Spray Analysis and Combustion Assessment of Diesel-LPG Fuel Blends in Compression Ignition Engine

Abstract

:1. Introduction

2. Materials and Methods

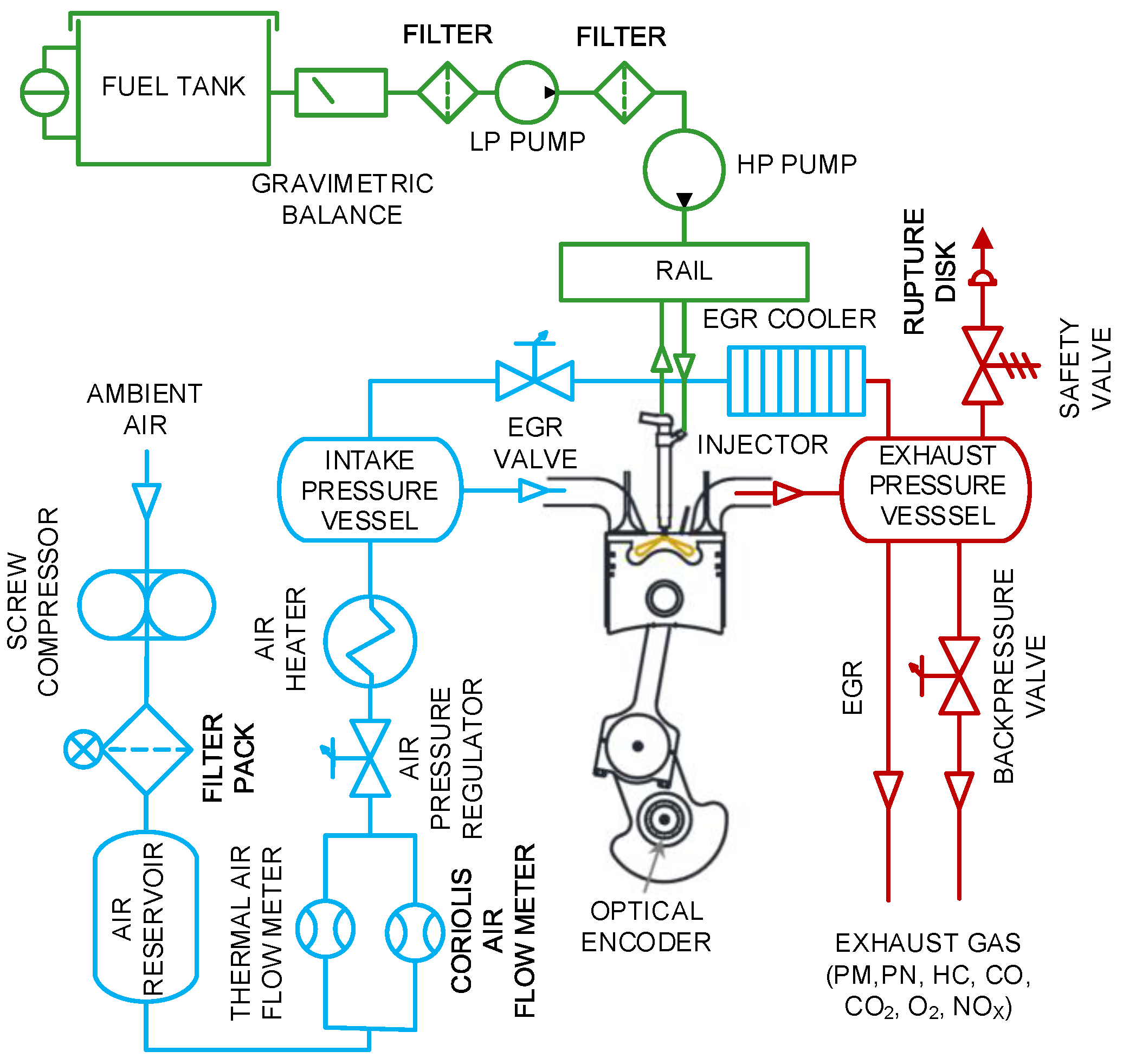

2.1. Single Cylinder Engine

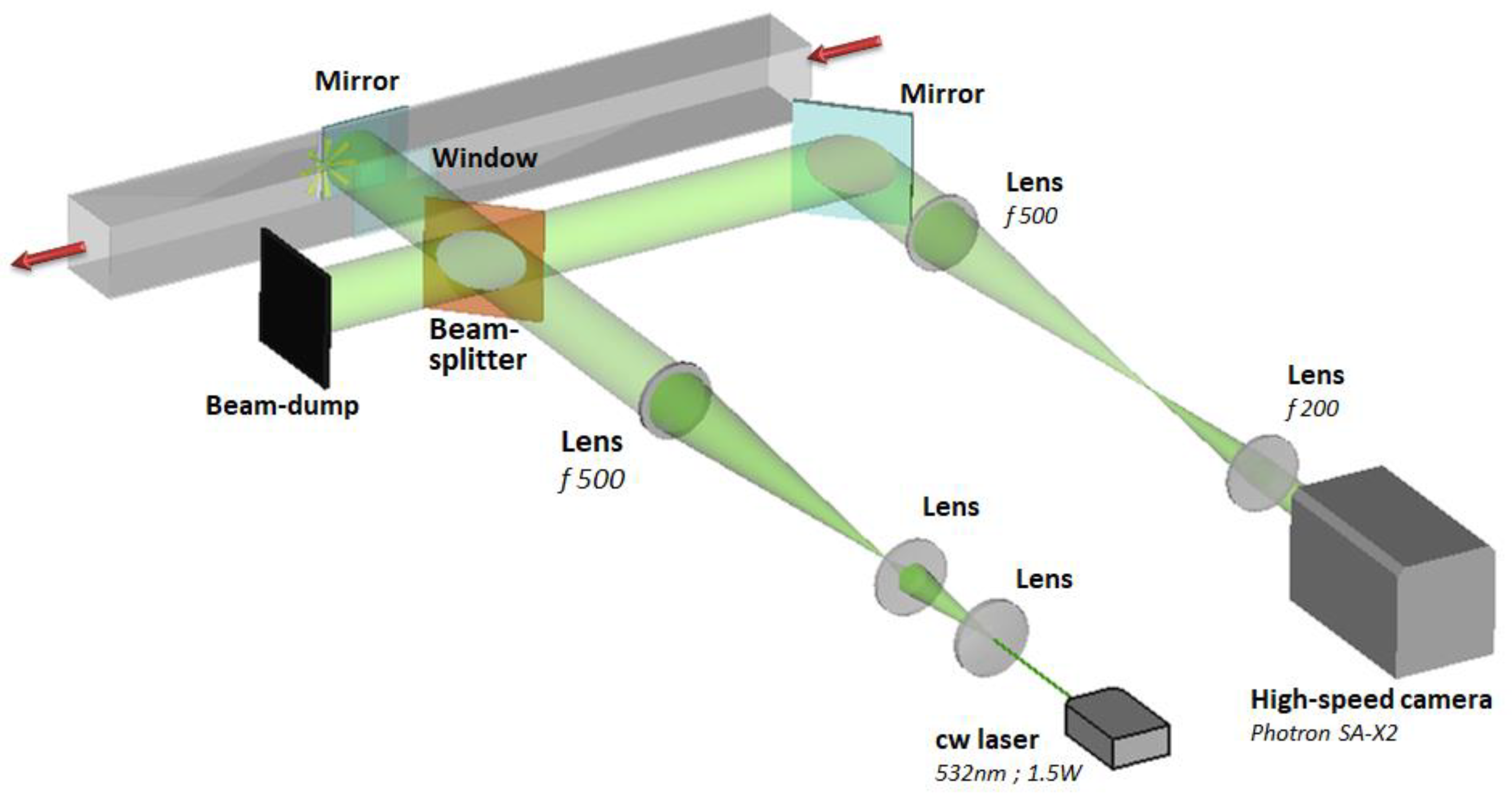

2.2. Optical Setup

2.3. Testing Methodology

2.4. Fuel Characteristics

- Commercial Diesel EN590.

- DLPG20 →20% w/w, L.P.G. in diesel.

- DLPG35 →35% w/w, L.P.G. in diesel.

3. Results

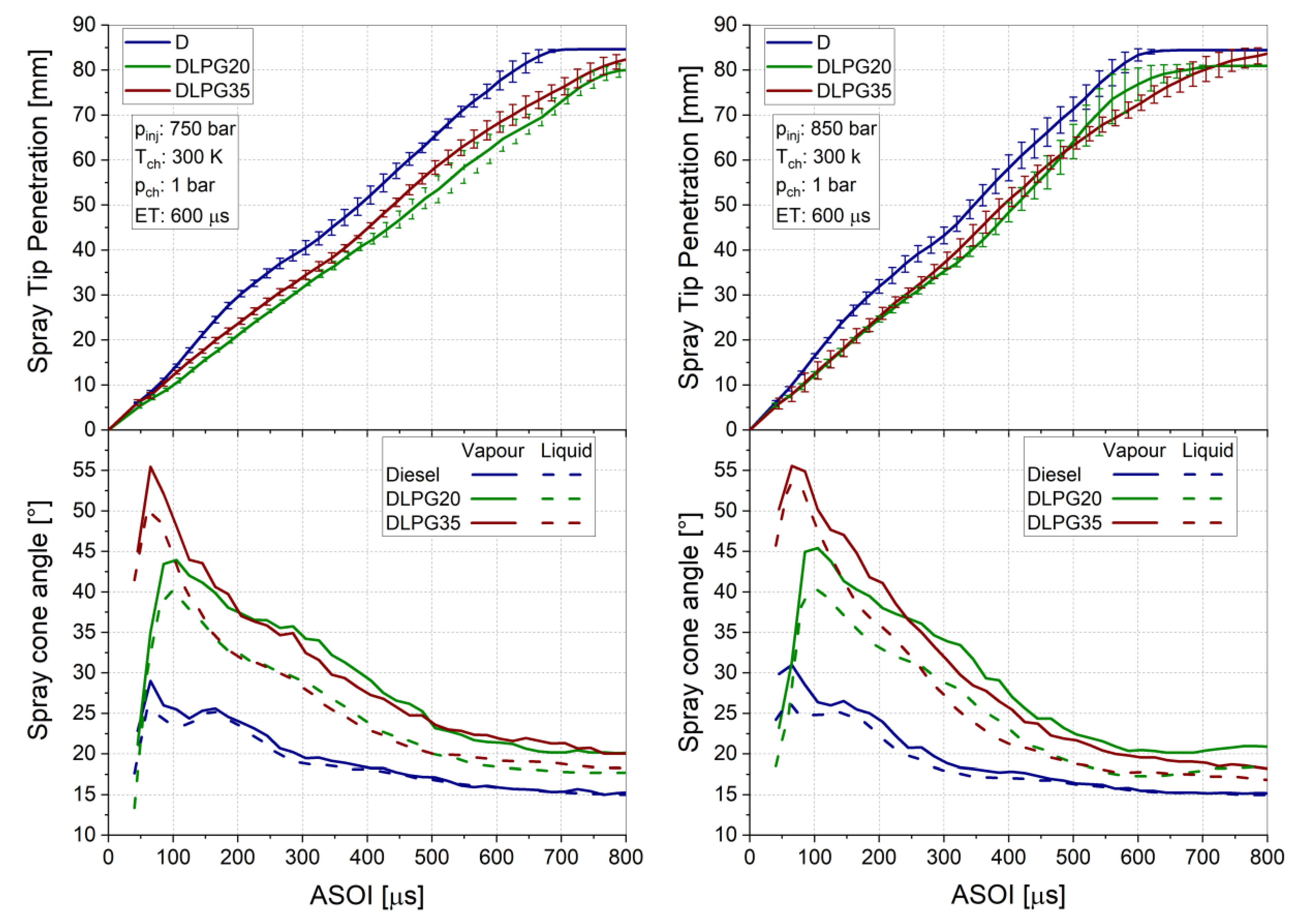

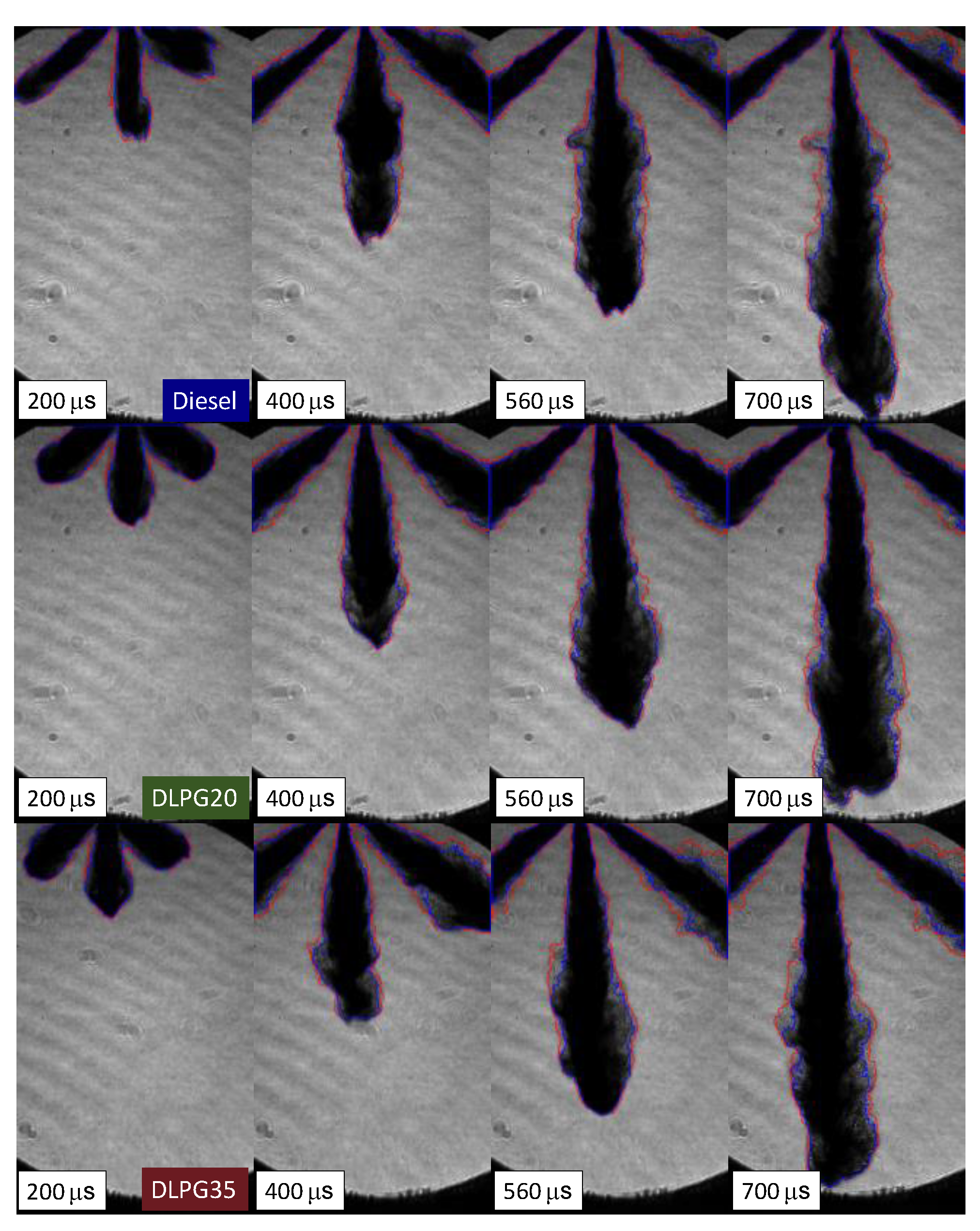

3.1. Spray Characterization of Diesel/LPG Blends

3.1.1. Non-Evaporation Condition (Tch = 300 K)

3.1.2. Evaporation Condition (Tch = 473 K)

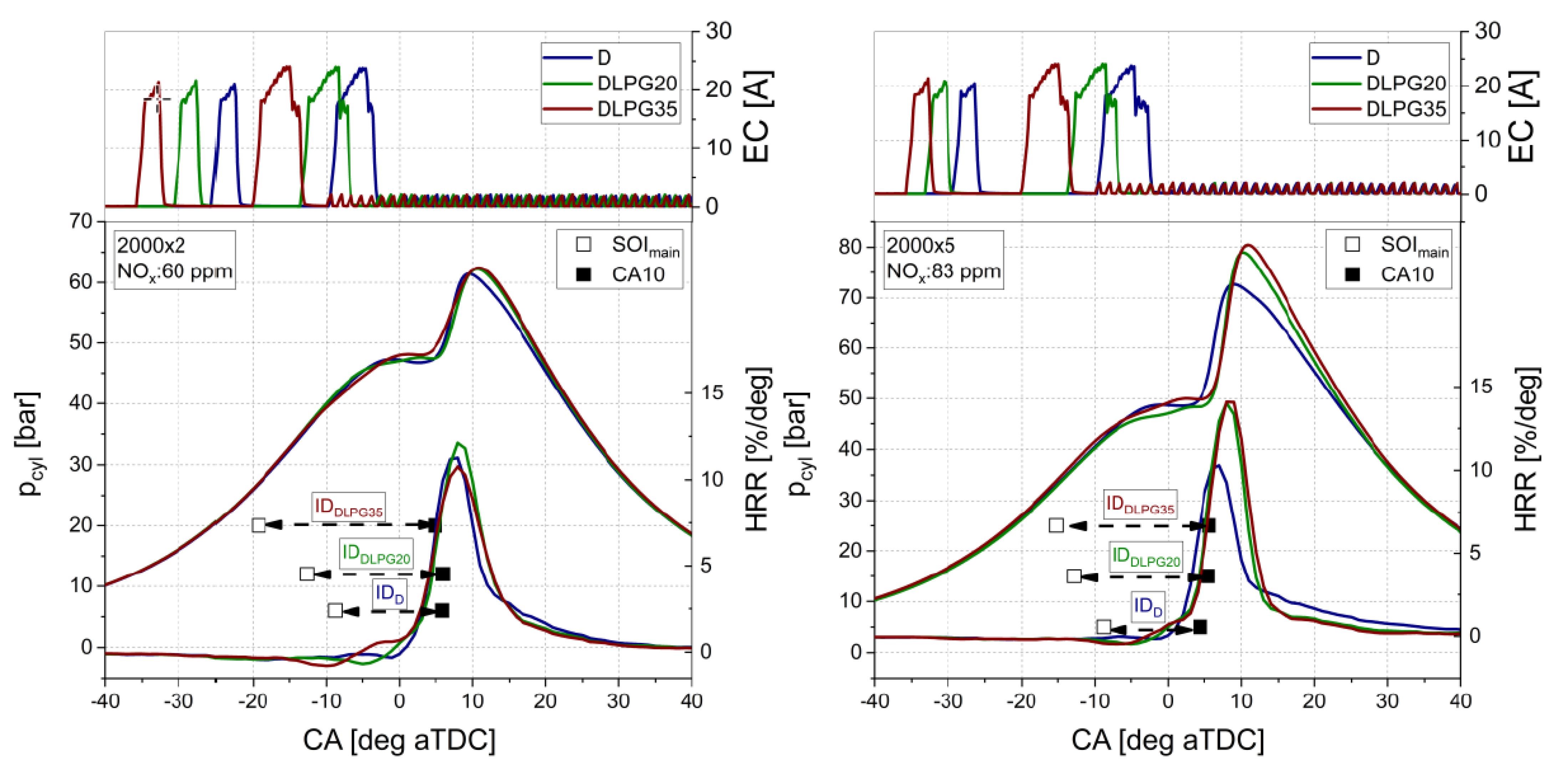

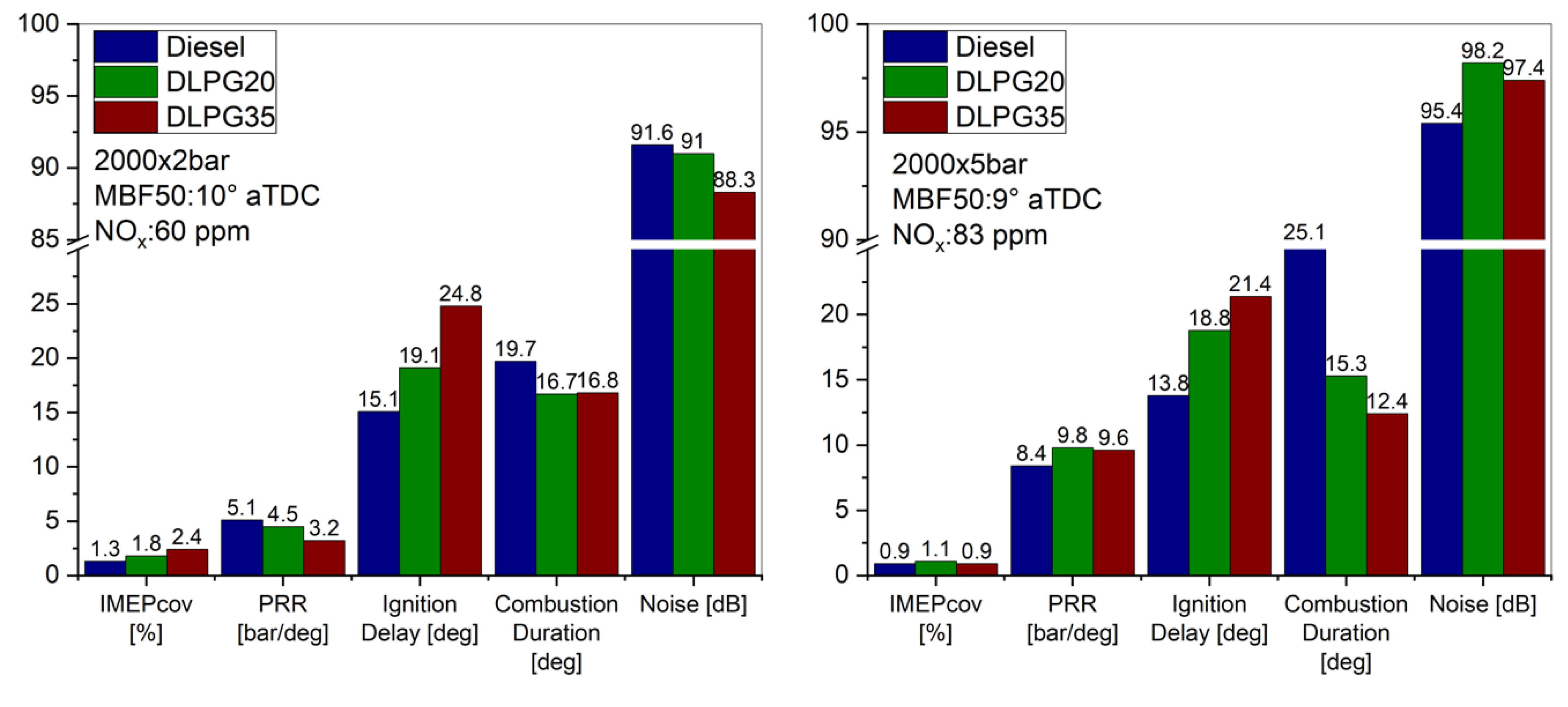

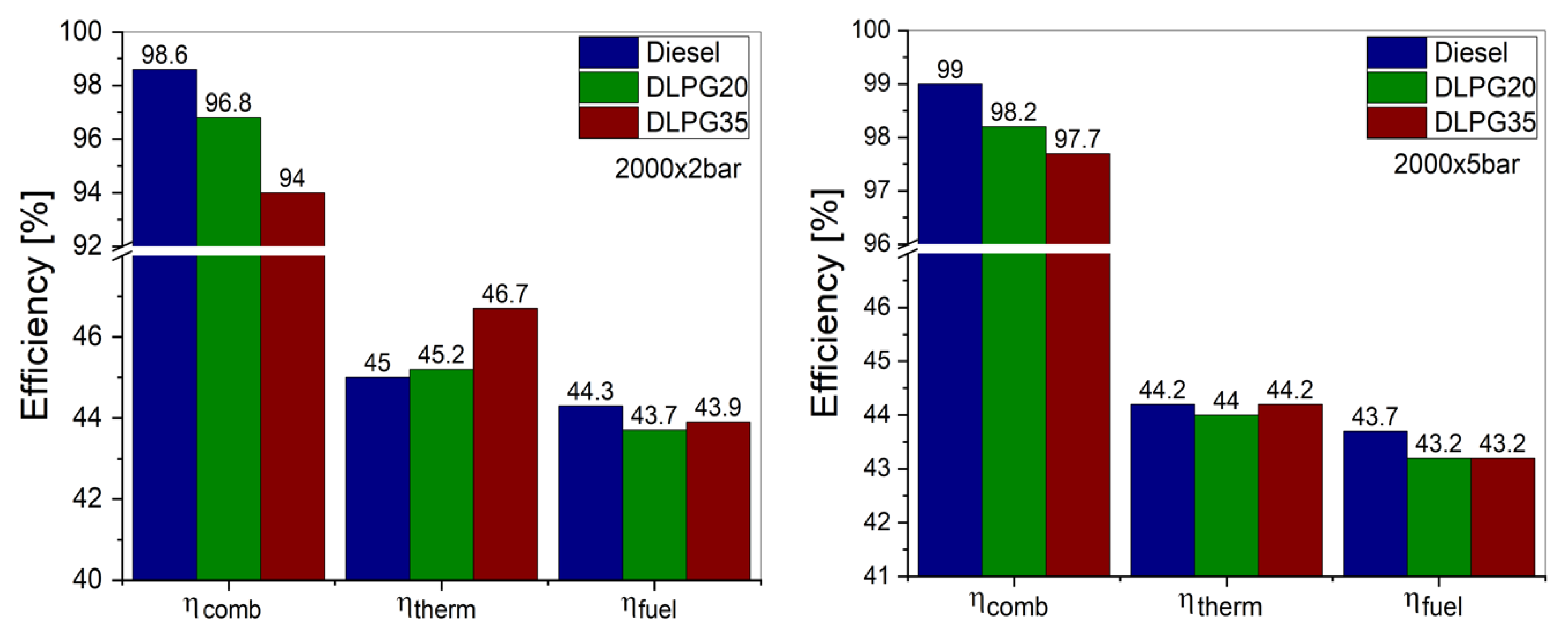

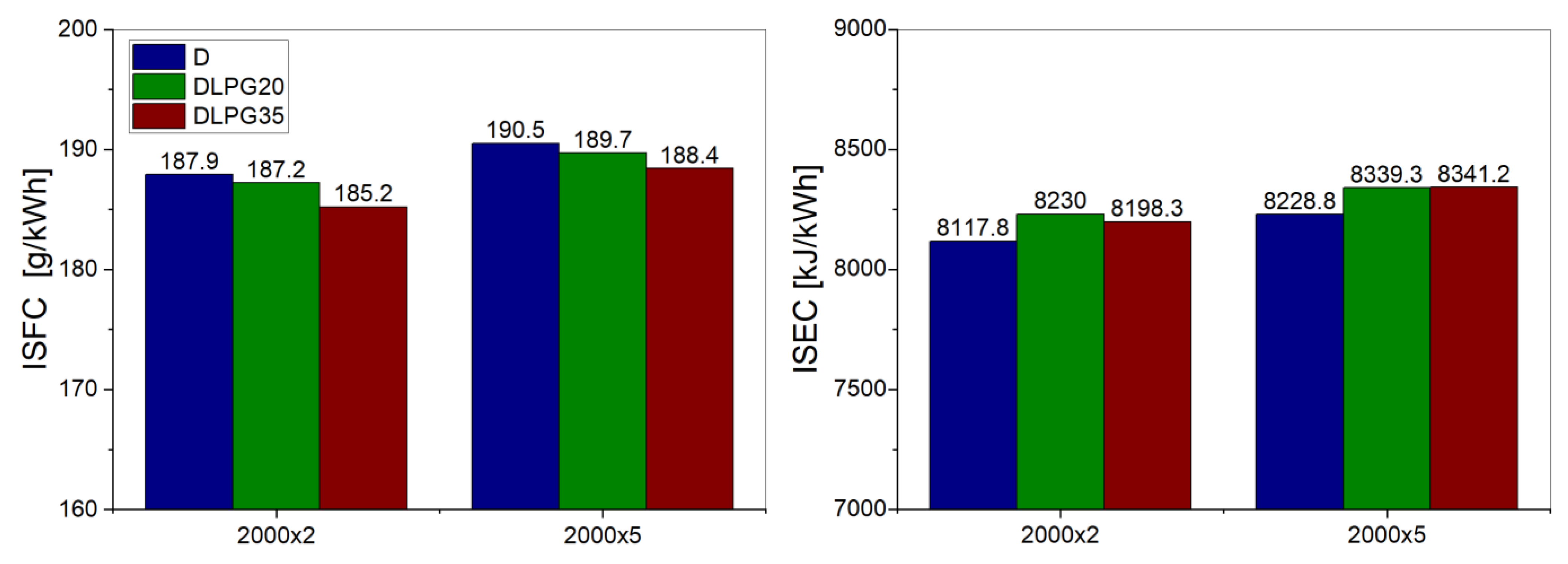

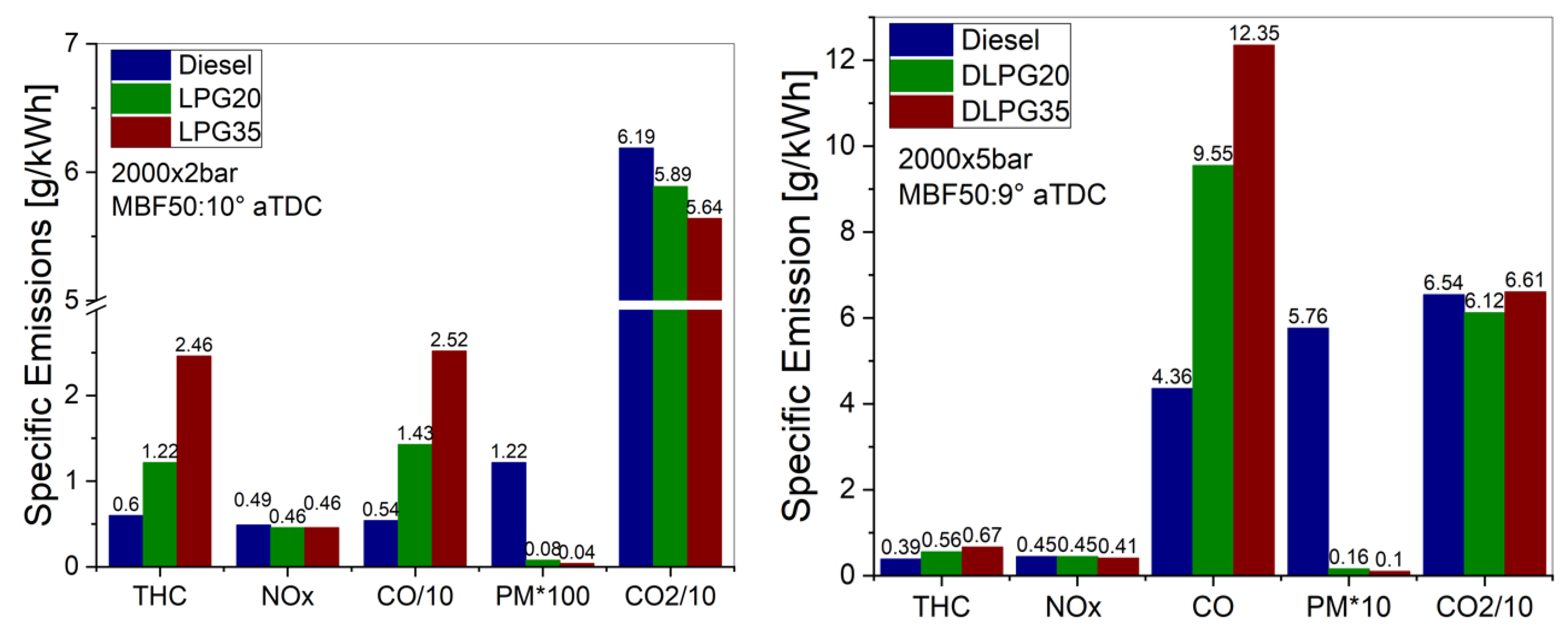

3.2. Combustion Analysis on SCE

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Definitions/Abbreviations

| ASOI | After Start of Injection |

| BMEP | Brake Mean Effective Pressure |

| CA | Crank Angle Degrees |

| CA10 | 10% Mass Burning Fraction |

| CA50 | 50% Mass Burning Fraction |

| CA90-10 | Combustion Duration |

| CI | Compression Ignition |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| cyl | cylinder |

| deg | degree |

| DLPG | Diesel-LPG blend |

| EC | Energizing Current |

| EGR | Exhaust Gas Recirculation |

| ET | Energizing Time |

| ET | Energizing Time |

| HC | Hydrocarbons |

| HRR | Heat Release Rate |

| ID | Ignition delay (SOI-CA10) |

| IMEP | Indicated Mean Effective Pressure |

| IMEPCOV | Covariance of IMEP |

| ISEC | Indicated Specific Energy Consumption |

| ISFC | Indicated Specific Fuel Consumption |

| isX | Indicated Specific Emissions |

| LHV | Lower Heating Value |

| LPG | Liquefied Petroleum Gas |

| NOx | Nitrogen Oxide |

| pch | Chamber pressure |

| pcyl | In-Cylinder Pressure |

| pexh | Back-pressure |

| pint | Boost Pressure |

| PM | Particulate Matter |

| prail | Rail Pressure |

| PRR | Pressure Rise Rate |

| Q | Injected amount |

| SCE | Single-Cylinder Engine |

| SOI | Start of Injection |

| Tch | Chamber temperature |

| TDC | Top Dead Centre |

| ηcomb | Combustion efficiency |

| ηfuel | Global efficiency |

| ηthermal | Thermal efficiency |

References

- Belgiorno, G.; Boscolo, A.; Dileo, G.; Numidi, F.; Pesce, F.C.; Vassallo, A.; Ianniello, R.; Beatrice, C.; Di Blasio, G. Experimental Study of Additive-Manufacturing-Enabled Innovative Diesel Combustion Bowl Features for Achieving Ultra-Low Emissions and High Efficiency. In SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Steinparzer, F.; Nefischer, P.; Stütz, W.; Hiemesch, D.; Kaufmann, M. The New BMW Six-Cylinder Top Engine With Innovative Turbocharging Concept, 37th ed.; Vienna Motoren Symposium: Wien, Austria, 2016. [Google Scholar]

- Di Blasio, G.; Beatrice, C.; Ianniello, R.; Pesce, F.C.; Vassallo, A.; Belgiorno, G.; Avolio, G. Balancing Hydraulic Flow and Fuel Injection Parameters for Low-Emission and High-Efficiency Automotive Diesel Engines. In SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Di Blasio, G.; Beatrice, C.; Belgiorno, G.; Pesce, F.C.; Vassallo, A. Functional Requirements to Exceed the 100 kW/l Milestone for High Power Density Automotive Diesel Engines. SAE Int. J. Engines 2017, 10, 2342–2353. [Google Scholar] [CrossRef]

- Gill, S.; Tsolakis, A.; Dearn, K.; Rodríguez-Fernández, J. Combustion characteristics and emissions of Fischer–Tropsch diesel fuels in IC engines. Prog. Energy Combust. Sci. 2011, 37, 503–523. [Google Scholar] [CrossRef]

- Lee, S.W.; Cho, Y.S.; Choi, W.C.; Lee, J.H.; Park, Y.J. Combustion characteristics of LPG and biodiesel mixed fuel in two blending ratios under compression ignition in a constant volume chamber. Int. J. Automot. Technol. 2012, 13, 1149–1157. [Google Scholar] [CrossRef]

- Qi, D.; Bian, Y.; Ma, Z.; Zhang, C.; Liu, S. Combustion and exhaust emission characteristics of a compression ignition engine using liquefied petroleum gas–Diesel blended fuel. Energy Convers. Manag. 2007, 48, 500–509. [Google Scholar] [CrossRef]

- Donghui, Q.; Longbao, Z.; Shenghua, L. Experimental studies on the combustion characteristics and performance of a naturally aspirated, direct injection engine fuelled with a liquid petroleum gas/diesel blend. Proc. Inst. Mech. Eng. Part D: J. Automob. Eng. 2005, 219, 253–261. [Google Scholar] [CrossRef]

- Cao, J.; Bian, Y.; Qi, D.; Cheng, Q.; Wu, T. Comparative investigation of diesel and mixed liquefied petroleum gas/diesel injection engines. Proc. Inst. Mech. Eng. Part D: J. Automob. Eng. 2004, 218, 557–565. [Google Scholar] [CrossRef]

- Beatrice, C.; Denbratt, I.; Di Blasio, G.; Di Luca, G.; Ianniello, R.; Saccullo, M. Experimental Assessment on Exploiting Low Carbon Ethanol Fuel in a Light-Duty Dual-Fuel Compression Ignition Engine. Appl. Sci. 2020, 10, 7182. [Google Scholar] [CrossRef]

- Cao, J. On the Theoretical Prediction of Fuel Droplet Size Distribution in Nonreactive Diesel Sprays. J. Fluids Eng. 2001, 124, 182–185. [Google Scholar] [CrossRef]

- Ma, Z.; Huang, Z.; Li, C.; Wang, A.X.; Miao, H. Effects of Fuel Injection Timing on Combustion and Emission Characteristics of a Diesel Engine Fueled with Diesel−Propane Blends. Energy Fuels 2007, 21, 1504–1510. [Google Scholar] [CrossRef]

- Ma, Z.; Huang, Z.; Li, C.; Wang, X.; Miao, H. Combustion and emission characteristics of a diesel engine fuelled with diesel–propane blends. Fuel 2008, 87, 1711–1717. [Google Scholar] [CrossRef]

- Pirouzpanah, V.; Kashani, B.O. Prediction of Major Pollutants Emission in Direct—Injection Dual—Fuel Diesel and Natural—Gas Engines. In SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef]

- Papagiannakis, R.; Hountalas, D.T. Experimental investigation concerning the effect of natural gas percentage on performance and emissions of a DI dual fuel diesel engine. Appl. Therm. Eng. 2003, 23, 353–365. [Google Scholar] [CrossRef]

- Myung, C.L.; Lee, H.; Choi, K.; Lee, Y.J.; Park, S. Effects of gasoline, diesel, LPG, and low-carbon fuels and various certification modes on nanoparticle emission characteristics in light-duty vehicles. Int. J. Automot. Technol. 2009, 10, 537–544. [Google Scholar] [CrossRef]

- Cardone, M.; Mancaruso, E.; Marialto, R.; Sequino, L.; Vaglieco, B.M. Characterization of Combustion and Emissions of a Propane-Diesel Blend in a Research Diesel Engine. In SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Marialto, R.; Sequino, L.; Di Blasio, G.; Cardone, M.; Beatrice, C.; Ianniello, R.; Fontana, G. Combustion and Emission Characteristics of a Diesel Engine Fuelled with Diesel-LPG Blends. In SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Di Blasio, G.; Belgiorno, G.; Beatrice, C. Effects on performances, emissions and particle size distributions of a dual fuel (methane-diesel) light-duty engine varying the compression ratio. Appl. Energy 2017, 204, 726–740. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Klein-Douwel, R.R.; Frijters, P.P.; Somers, L.; De Boer, W.W.; Baert, R.R. Macroscopic diesel fuel spray shadowgraphy using high speed digital imaging in a high pressure cell. Fuel 2007, 86, 1994–2007. [Google Scholar] [CrossRef]

- Lazzaro, M.; Ianniello, R. Image processing of vaporizing GDI sprays: A new curvature-based approach. Meas. Sci. Technol. 2017, 29, 015402. [Google Scholar] [CrossRef]

- Dijkstra, R.; Di Blasio, G.; Boot, M.; Beatrice, C.; Bertoli, C. Assessment of the Effect of Low Cetane Number Fuels on a Light Duty CI Engine: Preliminary Experimental Characterization in PCCI Operating Condition. In SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Litzinger, T.; Stoner, M.; Hess, H.; Boehman, A. Effects of oxygenated blending compounds on emissions from a turbocharged direct injection diesel engine. Int. J. Engine Res. 2000, 1, 57–70. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, H.J.; Suh, H.K.; Lee, C.S. Atomisation and spray characteristics of bioethanol and bioethanol blended gasoline fuel injected through a direct injection gasoline injector. Int. J. Heat Fluid Flow 2009, 30, 1183–1192. [Google Scholar] [CrossRef]

- Ma, Y.; Huang, S.; Huang, R.; Zhang, Y.; Xu, S. Spray and evaporation characteristics of n-pentanol–diesel blends in a constant volume chamber. Energy Convers. Manag. 2016, 130, 240–251. [Google Scholar] [CrossRef]

- Kim, K.; Kim, D.; Jung, Y.; Bae, C. Spray and combustion characteristics of gasoline and diesel in a direct injection compression ignition engine. Fuel 2013, 109, 616–626. [Google Scholar] [CrossRef]

- Yu, W.; Yang, W.; Mohan, B.; Tay, K.L.; Zhao, F. Macroscopic spray characteristics of wide distillation fuel (WDF). Appl. Energy 2017, 185, 1372–1382. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Z.; Kuti, O.A.; Zhang, W.; Nishida, K. Experimental and analytical study on biodiesel and diesel spray characteristics under ultra-high injection pressure. Int. J. Heat Fluid Flow 2010, 31, 659–666. [Google Scholar] [CrossRef]

- An, Y.; Jaasim, M.; Ali, M.; Vallinayagam, R.; Vedharaj, S.; Perez, F.H.; Sim, J.; Chang, J.; Im, H.; Johansson, B. Investigation of Premixed and Diffusion Flames in PPC and CI Combustion Modes (No. 2018-01-0899). In SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Li, C.; Yin, L.; Shamun, S.; Tuner, M.; Johansson, B.; Solsjo, R.; Bai, X.S. Transition from HCCI to PPC: The Sensitivity of Combustion Phasing to the Intake Temperature and the Injection Timing with and without EGR. In SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Johansson, B. Förbränningsmotorer, Division of Combustion Engines; LTH Sweden: Lund, Sweden, 2006. [Google Scholar]

- Al-Hassan, M. Effect of ethanol–unleaded gasoline blends on engine performance and exhaust emission. Energy Convers. Manag. 2003, 44, 1547–1561. [Google Scholar] [CrossRef]

- Beatrice, C.; Di Blasio, G.; Pesce, F.C.; Vassallo, A.; Avolio, G.; Ianniello, R. Key Fuel Injection System Features for Efficiency Improvement in Future Diesel Passenger Cars. SAE Tech. Pap. Ser. 2019, 1, 1084–1099. [Google Scholar] [CrossRef]

- Diwakar, R.; Domenech-Llopis, V. Physics of Combustion Noise Reduction with Multiple Injections in a DI Diesel Engine-A Computational Study. In SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- Koci, C.P.; Fitzgerald, R.P.; Ikonomou, V.; Sun, K. The effects of fuel–air mixing and injector dribble on diesel unburned hydrocarbon emissions. Int. J. Engine Res. 2019, 20, 105–127. [Google Scholar] [CrossRef]

| Displaced volume [cm3] | 477 |

| Stroke × Bore [mm] | 90.4 × 82 |

| Geometrical CR [–] | 16.5:1 |

| Max rail pressure [–] | 1800 bar |

| Injector type | Solenoid |

| Number of holes | 7 |

| Hole Diameter | 0.141 mm |

| Cone angle | 148° |

| Rated flow @ 100 bar | 440 cm3/30 s |

| Parameters | Engine | Spray | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| [rpm] × [bar] | IMEP [bar] | prail [bar] | CA50 [CAD aTDC] | pint [barG] | pexh [barG] | Tint [K] | NOx [ppm] | Tch [K] | pch [bar] | ET [ms] |

| 2000 × 2 | 4.1 | 750 | 10 | 0.11 | 0.32 | 339 | 60 | 300–473 | 1 | 0.6 |

| 2000 × 5 | 7.0 | 850 | 9 | 0.21 | 0.43 | 336 | 83 | |||

| Fuel Name | Diesel | DLPG20 | DLPG35 | LPG |

|---|---|---|---|---|

| LPG content w/w [%] | 0 | 20 | 35 | 100 |

| Density (liquid state) [kg/m3] | 836 | 772 | 723 | 514 |

| Low-Heating Value [MJ/kg] | 42.5 | 43.2 | 43.8 | 46.1 |

| Latent Heat of vaporization [kJ/kg] | 260 | 294 | 320 | 430 |

| Stoichiometric A/F [-] | 14.67 | 15.4 | 15.6 | 16.7 |

| Boiling point (0.1 MPa) [°C] | 362 | - | - | −42 |

| Autoignition Temperature [°C] | 250 | - | - | 365—470 |

| Cetane number | 56.2 | - | - | <2 |

| H/C [-] | 1.86 | 2.3 | 2.49 | 3.43 |

| λ | D | DLPG20 | DLPG35 |

|---|---|---|---|

| 2000 × 2 | 1.8 | 1.9 | 1.9 |

| 2000 × 5 | 1.2 | 1.3 | 1.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cardone, M.; Marialto, R.; Ianniello, R.; Lazzaro, M.; Di Blasio, G. Spray Analysis and Combustion Assessment of Diesel-LPG Fuel Blends in Compression Ignition Engine. Fuels 2021, 2, 1-15. https://doi.org/10.3390/fuels2010001

Cardone M, Marialto R, Ianniello R, Lazzaro M, Di Blasio G. Spray Analysis and Combustion Assessment of Diesel-LPG Fuel Blends in Compression Ignition Engine. Fuels. 2021; 2(1):1-15. https://doi.org/10.3390/fuels2010001

Chicago/Turabian StyleCardone, Massimo, Renato Marialto, Roberto Ianniello, Maurizio Lazzaro, and Gabriele Di Blasio. 2021. "Spray Analysis and Combustion Assessment of Diesel-LPG Fuel Blends in Compression Ignition Engine" Fuels 2, no. 1: 1-15. https://doi.org/10.3390/fuels2010001

APA StyleCardone, M., Marialto, R., Ianniello, R., Lazzaro, M., & Di Blasio, G. (2021). Spray Analysis and Combustion Assessment of Diesel-LPG Fuel Blends in Compression Ignition Engine. Fuels, 2(1), 1-15. https://doi.org/10.3390/fuels2010001