1. Introduction

The emergence of new technologies and the wide range of applications for lasers require new components to modify laser properties such as their intensity profile. Laser printing systems, optical data storage, and optical trapping are a few examples in which beam shaping techniques have important roles [

1]. Computer-generated holograms (CGHs) and diffractive optical elements (DOEs) enable an effective and easy way to modify the typical Gaussian intensity profile of a laser beam. The traditional fabrication methods of CGHs or DOEs rely on photolithographic processes that require several steps and can be time-consuming. In recent works, it has been shown that basic diffractive optical elements could be recorded in chalcogenide layers based on photo-induced refractive index change [

2,

3]. However, due to limited refractive index change, thick layers, up to 15–25 µm, were required to generate the desired phase change. An alternative approach to generating DOEs is by changing the locally transmitted amplitude instead of the locally transmitted phase. However, the amplitude CGHs for beam shaping are achievable by using the same patterns as those used to produce phase elements [

4].

In this work, we investigated the use of silver photodissolution to produce a flat amplitude CGH with a single step fabrication. Photodissolution is a phenomenon where a photochemical reaction causes the integration of a metal layer in an underlying amorphous chalcogenide layer, following a reaction also known as photodoping:

Even though it had been observed before, the research on this topic really started in 1971, when it was first proposed as a photo-microfabrication method [

5]. Several combinations of metals and chalcogenides have been proven to give rise to photodissolution, with efficiencies and effects depending on the involved materials. However, it has been shown that Ag yields the highest rates of photodissolution [

6]. Different possibilities of metal chalcogenide have been studied and their ability to produce photodissolution has been quantified [

7]. However, the most efficient one, to date, appears to be the combination of Ag and As

2S

3, which was chosen for this study.

While such effects have thoroughly been studied in the past, there have been no, or few, applications of this effect for the fabrication of optical elements and, in most of the literature, this effect has been introduced as an efficient method for enhancing photoinduced refractive index change. However, silver photodissolution in the As2S3 layer appears to be a very promising way to fabricate amplitude elements such as CGHs that work over a broad spectral range. No lithographic process is needed, and microstructures can directly be recorded, using laser light, into the SiO2/As2S3/Ag/glass stack resulting in a plane parallel element.

In this paper, first, we investigated the fabrication process of such a stack, and then the associated photodissolution kinetics. Such a preliminary study is necessary as the process is highly dependent on the fabrication procedure. Then, we investigated two alternative methods for recording of amplitude CGH. The first method relies on a CW laser, in which spatial intensity distribution is shaped with a LCD display, and then imaged in the recording plane where the SiO2/As2S3/Ag/glass stack is placed. The second method improves the spatial resolution with the use of a femtosecond laser focused in the sample plane and scanned across its aperture. Comparison between both techniques is finally provided.

3. Results

The kinetics of the photodissolution were studied with increasing dosage up to approximately 0.3 J/cm² (

Figure 4a,b). Increasing the dosage of exposure results in a gradual increase in the sample transparency. At the first stage of the exposure, the transmission increase is very slow. This can be easily explained by the exponential dependence of the transmission on Ag thickness. Indeed, a simple calculation allows us to show that if a photodissolution of half of the Ag has occurred, i.e., if the thickness of Ag decreases from 74 to 37 nm, the sample average transmission will increase from 1 to 7%. Such an effect can be observed during the first quarter of the exposure for dosage up to 0.07 J/cm². Other effects can be seen such as a red shift of the spectrum [

11]. This effect reveals an increase in the optical thickness of the transparent layer related to both an increase in the refractive index and a real increase in the physical thickness of the transparent layer (from 355 to 428 nm). Increasing the dosage of exposure results in a complete photodissolution of silver after 0.15 J/cm², the peak at 800 nm being the maximum. However, processes appear to be non-complete as an absorption band between 600 nm and 650 nm remains and tends to disappear as exposure is increased up to 0.3 J/cm². This absorption is most likely due to plasmon resonance of the silver particles that dissolved in the As

2S

3 layer and that are then bleached during a second process requiring larger exposure dosages [

12,

13]. Additional information on the kinetics of the photodissolution can be found in [

14].

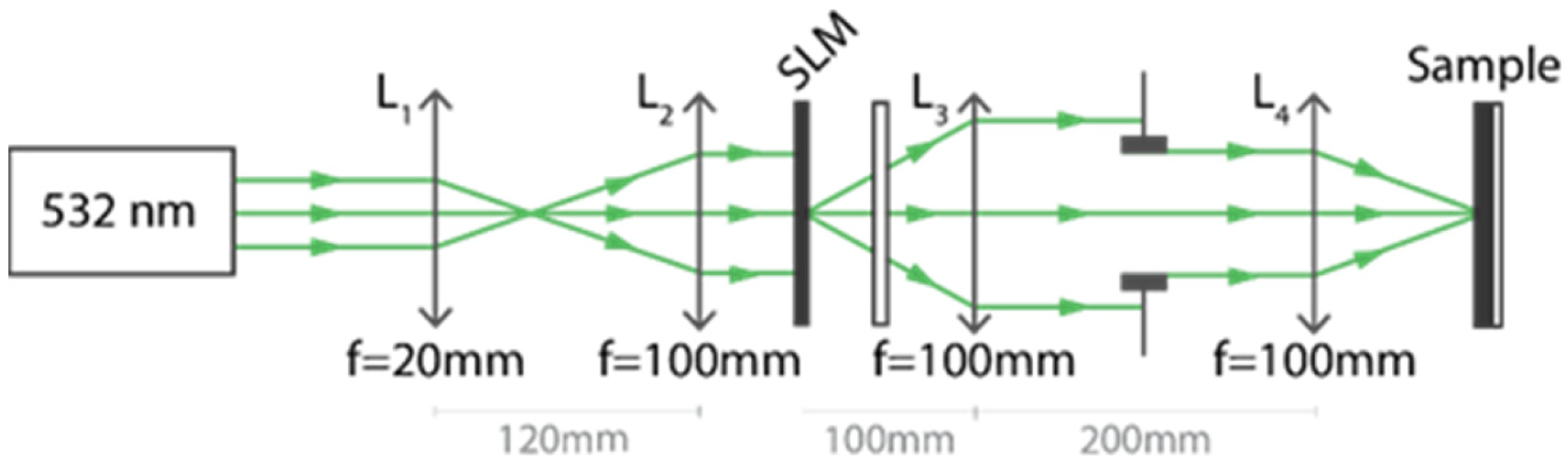

Two different CGHs with different pitch sizes were then recorded using the experimental setups given in

Figure 2 and

Figure 3. The amplitude profiles to be recorded were calculated using the VirtualLab Fusion software and designed to be compatible with the 8.5 µm resolution of the SLM. With such a large pitch, only limited diffraction angles were achieved, and the calculated far field profiles exhibited noise, especially for the largest patterns. Nevertheless, the potential of this method to record microstructures with different sizes was verified, especially when sub-micron resolution was achieved with femtosecond laser exposure. The exposure time for all the CGHs profiles using CW laser was set to ~4 min. Indeed, such exposure enabled the complete photodissolution of Ag in As

2S

3. The first element generates a crosshair target visor with the feature’s sizes going from 20 to 500 µm, while the second element results in two symmetrical guitars and has a typical pitch of 50 µm. In the case of femtosecond laser exposure, the patterns being the same, the typical pitches are one order of magnitude smaller.

First, these two types of elements were recorded using the setup shown in

Figure 2, and then the diffraction patterns were characterized using a 633 nm He-Ne laser using a CCD camera in the focal plane of a 100 mm focal length lens. The recorded amplitude profile was also characterized using an optical microscope and compared to the theoretical profiles.

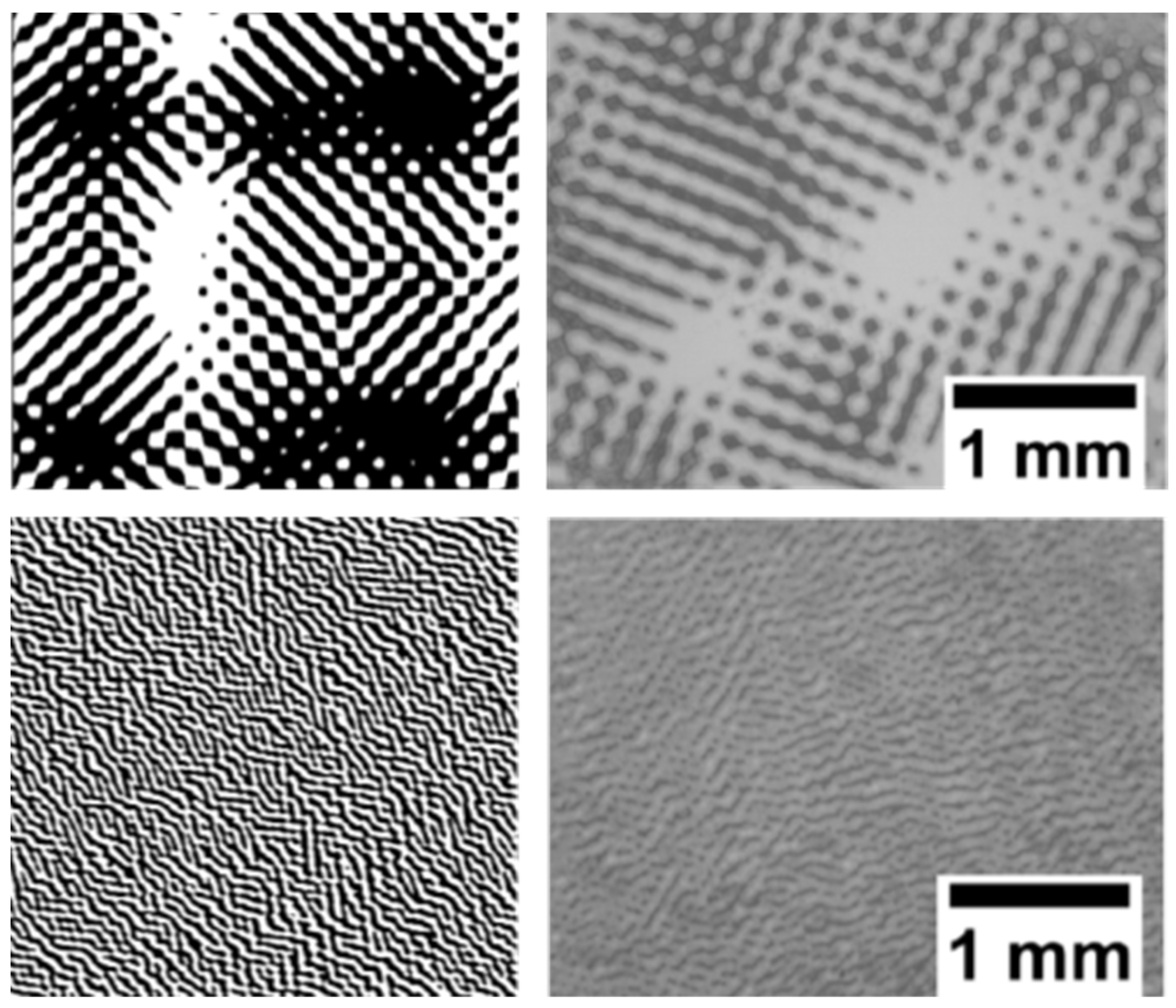

Figure 5 shows a comparison between the theoretical and experimental amplitude profiles recorded in the multilayer stack.

Figure 6 shows a comparison between the theoretical and experimental far-field diffracted intensity profiles for each type of CGH. Similar images were observed when characterized with lasers at longer wavelengths (e.g., 808 nm).

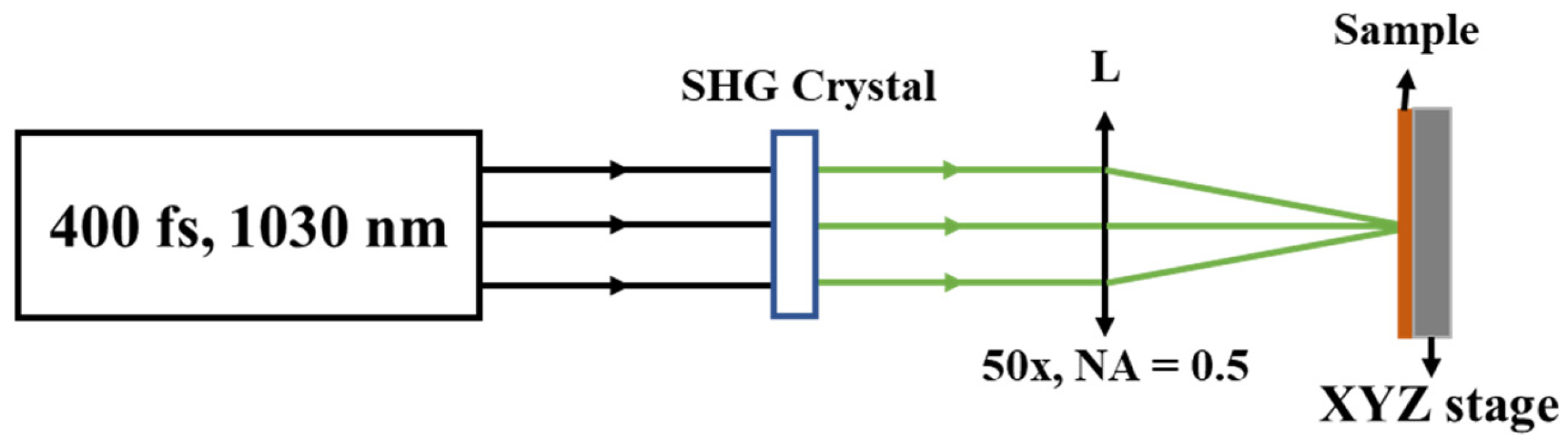

It has been shown in the past that efficient photodissolution can be also achieved by using pulsed lasers [

15]. A similar technique has been utilized in this work to achieve photodissolution. In order to enhance the spatial resolution during the recording, a femtosecond direct laser writing setup was employed (

Figure 3). The combination of well adjusted, high repetition rate, and laser fluence can induce photodissolution. The Ag: As

2S

3 was exposed at different combinations of repetition rates and energy per pulse to achieve large-area direct laser writing within minimal writing time. The laser irradiation parameters were optimized and set to an operating repetition rate of 200 kHz, 1 ms exposure time, and laser fluence between 0.01–0.03 J/cm

2, to achieve good quality diffracted images. The applied fluence is well below the damage threshold of silver thin films as reported previously, which is between 0.25–3 J/cm

2 [

16,

17].

The smallest feature size of the binary CGHs recorded using this setup was about 1 µm, i.e., one order of magnitude smaller as compared with the previous setup. The feature size is limited to 1 µm, due to the diffraction limit associated with the focusing objective lens, as well as the thermal propagation that arises during laser irradiation.

Figure 7 represents the microscopy image of the amplitude diffraction pattern recorded using femtosecond laser pulses (left) and the far-field diffracted image captured by transmitting a He-Ne laser through the recorded pattern (right).

All the recorded amplitude profiles, using both of the experimental setups, are very close to the theoretical ones, even for the smallest pitch size. For example, all features of the crosshair target visor amplitude profiles were accurately reproduced, even the small dots in the middle of the uniform zones. Similarly, the amplitude profiles of the guitars were well reproduced with sharp transitions between dark and clear regions. Regarding the intensity profiles, there is also a good agreement between the theoretical and experimental profiles. Sharp and quickly diverging diffracting images were achieved in the case of the femtosecond direct laser writing. Finally, zero order can be seen in both writing cases, however, the intensity of these zero orders does not exceed a few percent of the total intensity in the measurement plane. However, one must notice that the scale bars for amplitude profiles are one order of magnitude smaller in the case of femtosecond laser writing as compared with the CW laser writing. Therefore, this confirms the ability to record close to diffraction limit patterns with this method. A smaller resolution could be obtained with CW laser writing if a different imaging system was used to image the LCD in the recording plane. However, to obtain a resolution below 1 µm would require a more complex optical scheme.

Finally, while the recording time is longer with femtosecond laser writing as compared with CW laser writing since it requires scanning the sample, it is more versatile. Indeed, as the recorded pitch size was considerably smaller than the previous CGHs (about one order of magnitude), larger diffraction angles were achieved for femtosecond laser generated elements, resulting in a sharp and quickly diverging diffracted image. The diffracted images obtained with the femtosecond laser contained more details as compared with those obtained with continuous laser writing (

Figure 6 (right) and

Figure 7 (right)).

4. Conclusions

In this work, an alternative method for the fabrication of computer-generated holograms was proposed and successfully proved. Instead of traditional photolithography, a direct laser writing procedure was employed. Continuous-wave and femtosecond lasers were employed to locally photodissolve a thin layer of silver (74 nm) in a matrix of As2S3 (354 nm), reproducing an amplitude pattern that works as a computer-generated hologram for beam shaping. First, the photodissolution kinetics were characterized. Then, elements with 8.5 µm and <1 µm spatial resolution and close to theoretical performances, respectively, were demonstrated. The produced elements remain flat thanks to the dissolution process, and therefore, are less sensitive to the environment (if they are protected from short wavelength radiations). In addition, due to the broad spectral performances of both Ag and As2S3, Ag + As2S3 beam shaping could be achieved up to 10+ µm if the layers were deposited on visible and infrared transparent substrates such as, for example, ZnSe.