Two-Material-Based Transtibial Socket Designs for Enhanced Load-Bearing Capacity Using FEA

Abstract

1. Introduction

2. Materials and Methods

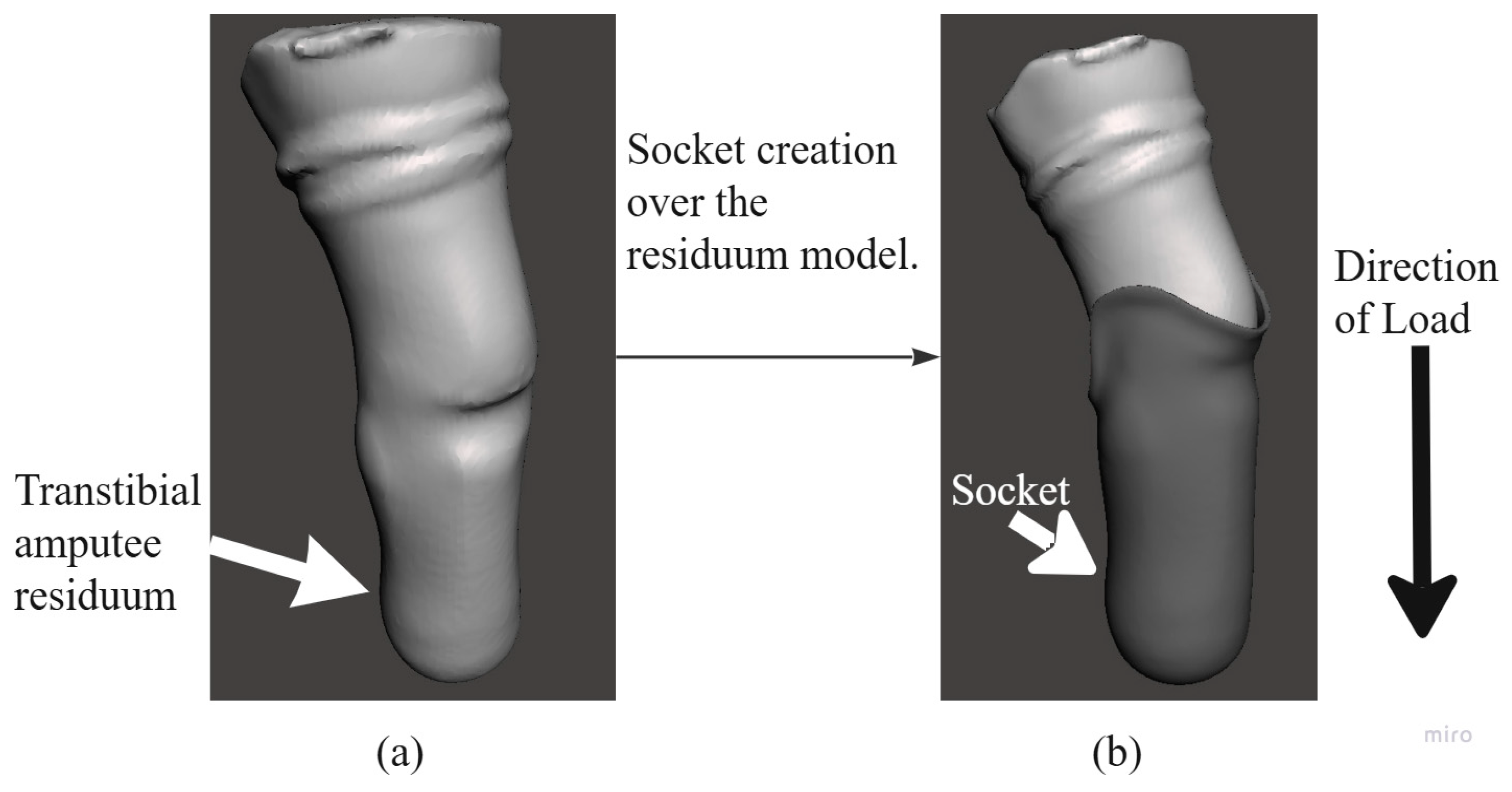

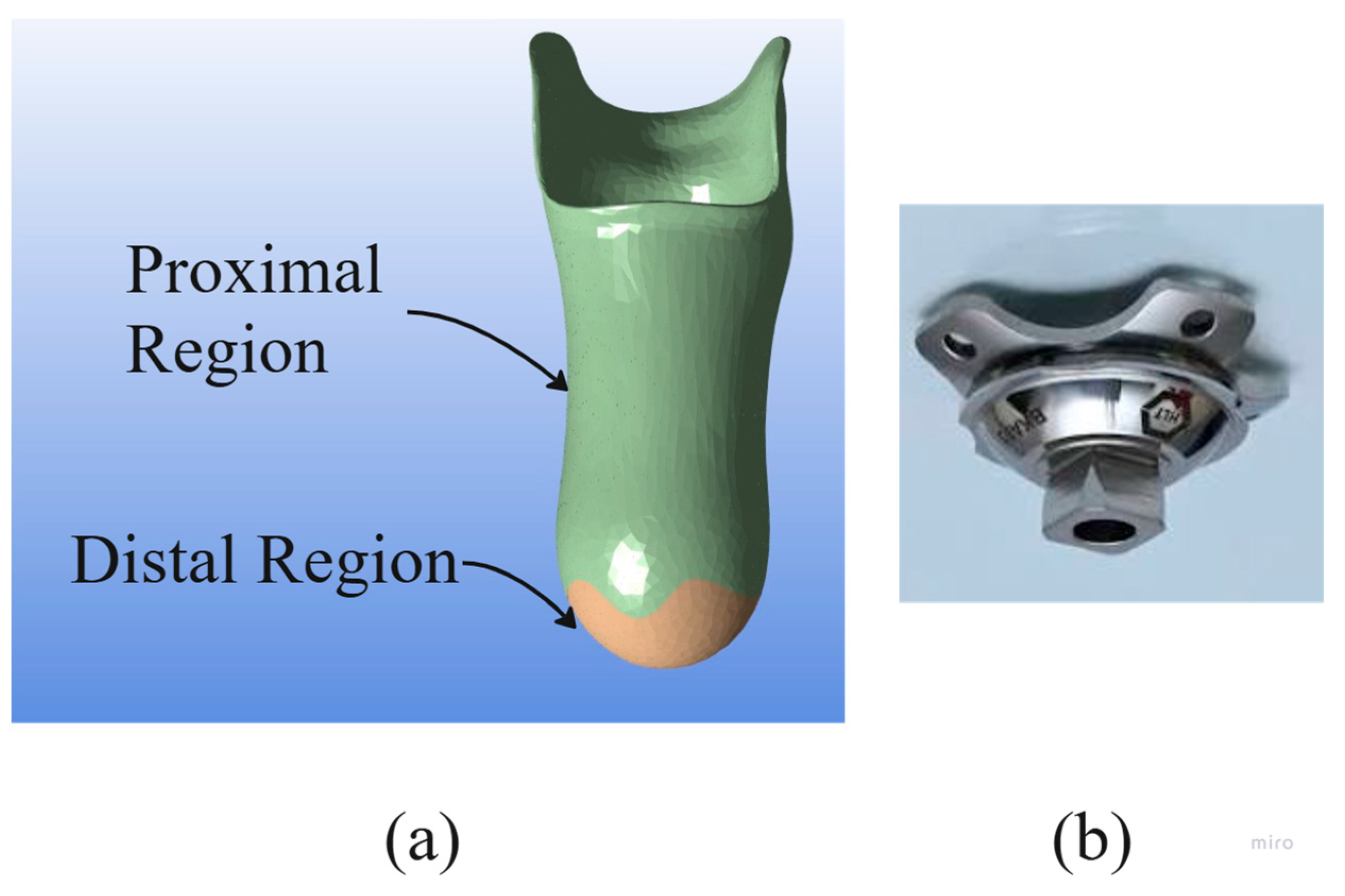

2.1. Transtibial Socket Design

2.2. Materials for Socket Design and Manufacturing

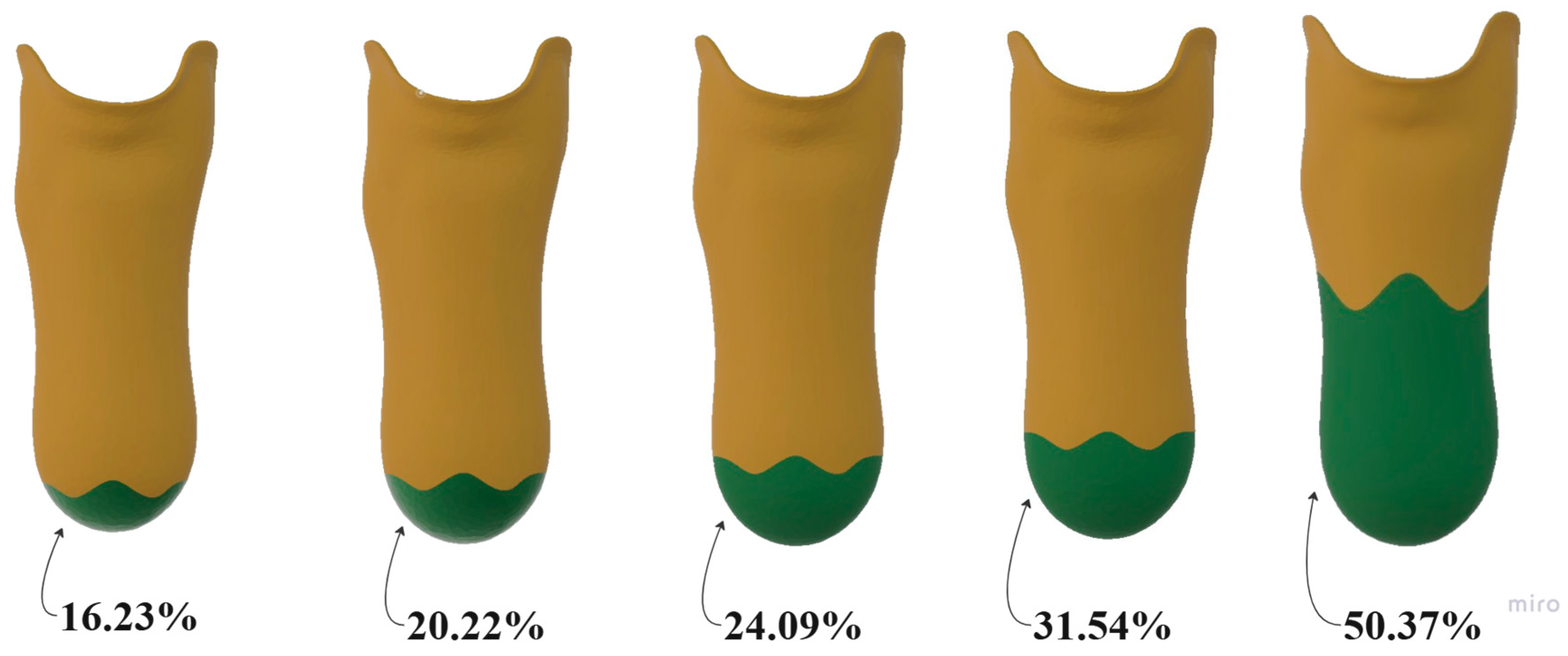

2.3. Two-Material Hybrid for Socket Design

3. Results

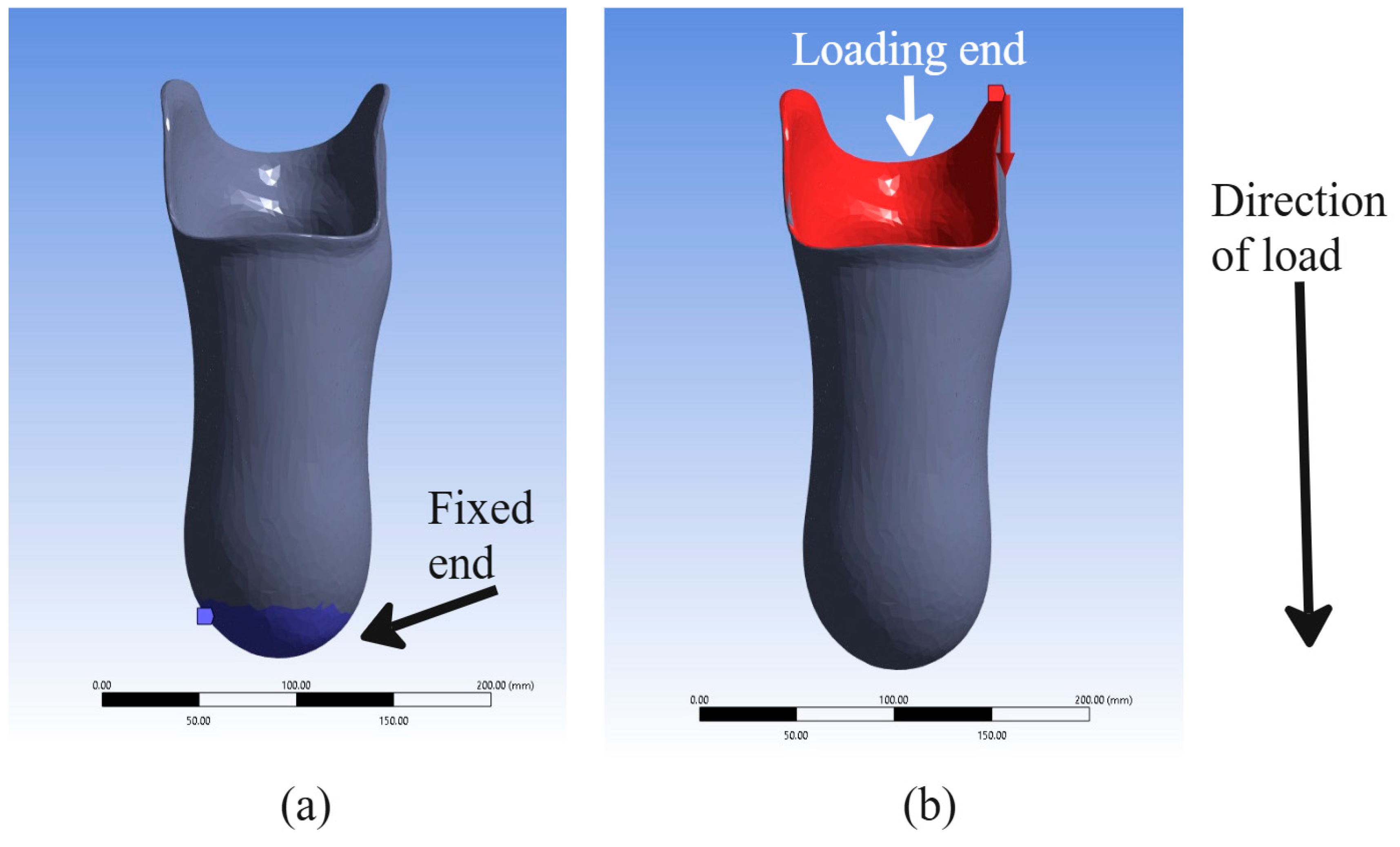

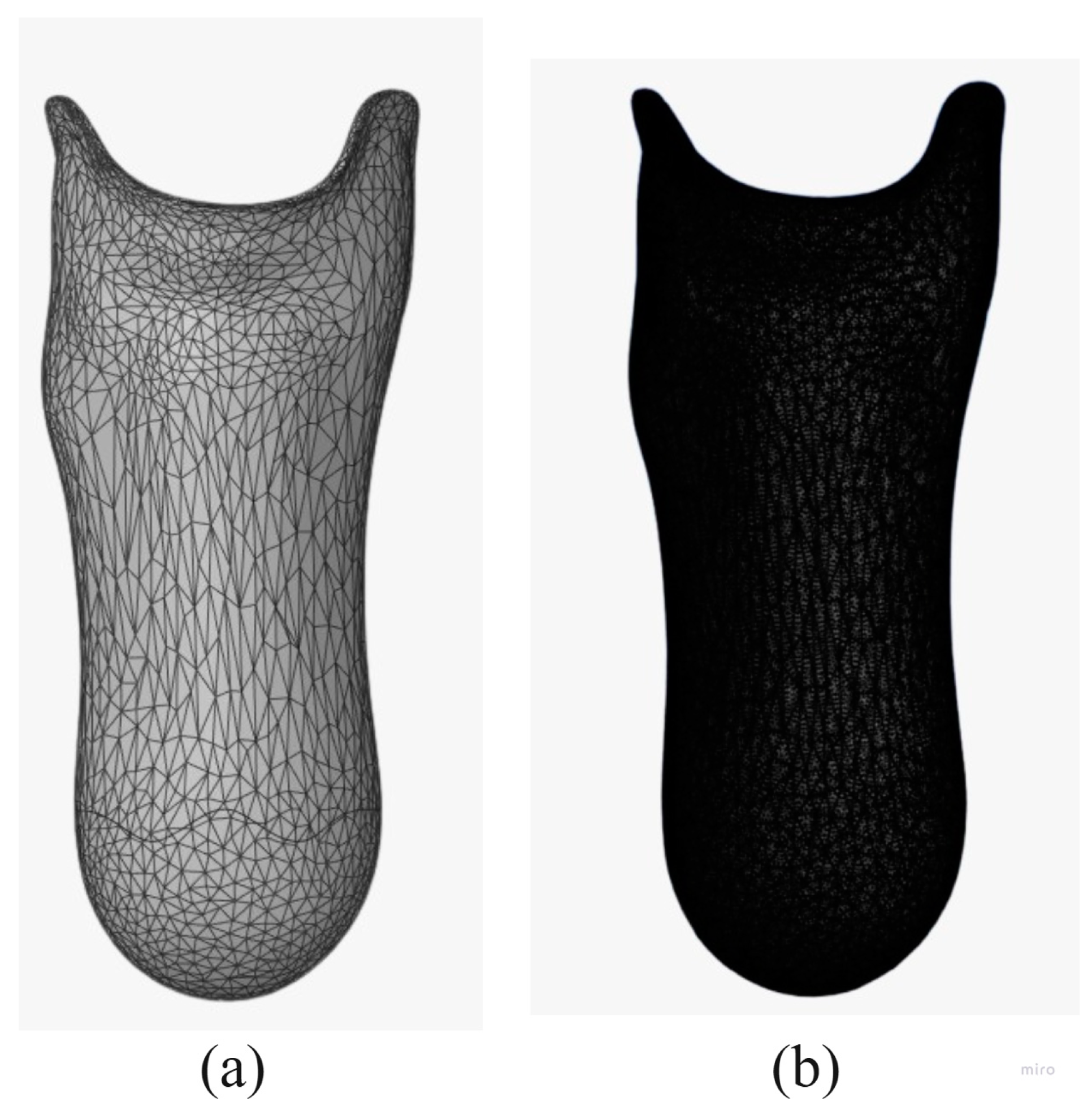

3.1. Finite Element Method (FEM)

3.2. Boundary Conditions

3.3. FEA

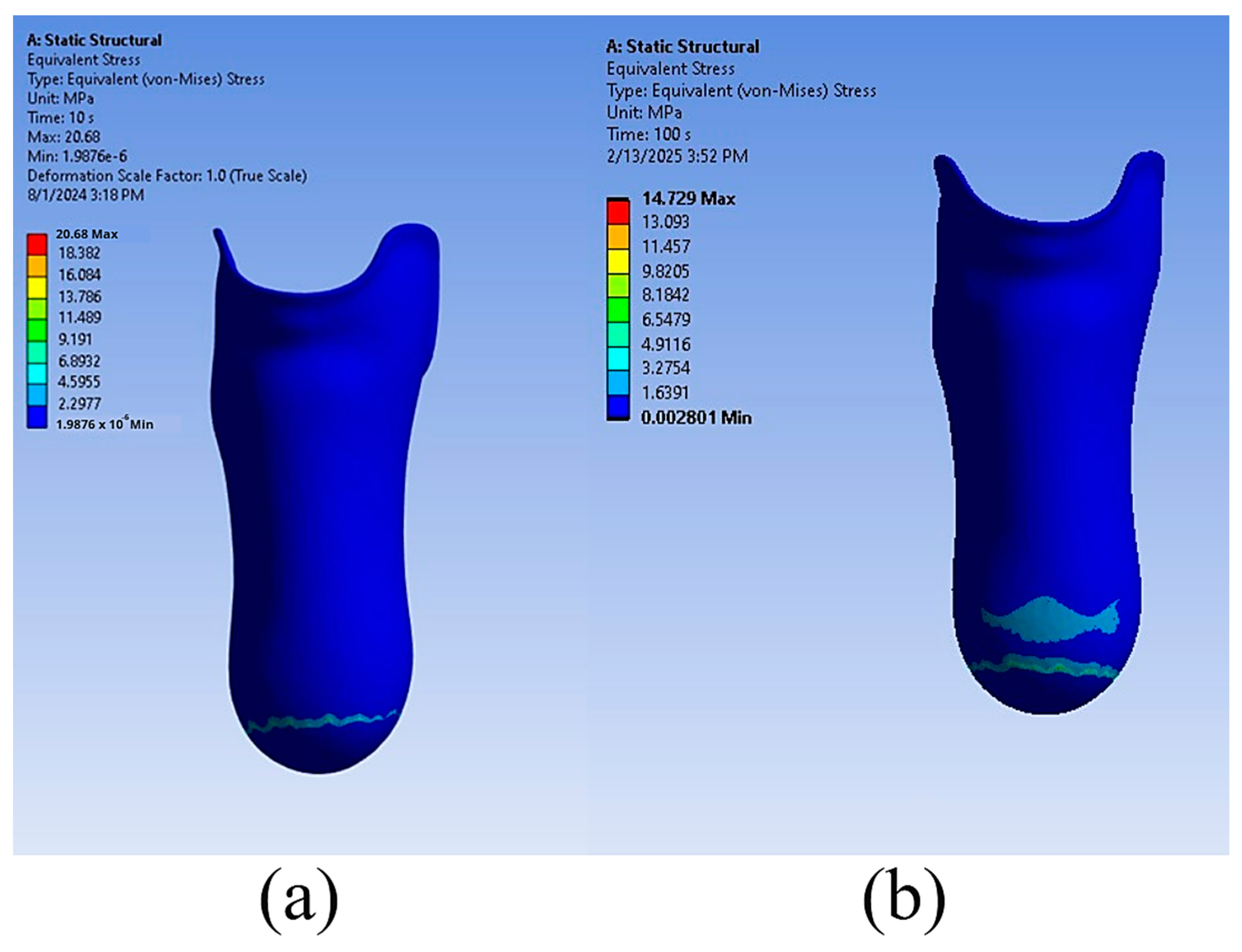

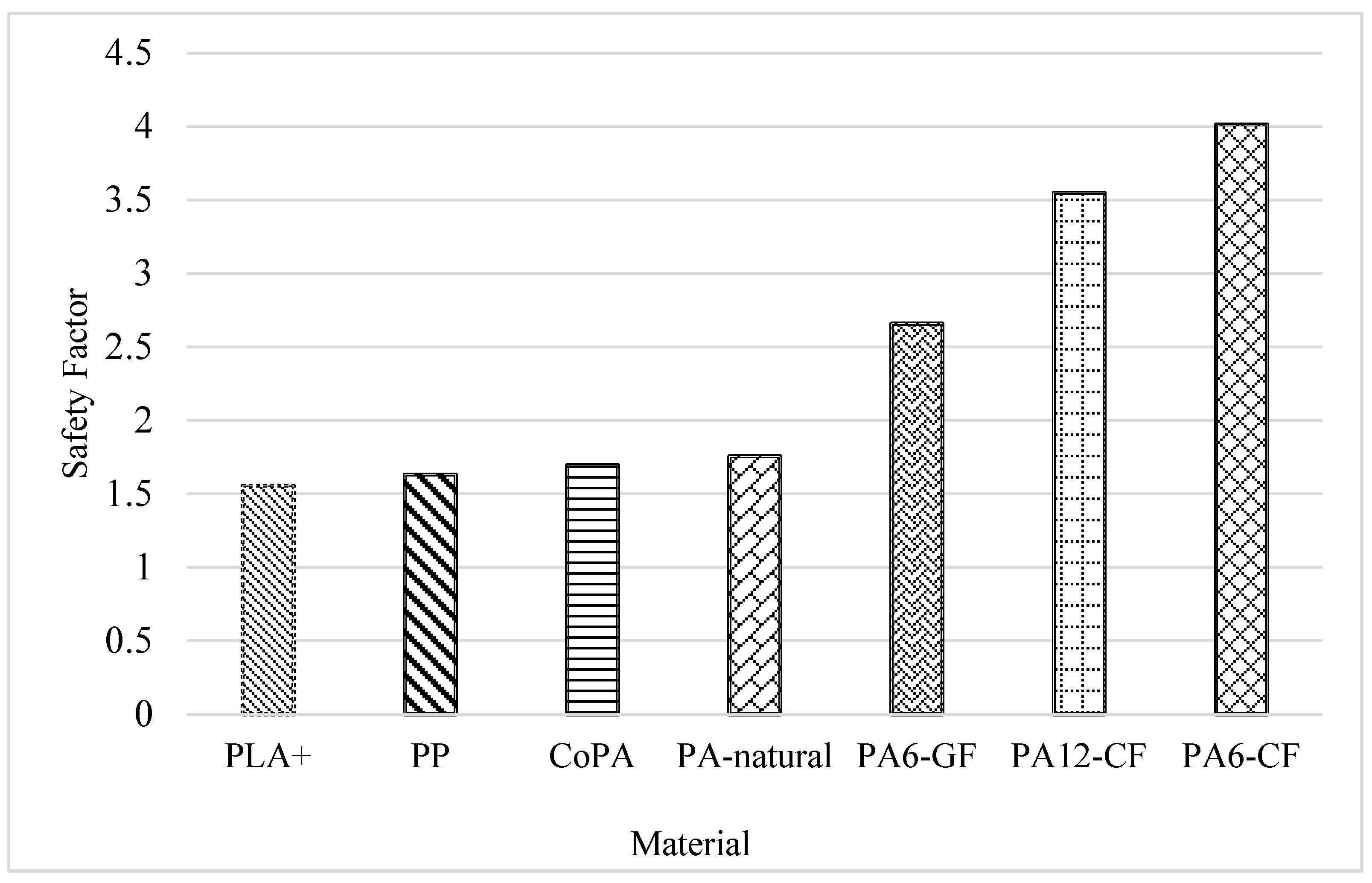

3.3.1. Single-Material Analysis

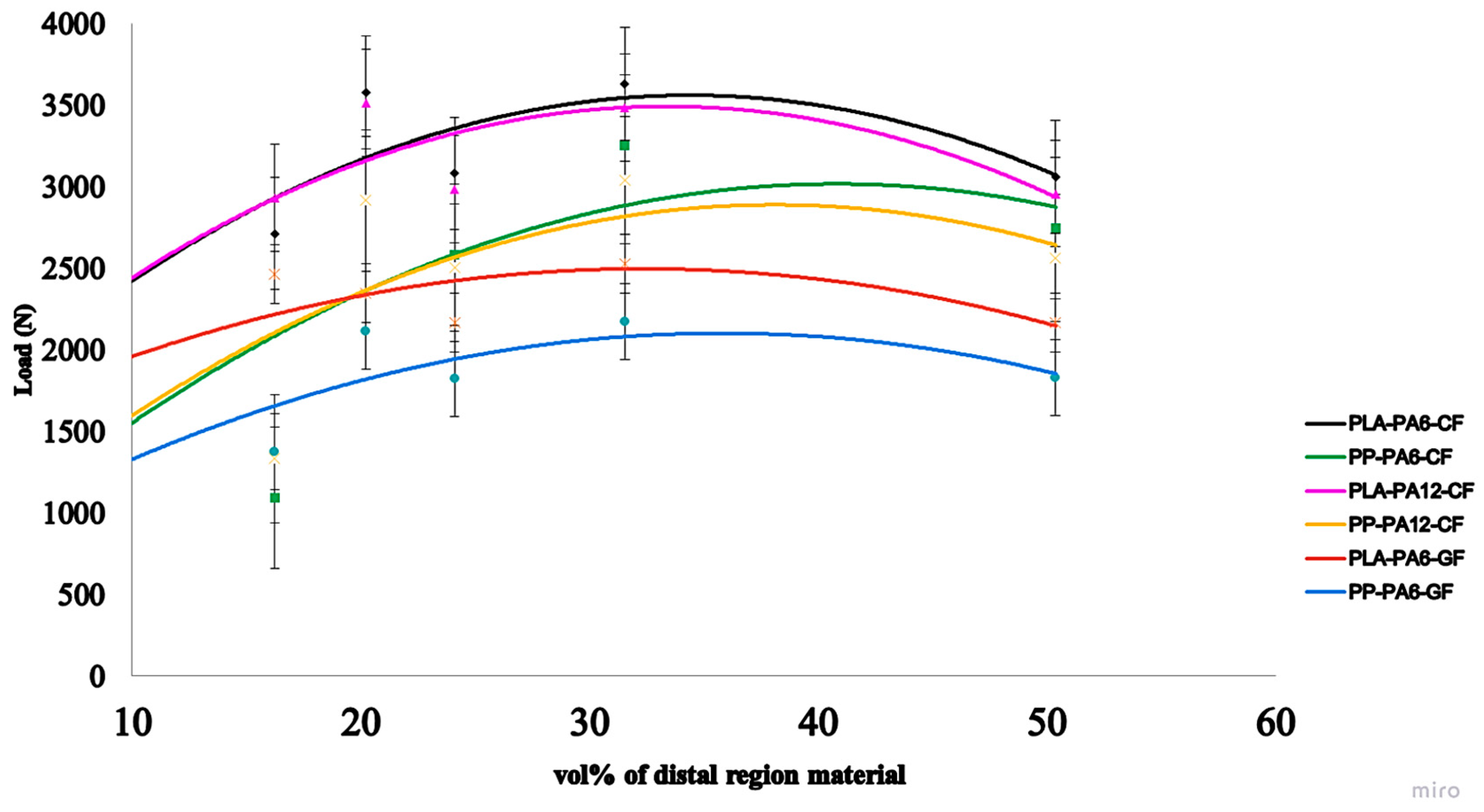

3.3.2. Two-Material Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| PP | Polypropylene |

| PLA+ | Polylactic-acid-plus |

| PA | Polyamide |

| PA6-GF | Polyamide-6-Glass-Fiber |

| CoPA | Polyamide-copolymer |

| PA6-CF | Polyamide-6-Carbon-Fiber |

| PA12-CF | Polyamide-12-Carbon-Fiber |

| FEA | Finite Element Analysis |

| FDM | Fused Deposition Modeling |

| CAD | Computer-Aided Design |

| FEM | Finite Element Method |

References

- Krishnan, A.A.; Ghyar, R.; Ravi, B. Comparison of four modular TKA prosthesis designs using static finite element analysis. J. Comput. Methods Sci. Eng. 2017, 17, 315–320. [Google Scholar] [CrossRef]

- Ezzatvar, Y.; García-Hermoso, A. Global estimates of diabetes-related amputations incidence in 2010–2020: A systematic review and meta-analysis. Diabetes Res. Clin. Pract. 2023, 195, 110194. [Google Scholar] [CrossRef]

- Moxey, P.W.; Gogalniceanu, P.; Hinchliffe, R.J.; Loftus, I.M.; Jones, K.J.; Thompson, M.M.; Holt, P.J. Lower extremity amputations—A review of global variability in incidence. Diabet. Med. 2011, 28, 1144–1153. [Google Scholar] [CrossRef] [PubMed]

- Ramlee, M.H.; Ammarullah, M.I.; Sukri, N.S.M.; Hassan, N.S.F.; Baharuddin, M.H.; Kadir, M.R.A. Investigation on three-dimensional printed prosthetics leg sockets coated with different reinforcement materials: Analysis on mechanical strength and microstructural. Sci. Rep. 2024, 14, 6842. [Google Scholar] [CrossRef]

- Al-Khazraji, K.; Kadhim, J.; Ahmed, P.S. Tensile and Fatigue Characteristics of Lower-Limb Prosthetic Socket Made from Composite Materials. In Proceedings of the 2012 International Conference on Industrial Engineering and Operations Management, Istanbul, Turkey, 3–6 July 2012. [Google Scholar]

- Manz, S.; Valette, R.; Damonte, F.; Gaudio, L.A.; Gonzalez-Vargas, J.; Sartori, M.; Dosen, S.; Rietman, J. A review of user needs to drive the development of lower limb prostheses. J. Neuroeng. Rehabil. 2022, 19, 119. [Google Scholar] [CrossRef]

- Waller-Cotterhill, C. Experimental Reconstruction of a Nineteenth Century Lower Limb Prosthetic Peg Leg—The Box Leg. EXARC J. 2018. Available online: https://exarc.net/ark:/88735/10365 (accessed on 10 March 2025).

- Gariboldi, F.; Scapinello, M.; Petrone, N.; Migliore, G.L.; Teti, G.; Cutti, A.G. Static strength of lower-limb prosthetic sockets: An exploratory study on the influence of stratigraphy, distal adapter and lamination resin. Med. Eng. Phys. 2023, 114, 103970. [Google Scholar] [CrossRef]

- Rai, P.; Jankiraman, V.; Teacher, M.; Velu, R.; Kumar, S.A.; Binedell, T.; Subburaj, K. Design and optimization of a 3D printed prosthetic socket for transtibial amputees. Mater. Today Proc. 2022, 70, 454–464. [Google Scholar] [CrossRef]

- Prosthetic Management: Overview, Methods, and Materials|O&P Virtual Library. Available online: http://www.oandplibrary.org/alp/chap04-01.asp (accessed on 12 February 2025).

- Pirouzi, G.; Abu Osman, N.A.; Eshraghi, A.; Ali, S.; Gholizadeh, H.; Abas, W.W. Review of the socket design and interface pressure measurement for transtibial prosthesis. Sci. World J. 2014, 2014, 849073. [Google Scholar] [CrossRef]

- Baldock, M.; Pickard, N.; Prince, M.; Kirkwood, S.; Chadwell, A.; Howard, D.; Dickinson, A.; Kenney, L.; Gill, N.; Curtin, S. Adjustable prosthetic sockets: A systematic review of industrial and research design characteristics and their justifications. J. Neuroeng. Rehabil. 2023, 20, 147. [Google Scholar] [CrossRef]

- Aimar, A.; Palermo, A.; Innocenti, B. The Role of 3D Printing in Medical Applications: A State of the Art. J. Healthc. Eng. 2019, 2019, 5340616. [Google Scholar] [CrossRef]

- Jweeg, M.; Radhi, S.; Al-Shuka, H. An Experimental comparative study between polypropylene and laminated lower limb prosthetic socket. Al-Khwarizmi Eng. J. 2007, 3, 40–47. [Google Scholar]

- Jindal, P.; Prakash, P.; Bassal, H.; Kumar, K.; Singh, P.; Din, M.A.M.; Barnett, C. Mechanical characterization of Lower Limb 3D printed socket materials under static external loading. Trans. Addit. Manuf. Meets Med. 2024, 6, 1885. [Google Scholar] [CrossRef]

- Marinopoulos, T.; Li, S.; Silberschmidt, V.V. AM lower-limb prosthetic socket: Using FEA for improved mechanical performance. Mater. Today Proc. 2022, 70, 499–503. [Google Scholar] [CrossRef]

- Myers, J.; Phillips, D. Characterization of 3D Printed Lattice Structures Used in the Design of Modified Compression Release Stabilized Transhumeral Prosthetic Sockets. Ph.D. Thesis, Kate Gleason College of Engineering, Rochester, NY, USA, 2023. [Google Scholar]

- Chiad, J.S.; Tahir, M.S.A.-D. A Suggested New Material to Manufacture Above-Knee Prosthetic Socket Using the Lamination of Monofilament, Cotton and Perlon Fibers. Al-Nahrain J. Eng. Sci. 2017, 20, 832–837. [Google Scholar]

- Irawan, A.P. Mechanical Characteristics Rattan Fiber Reinforced Epoxy Composites (RECO) as Above Knee Socket Prosthesis Materials. 2011. Available online: https://www.researchgate.net/publication/299409869 (accessed on 12 December 2024).

- Mechi, S.A.; Al-Waily, M. International Journal of Energy and Environment Manufacturing and Mechanical Behavior Investigation of Prosthetic Below Knee Socket by Using Natural Kenaf Fiber. 2021. Available online: www.IJEE.IEEFoundation.org (accessed on 12 December 2024).

- Wilson, A.B. Standards for lower limb prostheses. Prosthet. Orthot. Int. 1979, 3, 44–45. [Google Scholar] [CrossRef][Green Version]

- Peyer, K.E.; Brassey, C.A.; Rose, K.A.; Sellers, W.I. Locomotion pattern and foot pressure adjustments during gentle turns in healthy subjects. J. Biomech. 2017, 60, 65–71. [Google Scholar] [CrossRef]

- Kunishima, T.; Nagai, Y.; Nagai, S.; Kurokawa, T.; Bouvard, G.; Abry, J.-C.; Fridrici, V.; Kapsa, P. Effects of glass fiber properties and polymer molecular mass on the mechanical and tribological properties of a polyamide-66-based composite in contact with carbon steel under grease lubrication. Wear 2020, 462–463, 203500. [Google Scholar] [CrossRef]

- Sunderland, F.E.; Bramley, J.L.; Al-Dirini, R.M.A.; Steer, J.W.; Worsley, P.R.; Dickinson, A.S. OpenLimb: An Open Source Transtibial Residual Limb Model for Simulation and Design. In Proceedings of the International Society for Prosthetics & Orthotics (ISPO) World Congress 2023: The Art and the Science, Guadalajara, Mexico, 24–27 April 2023; International Society for Prosthetics and Orthotics: Copenhagen, Denmark, 2023; Volume 47. Available online: http://eprints.soton.ac.uk/id/eprint/474951 (accessed on 10 March 2025).

- Lenka, P.K.; Choudhury, A.R. Analysis of trans tibial prosthetic socket materials using finite element method. J. Biomed. Sci. Eng. 2011, 4, 762–768. [Google Scholar] [CrossRef]

- Rwei, S.-P.; Tseng, Y.-C.; Chiu, K.-C.; Chang, S.-M.; Chen, Y.-M. The crystallization kinetics of Nylon 6/6T and Nylon 66/6T copolymers. Thermochim. Acta 2013, 555, 37–45. [Google Scholar] [CrossRef]

- Polypropylene—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/materials-science/polypropylene (accessed on 15 December 2024).

- Sin, L.T.; Tueen, B.S. Eco-profile of plastics. In Plastics and Sustainability; Elsevier: Amsterdam, The Netherlands, 2023; pp. 45–89. [Google Scholar] [CrossRef]

- BASF, BASF PP. Available online: https://move.forward-am.com/hubfs/AES%20Documentation/Standard%20Filaments/PP/TDS/Ultrafuse_PP_TDS_EN_v4.0.pdf (accessed on 22 December 2024).

- Polymaker, PolyTerraTM PLA+ Filament. Available online: https://polymaker.com/wp-content/uploads/lana-downloads/PolyTerra-PLA-EN_V5.3.pdf (accessed on 22 December 2024).

- BASF, BASF PA Natural. Available online: https://move.forward-am.com/hubfs/AES%20Documentation/Engineering%20Filaments/PA/TDS/Ultrafuse_PA_TDS_EN_v2.2.pdf (accessed on 22 December 2024).

- Polymaker, PolyMide_PA6_GF_TDS_V5.1. Available online: https://polymaker.com/wp-content/uploads/lana-downloads/PolyMide_PA6_GF_TDS_V5.1.pdf (accessed on 22 December 2024).

- Polymaker, PolyMide_CoPA_TDS_V5.2. Available online: https://polymaker.com/wp-content/uploads/lana-downloads/PolyMide_CoPA_TDS_V5.2.pdf (accessed on 22 December 2024).

- Polymaker, PolyMide_PA6_CF_TDS_V5.2. Available online: https://polymaker.com/wp-content/uploads/lana-downloads/PolyMide_PA6_CF_TDS_V5.2.pdf (accessed on 22 December 2024).

- Polymaker, PolyMide_PA12_CF_TDS_V5.1.1. Available online: https://polymaker.com/wp-content/uploads/lana-downloads/PolyMide_PA12_CF_TDS_V5.1.1.pdf (accessed on 22 December 2024).

- Haque, M.S.; Siddiqui, M.A. Plastic Welding: Important Facts and Developments. Am. J. Mech. Ind. Eng. 2016, 1, 15–19. [Google Scholar] [CrossRef]

- Patil, H.; Jeyakarthikeyan, P.V. Mesh convergence study and estimation of discretization error of hub in clutch disc with integration of ANSYS. IOP Conf. Ser. Mater. Sci. Eng. 2018, 402, 012065. [Google Scholar] [CrossRef]

- Zhou, H. Direct Solver for Large Sparse Linear Systems of Equations. Available online: https://www.wias-berlin.de/people/john/BETREUUNG/bachelor_zhou.pdf (accessed on 11 February 2025).

- Choosing a Solver for FEM: Direct or Iterative?|SimScale. Available online: https://www.simscale.com/blog/how-to-choose-solvers-for-fem/ (accessed on 11 February 2025).

- Gould, N.I.M.; Scott, J.A.; Hu, Y. A Numerical Evaluation of Sparse Direct Solvers for the Solution of Large Sparse Symmetric Linear Systems of Equations. ACM Trans. Math. Softw. 2007, 33, 10-es. [Google Scholar] [CrossRef]

- ANSYS, Introduction to Contact. Available online: https://innovationspace.ansys.com/courses/wp-content/uploads/sites/5/2019/05/2.5.1-Introduction-on-contact_New_Template_Master.pdf (accessed on 12 February 2025).

- Elanchezhian, C.; Ramnath, B.V.; Hemalatha, J. Mechanical Behaviour of Glass and Carbon Fibre Reinforced Composites at Varying Strain Rates and Temperatures. Procedia Mater. Sci. 2014, 6, 1405–1418. [Google Scholar] [CrossRef]

- Gregor-Svetec, D. Polymers in printing filaments. In Polymers for 3D Printing: Methods, Properties, and Characteristics; William Andrew Publishing: Norwich, NY, USA, 2022; pp. 155–269. [Google Scholar] [CrossRef]

- Jia, X.; Hao, K.; Luo, Z.; Fan, Z. Plastic Deformation Behavior of Metal Materials: A Review of Constitutive Models. Metals 2022, 12, 2077. [Google Scholar] [CrossRef]

- Palaniyappan, S.; Sivakumar, N.K.; Bodaghi, M.; Kumar, M.; Rahaman, M. A feasibility study of various joining techniques for three-dimensional printed polylactic acid and wood-reinforced polylactic acid biocomposite. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 238, 475–480. [Google Scholar] [CrossRef]

- Li, X.; Qu, P.; Kong, H.; Lei, Y.; Guo, A.; Wang, S.; Wan, Y.; Takahashi, J. Enhanced mechanical properties of sandwich panels via integrated 3D printing of continuous fiber face sheet and TPMS core. Thin-Walled Struct. 2024, 204, 112312. [Google Scholar] [CrossRef]

- Li, X.; Qu, P.; Kong, H.; Zhu, Y.; Hua, C.; Guo, A.; Wang, S. Multi-scale numerical analysis of damage modes in 3D stitched composites. Int. J. Mech. Sci. 2024, 266, 108983. [Google Scholar] [CrossRef]

| S. No. | Material | Density (g/cm3) | Tensile Strength (MPa) | Young’s Modulus (MPa) | Cost (USD/gram) |

|---|---|---|---|---|---|

| 1. | PP sheet | 0.903 | 29.4 | 1383 | 0.00745 |

| 2. | PP filament [29] | 0.911 | 15.5 | 541 | 0.06953 |

| 3. | PLA+ filament [30] | 1.24 | 31.1 | 2245.9 | 0.02384 |

| 4. | PA Natural filament [31] | 1.115 | 32.2 | 2419 | 0.09216 |

| 5. | PA6-GF filament [32] | 1.2 | 50.8 | 2053 | 0.07272 |

| 6. | CoPA filament [33] | 1.12 | 31.4 | 1053 | 0.05699 |

| 7. | PA6-CF filament [34] | 1.17 | 81.7 | 5666 | 0.08548 |

| 8. | PA12-CF filament [35] | 1.06 | 73.4 | 3054 | 0.16369 |

| S. No. | Material | Maximum von Mises Stress (MPa) | Maximum von Mises Strain | Tensile Yield Strength (MPa) | Cost (USD/gram) |

|---|---|---|---|---|---|

| 1. | PLA+ | 19.99 | 0.0116 | 31.1 | 0.02384 |

| 2. | PP | 18.01 | 0.0167 | 29.4 | 0.06953 |

| 3. | CoPA | 18.52 | 0.023 | 31.4 | 0.05699 |

| 4. | PA-Natural | 18.33 | 0.060 | 32.2 | 0.09216 |

| 5. | PA6-GF | 19.11 | 0.012 | 50.8 | 0.07272 |

| 6. | PA12-CF | 20.68 | 0.009 | 73.4 | 0.16369 |

| 7. | PA6-CF | 20.35 | 0.005 | 81.7 | 0.08548 |

| S. No. | Material | Activity Type | ||

|---|---|---|---|---|

| Minimal Walking/Indoors | Normal Activities of Daily Living | Running/Extreme Activities | ||

| 1. | PLA+ | Yes | No | No |

| 2. | PA6-CF | Yes | Yes | Yes |

| 3. | PA12-CF | Yes | Yes | Yes |

| 4. | PA-Natural | Yes | No | No |

| 5. | CoPA | Yes | No | No |

| 6. | PA6-GF | Yes | Yes | No |

| 7. | PLA+-PA6-CF | Yes | Yes | Yes |

| 8. | PP-PA6-CF | Yes | Yes | Yes |

| 9. | PLA+-PA12-CF | Yes | Yes | Yes |

| 10. | PP-PA12-CF | Yes | Yes | Yes |

| 11. | PLA+-PA6-GF | Yes | Yes | No |

| 12. | PP-PA6-GF | Yes | Yes | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jindal, P.; Prakash, P.; Bassal, H.; Singh, P.; Din, M.A.M.; Barnett, C.T.; Breedon, P. Two-Material-Based Transtibial Socket Designs for Enhanced Load-Bearing Capacity Using FEA. Prosthesis 2025, 7, 30. https://doi.org/10.3390/prosthesis7020030

Jindal P, Prakash P, Bassal H, Singh P, Din MAM, Barnett CT, Breedon P. Two-Material-Based Transtibial Socket Designs for Enhanced Load-Bearing Capacity Using FEA. Prosthesis. 2025; 7(2):30. https://doi.org/10.3390/prosthesis7020030

Chicago/Turabian StyleJindal, Prashant, Prashant Prakash, Harsh Bassal, Prashant Singh, Muhammad Arsh M. Din, Cleveland T. Barnett, and Philip Breedon. 2025. "Two-Material-Based Transtibial Socket Designs for Enhanced Load-Bearing Capacity Using FEA" Prosthesis 7, no. 2: 30. https://doi.org/10.3390/prosthesis7020030

APA StyleJindal, P., Prakash, P., Bassal, H., Singh, P., Din, M. A. M., Barnett, C. T., & Breedon, P. (2025). Two-Material-Based Transtibial Socket Designs for Enhanced Load-Bearing Capacity Using FEA. Prosthesis, 7(2), 30. https://doi.org/10.3390/prosthesis7020030