Dynamic Modelling and Simulation of a Permanent Magnet Synchronous Motor (PMSM) Applied in a Prototype Race Car and the Comparison of Its Performance with BLDC Motor

Abstract

1. Introduction

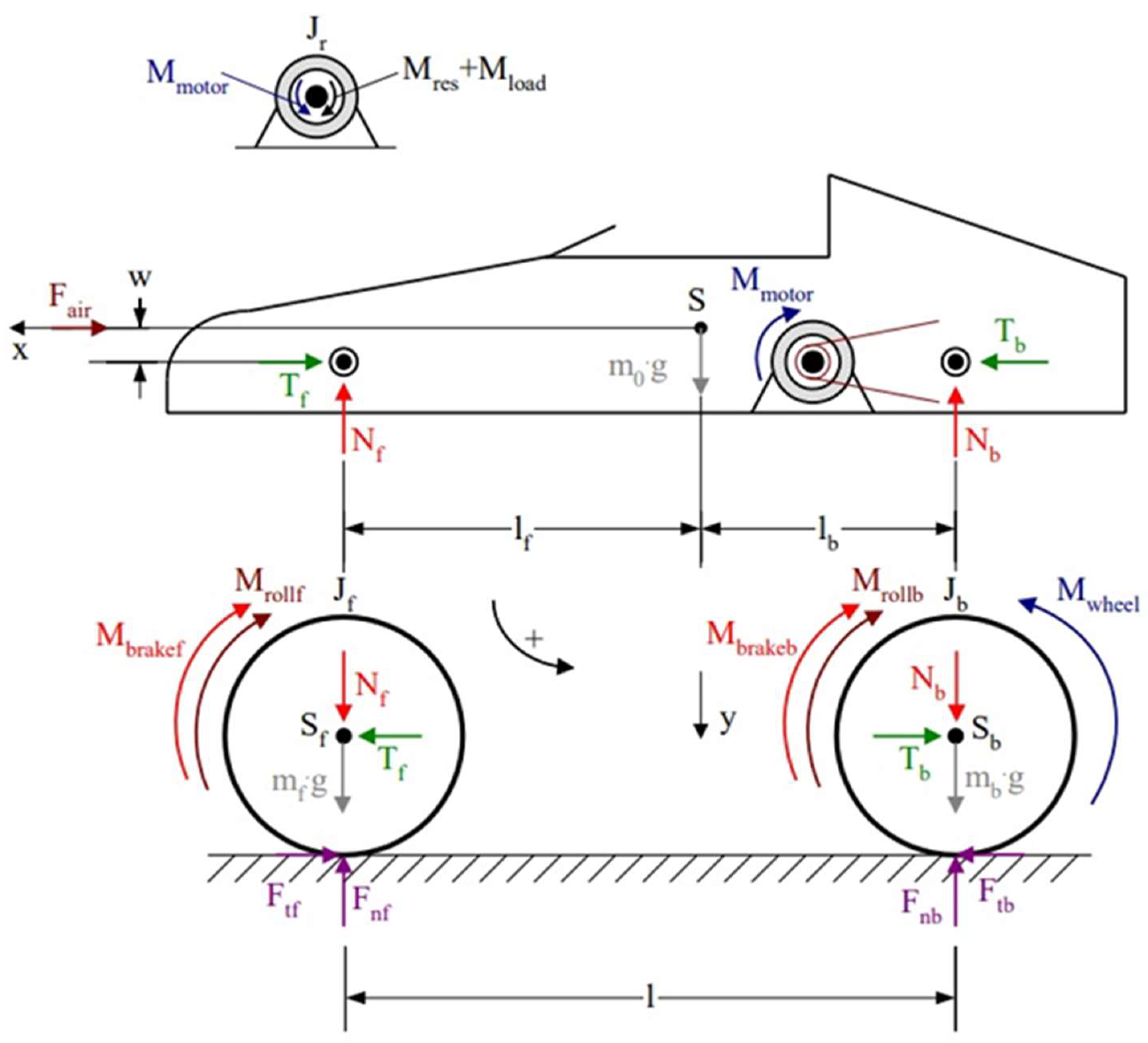

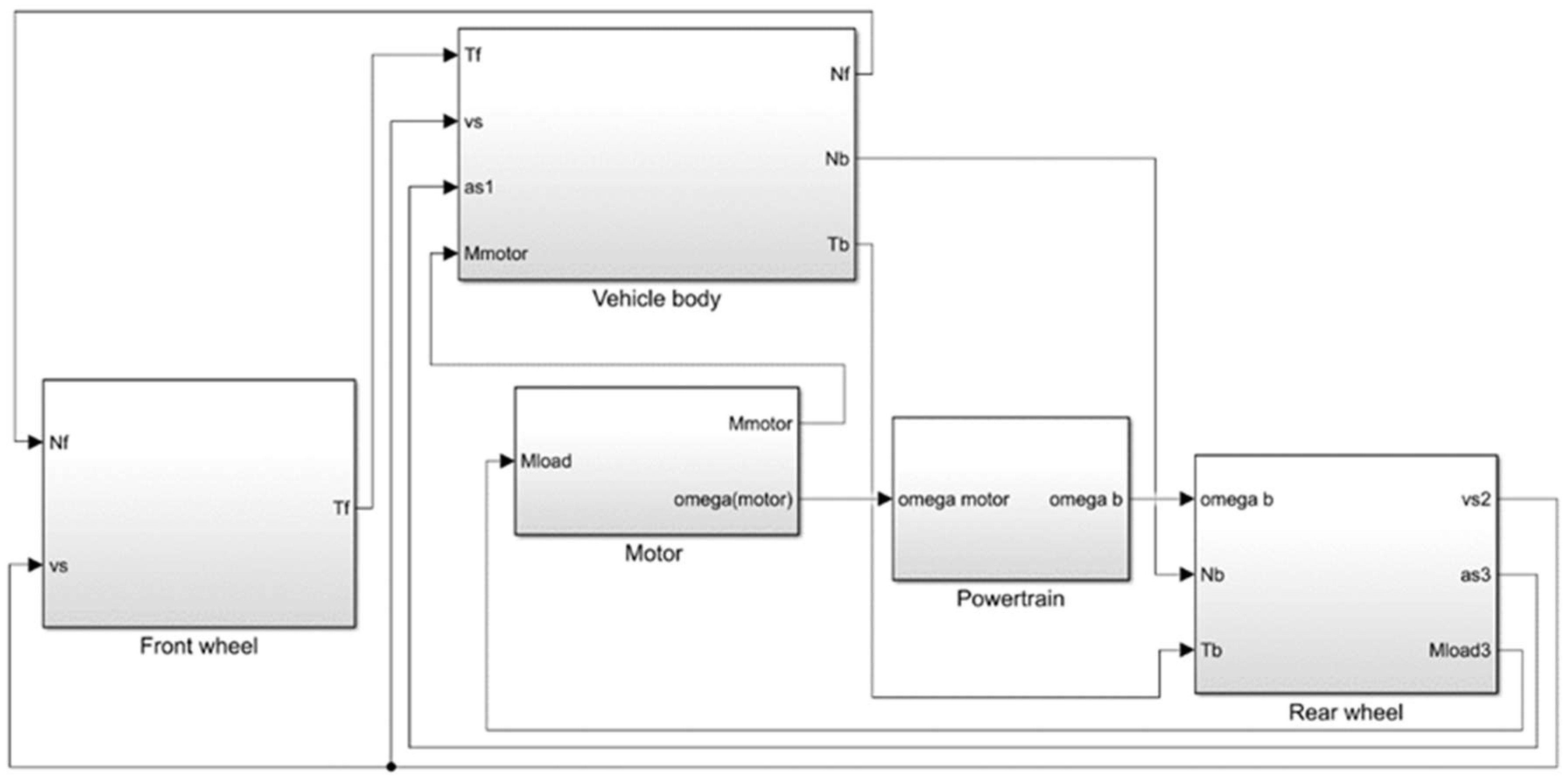

2. The Applied Vehicle Dynamics Simulation Program

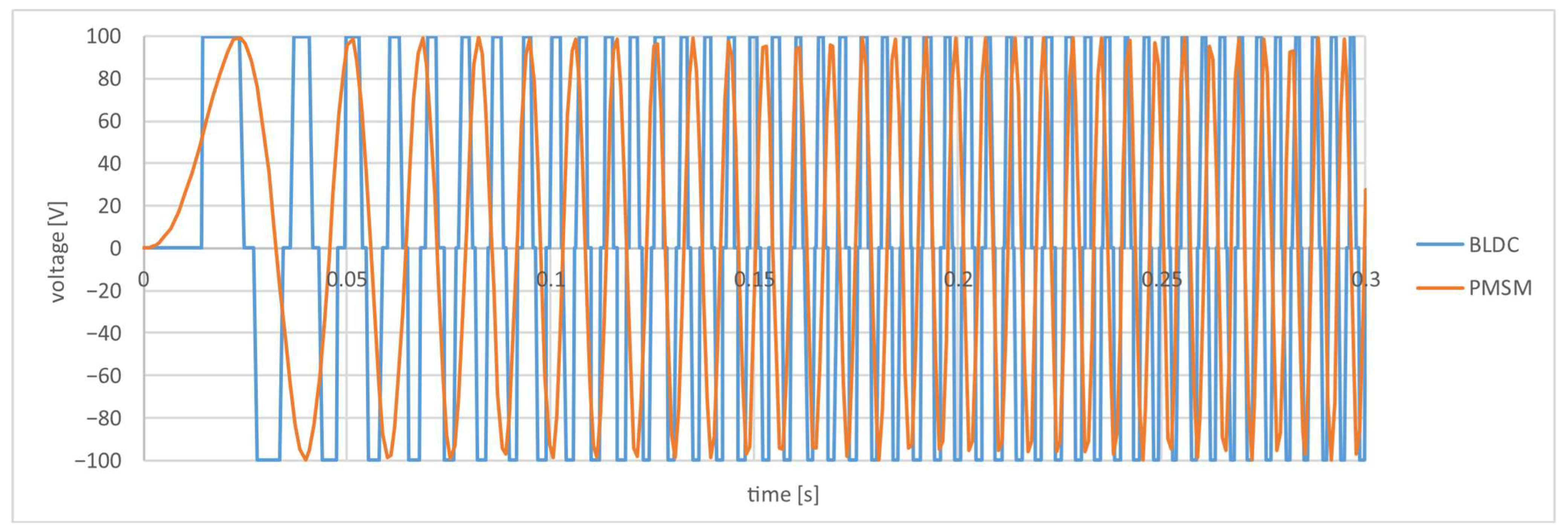

3. Permanent Magnet Synchronous Motor (PMSM) Modelling and Simulation

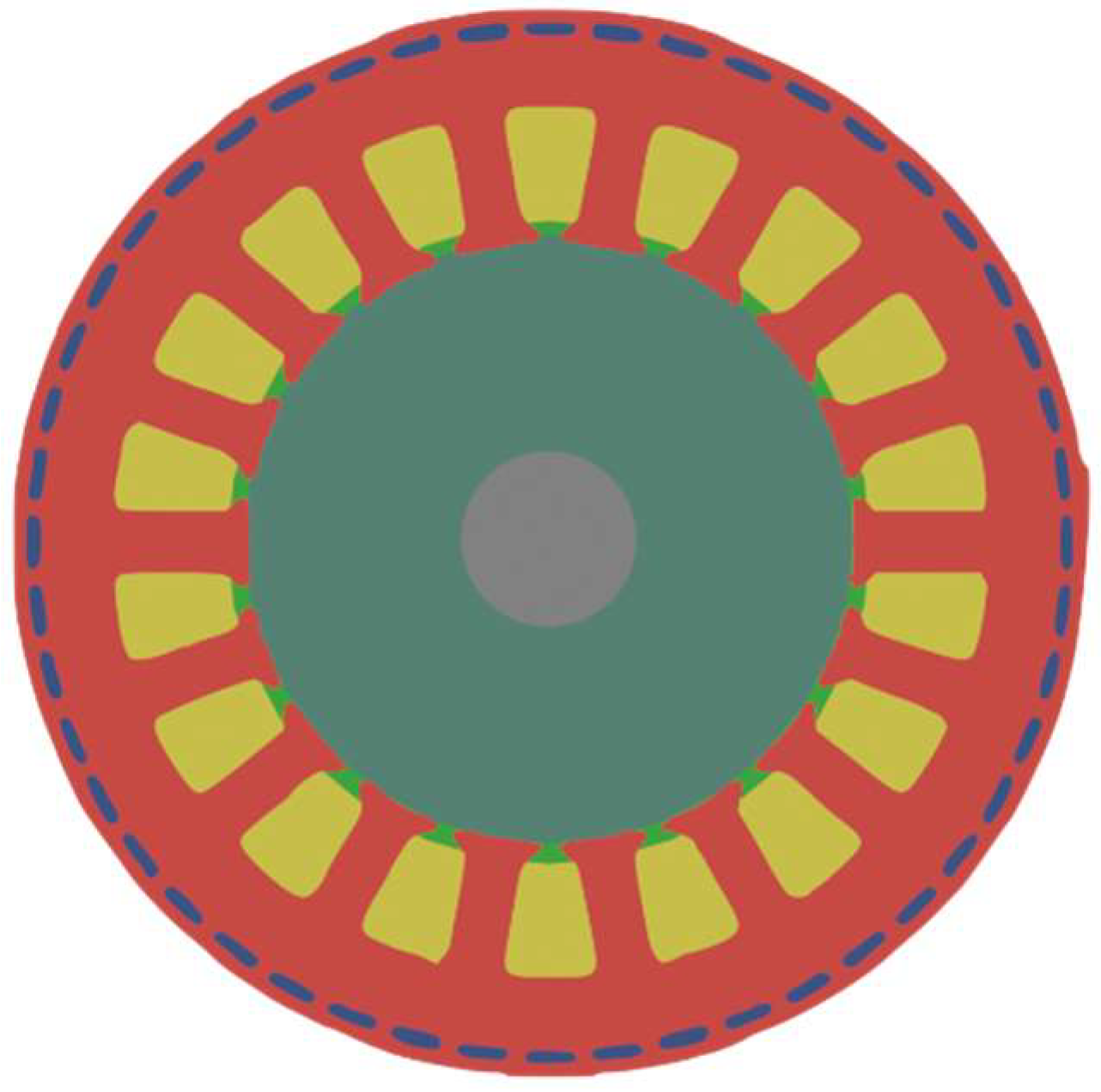

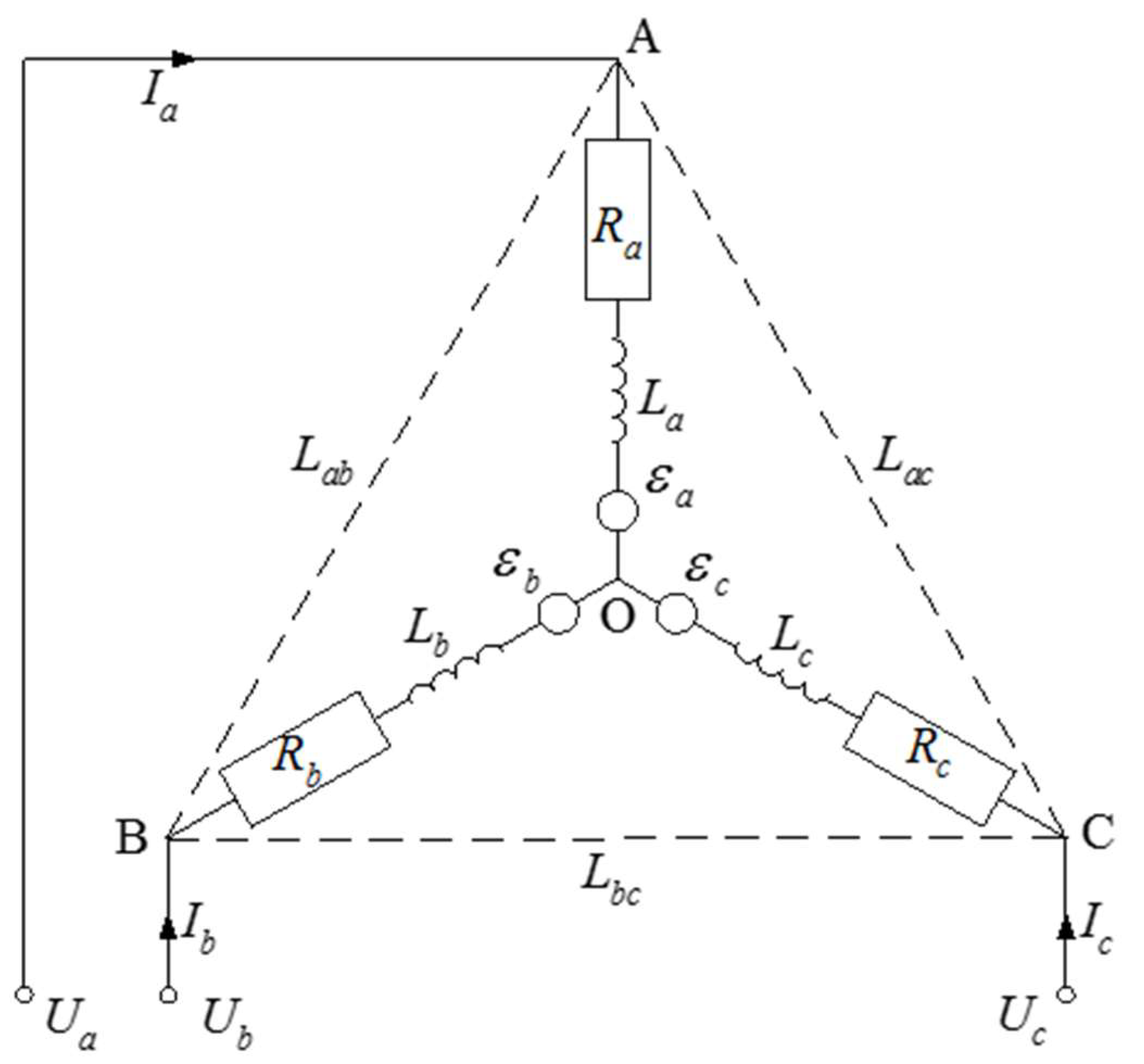

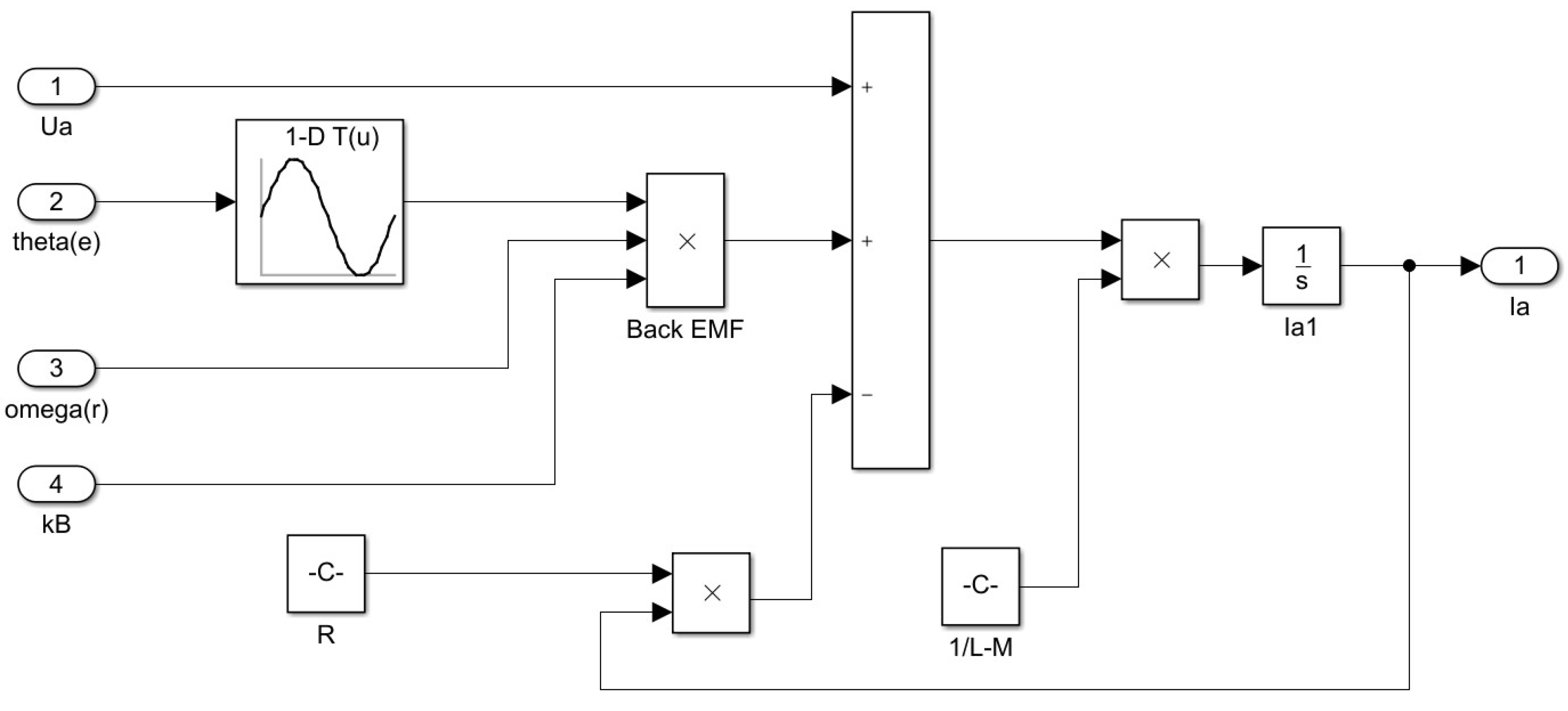

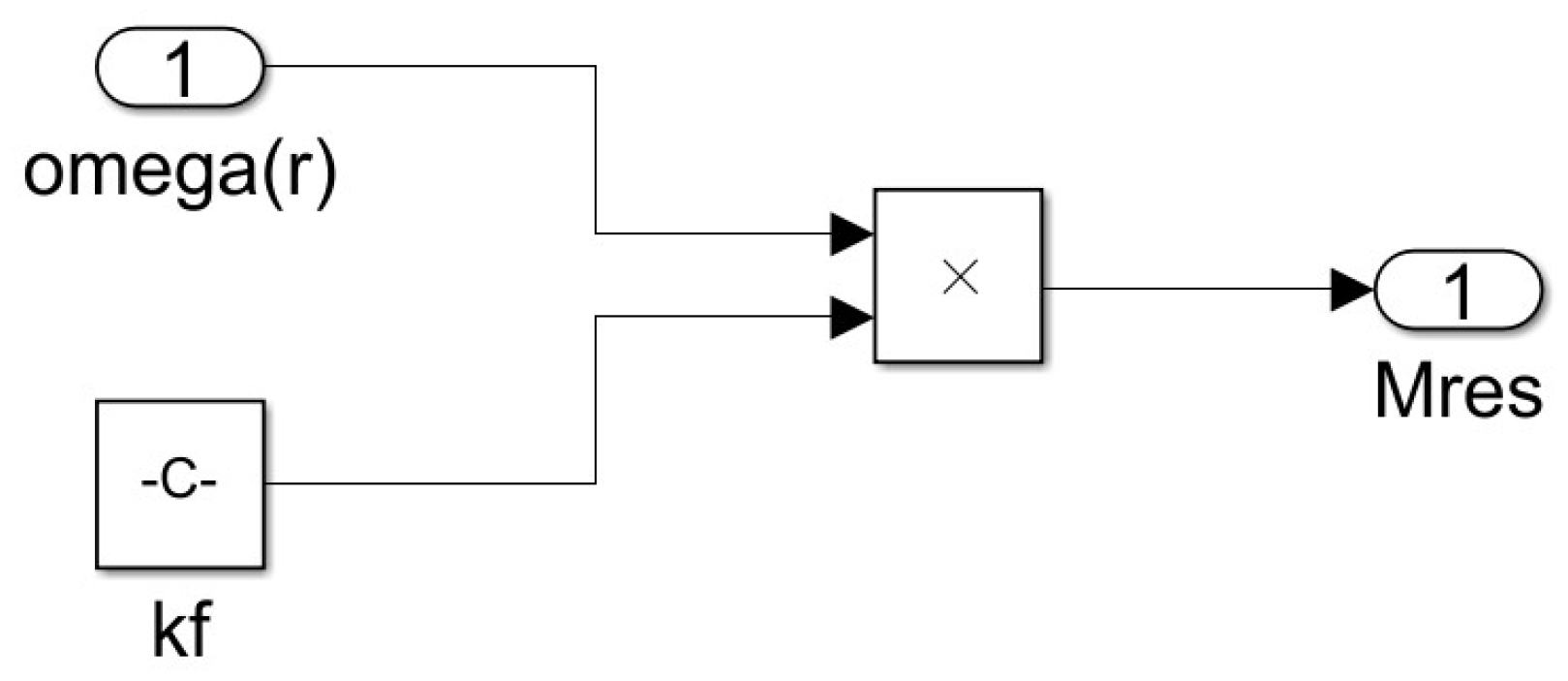

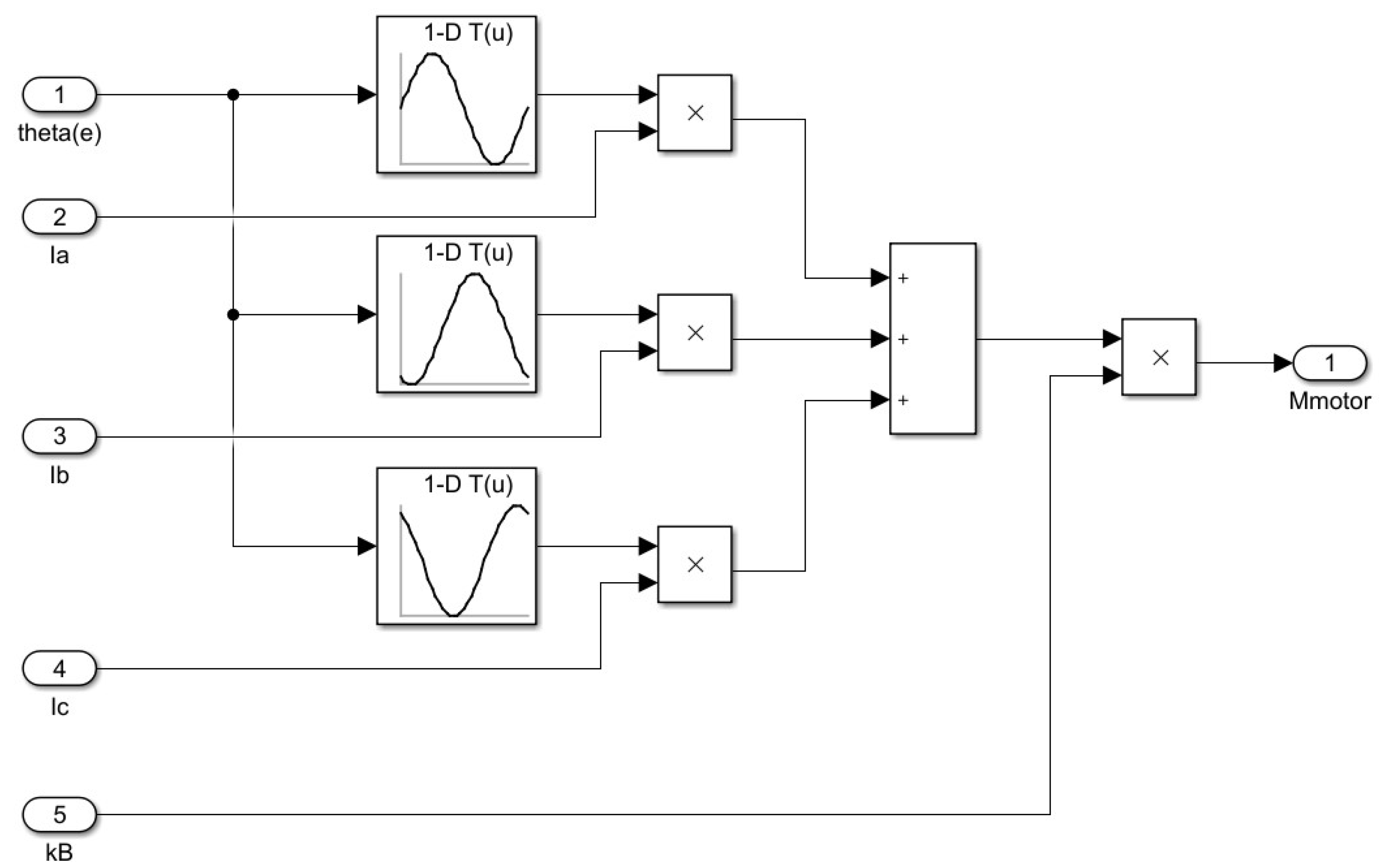

3.1. Brief Description and Modelling of the Permanent Magnet Synchronous Motor

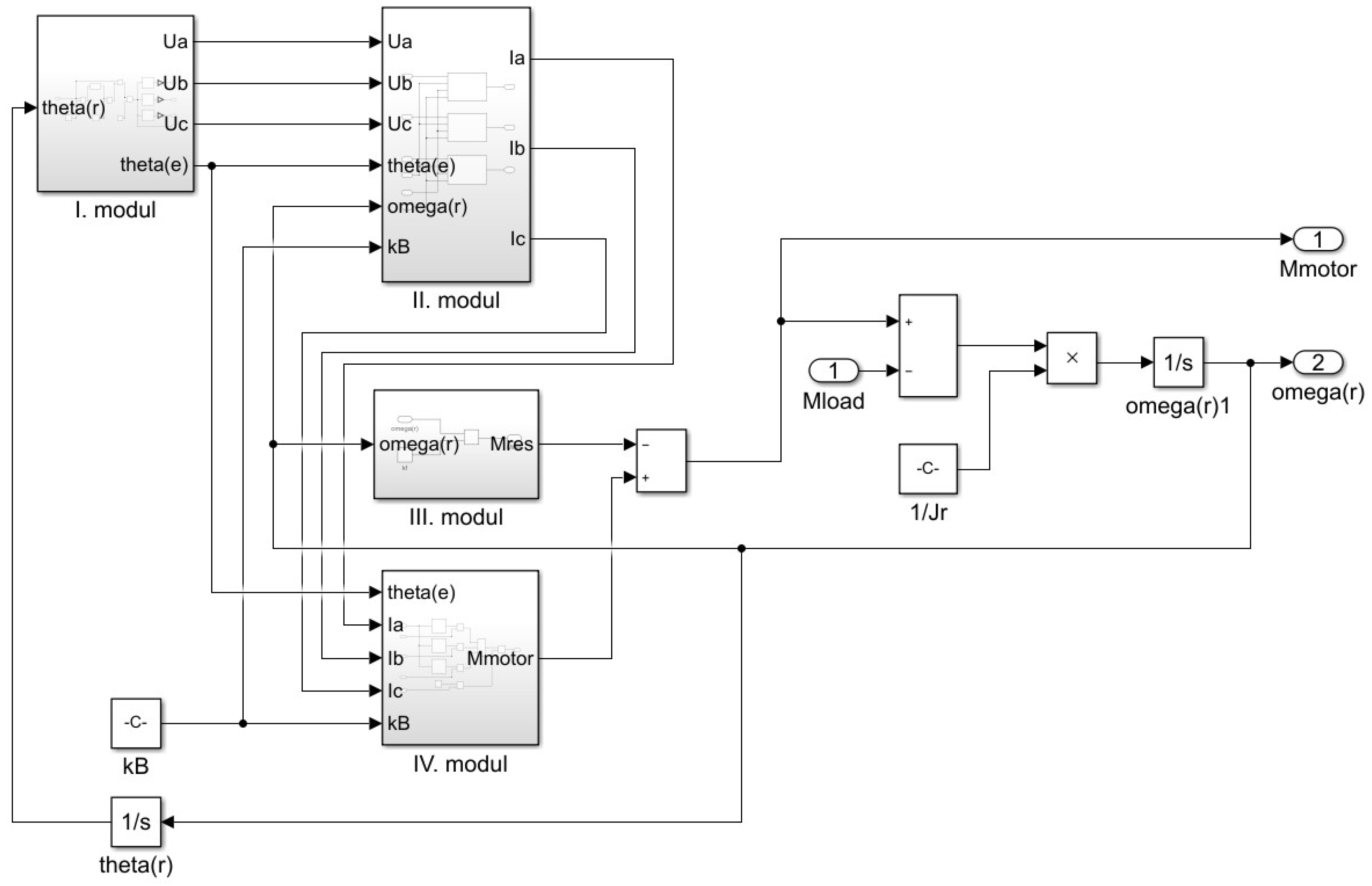

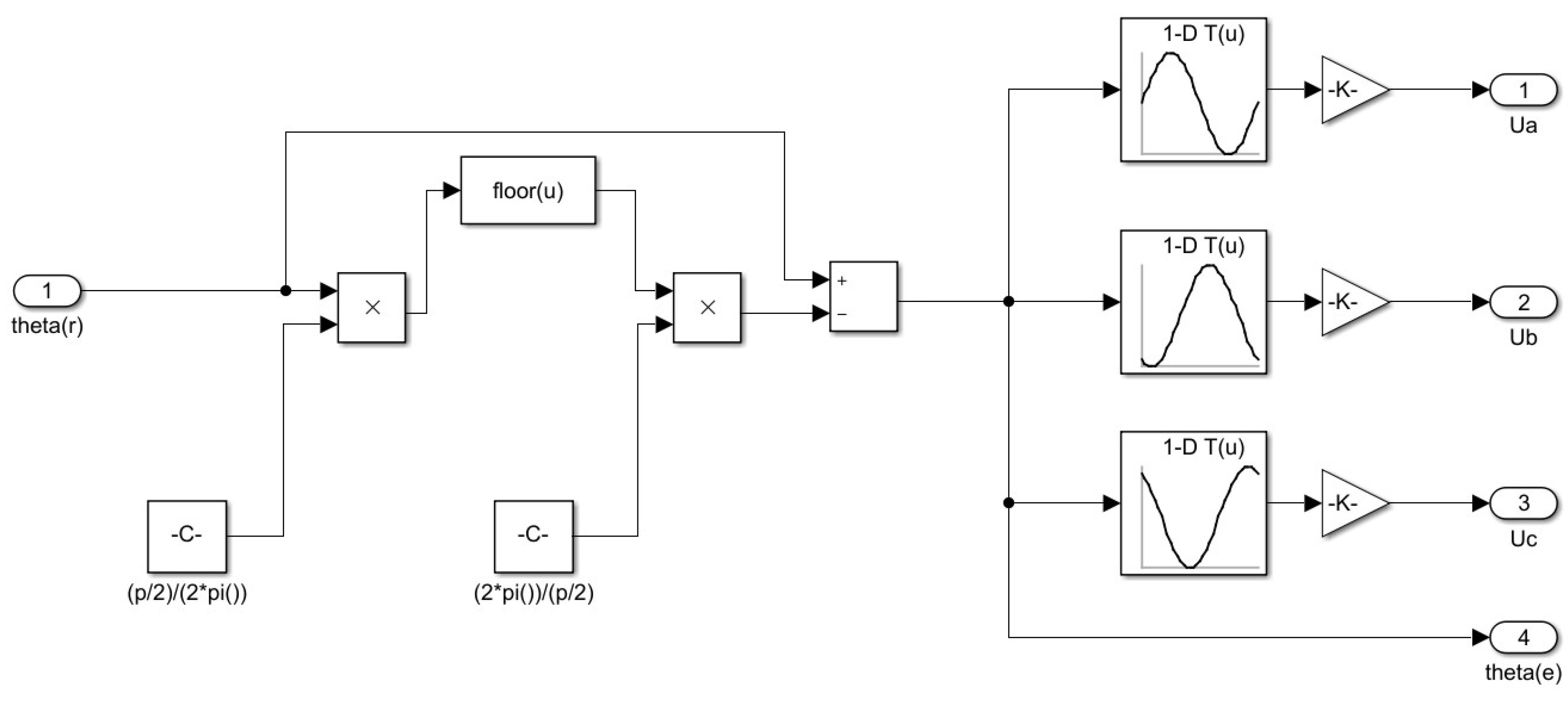

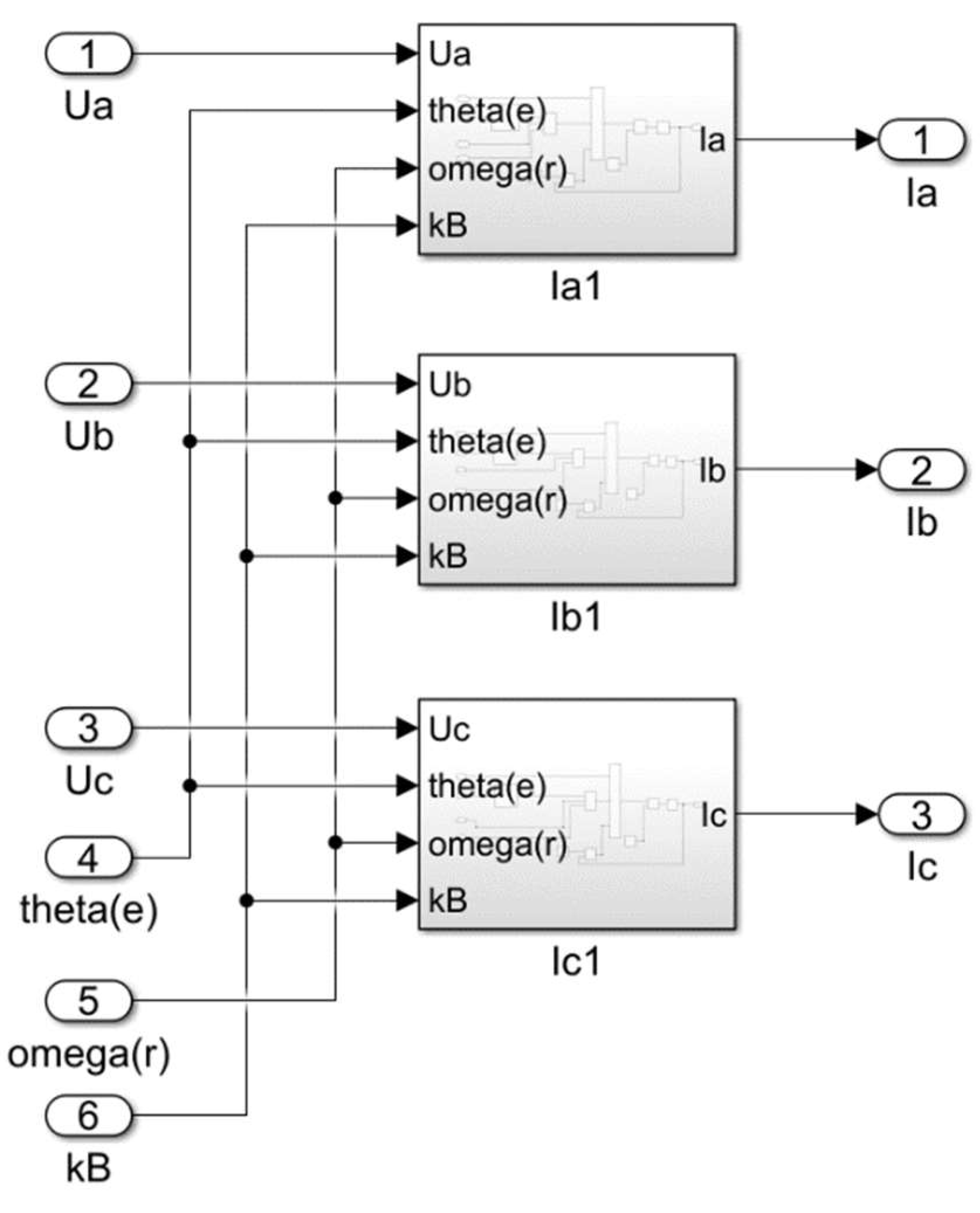

3.2. Simulation of the Permanent Magnet Synchronous Motor (PMSM)

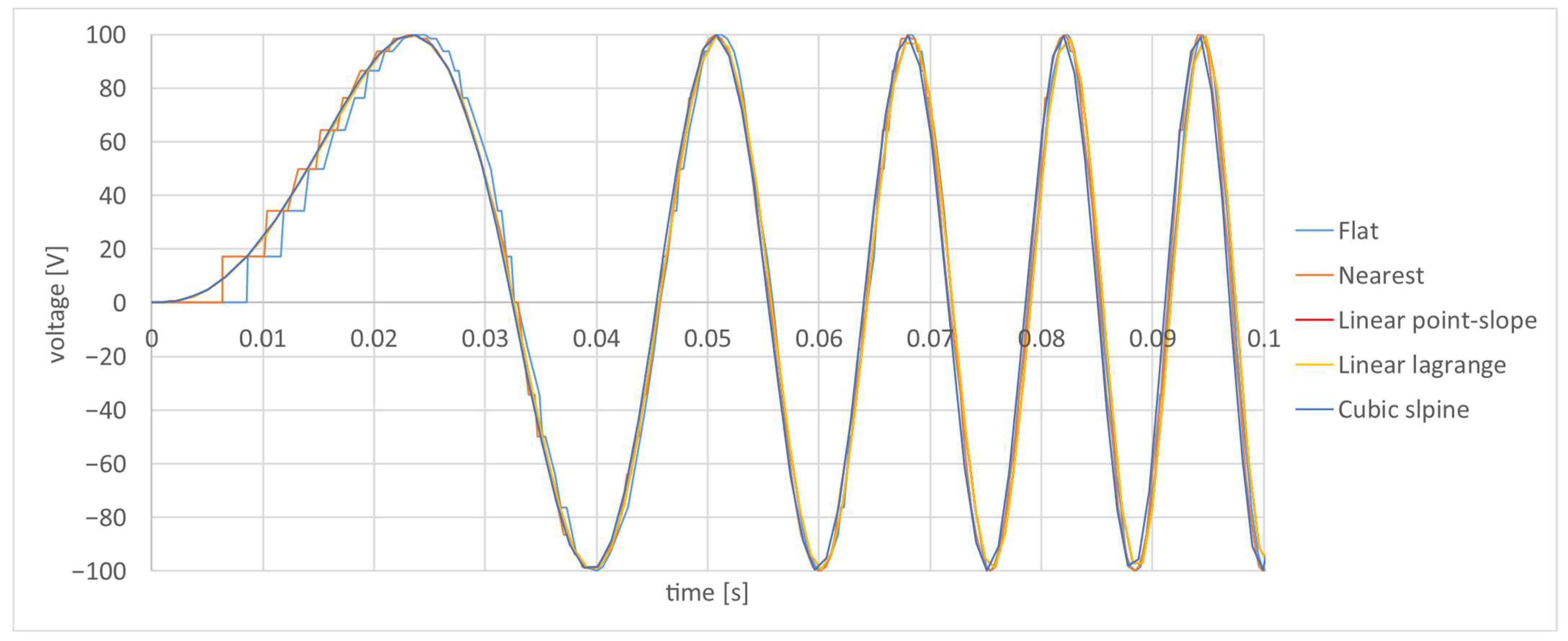

3.3. The Functions Obtained by Simulation

3.4. Determination of Motor Characteristics for Permanent Magnet Synchronous Motor (PMSM) Simulation

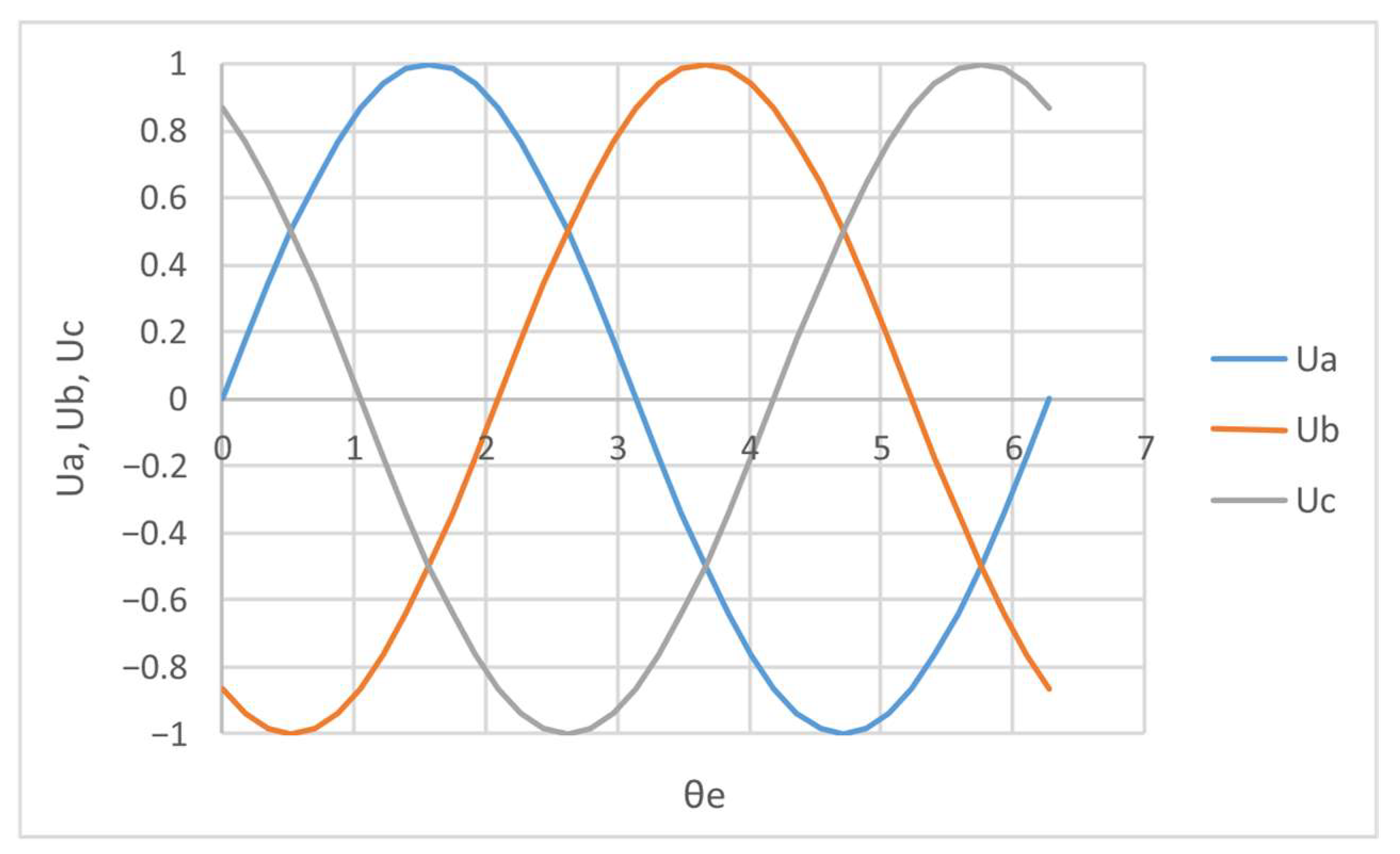

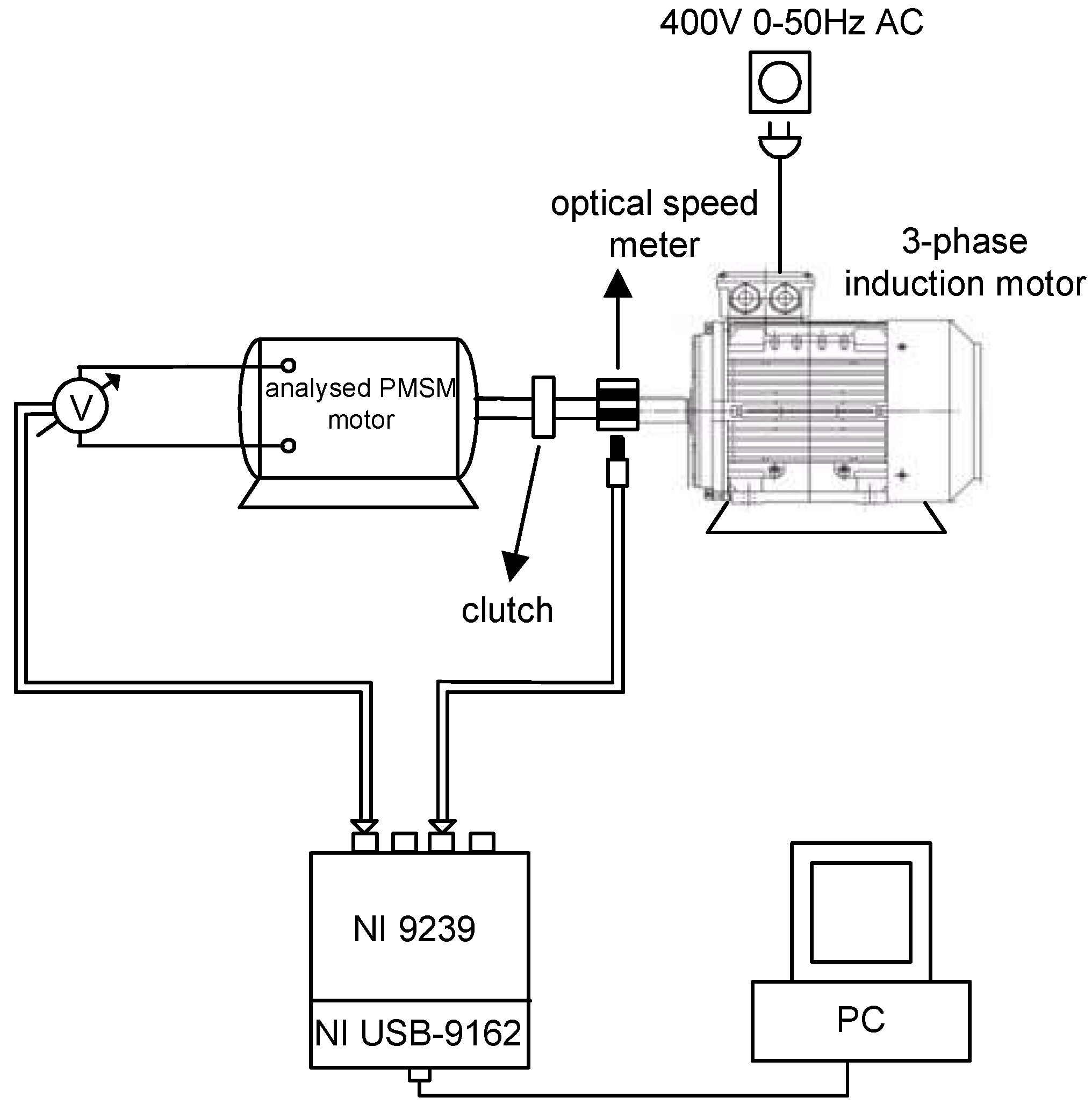

3.4.1. Experimental Determination of Back Electromotive Force (Back EMF)

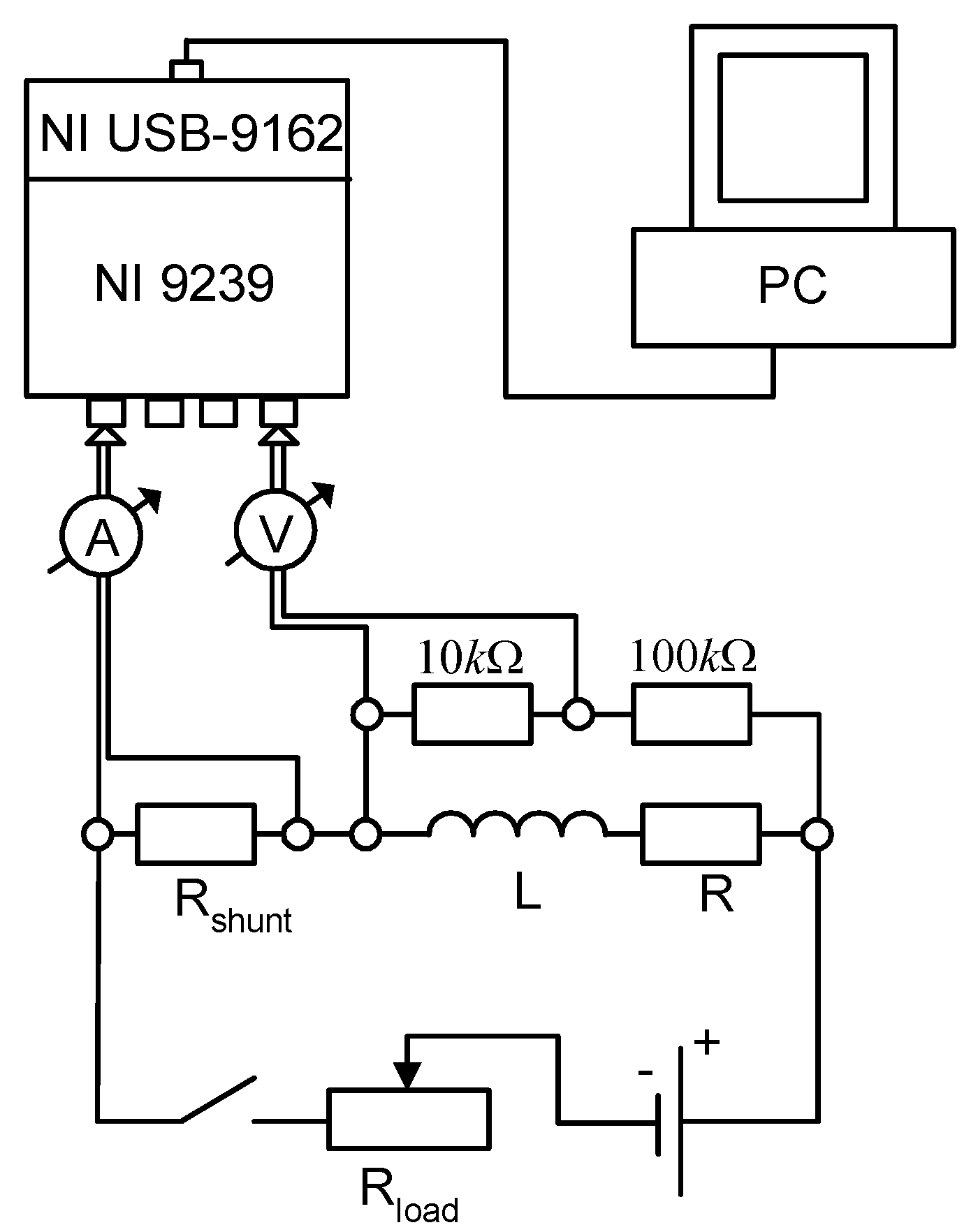

3.4.2. Experimental Determination of Electric Resistance of Windings

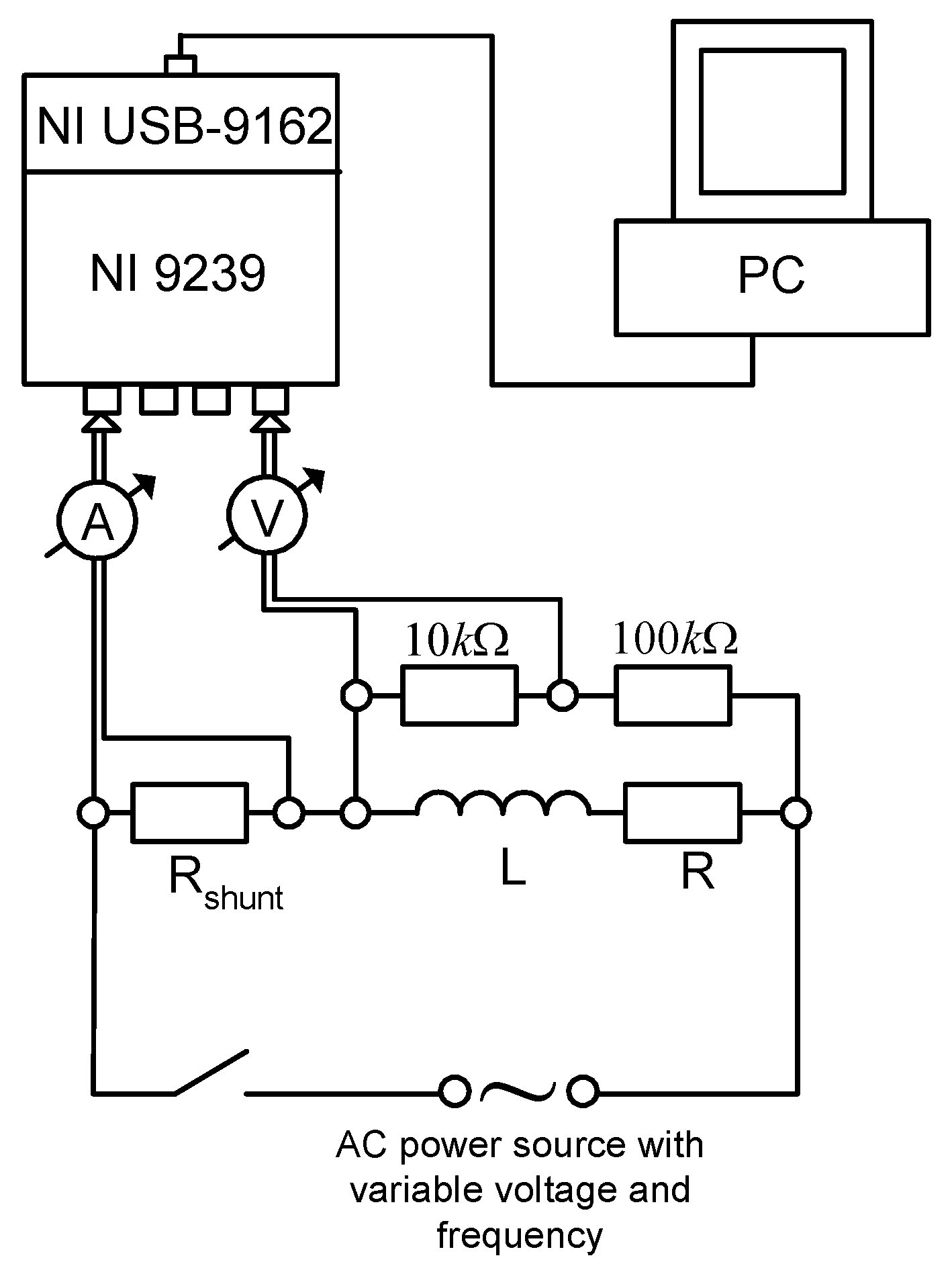

3.4.3. Experimental Determination of Self- and Mutual Inductance of Windings

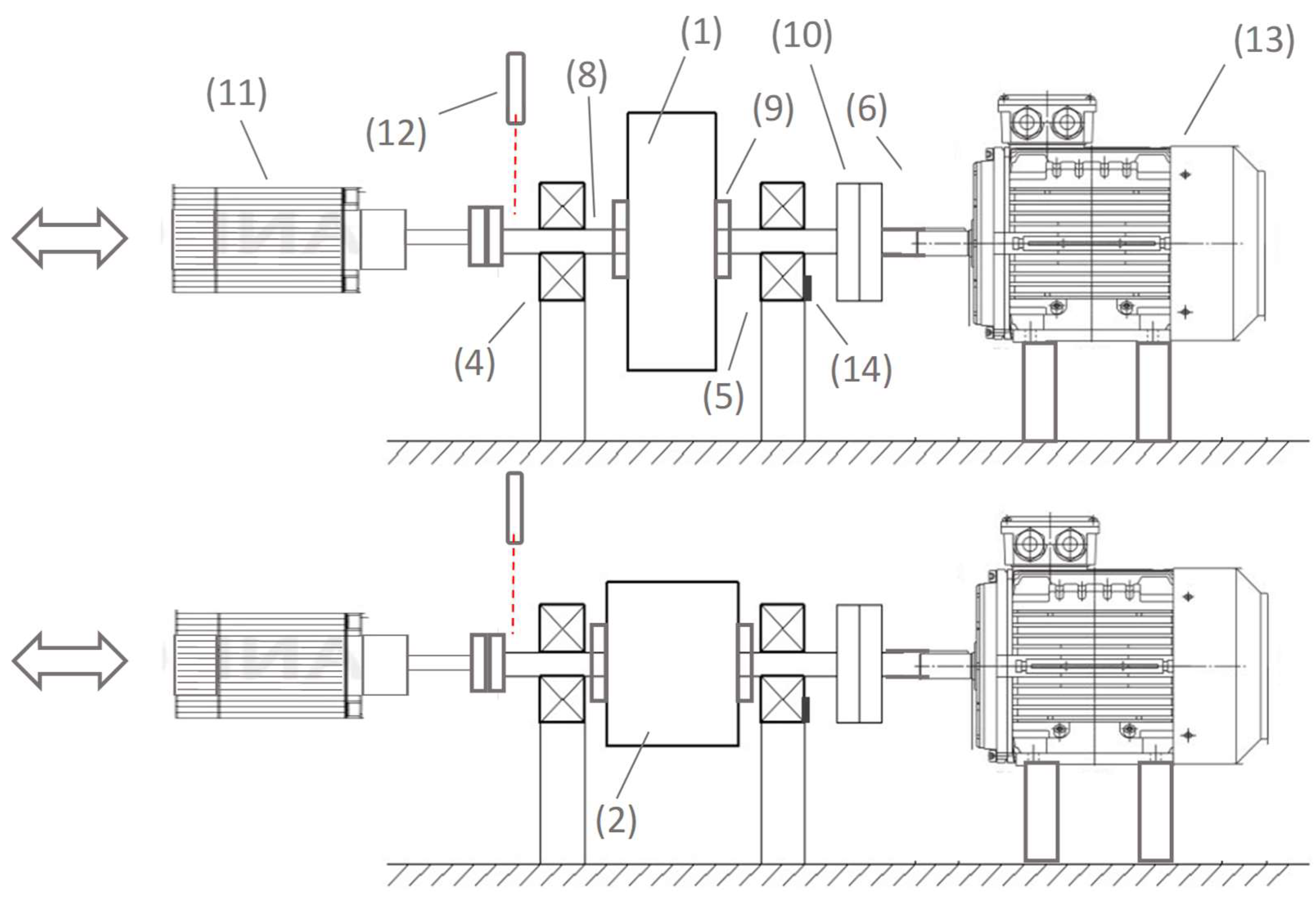

3.4.4. Experimental Determination of the Moment of Inertia and the Resistance Torque of the Rotor

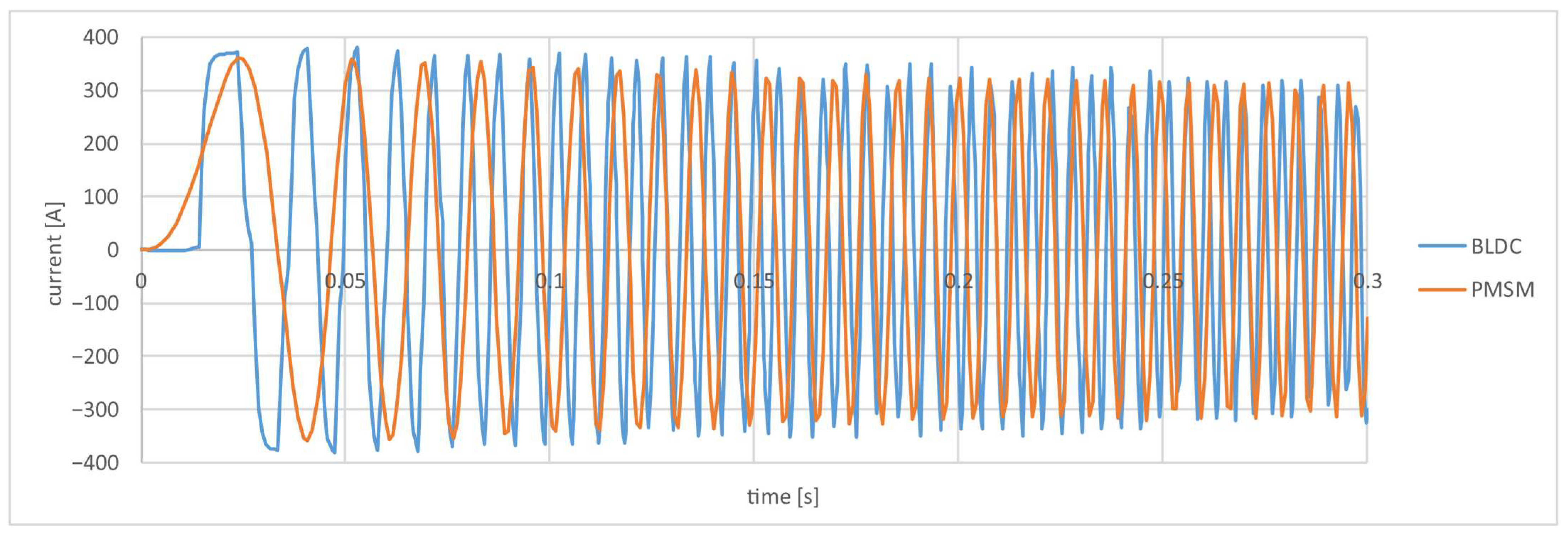

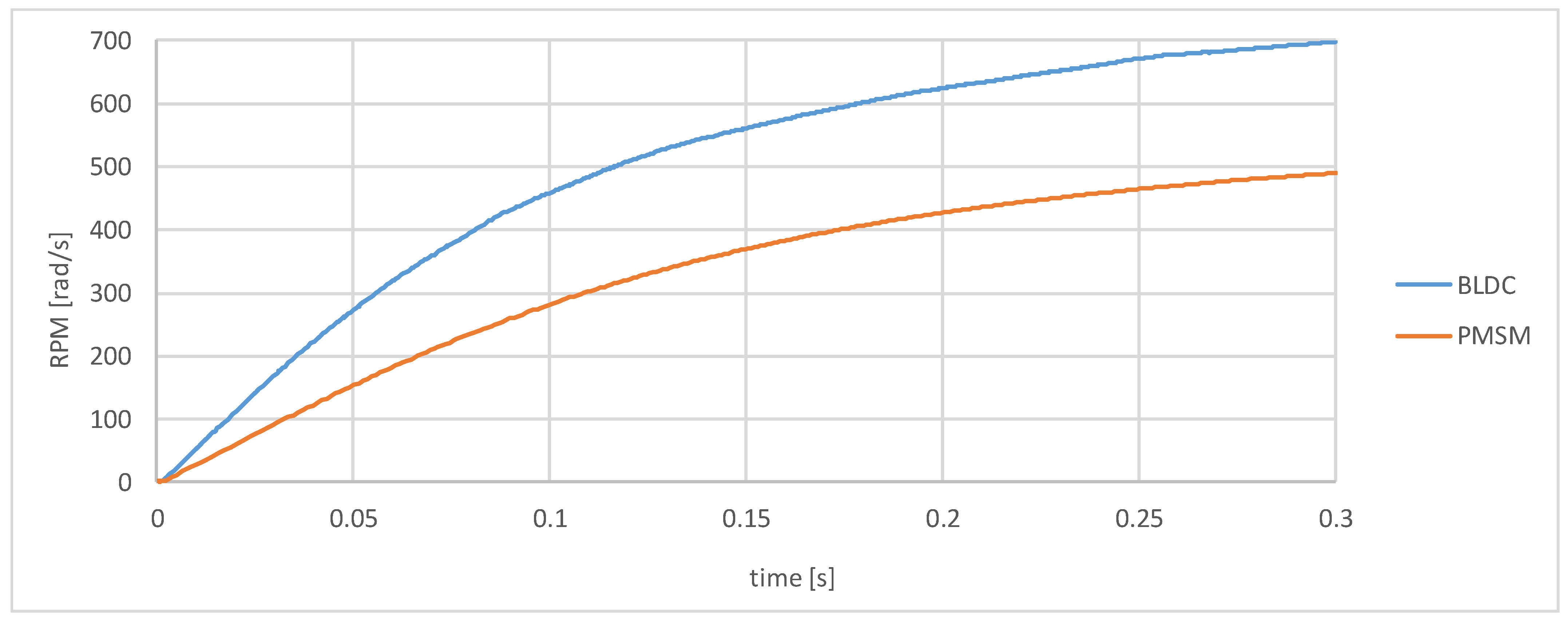

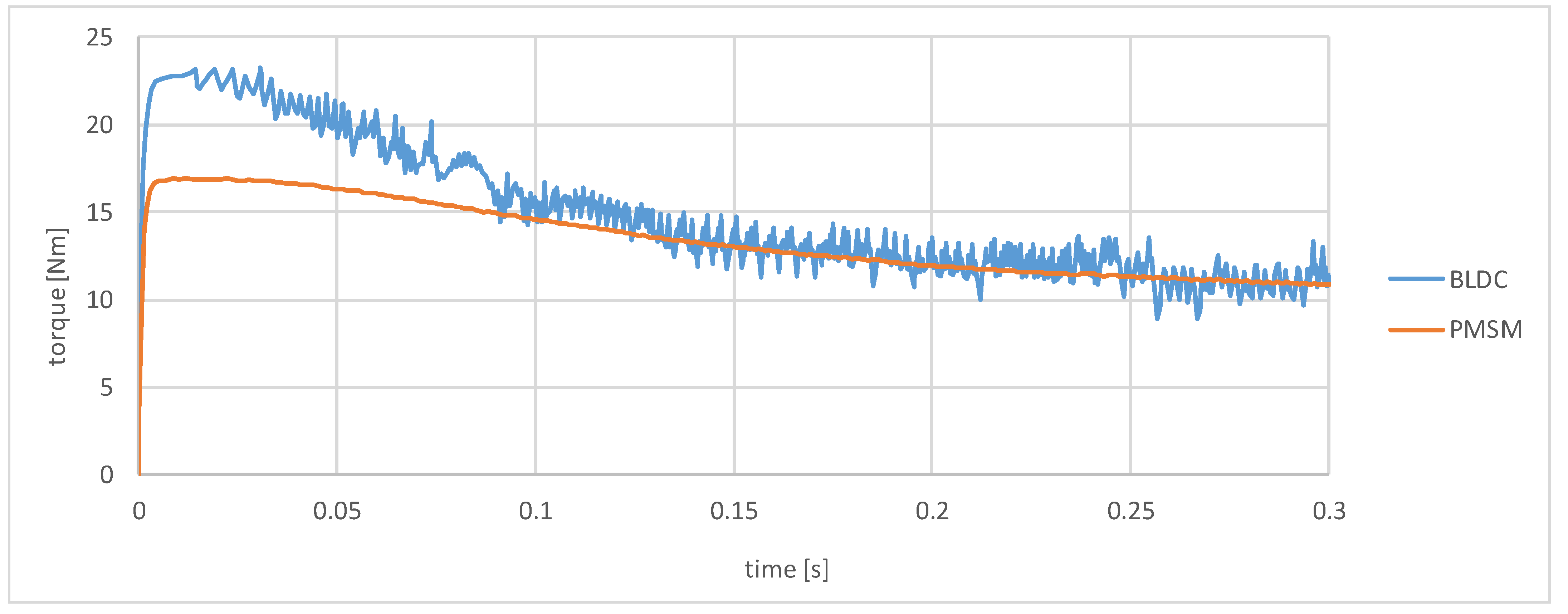

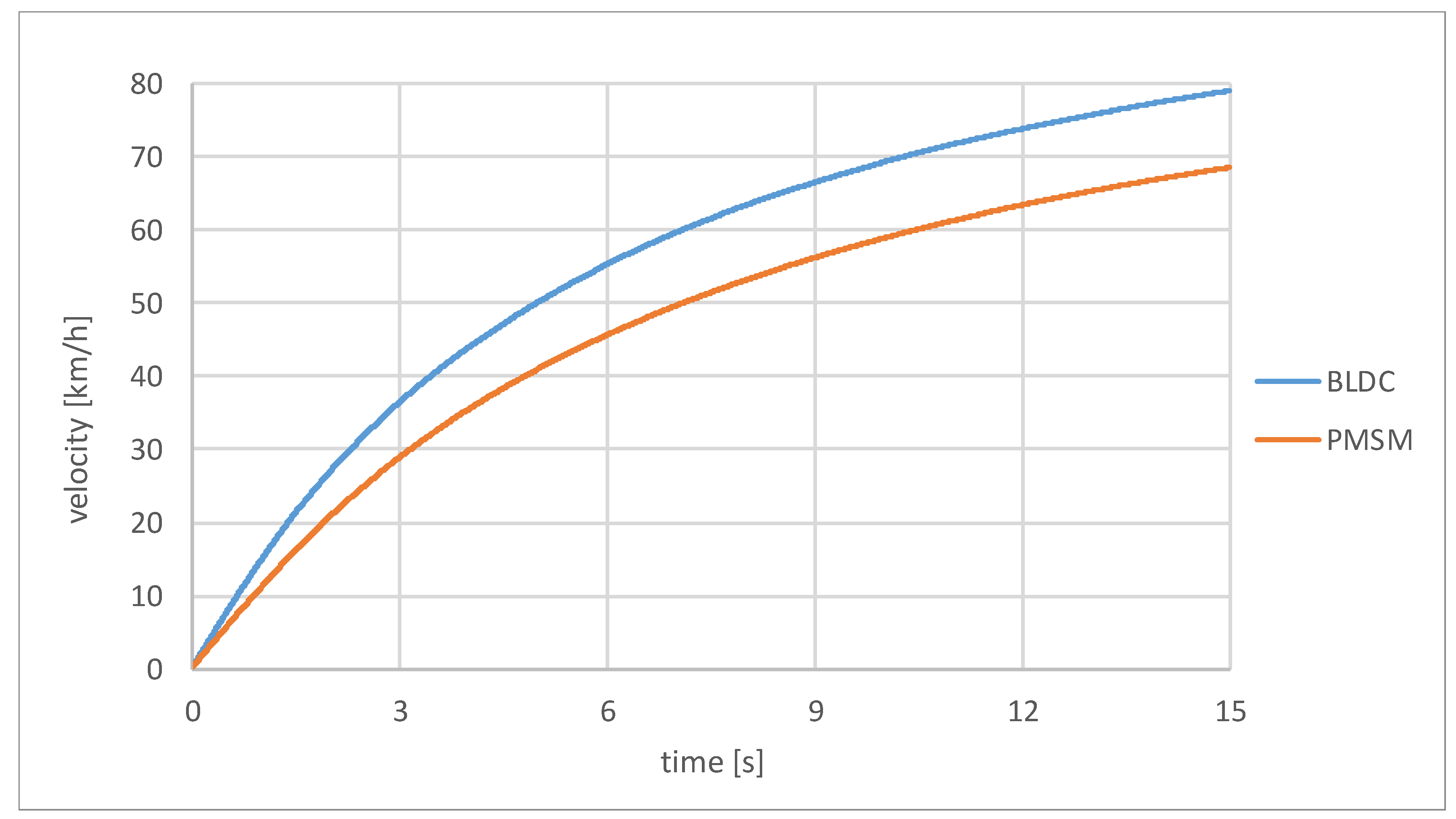

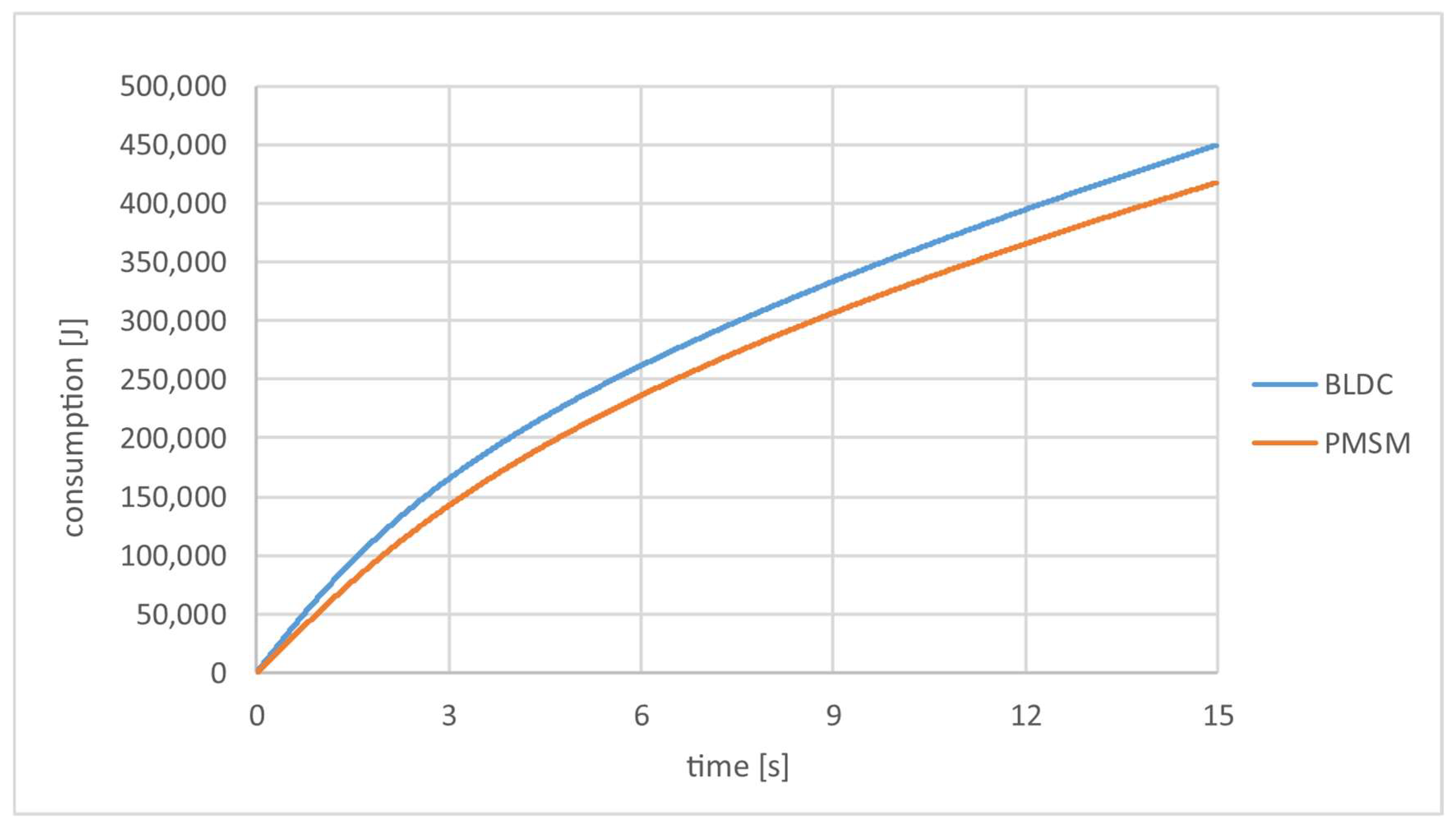

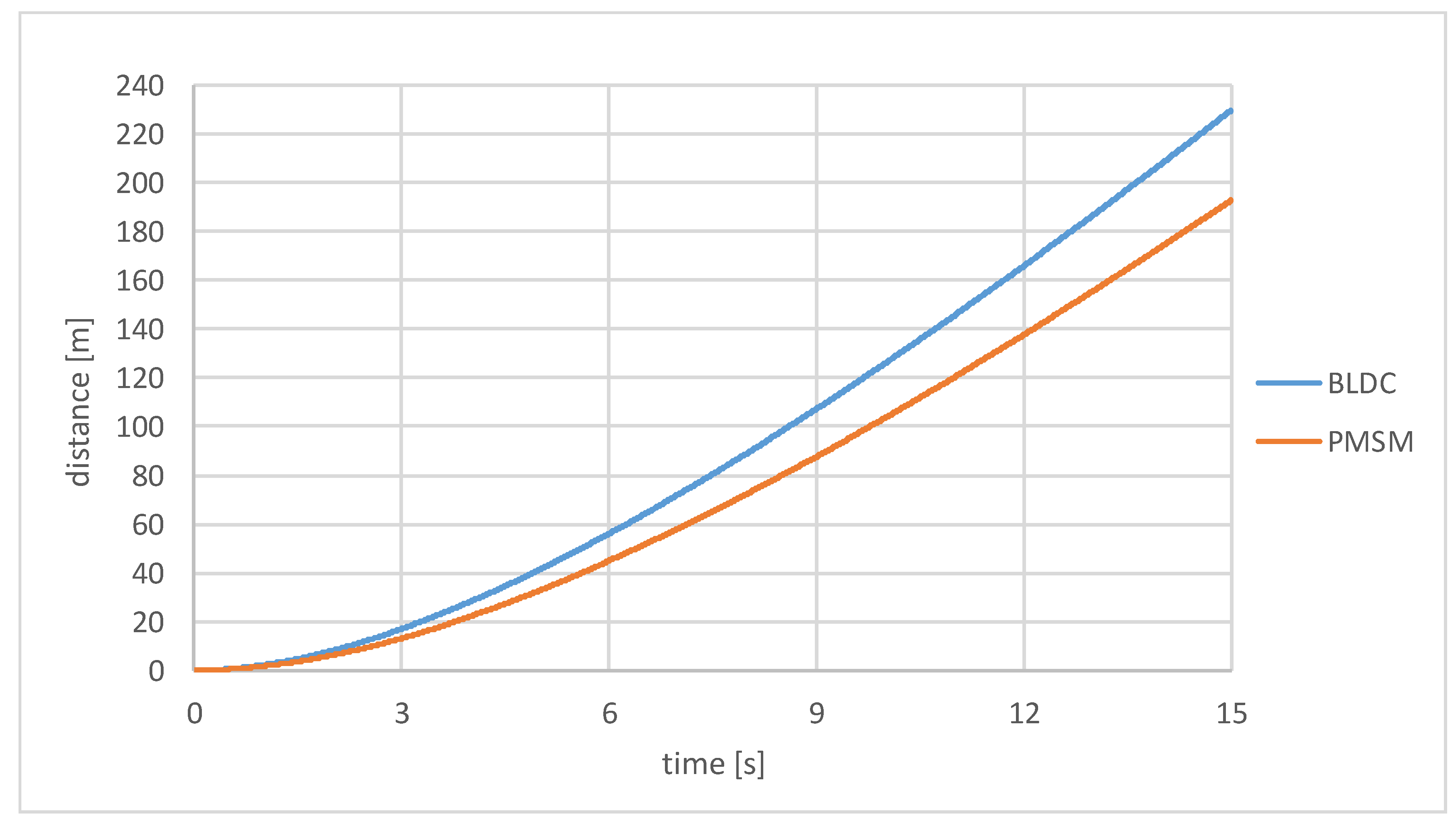

4. Comparison of PMSM and BLDC Motor Simulation in a Prototype Race Car

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cao, W.; Bukhari, A.A.S.; Aarniovuori, L. Review of electrical motor drives for electric vehicle applications. Mehran Univ. Res. J. Eng. Technol. 2019, 38, 525–540. [Google Scholar] [CrossRef]

- Cai, W.; Wu, X.; Zhou, M.; Liang, Y.; Wang, Y. Review and development of electric motor systems and electric powertrains for new energy vehicles. Automot. Innov. 2021, 4, 3–22. [Google Scholar] [CrossRef]

- Bhatt, P.; Mehar, H.; Sahajwani, M. Electrical motors for electric vehicle–a comparative study. In Proceedings of the Recent Advances in Interdisciplinary Trends in Engineering & Applications (RAITEA), Indore, India, 3 April 2019. [Google Scholar]

- Szántó, A.; Hajdu, S.; Sziki, G.Á. Dynamic simulation of a prototype race car driven by series wound DC motor in Matlab-Simulink. Acta Polytech. Hung. 2020, 17, 103–122. [Google Scholar] [CrossRef]

- Szíki, G.Á.; Szántó, A.; Mankovits, T. Dynamic modelling and simulation of a prototype race car in MATLAB/Simulink applying different types of electric motors. Int. Rev. Appl. Sci. Eng. 2021, 12, 57–63. [Google Scholar] [CrossRef]

- Haigang, Z.; Weiguo, Q.; Yanxiang, W.; Shihong, G.; Yuan, Y. Modeling and simulation of the permanent-magnet synchronous motor drive. In Proceedings of the 2011 International Conference on Uncertainty Reasoning and Knowledge Engineering, Bali, Indonesia, 4–7 August 2011; IEEE: Piscataway, NJ, USA, 2011; Volume 2, pp. 256–260. [Google Scholar]

- MAGNET, S.O.P. Mathematical modeling and simulation of permanent magnet synchronous motor. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2013, 3720–3726. [Google Scholar]

- Luo, G.; Zhang, R.; Chen, Z.; Tu, W.; Zhang, S.; Kennel, R. A novel nonlinear modeling method for permanent-magnet synchronous motors. IEEE Trans. Ind. Electron. 2016, 63, 6490–6498. [Google Scholar] [CrossRef]

- Pillay, P.; Krishnan, R. Modeling, simulation, and analysis of permanent-magnet motor drives. I. The permanent-magnet synchronous motor drive. IEEE Trans. Ind. Appl. 1989, 25, 265–273. [Google Scholar] [CrossRef]

- Mersha, T.K.; Du, C. Co-simulation and modeling of PMSM based on ANSYS software and Simulink for EVs. World Electr. Veh. J. 2021, 13, 4. [Google Scholar] [CrossRef]

- Mohamed, N.; Aymen, F.; Mouna, B.H.; Lassaad, S. Modeling and simulation of vector control for a Permanent Magnet Synchronous Motor in electric vehicle. In Proceedings of the 2021 4th International Symposium on Advanced Electrical and Communication Technologies (ISAECT), Alkhobar, Saudi Arabia, 6–8 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–5. [Google Scholar]

- Yu, Y.; Huang, X.; Li, Z.; Wu, M.; Shi, T.; Cao, Y.; Yang, G.; Niu, F. Full parameter estimation for permanent magnet synchronous motors. IEEE Trans. Ind. Electron. 2021, 69, 4376–4386. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, X.; Wang, W.; Lv, Y.; Yuan, B.; Li, W.; Li, Q.; Wang, S.; Chen, Q.; Zhang, Y. UKF-based parameter estimation and identification for permanent magnet synchronous motor. Front. Energy Res. 2022, 10, 855649. [Google Scholar] [CrossRef]

- Ahn, H.; Park, H.; Kim, C.; Lee, H. A review of state-of-the-art techniques for PMSM parameter identification. J. Electr. Eng. Technol. 2020, 15, 1177–1187. [Google Scholar] [CrossRef]

- Sziki, G.Á.; Sarvajcz, K.; Kiss, J.; Gál, T.; Szántó, A.; Gábora, A.; Husi, G. Experimental investigation of a series wound dc motor for modeling purpose in electric vehicles and mechatronics systems. Measurement 2017, 109, 111–118. [Google Scholar] [CrossRef]

- Szántó, A.; Kiss, J.; Mankovits, T.; Szíki, G.Á. Dynamic Test Measurements and Simulation on a Series Wound DC Motor. Appl. Sci. 2021, 11, 4542. [Google Scholar] [CrossRef]

- Sziki, G.A.; Szanto, A.; Adamko, E. Review of methods for determining the moment of inertia and friction torque of electric motors. Acta Polytech. Hung. 2024, 21, 203–218. [Google Scholar] [CrossRef]

- Szántó, A.; Ádámkó, É.; Juhász, G.; Sziki, G.Á. Simultaneous measurement of the moment of inertia and braking torque of electric motors applying additional inertia. Measurement 2022, 204, 112135. [Google Scholar] [CrossRef]

- Pálinkás, S. Influence of Speed to Rolling Resistance Factor in Case of Autobus. In Vehicle and Automotive Engineering 4: Select Proceedings of the 4th VAE2022, Miskolc, Hungary, Proceedings of the International Conference on Vehicle and Automotive Engineering, Miskolc, Hungary, 8–9 September 2022; Springer International Publishing: Cham, Switzerland, 2022; pp. 157–164. [Google Scholar]

- Pálinkás, S.; Tóth, Á. Development of a measurement method to determine rolling resistance. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1237, 012013. [Google Scholar] [CrossRef]

- Hadžiselimović, M.; Blaznik, M.; Štumberger, B.; Zagradišnik, I. Magnetically nonlinear dynamic model of a series wound DC motor. Przegląd Elektrotechniczny 2011, 87, 60–64. [Google Scholar]

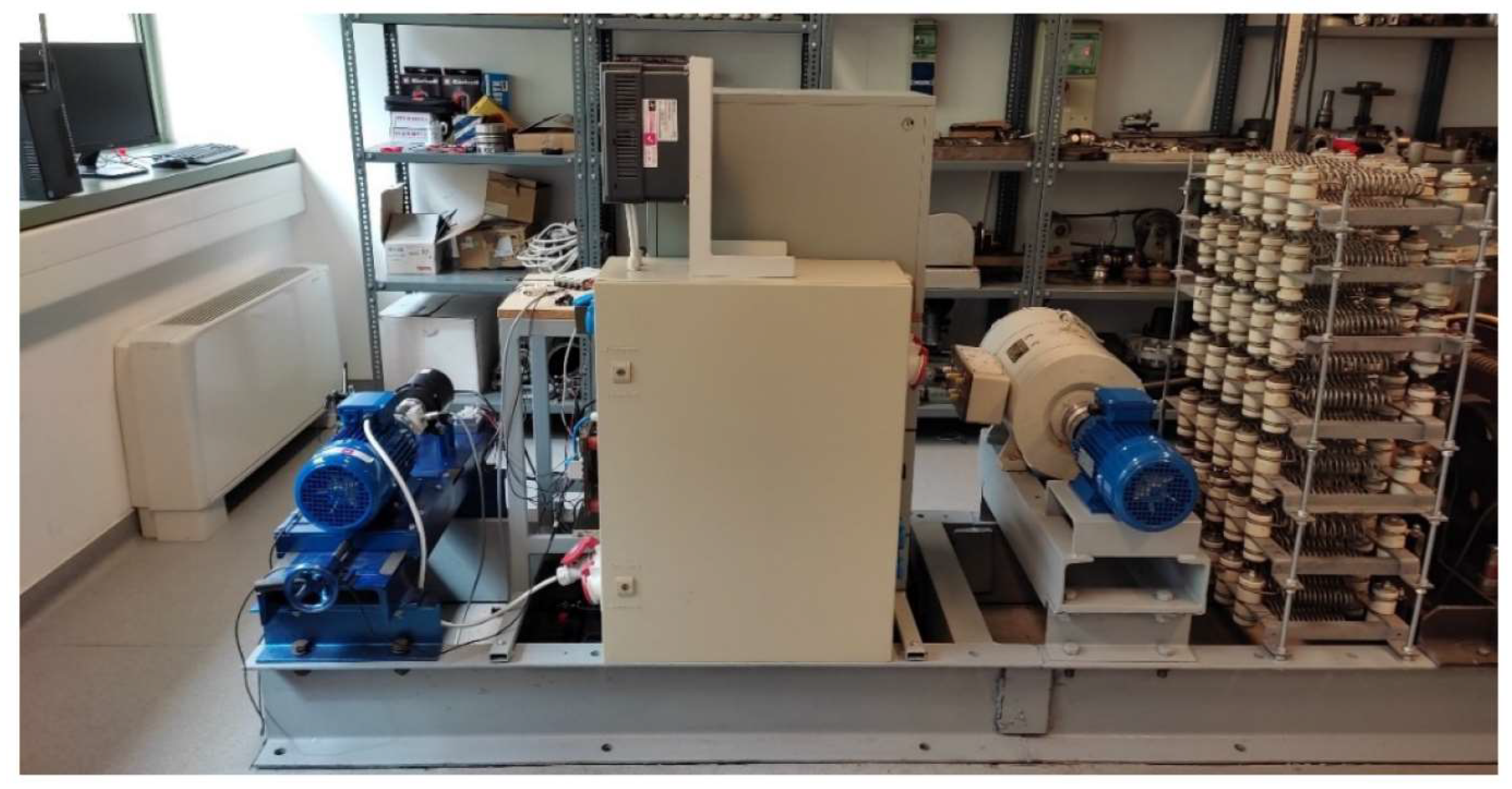

- Sziki, G.Á.; Szántó, A.; Kiss, J.; Juhász, G.; Ádámkó, É. Measurement system for the experimental study and testing of electric motors at the faculty of engineering, University of Debrecen. Appl. Sci. 2022, 12, 10095. [Google Scholar] [CrossRef]

- Espanet, C.; Kauffmann, J.M.; Bernard, R. Comparison of two in-wheel permanent magnet motors for military applications. In Proceedings of the 2006 IEEE Vehicle Power and Propulsion Conference, Windsor, UK, 6–8 September 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 1–6. [Google Scholar]

- Lidozzi, A.; Solero, L.; Crescimbini, F.; Di Napoli, A. SVM PMSM drive with low resolution Hall-effect sensors. IEEE Trans. Power Electron. 2007, 22, 282–290. [Google Scholar] [CrossRef]

- Tang, L.; Su, G.J. High-Performance Control of Two Three Phase Permanent Magnet Synchronous Machines in an Integrated Inverter for Automotive Applications. In Proceedings of the 2007 IEEE Power Electronics Specialists Conference, Orlando, FL, USA, 17–21 June 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 2001–2007. [Google Scholar]

- Rahim, N.A.; Hew, W.P.; Mahmoudi, A. Axial-flux permanent-magnet brushless dc traction motor for direct drive of electric vehicle. Int. Rev. Electr. Eng. 2011, 6, 760–769. [Google Scholar]

- Dai, P.; Sun, W.; Xu, N.; Lv, Y.; Zhu, X. Research on energy management system of hybrid electric vehicle based on permanent magnet synchronous motor. In Proceedings of the 2016 IEEE 11th Conference on Industrial Electronics and Applications (ICIEA), Hefei, China, 5–7 June 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 2345–2349. [Google Scholar]

- Zhu, Z.Q.; Howe, D. Electrical machines and drives for electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 746–765. [Google Scholar] [CrossRef]

- Usman, A.; Joshi, B.M.; Rajpurohit, B.S. Review of fault modeling methods for permanent magnet synchronous motors and their comparison. In Proceedings of the 2017 IEEE 11th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Tinos, Greece, 29 August–1 September 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 141–146. [Google Scholar]

- Szántó, A.; Hajdu, S.; Sziki, G.Á. Optimizing parameters for an electrical car employing vehicle dynamics simulation program. Appl. Sci. 2023, 13, 8897. [Google Scholar] [CrossRef]

- Liu, G.; Mao, K. A novel power failure compensation control method for active magnetic bearings used in high-speed permanent magnet motor. IEEE Trans. Power Electron. 2015, 31, 4565–4575. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szántó, A.; Abdullah, M.; Kapusi, T.P.; Diós, S.S. Dynamic Modelling and Simulation of a Permanent Magnet Synchronous Motor (PMSM) Applied in a Prototype Race Car and the Comparison of Its Performance with BLDC Motor. Modelling 2025, 6, 104. https://doi.org/10.3390/modelling6030104

Szántó A, Abdullah M, Kapusi TP, Diós SS. Dynamic Modelling and Simulation of a Permanent Magnet Synchronous Motor (PMSM) Applied in a Prototype Race Car and the Comparison of Its Performance with BLDC Motor. Modelling. 2025; 6(3):104. https://doi.org/10.3390/modelling6030104

Chicago/Turabian StyleSzántó, Attila, Masuk Abdullah, Tibor Péter Kapusi, and Szabolcs Sándor Diós. 2025. "Dynamic Modelling and Simulation of a Permanent Magnet Synchronous Motor (PMSM) Applied in a Prototype Race Car and the Comparison of Its Performance with BLDC Motor" Modelling 6, no. 3: 104. https://doi.org/10.3390/modelling6030104

APA StyleSzántó, A., Abdullah, M., Kapusi, T. P., & Diós, S. S. (2025). Dynamic Modelling and Simulation of a Permanent Magnet Synchronous Motor (PMSM) Applied in a Prototype Race Car and the Comparison of Its Performance with BLDC Motor. Modelling, 6(3), 104. https://doi.org/10.3390/modelling6030104