1. Introduction

To cope with global climate change, the construction of a new type of power system, mainly based on RE, is a trend for future development [

1]. However, RE, represented by wind power and PV, is characterized by intermittency, volatility, and uncertainty, negatively affecting power quality, the economy, and the stability of system operation [

2,

3,

4]. Therefore, there is an urgent need to balance and buffer with the help of new energy storage and other technological means [

5]. Hydrogen as an ideal clean energy carrier, has the advantages of low self-depletion rate, cross-seasonal storage, and high energy density [

6]. It is a high-quality energy storage medium for achieving carbon neutrality [

7,

8,

9].

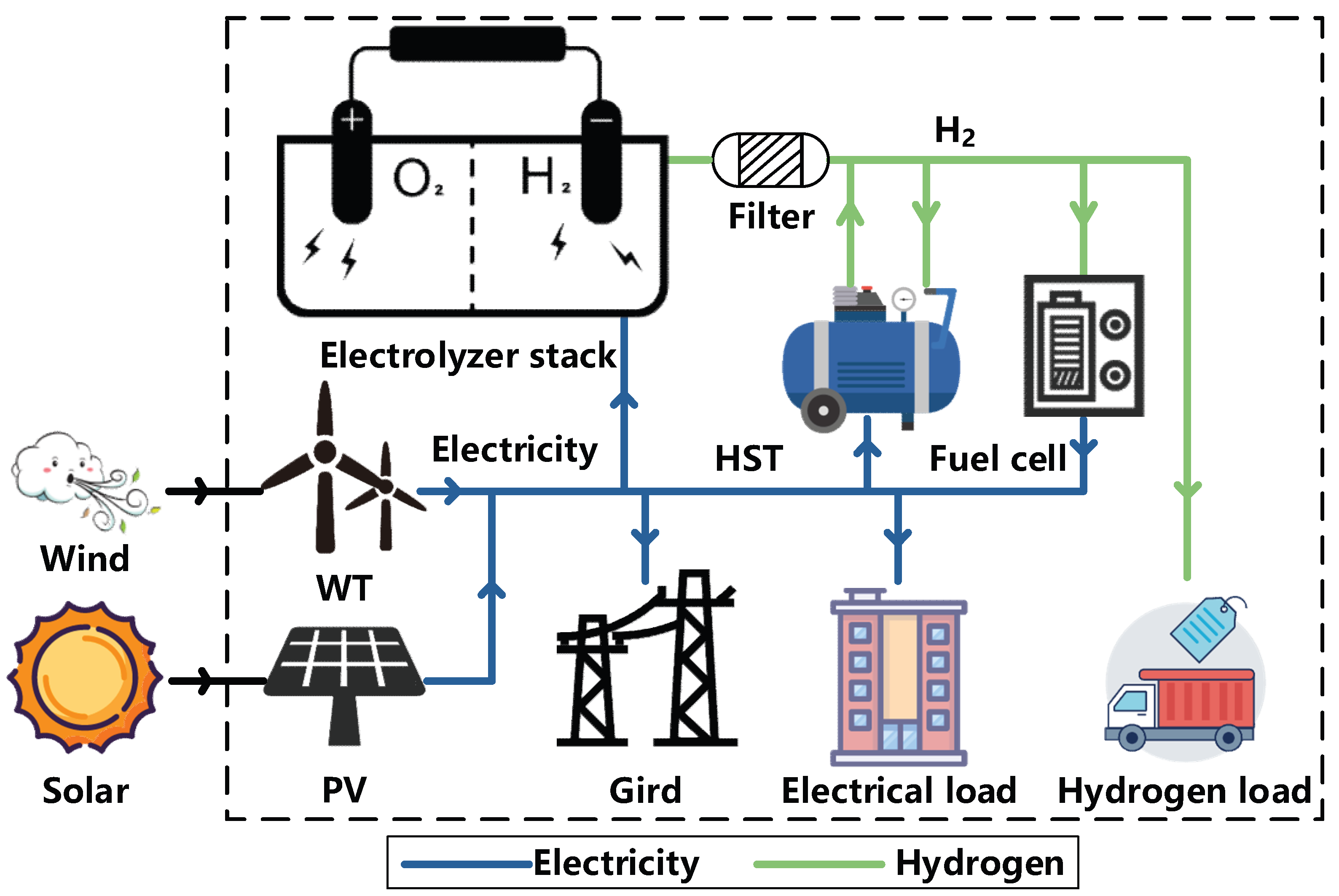

The wind-PV-hydrogen integrated microgrid system utilizes hydrogen as an energy carrier, which represents an effective strategy for promoting RE consumption [

10,

11,

12]. Reference [

13] describes the construction of a hydrogen hybrid energy system that includes wind power, PV, electrolyzer, and FC. The performance of this integrated energy system in both on-grid and off-grid modes has been verified through simulation. Given the high configuration cost of hydrogen energy storage, determining the optimal capacity of the system to ensure reliable energy supply while maximizing benefits has become a focal point of current research [

14]. References [

15,

16] focus on the operational economics of a wind-PV-hydrogen hybrid microgrid system and employ intelligent optimization algorithms to find the best capacity allocation; References [

17,

18] have developed a two-layer capacity optimization allocation model aimed at enhancing system operation scheduling and the economics of capacity allocation. Reference [

19] constructed a multi-energy complementary microgrid containing pumped storage, wind energy, PV, and hydrogen production systems, and enhanced the utilization rate of RE by fine modeling and optimizing the configuration of each device, and proposed a judgement matrix method to effectively evaluate the system performance. However, these studies did not consider the impact of different operating modes of the equipment within the system.

AEL as the core equipment of the integrated wind-PV-hydrogen microgrid system [

20,

21]. Conversion of system surplus electrical energy into hydrogen energy and storage by hydrogen storage equipment [

22], with the advantages of large single capacity and lower equipment cost, has good economy in the scale hydrogen production system [

23]. Multiple small-capacity electrolyzer units are usually used to form an MES in practical engineering, which has good flexibility and operational reliability compared to the simple-to-operate large-capacity electrolyzer operation for hydrogen production [

24]. Since MES is a multi-source system, the overall efficiency of the system is affected by the power allocation of each electrolyzer, the economic efficiency and operational efficiency of MES can be improved by a reasonable operation scheduling strategy [

25]. Reference [

26] optimized the electrolyzer operation mode through supercapacitors and segmented start-stop control strategies to enhance the hydrogen production and electrolyzer lifetime of the system; Reference [

27] de-signed a power equalisation strategy and a rotation strategy for multi-stack electrolyzers to improve the operational efficiency and hydrogen production in alkaline electrolyzers; Reference [

28] proposed a segmented fuzzy control based alkaline electrolyzer array efficiency improvement method to optimize the operating cost of the system to minimize the cost of hydrogen production. The above study is a switching strategy to change the operating state of the electrolyzer based on specific rules, but the operating characteristics of the electrolyzer are not sufficiently considered.

On this basis, Reference [

29] constructed an electrolyzer model considering the variation of hydrogen production efficiency and the start-stop process, and proposed a rolling optimization strategy taking into account the constraints on the operating state of the electrolyzer, which improves the operating efficiency of the electrolyzer and the system economy; Reference [

30] considers control strategies and capacity optimization methods for PV, battery storage and electrolyzer equipment state quantities to minimize the cost of hydrogen production from the electrolyzer; Reference [

31] modeled and analyzed the life decay characteristics of the electrolyzer and optimized the scheduling with the objectives of the life of the electrolyzer and the gain of the system, which improved the life of the equipment and the system economics. Reference [

32] proposes a hybrid electrolyzer hydrogen production system containing AEL and proton exchange membrane electrolyzer, and energy optimization algorithm based on bi-level variable-step fuzzy controller-genetic algorithm, and combines the two kinds of the characteristics of the two devices are combined to improve the solution speed and device lifetime of the hydrogen production system.

In addition, although the existing optimal scheduling strategies achieve the optimization of operation efficiency and hydrogen production cost, most of them assume that the power level, operation environment and performance of each electrolyzer in the MES are identical, so there is still a need to study the optimization method of MES operation efficiency in the presence of differences in the performance of electrolyzers. Rational configuration of hydrogen storage capacity can improve the economic performance of integrated wind-PV-hydrogen microgrid systems. Currently, most hydrogen production systems either use a single large-capacity electrolyzer for hydrogen production or operate multiple electrolyzers with simultaneous startup and shutdown. Research on the operation optimization of multi-electrolyzer systems remains limited, and most of the existing studies focus on rule-based switching strategies. To highlight the key research gaps in the existing literature,

Table 1 presents a comparative taxonomy of different capacity configuration methods for hydrogen energy storage systems. Based on the literature review and this taxonomy table, the main research gaps identified in the literature are as follows:

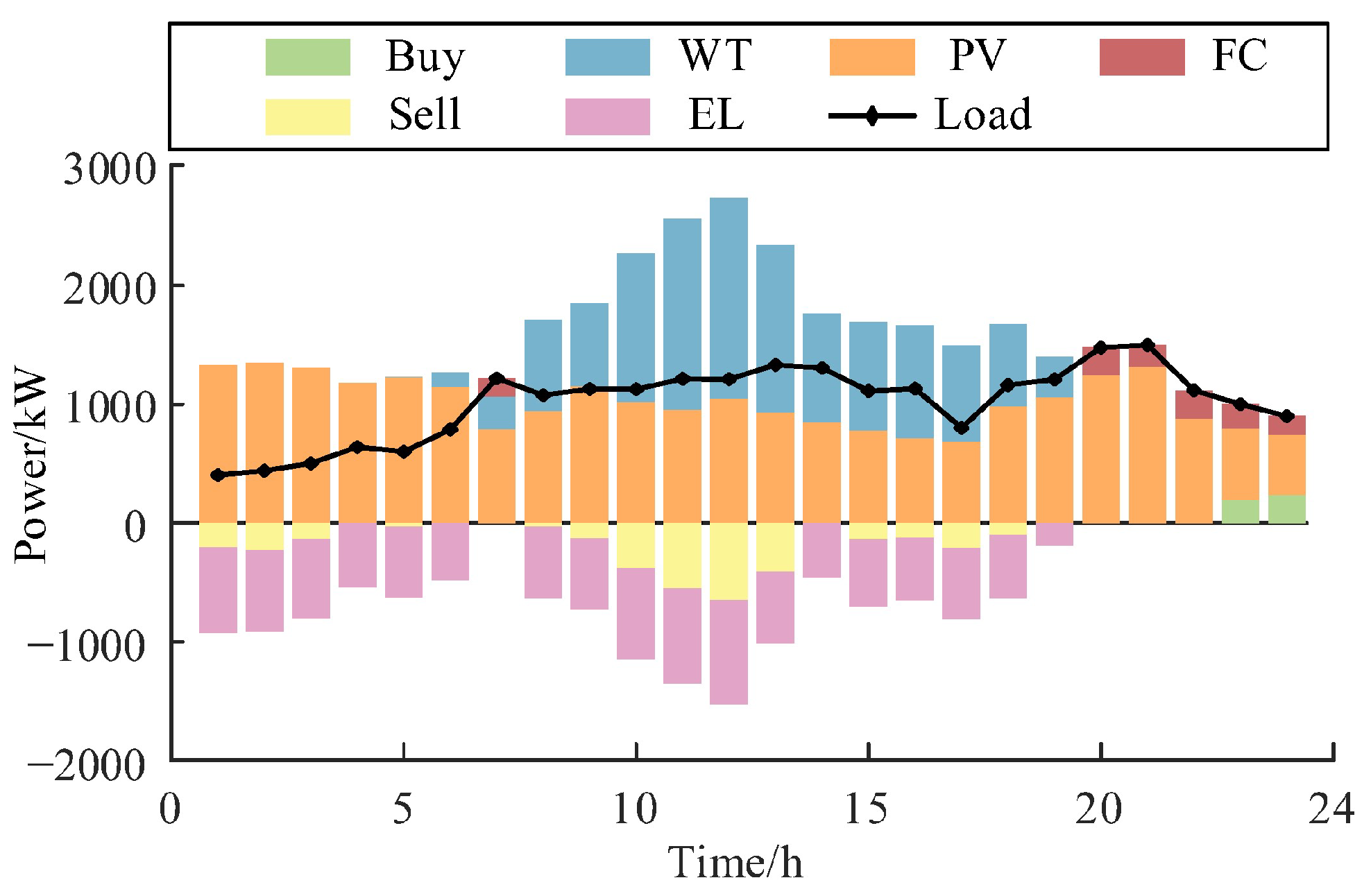

To adapt to the volatility of RE, it is necessary to dynamically adjust the output power of the electrolyzer array, and this process requires accurate assessment of the expected benefits under different electrolyzer operating efficiencies. Therefore, taking the integrated wind-PV-hydrogen microgrid system as the research background, this paper comprehensively considers RE consumption, microgrid system configuration costs, and operating benefits of hydrogen storage equipment, and proposes a double-layer optimal configuration method that balances hydrogen production efficiency optimization.

The research findings of this paper will offer new insights and valuable guidance for future capacity allocation work in wind-PV-hydrogen microgrids. The main contributions of this paper are as follows:

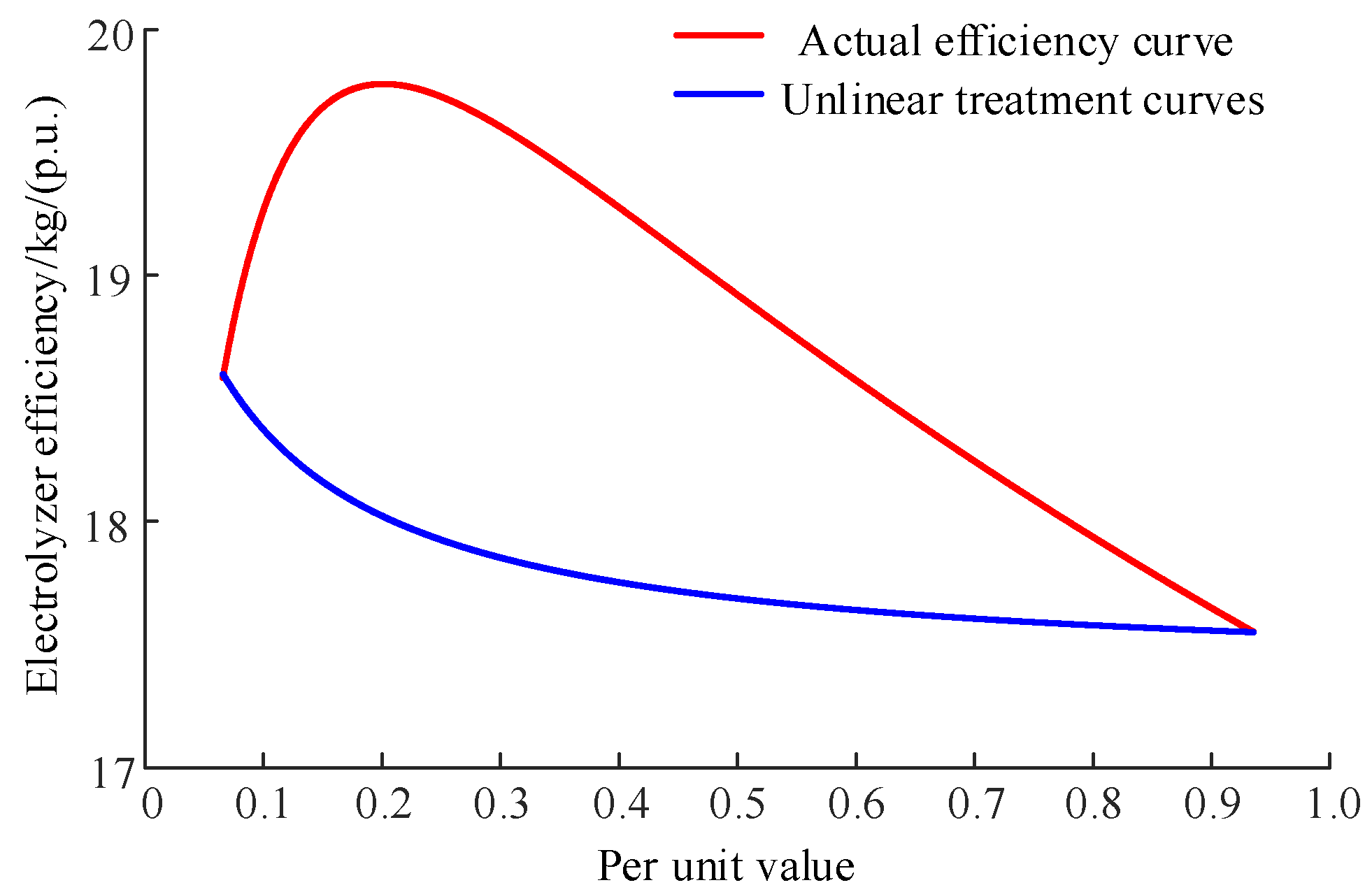

In this paper, we optimize the power scheduling and allocation strategy to enhance the hydrogen production and system economic returns by fine-modeling the AEL and segmented linearized hydrogen production efficiency curves, and introducing the AEL life decay model into the hydrogen storage operation cost function;

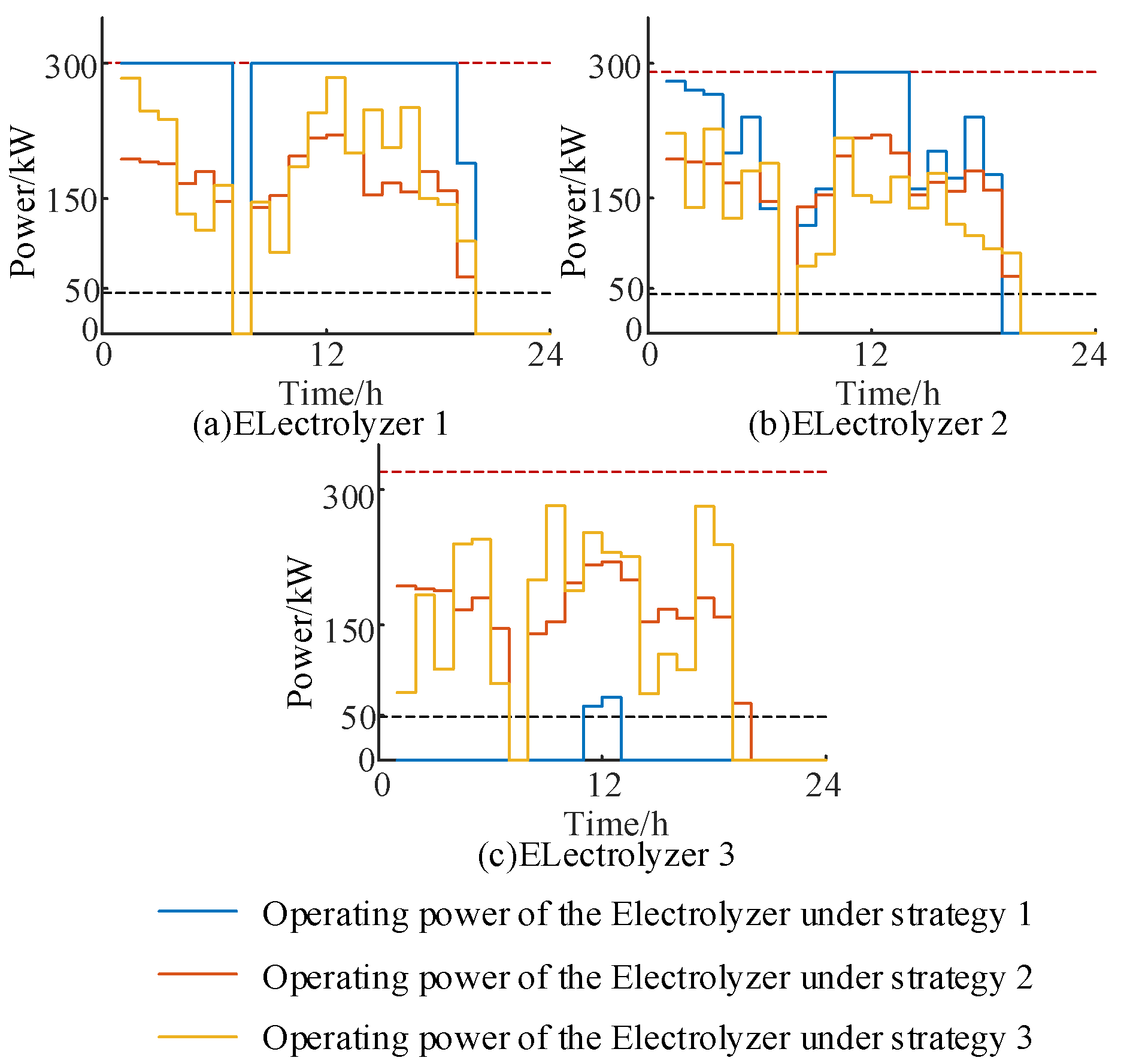

To improve the wide power adaptability of the hydrogen production system, the system adopts electrolysis tanks of different power levels to form the MES, and proposes an optimized scheduling strategy based on GA, which, compared with the traditional power equalization strategy and Daisy-chain power allocation strategy, can improve the system economy while enhancing the efficiency of the system for hydrogen production, and achieve the reasonable distribution of AEL power and average the use of AEL’ loss, which provides a useful reference for the operation of MES in the actual large-scale off-grid wind power alkaline hydrogen production system;

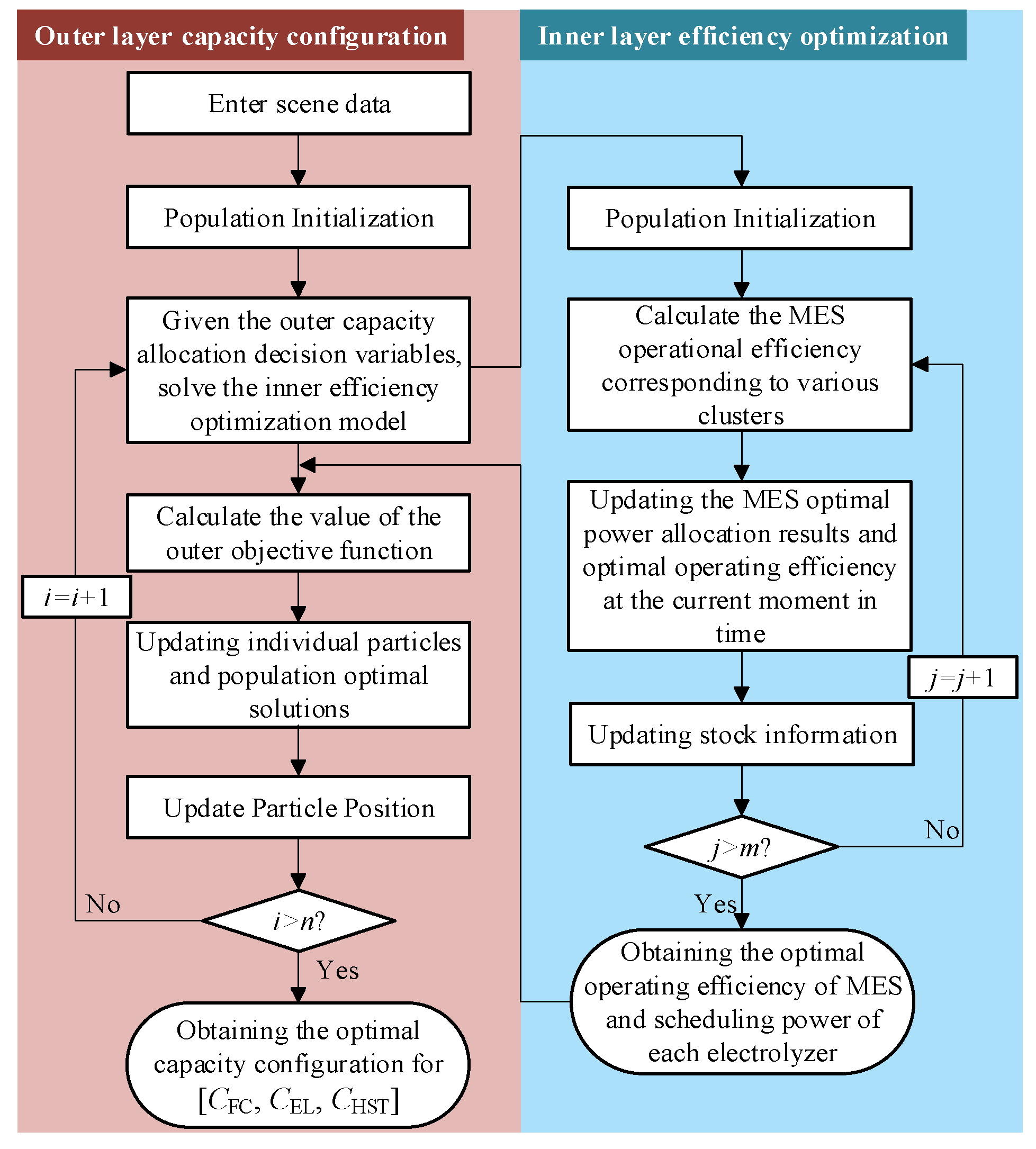

In this paper, we propose a double-layer capacity allocation model considering the optimization of hydrogen production efficiency, where the inner layer optimizes the output power allocation of the AEL at each moment of a typical day to maximize the operating efficiency of the MES, and the outer layer optimizes the system’s maximum daily integrated net return, which reduces the capacity allocation cost of the system and significantly improves the economy and flexibility of the integrated wind-PV-hydrogen microgrid system.

The rest of this paper is organized as follows:

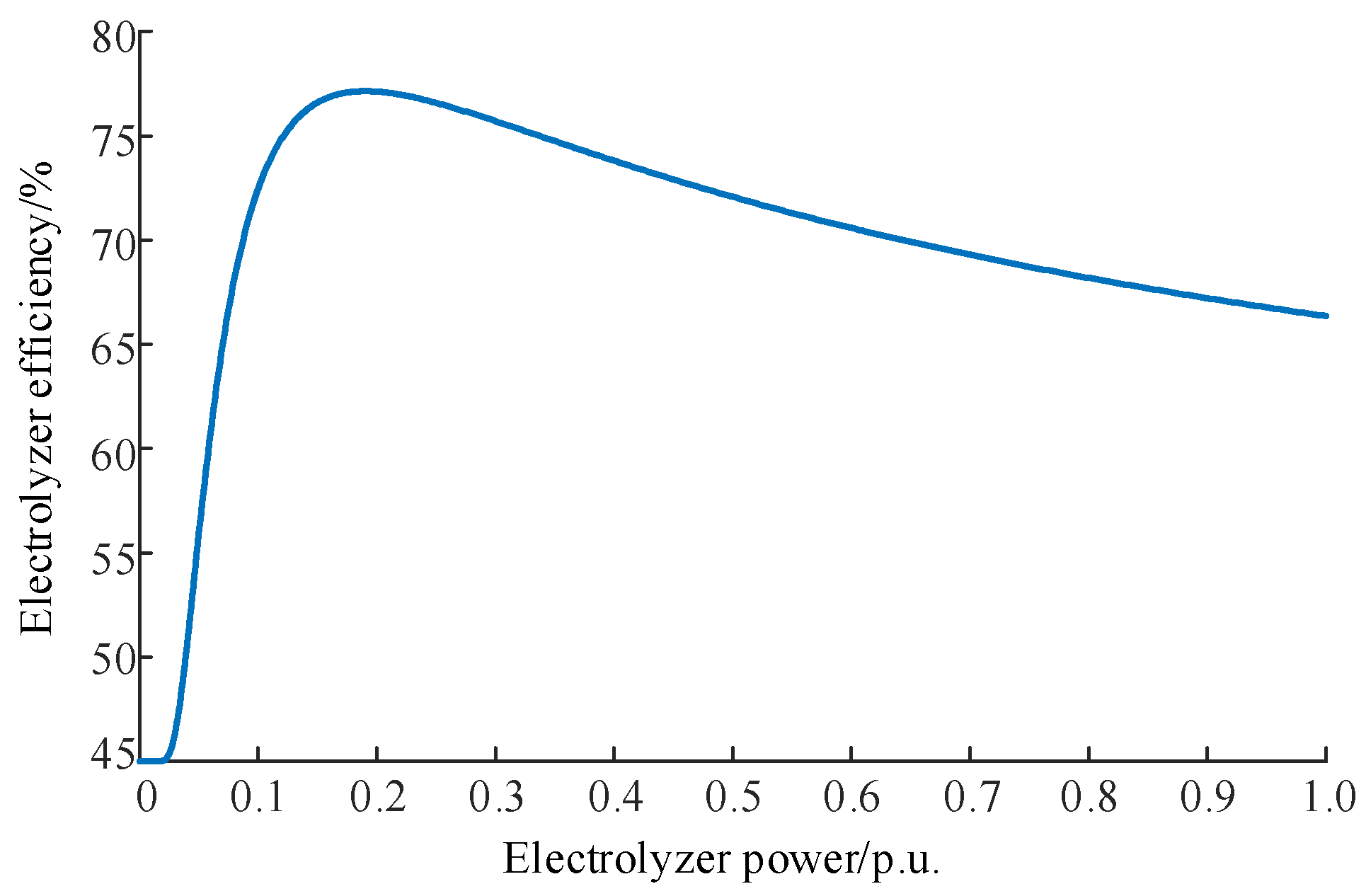

Section 2 provides the capacity efficiency modeling of electrolyzer systems, while

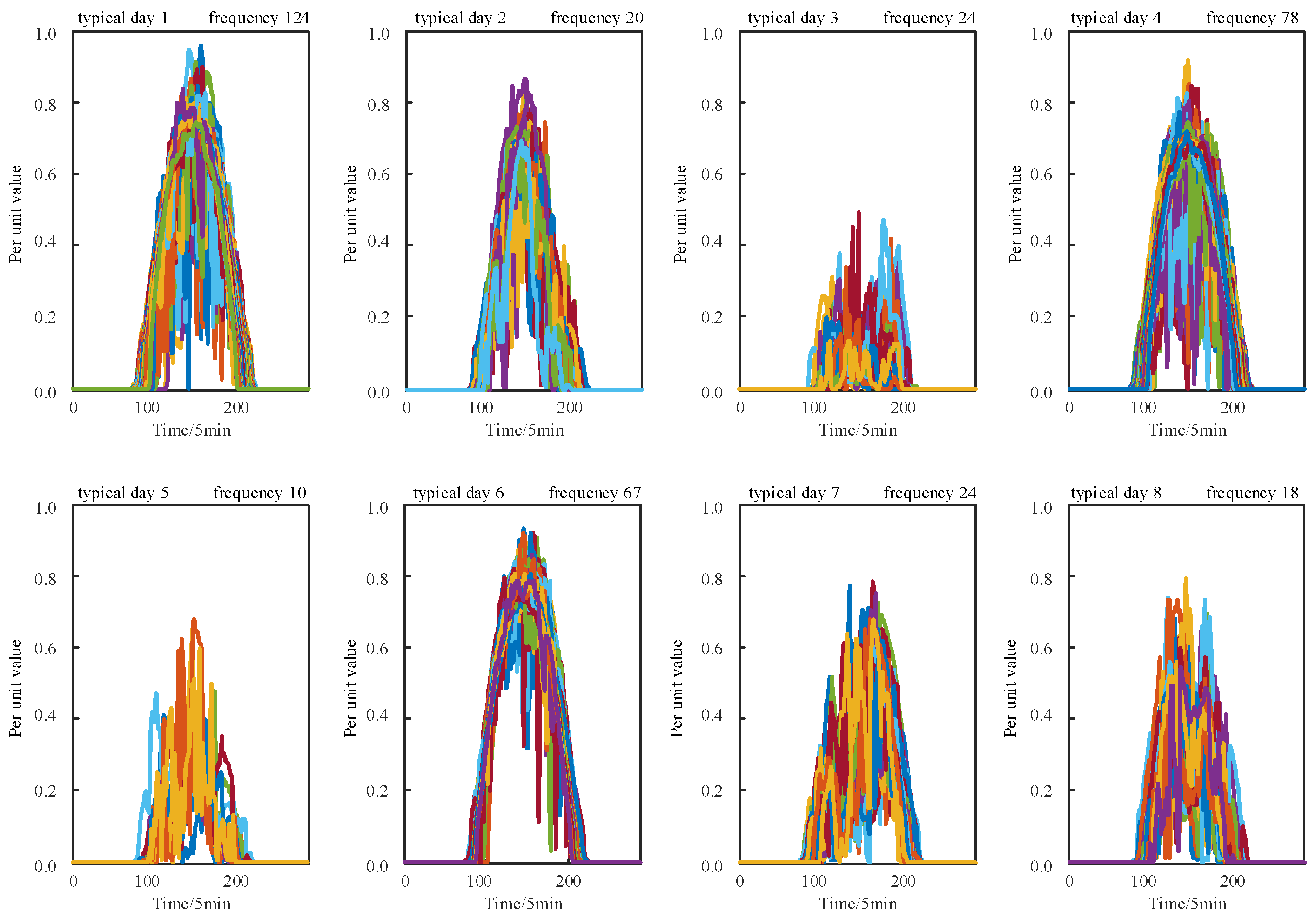

Section 3 provides a scene construction of wind-PV-hydrogen Integrated Microgrid System.

Section 4 outlines the double-layer capacity allocation model. The results of the simulations are given in

Section 5. Conclusions are drawn in

Section 6.