Abstract

Scientific studies on the impact of wood species on solid fuel production, performance, and sustainability are grossly inadequate. The knowledge of this is imperative as users of solid fuels are increasing rapidly, especially in Africa. On this note, it becomes necessary to explore measures that will improve its efficiency and sustainability as an energy source. This study investigates some properties of selected wood species used as an energy source in Nigeria and their pelleting potential. Nine samples were characterized and assessed for suitability of pelleting following four wood pellet quality standards. The properties investigated are physical (moisture content and density) and thermochemical (calorific value, ash content, volatile matter, fixed carbon, and ultimate properties (carbon, nitrogen, hydrogen, oxygen, sulfur, arsenic, cadmium, and lead)). These were selected because they are among the most important pellet parameters contained in the quality standards. The findings revealed a net calorific value between 10.61 MJ.kg−1 for Tectona grandis and 18.44 MJ.kg−1 for Eucalyptus cam. The ash content, volatile matter, and fixed carbon contents of the samples range between 2.1 and 24.4%, 65.94 and 87.77%, and 3.51 and 18.63%, respectively. Anogeissus leiocarpus was found to be the species with the best rating score in terms of fuel properties, while Vitellaria paradoxa was the lowest. However, in terms of conformity with the four wood pellet standards, Khaya senegalensis, Parkia biglobosa, and Eucalyptus cam., having presented density, calorific value, sulfur, arsenic, cadmium, and lead within the limits of the wood pellet quality standards, were considered the best wood species in terms of fuel suitability and pelleting potential. The findings therefore suggest that not all wood species are suitable as fuel. Thus, for species that do not meet the standard wood pellet requirements, alternatives such as the use of biomass blends, additives, or process adjustments can be employed to adapt the quality to the standards or by using the fuels in improved cookstoves.

1. Introduction

Woody biomass is one of the most used forms of biomass globally. Its use as fuel is increasing rapidly around the globe. About one-third of the world population, equivalent to 2.6 billion people, rely primarily on fuelwood to meet their energy needs [1]. This is more predominant in Africa where over 80% of the population relies on different forms of wood to meet their energy needs [2]. Based on this, the rate of deforestation and climate change has increased in recent years. In Africa, about 3.4 million hectares of forest land is lost per year [3]. Nigeria is among the top 10 countries globally with the highest rate of forest loss, as 5.0% (410,000 hectares) of forest land is lost per annum [4]. This figure may be exacerbated further as Nigeria is also the second-highest charcoal-producing nation in the world with an annual average production capacity of 4,828,689.00 tons as of 2022 [5]. Similarly, the country’s major consumer of wood is the fuelwood sector, which as of 2015 accounted for almost 87% of the total wood extracted [4]. More worrisome is the fact that the production process is devoid of sustainable mechanisms such as constant tree planting to account for the deforested ones. Apart from the environmental impacts recorded through deforestation in Nigeria, the gross domestic product GDP accrued from forest ecosystem services, which was valued at about NGN 1 million per hectare in 2015 (1,000,000 NGN/ha) has been drastically reduced due to deforestation [6]. To minimize the rate of deforestation in Nigeria, [6] has recommended the formulation of policies involving tree planting through agroforestry, carbon trading, and the payment of incentives for forest management.

For solutions involving the production and use of alternative energy to curtail the unsustainable use of forests for fuel, several studies have worked enormously on various aspects. Some of these include the processing of lignocellulosic biomass into fuels such as briquettes [7,8], pellets [9], and biogas [10], among others. The appropriate use of fuel, especially at low moisture content in improved cookstoves, is another approach that can considerably reduce the gaseous emissions encountered from incomplete combustion. In this vein, studies including [11,12] have developed improved biomass cookstoves to reduce fuel use and gaseous emissions. This has been proven as an effective approach to reduce the use of fuelwood and charcoal, with the potential of improved performance if the cookstoves are powered by pellets made from non-woody biomass [13]. Despite the numerous advances, charcoal and fuelwood production and use keep exacerbating. The use of polluting fuels including fuelwood and charcoal was projected to continue with more than one (1) billion people in sub-Saharan Africa by 2025 [14]. Thus, it becomes imperative to explore measures involving policy regulations that will improve sustainability in the use of wood. These may include limiting charcoal and fuelwood production to certain wood species or, more importantly, pelletizing the wood shavings and the residues into a more compact and durable form. To succeed in the aforementioned steps, it is pertinent to study the properties of the wood species conventionally used as fuelwood and charcoal to recommend the most efficient and cleaner option.

A couple of studies conducted on the characterization of selected wood species in Africa are presented in Table 1. This ranges from the study of [15] in Nigeria where species predominantly found in the southwestern part of Nigeria were characterized. Others include the study of [16] in Uganda, [17] in Senegal, [18] in Botswana, [19] in Ghana, and [20] in South Africa, among others. Most of the analyzed properties (calorific value, ash content, and nitrogen and sulfur content) of the wood species conform with the European Norm (ENplus) [21,22], as set by the European Pellet Council, the German Institute for Standardization (DIN 51731/DINplus) [23], the Austrian standard (ÖNORM M7135) [23], and the International Organization for Standardization ISO 17225-2 [24] for wood pellets. Although some of the reported studies did not consider toxic gases such as N and S, Afr. mesquite, one of the species studied by [20] in South Africa, was found to have properties within the acceptable limits of ENplus [22], DIN 51731/DINplus [23], ÖNORM M7135 [23], and ISO 17225-2 [24]. However, in the same study, in the Jacaranda species, despite having good calorific value and acceptable nitrogen (N) and sulfur (S) levels, the ash content was found to be above the required limits. A similar scenario was observed in the study of [15] for the M. excelsa species, where a high calorific value was recorded but with ash content above the acceptable limit. This suggests that when selecting fuel woods by species, calorific value alone is not sufficient to determine the best species [19].

Table 1.

A review of selected wood species in Africa and their conformity with international wood pellet standards.

Although several studies have been carried out on wood characterization, there is no adequate explanation of how species types affect charcoal or fuelwood production, performance, and sustainability. This may be because of the greater interest shown in valorizing lignocellulosic biomass into new forms of energy rather than conventional solid fuels (fuelwood and charcoal). In this vein, studies are focusing more on the use of agricultural residues in developing biofuels, such as briquettes, pellets, biogas, etc., to reduce the pressure on fuelwood and charcoal as a means of abating deforestation. Nonetheless, the knowledge of the effect of wood species on fuel production is imperative as users of charcoal and fuelwood are increasing rapidly. Thus, the findings in this study would serve as a guide in wood selection as it reports the most efficient and those with the best potential to be pelleted to augment the rapid deterioration of forests for fuelwood and charcoal production. Similarly, analyzing the wood’s proximate parameters with and without bark is an aspect that validates the influence of wood bark during combustion. This is equally missing in previous studies. Another novelty of this study is that it assessed the conformity of selected wood species from other African countries and those of this study with international wood pellet standards. Thus, the objective of this study is to evaluate the selected physical and thermochemical properties of some wood species used in fuelwood and charcoal production in Nigeria to determine the best in terms of fuel-related properties and the best in terms of compliance with ENplus [22], DIN 51731/DINplus [23], ÖNORM M7135 [23], and ISO 17225-2 [24] standards.

2. Materials and Methods

2.1. Sample Collection and Preparation

About 20 species were broadly identified. However, only the nine (9) most commonly used species in fuelwood and charcoal production in Kaduna State, Nigeria, were selected for this study. The samples were collected from the Savannah Forestry Research Institute of Nigeria, Zaria Kaduna State (latitude 11°10′ N and longitude 7°37′ E). Out of the nine (9) species collected, four (4) are mainly used in charcoal production, viz. Vitellaria paradoxa (shea), Mangifera indica (mango), Anogeissus leiocarpa (marke), and Tectona grandis (teak), four (4) for fuelwood, viz. Eucalyptus spp. (turare), Parkia biglobosa (dorawa), Albizia lebbeck, and Azadirachfa indica (neem), and one (1) for both, viz. Khaya senegalensis (mahogany).

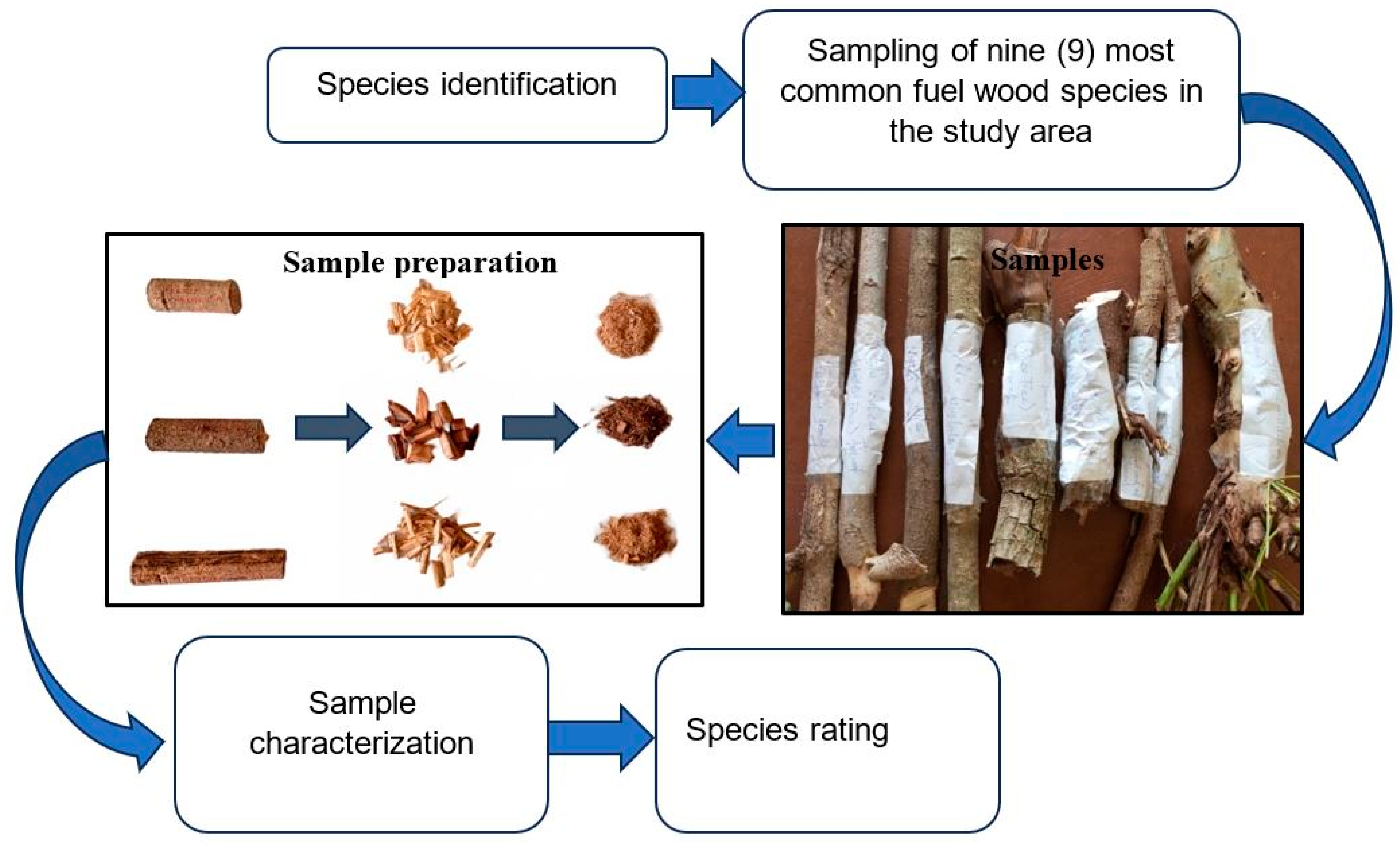

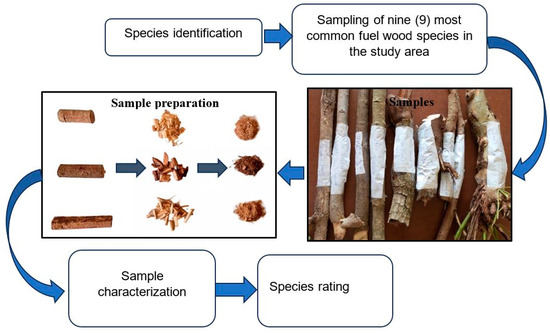

The samples were sundried for two days, shredded into smaller sizes, and heated for about 30 min at 105 °C in an oven to remove the core layer moisture. The dried samples were manually ground with the aid of a mortar and pestle. The ground samples were further sieved through a 1 mm mesh size for characterization. The overall study flowchart is presented in Figure 1.

Figure 1.

Study flowchart.

2.2. Sample Characterization

The samples were characterized based on physical (moisture content, volume, and density) and thermochemical properties (calorific value, proximate, and ultimate parameters).

2.2.1. Physical Properties

Three parameters, viz. moisture content, volume, and density, were determined. The moisture content was determined following the method described in [25]. Because the samples are irregularly shaped samples, the volume and density were determined using the water displacement method. The weights of the samples were taken using a digital scale balance (model: OPH-T3001, Optima Scale, Rancho Cucamonga, CA, USA) with an accuracy of 0.1 g. The individual volume was obtained as the difference in volume after immersing each sample into a 500 mL volume of water in a transparent cylinder. Hence, the density was computed as the ratio of the mass and volume.

2.2.2. Thermochemical Properties

Gross Calorific Value (GHV) and Net Calorific Value (NHV)

The gross calorific value was determined using a bomb calorimeter (model: 6100, Parr Instrument Company, Moline, IL, USA) following the method described in [26]. The value indicates the energy content of the samples per unit mass (MJ.kg−1) [27]. Thus, the higher the value, the better the thermal performance of the wood species.

The net calorific value was estimated from the gross calorific value using Equation (1), as given by [28]:

where MC is the moisture content of the wood sample on a wet basis (decimal), H is the hydrogen concentration, percent by weight dry basis, and is the latent energy of vaporization of water (MJ.kg−1) (2.26 MJ.kg−1).

Proximate Analysis

Proximate analysis was performed to determine the content of volatile matter, ash content, and fixed carbon contained in the wood samples. Unlike the physical analysis, the proximate analysis was analyzed with bark (WB) and without bark (WoB). This was to figure out the differences between wood samples in terms of ash content and volatile matter with and without bark.

Volatile Matter

The sample’s volatile matter was determined using the modified procedure described in [29] for all sparking fuels. One gram of each sample was weighed into a crucible, covered with a lid, and gradually heated to 650 °C for six minutes in a furnace (BIOB Muffle furnace, Biobase, Jinan, China), after which the samples were heated further at 930 °C for another six minutes. The percentage of volatile matter in each sample was determined with Equation (2) [19].

where A is the weight of the oven-dried sample and B is the weight of the sample after heating in the furnace.

Ash Content

The ash content was estimated by heating 1 g of the sample in a furnace (BIOB Muffle furnace, Biobase, Jinan, China) for four hours, starting at room temperature, rising to 500 °C in the first hour, and heating to 700 °C in the second hour. After the first two hours, the sample was heated continuously at 700 °C for an additional two hours as per [30]. The percentage of ash content was determined using Equation (3) [19].

where is the mass of the ash and is the mass of the oven-dried sample.

Fixed Carbon

The fixed carbon (FC) was estimated by subtracting the value of the volatile matter (VM) and ash content from 100%, as given in Equation (4) [31]:

Ultimate Analysis

The ultimate analysis was restricted to carbon, nitrogen, sulfur, hydrogen, oxygen, and three heavy metals (cadmium, lead, and arsenic). The nitrogen content was determined using the micro-Kjeldahl method using the micro-Kjeldahl digestion distillation apparatus, the sulfur content was determined using the aluminum block method in a Tecator (Model 40 digestor, Tecator AB, Sweden), and the heavy metals were determined through the perchloric acid digestion method using the Tecator (Model 40 digestor, Tecator AB, Sweden). However, the contents of carbon, hydrogen, and oxygen were estimated from the result of proximate analysis with an accuracy of ±2% using Equations (5)–(7) [32].

where FC = fixed carbon, AC = ash matter, and VM = volatile matter.

2.3. Rating of the Properties of the Wood Species

To determine the most suitable species and vice versa, the samples were rated between 1 and 9, with 1 indicating the best and 9 being the worst. The method employed in the rating was based on the average scores of each tested property [19]. The rating scores were allocated based on the role of each tested property in solid fuels (i.e., either required or not required for efficient and clean combustion). For example, species with the highest calorific value, carbon, and fixed carbon content were allocated a rating score of 1 because they are essential properties required for effective fuel performance. However, in the case of ash, sulfur, nitrogen, arsenic, lead, and cadmium content, species with the lowest content were allocated the best rating score because they contribute to toxic gas emissions, which are not required in fuels. Overall, species with the lowest average rating score were considered the best in terms of suitability for use as fuel. However, for pelleting potential assessment, the species whose physical and thermochemical properties meet the four wood pellet standards are considered the best.

3. Results and Discussion

3.1. Physical Properties

The results of the physical properties are presented in Table 2. The moisture content of the samples ranges between 4.08% and 7%. This indicates that the samples were properly dried and within the optimum range of moisture required for wood pellets as set by ENplus [22], DIN 51731/DINplus [23], ÖNORM M7135 [23], and ISO 17225-2 [24].

Table 2.

Physical Properties.

The density ranges between 398.00 kg/m3 for Vitellaria paradoxa and 977.50 kg/m3 for Khaya senegalensis. Although the obtained values are below the DIN 51731/DINplus [23] and ÖNORM M7135 [23] standards for wood pellets, all the samples except Vitellaria paradoxa conform with the density requirements of wood pellets for ENplus [22] and ISO 17225-2 [24]. This shows that the species (except Vitellaria paradoxa) meet the required threshold density for wood pellets. Density is an important parameter in wood pellet production as it simulates the strength of the pellets during transportation and storage. Similarly, density also influences the thermal performance of the pellets as low-density fuels that have higher burning rates and specific fuel consumption, whereas very-high-density fuels are associated with incomplete combustion and high emission. However, pellets with high density do not always imply better durability or strength [33]. Therefore, the set threshold values reported in the standards are perceived to be optimum, and for a wood species to be suitable, the density must be within the range and not too low or high. The variation in density by species shows that they will react differently during combustion. This is because density significantly influences the gasification process of fuels [34]. Similarly, the sample densities are consistent with the findings of [24] (553 kg/m3 to 914 kg/m3) for selected wood species in Ethiopia and higher than the findings (409.22 kg/m3 to 764.11 kg/m3) of [19] for selected wood species in Ghana. However, the densities of these species are below the density (1250.0 ± 26.2 kg/m2) of grenadilla, a wood species common in the tropical part of Africa [35].

3.2. Thermochemical Properties

Table 3.

Calorific value.

Table 4.

Proximate analysis.

Table 5.

Ultimate analysis.

3.2.1. Calorific Value

Table 3 shows the result of the calorific value of the samples. Because the calorific value is an estimate of the energy content present per unit mass in the wood species, it is considered one of the most important parameters for assessing the suitability of the various species as fuel. Hence, the higher the calorific value, the better the thermal performance of the resulting wood pellets during combustion. The gross calorific value of the samples is between 10.92 MJ.kg−1 for Tectona grandis and 18.85 MJ.kg−1 for Khaya senegalensis, while the net calorific value is between 10.61 MJ.kg−1 for Tectona grandis and 18.44 MJ.kg−1 for Eucalyptus cam. The net calorific values recorded in Khaya senegalensis, Parkia biglobosa, Anogeissus leiocarpus, and Eucalyptus cam. are in agreement with ENplus [22] and ISO 17225-2 [24] standards. Similarly, the aforementioned samples, except Anogeissus leiocarpus, also conform with DIN 51731/DIN plus [23] and ÖNORM M7135 [23] requirements for wood pellets. These species, therefore, have better potential to be transformed into pellets as they would yield higher thermal efficiency. However, it is pertinent to note that due to the hygroscopic nature of wood, it can easily absorb moisture during handling and storage, which in turn will affect the net calorific value. Species with higher calorific values were observed to have higher fixed carbon. Thus, the fixed carbon content of biomass directly influences the calorific value [16]. The values obtained are consistent with the calorific values of some native wood species in Africa [16,17,18]. While moisture content significantly influences the energy content of fuels [36], this fact is not consistent with all the samples in this study, possibly due to the moisture loss during pretreatment. Although calorific value is an important parameter, it is not sufficient in selecting wood species with the best pelleting potential [19]. Therefore, other parameters such as ash, carbon content, and elemental constituents must be examined accordingly.

3.2.2. Proximate Analysis

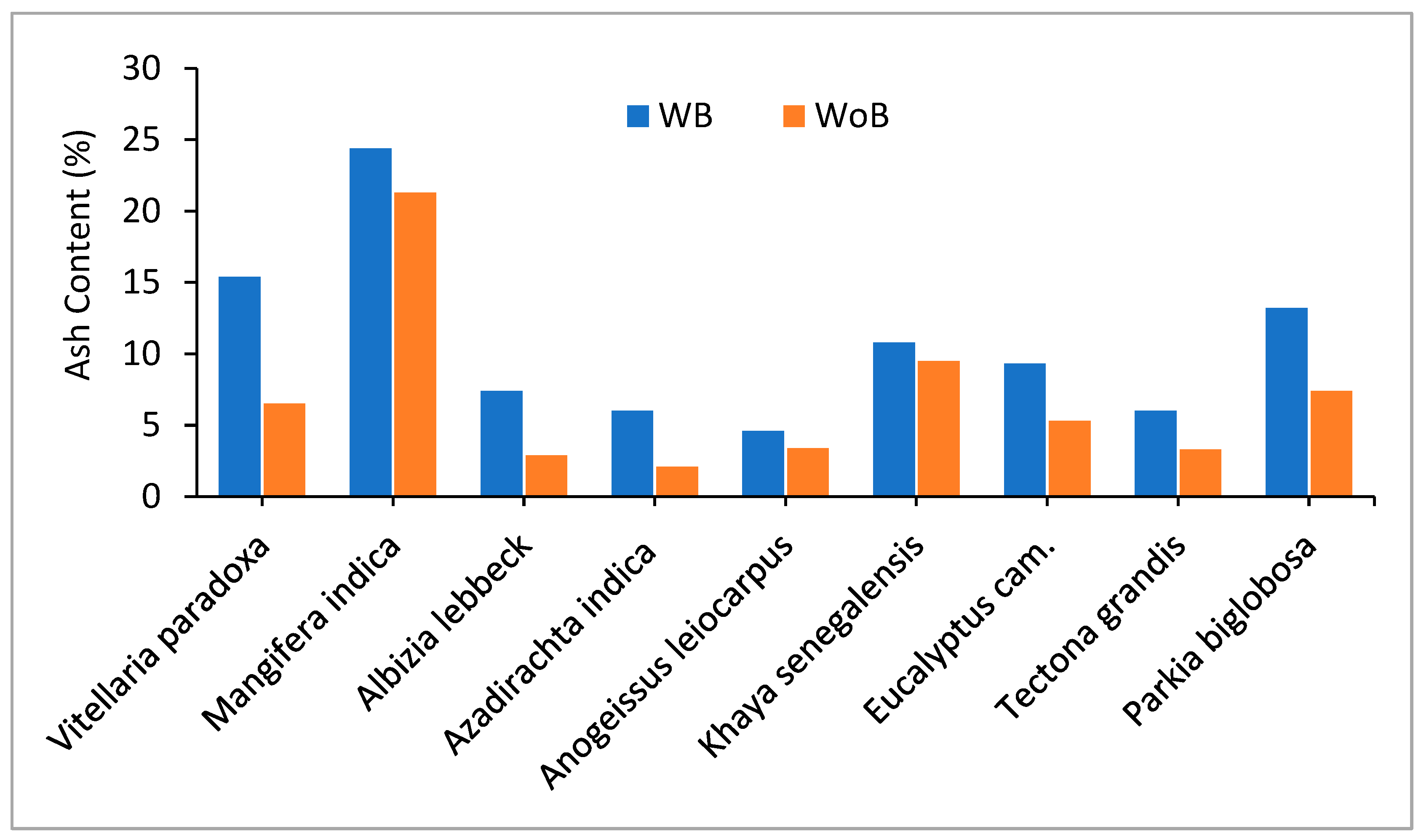

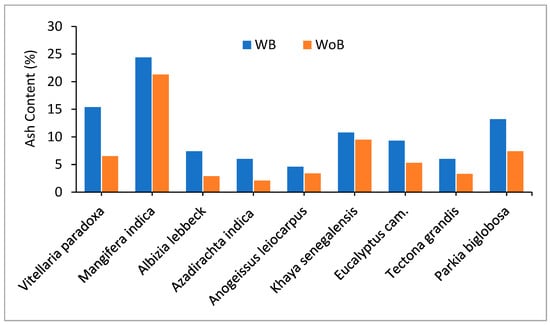

The results of the proximate analysis are presented in Table 4. The ash content, volatile matter, and fixed carbon range between 4.6 and 24.4%, 65.94 and 87.77%, and 3.51 and 13.25% for the samples analyzed with bark and between 2.1 and 21.3%, 73.98 and 85.99%, and 4.72 and 18.63% for the samples analyzed without bark.

The ash content was observed to vary with the presence of bark as the samples without bark depict lower ash levels compared with those with bark (Figure 2). This shows that, irrespective of the wood species, ash content increases with an increase in the quantity of bark. Moreover, because the content of ash depicts the slagging nature of the wood during combustion, the lower the ash content, the better the heating value [37]. Overall, an ash content of less than 4% is generally preferred as it reduces slagging potential [38,39]. However, when the woods have been carbonized into charcoal, an ash content of up to 8% is acceptable [38]. While ash content can go relatively high in other solid fuels, a very low ash content (0.5–2.0%) is required for wood pellets. This implies that wood species having ash content above the stated range are not suitable for pelleting. If they must be used, then pretreatment measures such as carbonization or the use of additives could be employed to reduce the content of ash. Overall, Azadirachta indica, Albizia lebbeck, Tectona grandis, and Anogeissus leiocarpus, all without bark, yielded the best ash contents of 2.1%, 2.9%, 3.3%, and 3.4%, respectively.

Figure 2.

Variation in ash content in the nine wood species with and without bark.

However, in the case of volatile matter, all the species except Mangifera indica, Albizia lebbeck, and Parkia biglobosa depict higher values of volatile matter in samples with bark. Higher volatile matter shows the fuel ignitability and combustion potential [16]. In contrast, all samples without bark except Mangifera indica and Parkia biglobosa depict higher values of fixed carbon. Thus, since volatile matter is a measure of the quantity of fuel that combusts into gas when subjected to temperatures of 400 °C to 500 °C or more [40] and fixed carbon is the remnant of combustible fuel after the volatile matter, moisture, and ash content have been removed [41], it implies that fixed carbon is more essential in fuels. Thus, wood species without bark that present higher fixed carbon values in most of the samples are perceived to be more efficient as fuel with better pelleting potential than samples with bark.

In terms of conformity with the ash content limit of the wood pellet standards, only Azadirachta indica (WoB) is at par with the ENplus B [22] and ISO 17225-2 [24] standards, as none of the samples meet ENplus A1 and A2 [22], DIN 51731/DINplus, and Austria ÖNORM M7135 [23] standards. With this, the use of blends and additives becomes imperative to reduce the ash contents.

Table 5 shows the results of the ultimate analysis. Here, major elemental constituents like carbon, oxygen, and hydrogen are higher in Anogeissus leiocarpus (44.78%, 43.65%, and 5.76%, respectively), Azadirachta indica (44.29%, 42.76%, and 5.69%, respectively), Albizia lebbeck (44.21%, 41.55%, and 5.62%, respectively), and Tectona grandis (43.92%, 43.03%, and 5.69%, respectively). This shows that the mentioned samples will have better combustion efficiency when used as fuel or when pelleted. On the other hand, minor constituents such as nitrogen and sulfur are measures depicting the extent of nitrogen- and sulfur-based emissions during combustion. Thus, the lower their percentages, the cleaner the wood specie when combusted. Overall, the values of sulfur recorded (0.0031–0.0115%) in all the samples are in agreement with the ENplus [22], DIN 51731/DINplus [23], Austria ÖNORM M7135 [23], and ISO 17225-2 [24] standards. However, none of the samples meet the aforementioned standards in the case of nitrogen, where the contents are required to be ≤0.3 to ≤1.

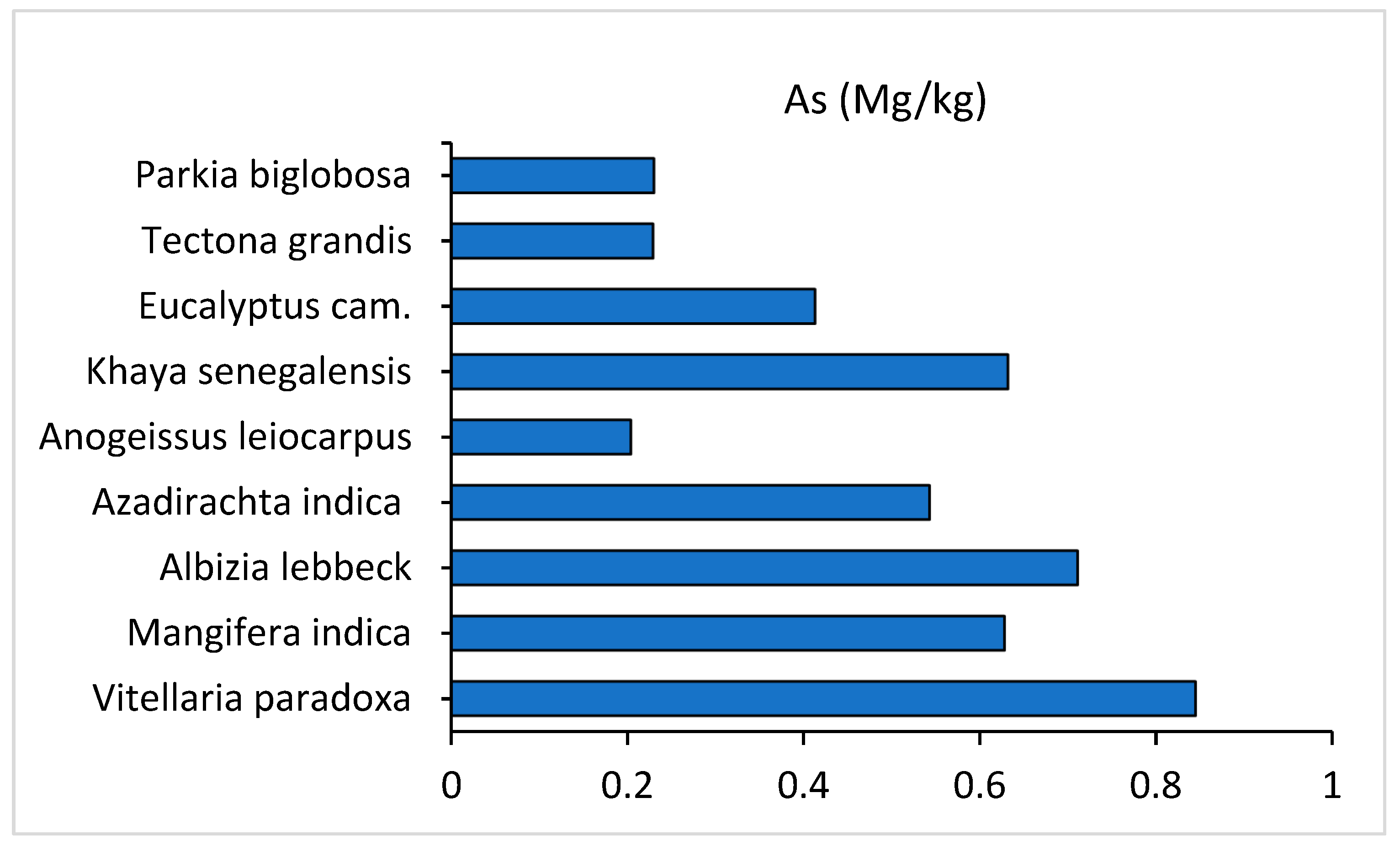

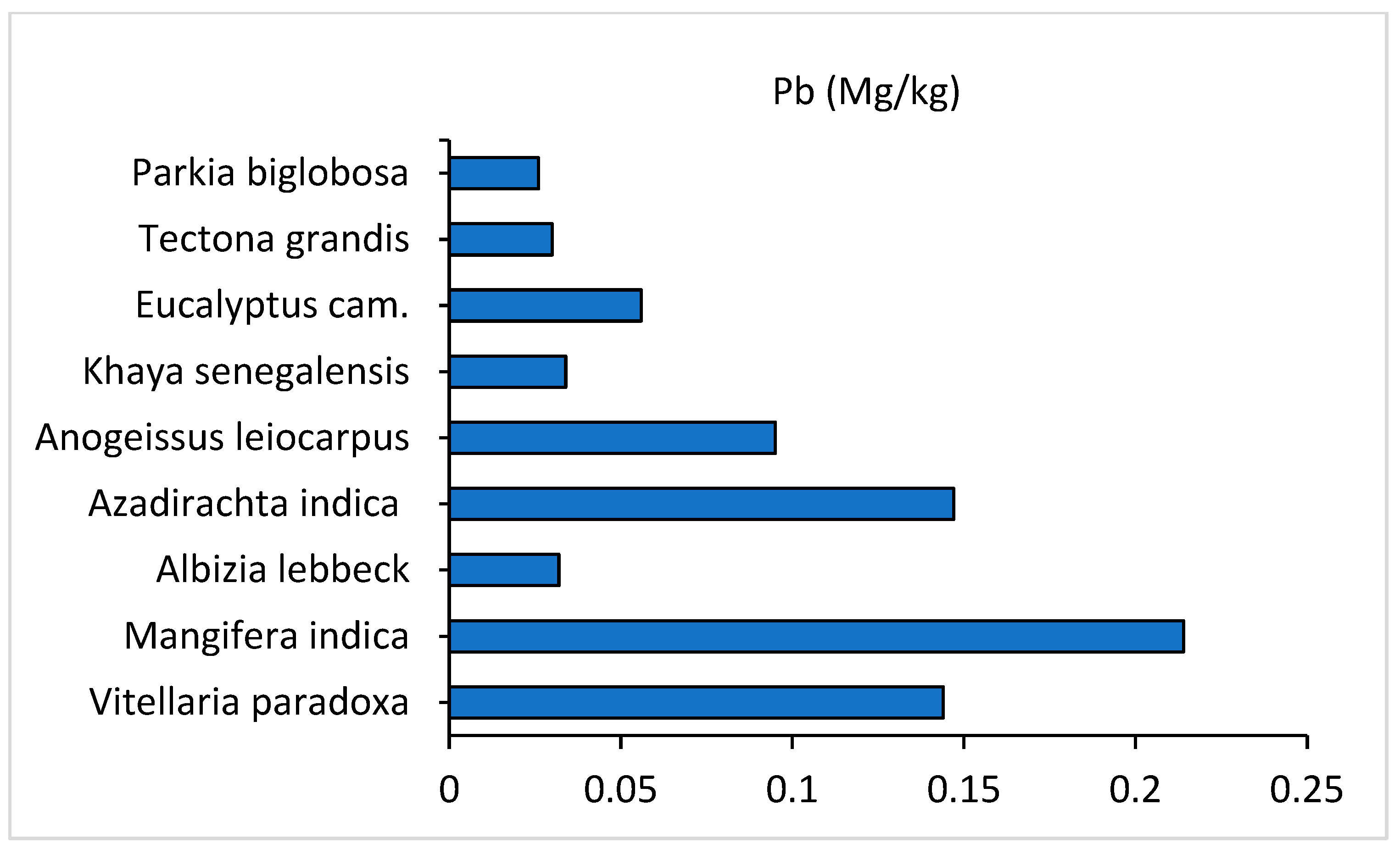

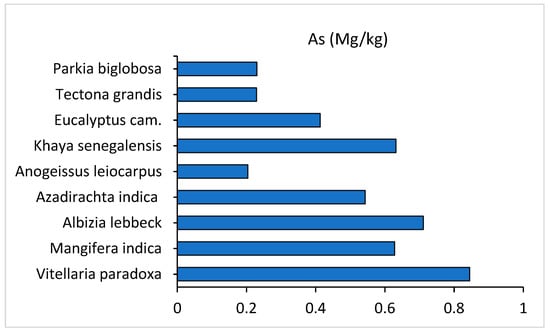

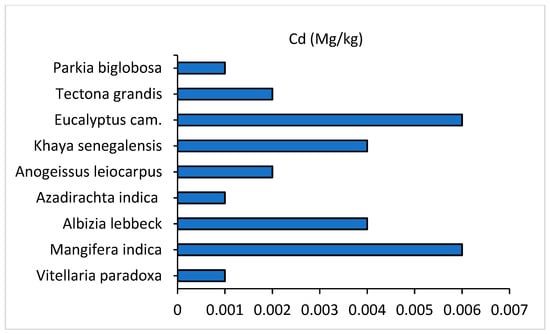

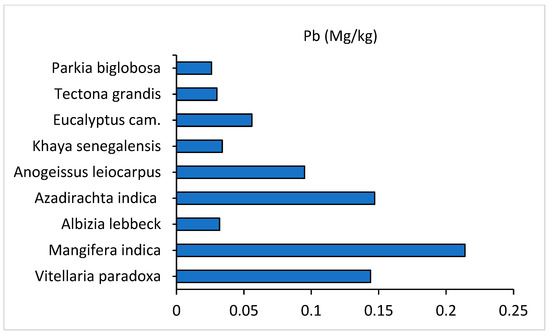

Figure 3, Figure 4 and Figure 5 show the result of heavy metals in the wood samples. Heavy metals in fuels significantly affect human health and the environment [19]. Hence, the content must be considerably low and in conformity with the set limits to make the species safe for use as fuel. Figure 3 shows the content of arsenic in the nine wood species. The values obtained are between 0.204 mg/kg for Anogeissus leiocarpus and 0.845 mg/kg for Vitellaria paradoxa. The values recorded meet the limit of ENplus [22] and ISO 17225-2 [24] (≤1 mg/kg).

Figure 3.

The content of arsenic in the wood species.

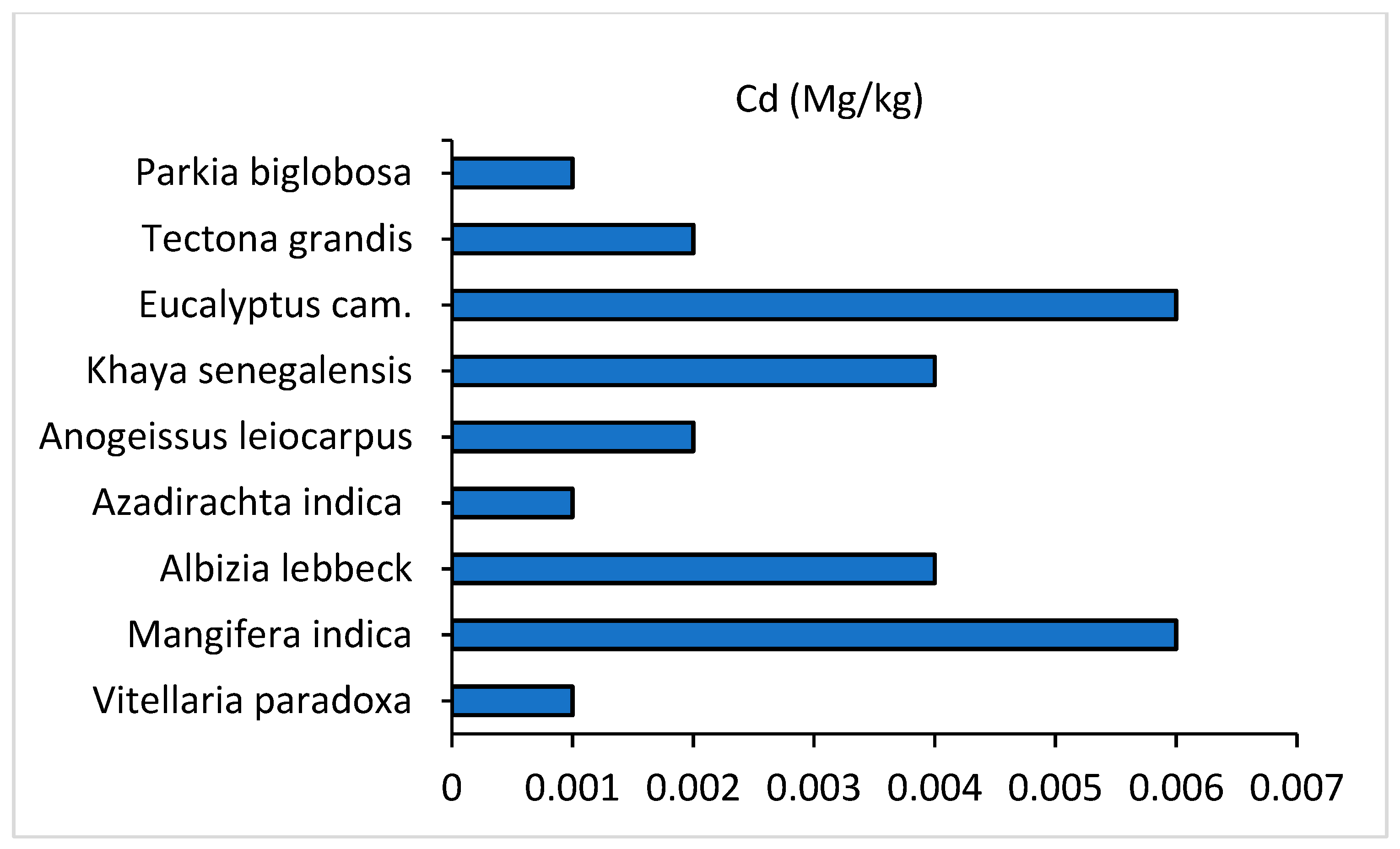

Figure 4.

Content of cadmium in the wood species.

Figure 5.

Content of lead in the wood species.

Figure 4 shows the content of cadmium in the samples. The values recorded are between 0.001 mg/kg for Parkia biglobosa, Azadirachta indica, and Vitellaria paradoxa and 0.006 mg/kg for Mangifera indica and Eucalyptus cam. Overall, the content of Cd in all the samples conforms with the ENplus [22] and ISO 17225-2 [24] standards (≤0.5 mg/kg).

Figure 5 shows the content of lead obtained in the wood samples. The values obtained are between 0.026 mg/kg for Parkia biglobosa and 0.214 mg/kg for Mangifera indica. All the samples conform with the ENplus [22] and ISO 17225-2 [24] standards (≤10 mg/kg).

3.3. Rating of the Properties of the Wood Species

The ratings of the evaluated fuel properties for the nine wood species are presented in Table 6. The species were rated between 1 and 9, with 1 indicating the best and 9 being the worst. The overall rating was defined as the average rating of the properties of each wood species [19]. Based on the result, Anogeissus leiocarpus revealed the best fuel properties with an average rating score of 3, while Vitellaria paradoxa, on the other hand, revealed the worst properties with an average rating score of 6.38.

Table 6.

Rating of the physical and thermochemical properties of the wood species.

However, in terms of conformity with the four wood pellets standards (Table 7), Khaya senegalensis, Parkia biglobosa, and Eucalyptus cam., having presented moisture content, density, calorific value, sulfur content, arsenic, cadmium, and lead within the set limits of ENplus [22], DIN 51731/DINplus [23], ÖNORM M7135 [23], and ISO 17225-2 [24], are therefore considered the best wood species. Although Anogeissus leiocarpus had the best rating score, its calorific value (17.35 MJ.kg−1) is below the DIN 51731/DINplus [23] and ÖNORM M7135 [23] standards.

Table 7.

Summary of wood species’ compliance with evaluated standards.

3.4. Improving the Properties of Non-Suitable Wood Species

As discovered in previous sections, some wood species were found to be more suitable as fuel than others. Thus, this study is not oblivious to the fact that, in certain environments, the non-suitable species might be the only woods available or probably the more sustainable. In these cases, the use of additives, blends, and combinations of two or more species to augment the low properties is recommended. This is more typical if the wood residues or shavings are to be pelleted. Here, biomass residues such as groundnut shells, sawdust, or leaf litter waste may be used as blends to enhance the physical and thermal properties of the pellets [42]. Similarly, bio-additives such as alkali lignin, glycerol, and L-proline can also be used [43]. Chemical additives such as adenylate kinase 2 (AK2) [44], crude glycerin, and paraffin also showed good results in wood pellet production [45]. Other additives reported in the literature include lignosulphonate, dolomite, starches, potato flour and peel, and some lubricating and vegetable oils [46]. These additives have excellent thermal properties that, when mixed with non-suitable biomass or wood species, tend to reduce the ash fusion and improve the calorific values. However, a careful selection of the type of additive and the use of the appropriate biomass is imperative in attaining wood pellets with desired physical and thermal characteristics [46]. For example, the addition of AK2 as an additive in pelleting barley and oat straw was observed to improve density and durability but increased the level of ash [44].

In the case of combining or co-pelleting two or more species, it is equally important to check both properties carefully to ensure the resulting mixture yields an improved output. For example, a biomass with very low ash content may be mixed with another with high ash content to reduce the resulting ash content of the mixture [42]. A 0.5% content of motor oil and vegetable oil was observed to have increased calorific value, while a 0.5% content of wheat starch as an additive significantly reduced ash formation by 200% [46]. Similarly, the addition of 20 wt% sawdust or 20% groundnut shell reduces ash content by between 8.6% and 10.44% [42].

If the following recommendations as sourced from previous findings are applied, the properties of some unsuitable species could be improved and meet the designated standards:

- (a)

- Using 5% lignin and 10% proline additives was found to improve density significantly, reduce ash content (AC) by 0.04%, and increase gross calorific value (GHV) by 0.2 MJ.kg−1 [47].

- (b)

- The calorific values may be improved using lignin additives. Based on this, the original content of lignin in the species can be added to the percentage of additives to obtain the total lignin (L). Thus, the gross calorific value (GHV) can be determined from Equation (8) [48].

Since the lignin content of the samples was not determined, values from previous studies were considered. The lignin content of Vitellaria paradoxa is about 35.7 ± 0.2% [49], and it is 23.75% for Magnifera indica [50], 25.67% for Albizia lebbeck [51], 13.58% for Azadirachta indica [52], and 35.4% for Tectona grandis [53]. Following this, the five (5) species with calorific values below the standard minimum can be improved by adding 5% content of lignin as an additive and recomputing the calorific value following Equation (8) (Table 8).

Table 8.

Improved calorific value of species with low calorific values.

Similarly, the ash contents and gaseous emissions of the samples would be drastically reduced if the wood barks were shaved out before pelleting or direct use as fuel. This is more peculiar to Albizia lebbeck (WoB) and Azadirachta indica (WoB), which recorded lower ash contents of 2.9% and 2.1%, respectively.

If the above assertions are followed, Tectona grandis, Albizia lebbeck, and Azadirachta indica, with their calorific values improved to the standard limit and other parameters (density, sulfur, arsenic, cadmium, and lead) within the limits of ENplus [22], DIN 51731/DINplus [23], ÖNORM M7135 [23], and ISO 17225-2 [24], would be equally suitable for use as fuel.

3.5. Research Limitations, Practical Implications, and Future Perspectives

While this study has assessed the suitability of the wood species as fuel based on their physical and thermochemical properties, this paper has not practically assessed the use of blends and additives to determine the improvement in ash content and calorific values. Thus, only a theoretical approach was used to predict the improvement. In this vein, future research could evaluate the effect of various blends and additives on species found particularly unsuitable in this study to track the improvement and compare the outputs with the theoretical method as a way of validation. Although the samples were pretreated before characterization, there was no measure employed in this study to eliminate contaminants embedded in the samples. This might have influenced the output of the experiments, especially the ash and nitrogen content. Future research could include the removal of toxic contaminants to simulate the actual properties of the species.

4. Conclusions

Selected physical and thermochemical properties of nine wood species used in charcoal and fuelwood production in Nigeria were evaluated. This was to assess their suitability as fuel and their pelleting potential based on four wood pellet standards. To determine the influence of wood bark on thermal performance, a proximate analysis was carried out on the samples with bark and without bark. The findings revealed a net calorific value between 10.61 MJ.kg−1 for Tectona grandis and 18.44 MJ.kg−1 for Eucalyptus cam. The ash content, volatile matter, and fixed carbon range between 2.1 and 24.4%, 65.94 and 87.77%, and 3.51 and 18.63%, respectively. Overall, it can be inferred from the study that wood samples without bark have lower ash content and higher fixed carbon content compared to samples with bark. Thus, they have better thermal and combustion performance than samples with bark.

In terms of suitability as fuel based on the physical and thermal properties, the findings showed Anogeissus leiocarpus to contain the best fuel properties. However, in terms of conformity with the four wood pellet standards, Khaya senegalensis, Parkia biglobosa, and Eucalyptus cam., having presented moisture content, density, calorific value, sulfur content, arsenic, cadmium, and lead within the set limits of ENplus, DIN 51731/DINplus, ÖNORM M7135, and ISO 17225-2, are therefore considered the best wood species with the highest pelleting potential. Thus, the findings further revealed that not all wood species are suitable as fuel. Therefore, it is important to set policies that would curtail the indiscriminate cutting of trees for fuel to help mitigate climate change and improve energy efficiency. However, in environments where the non-suitable species are the dominant or available woods, the use of biomass blends or additives could be employed to adapt the quality to the ISO commercialization standards. In the same context, the use of improved cookstoves is another measure to minimize fuel use and toxic gas emissions during combustion.

Author Contributions

Literature search, investigation, formal analysis, writing—original draft, S.U.Y.; conceptualization, supervision, writing—review and editing, S.N.; conceptualization, supervision, E.M.; supervision, K.P.; supervision, A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the German Federal Ministry of Education and Research (BMBF) through the West African Science Service Centre on Climate Change and Adapted Land Use (WASCAL) Ph.D. scholarship grant.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors are grateful to the German Federal Ministry of Education and Research (BMBF) for funding the study through the West African Science Service Centre on Climate Change and Adapted Land Use (WASCAL), under the Graduate Research Programme on Climate Change and Land Use (CCLU), College of Engineering, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana. The Authors are also grateful to the Savannah Forestry Research Station Zaria, Kaduna State, Nigeria, for providing the samples and Ahmadu Bello University Zaria, Kaduna State, Nigeria for providing the working space for this study.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| GDP | Gross Domestic Product |

| ISO | International Organization for Standardization |

| EN | European Norm |

| DIN | German Institute for Standardization |

| ÖNORM | Austrian Standard Institute |

| ₦ | Naira |

| N | Nitrogen |

| S | Sulfur |

| C | Carbon |

| H | Hydrogen |

| O | Oxygen |

| Cd | Cadmium |

| Pb | Lead |

| Ar | Arsenic |

| AC | Ash Content |

| VM | Volatile Matter |

| FC | Fixed Carbon |

| CV | Calorific Value |

| GHV | Gross Calorific Value |

| NCV | Net Calorific Value |

| USA | United States of America |

| MC | Moisture Content |

| WB | With Bark |

| WoB | Without Bark |

| MM | Most Properties Meet the Standards |

| FM | Few Properties Meet the Standards |

| AK2 | Adenylate Kinase 2 |

| L | Lignin |

References

- Schilmann, A.; Ruiz-García, V.; Serrano-Medrano, M. Just and fair household energy transition in rural Latin American households: Are we moving forward? Environ. Res. Lett. 2021, 16, 105012. [Google Scholar] [CrossRef]

- Boafo-mensah, G.; Darkwa, M.K.; Laryea, G. Effect of combustion chamber material on the performance of an improved biomass cookstove. Case Stud. Therm. Eng. 2020, 21, 100688. [Google Scholar] [CrossRef]

- Food and Agricultural Organization FAO. Global Forest Resources Assessment 2010: Main Report. Available online: https://www.fao.org/3/i1757e/i1757e.pdf (accessed on 3 January 2023).

- Food and Agriculture Organization FAO. Global Forest Resources Assessment 2015: How Are the World’s Forests Changing? Available online: https://www.fao.org/3/i4793e/i4793e.pdf (accessed on 8 January 2024).

- Food and Agricultural Organization FAO. FAOSTAT: Food and Agriculture Data. Available online: https://www.fao.org/faostat/en/#home (accessed on 16 March 2024).

- United Nations Environment Programme. Available online: https://www.uncclearn.org/wp-content/uploads/library/final_report_summary_for_decision_makers_redd_nigeria_unep.pdf (accessed on 17 March 2024).

- Akogun, O.A.; Waheed, M.A.; Ismaila, S.O.; Dairo, O.U. Physical and Combustion Indices of Thermally Treated Cornhusk and Sawdust Briquettes for Heating Applications in Nigeria. J. Nat. Fibers 2022, 19, 1201–1216. [Google Scholar] [CrossRef]

- Yunusa, S.U.; Mensah, E.; Preko, K.; Narra, S.; Saleh, A.; Sanfo, S. A comprehensive review on the technical aspects of biomass briquetting. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Narra, S.; Dasgupta, S.; Ay, P.; Zheng, T.; Weller, N. Pelletisation of Rye- and Wheat straw with additives. In Proceedings of the 19th European Biomass Conference and Exhibition, Berlin, Germany, 6–10 June 2011. [Google Scholar]

- Pal, D.B.; Tiwari, A.K.; Mohammad, A.; Prasad, N.; Srivastava, N.; Srivastava, K.R.; Singh, R.; Yoon, T.; Syed, A.; Bahkali, A.H.; et al. Enhanced biogas production potential analysis of rice straw: Biomass characterization, kinetics and anaerobic co-digestion investigations. Bioresour. Technol. 2022, 358, 127391. [Google Scholar] [CrossRef] [PubMed]

- Barbour, M.; Udesen, D.; Bentson, S.; Pundle, A.; Tackman, C.; Evitt, D.; Means, P.; Scott, P.; Still, D.; Kramlich, J.; et al. Development of wood-burning rocket cookstove with forced air-injection. Energy Sustain. Dev. 2021, 65, 12–24. [Google Scholar] [CrossRef]

- Yunusa, S.U.; Isiaka, M.; Saleh, A. Development of double burner natural-draft biomass cookstove. Agric. Eng. Int. CIGR J. 2022, 24, 194–206. [Google Scholar]

- Yunusa, S.U.; Mensah, E.; Preko, K.; Narra, S.; Saleh, A.; Sanfo, S.; Isiaka, M.; Dalha, I.B.; Abdulsalam, M. Biomass cookstoves: A review of technical aspects and recent advances. Energy Nexus 2023, 11, 100225. [Google Scholar] [CrossRef]

- Stoner, O.; Lewis, J.; Martínez, I.L.; Gumy, S.; Economou, T.; Adair-Rohani, H. Household cooking fuel estimates at global and country level for 1990 to 2030. Nat. Commun. 2021, 12, 5793. [Google Scholar] [CrossRef] [PubMed]

- Ogunsola, O.E.; Adeleke, O.; Aruna, A.T. Wood fuel analysis of some selected wood species within Ibadan. IOP Conf. Ser. Earth Environ. Sci. 2018, 173, 012043. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A.; Ssempijja, I.; Lubwama, H.N. Thermal and mechanical characteristics of local firewood species and resulting charcoal produced by slow pyrolysis. Biomass Convers. Biorefinery 2023, 13, 6689–6704. [Google Scholar] [CrossRef]

- Ndecky, A.; Tavares, P.W.; Senghor, A.; Kane, M.; Ndiath, H.; Youm, I. Proximate Analysis of Alternatives Cooking Solides Fuels in Sub Saharan by Using Astm Standards. Int. J. Clean Coal Energy 2022, 11, 1–12. [Google Scholar] [CrossRef]

- Charis, G.; Danha, G.; Muzenda, E. Characterizations of biomasses for subsequent thermochemical conversion: A comparative study of pine sawdust and acacia tortilis. Processes 2020, 8, 546. [Google Scholar] [CrossRef]

- Mitchual, S.J.; Frimpong-mensah, K.; Darkwa, N.A. Evaluation of Fuel Properties of Six Tropical Hardwood Timber Species for Briquettes. J. Sustain. Bioenergy Syst. 2014, 4, 44225. [Google Scholar] [CrossRef]

- Okoro, N.M.; Ikegwu, U.M.; Harding, K.G.; Daramola, M.O. Evaluation of Fuel Quality of Invasive Alien Plants and Tropical Hardwoods as Potential Feedstock Materials for Pyro-Gasification. Waste Biomass Valorization 2022, 13, 1293–1310. [Google Scholar] [CrossRef]

- Desta, H.M.; Ambaye, C.S. Determination of Energy Properties of Fuelwood from Five Selected Tree Species in Tropical Highlands of Southeast Ethiopia. J. Energy 2020, 2020, 3635094. [Google Scholar] [CrossRef]

- European Pellet Council (EPC). Quality Certification Scheme For Wood Pellets. Part 3: Pellet Quality Requirements. In The EN Plus Handbook; European Pellet Council: Brussels, Belgium, 2015; pp. 1–10. [Google Scholar]

- Pellets Atlas. Available online: www.pelletsatlas.info (accessed on 18 October 2023).

- International Organization for Standardization ISO. Available online: https://www.iso.org/standard/76088.html (accessed on 19 March 2024).

- ASTM D3173-87; Standard Test Method for Moisture in the Analysis Sample of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 1996; pp. 315–316.

- ASTM D5865-10a; Standard Test Method for Gross Calorific Value of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2010; pp. 1–14.

- Musabbikhah; Saptoadi, H.; Subarmono; Wibisono, M.A. Analysis and Selection of the Best Model of Biomass Briquette Based on Calorific Value. J. Phys. Conf. Ser. 2019, 1175, 012270. [Google Scholar]

- Ebeling, J.M.; Jenkins, B.M. Physical and Chemical Properties of Biomass Fuels. Trans. Am. Soc. Agric. Eng. 1985, 28, 898–902. [Google Scholar] [CrossRef]

- ASTM D3175-07; Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D3174-02; Standard Test Method for Ash in the Analysis Sample of Coal and Coke from Coal. ASTM International: West Conshohocken, PA, USA, 2002.

- Mansaray, K.G.; Ghaly, A.E. Physical and thermochemical properties of rice husk. Energy Sources 1997, 19, 989–1004. [Google Scholar] [CrossRef]

- TT, A.K.; Mech, N.; Ramesh, S.T.; Gandhimathi, R. Evaluation of composite briquettes from dry leaves in energy applications for agrarian communities in India. J. Clean. Prod. 2022, 350, 131312. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Sakthivadivel, D.; Iniyan, S. Characterization, density and size effects of fuels in an advanced micro-gasifier stove. Biofuels 2020, 11, 857–869. [Google Scholar] [CrossRef]

- Alkadri, A.; Jullien, D.; Arnould, O.; Rosenkrantz, E.; Langbour, P.; Hovasse, L.; Gril, J. Hygromechanical properties of grenadilla wood (Dalbergia melanoxylon). Wood Sci. Technol. 2020, 54, 1269–1297. [Google Scholar] [CrossRef]

- Mierzwa-Hersztek, M.; Gondek, K.; Jewiarz, M.; Dziedzic, K. Assessment of energy parameters of biomass and biochars, leachability of heavy metals and phytotoxicity of their ashes. J. Mater. Cycles Waste Manag. 2019, 21, 786–800. [Google Scholar] [CrossRef]

- Thabuot, M.; Pagketanang, T.; Panyacharoen, K.; Mongkut, P.; Wongwicha, P. Effect of Applied Pressure and Binder Proportion on the Fuel Properties of Holey Bio-Briquettes. Energy Procedia 2015, 79, 890–895. [Google Scholar] [CrossRef]

- Nagarajan, J.; Prakash, L. Preparation and characterization of biomass briquettes using sugarcane bagasse, corncob and rice husk. Mater. Today Proc. 2021, 47, 4194–4198. [Google Scholar] [CrossRef]

- European Committee for Standardization EN 1860-2. Appliances, Solid Fuels and Firelighters for Barbecueing, Part 2: Barbecue Charcoal and Barbecue Charcoal Briquettes. Requirements and Test Methods. 2005. Available online: https://www.cleanfuels.nl/Sitepdfs/EN-1860-2_eng_.pdf (accessed on 19 March 2024).

- Sunnu, A.K.; Adu-Poku, K.A.; Ayetor, G.K. Production and Characterization of Charred Briquettes from Various Agricultural Waste. Combust. Sci. Technol. 2023, 195, 1000–1021. [Google Scholar] [CrossRef]

- Sarkar, D. Fuels and Combustion. In Thermal Power Plant; Elsevier: Amsterdam, The Netherlands, 2015; pp. 91–137. [Google Scholar]

- Rajput, S.P.; Jadhav, S.V.; Thorat, B.N. Methods to improve properties of fuel pellets obtained from different biomass sources: Effect of biomass blends and binders. Fuel Process. Technol. 2020, 199, 106255. [Google Scholar] [CrossRef]

- Azargohar, R.; Nanda, S.; Kang, K.; Bond, T.; Karunakaran, C.; Dalai, A.K.; Kozinski, J.A. Effects of bio-additives on the physicochemical properties and mechanical behavior of canola hull fuel pellets. Renew. Energy 2019, 132, 296–307. [Google Scholar] [CrossRef]

- Emami, S.; Tabil, L.G.; Adapa, P.; George, E.; Tilay, A.; Dalai, A.; Drisdelle, M.; Ketabi, L. Effect of fuel additives on agricultural straw pellet quality. Int. J. Agric. Biol. Eng. 2014, 7, 92–100. [Google Scholar]

- Xia, X.; Zhang, K.; Xiao, H.; Xiao, S.; Song, Z.; Yang, Z. Effects of additives and hydrothermal pretreatment on the pelleting process of rice straw: Energy consumption and pellets quality. Ind. Crops Prod. 2019, 133, 178–184. [Google Scholar] [CrossRef]

- Tarasov, D.; Shahi, C.; Leitch, M. Effect of Additives on Wood Pellet Physical and Thermal Characteristics: A Review. Int. Sch. Res. Not. 2013, 2013, 876939. [Google Scholar] [CrossRef]

- Abedi, A.; Cheng, H.; Dalai, A.K. Effects of Natural Additives on the Properties of Sawdust Fuel Pellets. Energy Fuels 2018, 32, 1863–1873. [Google Scholar] [CrossRef]

- Demirbaş, A. Relationships between lignin contents and heating values of biomass. Energy Convers. Manag. 2001, 42, 183–188. [Google Scholar] [CrossRef]

- Olabisi, A.S.; Balogun, A.O.; Oni, T.O.; Fakinle, B.S.; Sotoudehnia, F.; McDonald, A.G.; Ikubanni, P.P. Physicochemical Characterization of Woody Lignocellulosic Biomass and Charcoal for Bio-energy Heat Generation. Sci. Rep. 2023, 13, 19242. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Mohanty, B. Thermal degradation of mango (Mangifera indica) wood sawdust in a nitrogen environment: Characterization, kinetics, reaction mechanism, and thermodynamic analysis. RSC Adv. 2021, 11, 13396. [Google Scholar] [CrossRef] [PubMed]

- Sultana, S.; Reja, M.M.; Hilary, L.N.; Saiful Islam, M.; Zamsed Uddin, M.; Ajmotgir, W.M. Preparation and characterization of nanocellulose from Albizia lebbeck sawdust and their application in nanocomposites using poly (vinyl chloride) (PVC). Res. Sq. 2021. [CrossRef]

- Manimaran, P.; Senthamaraikannan, P.; Sanjay, M.R.; Barile, C. Comparison of fibres properties of azadirachta indica and acacia arabica plant for lightweight composite applications. Struct. Integr. Life 2018, 18, 37–43. [Google Scholar]

- Lourenço, A.; Neiva, D.M.; Gominho, J.; Marques, A.V.; Pereira, H. Characterization of lignin in heartwood, sapwood and bark from Tectona grandis using Py–GC–MS/FID. Wood Sci. Technol. 2015, 49, 159–175. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).