhnyi, D. Digestate Potential to Substitute Mineral Fertilizers: Engineering Approaches. JES 2022, 9, H1–H10. [Google Scholar] [CrossRef]

- Nongbet, A.; Mohata, Y.; Hakeem, K.; Chakrabartty, I. Biofuels: Opportunities, Challenges, Risks, and Sustainability. In The Microbiology of the Drop-In Biofuel Production; Springer: Berlin/Heidelberg, Germany, 2024; pp. 1–13. ISBN 978-3-031-61636-5. [Google Scholar]

- Cathcart, A.; Smyth, B.M.; Lyons, G.; Murray, S.T.; Rooney, D.; Johnston, C.R. An Economic Analysis of Anaerobic Digestate Fuel Pellet Production: Can Digestate Fuel Pellets Add Value to Existing Operations? Clean. Eng. Technol. 2021, 3, 100098. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Golkowska, K.; Lebuf, V.; Vaneeckhaute, C.; Michels, E.; Meers, E.; Benetto, E.; Koster, D. Environmental Assessment of Digestate Treatment Technologies Using LCA Methodology. Waste Manag. 2015, 43, 442–459. [Google Scholar] [CrossRef]

- Łysiak, G.; Kulig, R.; Kowalczyk-Juśko, A. Toward New Value-Added Products Made from Anaerobic Digestate: Part 2—Effect of Loading Level on the Densification of Solid Digestate. Sustainability 2023, 15, 7396. [Google Scholar] [CrossRef]

- Geletukha, G.; Zheliezna, T. Prospects for Bioenergy Development in Ukraine: Roadmap until 2050. Ecol. Eng. Environ. Technol. 2021, 22, 73–81. [Google Scholar] [CrossRef]

- Abdelfatah-Aldayyat, E.; González-Rojo, S.; Gómez, X. Reviewing Digestate Thermal Valorization: Focusing on the Energy Demand and the Treatment of Process Water. Environments 2024, 11, 239. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R.; Miles, T.R. Combustion Properties of Biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Werther, J.; Saenger, M.; Hartge, E.-U.; Ogada, T.; Siagi, Z. Combustion of Agricultural Residues. Prog. Energy Combust. Sci. 2000, 26, 1–27. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Lachman, J.; Baláš, M.; Lisý, M.; Lisá, H.; Milčák, P.; Elbl, P. An Overview of Slagging and Fouling Indicators and Their Applicability to Biomass Fuels. Fuel Process. Technol. 2021, 217, 106804. [Google Scholar] [CrossRef]

- Pochwatka, P.; Kowalczyk-Juśko, A.; Pituła, M.; Mazur, A.; Vaskina, I.; Dach, J. Energetic Potential of Tobacco Waste Within Combustion or Anaerobic Digestion. Energies 2025, 18, 762. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Barnthaler, G. Chemical Properties of Solid Biofuels—Significance and Impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Williams, A.; Jones, J.M.; Ma, L.; Pourkashanian, M. Pollutants from the Combustion of Solid Biomass Fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Czekała, W.; Bartnikowska, S.; Dach, J.; Janczak, D.; Smurzyńska, A.; Kozłowski, K.; Bugała, A.; Lewicki, A.; Cieślik, M.; Typańska, D.; et al. The Energy Value and Economic Efficiency of Solid Biofuels Produced from Digestate and Sawdust. Energy 2018, 159, 1118–1122. [Google Scholar] [CrossRef]

- Milčák, P.; Baláš, M.; Lisý, M.; Lisá, H.; Kracík, P.; Lachman, J. Digestate and Woodchips Gasification: A Comparison of Different Gasifying Agents. Fuel Process. Technol. 2024, 258, 108091. [Google Scholar] [CrossRef]

- Whitely, N.; Ozao, R.; Artiaga, R.; Cao, Y.; Pan, W.-P. Multi-Utilization of Chicken Litter as Biomass Source. Part I. Combustion. Energy Fuels 2006, 20, 2660–2665. [Google Scholar] [CrossRef]

- Zhu, S.; Lee, S.W. Co-Combustion Performance of Poultry Wastes and Natural Gas in the Advanced Swirling Fluidized Bed Combustor (SFBC). Waste Manag. 2005, 25, 511–518. [Google Scholar] [CrossRef]

- Kratzeisen, M.; Starcevic, N.; Martinov, M.; Maurer, C.; Müller, J. Applicability of Biogas Digestate as Solid Fuel. Fuel 2010, 89, 2544–2548. [Google Scholar] [CrossRef]

- Chen, H.; Forbes, E.G.A.; Archer, J.; De Priall, O.; Allen, M.; Johnston, C.; Rooney, D. Production and Characterization of Granules from Agricultural Wastes and Comparison of Combustion and Emission Results with Wood Based Fuels. Fuel 2019, 256, 115897. [Google Scholar] [CrossRef]

- Rhén, C.; Öhman, M.; Gref, R.; Wästerlund, I. Effect of Raw Material Composition in Woody Biomass Pellets on Combustion Characteristics. Biomass Bioenergy 2007, 31, 66–72. [Google Scholar] [CrossRef]

- Hossain, A.K.; Sharma, V.; Serrano, C.; Krishnasamy, A.; Ganesh, D. Production of Biofuel from AD Digestate Waste and Their Combustion Characteristics in a Low-Speed Diesel Engine. Renew. Energy 2024, 222, 119884. [Google Scholar] [CrossRef]

- Jagtap, A.; Kalbande, S. Physio-Chemical Properties of Pellets Using Different Feedstocks. Int. J. Agric. Sci. 2022, 18, 18–23. [Google Scholar] [CrossRef]

- Matúš, M.; Križan, P.; Beniak, J.; Šooš, L’. Effects of initial moisture content on the production and quality properties of solid biofuel. Acta Polytech. 2015, 55, 335–341. [Google Scholar] [CrossRef]

- Dziedzic, K.; Łapczyńska-Kordon, B.; Jurczyk, M.; Arczewska, M.; Wróbel, M.; Jewiarz, M.; Mudryk, K.; Pająk, T. Solid Digestate—Physicochemical and Thermal Study. Energies 2021, 14, 7224. [Google Scholar] [CrossRef]

- Pedrazzi, S.; Allesina, G.; Belló, T.; Rinaldini, C.A.; Tartarini, P. Digestate as Bio-Fuel in Domestic Furnaces. Fuel Process. Technol. 2015, 130, 172–178. [Google Scholar] [CrossRef]

- Andersone, A.; Janceva, S.; Lauberte, L.; Zaharova, N.; Chervenkov, M.; Jurkjane, V.; Jashina, L.; Rieksts, G.; Telysheva, G. Granulated Animal Feed and Fuel Based on Sea Buckthorn Agro-Waste Biomass for Sustainable Berry Production. Sustainability 2023, 15, 11152. [Google Scholar] [CrossRef]

- Obidziński, S.; Dołżyńska, M.; Kowczyk-Sadowy, M.; Jadwisieńczak, K.; Sobczak, P. Densification and Fuel Properties of Onion Husks. Energies 2019, 12, 4687. [Google Scholar] [CrossRef]

- Dołżyńska, M.; Obidziński, S.; Kowczyk-Sadowy, M.; Krasowska, M. Densification and Combustion of Cherry Stones. Energies 2019, 12, 3042. [Google Scholar] [CrossRef]

- Ståhl, M.; Berghel, J. Energy Efficient Pilot-Scale Production of Wood Fuel Pellets Made from a Raw Material Mix Including Sawdust and Rapeseed Cake. Biomass Bioenergy 2011, 35, 4849–4854. [Google Scholar] [CrossRef]

- Ruiz Celma, A.; Cuadros, F.; López-Rodríguez, F. Characterization of Pellets from Industrial Tomato Residues. Food Bioprod. Process. 2012, 90, 700–706. [Google Scholar] [CrossRef]

- Sotannde, O.; Oluyege, A.; Anguruwa, G. Physical and Combustion Properties of Charcoal Briquettes from Neem Wood Residues. Int. Agrophys. 2010, 24, 189–194. [Google Scholar]

- Nguyen, Q.N.; Cloutier, A.; Stevanovic, T.; Achim, A. Pressurized Hot Water Treatment of Sugar Maple and Yellow Birch Wood Particles for High Quality Fuel Pellet Production. Biomass Bioenergy 2017, 98, 206–213. [Google Scholar] [CrossRef]

- Yu, Y.; Lau, A.; Sokhansanj, S. Improvement of the Pellet Quality and Fuel Characteristics of Agricultural Residues through Mild Hydrothermal Treatment. Ind. Crops Prod. 2021, 169, 113654. [Google Scholar] [CrossRef]

- Abdoli, A.; Golzary, A.; Hosseini, A.; Sadeghi, P. Biomass Densification. In Wood Pellet as a Renewable Source of Energy: From Production to Consumption; Springer: Tehran, Iran, 2019; pp. 33–46. ISBN 978-3-319-74481-0. [Google Scholar]

- Muramatsu, K.; Massuquetto, A.; Dahlke, F.; Maiorka, A. Factors That Affect Pellet Quality: A Review. J. Agric. Sci. Technol. 2015, 5, 717–722. [Google Scholar] [CrossRef]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The Significance of Pelletization Operating Conditions: An Analysis of Physical and Mechanical Characteristics as Well as Energy Consumption of Biomass Pellets. Renew. Sustain. Energy Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- ISO 17225-6:2021; Solid Biofuels—Fuel Specifications and Classes. Part 6: Graded Non-Woody Pellets. Polski Komitet Normalizacyjny: Warszawa, Poland, 2021.

- Nussbaumer, T. Combustion and Co-Combustion of Biomass: Fundamentals, Technologies, and Primary Measures for Emission Reduction. Energy Fuels 2003, 17, 1510–1521. [Google Scholar] [CrossRef]

- ISO 16948:2015; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. Polski Komitet Normalizacyjny: Warszawa, Poland, 2015. Available online: https://www.iso.org/standard/58004.html (accessed on 28 February 2025).

- ISO 18125:2017; Solid Biofuels—Determination of Calorific Value. Polski Komitet Normalizacyjny: Warszawa, Poland, 2017. Available online: https://standards.iteh.ai/catalog/standards/iso/845d7dc1-7df3-4abd-9051-d8e842811a5e/iso-18125-2017 (accessed on 13 February 2025).

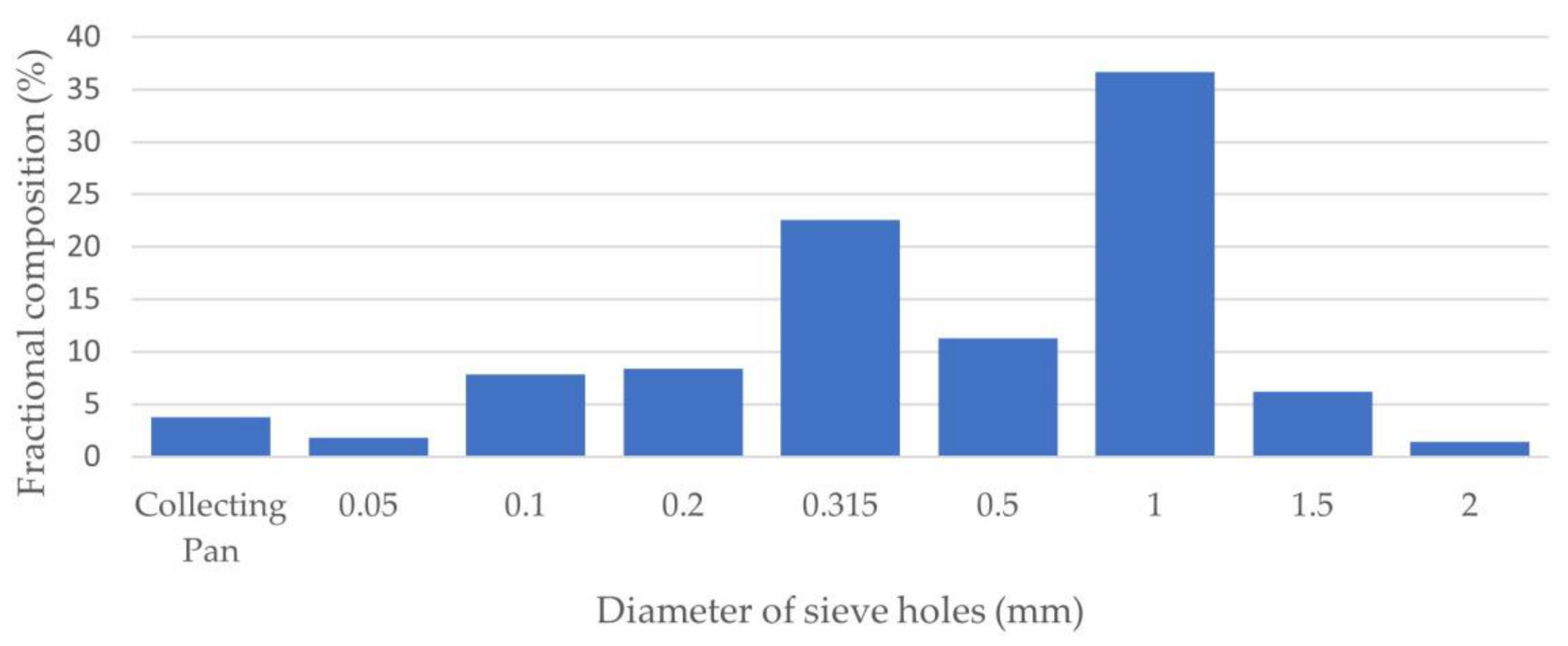

- ISO 2591-1:1988; Test Sieving—Part 1: Methods Using Test Sieves of Woven Wire Cloth and Perforated Metal Plate. Polski Komitet Normalizacyjny: Warszawa, Poland, 2015. Available online: https://www.iso.org/ru/standard/7569.html (accessed on 28 February 2025).

- SIST EN 15149-1:2011; Solid Biofuels—Determination of Particle Size Distribution—Part 1: Oscillating Screen Method Using Sieve Apertures of 1 mm and Above. Polski Komitet Normalizacyjny: Warszawa, Poland, 2011. Available online: https://standards.iteh.ai/catalog/standards/sist/d7aa2a37-27f1-41d9-9372-0f8f2760f52b/sist-en-15149-1-2011 (accessed on 13 February 2025).

- SIST EN ISO 18134-1:2022; Solid Biofuels—Determination of Moisture Content—Part 1: Reference Method (ISO 18134-1:2022). Polski Komitet Normalizacyjny: Warszawa, Poland, 2022. Available online: https://standards.iteh.ai/catalog/standards/sist/9b28773d-2259-46de-874b-b0e990a7b4e3/sist-en-iso-18134-1-2022 (accessed on 13 February 2025).

- SIST EN ISO 17828:2016; Solid Biofuels—Determination of Bulk Density (ISO 17828:2015). Polski Komitet Normalizacyjny: Warszawa, Poland, 2016. Available online: https://standards.iteh.ai/catalog/standards/sist/3d670a82-73f5-45aa-a2e0-bc8958e6d694/sist-en-iso-17828-2016 (accessed on 13 February 2025).

- SIST EN ISO 17831-1:2016; Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets (ISO 17831-1:2015). Polski Komitet Normalizacyjny: Warszawa, Poland, 2016. Available online: https://standards.iteh.ai/catalog/standards/sist/6f2c3a1a-366b-49c6-b2bb-b94f97e9b169/sist-en-iso-17831-1-2016 (accessed on 13 February 2025).

- SIST EN ISO 18122:2023; Solid Biofuels—Determination of Ash Content (ISO 18122:2022). Polski Komitet Normalizacyjny: Warszawa, Poland, 2023. Available online: https://standards.iteh.ai/catalog/standards/sist/3bd743d6-8afe-4937-83e4-6525f0701e1a/sist-en-iso-18122-2023 (accessed on 13 February 2025).

- Abdollahi, M.R.; Ravindran, V.; Wester, T.J.; Ravindran, G.; Thomas, D.V. Effect of Improved Pellet Quality from the Addition of a Pellet Binder and/or Moisture to a Wheat-Based Diet Conditioned at Two Different Temperatures on Performance, Apparent Metabolisable Energy and Ileal Digestibility of Starch and Nitrogen in Broilers. Anim. Feed. Sci. Technol. 2012, 175, 150–157. [Google Scholar] [CrossRef]

- Alakangas, E. Wood Pellets in Finland—Technology, Economy and Market; VTT Technical Research Centre of Finland: Espoo, Finland, 2002. [Google Scholar]

- Hejft, R. Ciśnieniowa Aglomeracja Materiałów Roślinnych; Biblioteka Problemów Eksploatacji; Politechnika Białostocka, Instytut Technologii Eksploatacji: Radom, Poland, 2002; ISBN 978-83-7204-251-4. [Google Scholar]

- Jiang, L.; Liang, J.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Huang, H.; Wang, H.; Zeng, G. Co-Pelletization of Sewage Sludge and Biomass: The Density and Hardness of Pellet. Bioresour. Technol. 2014, 166, 435–443. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Effect of Process Variables on the Density and Durability of the Pellets Made from High Moisture Corn Stover. Biosyst. Eng. 2014, 119, 44–57. [Google Scholar] [CrossRef]

- Ileleji, K.E.; Li, Y.; Ambrose, R.P.K.; Doane, P.H. Experimental Investigations towards Understanding Important Parameters in Wet Drum Granulation of Corn Stover Biomass. Powder Technol. 2016, 300, 126–135. [Google Scholar] [CrossRef]

- Zhao, X.; Xu, H.; Shen, J.; Yu, B.; Wang, X. Decreasing Effect and Mechanism of Moisture Content of Sludge Biomass by Granulation Process. Environ. Technol. 2016, 37, 192–201. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of Compressive Force, Particle Size and Moisture Content on Mechanical Properties of Biomass Pellets from Grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Shaw, M.D.; Tabil, L.G. Compression and Relaxation Characteristics of Selected Biomass ‘Grinds. In Proceedings of the 2007 ASAE Annual Meeting, Minneapolis, MN, USA, 17–20 June 2007; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007. [Google Scholar]

- Karamchandani, A.; Yi, H.; Puri, V.M. Determination of Optimum Densification Conditions for Production of Corn Stover Pellets; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2013. [Google Scholar]

- Reeves, J.B.; Van Kessel, J.A.S. Influence of Ash on the Fiber Composition of Dried Dairy Manures. Environ. Pollut. 2002, 120, 239–244. [Google Scholar] [CrossRef]

- Mammarella, D.; Di Giuliano, A.; Gallucci, K. Reuse and Valorization of Solid Digestate Ashes from Biogas Production. Energies 2024, 17, 751. [Google Scholar] [CrossRef]

- Waliszewska, B.; Waliszewska, H.; Grzelak, M.; Majchrzak, L.; Gaweł, E.; Murawski, M.; Sieradzka, A.; Vaskina, I.; Spek-Dźwigała, A. Evaluation of Changes in the Chemical Composition of Grasses as a Result of the Methane Fermentation Process and Biogas Production Efficiency. Energies 2024, 17, 4100. [Google Scholar] [CrossRef]

- Ogwang, I.; Kasedde, H.; Nabuuma, B.; Kirabira, J.B.; Lwanyaga, J.D. Characterization of Biogas Digestate for Solid Biofuel Production in Uganda. Sci. Afr. 2021, 12, e00735. [Google Scholar] [CrossRef]

- Matijašević, V.; Beňo, Z.; Tekáč, V.; Duong, V.M. Characterization of Beech Wood Pellets as Low-Emission Solid Biofuel for Residential Heating in Serbia. Resources 2024, 13, 104. [Google Scholar] [CrossRef]

- Saletnik, B.; Saletnik, A.; Zaguła, G.; Bajcar, M.; Puchalski, C. The Use of Wood Pellets in the Production of High Quality Biocarbon Materials. Materials 2022, 15, 4404. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. Heating Values of Wood Pellets from Different Species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Niedziółka, I.; Szpryngiel, M.; Kachel-Jakubowska, M.; Kraszkiewicz, A.; Zawiślak, K.; Sobczak, P.; Nadulski, R. Assessment of the Energetic and Mechanical Properties of Pellets Produced from Agricultural Biomass. Renew. Energy 2015, 76, 312–317. [Google Scholar] [CrossRef]

- Derehajło, S.; Tymińska, M.; Skibko, Z.; Borusiewicz, A.; Romaniuk, W.; Kuboń, M.; Olech, E.; Koszel, M. Heavy Metal Content in Substrates in Agricultural Biogas Plants. Agric. Eng. 2023, 27, 315–329. [Google Scholar] [CrossRef]

- Popovic, O.; Jensen, L.S. Storage Temperature Affects Distribution of Carbon, VFA, Ammonia, Phosphorus, Copper and Zinc in Raw Pig Slurry and Its Separated Liquid Fraction. Water Res. 2012, 46, 3849–3858. [Google Scholar] [CrossRef]

- McCord, A.I.; Stefanos, S.A.; Tumwesige, V.; Lsoto, D.; Kawala, M.; Mutebi, J.; Nansubuga, I.; Larson, R.A. Anaerobic Digestion in Uganda: Risks and Opportunities for Integration of Waste Management and Agricultural Systems. Renew. Agric. Food Syst. 2020, 35, 678–687. [Google Scholar] [CrossRef]

- Rađenović, D.; Kerkez, Đ.; Pilipović, D.T.; Dubovina, M.; Grba, N.; Krčmar, D.; Dalmacija, B. Long-Term Application of Stabilization/Solidification Technique on Highly Contaminated Sediments with Environment Risk Assessment. Sci. Total Environ. 2019, 684, 186–195. [Google Scholar] [CrossRef]

- Demirel, B.; Göl, N.P.; Onay, T.T. Evaluation of Heavy Metal Content in Digestate from Batch Anaerobic Co-Digestion of Sunflower Hulls and Poultry Manure. J. Mater. Cycles Waste Manag. 2013, 15, 242–246. [Google Scholar] [CrossRef]

| Name | Feedstock Components | Content (%) |

|---|---|---|

| Digestate 1 (D1) | Maize silage | 60 |

| Sugar beet pulp | 40 | |

| Digestate 2 (D2) | Cattle manure | 10 |

| Sugar beet pulp | 60 | |

| Maize silage | 30 | |

| Digestate (D1) + biochar (Mix DBC) | Maize silage | 54 |

| Sugar beet pulp | 36 | |

| Biochar | 10 |

| Parameter | Moisture (%) | Ash (%) | C (%) | H (%) | N (%) | GCV (MJ/kg) | NCV (MJ/kg) |

|---|---|---|---|---|---|---|---|

| Biochar (sunflower husk) | 13.2 | 5.2 | 74.0 | 3.6 | 0.8 | 25.8 | 23.2 |

| No. of the Batch | PDI (%) | Moisture (%) | Consumed Power (kWt) |

|---|---|---|---|

| №1 | 97.67 | 7.35 | 6.764 |

| №2 | 95.07 | 7.45 | 6.232 |

| №3 | 88.63 | 8.00 | 5.586 |

| №4 | 78.40 | 9.50 | 5.320 |

| №5 | 76.50 | 10.20 | 5.120 |

| Parameter | Unit | D1 | D2 | Mix DBC | ISO 17225-6:2021 |

|---|---|---|---|---|---|

| Diameter | mm | 6.00 | 6.00 | 6.00 | 6.00 |

| Length | mm | 7.50–28.50 | 8.00–29.40 | 8.40–30.20 | 3.15–40.00 |

| Moisture content | % | 6.16 | 6.35 | 5.85 | ≤12.00 |

| Dry weight | % | 93.84 | 93.65 | 94.15 | – |

| Ash content | % | 4.40 | 5.20 | 9.05 | ≤6.00 |

| Bulk density | kg/m3 | 710.00 | 706.00 | 730.00 | ≥600.00 |

| Mechanical durability | % | 97.67 | 97.74 | 97.45 | ≥97.50 |

| Moisture Content (%) | Calorific Value (MJ/kg) | ||

|---|---|---|---|

| Gross | Net | ||

| D1 | 6.16 | 18.65 | 17.07 |

| D2 | 6.35 | 18.71 | 17.11 |

| Mix DBC | 5.85 | 20.44 | 18.86 |

| ISO 17225-6:2021 | ≥14.5 | ||

| Element | (%) Dry Matter | (mg/kg) Dry Matter | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | N | O | H | P | S | K | Cl | Ca | As | Cd | Cr | Cu | Pb | Hg | Ni | Zn | |

| D1 | 43.4 | 1.6 | 35.4 | 5.3 | 0.1147 | 0.1303 | 0.296 | 0.0700 | 0.305 | 3 | 2 | 3 | 44 | ||||

| D2 | 45.2 | 1.8 | 26.4 | 5.1 | 0.1230 | 0.1330 | 0.285 | 0.0650 | 0.280 | 4 | 1 | 2 | 52 | ||||

| Mix DBC | 62.8 | 3.4 | 18.8 | 5.8 | 0.5200 | 0.4494 | 1.320 | 0.3377 | 1.810 | 13 | 4 | 21 | 160 | ||||

| ISO 17225-6:2021 | ≤1.5 | ≤0.2 | ≤0.1 | ≤1 | ≤0.5 | ≤50 | ≤20 | ≤10 | ≤0.1 | ≤10 | ≤100 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaskina, I.; Vaskin, R.; Ostroha, R.; Yukhymenko, M.; Skydanenko, M.; Kupryaniuk, K.; Demkova, L.; Sydorenko, S. Fuel Pelletization of Digestate: A Pathway to Renewable and Sustainable Energy Sources. Fuels 2025, 6, 32. https://doi.org/10.3390/fuels6020032

Vaskina I, Vaskin R, Ostroha R, Yukhymenko M, Skydanenko M, Kupryaniuk K, Demkova L, Sydorenko S. Fuel Pelletization of Digestate: A Pathway to Renewable and Sustainable Energy Sources. Fuels. 2025; 6(2):32. https://doi.org/10.3390/fuels6020032

Chicago/Turabian StyleVaskina, Iryna, Roman Vaskin, Ruslan Ostroha, Mykola Yukhymenko, Maksym Skydanenko, Karol Kupryaniuk, Lenka Demkova, and Serhii Sydorenko. 2025. "Fuel Pelletization of Digestate: A Pathway to Renewable and Sustainable Energy Sources" Fuels 6, no. 2: 32. https://doi.org/10.3390/fuels6020032

APA StyleVaskina, I., Vaskin, R., Ostroha, R., Yukhymenko, M., Skydanenko, M., Kupryaniuk, K., Demkova, L., & Sydorenko, S. (2025). Fuel Pelletization of Digestate: A Pathway to Renewable and Sustainable Energy Sources. Fuels, 6(2), 32. https://doi.org/10.3390/fuels6020032