Abstract

Torrefaction pretreatment is a mild form of pyrolysis that has the potential to produce a high-quality raw material for making biofuel that serves as a replacement for coal in the bioenergy industry. Microwave-assisted torrefaction was conducted on white spruce sawdust (WSS) at temperatures of 200 °C, 250 °C, and 300 °C and retention times of 5 min, 7 min, and 9 min in an inert environment. The torrefaction process produces a solid carbon, commonly known as biochar, and condensable (torrefaction liquid (TL)) and non-condensable gases. In this study, torrefaction characteristics were investigated to observe its effects on the thermal and physiochemical properties of the pellets produced. During the torrefaction process, a significant mass loss associated with the decomposition of hemicellulose was observed. The hemicellulose content drastically reduced to approximately 1.8% and the cellulose content was reduced by approximately 10%, while the lignin gained approximately 35% as the severity increased. This led to an improvement in the higher heating value (HHV), hydrophobicity, bulk, particle density, pellet dimensional stability, and pellet density. However, the pellet tensile strength decreased as the torrefaction severity increased. Pellet tensile strength is a critical indicator of biomass pellets that expresses the force required to crush or damage a pellet. Therefore, to enhance the tensile strength of the pellets, the introduction of a binder was necessary. Torrefaction liquid and sawdust were used as additives at different proportions during pelletization. The addition of binders (torrefaction liquid and sawdust) to the pellet formulation increased the tensile strength of the torrefied WSS by approximately 50%. The OH groups in the biomass break down to a limited degree due to dehydration. This hinders the formation of H bonds, thereby increasing the chances that the pretreated biomass will become hydrophobic. The SEM graphs showed that the torrefied WSS pellets demonstrated more firmly glued surfaces with fewer pores spaces when set side by side with the raw pellets. The thermogravimetric analysis conducted showed that the torrefaction of WSS slightly reduced its thermal stability.

1. Introduction

A genuine solicitude is drawn regarding the increased risk of environmental threats linked with fossil fuel utilization [1,2]. With the constant unsteadiness of energy prices and the rapid depletion of conventional energy resources, it is urgent to source sustainable, renewable, and eco-friendly forms of energy [3]. Biomass stands out in the substitute energy competition because it is a carbon-neutral bioenergy source, has a low cost, and is abundantly available [4,5]. However, some difficulties linked with the utilization of biomass in its unprocessed state (such as a low energy density, low bulk density, a heterogeneous nature, low efficiency, ash accumulation, and a high moisture content) compromise its potential development in the bioenergy industry [6,7]. In recent years, the pretreatment of biomass has demonstrated some improvement in the characteristics of the treated biomass. Torrefaction is a biomass heat operation associated with roasting a biomass sample in a controlled environment at temperatures, which range from 200 to 300 °C. Torrefaction is commonly known as mild pyrolysis, and it has been investigated for the pretreatment of biomass to make it more hydrophobic, reduce its moisture content, and increase its calorific value, resulting in an increase in the volumetric energy density of the biomass. In addition, torrefaction with pelletization can reduce the transportation costs of biomass and intensify its heating value and hydrophobicity [8,9]. These changes make biomass more combustible, storable, and attractive [5,10].

Approximately 350 million hectares of land in Canada are forest, making Canada the third in the world with respect to forest area [11]. The forestry industry contributes majorly to the country’s economy. In 2020, the wood-product-manufacturing sector had a nominal GDP of approximately CAD 12.6 billion, making it the most lucrative of the forestry industries [11]. Canada’s main trading partner in forest resources is the United States, with Canadian exports valued at approximately CAD 25 billion in the year 2020. The most-sold Canadian forest products are millwork, sawmill, and lumber, with export rates valued slightly above CAD 22 billion worldwide [11]. The utilization of forestry residues to generate energy has traditionally existed in Canada, especially in the forestry industry [12]. The feedstock used by these industries for generating electricity and other forms of energy are forest residues such as sawdust, bark, and branches. Some varieties of trees found in Saskatchewan (SK), Canada, include trembling aspen, white spruce, jack pine, and black spruce. Saskatchewan has four large sawmills and several smaller sawmills; approximately 1.3 million m3 (545 million board feet) of spruce-pine-fir (SPF) lumber is produced annually from these mills [13]. In Canada, white spruce (Picea glauca) is found mostly in the boreal forest (northern coniferous forest). In Saskatchewan, the total annual allowable harvest is 28% of the coniferous forest and 16% of the total forest. Consequently, white spruce accounts for a substantial part of these harvests [13]. Lignocellulosic biomass is readily available and can settle the issues arising from the use of biomass between food and energy [14]. The utilization of forest residues, especially sawdust, for biofuel production decreases the dependency on food-resource biomass while also adding value to forest residues [15].

Densification using binders such as starch, lignin, sawdust, and moisture has been studied by different researchers. Table 1 summarizes the effect of different binders on the pelletization of biomass as it has been reported by other researchers. Frequently used binders include starch and lignin; however, they are expensive and have competing use as food ingredients [5]. While it intends to enhance the thermal, mechanical, and physiochemical properties of torrefied sawdust pellets, this research also explores the utilization of cheap and non-food-based binders. In this study, white spruce sawdust and torrefaction liquid (TL) were introduced as binders during the pelletization process after the microwave-assisted torrefaction of WSS. The torrefaction gases (a condensable liquid) contain a large amount of energy. Therefore, introducing a closed recycling system has an economically viable potential for the torrefaction system. It is significant that this energy is utilized productively in the system (torrefaction and densification) to approach and settle the process stability, system reliability, and safety problems that currently avert commercial-scale torrefaction. This study also emphasizes the consequences of torrefaction and binders on the thermal, mechanical, and physiochemical characteristics of pellets formed from torrefied WSS.

Table 1.

Effect of binders on the pelletization of biomass, as determined by other researchers.

2. Materials and Methods

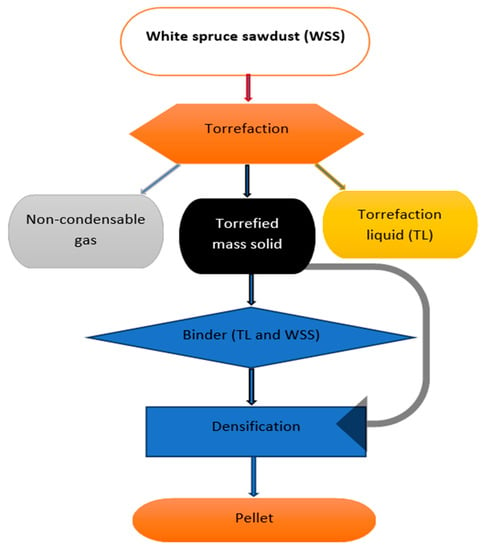

The torrefaction and pelletization process for white spruce sawdust (WSS) is shown in Figure 1. These processes and their effects are exhaustively discussed in depth in the consequent sub-heading. The torrefaction pretreatment process of WSS saves cost and energy since the feedstock in this study requires little or no preprocessing due to its nature (a fine particle).

Figure 1.

Torrefaction and pelletization process for white spruce sawdust.

2.1. Feedstock Collection and Preparation

White spruce sawdust (WSS) was received from the sawmill of NorSask Forest Products Inc. (Meadow Lake, SK, Canada) in the middle of 2020. The moisture content of the as-received sawdust was approximately 42% wet basis (w.b.). The samples were screened with a 0.8 mm sieve size to remove irregular particles. They were then preserved in a fastened plastic container in a conditioned space at a temperature of approximately 4 °C to be used for experimentation. The torrefaction liquid (TL) used as an additive during pelletization was a product of this study.

2.2. Torrefaction Experiment

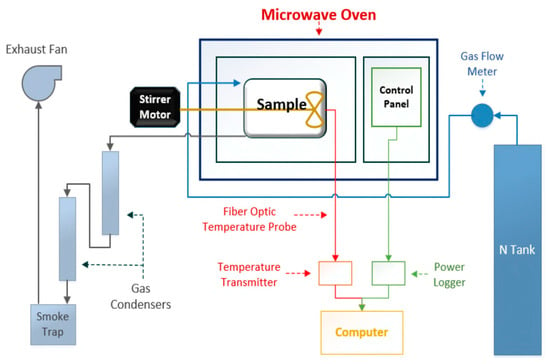

The torrefaction pretreatment of the WSS was carried out to improve its physicochemical characteristics. The setup of the lab-scale microwave oven and the pretreatment operation were similarly narrated by Valdez et al. [21]. Figure 2 shows a schematic diagram of the microwave torrefaction setup. Different temperatures of 200 °C (light torrefaction), 250 °C (moderate torrefaction), and 300 °C (severe torrefaction) and residence times of 5, 7, and 9 min were considered. Initially, a power level of 650 W was set before the microwave oven was turned on. The power level had to be controlled at different torrefaction residence times (decreased or increased) to attain a constant temperature (200, 250, or 300 °C) for the total residence time. A power level ranging from 400 to 750 W was recorded throughout the torrefaction process. The masses of torrefied solid (biochar) and liquid produced were recorded after each experiment. Equation (1) by Overend et al. [22] was used to estimate the degree of torrefaction, which is a function of the residence time and temperature [22] that is also known as the severity factor.

where SF indicates the severity factor, T represents the torrefaction temperature (°C), and t represents the residence time (min).

Figure 2.

Schematic diagram of the microwave-assisted torrefaction pretreatment setup. Extracted from [21].

2.3. Experimental Design of Torrefaction Pretreatment

A factorial experimental design of two independent variables, the temperature of operation (°C) and the residence time of the process (min) at three levels for each factor (temperature at 200, 250, and 300 °C and retention time at 5, 7, or 9 min), were studied. The experiments were performed three times and the results were averaged. An analysis of variance (ANOVA) was carried out to evaluate the effect of the pretreatment operation on the response variables (dimensional stability, pellet tensile strength, and pellet density).

2.4. Densification

The torrefied WSS was pelletized to investigate the influence of residence time and torrefaction temperature on the pellets formed. The effect of binders on the pelletization was also studied using different formulations (torrefaction liquid (TL) and sawdust) and torrefied samples. Table 2 shows the different formulations that were pelletized to analyze the effect of the binders on the physiochemical characteristics of the respective pellets.

Table 2.

Formulations for pelletizing with the torrefaction liquid and sawdust.

The pelletization of torrefied spruce sawdust samples and untreated spruce sawdust samples was executed using a similar setup and procedure as narrated by Onyenwoke et al. [12].

2.5. Characterization of Torrefied White Spruce Sawdust

The characterization of the untreated and treated white spruce sawdust was carried out to estimate the influence of the residence time and torrefaction temperature on the WSS.

2.5.1. Moisture Content and Torrefaction Yield

The amount of moisture present in the white spruce sawdust when it was collected was evaluated using ASAES358 [23], while the quantity of moisture available after the torrefaction process was calculated by following the AACC Standard 44-15A [24]. The experiments were performed three times and the results were averaged. Equation (2) was used to evaluate the mass yield of the pretreatment process. After each pretreatment, the biochar and the TL were weighed and kept in airtight Ziploc bags. The gas yield was determined by summing the solid yield and the TL yield and then subtracting them from the initial sample introduced.

where represents the percent mass yield of the torrefaction operation (%), represents the mass of the torrefied sample (g), and represents the mass of the untreated WSS sample (g). The quantity of weight loss and the amount of energy output were determined using Equations (3) and (4), respectively.

where represents the weight loss; represents the energy yield; represents the mass of the untreated WSS; represents the mass of torrefied WSS; represents the higher heating value (HHV) of the WSS after torrefaction, and represents the HHV of the untreated WSS sample.

2.5.2. Particle Size Analysis

The ASABE [25] procedure was used to examine the particle size of the WSS samples. Some researchers have reported a similar experiment in which the same setup and procedure were considered in evaluating the particle size of torrefied and untreated biomass [25,26,27]. Approximately 100 g of biochar and controlled samples were introduced into stacked sieves of various size openings, and the mechanical sieve shaker was left to run for approximately 10 min. The experiment was performed in three replicates and the results were averaged. Equations (5) and (6) were used to determine the geometric mean diameter (dgw) and the standard deviation of the particle diameter (Sgw) of the WSS samples, respectively.

where dgw denotes the geometric mean diameter (mm); n denotes the number of sieves + 1 pan; Wi denotes the mass on the ith sieve (g); di represents the nominal sieve opening size of the ith sieve (mm); Slog represents the geometric standard deviation of log-normal distribution by mass in the common (base 10) logarithm.

2.5.3. Bulk and Particle Density

The bulk density of the unprocessed and torrefied WSS was determined due to its importance in logistics, storage, and densification. The setup and procedure for determining the bulk and particle density were similar to what was described by Onyenwoke et al. [12]. The bulk density of the WSS samples in kg/m3 was estimated by the weight of the sample per its unit volume. The experiment for bulk density was performed in three replicates and averaged, while particle density data were obtained in replicates of 10 and the results were averaged.

2.5.4. Elemental and Proximate Analysis

An Elementar analyzer (Vario EL III, Elementar Americas Inc., Ronkonkoma, NY, USA) was utilized to evaluate the amount of carbon (C), hydrogen (H), nitrogen (N), and sulfur (S) present in the raw sample and the biochar samples, while the quantity of oxygen available in the sample was estimated by difference. The setup of the equipment and procedures was similarly described by Onyenwoke et al. [12].

The proximate analysis of the unprocessed WSS sample and biochar was evaluated by the ASTM standard procedures. The quantity of ash in the untreated WSS and the WSS biochar, moisture content (MC), and volatile matter (VM) were evaluated by the ASTM 3173-87 [28], ASTM D3175-89 [29], and ASTM 3174-04 [30] standard procedures, respectively. Additionally, the amount of fixed carbon (FC) present in the samples was determined by differences [31], as provided in Equation (7).

2.5.5. Higher Heating Value (HHV)

The HHV evaluation of both the biochar and the untreated WSS was carried out with the aid of a bomb calorimeter (6400 Automatic Isoperibol, Parr Instrument Company, Moline, IL, USA). The setup and the procedure for determining the HHV were similar to what was described by Onyenwoke et al. [12]. The test was executed three times and the results were averaged.

2.5.6. Chemical Composition of Torrefied WSS

The chemical content available of the torrefied WSS and the untreated WSS was estimated using the ANKOM methods for neutral detergent fiber (NDF), acid detergent fiber (ADF), and acid detergent lignin (ADL). ANKOM methods 5, 6, and 8 were used to determine the ADF, NDF, and ADL, respectively [32,33,34]. A similar setup and procedure were used by Alizadeh et al. [20] to determine the chemical composition of sawdust.

2.6. Pellet Quality Analysis

Analyzing the pellet quality was essential because of handling, transportation, and storage. It is also important in terms of designing a torrefaction system for a new pellet mill or scaling up an existing pellet mill.

2.6.1. Pellet Unit Density and Dimensional Stability

Pellet density and dimensional stability are two basic characteristics that enhance pellet quality. After the production of a pellet, its weight and volume were measured immediately, and it was kept in airtight Ziploc bags for further experiments. The pellet density is the ratio between the mass of the pellet and its volume. Approximately 10 pellet samples were used for this experiment. The pellets were carefully examined and stored for 14 d under 30–40% relative humidity and a temperature of 20–25 °C. The change in volume after 14 d (V14) was then observed and recorded. The pellet dimensional stability is expressed as the ratio of the change in volume after storage for 14 d (V14) and the initial volume of the pellet after production (V0), which is evaluated using Equation (8).

2.6.2. Pellet Tensile Strength

A diametral compression experiment was performed with the aid of the Instron tester to determine the tensile strength of the sawdust pellet. Kashaninejad and Tabil [35] conducted the same test using a similar instrument to evaluate the pellet tensile strength. The experiment was replicated ten times and the results were averaged. Equation (9) was used to calculate the tensile strength of pellets.

where δx represents the tensile strength in Pa; F is the applied load (N); d is the pellet diameter (m); is the pellet sample thickness (m).

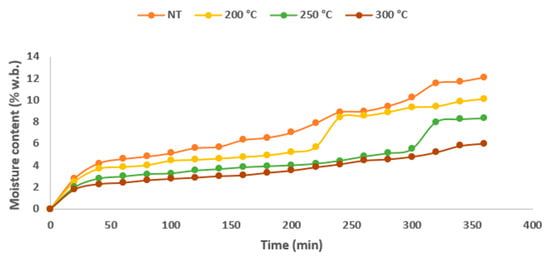

2.6.3. Moisture Uptake Test

A humidifier chamber (Espec SH-641 Benchtop chamber, ESPEC Corp., Osaka, Japan) operating = ng under 90% humidity and a temperature of 25 °C was considered when carrying out the moisture uptake experiment in this study. This was necessary because pellets tend to absorb moisture and distort during transportation through the harsh weather conditions in Canada. The influence of the binders introduced during the pelletization of the WSS biochar samples was investigated through the moisture absorption experiment. The setup and the procedure for this experiment were similar to what was described by other researchers [36,37,38].

2.6.4. Microstructural Examination

The surface and structural transformation of the biochar pellet were examined with the help of a scanning electron microscope (SEM) (Phenom-World, Eindhoven, The Netherlands) combined with a stereoscope. The biochar pellet samples were first prepared and coated with gold, following a procedure similar to what was described by Onyenwoke et al. [12].

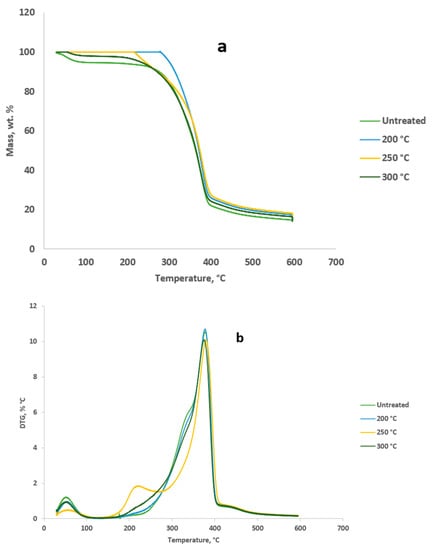

2.6.5. Thermogravimetric Analysis (TGA)

The TGA of the untreated and torrefied WSS was determined with the aid of Pyris Diamond TG/DTA equipment (Perkin-Elmer, Waltham, MA, USA). The setup and procedure for determining the TGA were similar to what was described by Alizadeh et al. [20].

3. Results and Discussions

3.1. Torrefaction Severity Factor

The severity factor (SF) represents both the residence time and the temperature [22]. Table 3 represents the SF results acquired from this study: the temperature and time increased as the SF increased. The basic reaction that occurs during torrefaction pretreatment includes the depolymerization, carbonization, and devolatilization of hemicellulose, cellulose, and lignin [39]. Based on the torrefaction temperature, the traditional torrefaction pretreatment processes can be categorized into light (200–235 °C), mild (235–275 °C), and severe (275–300 °C) torrefaction [21]. Among the three main components of biomass, the most affected component is hemicellulose due to its thermal decomposition temperature, which ranges between 215 and 315 °C. Light torrefaction thermally degraded the hemicellulose in biomass to some certain extent, while lignin and cellulose were hardly or slightly affected owing to their higher thermal decomposition temperatures [40]. During mild torrefaction, hemicellulose was significantly reduced, and the cellulose was slightly consumed. The severe torrefaction process significantly affected the cellulose and hemicellulose component of the biomass as well as the energy density, solid, and energy value.

Table 3.

Severity factor of microwave-assisted torrefaction of white spruce sawdust.

3.2. Characterization of Untreated and Torrefied White Spruce Sawdust

The characterization of the untreated and torrefied WSS was carried out to investigate the effect of torrefaction on the physiochemical properties of the WSS. The results from the samples analysis are subsequently presented and discussed.

3.2.1. Moisture Content and Torrefaction Yield

The amount of moisture present in the white spruce sawdust samples after the torrefaction pretreatment ranged between approximately 1% and 4%. The average moisture content of torrefied WSS at 200 °C was significantly (α = 0.05) higher when set side by side with the average moisture content of torrefied WSS at 250 °C and 300 °C. The average moisture content of WSS torrefied for 5 min was significantly (α = 0.05) higher compared to the average moisture content of WSS torrefied for 7 min and 9 min. Normally, the quantity of moisture recorded for the raw biomass ranged from 10 to 50%. Torrefaction is a moisture-reduction process that reduces the amount of water present in the torrefied sample to approximately 1–3% on a weight basis [39]. The high presence of moisture in the raw biomass reduces the torrefaction efficiency and increases the cost of producing fuel [41]. The initial moisture content of the WSS sample used in this study was approximately 25%, which reduced drastically to approximately 1–3% after the severe torrefaction pretreatment. Cai et al. [5] reported a moisture content as low as 0.07% after torrefaction under 280−300 °C. This could be due to the initial quantity of water present in the raw biomass sample and the severity of the torrefaction. Basically, as the SF increases, the moisture content reduces, thereby reducing the risk of biological deterioration and storage and transportation costs [39].

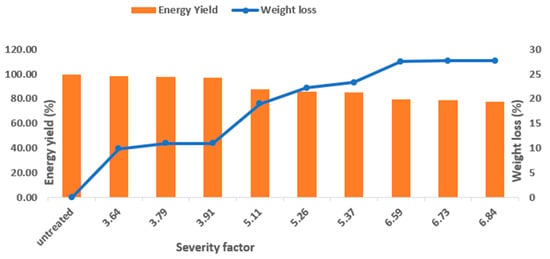

Supplementary Material Figure S1 shows the product yields of torrefaction, which constitute a brown to solid-black mass known as biochar, condensable gas (torrefaction liquid), and non-condensable gas. The biochar yield decreased as the SF increased, but the liquid and gas yield increased with its increasing severity. When raw biomass is subjected to torrefaction, its dry matter reduces because of thermal breakdown. The biochar yield is a critical measure of how biomass resists thermal breakdown [42]. During the torrefaction operation, weight loss is a crucial factor for evaluating the process advancement. Figure 3 shows the weight loss and energy yield of the WSS at different SFs. As the severity increased, a higher weight loss was observed. The most significant weight loss was noted at a severity factor of 6.84, having a weight loss of about 25%. A similar result was reported [5] when sawdust was torrefied at a temperature of 280−300 °C, which yielded a weight loss of 27.72%. However, the weight loss is attributed to the thermal breakdown of the three major contents: cellulose, hemicellulose, and lignin [43]. The energy yield decreased as the SF intensified. This concurs with the result reported by Cai et al. [5] in which 22.37% was the amount of energy lost as the torrefaction became severe. Although a mass loss was observed, the biomass characteristics improved [43,44,45,46].

Figure 3.

Weight loss and energy yield of WSS at different severity factors.

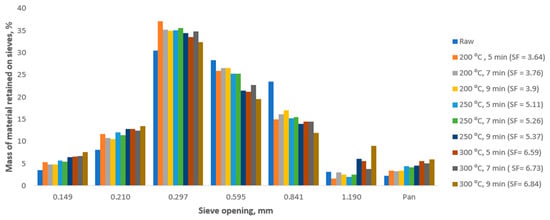

3.2.2. Particle Size Analysis

The size and shape of particles determine the available surface area needed for the particles to join firmly during pellet formation. This is a critical factor for not only the mechanical properties of pellets [47,48] but also the energy utilized during pelletization [49,50]. Figure 4 represents the normal size distribution of torrefied WSS at different severities. A narrower particle size distribution was observed, making it suitable for densification [51]. This is possible when tiny particles rearrange and fill the gaps between larger particles [52]. The increasing severity condition resulted in an increase in the proportion of fine particles in the sample. A Shapiro–Wilk test (p > 0.05) demonstrated that the biochar particle sizes from the different severity conditions were approximately normally distributed. A similar trend was reported [53] when the same experiment was carried out on pine chips and logging residues. A geometric mean particle size of 0.36 mm was recorded for the untreated WSS. Table 4 shows the geometric mean diameter (dgw) and geometric standard deviation (Sgw) of the untreated WSS and WSS biochar particles. The dgw ranged from 0.32 mm to 0.35 mm, while the Sgw ranged from 0.14 mm to 0.22 mm. Chen et al. [54] observed similar results using the torrefaction of bamboo, pine chips, and logging residues. Alizadeh et al. [20] also reported a 0.32 mm to 0.38 mm range for the dgw of torrefied sawdust and an Sgw range from 0.14 mm to 0.21 mm.

Figure 4.

Particle size distribution of torrefied WSS at different severities.

Table 4.

Particle size, bulk, and particle density of raw and torrefied WSS at different temperatures.

3.2.3. Bulk and Particle Density

Table 4 depicts the bulk and particle density of the unprocessed WSS and torrefied WSS at different temperatures. The bulk density of the raw WSS was notably higher than the treated samples. This could be because the torrefaction pretreatment application tends to disintegrate the organized and compacted lignocellulosic structure (cellulose, hemicellulose, and lignin) of biomass, resulting in a lowered bulk density. This agrees with results reported by other researchers [55,56]. The bulk density of the biochar WSS ranged from 110.24 kg/m3 to 167.24 kg/m3. The particle density of the biochar WSS was greater than the untreated samples. The higher particle density of the torrefied WSS could be because of the shrinkage of biomass samples that occurs during the torrefaction process [57]. The particle densities of the treated WSS ranged from 1250.68 kg/m3 to 1454.84 kg/m3. Peng et al. [55] obtained similar results when spruce sawdust was torrefied at 240–340 °C.

3.2.4. Elemental and Proximate Analysis

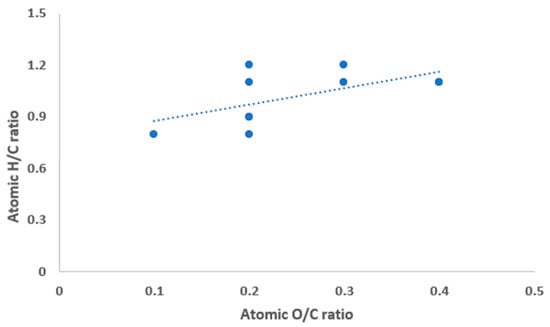

Table S1 depicts that SF affected the elemental and proximate contents of WSS on a dry-matter basis. The carbon (C), hydrogen (H), sulfur (S), and nitrogen (N) contents of the raw WSS were 47.47%, 6.66%, 0.21%, and 0.11%, respectively, while the amount of oxygen (O) present in the raw WSS was determined by difference to be 45.41%. After the pretreatment operation, the hydrogen and oxygen contents of the samples decreased, while the quantities of carbon and nitrogen present in the biochar significantly increased (p < 0.05) as the SF increased. Zanzi et al. [58] reported a similar trend when miscanthus was torrefied. Additionally, in their respective studies on torrefaction of sawdust, barley straw, and oat hull, Alizadeh et al. [20], Sarker et al. [59], and Valdez et al. [21] made similar observations in which an increase in severity led to increases in C and decreases in H and O. Generally, during the torrefaction pretreatment, the energy density of the biochar (residual carbon-rich solids) increases due to the volatilization of the smaller hydrocarbon compounds, which have less energy density. In this study, the decrease in H and O was assumed to be due to the formation of carbon dioxide and water during the process. The changes occurring elementally in the biomass are usually demonstrated by the Van Krevelen diagram. The theory of the Van Krevelen diagram of the untreated WSS and WSS biochar is illustrated in Figure 5. The atomic H/C and the atomic O/C proportions follow an almost linear relationship. The O/C and H/C proportions also reduced as the severity increased, which resulted in a lower production of smoke and water vapor during burning. The energy loss was also reduced during combustion because of the reduction in the proportions of O/C and H/C in the WSS biochar.

Figure 5.

Van Krevelen diagram of untreated and WSS biochar.

The characterization of solid biomass fuels showed that FC and VM were the two significant measures. Fuels with a higher VM normally have a lower FC, resulting in a lower calorific value and a higher reactivity. Subsequently, when the amount of FC in the solid fuel is very large, the VM value is usually very low, leading to an improvement in the energy value. In this study, it was observed that as the SF intensified, the VM reduced, while the FC increased. The drastic reduction in VM may be due to partial carbonization and dehydration during the torrefaction process. Similar trends were observed by other researchers [20,59,60,61,62].

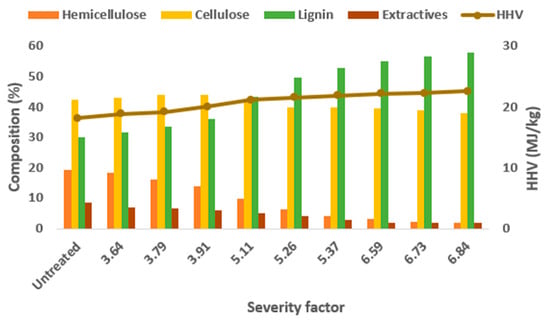

3.2.5. Energy Value and Chemical Composition of Untreated and WSS Biochar

The energy value of biochar, simply known as the calorific or higher heating value (HHV) of biochar, is the total amount of energy produced as heat when the biochar is subjected to complete combustion. The biomass loses more hydrogen and oxygen content compared to the carbon content during the pretreatment operation, which improves the HHV of the resulting product. Recent studies [12,20,59] have shown that an increase in FC leads to an enhancement of the calorific value. Figure 6 represents the higher heating value and chemical content of the untreated and treated WSS. The HHV improved as the SF intensified. The HHV of the untreated WSS was 18.21 MJ/kg, which increased by approximately 25% as the torrefaction severity increased. Chen et al. [42] reported that the HHV of a torrefied sample improved with the severity condition of torrefaction. Sarker et al. [59] recorded an HHV between 22 and 25 MJ/kg when selected agricultural biomasses were torrefied.

Figure 6.

HHV and chemical composition of untreated and treated WSS.

The major composition of a lignocellulosic biomass is cellulose, hemicellulose, lignin, and minor traces of extractives. These structures have different thermal stability, and the level of their chemical alteration is subject to the type of feedstock and torrefaction conditions used. Tumuluru et al. [39] reported three temperature zones that were observed during the torrefaction operation: (1) non-reactive (50–150 °C); (2) reactive (150–200 °C); and (3) destructive (200–300 °C). The different occurrence in these zones were the dehydration, devolatilization, and carbonization of hemicellulose and, finally, the depolymerization and softening of lignin and the depolymerization devolatilization of cellulose. These reactions significantly improved the physiochemical properties and energy content of the biomass [39,63].

The lignocellulosic component analysis of the WSS at different SFs is shown in Figure 6. Through the torrefaction operation, a huge mass loss was observed. This mass loss was linked with the breakdown of hemicellulose. Cellulose also undergoes decomposition, similar to hemicellulose but to a lesser extent. Lignin is difficult to decompose during torrefaction because of its higher thermal decomposition temperature. The hemicellulose content drastically reduced to approximately 1.8% and the cellulose content reduced by approximately 10%, while the lignin gained approximately 35% as the severity increased. Results from other researchers agree with these findings [64,65,66].

3.3. Pellet Properties

Peng et al. [18] reported that the pelletization of torrefied samples was difficult when compared with untreated samples. However, the addition of binders not only makes pelletization much easier but also improved the pellet properties [19,20]. The effect of additives during pelletization was investigated and is described in the following sub-sections.

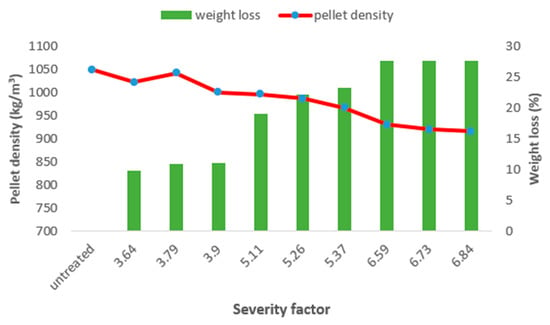

3.3.1. Pellet Unit Density and Dimensional Stability (DS)

Figure 7 represents the pellet unit density and the weight loss at different SFs. The pellet density was observed to have decreased after the torrefaction pretreatment process. The pellet unit density reduced to approximately 915.42 kg/m3 from 1048.56 kg/m3 at a weight loss of 18%, while the mass loss through the torrefaction process of the WSS led to lower pellet densities of the torrefied WSS [67]. In their study, Peng et al. [55] reported that at a 30% weight loss, the pellet density decreased to 930 kg/m3 from 1190 kg/m3 and from 1230 kg/m3 to 970 kg/m3 for commercial white and brown wood pellets, respectively. Alizadeh et al. [20] also reported a reduction in the pellet unit value from 1044.6 kg/m3 to 955.96 kg/m3 for a higher SF.

Figure 7.

Pellet unit density and weight loss of raw WSS and WSS biochar for different severity factors.

Table S2 depicts the pellet properties of the torrefied WSS, indicating that the DS of the pellets improved as the torrefaction severity increased. The DS provides information about the firmness of the produced pellets through handling, transportation, and storage. When lesser values are obtained during this test, it shows that the pellet stability is good, while large values indicate that the pellet is unstable. When positive and negative values are obtained, it indicates that expansion and contraction were observed in the pellet, respectively. Results from other researchers agree with these findings [12,20,21].

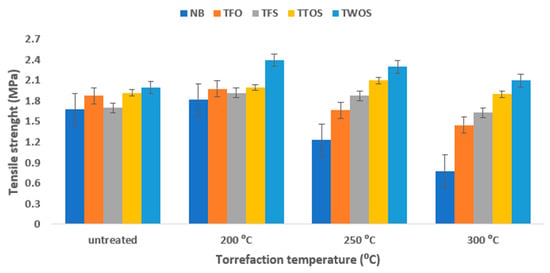

3.3.2. Pellet Tensile Strength

The tensile strength and particle density are two major characteristics that define the quality of biomass pellets [68]. Pellet tensile strength is an important property of biomass pellets that expresses the force required to crush or damage a pellet. Generally, the results obtained in this study showed a decrease in value as the torrefaction severity increased. Hemicellulose and cellulose polymer degradation was believed to be one reason for the tensile strength loss of biomass pellets under severe torrefaction treatment [69]. Shang et al. [70] reported that the pellet tensile strength reduced by 90% after severe torrefaction. Figure 8 shows the pellet tensile strength after torrefaction. The tensile strength of the raw WSS pellet was 1.68 MPa, which slightly increased to 1.82 MPa after light torrefaction, reduced to 1.23 MPa after mild torrefaction, and decreased further to 0.78 MPa when the torrefaction became severe. This was possibly due to the variance in the thermal stability of the WSS structures and the degree of their chemical changes in different stages of torrefaction.

Figure 8.

Tensile strength of pellets from WSS untreated and torrefied with or without binders. NB: Without binder; TFO: 75% torrefied WSS with 25% TL; TFS: 75% torrefied WSS with 25% sawdust; TTOS: 33.3% torrefied WSS with 33.3% sawdust and TL; TWOS: 75% torrefied WSS with 12.5% sawdust and TL each.

To improve the strength of the torrefied sawdust pellets in this study, the utilization of cheap and non-food-based binders was explored. White spruce sawdust and torrefaction liquid (TL) were introduced to the pelletization step in different formulations after the microwave-assisted torrefaction of the WSS. Figure 8 represents the tensile strength of the pellets with and without binders. It was observed that the additives improved the binding mechanism between torrefied particles during densification, which improved the tensile strength of the pellet. This agrees with other researchers [31,71,72] who conducted similar works using different binders in pellet making.

3.3.3. Moisture Uptake of Pellets

Due to the different weather circumstances in Canada for the storage and transportation of biomass pellets, it was necessary to conduct a moisture uptake test. The pellets might be exposed to harsh weather conditions which could affect their quality. Figure 9 demonstrates the absorption results for pellets from different torrefaction temperatures. During the experiment, the untreated pellets were observed to have enlarged and distorted within a short time in the humidifier chamber. Although the torrefied WSS pellets maintained a good form of firmness, they also swelled and disintegrated after some hours in the chamber. The moisture absorption of torrefied sample pellets compared to untreated pellets was previously studied by other researchers [73,74,75]. During the torrefaction operation, the OH groups in the biomass are destroyed to a limited degree by dehydration, hindering the formation of H bonds and thereby encouraging the pretreated biomass to become hydrophobic [63]. In general, the WSS biochar pellets treated under severe torrefaction had a low moisture uptake capacity, which may be due to the more intensive breakdown of polymers and the decrease in H bonding sites [68]. For example, the WSS torrefied at 200 °C in which approximately 6% of the hemicellulose was degraded had a moisture uptake of up to 10%, while the WSS torrefied at 300 °C was able to take up less than 5% moisture due to the degradation of almost 60% of the hemicellulose. The effect of the binders on the water absorption rate of the pellets was also examined; these results are displayed in Figure S2. The introduction of TL and sawdust to the biochar pellet formulation ameliorated the surface structure by enhancing the adhesive mechanism of the biochar particles. This lessened the microporous surface tension, which decreased the uptake rate of the available water [12,76].

Figure 9.

Moisture absorption of torrefied and non-torrefied WSS pellets.

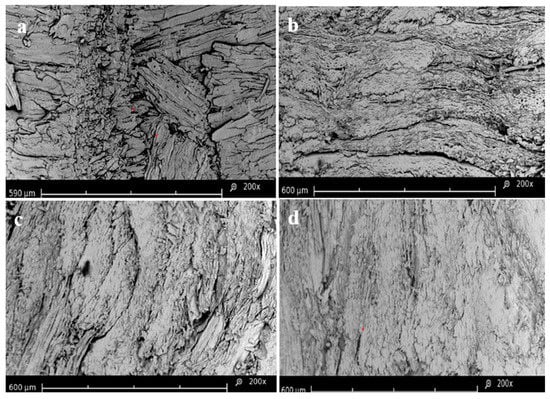

3.3.4. SEM Analysis

The binding mechanism of the pelleted biochar particles was further analyzed with the help of scanning electron microscopy (SEM), which aided in the observation of the internal stratification of the pellets formed. The microscale effect of the pretreatment process on the WSS was justified by a microstructural examination, which provided a perception of the structural pattern of the biochar pellet samples. Figure 10a–d shows the SEM micrograph images of the WSS pellets. Figure 10a presents the micrographs of the untreated WSS pellet, while Figure 10b,c show the micrograph of the torrefied pellets at temperatures of 200 °C, 250 °C, and 300 °C, respectively. It was observed that the torrefied WSS pellets showed more firmly glued surfaces with fewer pore spaces when set side by side with the raw pellets. The WSS biochar pellets also showed less porosity when compared with raw pellets. This may be due to the breakdown of and depolymerization of the hemicellulose and cellulose matrix through the torrefaction of the WSS. The structural breakdown exposes more surface area, which is suitable for pelletization. Similar observations were reported by other researchers [77,78]. The micrographs of the untreated WSS pellet and the torrefied pellets at a higher magnification are presented in Figures S3–S6, respectively.

Figure 10.

SEM micrographs images of WSS pellets: (a) un-torrefied WSS; (b) WSS torrefied at 200 °C; (c) WSS torrefied at 250 °C; (d) WSS torrefied at 300 °C.

3.3.5. Differential Thermogravimetric Analysis (DTG)

To determine the heat stability of the WSS pellet, a DTG analysis was conducted. The degradation, decomposition, and chemical stability of biomass pellets are critical indicators. The DTG analysis graph of the raw and torrefied WSS pellets are presented in Figure 11a,b. It was observed that the WSS pellets displayed a similar thermal degradation trail for the studied samples. Four identical regions were observed. The first region is where weight loss occurred at 50–150 °C due to the evaporation of free water and the escape of organic substances with low boiling points [79]. The second region was the breakdown of hemicellulose and the escape of volatile matter, noted at a temperature of 200–235 °C. The third region was the breakdown of cellulose (250–275 °C), while the final region referred to the oxidation of char at high temperatures [72]. This implies that the torrefaction of the WSS slightly reduced its thermal stability. Sarker et al. [72] made a similar observation when a DTG analysis of some torrefied agricultural residues was performed.

Figure 11.

The DTG analysis graph of the raw and torrefied WSS: (a) thermogravimetry curves of the untreated and torrefied WSS; (b) differential thermogravimetry curves of the untreated, torrefied WSS.

4. Conclusions

The torrefaction pretreatment of white spruce sawdust (WSS) was conducted using a lab-scale microwave oven at temperatures in the range of 200–300 °C and a retention time of 5–9 min in an inert environment to ascertain the effect of these two process variables on the physiochemical properties of the WSS. The products of this process are solid carbon, commonly known as biochar, and condensable (torrefaction liquid (TL)) and non-condensable gases. The result from this study indicates the potential for the torrefaction pretreatment operation to enhance the physiochemical properties of WSS. The hemicellulose content underwent a major degradation as the torrefaction severity increased. Similarly, the cellulose also underwent decomposition, but with less degradation. The incomplete depolymerization of cellulose and the disintegration of hemicellulose at the same time increased the lignin content during the pretreatment process, enhancing the FC and drastically decreasing the VM content. This led to an improvement in the higher heating value (HHV), hydrophobicity, bulk, particle density, pellet dimensional stability, and pellet density.

During the torrefaction process, a significant mass loss associated with the decomposition of hemicellulose was observed. The hemicellulose content drastically reduced to approximately 1.8% and the cellulose content reduced by approximately 10%, while the lignin gained approximately 35% as the severity increased. The pellet unit density and pellet tensile strength in this study decreased as the torrefaction severity increased. The breakdown of the hemicellulose and cellulose polymer was suggested to be one reason for the tensile strength loss of the biomass pellets under severe torrefaction treatment. However, the tensile strength of the studied pellets was improved by the introduction of binders. The OH groups in the biomass are destroyed to a limited degree by dehydration. This hinders the formation of H bonds, thereby encouraging the pretreated biomass to become hydrophobic. From the SEM graphs, it was observed that the torrefied WSS pellets showed more firmly glued surfaces with fewer pore spaces when compared with the raw pellets. The thermogravimetric analysis conducted showed that the torrefaction of the WSS slightly reduced its thermal stability.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/fuels4010008/s1, Figure S1: Product yields of torrefied white spruce sawdust (WSS); Figure S2: Effect of the binders on the moisture absorption rate of the pellets; Figures S3–S6: Higher magnification of scanning electron microscope image of the longitudinal cross-section of the pellets; Table S1: Elemental and proximate composition of untreated and torrefied WSS; Table S2: Pellet properties of torrefied WSS.

Author Contributions

Conceptualization, C.O., L.G.T. and P.A.; methodology, C.O. and L.G.T.; software, C.O.; validation, L.G.T.; formal analysis, C.O.; investigation, C.O.; resources, L.G.T., E.M., D.C. and P.A.; data curation, C.O.; writing—original draft preparation, C.O.; writing—review and editing C.O., L.G.T., E.M., D.C. and P.A.; visualization, C.O.; supervision, L.G.T.; project administration, L.G.T., E.M. and D.C.; funding acquisition, L.G.T., E.M. and D.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Biofuel Network (BFN) (ASC-16) and the Natural Sciences and Engineering Council of Canada (NSERC) (RGPIN-2017-05287). We also acknowledge the funding support provided by the University of Saskatchewan through the CGPS Dean’s Scholarship.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors sincere gratitude goes to Robert Follett of Mistik Management Ltd. for providing the white spruce sawdust sample. Esteban Valdez, Alizadeh Peyman, Onu Olughu Onu, and Obiora Agu of the University of Saskatchewan are acknowledged for their technical support of this experiment. Tim Dumonceaux of the Saskatoon Research and Development Centre of Agriculture and Agri-Food Canada is also acknowledged for reviewing this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| TL | Torrefaction liquid |

| SF | Severity factor |

| DS | Dimensional stability |

| ANOVA | Analysis of variance |

| NDF | Neutral detergent fibre |

| ADF | Acid detergent fibre |

| ADL | Acid detergent lignin |

| OH | Hydroxyl |

| HHV | Higher heating value |

| DTG | Differential thermogravimetric |

| TGA | Thermogravimetric analysis |

| WSS | White spruce sawdust |

| FC | Fixed carbon |

| VM | Volatile matter |

| C | Carbon |

| H | Hydrogen |

| N | Nitrogen |

| S | Sulfur |

| O | Oxygen |

| O/C | Oxygen-carbon ratio |

| H/C | Hydrogen-carbon ratio |

| SEM | Scanning electron microscope |

References

- Dai, L.; Wang, Y.; Liu, Y.; He, C.; Ruan, R.; Yu, Z.; Jiang, L.; Zeng, Z.; Wu, Q. A review on selective production of value-added chemicals via catalytic pyrolysis of lignocellulosic biomass. Sci. Total Environ. 2020, 749, 142386. [Google Scholar] [CrossRef]

- Lehmann, J. Bioenergy in the black. Front. Ecol. Environ. 2007, 5, 381–387. [Google Scholar] [CrossRef]

- Czernik, S.; Bridgwater, A. Overview of applications of biomass fast pyrolysis oil. Energy Fuels 2004, 18, 590–598. [Google Scholar] [CrossRef]

- Zhang, B.; Yang, B.; Wu, S.; Guo, W.; Zhang, J.; Wu, Z.; Wang, Z.; Lim, J.C. Effect of torrefaction pretreatment on the fast pyrolysis behavior of biomass: Product distribution and kinetic analysis on spruce-pin-fir sawdust. J. Anal. Appl. Pyrolysis 2021, 158, 105259. [Google Scholar] [CrossRef]

- Cai, W.; Fivga, A.; Kaario, O.; Liu, R. Effects of torrefaction on the physicochemical characteristics of sawdust and rice husk and their pyrolysis behavior by thermogravimetric analysis and pyrolysis–gas chromatography/mass spectrometry. Energy Fuels 2017, 31, 1544–1554. [Google Scholar] [CrossRef]

- Arias, B.; Pevida, C.; Fermoso, J.; Plaza, M.; Rubiera, F.; Pis, J. Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel Process. Technol. 2008, 89, 169–175. [Google Scholar] [CrossRef]

- Strandberg, M.; Olofsson, I.; Pommer, L.; Wiklund-Lindström, S.; Åberg, K.; Nordin, A. Effects of temperature and residence time on continuous torrefaction of spruce wood. Fuel Process. Technol. 2015, 134, 387–398. [Google Scholar] [CrossRef]

- Li, J.; Brzdekiewicz, A.; Yang, W.; Blasiak, W. Co-firing based on biomass torrefaction in a pulverized coal boiler with aim of 100% fuel switching. Appl. Energy 2012, 99, 344–354. [Google Scholar] [CrossRef]

- Dudyński, M.; van Dyk, J.C.; Kwiatkowski, K.; Sosnowska, M. Biomass gasification: Influence of torrefaction on syngas production and tar formation. Fuel Process. Technol. 2015, 131, 203–212. [Google Scholar] [CrossRef]

- Bach, Q.; Tran, K.; Skreiberg, Ø. Comparative study on the thermal degradation of dry-and wet-torrefied woods. Appl. Energy 2017, 185, 1051. [Google Scholar] [CrossRef]

- Statista Research Department. Statists Research Forestry in Canada—Statistics & Facts. Available online: https://www.statista.com/topics/4763/forestry-in-canada/#topicHeader__wrapper (accessed on 24 December 2022).

- Onyenwoke, C.; Tabil, L.G.; Dumonceaux, T.; Cree, D.; Mupondwa, E.; Adapa, P.K.; Karunakaran, C. Investigation of steam explosion pretreatment of sawdust and oat straw to improve their quality as biofuel pellets. Energies 2022, 15, 7168. [Google Scholar] [CrossRef]

- Saskatchewan Forest Products Buyers’ Guide. 2019. Available online: http://reaerch.yahoo.com/fpinnovations.ca (accessed on 6 April 2021).

- Rabemanolontsoa, H.; Saka, S. Various pretreatments of lignocellulosics. Bioresour. Technol. 2016, 199, 83–91. [Google Scholar] [CrossRef]

- Adapa, P.K.; Schonenau, L.G.; Canam, T.; Dumonceaux, T. Quantitative analysis of lignocellulosic components of non-treated and steam exploded barley, canola, oat, and wheat straw using Fourier transform infrared spectroscopy. J. Agric. Sci. Technol. 2011, 1, 177–188. [Google Scholar]

- Ståhl, M.; Berghel, J.; Frodeson, S.; Granström, K.; Renström, R. Effects on pellet properties and energy use when starch is added in the wood-fuel pelletizing process. Energy Fuels 2012, 26, 1937–1945. [Google Scholar] [CrossRef]

- Abedi, A.; Cheng, H.; Dalai, A.K. Effects of natural additives on the properties of sawdust fuel pellets. Energy Fuels 2018, 32, 1863–1873. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, X.T.; Sokhansanj, S.; Lim, C.J. Torrefaction and densification of different species of softwood residues. Fuel 2013, 111, 411–421. [Google Scholar] [CrossRef]

- Peng, J.; Bi, X.T.; Lim, C.J.; Peng, H.; Kim, C.S.; Jia, D.; Zuo, H. Sawdust as an effective binder for making torrefied pellets. Appl. Energy 2015, 157, 491–498. [Google Scholar] [CrossRef]

- Alizadeh, P.; Tabil, L.G.; Adapa, P.K.; Cree, D.; Mupondwa, E.; Emadi, B. Torrefaction and densification of wood sawdust for bioenergy applications. Fuels 2022, 3, 152–175. [Google Scholar] [CrossRef]

- Valdez, E.; Tabil, L.G.; Mupondwa, E.; Cree, D.; Moazed, H. Microwave torrefaction of oat hull: Effect of temperature and residence time. Energies 2021, 14, 4298. [Google Scholar] [CrossRef]

- Overend, R.P.; Chornet, E.; Gascoigne, J.A.; Hartley, B.S.; Broda, P.M.A.; Senior, P.J. Fractionation of lignocellulosics by steam-aqueous pretreatments. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1987, 321, 523–536. [Google Scholar]

- ANSI/ASAE S358.3; American Society of Agricultural Engineers. Standard Test for Moisture Content Measurement of Forages. American Society of Agricultural Engineers: St. Joseph, MI, USA, 2012.

- AACC Standard 44-15A; Determination of Moisture Content by the Air-Oven Method. The American Association of Cereal Chemists (AACC International): St. Paul, MN, USA, 2005.

- ASABE Standards EP496.3; 49th ed. Agricultural Machinery Management. ASABE: St. Joseph, MI, USA, 2006; pp. 385–390.

- Iroba, K.L.; Baik, O.-D.; Tabil, L.G. Torrefaction of biomass from municipal solid waste fractions ii: Grindability characteristics, higher heating value, palatability, and moisture adsorption. Biomass Bioenergy 2017, 106, 8–20. [Google Scholar] [CrossRef]

- Satpathy, S.K.; Tabil, L.G.; Meda, V.; Narayana, S.; Rajendra, S. Torrefaction and Grinding Performance of Wheat and Barley Straw after Microwave Heating. In Proceedings of the CSBE/SCGAB 2013 Annual Conference, Saskatoon, SK, Canada, 7–10 July 2013; Available online: http://www.csbescgab.ca/docs/meetings/2013/CSBE13065 (accessed on 15 May 2022).

- ASTM D3174-04(2010); Standard Test Method for Ash in the Analysis Sample of Coal and Coke from Coal. ASTM: West Conshohocken, PA, USA, 2010. [CrossRef]

- ASTM D3173-03; Standard Test Method for Moisture in the Analysis Sample of Coal and Coke. ASTM: West Conshohocken, PA, USA, 1996. [CrossRef]

- ASTM D3175-20; Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke. ASTM: West Conshohocken, PA, USA, 1997. [CrossRef]

- Bai, X.G.; Wang, Y.; Sun, Y.; Yu, J.; Liu, D.; Wang, Z. Effects of combined pretreatment with rod-milled and torrefaction on physicochemical and fuel characteristics of wheat straw. Bioresour. Technol. 2018, 267, 38–45. [Google Scholar] [CrossRef]

- ANKOM Technology. Method 5: Acid Detergent Fiber in Feeds—Filter Bag Technique (for A200 and A200I). Available online: https://www.ankom.com/sites/default/files/document-files/Method_5_ADF_A200.pdf (accessed on 1 April 2021).

- ANKOM Technology. Method 6: Neutral Detergent Fiber in Feeds—Filter Bag Technique (for A200 and A200I). Available online: https://www.ankom.com/sites/default/files/document-files/Method_6_NDF_A200.pdf (accessed on 1 April 2021).

- ANKOM Technology. Method 8: Determining Acid Detergent Lignin in Beakers. Available online: https://www.ankom.com/sites/default/files/document-files/Method_8_Lignin_in_beakers_0.pdf (accessed on 1 April 2021).

- Kashaninejad, M.; Tabil, L.G. Effect of microwave-chemical pre-treatment on compression characteristics of biomass grinds. Biosyst. Eng. 2011, 108, 36–45. [Google Scholar] [CrossRef]

- Azargohar, R.; Soleimani, M.; Nosran, S.; Bond, T.; Karunakaran, C.; Dalai, A.K.; Tabil, L.G. Thermo-physical characterization of torrefied fuel pellet from co-pelletization of canola hulls and meal. Ind. Crops Prod. 2019, 128, 424–435. [Google Scholar] [CrossRef]

- Lam, P.S.; Sokhansanj, S.; Bi, X.T.; Lim, C.J.; Larsson, S.H. Drying characteristics and equilibrium moisture content of steam-treated douglas fir (Pseudotsuga menziesii L.). Bioresour. Technol. 2012, 116, 396–402. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yan, J.; Yang, J.; Peng, T.; Yang, Q. Study on processing technology for microwave pyrolysis of municipal solid waste. In Proceedings of the 2011 International Conference on Materials for Renewable Energy Environment, Shanghai, China, 20–22 May 2011; pp. 336–340. [Google Scholar]

- Tumuluru, S.J.; Sokhansanj, S.; Wright, C.T.; Boardman, R.D. Review: A review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Rousset, P.; Aguiar, C.; Labbe, N.; Commandre, J.M. Enhancing the combustible properties of bamboo by torrefaction. Bioresour. Technol. 2011, 102, 8225–8231. [Google Scholar] [CrossRef]

- Evergreen Renewables, LLC (2022) Biomass Torrefaction as a Preprocessing Step for Thermal Conversion: Reducing Costs in the Biomass Supply Chain (Online). Available online: http//evergreenrenewable.com/welcome_files/Biomass%20torrefaction.pdf (accessed on 19 October 2022).

- Chen, W.H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification, and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Chew, J.J.; Doshi, V. Recent advances in biomass pretreatment torrefaction fundamentals and technology. Renew. Sustain. Energy Rev. 2011, 15, 4212–4222. [Google Scholar] [CrossRef]

- Yan, W.; Hastings, J.T.; Acharjee, T.C.; Coronella, C.J.; Vásquez, V.R. Mass and energy balances of wet torrefaction of lignocellulosic biomass. Energy Fuels 2010, 24, 4738–4742. [Google Scholar] [CrossRef]

- Van der Stelt, M.; Gerhauser, H.; Kiel, J.; Ptasinski, K. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.; Legros, R.; Bi, X.T.; Lim, C.J.; Sokhansanj, S. Pelletization of torrefied sawdust and properties of torrefied pellets. Appl. Energy 2012, 93, 680–685. [Google Scholar] [CrossRef]

- Rudolfsson, M.; Stelte, W.; Lestander, T.A. Process optimization of combined biomass torrefaction and pelletization for fuel pellet production—A parametric study. Appl. Energy 2015, 140, 378–384. [Google Scholar] [CrossRef]

- Serrano, C.; Monedero, E.; Lapuerta, M.; Portero, H. Effect of moisture content, particle size and pine addition on quality parameters of barley straw pellets. Fuel Process. Technol. 2011, 92, 699–706. [Google Scholar] [CrossRef]

- Ghiasisis, B. Steam-Assisted Pelletization and Torrefaction of Lignocellulosic Biomass. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 2020. [Google Scholar]

- Huang, Y.; Finell, M.; Larsson, S.; Wang, X.; Zhang, J.; Wei, R.; Liu, L. Biofuel pellets made at low moisture content—Influence of water in the binding mechanism of densified biomass. Biomass Bioenergy 2017, 98, 8–14. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding performance and physical properties of wheat and barley straws, corn stover, and switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Tabil, L.G. Binding and Pelleting Characteristics of Alfalfa. Ph.D. Thesis, Department of Agricultural and Bioresource Engineering, University of Saskatchewan, Saskatoon, SK, Canada, 1996. [Google Scholar]

- Phanphanich, M.; Mani, S. Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef]

- Chen, W.H.; Hsu, H.C.; Lu, K.M.; Lee, W.C.; Lin, D.C. Thermal pretreatment of wood (Lauan) block by torrefaction and its influence on the properties of biomass. Energy 2011, 36, 3012–3021. [Google Scholar] [CrossRef]

- Peng, J.; Wang, J.; Bi, X.T.; Lim, C.J.L.; Sokhansanj, S.; Peng, H.; Jia, D. Effects of thermal treatment on energy density and hardness of torrefied wood pellets. Fuel Process. Technol. 2014, 129, 168–173. [Google Scholar] [CrossRef]

- Chen, W.H.; Kuo, P.C. Torrefaction and co-torrefaction characterization of hemicellulose, cellulose, and lignin as well as torrefaction of some basic constituents in biomass. Energy 2011, 36, 803–811. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Zanzi, R.; Ferro, D.T.; Torres, A.; Soler, P.B.; Bjornbom, E. Biomass torrefaction. In Proceedings of the 6th Asian-Pacific International Symposium on Combustion and Energy Utilization, Kuala Lumpur, Malaysia, 20–22 May 2022. [Google Scholar]

- Sarker, T.R.; Azargohar, R.; Dalai, A.K.; Venkatesh, M. Physicochemical and fuel characteristics of torrefied agricultural residues for sustainable fuel production. Energy Fuels 2020, 34, 14169–14181. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Shield, I.; Williams, P.T. Torrefaction of reed canary grass, wheat straw, and willow to enhance solid fuel qualities and combustion properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- Lu, K.M.; Lee, W.J.; Chen, W.H.; Lin, T.C. Torrefaction and low-temperature carbonization of oil palm fiber and eucalyptus in nitrogen and air atmospheres. Bioresour Technol. 2012, 123, 98–105. [Google Scholar] [CrossRef]

- Wannapeera, J.; Fungtammasan, B.; Worasuwannarak, B. Effects of temperature and holding time during torrefaction on the pyrolysis behaviours of woody biomass. J. Anal. Appl. Pyrolysis 2011, 92, 99–105. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Ghiasi, B.; Soelberg, N.R.; Sokhansanj, S. Biomass torrefaction process, product properties, reactor types, and moving bed reactor design concepts. Front. Energy Res. 2021, 9, 728140. [Google Scholar] [CrossRef]

- Phusunti, N.; Phetwarotai, W.; Tekasakul, S. Effects of torrefaction on physical properties, chemical composition, and reactivity of microalgae. Korean J. Chem. Eng. 2018, 35, 503–510. [Google Scholar] [CrossRef]

- Oyebode, W.A.; Ogunsuyi, H.O. Impact of torrefaction process temperature on the energy content and chemical composition of stool tree (Alstonia congenisis Engl) woody biomass. Curr. Res. Green Sust. Chem. 2021, 4, 100115. [Google Scholar] [CrossRef]

- Baicar, M.; Zagula, G.; Saletnik, B.; Tarapatskyy, M.; Puchalski, C. Relationship between torrefaction parameters and physicochemical properties of torrefied products obtained from selected plant biomass. Energies 2018, 11, 2919. [Google Scholar] [CrossRef]

- Poudel, J.; Karki, S.; Oh, S.C. Valorization of waste wood as a solid fuel by torrefaction. Energies 2018, 11, 1641. [Google Scholar] [CrossRef]

- Wang, L.; Riva, L.; Skreiberg, Ø.; Khalil, R.; Bartocci, P.; Yang, Q.; Yang, H.; Wang, X.; Chen, D.; Rudolfsson, M.; et al. Effect of torrefaction on properties of pellets produced from woody biomass. Energy Fuels 2020, 34, 15343–15354. [Google Scholar] [CrossRef]

- Pellet Fuel Institute (PFI) Standards Committee. Pellet Fuel Institute (PFI) Standard Specification for Residential/Commercial Densified Fuel; PFI Standards Committee: Seattle, WA, USA, 2011. [Google Scholar]

- Shang, L.; Nielsen, N.P.K.; Dahl, J.; Stelte, W.; Ahrenfeldt, J.; Holm, J.K.; Thomsen, T.H. Quality effects caused by torrefaction of pellets made from Scots pine. Fuel Process. Technol. 2012, 101, 23–28. [Google Scholar] [CrossRef]

- Kanwal, S.N.; Chaudhry, S.; Munir, H.; Sana, H. Effect of torrefaction conditions on the physicochemical characterization of agricultural waste (sugarcane bagasse). Waste Manag. 2019, 88, 280–290. [Google Scholar] [CrossRef] [PubMed]

- Sarker, T.R.; Azargohar, R.; Dalai, A.K.; Meda, V. Characteristics of torrefied fuel pellets obtained from co-pelletization of agriculture residues with pyrolysis oil. Biomass Bioenergy 2021, 150, 106139. [Google Scholar] [CrossRef]

- Rudolfsson, M.; Boren, E.; Pommer, L.; Nordin, A.; Lestander, T.A. Combined effects of torrefaction and pelletization parameters on the quality of pellets produced from torrefied biomass. Appl. Energy 2017, 191, 414–424. [Google Scholar] [CrossRef]

- Ghiasi, B.; Kumar, L.; Furubayashi, T.; Lim, C.J.; Bi, X.; Kim, C.S.; Sokhansanj, S. Densified biocoal from woodchips: Is it better to do torrefaction before or after densification? Appl. Energy 2014, 134, 133–142. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, F.; Chen, D.; Cen, K.; Zhang, J.; Cao, X. Upgrading of biomass pellets by torrefaction and its influence on the hydrophobicity, mechanical property, and fuel quality. Biomass Convers. Biorefin. 2020, 12, 2061–2070. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. Strength, storage, and combustion characteristics of densified lignocellulosic biomass produced via torrefaction and hydrothermal carbonization. Appl. Energy 2014, 135, 182–191. [Google Scholar] [CrossRef]

- Gastaldi, G.; Capretti, G.; Focher, B.; Cosentino, C. Characterization and properties of cellulose isolated from the Crambe abyssinica hull. Ind. Crops Prod. 1998, 8, 208–218. [Google Scholar] [CrossRef]

- Kristensen, J.B.; Thygesen, L.G.; Felby, C.; Jorgensen, H.; Elder, T. Cell-wall structural changes in wheat straw pretreated for bioethanol production. Biotechnol. Biofuels 2008, 1, 5. [Google Scholar] [CrossRef]

- Kang, K.; Zhu, M.; Sun, G.; Qiu, L.; Guo, X.; Meda, V.; Sun, R. Codensification of Eucommia ulmoides Oliver stem with pyrolysis oil and char for solid biofuel: An optimization and characterization study. Appl. Energy 2018, 223, 347–357. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).