Abstract

With increased worldwide energy demand and carbon dioxide emissions from the use of fossil fuels, severe problems are being experienced in modern times. Energy is one of the most important resources for humankind, and its needs have been drastically increasing due to energy consumption, the rapid depletion of fossil fuels, and environmental crises. Therefore, it is important to identify and search for an alternative to fossil fuels that provides energy in a reliable, constant, and sustainable way that could use available energy sources efficiently for alternative renewable sources of fuel that are clean, non-toxic, and eco-friendly. In this way, there is a dire need to develop technologies for biofuel production with a focus on economic feasibility, sustainability, and renewability. Several technologies, such as biological and thermochemical approaches, are derived from abundant renewable biological sources, such as biomass and agricultural waste, using advanced conversion technologies for biofuel production. Biofuels are non-toxic, biodegradable, and recognized as an important sustainable greener energy source to conventional fossil fuels with lower carbon emissions, combat air pollution, empower rural communities, and increase economic growth and energy supply. The purpose of this review is to explain the basic aspects of biofuels and their sustainability criteria, with a particular focus on conversion technologies for biofuel production, challenges, and future perspectives.

1. Introduction

Today, energy is the most important potential need for humanity, and its requirements have been radically increasing due to increased energy consumption, fossil fuel depletion, and environmental degradation [1]. Likewise, fuels are also of potential importance because they could be burned to produce energy [2]. Worldwide demands for fuel efficiency, instability of oil prices, global warming, energy security, and future requirements are some of the most important problems that we have faced [3]. Worldwide, the maximum (about 90%) energy requirements are met by fossil fuels, but by 2040, it is expected that usage of renewable resources will increase to about 50% [4,5]. To fulfil these requirements, there is a continuous demand to look for an alternative fuel that is renewable, inexpensive, eco-friendly, has lower GHGG emissions, sustainable, and is economically competitive, with several major benefits [6,7].

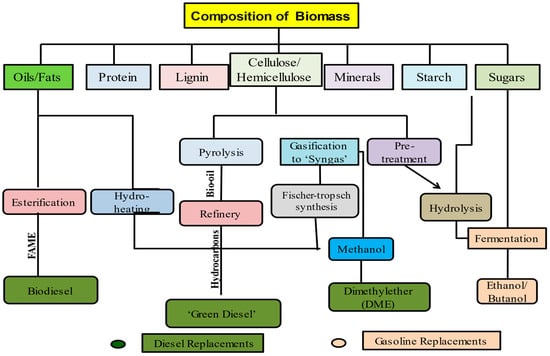

The use of biomass resources for the production of biofuel has drawn more attention globally. Due to rising prices of oil and climate change, researchers have been interested in renewable technology for biofuel production [8]. One of the sustainable energy sources, biofuel, is derived from biomass and used as an alternative to conventional fuel sources. Additionally, biofuels possess special qualities, such as non-toxicity, biodegradability, economic effectiveness, and being plentifully available [9]. The composition of the biomass and optimal production conditions like temperature, catalytic reaction time, chemicals, and kind of catalyst have all been taken into consideration when using biofuels as energy supplies in an eco-friendly and sustainable manner [10]. There is a dire need to search for alternatives to traditional fuels that provide constant, reliable, and sustainable energy sources which can be utilized efficiently. However, the use of fossil fuels has caused much harm to the environment and human beings due to the development of and increases in modernization, industrialization, economic enlargement, and growth of the population, which leads to economic calamities [11].

In the current scenario, fossil fuels (petrol, diesel, coal, and natural gas) are broadly used for power generation or mechanical energy in different sectors, such as transport, commercial, agriculture, domestic, and industrial [12]. In the transport sector, about 98% of the total energy consumed is derived from fossil fuels. Today, there are several technological challenges to producing renewable energy in sustainable ways. There is an urgent need to search for a substitute for fossil fuels that is renewable, inexpensive, environmentally friendly, and emits fewer greenhouse gases. The potential alternate for fossil fuels is biofuel production [13]. In this direction, developing countries have taken initiatives to replace traditional fuels with biofuels, which are renewable and produced from biomass used as biological substrates [14]. Moreover, biofuels have the potential to substitute for transport fuels like petroleum, jet fuel, and diesel fuel. Secondly, environmental degradation and climate change have led to numerous recent advances that could encourage the application of reliable and useful innovative technologies [5]. In this direction, biofuel is the most favorable alternative that can be produced domestically and can be substituted for gasoline that fulfils the requirements of the transportation sector [15].

In recent years, worldwide, there has been more emphasis on the replacement of petroleum products by the efficient utilization of renewable resources (lignocellulose biomass) into biofuels [16,17,18]. Today, liquid biofuels are gaining more interest as a substitute for fossil fuels derived from petroleum and gasoline in terms of energy requirements, oil prices, health issues, and global warming [19]. Similarly, to develop a sustainable energy matrix and reduce the level of CO2 in the transport division, biofuel has become one of the most promising forms of energy [20]. Mainly, biofuels are solid, liquid, and gaseous fuels that are obtained using feedstocks from different sources, such as animal fats, agriwaste (biomass), waste oils, etc. Biofuel is biodegradable, nontoxic, and carbon-neutral, and it releases less carbon and greenhouse gases with less CO, oxides (nitrogen and sulphur), hydrocarbons (unburnt), and particulate matter as compared to fossil and traditional fuels [21,22].

Biomass (agriwaste) is composed of abundantly available raw materials which are renewable and eco-friendly, do not increase the level of CO2, produce lesser amounts of sulphur and nitrogen in the environment [23], and are carbon neutral [24]. Biomass is classified as traditional and advanced according to its origin and the type of process adopted. First, traditional/conventional biomass is producing energy from unsustainable resources with low efficiency that release of high amounts of toxic pollutants. Modern biomass is derived from suitable conversion technologies, and under proper management, high quality biofuels, including of biofuels i.e., bioethanol, biogas, bio-oil, and biodiesel, are produced from vegetable oils, industrial and organic wastes [25]. It is one of the oldest energy sources used by humankind. About 90% or one-third of the global population have depended on conventional biomass for a common energy source, drawing from wood, forestry, agricultural residues, livestock etc. However, the problem of deforestation creates problems; it increases the pressure on the local environment, and greenhouse gases emissions could be increased due to fuel production from traditional biomass. Despite these drawbacks, billions of people still use traditional biomass as a source of energy because it is easily available and cheap. So, biofuels act as an energy vector and are produced from modern biomass through physical, chemical, and biological conversion processes. Production of biofuels (liquid) is a promising alternative source of energy that could replace petrol, diesel, and gasoline fuels. Similarly, bio-hydrogen has received significant consideration due to its numerous advantages. Biomass from lignocellulosic materials is used as feedstock for biohydrogen production, which is the best alternative to petroleum-based fossil fuels due to its properties, i.e., being environmentally friendly and emitting no greenhouse gases during combustion [26,27]. It is a safe, clean, and non-toxic biofuel that is sustainable and can be used as a vehicle fuel or to generate heat or electricity, as its burning provides mechanical energy without the emission of CO2. However, the applications of biohydrogen (H2) are still limited due to its capture, storage, and transformation methods on a large scale. Therefore, biohydrogen is a cost-effective as well as eco-friendly approach to resolving this problem. In this way, lignocellulosic and algal (macro and micro) biomass has attracted great research interest with the goal of producing biohydrogen and other biofuels [28]. The development of an economically viable process for biohydrogen production from bioconversion of lignocellulosic biomass (LCB) by applying the consolidated bioprocessing (CBP) method via nanotechnology is the best solution to move toward carbon neutrality and sustainability [29,30]. This review highlights basic information about biofuel production, comparisons between traditional and advanced biofuel conversion technologies, and future prospects and challenges with energy sustainability issues.

2. Biomass Energy

Various biomass resources could be used for energy purposes. These can be divided into four basic categories:

- Energy crop-based: Biomass from different energy crops such as herbaceous crops, woody, industrial crops, agricultural and aquatic crops are used for energy purposes.

- Agricultural residues and waste: Agriwaste (rice and wheat straw) and animal farm waste.

- Forestry waste and residues: Various mill wood waste, logging residues, trees and shrub residues etc.

- Industrial and municipal wastes: Municipal solid waste (MSW), sewage sludge and different industrial waste.

Consequently, the suitability of various aspirants for biofuel is being continuously researched by scientists and ecologists in terms of economic viability, reliability and future sustainability. Adapting blending capability with gasoline without much alteration makes fuel from plant origin (biofuel) an ideal candidate for an alternative to petroleum-based products. Therefore, the present chapter highlighted the types, classification/generation, and bioconversion processes for biofuel production with their safety challenges and future perspective.

3. Types of Biofuels

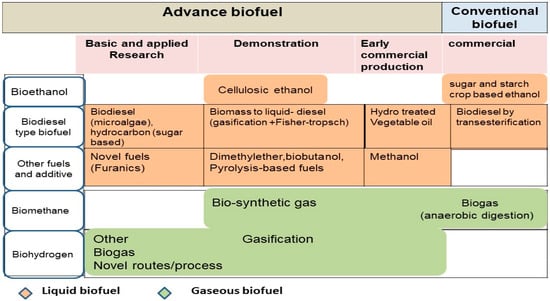

Different processes/technologies for energy conversion from various biomass/feedstock are appropriate for pilot and large scales production of biofuels. According to International Energy Agency [31], biofuels are usually divided into two types: conventional (first generation) and advanced biofuels (second and third generation). Figure 1 represents a view of the conventional and advanced biofuels and depicts the number of applications, basic R & D, and commercial production of liquid and gaseous biofuel. The types of biofuel production mainly depend on the types of feedstocks and their conversion process [32].

Figure 1.

An overview of conventional and advanced biofuels.

3.1. Conventional/Traditional Biofuels

These biofuels have well established processes/technologies for bioethanol production from sugars and starchy feedstock via fermentation and biodiesel production from transesterification of vegetable/edible oils. Basically, the conventional biofuels (bioethanol and biodiesel) are based on planting materials and share only 4% of the total transport fuel consumption due to several main constraints, viz., shortage of feedstock, low CO2 abatement, blending limit, and low cost [33]. These biofuels possess many advantages, including being carbon neutral and having low emission of greenhouse gases [34]. The first generation of biofuels, also called conventional biofuels, are made from sugar, starch, grains, maize, and vegetable oil. Typical feedstocks for biofuel production include sugarcane, sugar beet, corn and wheat grains, rapeseed, soybean oil crops, oil palm, animal fats, vegetable oil and municipal waste, and they are produced through optimized fermentation, distillation, and transesterification processes [35]. Another biofuel, called biodiesel, is produced from cooking oils, plant oil, and animal fat using transesterification with alcohol and methanol used as catalysts. The conventional biofuels are bioethanol, biodiesel, and biogas. Conventional biofuel pathway/technologies are well-known processes which are standardized at a commercial scale for biofuel production.

3.2. Advanced Biofuels

These types of biofuels mainly refer to second generation (from non-consumable materials), third generation (from micro and macro algae), and fourth generation (from genetically modified organisms) biofuels that are more sustainable and have low greenhouse gas emissions [36,37]. Advanced biofuels offer improved properties, compatibility with existing infrastructure, and greater potential for reducing greenhouse gas emissions [38]. Feedstocks mainly contain lignin cellulosic residues, which are obtained from agriculture and forest residues (eucalyptus, poplar, robinia etc.), non-food crops, which are grown on marginal and non-arable land, organic waste, woody parts of urban waste and perennial shrubs and grasses (e.g., jatropha, miscanthus, switch grass), agro and agri by-products, seaweed, and macro and micro-algae [39]. These biofuel production technologies mainly focus on non-food-based feed stock, including agriculture and genetically modified crops, and are grown on marginal, non-arable land with moderate crop yields. Advanced biofuels resources are LC-based biomass, algae/microbes-based biomass, biodiesel and bio-synthetic gas, animal fat-based biofuels (hydro treated vegetable) such as 2G ethanol, biomass-to-liquids (BTLs) biodiesel, biobutanol, DME, and bio-synthetic gas (bio-SG). More research and development should be required at pilot or demonstration phases for the production of advanced biofuels [19,40]. However, advanced biofuels offer a promising route towards a cleaner and more sustainable energy future [41,42]. These biofuels have a significantly lower carbon footprint and reduce climate change and global warming greenhouse gas emissions that help to mitigate of climate change and promote sustainable land use [33].

Currently, new technology should be designed for process improvements that are more efficient and cost effective [43].

Advances and recent separation technologies (wet and dry milling)

- Enzymatic dry milling

- Dry fractionation

- Ammoniation process in the wet mill

- Continuous membrane reactor for starch hydrolysis

- High-gravity fermentation

- Improved and efficient yeast (recombinant DNA techniques)

- Conversion of pentose and hexoses sugars to ethanol

- New enzymes for liquefaction and saccharification

- Optimized systems/conditions

4. Biofuels Generations/Classifications

Biofuels are recognized as vital renewable and sustainable energy sources that are alternatives to traditional or fossil fuel [44]. These are produced by biological process like anaerobic digestion and fermentation. Biofuel use as energy and fuel resources have been depending on the class, nature, and types of biomasses, feedstock, production technologies, standardized conditions for the production processes (temperature, pH, catalytic reaction time, reagents/solutions) and type of catalyst used in an eco-friendly and sustainable manner [45].

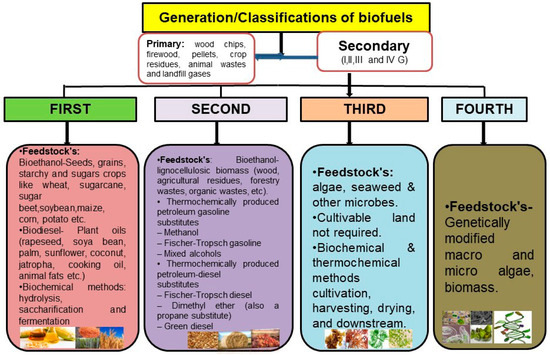

Biofuels are classified into first generation, second generation, third generation, and fourth generation (Table 1).

Table 1.

Classifications, product and feedstocks of different generations of biofuels.

The composition and calorific value of biofuels depend upon the type of biomass and process employed. Successfully using advance technologies for the large-scale for biofuel production from biomass would help save energy [46]. Basically, there are two types of biofuels: primary and secondary. The primary biofuels are mainly fuel from wood, wood chips, pellets, and organic waste materials, which are normally used for cooking in households and heating and electricity generation in industries. Likewise, secondary biofuels are generally developed from biomass (cultured), which consists of liquid fuels that are widely used in transportation and industrial sectors [47].

Further, biofuels are subdivided into four generations/classifications/categories (Figure 2) of biofuels: The first generation includes: biodiesel, bioethanol, vegetable oil, bio- ethers, solid biofuels, and biogas [48,49]. The various edible sources, like food crops, sugar, starch, animal or oil fats, and grains, are mostly used for producing first generation of biofuels [48].

Figure 2.

A schematic represents of different classification/generations of biofuels with their feedstock’s characteristics [48].

Generally, the second generation of biofuels is based on non-food crops like lignocellulosic biomass (agricultural residues such as straw, stover, sugarcane bagasse, and husk), wood and wood chips, wasted oil from edible food, and planting materials and organic waste from household and industries. Biohydrogen, biomethanol, mixed alcohols, ethanol and wood-based biodiesel are also categorized in second generation of biofuels.

The third generation of biofuels includes complex feedstocks, such as macro and microalgae algae, that produce a large number of energy sources. The fourth generation includes metabolic engineered plant and algae that generates biofuels from oxygenic photosynthetic microbes and creates artificial carbon sinks [50,51].

4.1. First-Generation Biofuels

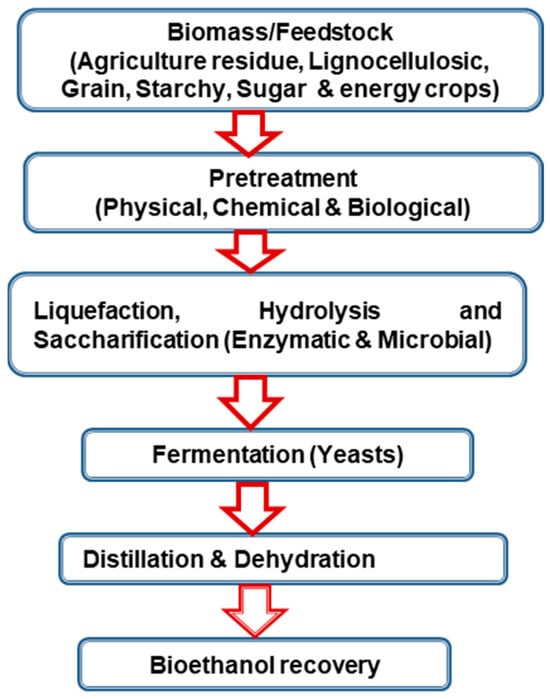

These biofuels are produced through well-established processes, viz., cold pressing, extraction, trans-esterification, hydrolysis, saccharification, fermentation, and chemical synthesis, and are optimized up to commercial production [48]. These biofuels have been mainly derived from starch, sugar, grains, animal fats, and vegetable oil sources. These types of biofuels (biodiesel, vegetable oil, bioethanol, and biogas) are already well-known in the fuel markets and are generally produced from fuel crops [49]. The production process for the first generation of biofuels consists of various conversion technologies depending on the type of feedstock and products (Table 2). The production process of bioethanol includes downstream and upstream process, namely hydrolysis, liquefaction, saccharification, fermentation, and product recovery (Figure 3).

Table 2.

Processes/technologies for producing the first generation of biofuels.

Figure 3.

Overall bioethanol production process from biomass.

4.2. Second-Generation (2G) Biofuels

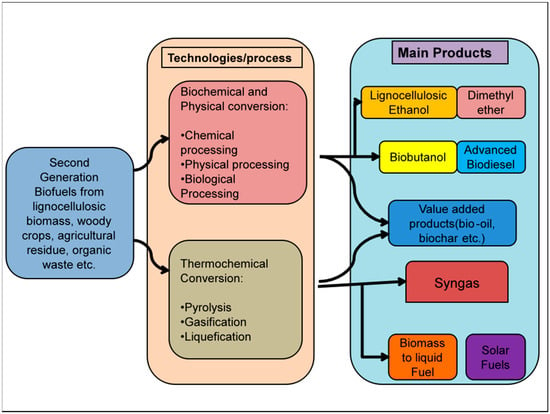

Conversion technologies for the production of 2G biofuel at commercial or large scale are still in development stage. The 2G biofuels are produced through more advanced technologies, such as pre-treatment, hydrolysis, saccharification and fermentation, and gasification and chemical synthesis.

The potential feedstocks that could be used in the production of 2G biofuels include lignin-cellulosic biomass, woody crops, agricultural residues, municipal and industrial wastes, processed wastes, and organic waste sources [17,52]. The biodiesel, bioethanol, synthetic fuels, and biohydrogen are mainly considered as 2G biofuels [48]. Second generation biofuels are used in various bioconversion/production routes which aim to avoid the “fuel versus food” problem. However, they could be competing with the use of agricultural lands for growth of food crops [49]. As lignocellulosic biomass is seen in various physio-chemical characteristics and compositions, it should be pretreated before further conversion into biofuel [53].

The conversion process of 2G feedstocks is obtained using two basic approaches (thermochemical and biological). Thermochemical decomposition processes are including gasification, biocarbonization, liquefaction, and pyrolysis. Biological digestion basically refers to microbial fermentation (Figure 4). Generally, the biological digestion process is very common and produces a small number of different products with high yields in the presence of some biological catalysts. The thermochemical conversion process produces multiple and complex products within short reaction times and used inorganic catalysts to improve the quality of products [53].

Figure 4.

Overall processes for the production of second generation biofuels (Bacovsky et al. [54]).

Biofuel could be blended with petroleum-based fuels in existing internal combustion engines, and then expand through existing infrastructure. With slight modifications, it could be also used in vehicles with internal combustion engines, for example, vehicles used for dimethyl ether. The biomass-to-liquids (BTLs), biobutanol, and bioethanol from lignocellulosic biomass are the main resources in 2G biofuel production [55]. The environment-friendly conversion process for utilizing raw corn cob biomass materials was developed without pretreatment stages by utilizing the enzyme mimicking features of cerium-doped iron oxide (CeFe3O4) NPs for bioethanol fermentation [56].

4.3. Third Generations of Biofuels

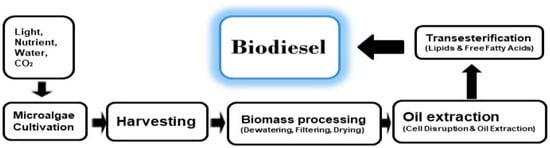

The third generation of biofuels mainly derived from algae or “algae-to-biofuels” technology, which is also known as oilgae (production of biodiesel and bioethanol), and biohydrogen produced from lignocellulosic biomass that does not require land to grow [57]. For production of bioethanol, different catalysts are used to convert sugar, starch, and lignin-cellulosic into simple short-chain carbohydrates [58]. Algae is a photosynthetically efficient feedstock as compared to other energy crops; it converts solar energy into chemical energy and stores it in the form of oils, carbohydrates, and proteins [59]. Biodiesel produced from algae is a potential alternative biofuel that is cost-effective. Microalgae have also been used as a promising feedstock for biodiesel because of their high productivities compared to other conventional energy crops. These algae are microscopically (colonial or single cell), large in size, and photosynthetic, with a diverse group of eukaryotic microorganisms that produce carbohydrates, proteins, and lipids. Therefore, microalgae can be used as feedstock for a third-generation energy source [45]. Biodiesel is a green fuel which does not contribute to the carbon dioxide emission and reduced engine emission; it contributes approximately 40–50% of the oxygen in the atmosphere [59]. It is safer, renewable, non-toxic, and biodegradable; it contains no sulphur; and it is a better lubricant. Therefore, biodiesel is the best option for replacement of conventional fuels. Moreover, its use creates numerous societal benefits: rural regeneration, employment opportunities, and reduced global warming [8,60,61]. Microalgae is a renewable source for biodiesel production that is capable of decreasing the demand for transport fuels globally [62]. It is the largest primary producers of the aquatic ecosystem. However, microalgae are a suitable feedstock for biodiesel production compared to other energy crops due to a numerous advantage, such as high photosynthetic efficiency, biomass production, and higher growth rate with high oil content, less freshwater consumption, short life duration, and simple structures.

Moreover, biodiesel produced from microalgal oil is showing similar characteristics to standard or conventional biodiesel. According to the flash point values, it is more stable [63]. These technologies could be increased in the biomass as well as lipid production, and microalgae production at the industrial scale will be improved [64]. To date, technologies for large scale production of third generation biofuels have not been successfully developed. Therefore, in future, these technologies could be established by using the latest and most advanced methods for mass production of biofuel. The overall sequence mentioned for biomass downstream processing includes cultivation, separation of the cells from the liquid growth medium, and oil extraction using the transesterification process for biodiesel production from microalgae (Figure 5).

Figure 5.

The overall integrated process of producing biodiesel from microalgae.

4.4. Fourth Generations of Biofuels

Biofuels are produced from macro and microalgae, and engineered crops/feedstock and microorganisms are used for bioethanol, biodiesel, and biohydrogen production. Recently, the concept has been introduced as “fourth generation algal biofuels” or “photosynthetic biofuels”. The algal biofuels would come from the metabolic and genetically engineered photosynthetic micro-organisms which are produced in fourth generation biofuel [63]. This generation of biofuels are based on raw materials/feedstocks that are basically rare, expensive, and difficult to source.

Fourth generation technologies are combined with genetically modified/optimized feedstocks that are mainly designed for capturing of huge amounts of carbon using genomically modified microbes that can efficiently produce biofuels [64]. The key process is required for capturing and sequestration of CO2, which renders fourth generation biofuels as a carbon negative source [65]. For high biofuel productivity, the product separation methods play significant roles in decreasing the production cost along with reducing the biomass separation and processing compared to conventional methods [40]. During biofuel production, volatile compounds like lower alcohols, aldehydes, and gases could be easily removed from the growth medium and distilled to liquid biofuel to avoid energy that requires dewatering steps [66]. Moreover, genetically modified (GM) algae can enhance biofuel production and are a potentially well-known alternative to fossil fuels [67].

Numerous studies have been conducted to enhance the various steps involved in producing biofuels, including pretreatment, hydrolysis, saccharification, fermentation, anaerobic digestion, transesterification of biomass under optimal conditions, reactor designs, product quality and yield while taking into account capital costs, consumer acceptance, and market value [68].

Bioethanol and biohydrogen are important renewable fuels which are produced from different feedstocks by using various fermentation processes, as mentioned in Table 3.

Table 3.

Comparison between bioethanol and biohydrogen production using different substrates.

5. Biomass Conversion Technologies for Biofuel Production

There are several existing and developing routes to convert biomass and other feedstocks and raw materials into different value-added products [53]. Basically, there are four routes that could be further sub-classified into different categories:

- Physical route/processes

- Briquetting

- Pelletization

- Agrochemical route/processes

- Thermochemical route/Processes

- Combustion in excess air

- Carbonization

- Pyrolysis

- Very little air/no oxygen added

- 750 °F to 1500 °F

- Gasification

- Some air/oxygen used but less than for incineration

- Begins at 1300 °F

- Biochemical route/Processes

- Anaerobic Digestion

- Bacteria breaks down feedstock

- No oxygen

- Fermentation

- Anaerobic process

- Microbes used to produce ethanol

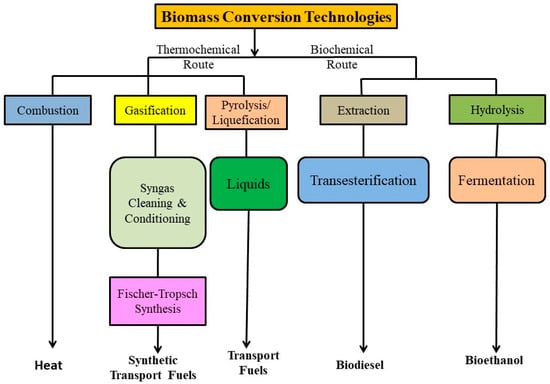

Basically, the biomass or feedstocks are transformed into liquid biofuels using two routes, namely, biochemical and thermochemical conversion technologies, into different products, such as bioethanol, biogas, biodiesel, bio-oil, biosyngas, biohydrogen, transport fuels, and heat generation by using fermentation, pyrolysis, liquefication, transesterification, chemical synthesis, and combustion processes (Figure 6).

Figure 6.

Biomass conversion technology for biofuels production [39].

The thermochemical process is characterized as having higher temperature and high conversion rates that are suitable for dry biomass/feedstock with lower moisture and is generally less selective for limited products. On the other hand, biochemical technologies are more suitable for wet wastes that are rich in organic matter [69]. Biofuels derived from renewable sources of biomass used as feedstock (agricultural residues, planting materials, starch and sugars crops, and wood) for bioethanol, and biogas production via liquefaction, enzymatic hydrolysis, saccharification, fermentation, and anaerobic digestion conversion technologies. Likewise, biodiesel is derived from feedstocks of plant oils, animal fats, and algae through transesterification and dark fermentation process [70]. Table 4 shows an outline of the types of biofuels and their conversion processes from different biomass as substrates and their applications in energy and fuel sectors [71,72].

Table 4.

Feedstock conversion technologies for biofuel production and its applications.

6. Comparison between Biofuels and Fossil Fuels

Biofuels have an advantage over traditional or conventional fuels and other renewable sources of energy, which reduces the dependency on oil imports and has zero or negligible emissions of oxides that cause environmental pollution, health hazards, and global warming [73]. Biofuels are a complement to traditional fossil fuels, which are produced from organic materials converted into fuel. Fossil fuels are hydrocarbons containing non-renewable natural sources, such as coal, fuel oil, and natural gas and are derived from dead plants, organisms, and animals [74]. When compared with the overall costs and benefits of biofuel and fossil fuel production, biofuels are cheap, renewable, and abundant organic materials used as feedstock compared to fossil fuels (Table 5). Le et al. [75] reported the energy and greenhouse gas effects and efficiency of both fuels. Biofuel was more profitable compared to fossil fuels. Worldwide, a sustainable biofuel market should be concentrated on efficiency improvement, optimized production processes, and blending properties [76]. As per the IRENA report, about 129 billion liters of liquid biofuel were used in 2016, which is projected to rise to 652 billion liters by 2050, while about 180 billion liters of biodiesel will be needed in the transport sector in 2050 [77,78]. Biofuels have been widely accepted as alternative fuels for the transportation sector to enhance the performance of transport vehicles.

Table 5.

Comparison of characteristics of biofuel and fossil fuels.

7. Future Prospective for Biofuels Production

In recent years, the production cost has been uncertain, and the availability of feedstock has also varied. Therefore, it is difficult to identify the best technology for a cost-effective pathway for biofuel production via thermochemical and biochemical processes. Depending on the scale of market value, the various processes for the mass production of biofuels could be associated with different steps required for conducting research, development, and innovation. However, presently, first-generation biofuel production has been developed at a commercial or mass scale, but second-generation biofuel production is entering the market, and third-generation biofuels are still under research and development. Nevertheless, it is predictable that they will all be moved to the industrial or commercial scale within the next era. In fact, at present, many countries are developing, evaluating, or promoting biofuel-based programs; only a few cases have observed good prospects when the proper productivity and production system have been used [77]. However, in the future, more efforts should be made in research and development for technology and demonstration. Also, the sustainable production of biofuel from various biomass feedstocks could be undertaken by adopting the best conversion technologies, which are advanced, cost-effective, and viable. New routes and processes in the production of new-generation biofuels should be adopted for cost reduction and high production efficiency. Production of biofuels should be economically viable with proper utilization of various biomasses, not only for fuel production but also for the production of other valuable products and energy. Biomass has unique properties, i.e., renewable sources of carbon that could be converted into solid, liquid, and gaseous fuels that are non-toxic and eco-friendly [79]. Therefore, in this situation, the biofuels from the different biomasses and feedstocks play a significant role in the replacement of traditional fuels.

Various factors have an effect on advanced bio-fuel production, such as the amount of biomass available, the variety of products that could be produced, the nature and conditions of the conversion processes adopted, the ability to utilize biomass efficiently, the requirement of energy, and the characteristics and size of biomass. The future challenges would be focused on the enzymatic conversion of biomass (LC), which includes efficient pre-treatment methods, effective separation of lignin, cellulose, and hemicellulose, cost of enzymes, identification of potent or viable microorganisms that should be producing cellulase enzymes, enzyme immobilization, optimization of the hydrolysis process for efficient saccharification, downstream processing for the conversion of cellulose and hemicellulose into ethanol, and other value-added products that reduce the overall processing cost [80,81]. Figure 7 depicts an overview of advanced biofuels with the latest technologies and products. More research efforts should be made for the development of cost-effective conversion technologies for biofuel production before focusing on feedstock utilization, enzyme cost reduction, and downstream processes for production. The long-term prospects for biofuels remain uncertain. On the other hand, new technologies may produce more efficient biofuels in the future. To date, these technologies remain unrealized and may not be operationally or commercially viable for another decade or more.

Figure 7.

A schematic representation of advance biofuels with value added products under different process.

Biofuel production is still challenging on a commercial scale, and new strains with commercial potential are still needed to be explored. The combination of multiple genetic engineering strategies for optimizing biofuel production will surely be useful. Thus, to overcome the energy crisis, global cooperative efforts are very important for transforming biofuels into our current energy system, which will further aid in cultivation methodology development as well as the technological advancement of biofuel production.

8. National Policy on Biofuels

India has placed more emphasis on the replacement of petroleum products with biofuels [16]. Today, liquid biofuels are gaining more interest as a substitute for fossil fuels derived from petroleum and gasoline in terms of energy requirements, oil prices, health issues, and global warming [19]. Similarly, biofuel has become one of the most promising forms of energy to develop a sustainable energy matrix and reduce CO2 level in the transport division [12,20]. Mainly, biofuel is made from different fuels, such as solid, liquid, and gaseous, that are obtained from different sources used as feedstocks, such as animal fats, agriwaste (biomass), waste oils, etc. Biofuel is biodegradable, non-toxic, and carbon neutral, releasing less carbon and greenhouse gases with less CO, oxides (nitrogen and sulphur), hydrocarbons (unburnt), and particulate matter as compared to fossil and traditional fuels [21,22].

Globally, the US, Brazil, and India are the major producers and consumers of biofuels and collectively contribute to 85% of the production and 81% of the consumption of ethanol. The global ethanol market was valued at 99 billion USD in 2022 and is expected to grow at a compounded annual growth rate of 5% by 2032, creating a huge opportunity for Indian industries and contributing to farmers’ income, job creation, and the overall development of the Indian ecosystem [78]. It was estimated that currently, about 98% of the fuel requirement in India for the transportation sector is met by fossil fuels and the remaining 2% by biofuels. India’s import of petroleum in 2020–2021 cost about 55 billion USD to the exchequer [82,83].

Recently, the Union Cabinet approved the National Policy on Biofuels for 2018 in order to promote biofuels in the country [84]. The objective of the National Policy on Biofuels has been to encourage domestic production of ethanol and further the Ethanol Blending Programme (EBP) in the country. Some other objectives of the National Policy on Biofuels are:

- To meet the energy needs of India’s rural population and create employment opportunities;

- To address global concerns by tightening automotive vehicle emission standards to curb air pollution;

- To reduce the dependence on the import of fossil fuels, provide a higher degree of national energy security;

- To derive biofuels from non-edible feedstock on degraded soils or wastelands unsuited to agriculture, avoiding a possible conflict between food and fuel.

For an optimum development of indigenous biomass and promotion of next-generation biofuels (Ministry of New and Renewable Energy, 2009), a target of 20% blending of ethanol in gasoline is proposed by Ethanol Supply Year (ESY) 2025–2026. An indicative target of 5% blending of biodiesel in diesel or direct sale of biodiesel is proposed by 2030 [83].

Biofuels in India are of strategic importance as they align well with ongoing government initiatives such as Make in India, Skill Development, and Swachh Bharat Abhiyan. It also offers a great opportunity to integrate with ambitious targets of doubling import reduction, farmers’ income and employment generation, and the waste to wealth concept.

9. Major Challenges in Biofuels Production

Today, the world is facing several challenges in the energy sector, including increases in oil prices, the depletion of natural resources, and environmental degradation. All of these challenges have direct or indirect effects on the environment and human beings. In this direction, biofuels have the potential to ease these problems in a sustainable and economical way. Worldwide, research into how to improve the production process of biofuels is ongoing. Nowadays, biofuel is a tremendous research area in which various advanced technologies used for biofuel production have also been developed, but fossil fuels cannot be completely replaced, and numerous integrated approaches in biological and genetic engineering are still important to standardize biofuel production at a marketable scale [79]. Recently, plant biomass has also been recognized as a potential source of biofuels, but presently, it is problematic and poses many challenges for biofuel at the commercial level compared to fossil fuels. It is necessary to develop potential strains for biofuel production using an advanced integrated approach. Presently, high-energy-requiring processes have been used for the utilization of biomass, i.e., the pretreatment process, purification of the biofuels, reactor design, operation conditions, and reaction mechanisms for thermochemical and biochemical processes for biofuel production [41,42]. These could be challenges in the commercialization of biofuel technologies. Recent technology or integrated processes for biofuels are still needed [80]. Moreover, there is a necessity to search for potential options related to various feedstocks or production technologies for the commercial production of biofuels [85,86]. Therefore, operation optimization is the major research area for increasing biofuel production [87]. On the other hand, lignin removal from biomass through pretreatment is also an important challenge due to lignan’s toxicity. It also acts as an inhibitor for the growth of microorganisms and has an adverse effect on the saccharification and fermentation processes during biofuel production [88]. Therefore, extensive research will be focused on innovative technologies in the sustainable production of value-added chemicals, functional polymers, hydrocarbon liquid fuels (hydrodeoxygenation), and other end products from lignin-derived feedstock through depolymerization, functionalization, and downstream processing [89,90]. However, further research is needed to optimize cultural conditions for biofuel production by developing novel microbial strains and integrating the different genetic engineering methods. However, large-scale production remains challenging. To resolve this problem, it is essential to convert biomass into biofuels by developing novel technology to increase biofuel production that can fulfil current and future energy demand.

10. Conclusions

Currently, India is one of the fastest-growing countries, with an increase in demand for fuel and energy. With the depletion of fossil fuels, high oil prices, a huge population, and limited energy resources in mind, the nation is searching for alternative renewable sources of fuel that are clean, non-toxic, and eco-friendly. In this context, biofuel production plays an important role in the environment and energy sectors. At present, biofuels play a vital role as a source of energy, potentially addressing several aspects, such as environmental degradation, global warming, climate change, energy security, rural development, business, and job opportunities. Bioethanol, biodiesel, and biogas are the major biofuels. However, there is a dire need to conquer the major technical hurdle towards lower capital costs for cellulosic ethanol production and make it cost-competitive with conventional biofuel systems for large-scale commercialization and production. The complete replacement of fossil fuels by biofuels is not feasible to achieve, but nevertheless, modern or advanced biofuels play a crucial role in fulfilling that requirement, helping to reduce greenhouse gas emissions, and leading society towards a better option that is sustainable and environmentally friendly. However, it is necessary to identify new renewable energy sources that have less of an impact on the accessibility and utilization of other resources and whose production is cost-effective. This must be intensified in order to maintain a sustainable environment for the production of biofuels and the consumption of energy.

There are multiple areas where the application of advanced technologies, such as biotechnology and nanotechnology, can significantly impact the economics of biofuel production. These improved technologies could play an important role in making the production of biofuels more sustainable and eco-friendlier, which represents a promising renewable source of electricity and gases. Biofuels still need to be improved as they are currently being developed. The need for biofuel is high, but effective technologies are needed to increase productivity and meet the desired requirements. In conclusion, to establish a more sustainable production of biofuel, there is a dire need for continuous research and development on all sustainability-related aspects.

Author Contributions

K.M.: Conceptualization, Methodology, Software, Writing—original draft, Writing—review & editing; S.C.C.: Writing, review and editing; B.R.K.: Review & editing; S.M.: Review & editing; K.S.: Review & editing; S.A.: Review & editing; D.K.B.: Review & editing. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by NAHEP-ICAR.

Data Availability Statement

Data are contained within the article.

Acknowledgments

I would like to express my deep sense of gratitude and obligation to my university, CCS Haryana Agricultural University, for giving me the opportunity for an international academic experience under the NAHEP-IDP training program and to NAHEP-ICAR for supporting me with the funds for this program. I am grateful to B. R. Kamboj, Worthy Vice-Chancellor, CCSHAU, Hisar for his overwhelming support in obtaining this opportunity. I express my indebtedness to my mentor at Texas A&M University, Sergio Capareda, Head BETA Lab for his guidance, encouragement, suggestions, intellectual stimulation, and magnanimous help during the training period.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

References

- Dale, B. Biofuels: Thinking Clearly About the Issues. J. Agric. Food Chem. 2008, 56, 3885–3891. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, D.; Dai, L.; Chen, Y.; Dai, X. Effects of Metal Nanoparticles on Methane Production from Waste-Activated Sludge and Microorganism Community Shift in Anaerobic Granular Sludge. Sci. Rep. 2016, 6, 25857–25862. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, A.; Prasad, R. Triglycerides Based Diesel Fuels. Renew. Sustain. Energy Rev. 2000, 4, 111–133. [Google Scholar] [CrossRef]

- Hussein, A.K. Applications of Nanotechnology in Renewable Energies—A comprehensive overview and understanding. Renew. Sustain. Energy Rev. 2015, 42, 460–476. [Google Scholar] [CrossRef]

- Palaniappan, K. An Overview of Applications of Nanotechnology in Biofuel Production. World Appl. Sci. J. 2017, 35, 1305–1311. [Google Scholar]

- Serrano, E.; Rus, G.; Garcia-Martinez, J. Nanotechnology for Sustainable Energy. Renew. Sustain. Energy Rev. 2009, 13, 2373–2384. [Google Scholar] [CrossRef]

- Ingle, A.; Paralikar, P.; Silva, D.S.S.; Rai, M. Nanotechnology-Based Developments in Biofuel Production: Current Trends and Appli. In Sustainable Biotechnology—Enzymatic Resources of Renewable Energy; Singh, O.V., Chandel, K.A., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 289–305. [Google Scholar]

- Aransiola, E.F.; Betiku, E.; Ikhuomoregbe, D.; Ojumu, T.V. Production of Biodiesel from Crude Neem Oil Feedstock and Its Emissions from Internal Combustion Engines. Afr. J. Biotechnol. 2012, 11, 6178–6186. [Google Scholar] [CrossRef]

- Pugh, S.; McKenna, R.; Moolick, R.; Nielsen, D.R. Advances and Opportunities at the Interface Between Microbial Bioenergy and Nanotechnology. Can. J. Chem. Eng. 2011, 89, 2–12. [Google Scholar] [CrossRef]

- Puri, M.; Abraham, R.E.; Barrow, C.J. Biofuel Production: Prospects, Challenges and Feedstock in Australia. Renew. Sustain. Energy Rev. 2012, 16, 6022–6031. [Google Scholar] [CrossRef]

- AFDC; Alternative Fuels Data Center; US Department of Energy. Energy Efficiency and Renewable Energy (EERE). 2006. Available online: https://afdc.energy.gov/ (accessed on 1 March 2006).

- Demirbas, A. Political, Economic and Environmental Impacts of Biofuels: A review. Appl. Energy 2009, 86, 108–117. [Google Scholar] [CrossRef]

- Nizami, A.; Rehan, M. Towards Nanotechnology Based Biofuel Industry. Biofuel Res. J. 2018, 18, 798–799. [Google Scholar] [CrossRef]

- Bandyopadhyay, K.R. Biofuel Promotion in India for Transport: Exploring the Grey Areas; The Energy and Resources Institute, TERI: Mithapur, India, 2015; Available online: https://www.teriin.org/policy-brief/biofuel-promotion-india-transport-exploring-grey-areas (accessed on 7 February 2015).

- Reddy, B.V.S.; Ramesh, S.; Kumar, A.A.; Wani, S.P. Biofuel Crops Research for Energy Security and Rural Development in Developing Countries. Bioenergy Res. 2008, 1, 248–258. [Google Scholar] [CrossRef]

- GOI (Government of India). Report of the Committee on Development of Bio-Fuel; Planning Commission, Government of India: New Delhi, India, 2016; 130p. Available online: https://fas.usda.gov/ (accessed on 24 June 2016).

- Talukdar, D.; Verma, D.K.; Malik, K.; Mohapatra, B.; Yulianto, R. Sugarcane as a Potential Biofuel Crop. In Sugarcane Biotechnology; Mohan, C., Ed.; Challenges and Prospects; Springer International Publishing: Cham, Switzerland, 2017; pp. 123–137. [Google Scholar]

- Shu, R.; Li, R.; Lin, B.; Wang, C.; Cheng, Z.; Chen, Y. A review on the catalytic hydrodeoxygenation of lignin-derived phenolic compounds and the conversion of raw lignin to hydrocarbon liquid fuels. Biomass Bioenergy 2020, 132, 105432. [Google Scholar] [CrossRef]

- Goldemberg, J. Biomass and Energy. Química Nova 2008, 32, 582–587. [Google Scholar] [CrossRef]

- Demirbas, A. Biofuels Securing the Planet’s Future Energy Needs. Energy Convers. Manag. 2009, 50, 2239–2249. [Google Scholar] [CrossRef]

- Čuček, L.; Klemeš, J.; Kravanja, Z. Carbon and nitrogen trade-offs in Biomass Energy Production. Clean Technol. Environ. Policy 2012, 14, 389–397. [Google Scholar] [CrossRef]

- DieCorrea, D.F.; Beyer, H.L.; Fargione, J.E.; Hill, J.D.; Possingham, H.P.; Thomas-Hall, S.R.; Schenka, P.M. Towards the Implementation of Sustainable Biofuel Production Systems. Renew. Sustain. Energy Rev. 2019, 107, 250–263. [Google Scholar]

- NREL. Biomass Research. 2009. Available online: https://www.nrel.gov/ (accessed on 1 August 2009).

- Cramer, J.; Wissema, E.; Lammers, E.; Dijk, D.; Jager, H.; Bennekom, S.; Breunesse, E.; Horster, R.; Leenders, C.; Wolters, W. Criteria for Sustainable Biomass Production. Final Report of the Project Group Sustainable Production of Biomass. 2006. Available online: https://www.globalbioenergy.org/bioenergyinfo/bioenergy-and-food-security/detail/en/c/1488/ (accessed on 2 September 2008).

- Ravindranath, N.H.; Sita Lakshmi, C.; Manuvie, R.; Balachandra, P. Biofuel Production and Implications for Land Use, Food Production and Environment in India. Energy Policy 2011, 39, 5737–5745. [Google Scholar] [CrossRef]

- Sivagurunathan, P.; Kumar, G.; Bakonyi, P.; Kim, S.H.; Kobayashi, T.; Nemestóthy, N.; Bélafi-Bakó, K. A Critical Review on Issues and Overcoming Strategies for the Enhancement of Dark Fermentative Hydrogen Production in Continuous Systems. Int. J. Hydrogen Energy 2016, 41, 3820–3836. [Google Scholar] [CrossRef]

- Singhvi, M.; Zinjarde, S.; Kim, B.S. Sustainable Strategies for the Conversion of Lignocellulosic Materials into Biohydrogen: Challenges and Solutions toward Carbon Neutrality. Energies 2022, 15, 8987. [Google Scholar] [CrossRef]

- Akram, H.A.; Imran, M.; Javaid, A.; Latif, S.; Rizvi, N.B.; Jesionowski, T.; Bilal, M. Pretreatment and catalytic conversion of lignocellulosic and algal biomass into biofuels by metal organic frameworks. Mol. Catal. 2023, 539, 112893. [Google Scholar] [CrossRef]

- Singhvi, M.; Kim, B.S. Green Hydrogen Production through Consolidated Bioprocessing of Lignocellulosic Biomass using Nanobiotechnology Approach. Bioresour. Technol. 2022, 365, 128108. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Sevda, S.; Abu Reesh, I.M.; Vanbroekhoven, K.; Rathore, D.; Pant, D. Biohydrogen Production from Lignocellulosic Biomass: Technology and Sustainability. Energies 2015, 8, 13062–13080. [Google Scholar] [CrossRef]

- IEA. Technology Roadmap Biofuels for Transport; International Energy Agency: Paris, France, 2011; p. 52. [Google Scholar]

- Available online: https://fuelsmarketnews.com/exploring-biofuels-conventional-and-advanced-biofuels-part-1 (accessed on 17 February 2021).

- Oh, Y.K.; Hwang, K.R.; Kim, C.; Kim, J.R.; Lee, J.S. Recent developments and key barriers to advanced biofuels: A short review. Bioresour Technol. 2018, 257, 320–333. [Google Scholar] [CrossRef]

- Singh, S.; Singh, S. Plant-Based Biofuels: An Overview. In Green Approach to Alternative Fuel for a Sustainable Future; Elsevier: Amsterdam, The Netherlands, 2023; pp. 433–442. [Google Scholar]

- Sindhu, R.; Binod, P.; Pandey, A.; Ankaram, S.; Duan, Y.; Awasthi, M.K. Biofuel Production from Biomass. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 79–92. [Google Scholar]

- Dickson, R.; Liu, J.J. A strategy for advanced biofuel production and emission utilization from macroalgal biorefinery using superstructure optimization. Energy 2021, 221, 119883. [Google Scholar] [CrossRef]

- Khan, M.A.H.; Bonifacio, S.; Clowes, J.; Foulds, A.; Holland, R.; Matthews, J.C.; Percival, C.J.; Shallcross, D.E. Investigation of Biofuel as a Potential Renewable Energy Source. Atmosphere 2021, 12, 1289. [Google Scholar] [CrossRef]

- Kolakoti, A.; Prasadarao, B.; Satyanarayana, K.; Setiyo, M.; Köten, H.; Raghu, M. Elemental Thermal and Physicochemical Investigation of Novel Biodiesel from Wodyetia Bifurcata and Its Properties Optimization using Artificial Neural Network (ANN). Automot. Exp. 2022, 5, 3–15. [Google Scholar] [CrossRef]

- Sekhon, B.S. Nanotechnology in Agri-food Production: An Overview. Nanotechnol. Sci. Appl. 2014, 7, 31–53. [Google Scholar] [CrossRef]

- IEA. Energy Technology Perspectives 2012: Pathways to a Clean Energy System; International Energy Agency: Paris, France, 2012; p. 690. [Google Scholar]

- Trindade, S.C. Nanotech Biofuels and Fuel Additives; MADS; InTech: Berlin, Germany, 2011. [Google Scholar]

- Cavelius, P.; Engelhart-Straub, S.; Mehlmer, N.; Lercher, J.; Awad, D.; Bruck, T. The Potential of Biofuels from First to Fourth Generation. PloS Biol. 2023, 21, e3002063. [Google Scholar] [CrossRef]

- Mizik, T.; Gyarmati, G. Three pillars of advanced biofuels’ sustainability. Fuels 2022, 3, 607–626. [Google Scholar] [CrossRef]

- Gnanasekaran, L.; Priya, A.K.; Thanigaivel, S.; Tuan, K.A.H.; Moscoso, M.S. The conversion of biomass to fuels via cutting-edge technologies: Explorations from natural utilization systems. Fuel 2023, 33, 125668. [Google Scholar] [CrossRef]

- Hofsetz, K.; Silva, M.A. Brazilian Sugarcane Bagasse: Energy and Non-Energy Consumption. Biomass Bioenergy 2012, 46, 564–573. [Google Scholar] [CrossRef]

- Nanda, S.; Rana, R.; Sarangi, P.K.; Dalai, A.K.; Kozinski, J.A. A Broad Introduction to First, Second and Third Generation Biofuels. In Recent Advancements in Biofuels and Bioenergy Utilization; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–25. [Google Scholar]

- Malik, K.; Anand, R.C.; Kadian, D.; Narula, A. Microalgae: A Promising Feedstock as Source for Third Generation Renewable Energy. In Microorganisms in Sustainable Agriculture, Food and the Environment; Verma, D.K., Srivastav, P.P., Eds.; Apple Academic Press Inc.: Palm Bay, FL, USA, 2018; pp. 395–420. [Google Scholar]

- Lin, Y.; Tanaka, S. Ethanol Fermentation from Biomass Resources: Current state and Prospects. Appl. Microbiol. Biotechnol. 2006, 69, 627–642. [Google Scholar] [CrossRef]

- Sikarwal, V.S.; Zhao, M.; Fennell, P.; Shah, N.; Anthony, E.J. Progress in Biofuel Production from Gasification. Prog. Energy Combust. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- Hayder, A.; Alalwan, A.; Alminshid, A.H.; Haydar, A.S. Promising Evolution of Biofuel Generations: A Review. Renew. Energy Focus 2019, 28, 127–139. [Google Scholar]

- Naik, S.N.; Goud, V.; Rout, P.K.; Dalai, A.K. Production of First- and Second-Generation Biofuels: A Comprehensive Review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Koçar, G.; Civas, N. An Overview of Biofuels from Energy Crops: Current Status and Future Prospects. Renew. Sustain. Energy Rev. 2013, 28, 900–916. [Google Scholar] [CrossRef]

- Rathmann, R.; Szklo, A.; Schaeffer, R. Land Use Competition for Production of Food and Liquid Biofuels: An Analysis of the Arguments in the Current Debate. Renew. Energy 2010, 35, 14–22. [Google Scholar] [CrossRef]

- Tuli, D.K. Opportunities in 2nd Generation Biofuel-Current Status; Petrofed, Indian Oil Corporation Limited: New Delhi, India, 2011. [Google Scholar]

- El-Desouky, M.G.; Khalil, M.A.; El-Bindary, A.A.; El-Bindary, M.A. Biological, Biochemical and Thermochemical Techniques for Biofuel Production: An Updated Review. Biol. Interface Res. Appl. Chem. 2022, 12, 3034–3054. [Google Scholar]

- Bacovsky, D.; Michal, D.; Wörgetter, M. Status of 2nd Generation Biofuels Demonstration Facilities in June 2010; Report T39-P1b; IEA: Paris, France, 2010. [Google Scholar]

- Swanson, R.M.; Platon, A.; Satrio, J.A.; Brown, R.C. Techno-Economic Analysis of Biomass-to-Liquids Production Based on Gasification. Fuel 2010, 89, 11–19. [Google Scholar] [CrossRef]

- Kim, M.; Singhvi, M.S.; Kim, B.S. Eco-Friendly and Rapid One-Step Fermentable Sugar Production from Raw Lignocellulosic Biomass using Enzyme Mimicking Nanomaterials: A Novel Cost-Effective Approach to Biofuel Production. Chem. Eng. J. 2023, 465, 142879. [Google Scholar] [CrossRef]

- Demirbas, A. Social, Economic, Environmental and Policy Aspects of Biofuels. Energy Educ. Sci. Technol. Part B Soc. Educ. Study 2010, 2, 75–109. [Google Scholar]

- Sivasubramanian, V. Algal Biofuels: Indian Scenario. In Proceedings of the Sahyog Minisymposium and Twinning Workshop Developments in Sustainable Biomass Valorization EU-India R&D Collaboration in Biomass and Biowaste, Utrecht, The Netherlands, 28–29 October 2013. [Google Scholar]

- Um, B.H.; Kim, Y.S. Review: A Chance for Korea to Advance Algal-Biodiesel Technology. J. Ind. Eng. Chem. 2009, 15, 1–7. [Google Scholar] [CrossRef]

- Bastianoni, S.; Coppola, F.T.; Colacevicin, A.; Borghini, F.; Focardi, S. Biofuel Potential Production from the Orbetello Lagoon Macroalgae: A Comparision with Sunflower Feedstock. Biomass Bioenergy 2008, 32, 619–628. [Google Scholar] [CrossRef]

- Lang, X.; Dalai, A.K.; Bakshi, N.N. Preparation and Characterization of Biodiesels from Various Bio Oils. Biores. Technol. 2001, 80, 53–62. [Google Scholar] [CrossRef] [PubMed]

- Chisti, Y. Biodiesel from Microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef]

- Rajvanshi, S.; Sharma, M.P. Microalgae: A Potential Source of Biodiesel. J. Sustain. Bioenergy Syst. 2012, 2, 49–59. [Google Scholar] [CrossRef]

- Nigam, P.S.; Singh, A. Production of Liquid Biofuels from Renewable Resources. Prog. Energy Combust. Sci. 2011, 37, 52–68. [Google Scholar] [CrossRef]

- Abdullah, B.; Syed, A.; Muhammad, E.S.; Mahmood, A.N. Fourth Generation Biofuel: A Review on Risks and Mitigation Strategies. Renew. Sust. Energy Rev. 2019, 107, 37–50. [Google Scholar] [CrossRef]

- Hallenbeck, P. Hydrogen Production by Cyanobacteria. Microbial Technologies. In Advanced Biofuels Production; Hallenbeck, P.C., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 15–28. [Google Scholar]

- Fritsche, U.R.; Fehrenbach, H.; Koppen, S. Biofuels—What Role in the Future Energy Mix? Shell Deutschland Oil: Darmstadt, Germany, 2012; p. 42. [Google Scholar]

- Farghali, P.M.; Mayumi, M.; Syo, K.; Satoshi, A.; Takashima, S.; Moustaf, T.Y. Potential of Biogas Production from Manure of Dairy Cattle Fed on Natural Soil Supplement Rich in Iron Under Batch and Semi-Continous Anaerobic Digestion. Bioresour. Technol. 2020, 309, 123298. [Google Scholar] [CrossRef]

- Sohel, M.I.; Jack, M.W. Thermodynamic Analysis of Lignocellulosic Biofuel Production via a Biochemical Process: Guiding Technology Selection and Research Focus. Bioresour. Technol. 2011, 102, 2617–2622. [Google Scholar] [CrossRef]

- Malik, K.; Verma, D.K.; Srivastava, S.; Mehta, S.; Khushboo, N.K.; Verma, M.; Kumar, A.; Tiwari, A.K.; Singh, K.P. Sugarcane Production and It’s Utilization as Biofuel. In India: Current Policy and Status; Verma, D.K., Ed.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 123–138. [Google Scholar]

- Mussatto, S.I.; Dragonea, G.; Guimarãesa, P.M.R.; Silva, J.P.A.; Carneiro, L.M.; Roberto, I.C.; Vicentea, A.; Domingues, L.; Teixeira, J.A. Technological trends, global market, and challenges of bio-ethanol production. Biotechnol. Adv. 2010, 28, 817–830. [Google Scholar] [CrossRef]

- Pradoand, J.M.; Meireles, M.A.A. Production of Valuable Compounds by Supercritical Technology Using Residues from Sugarcane Processing. In Biorefinery Co-Products: Phytochemicals, Primary Metabolites and Value-Added Biomass Processing; Bergeron, C., Carrier, D.J., Ramaswamy, S., Eds.; Wiley: Hoboken, NJ, USA, 2012; pp. 133–151. [Google Scholar]

- Muhammad, U.L.; Shamsuddin, I.M.; Danjuma, A.; Musawa, R.S.; Dembo, U.A. Biofuels as the Starring Substitute to Fossil Fuels. Pet. Sci. Eng. 2018, 2, 44–49. [Google Scholar]

- Reijnders, L. The Life Cycle Emission of Greenhouse Gases Associated with Plant Oils used as Biofuel. Renew. Energy 2011, 36, 879–880. [Google Scholar] [CrossRef][Green Version]

- Le, T.L.; van Ierland, E.C.; Zhu, X.; Wesseler, J. Energy and Greenhouse Gas Balances of Cassava-Based Ethanol. Biomass Bioenergy 2013, 51, 125–135. [Google Scholar] [CrossRef]

- Duer, H.; Christensen, P.O. Socio-Economic Aspects of Different Biofuel Development Pathways. Biomass Bioenergy 2010, 34, 237–243. [Google Scholar] [CrossRef]

- Nogueira, L.A. Does Biodiesel make Sense? Energy 2011, 36, 3659–3666. [Google Scholar] [CrossRef]

- IRENA. Global Energy Transformation: The REmap Transition Pathway; Background Report to 2019 Edition; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019; Available online: https://www.irena.org/publications/2019/Apr/Global-energy-transformation-The-REmap-transition-pathway (accessed on 4 August 2020).

- Khan, S.; Naushad, M.; Iqbal, J.; Bathula, C.; AL-Muhtaseb, A.H. Challenges and Perspectives on Innovative Technologies for Biofuel Production and Sustainable Environmental Management. Fuel 2022, 325, 124845. [Google Scholar] [CrossRef]

- Ambaye, T.G.; Mentore Vaccari, M.; Bonilla-Petriciolet, A.; Prasad, S.; van Hullebusch, E.D.; Rtimi, S. Emerging technologies for biofuel production: A critical review on recent progress, challenges and perspectives. J. Environ. Manag. 2021, 290, 112627. [Google Scholar] [CrossRef] [PubMed]

- De Araujo, B.M.C.; Costa, I.O.; de Brito, H.G.; Rios, N.S.; Dos, S. Enzyme technology in bioethanol production from lignocellulosic biomass: Recent trends with a focus on immobilized enzymes. Bioresources 2023, 18, 352023. [Google Scholar] [CrossRef]

- Ministry of New and Renewable Energy. National Policy on Biofuels; Ministry of New and Renewable Energy: New Delhi, India, 2009. [Google Scholar]

- Available online: https://pib.gov.in/PressReleaseIframePage.aspx?PRID=1960491 (accessed on 25 September 2023).

- National Biofuel Policy. 2018. Available online: https://mnre.gov.in/file-manager/UserFiles/biofuel_policy.pdf (accessed on 20 September 2015).

- Mandade, P.P.; Yogesh, M.; Nimdeo, N. Techno-economic assessment of biofuel production using thermochemical pathways. In Biofuels Bioenergy; Elsevier: Amsterdam, The Netherlands, 2022; pp. 653–671. [Google Scholar]

- Lee, S.Y.; Sankaran, R.; Chew, K.W.; Tan, C.H.; Krishnamoorthy, R.; Chu, D.T.; Show, P.L. Waste to Bioenergy: A Review on the Recent Conversion Technologies. BMC Energy 2019, 1, 4. [Google Scholar] [CrossRef]

- Prasad, S.; Singh, A.; Korres, N.E.; Rathore, D.; Pant, D. Sustainable utilization of crop residues for energy generation: A life cycle assessment (LCA) perspective. Bioresour. Technol. 2020, 303, 122964. [Google Scholar] [CrossRef] [PubMed]

- Sie, S.W.; Riyang, S.; Zhang, J.; Liu, H.; Ning, Y. Downstream processing of lignin derived feedstock into end products. Chem. Soc. Rev. 2020, 49, 5510–5560. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).