Design of Refractive/Diffractive Hybrid Projection Lens for DMD-Based Maskless Lithography

Abstract

:1. Introduction

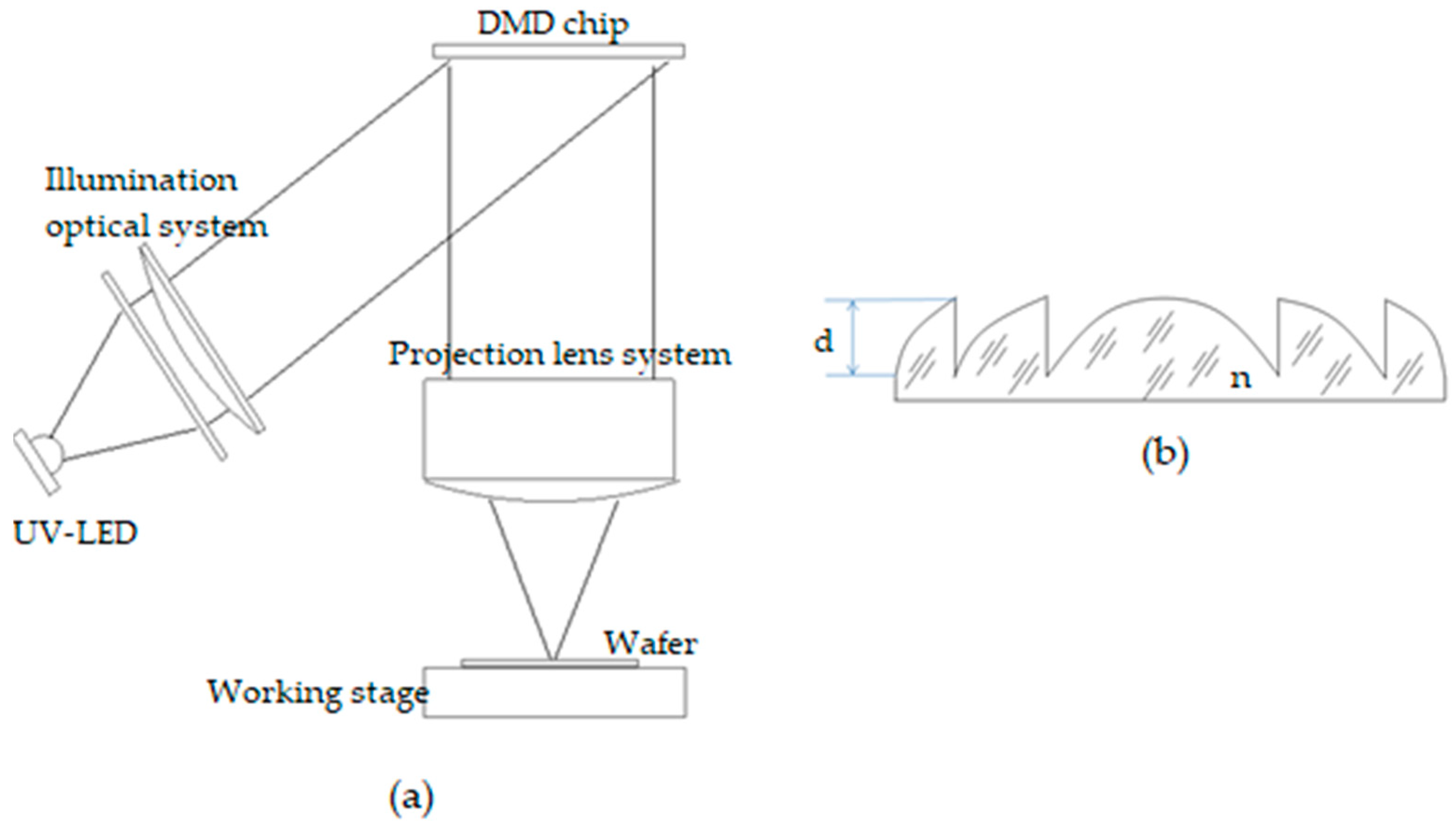

2. DMD-Based Maskless Lithography System and Diffraction Efficiency of DOE

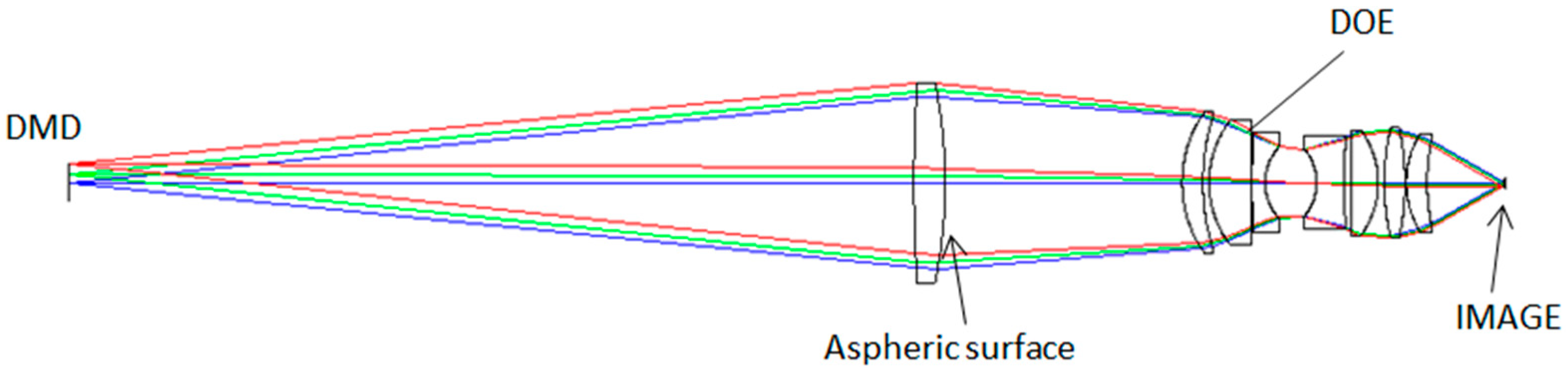

3. Optical Design of Projection Lens Using DOE for DMD-Based Maskless Lithography

3.1. Design Specification

3.2. Design Process

3.3. Diffraction Efficiency Analysis of Single Layer DOE

4. The Comparison of Optical Performance Between Two Projection Lens Systems

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vieu, C.; Carcenac, F.; Pépin, A.; Chen, Y.; Mejias, M.; Lebib, A.; Manin-Ferlazzo, L.; Couraud, L.; Launois, H. Electron beam lithography: Resolution limits and applications. Appl. Surface Sci. 2000, 164, 111–117. [Google Scholar] [CrossRef]

- Drost, M.; Tu, F.; Berger, L.; Preischl, C.; Zhou, W.; Gliemann, H.; Wöll, C.; Marbach, H. Surface-Anchored Metal–Organic Frameworks as Versatile Resists for Gas-Assisted E-Beam Lithography: Fabrication of Sub-10 Nanometer Structures. ACS Nano 2018, 12, 3825–3835. [Google Scholar] [CrossRef] [PubMed]

- Jiang, N.; Zarkadoula, E.; Narang, P.; Maksov, A.; Kravchenko, I.; Borisevich, A.; Jesse, S.; Kalinin, S.V. Atom-by-atom fabrication by electron beam via induced phase transformations. MRS Bull. 2017, 42, 653–659. [Google Scholar] [CrossRef]

- Zhang, S.J.; To, S.; Zhu, Z.W.; Zhang, G.Q. A review of fly cutting applied to surface generation in ultraprecision machining. Int. J. Mach. Tools Manuf. 2016, 103, 13–27. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, Y.; Ma, J.; Li, J.; Huang, W.; Chu, J. High-efficiency fabrication of aspheric microlens arrays by holographic femtosecond laser-induced photopolymerization. Appl. Phys. Lett. 2013, 103, 141112. [Google Scholar] [CrossRef]

- Cai, J.; Zhu, Z.; Alkemade, P.F.A.; Veldhoven, E.v.; Wang, Q.; Ge, H.; Rodrigues, S.P.; Cai, W.; Li, W.-D. 3D Volumetric Energy Deposition of Focused Helium Ion Beam Lithography: Visualization, Modeling, and Applications in Nanofabrication. Adv. Mater. Interface 2018, 5, 1800203. [Google Scholar] [CrossRef]

- Henry, M.D.; Shearn, M.J.; Chhim, B.; Scherer, A. Ga+ beam lithography for nanoscale silicon reactive ion etching. Nanotechnology 2010, 21, 245303. [Google Scholar] [CrossRef] [PubMed]

- Lin, B.J. Immersion lithography and its impact on semiconductor manufacturing. J. Microlithogr. Microfabr. Microsyst. 2004, 3, 1–7. [Google Scholar]

- Ogawa, K.; Sasago, M.; Endo, M.; Ishihara, T. A KrF Excimer Laser Lithography for Half Micron Devices. Jpn. J. Appl. Phys. 1988, 27, 1521–1525. [Google Scholar] [CrossRef]

- Biao, Y.; Zhou, J.; Chen, Q.; Lei, L.; Wen, K. Fabrication of hexagonal compound eye microlens array using DMD-based lithography with dose modulation. Opt. Express 2018, 26, 28927–28937. [Google Scholar]

- Zheng, Q.; Zhou, J.; Chen, Q.; Lei, L.; Wen, K.; Hu, Y. Rapid Prototyping of a Dammann Grating in DMD-Based Maskless Lithography. IEEE Photonics J. 2019, 11, 2400410. [Google Scholar] [CrossRef]

- Erdmann, L.H.; Deparnay, A.; Wirth, F.; Brunner, R. MEMS-based lithography for the fabrication of micro-optical components. In Micromachining Technology for Micro-Optics & Nano-Optics II; International Society for Optics and Photonics: San Jose, CA, USA, 2003; Volume 5347, pp. 79–84. [Google Scholar]

- Chen, R.H.; Liu, H.; Zhang, H.L.; Zhang, W.J.; Xu, J.; Xu, W.B.; Li, J.H. Edge smoothness enhancement in DMD scanning lithography system based on a wobulation technique. Opt. Express 2017, 25, 21958–21968. [Google Scholar] [CrossRef]

- Levenson, M.D. Using Destructive Optical Interference in Semiconductor Lithography. Opt. Photonics News 2006, 17, 30–35. [Google Scholar] [CrossRef]

- Bel’skiĭ, A.B.; Gan, M.A.; Mironov, I.A.; Seĭsyan, R.P. Prospects for the development of optical systems for nanolithography. J. Opt. Technol. 2009, 76, 496–503. [Google Scholar] [CrossRef]

- Liu, F.; Li, Y. Initial structure design of coaxial six–ten mirror central-obscured extreme ultraviolet lithographic objective. Appl. Opt. 2014, 53, 6444–6451. [Google Scholar] [CrossRef] [PubMed]

- Omura, Y.; Ikezawa, H. Projection Optical System and Method for Photolithography and Exposure Apparatus and Method Using Same. U.S. Patent 7,609,455, 27 October 2009. [Google Scholar]

- Epple, A.; Kamenov, V.; Gruner, T.; Schicketanz, T. Catadioptric Projection Objective. U.S. Patent 8,446,665, 21 May 2013. [Google Scholar]

- Mao, S.; Li, Y.; Jiang, J.; Shen, S.; Liu, K.; Zheng, M. Design of a hyper-numerical-aperture deep ultraviolet lithography objective with freeform surfaces. Chin. Opt. Lett. 2018, 16, 030801. [Google Scholar]

- Wu, Y.; Wang, L.; Yu, J.; Yu, B.; Jin, C. Design method for off-axis aspheric reflective optical system with extremely low aberration and large field of view. Appl. Opt. 2020, 59, 10185–10193. [Google Scholar] [CrossRef]

- Matsuyama, T.; Ohmura, Y.; Williamson, D.M. The lithographic lens: Its history and evolution. In Optical Microlithography XIX; SPIE: San Jose, CA, USA, 2006; Volume 6154, p. 615403. [Google Scholar]

- Zhou, J.; Fan, Y.; Bourv, A.; Smith, B.W. Inorganic immersion fluids for ultrahigh numerical aperture 193 nm lithography. Appl. Opt. 2006, 45, 3077–3082. [Google Scholar] [CrossRef]

- Smith, B.W.; Bourov, A.; Zhou, J.; Zavyalova, L.; Lafferty, N.; Fan, Y.; Cropanese, F.; Estroff, A. Hyper NA water immersion lithography. In Frontiers in Optics 2004/Laser Science XXII/Diffractive Optics and Micro-Optics/Optical Fabrication and Testing, OSA Technical Digest (CD); Optical Society of America: Rochester, New York, NY, USA, 2004. [Google Scholar]

- Hong, Y.G.; Kim, S.I.; Yeo, W.G.; Lee, C.K. Telephotolens design with refractove/diffractive hybrid lens. J. Opt. Soc. Korea 1997, 1, 74–80. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.B.; Hegg, R.G.; Johnson, W.T.; King, W.B.; Rock, D.F.; Spande, R. Visible-band testbed projector with a replicated diffractive optical element. Appl. Opt. 1999, 38, 7105–7111. [Google Scholar] [CrossRef]

- Sauer, H.; Chavel, P.; Erdei, G. Diffractive optical elements in hybrid lenses: Modeling and design by zone decomposition. Appl. Opt. 1999, 38, 6482. [Google Scholar] [CrossRef] [PubMed]

- Wood, A.P. Design of infrared hybrid refractive-diffractive lenses. Appl. Opt. 1992, 31, 2253–2258. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Liu, H.; Zhang, H.; Zhang, H.; Sun, Q.; Lu, Z. Effect of incidence angles and manufacturing errors on the imaging performance of hybrid systems. J. Opt. 2011, 13, 035711. [Google Scholar] [CrossRef]

- Lee, D.-H. Optical System with 4 μm Resolution for Maskless Lithography Using Digital Micromirror Device. J. Opt. Soc. Korea 2010, 14, 266–276. [Google Scholar] [CrossRef] [Green Version]

- Optical Design Program. Available online: http://neurophysics.ucsd.edu/Manuals/Zemax/ZemaxManual.pdf (accessed on 10 January 2021).

- Blough, C.G.; Rossi, M.; Mack, S.K.; Michaels, R.L. Single-point diamond turning and replication of visible and near-infrared diffractive optical elements. Appl. Opt. 1997, 36, 4648–4654. [Google Scholar] [CrossRef]

- Bittner, R. Tolerancing of single point diamond turned diffractive optical elements and optical surfaces. J. Eur. Opt. Soc. 2007, 2, 07028. [Google Scholar] [CrossRef] [Green Version]

- Buralli, D.A.; Morris, G.M. Effects of diffraction efficiency on the modulation transfer function of diffractive lenses. Appl. Opt. 1992, 31, 4389–4396. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Parameter | Specification |

|---|---|

| Object height | 7 mm |

| Object Space NA | 0.1 |

| Primary Wavelength | 405 nm |

| Magnification | −0.2 |

| Image Space NA | 0.449 |

| Distortion | <0.0002% |

| Ray Aberration | <0.001 mm |

| Total length | <200 mm |

| The working distance from the substrate | >29 mm |

| Surface | Type | Radius | Thickness | Glass | Conic |

|---|---|---|---|---|---|

| Object | Standard | Infinity | 324.3549 | 0 | |

| 1 | Standard | 586.0791 | 12 | S-LAL59 | 0 |

| 2 | Even Asphere | −185.103 | 90.9103 | −1.2953 | |

| 3 | Standard | 46.8635 | 8 | S-LAL59 | 0 |

| 4 | Standard | 85.5637 | 2.3721 | 0 | |

| 5 | Standard | 39.2291 | 16.0998 | PMMA | 0 |

| 6 | Binary 2 | Infinity | 0.4098 | 0 | |

| 7 | Standard | 516.8111 | 5 | N-SF8 | 0 |

| 8 | Standard | 20.2947 | 15.0814 | 0 | |

| STO | Standard | Infinity | 4.6654 | 0 | |

| 10 | Standard | −20.2242 | 10.5918 | N-SF8 | 0 |

| 11 | Standard | 224.1633 | 2.4215 | 0 | |

| 12 | Standard | 832.188 | 10.6521 | LAK9G15 | 0 |

| 13 | Standard | −33.9959 | 2.2713 | 0 | |

| 14 | Standard | 88.5799 | 8 | S-LAL59 | 0 |

| 15 | Standard | −104.0771 | 0.5 | 0 | |

| 16 | Standard | 35.9804 | 8 | S-LAL59 | 0 |

| 17 | Standard | 76.21 | 29.0782 | 0 | |

| Image | Standard | Infinity | 324.3549 | 0 |

| Surface | Type | Diffraction Order | A1 | A2 | A3 |

|---|---|---|---|---|---|

| 6 | Binary2 | 1 | −1.045 × 105 | 6.666 × 104 | 5.408 × 105 |

| Surface | Type | Conic | Polynomial Coefficient | ||

|---|---|---|---|---|---|

| α2 | α3 | α4 | |||

| 2 | Even Asphere | −1.2953 | 2.461 × 10−8 | −6.604 × 10−13 | 3.047 × 10−16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Zhou, J.; Wang, B.; Meng, Z. Design of Refractive/Diffractive Hybrid Projection Lens for DMD-Based Maskless Lithography. Optics 2021, 2, 103-112. https://doi.org/10.3390/opt2020011

Xu Z, Zhou J, Wang B, Meng Z. Design of Refractive/Diffractive Hybrid Projection Lens for DMD-Based Maskless Lithography. Optics. 2021; 2(2):103-112. https://doi.org/10.3390/opt2020011

Chicago/Turabian StyleXu, Zhuohui, Jinyun Zhou, Bo Wang, and Ziming Meng. 2021. "Design of Refractive/Diffractive Hybrid Projection Lens for DMD-Based Maskless Lithography" Optics 2, no. 2: 103-112. https://doi.org/10.3390/opt2020011

APA StyleXu, Z., Zhou, J., Wang, B., & Meng, Z. (2021). Design of Refractive/Diffractive Hybrid Projection Lens for DMD-Based Maskless Lithography. Optics, 2(2), 103-112. https://doi.org/10.3390/opt2020011