Design and Investigation of Mechanical Properties of Additively Manufactured Novel Coil-Shaped Wave Springs

Abstract

1. Introduction

2. Materials and Methods

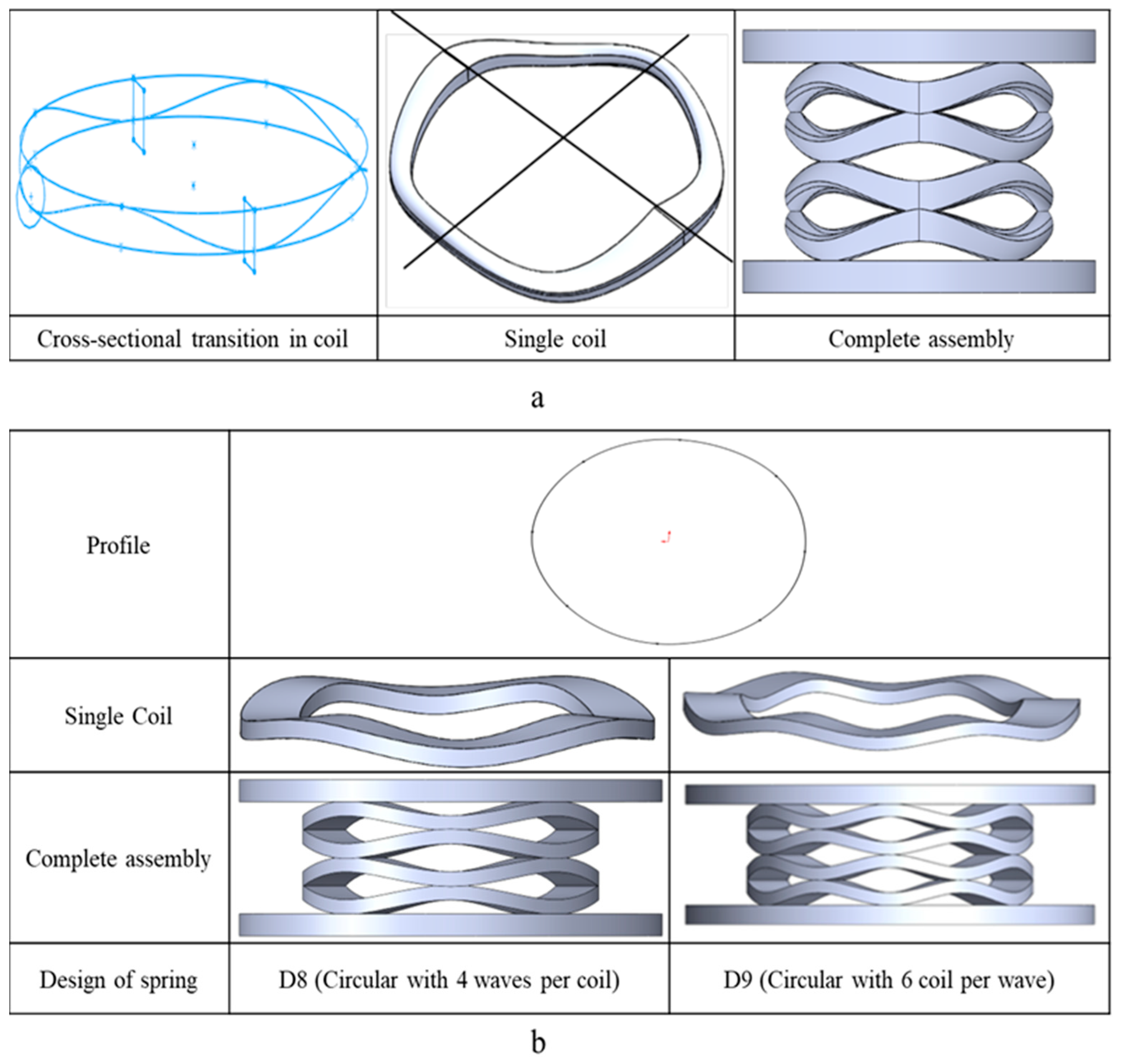

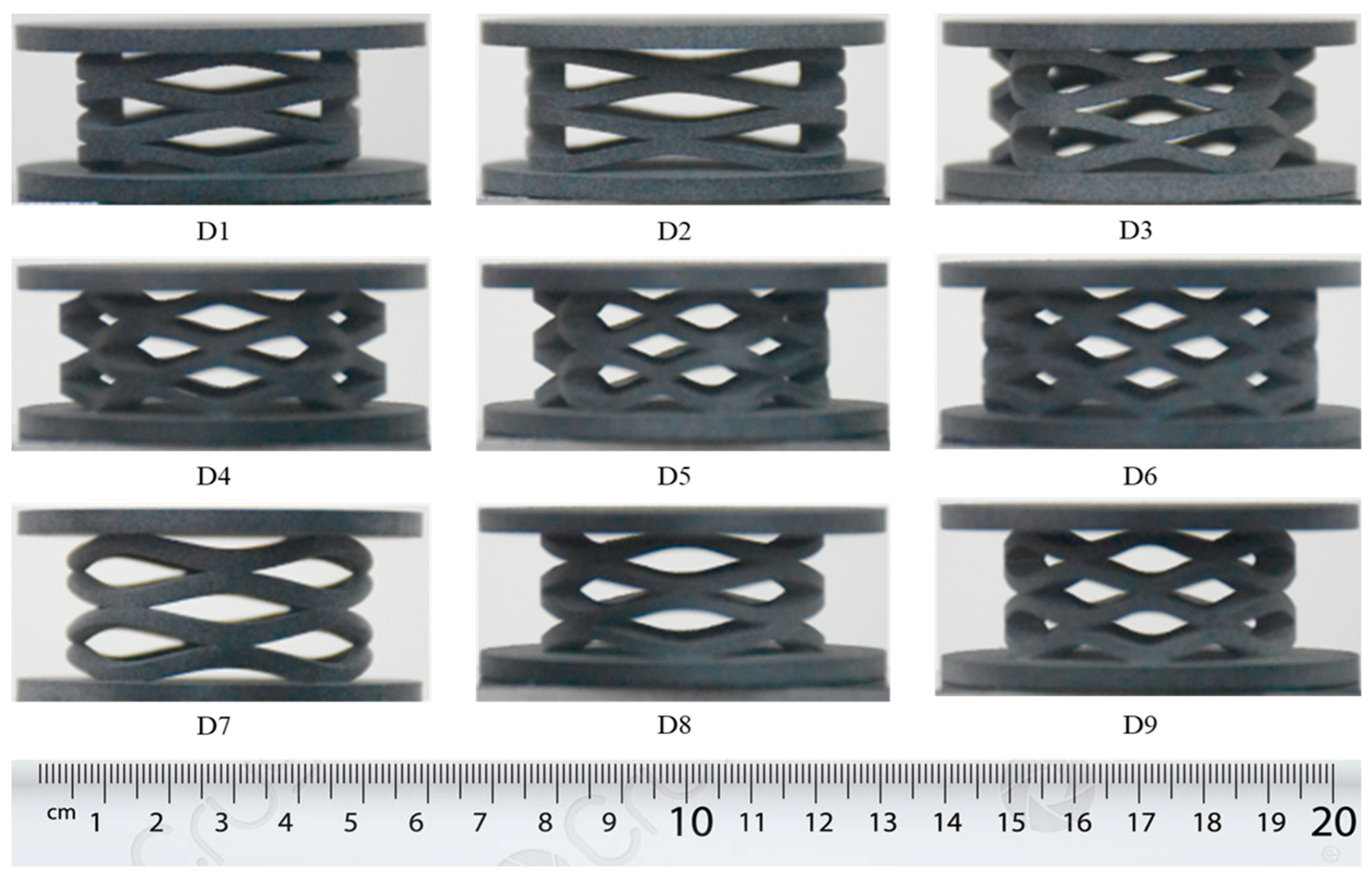

2.1. Designing of Non-Circular Contact Wave Spring

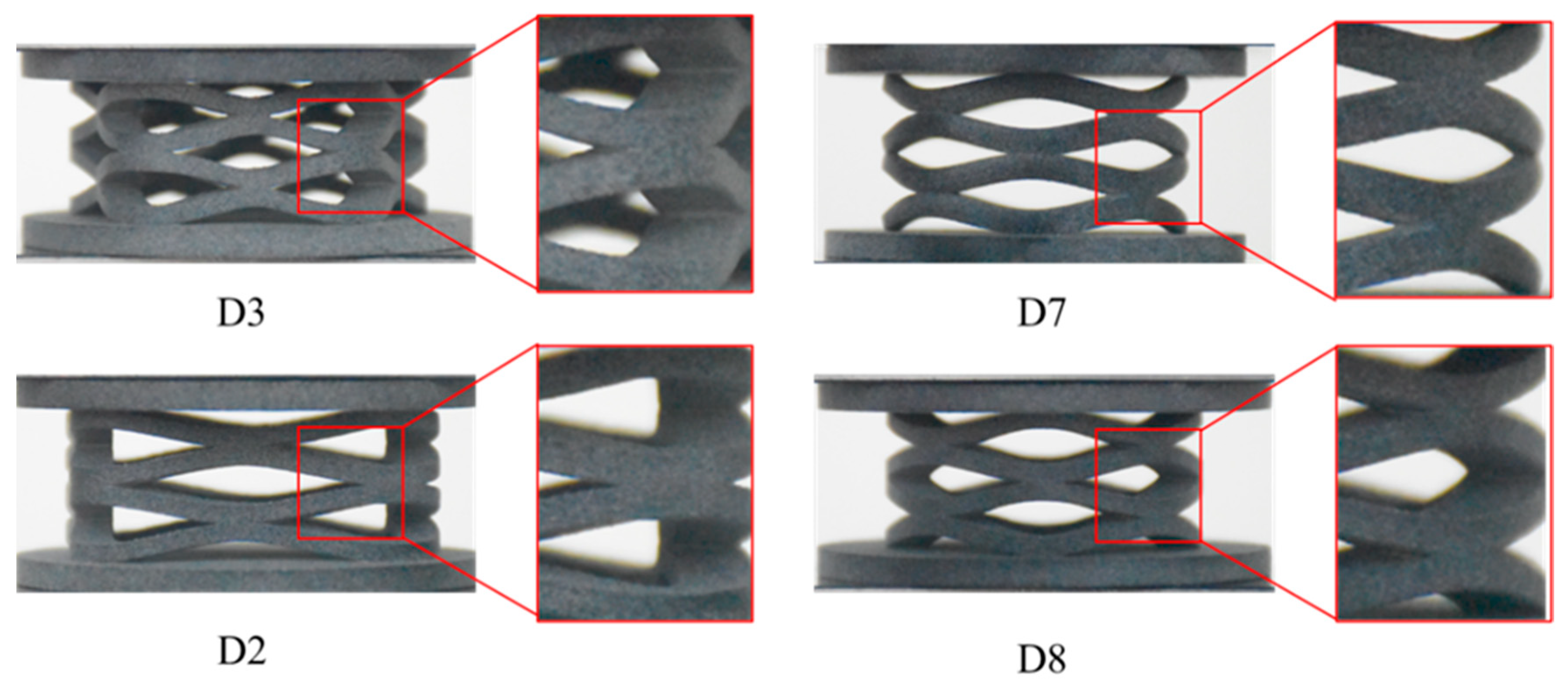

2.2. Additive Manufacturing of Samples

2.3. Uni-Axial Compression Testing (Loading–Unloading)

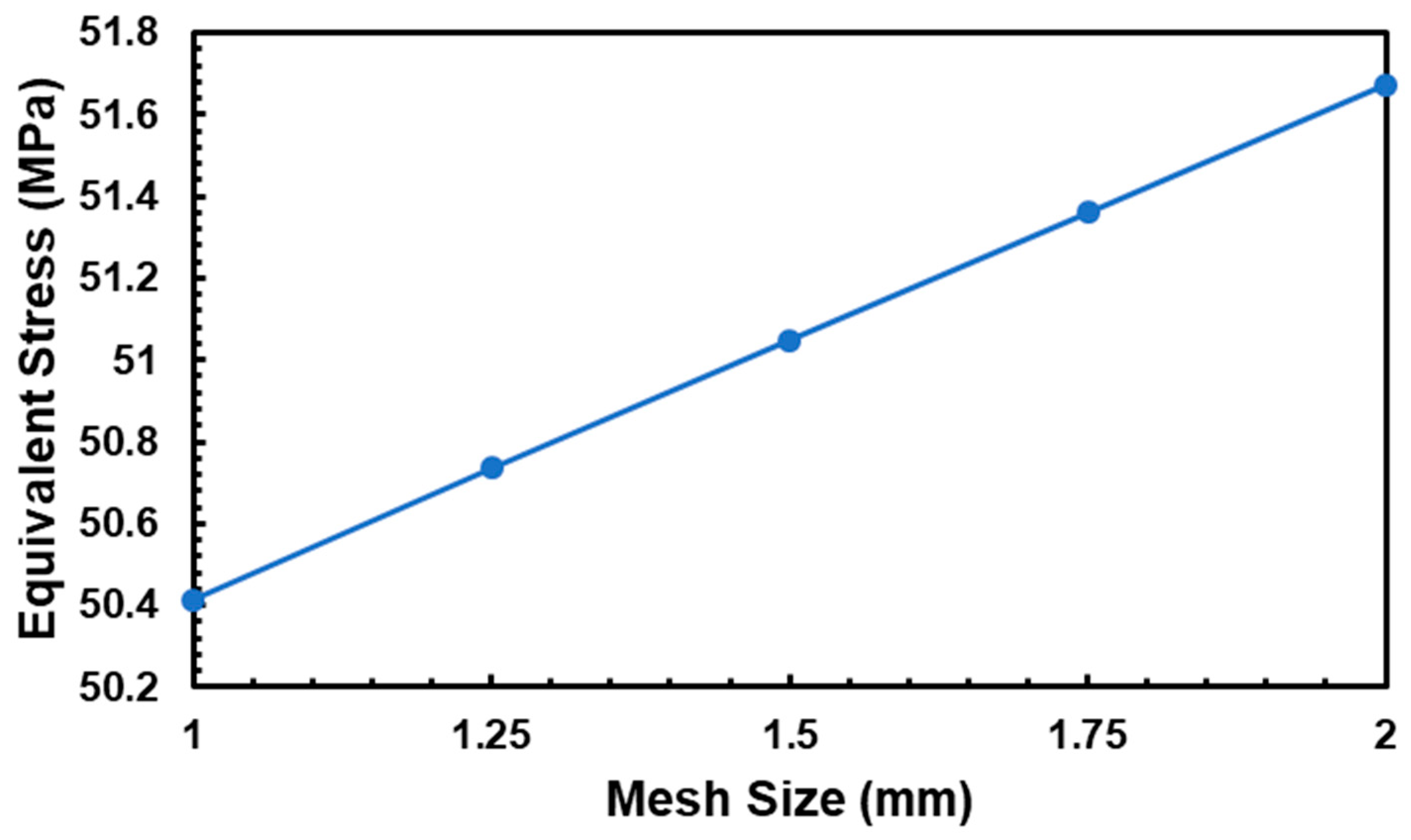

2.4. Simulation Framework

3. Results and Discussion

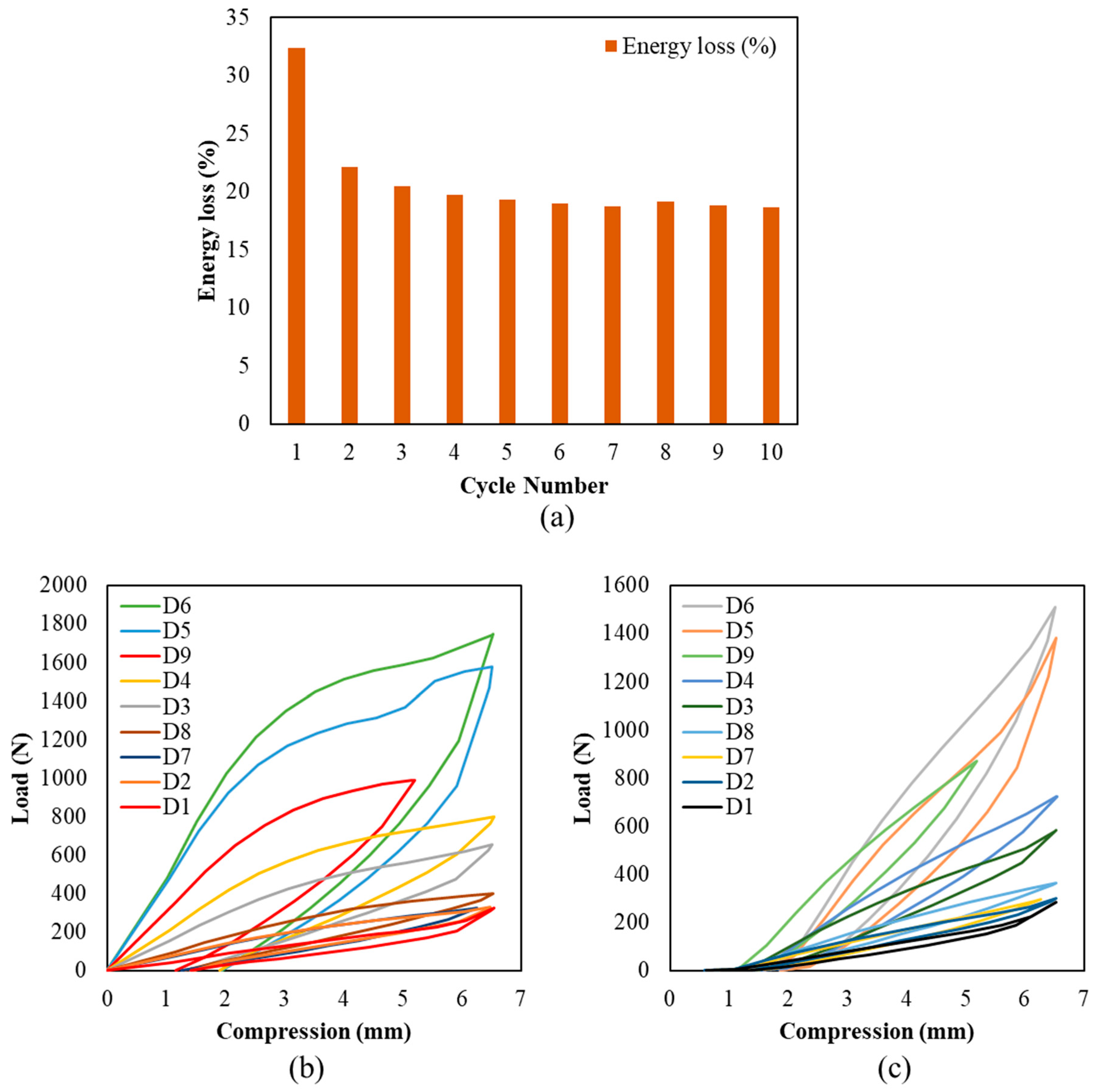

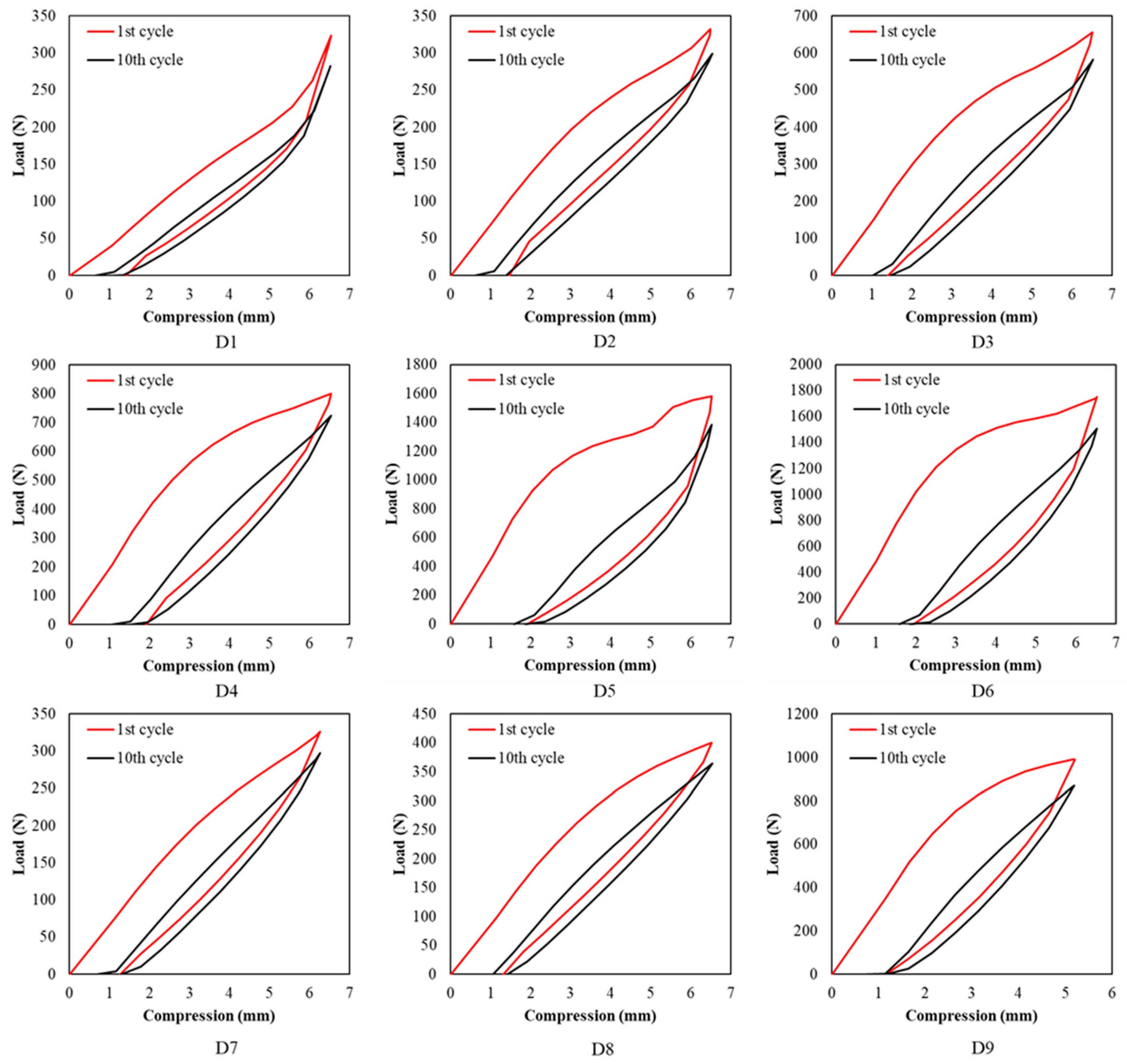

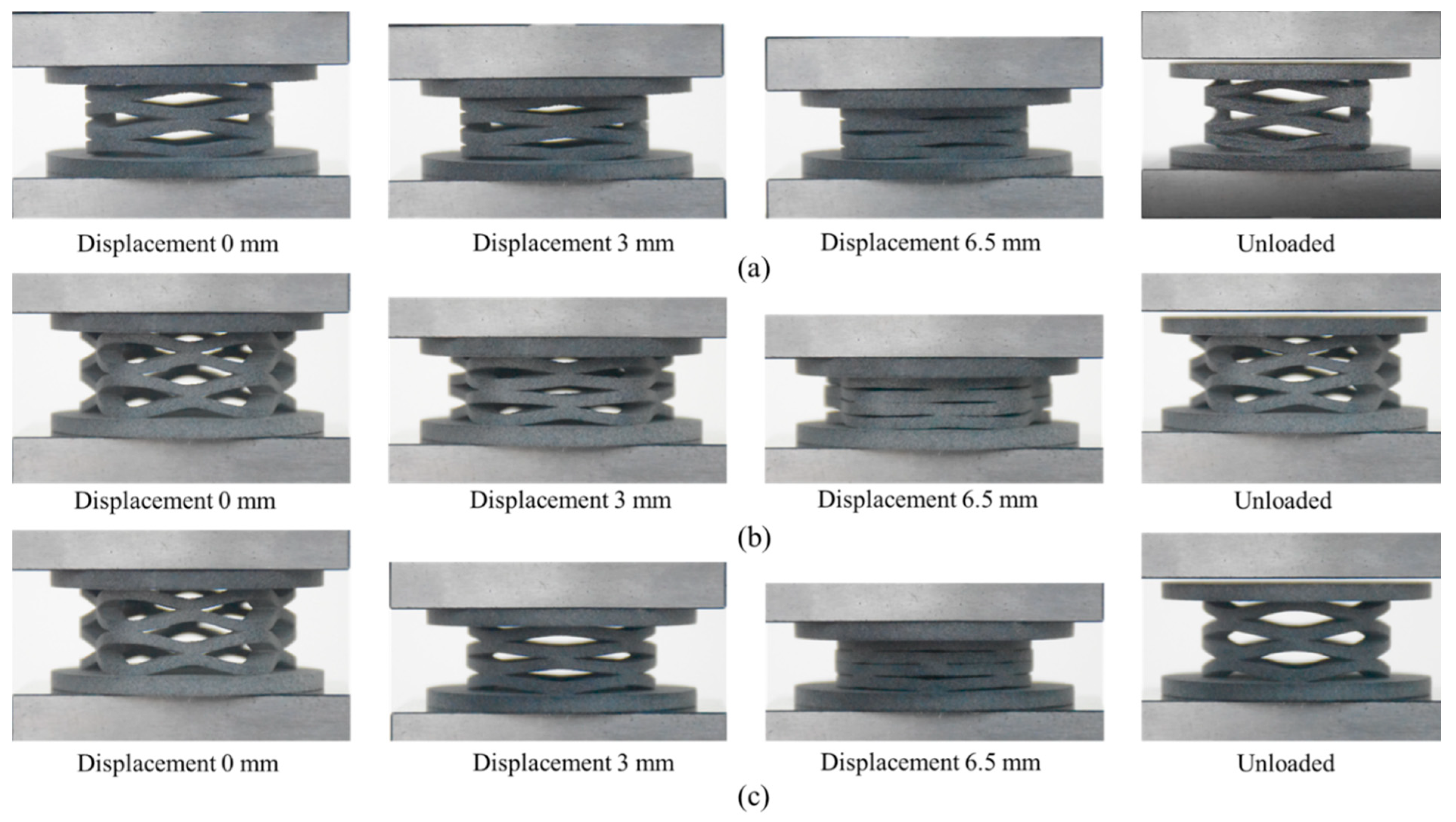

3.1. Compression Testing (Loading–Unloading)

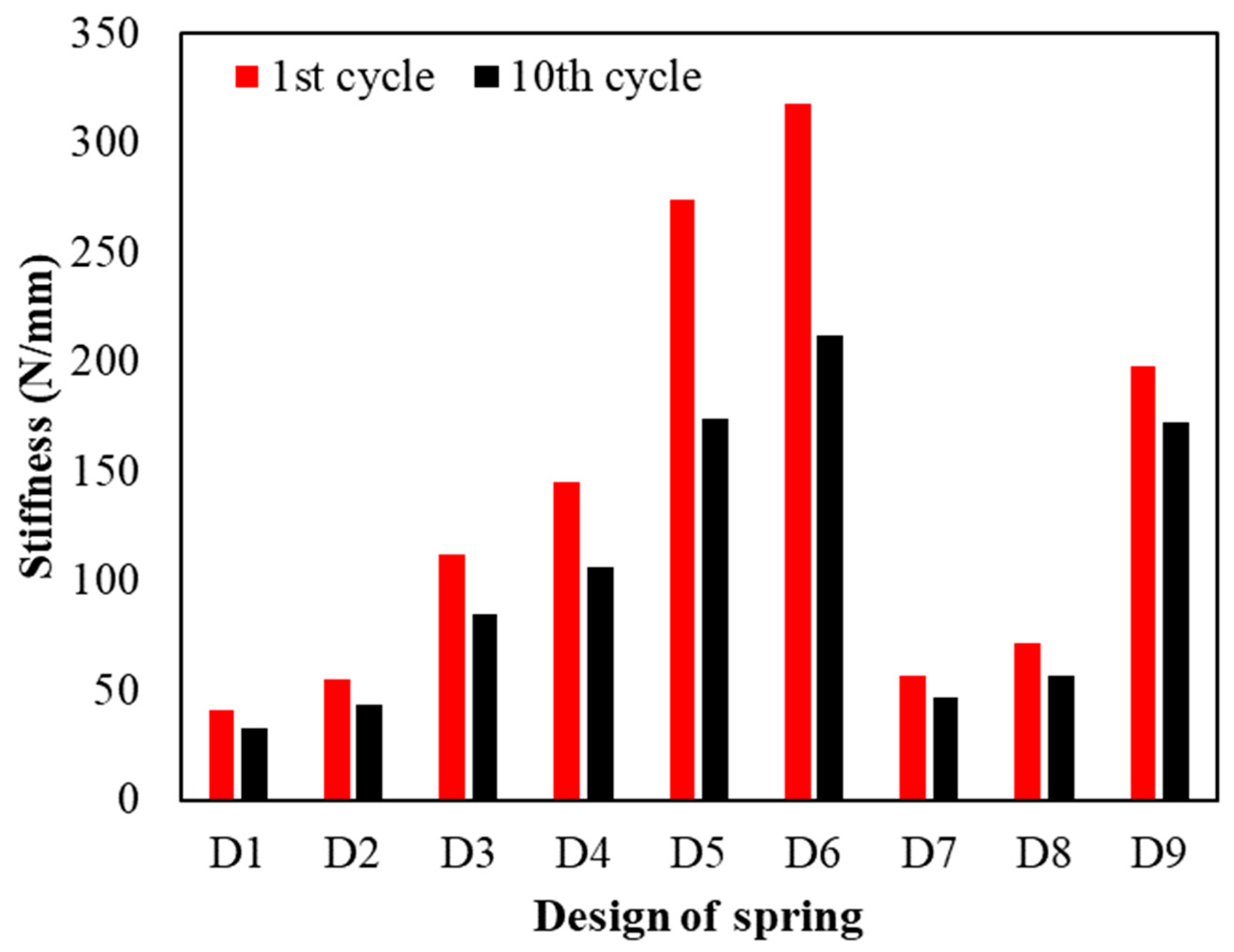

3.2. Stiffness

3.3. Energy Absorption

4. Comparison of Experimental and Simulation Results

5. Conclusions

- Square and rectangular wave springs lost 13% less energy than their heptagonal and octagonal counterparts. The octagonal shape has the maximum stiffness followed by the heptagonal and hexagonal shapes, while the square and rectangular designs showed the least rigidity.

- Energy absorption and stiffness of square and rectangular designs were almost identical to those of circular designs.

- The FEA and experiments showed similar behavior in compression, and the load-bearing graphs of each design are comparable. Non-linear regions of load-bearing graphs illustrated variations due to changes in thickness and the assumption that printed samples behaved isotopically during FEA.

- Although the above presented study has given encouraging and new dimensions towards customized springs, it needs to be further investigated for fatigue as well as impact properties under different dynamic loadings. The number of waves in each coil needs to be a requirement of mechanical properties for specific applications as when the number of waves is increased, energy absorption is increased, but at the same time, the stress concentration points in each coil also increase, which is a prime limitation of this study. Similarly, more materials need to be used for manufacturing of these wave springs to investigate the mechanical properties as only one material was being used in the presented study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shah, G.J.; Nazir, A.; Lin, S.-C.; Jeng, J.-Y.; Fu, R.Y.; Torun, H.; Feng, H.; Shah, G.J.; Nazir, A.; Lin, S.-C.; et al. Design for Additive Manufacturing and Investigation of Surface-Based Lattice Structures for Buckling Properties Using Experimental and Finite Element Methods. Materials 2022, 15, 4037. [Google Scholar] [CrossRef] [PubMed]

- Nazir, A.; Jeng, J.Y. Buckling Behavior of Additively Manufactured Cellular Columns: Experimental and Simulation Validation. Mater. Des. 2020, 186, 108349. [Google Scholar] [CrossRef]

- Dobos, J.; Hanon, M.M.; Keresztes, R.Z.; Oldal, I. Threshold Investigation of Shell Thickness for Enhanced Mechanical and Tribological Performance in 3D-Printed Curved Sandwich Structures. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 401. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, Y.; Zhao, M.; Bosiakov, S.; Li, L. A Critical Review of Additive Manufacturing Techniques and Associated Biomaterials Used in Bone Tissue Engineering. Polymers 2022, 14, 2117. [Google Scholar] [CrossRef]

- Ciccone, F.; Bacciaglia, A.; Ceruti, A. Optimization with Artificial Intelligence in Additive Manufacturing: A Systematic Review. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 303. [Google Scholar] [CrossRef]

- Momeni, F.; Mehdi, M.; Hassani, N.S.; Liu, X.; Ni, J. A Review of 4D Printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Haq, M.R.U.; Nazir, A.; Lin, S.-C.; Jeng, J.-Y. Investigating the Effect of Design Parameters on the Mechanical Performance of Contact Wave Springs Designed for Additive Manufacturing. 3D Print. Addit. Manuf. 2022, 11, 94–114. [Google Scholar] [CrossRef]

- Hassan, I.M.; Enab, T.A.; Fouda, N.; Eldesouky, I. Design, Fabrication, and Evaluation of Functionally Graded Triply Periodic Minimal Surface Structures Fabricated by 3D Printing. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 66. [Google Scholar] [CrossRef]

- Li, C.; Lei, H.; Liu, Y.; Zhang, X.; Xiong, J.; Zhou, H.; Fang, D. Crushing Behavior of Multi-Layer Metal Lattice Panel Fabricated by Selective Laser Melting. Int. J. Mech. Sci. 2018, 145, 389–399. [Google Scholar] [CrossRef]

- Baranowski, P.; Płatek, P.; Antolak-Dudka, A.; Sarzyński, M.; Kucewicz, M.; Durejko, T.; Małachowski, J.; Janiszewski, J.; Czujko, T. Deformation of Honeycomb Cellular Structures Manufactured with Laser Engineered Net Shaping (LENS) Technology under Quasi-Static Loading: Experimental Testing and Simulation. Addit. Manuf. 2019, 25, 307–316. [Google Scholar] [CrossRef]

- Al-Saedi, D.S.J.; Masood, S.H.; Faizan-Ur-Rab, M.; Alomarah, A.; Ponnusamy, P. Mechanical Properties and Energy Absorption Capability of Functionally Graded F2BCC Lattice Fabricated by SLM. Mater. Des. 2018, 144, 32–44. [Google Scholar] [CrossRef]

- Zhang, L.; Feih, S.; Daynes, S.; Chang, S.; Wang, M.Y.; Wei, J.; Lu, W.F. Energy Absorption Characteristics of Metallic Triply Periodic Minimal Surface Sheet Structures under Compressive Loading. Addit. Manuf. 2018, 23, 505–515. [Google Scholar] [CrossRef]

- Kumar, S.; Ubaid, J.; Abishera, R.; Schiffer, A.; Deshpande, V.S. Tunable Energy Absorption Characteristics of Architected Honeycombs Enabled via Additive Manufacturing. ACS Appl. Mater. Interfaces 2019, 11, 42549–42560. [Google Scholar] [CrossRef]

- McGregor, D.J.; Tawfick, S.; King, W.P. Mechanical Properties of Hexagonal Lattice Structures Fabricated Using Continuous Liquid Interface Production Additive Manufacturing. Addit. Manuf. 2019, 25, 10–18. [Google Scholar] [CrossRef]

- Ingrole, A.; Hao, A.; Liang, R. Design and Modeling of Auxetic and Hybrid Honeycomb Structures for In-Plane Property Enhancement. Mater. Des. 2017, 117, 72–83. [Google Scholar] [CrossRef]

- Types of Springs and Their Uses-Grainger KnowHow. Available online: https://www.grainger.com/know-how/equipment/kh-types-springs?utm_source (accessed on 2 April 2025).

- Types of Springs and Their Applications-SMLease Design. Available online: https://www.smlease.com/entries/mechanism/types-of-springs-and-their-applications/ (accessed on 2 April 2025).

- Ali, M.; Nazir, A.; Jeng, J.Y. Mechanical Performance of Additive Manufactured Shoe Midsole Designed Using Variable-Dimension Helical Springs. Int. J. Adv. Manuf. Technol. 2020, 111, 3273–3292. [Google Scholar] [CrossRef]

- Wave Spring vs. Coil Spring|Smalley. Available online: https://www.smalley.com/blog/wave-spring-vs-coil-spring?utm_source (accessed on 10 April 2025).

- Smalley Wave Springs|Smalley. Available online: https://www.smalley.com/wave-springs (accessed on 9 March 2023).

- Fonte, M. Wave Spring for a Spinal Implant No. US9039766B1. Available online: https://patents.google.com/patent/US9039766B1/en (accessed on 10 March 2025).

- Le Vert, F.; Krafsur, D. Spring Cushioned Shoe-Google Patents. No. US20050126039A1. Available online: https://patents.google.com/patent/US20080209762A1/en (accessed on 15 April 2025).

- Custom Wave Spring Manufacturer|Teamco. Available online: https://www.teamco.com.tw/en/product/wave-springs.html (accessed on 2 March 2025).

- Haq, M.R.U.; Nazir, A.; Jeng, J.Y. Design for Additive Manufacturing of Variable Dimension Wave Springs Analyzed Using Experimental and Finite Element Methods. Addit. Manuf. 2021, 44, 102032. [Google Scholar] [CrossRef]

- Erfanian-Naziftoosi, H.R.; Shams, S.S.; Elhajjar, R. Composite Wave Springs: Theory and Design. Mater. Des. 2016, 95, 48–53. [Google Scholar] [CrossRef]

- Dragoni, E. A Contribution to Wave Spring Design. J. Strain Anal. Eng. Des. 2007, 23, 145–153. [Google Scholar] [CrossRef]

- Chaudhury, A.N.; Datta, D. Analysis of Prismatic Springs of Non-Circular Coil Shape and Non-Prismatic Springs of Circular Coil Shape by Analytical and Finite Element Methods. J. Comput. Des. Eng. 2017, 4, 178–191. [Google Scholar] [CrossRef]

- SOLIDWORKS. Available online: https://www.solidworks.com (accessed on 9 March 2023).

- HP 3D Jet Fusion 4200-Commercial & Industrial 3D Printer|HP® Official Site|HP® Official Site. Available online: https://www.hp.com/us-en/printers/3d-printers/products/multi-jet-fusion-4200.html (accessed on 20 March 2025).

- Cai, C.; Tey, W.S.; Chen, J.; Zhu, W.; Liu, X.; Liu, T.; Zhao, L.; Zhou, K. Comparative Study on 3D Printing of Polyamide 12 by Selective Laser Sintering and Multi Jet Fusion. J. Mater. Process. Technol. 2021, 288, 116882. [Google Scholar] [CrossRef]

- Polyamide 12 (PA 12)-3D Printing with Nylon Plastic|Fast Radius. Available online: https://www.fastradius.com/resources/polyamide-12/ (accessed on 9 March 2023).

- Introduction the Characteristics and Application of Nylon 12 (Polyamide 12/PA 12) Material|Over 40 Years of World-Class Wire & Cable Management Products Manufacturing|HUA WEI. Available online: https://www.hwlok.com/en/technical-info/Material-PA12.html (accessed on 30 January 2025).

- Materials Test Systems. Available online: https://www.mts.com/en/applications/materials/test-type/compression (accessed on 10 February 2025).

- Sun, P.C.; Wei, H.W.; Chen, C.H.; Wu, C.H.; Kao, H.C.; Cheng, C.K. Effects of Varying Material Properties on the Load Deformation Characteristics of Heel Cushions. Med. Eng. Phys. 2008, 30, 687–692. [Google Scholar] [CrossRef]

- Ansys|Engineering Simulation Software. Available online: https://www.ansys.com/ (accessed on 10 April 2025).

- Bai, J.; Song, J.; Wei, J. Tribological and Mechanical Properties of MoS2 Enhanced Polyamide 12 for Selective Laser Sintering. J. Mater. Process. Technol. 2019, 264, 382–388. [Google Scholar] [CrossRef]

- Habib, F.N.; Iovenitti, P.; Masood, S.H.; Nikzad, M. Fabrication of Polymeric Lattice Structures for Optimum Energy Absorption Using Multi Jet Fusion Technology. Mater. Des. 2018, 155, 86–98. [Google Scholar] [CrossRef]

- Lee, K.P.M.; Pandelidi, C.; Kajtaz, M. Build Orientation Effects on Mechanical Properties and Porosity of Polyamide-11 Fabricated via Multi Jet Fusion. Addit. Manuf. 2020, 36, 101533. [Google Scholar] [CrossRef]

- Sui, Q.; Fan, H.; Lai, C. Failure Analysis of 1D Lattice Truss Composite Structure in Uniaxial Compression. Compos. Sci. Technol. 2015, 118, 207–216. [Google Scholar] [CrossRef]

- Schenk, C.A.; Schuëller, G.I. Buckling Analysis of Cylindrical Shells with Cutouts Including Random Boundary and Geometric Imperfections. Comput. Methods Appl. Mech. Eng. 2007, 196, 3424–3434. [Google Scholar] [CrossRef]

| Design | Name of Coil Shape | Height (mm) | Weight (g) |

|---|---|---|---|

| D1 | Square | 21.2 | 13.87 |

| D2 | Rectangular | 21.6 | 14.36 |

| D3 | Pentagonal | 21.2 | 14.60 |

| D4 | Hexagonal | 21.2 | 14.67 |

| D5 | Heptagonal | 21.2 | 14.37 |

| D6 | Octagonal | 21.2 | 14.82 |

| D7 | Quadro | 24.4 | 13.36 |

| D8 | Circular (4 wave per coil) | 21.2 | 14.22 |

| D9 | Circular (6 wave per coil) | 21.7 | 14.25 |

| Design | CAD Height (mm) | Printed Height (mm) | Variation (%) | CAD Weight (g) | Printed Weight (g) | Variation (%) |

|---|---|---|---|---|---|---|

| D1 | 21.2 | 21.50 ± 0.03 | 1.4% | 13.87 | 14.07 ± 0.05 | 1.4% |

| D2 | 21.6 | 21.80 ± 0.03 | 0.9% | 14.36 | 14.55 ± 0.05 | 1.3% |

| D3 | 21.2 | 21.60 ± 0.03 | 1.9% | 14.60 | 14.94 ± 0.05 | 2.3% |

| D4 | 21.2 | 21.50 ± 0.03 | 1.4% | 14.67 | 14.72 ± 0.05 | 0.3% |

| D5 | 21.2 | 21.70 ± 0.03 | 2.4% | 14.37 | 14.49 ± 0.05 | 0.8% |

| D6 | 21.2 | 21.70 ± 0.03 | 2.4% | 14.82 | 15.36 ± 0.05 | 3.6% |

| D7 | 24.4 | 25.10 ± 0.03 | 2.9% | 13.36 | 13.66 ± 0.05 | 2.2% |

| D8 | 21.2 | 21.50 ± 0.03 | 1.4% | 14.22 | 14.51 ± 0.05 | 2.0% |

| D9 | 21.7 | 22.10 ± 0.03 | 1.8% | 14.25 | 14.60 ± 0.05 | 2.5% |

| Design | Total Height (mm) | Compressible Height (mm) | 90% of Compressible Height (mm) | Strain End Point |

|---|---|---|---|---|

| D1 | 21.50 ± 0.03 | 7.20 ± 0.03 | 6.50 ± 0.03 | 0.30 |

| D2 | 21.80 ± 0.03 | 7.20 ± 0.03 | 6.50 ± 0.03 | 0.30 |

| D3 | 21.60 ± 0.03 | 7.20 ± 0.03 | 6.50 ± 0.03 | 0.30 |

| D4 | 21.50 ± 0.03 | 7.20 ± 0.03 | 6.50 ± 0.03 | 0.30 |

| D5 | 21.70 ± 0.03 | 7.20 ± 0.03 | 6.50 ± 0.03 | 0.30 |

| D6 | 21.70 ± 0.03 | 7.20 ± 0.03 | 6.50 ± 0.03 | 0.30 |

| D7 | 25.10 ± 0.03 | 7.00 ± 0.03 | 6.30 ± 0.03 | 0.25 |

| D8 | 21.50 ± 0.03 | 7.20 ± 0.03 | 6.50 ± 0.03 | 0.30 |

| D9 | 22.10 ± 0.03 | 5.70 ± 0.03 | 5.20 ± 0.03 | 0.23 |

| Mesh Size (mm) | Equivalent Stress (MPa) | Change % | Nodes | Elements |

|---|---|---|---|---|

| 1. | 50.413 | 57,573 | 33,360 | |

| 2. | 50.735 | 9.25 | 120,851 | 74,434 |

| 3. | 51.048 | 6.46 | 184,438 | 115,809 |

| 4. | 51.361 | 5.31 | 248,136 | 157,283 |

| 5. | 52.584 | 2.19 | 311,123 | 198,057 |

| Design | Energy | ||||||

|---|---|---|---|---|---|---|---|

| 1st Cycle | 10th Cycle | (Cycle 1st–10th) | |||||

| Applied (mm2) | Released (mm2) | Loss (%) | Applied (mm2) | Released (mm2) | Loss (%) | Loss (%) | |

| D1 | 0.23 | −0.15 | 35 | 0.16 | −0.13 | 18 | 17 |

| D2 | 0.31 | −0.19 | 39 | 0.22 | −0.17 | 21 | 17 |

| D3 | 0.66 | −0.35 | 47 | 0.41 | −0.31 | 25 | 21 |

| D4 | 0.87 | −0.41 | 52 | 0.51 | −0.36 | 28 | 24 |

| D5 | 1.75 | −0.61 | 65 | 0.79 | −0.51 | 35 | 30 |

| D6 | 1.99 | −0.74 | 63 | 0.94 | −0.62 | 34 | 29 |

| D7 | 0.25 | −0.15 | 40 | 0.17 | −0.13 | 23 | 17 |

| D8 | 0.41 | −0.25 | 40 | 0.28 | −0.21 | 22 | 17 |

| D9 | 0.84 | −0.40 | 52 | 0.47 | −0.34 | 27 | 24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, G.J.; Haq, M.R.u.; Jeng, J.-Y. Design and Investigation of Mechanical Properties of Additively Manufactured Novel Coil-Shaped Wave Springs. Appl. Mech. 2025, 6, 61. https://doi.org/10.3390/applmech6030061

Shah GJ, Haq MRu, Jeng J-Y. Design and Investigation of Mechanical Properties of Additively Manufactured Novel Coil-Shaped Wave Springs. Applied Mechanics. 2025; 6(3):61. https://doi.org/10.3390/applmech6030061

Chicago/Turabian StyleShah, Gul Jamil, Muhammad Rizwan ul Haq, and Jeng-Ywan Jeng. 2025. "Design and Investigation of Mechanical Properties of Additively Manufactured Novel Coil-Shaped Wave Springs" Applied Mechanics 6, no. 3: 61. https://doi.org/10.3390/applmech6030061

APA StyleShah, G. J., Haq, M. R. u., & Jeng, J.-Y. (2025). Design and Investigation of Mechanical Properties of Additively Manufactured Novel Coil-Shaped Wave Springs. Applied Mechanics, 6(3), 61. https://doi.org/10.3390/applmech6030061