Controlling a Below-the-Elbow Prosthetic Arm Using the Infinity Foot Controller

Abstract

:1. Introduction

2. Materials and Methods

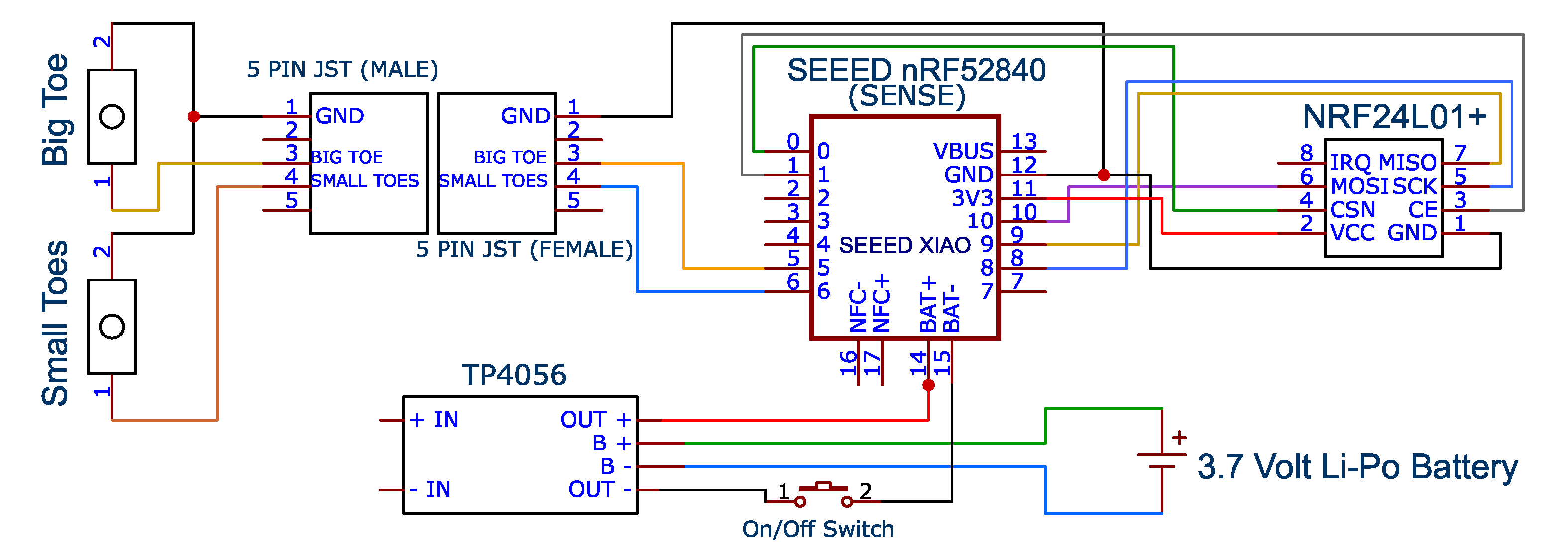

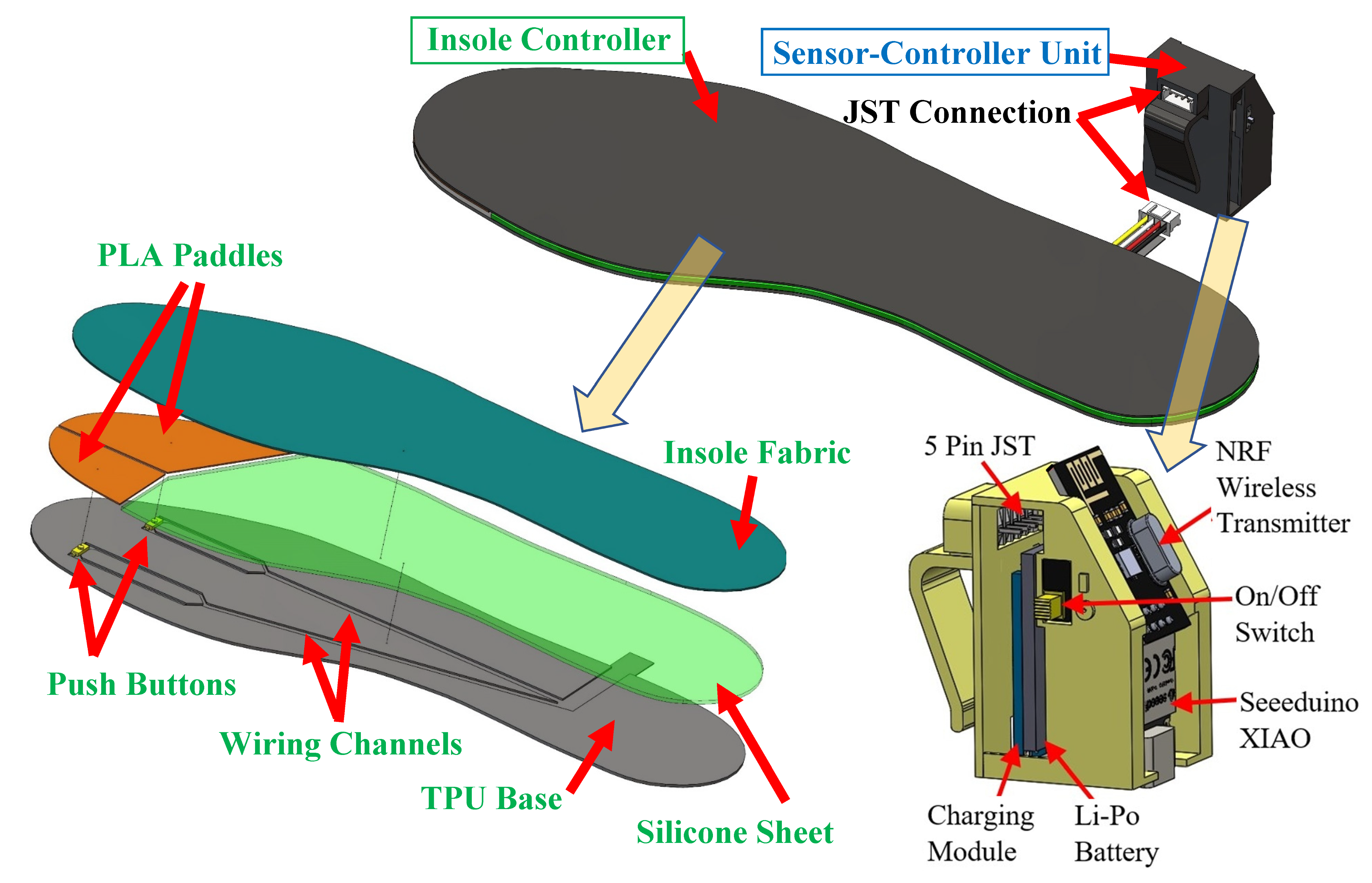

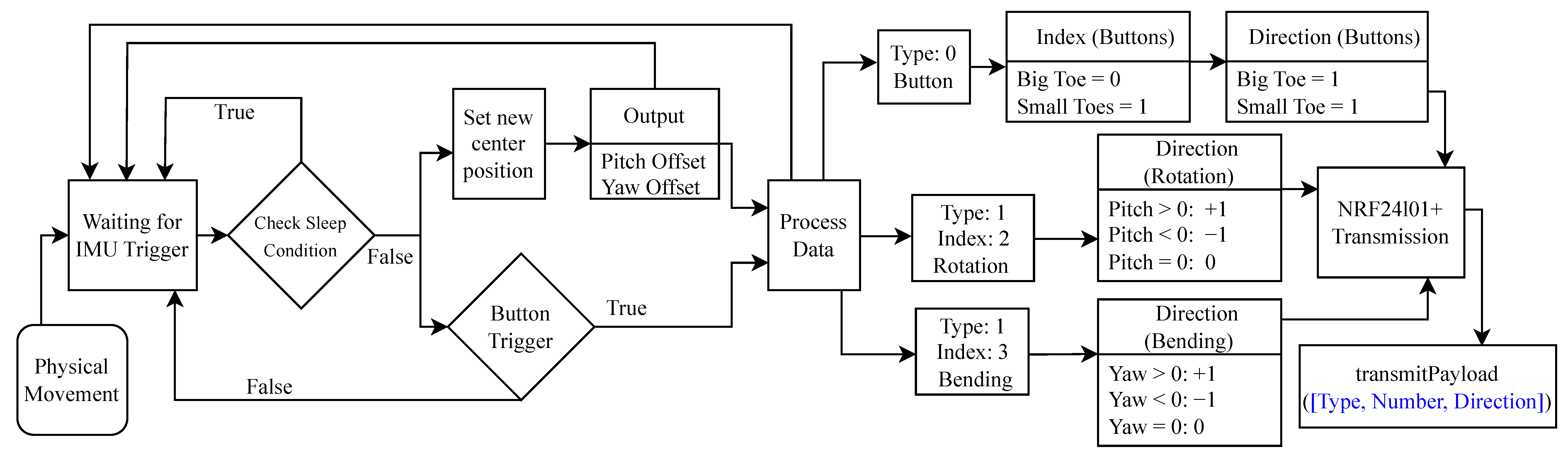

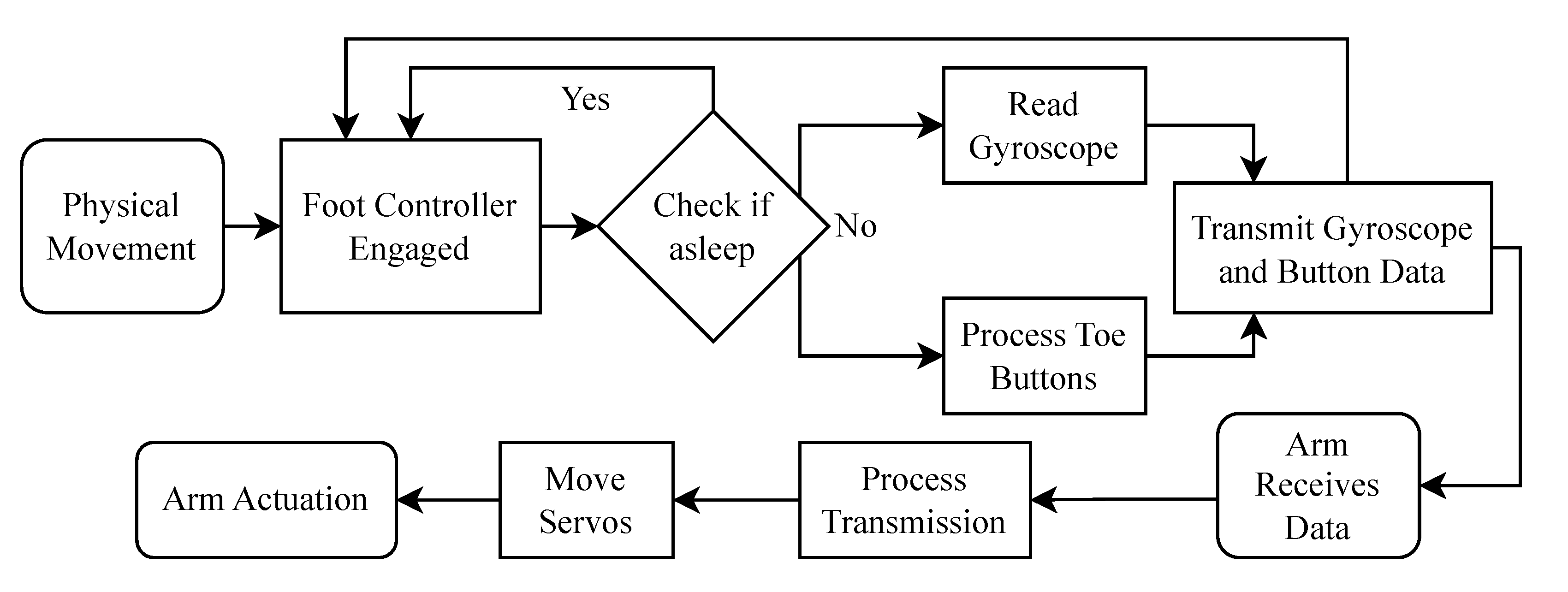

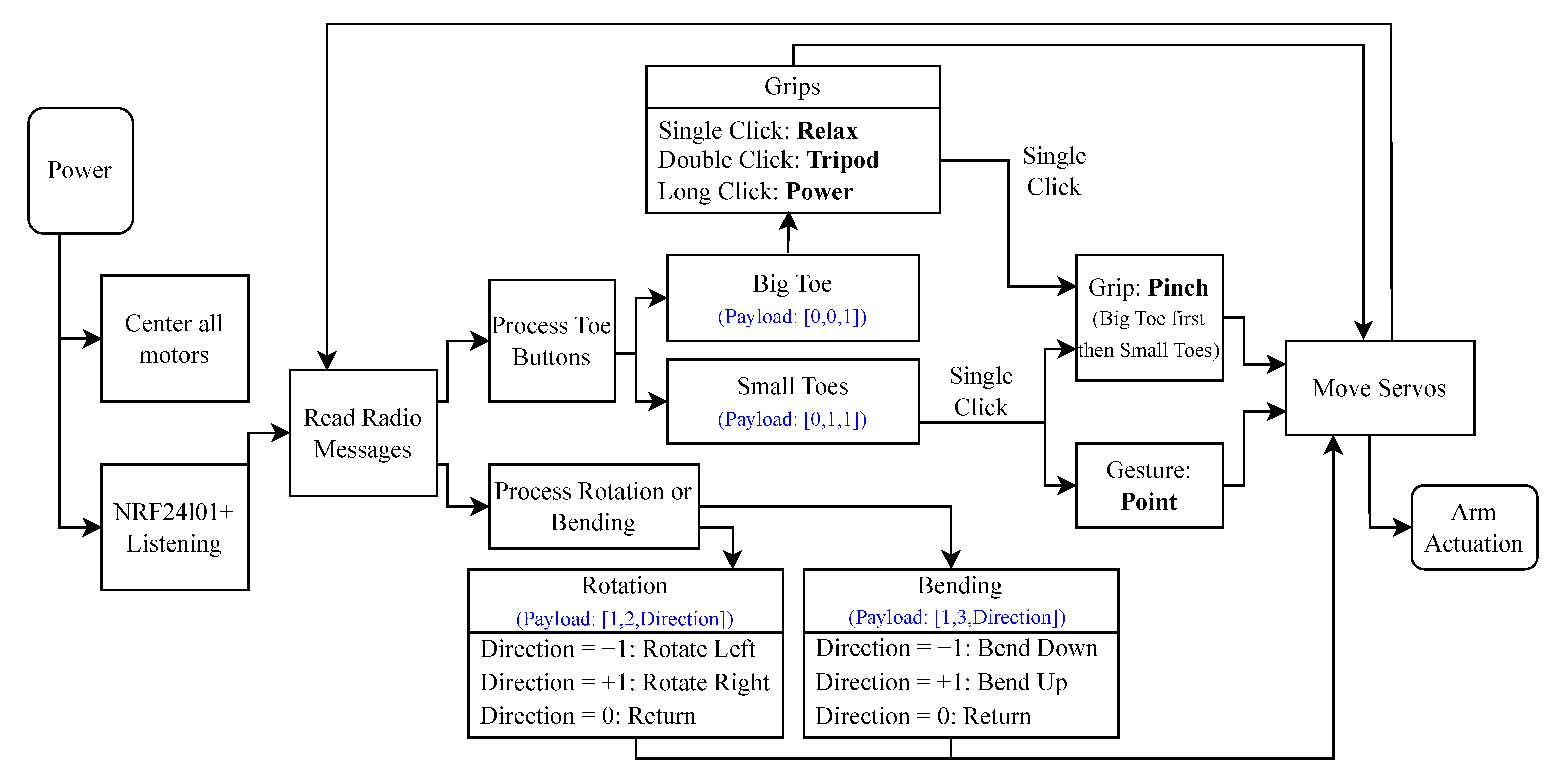

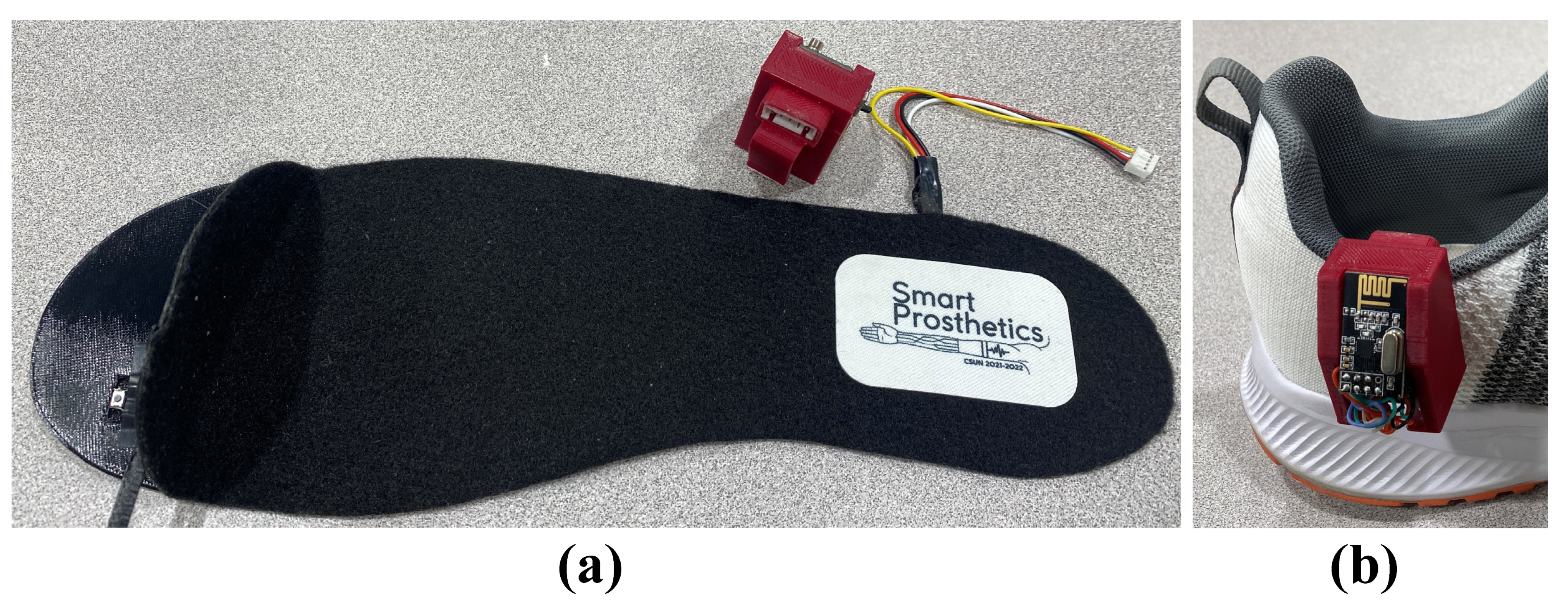

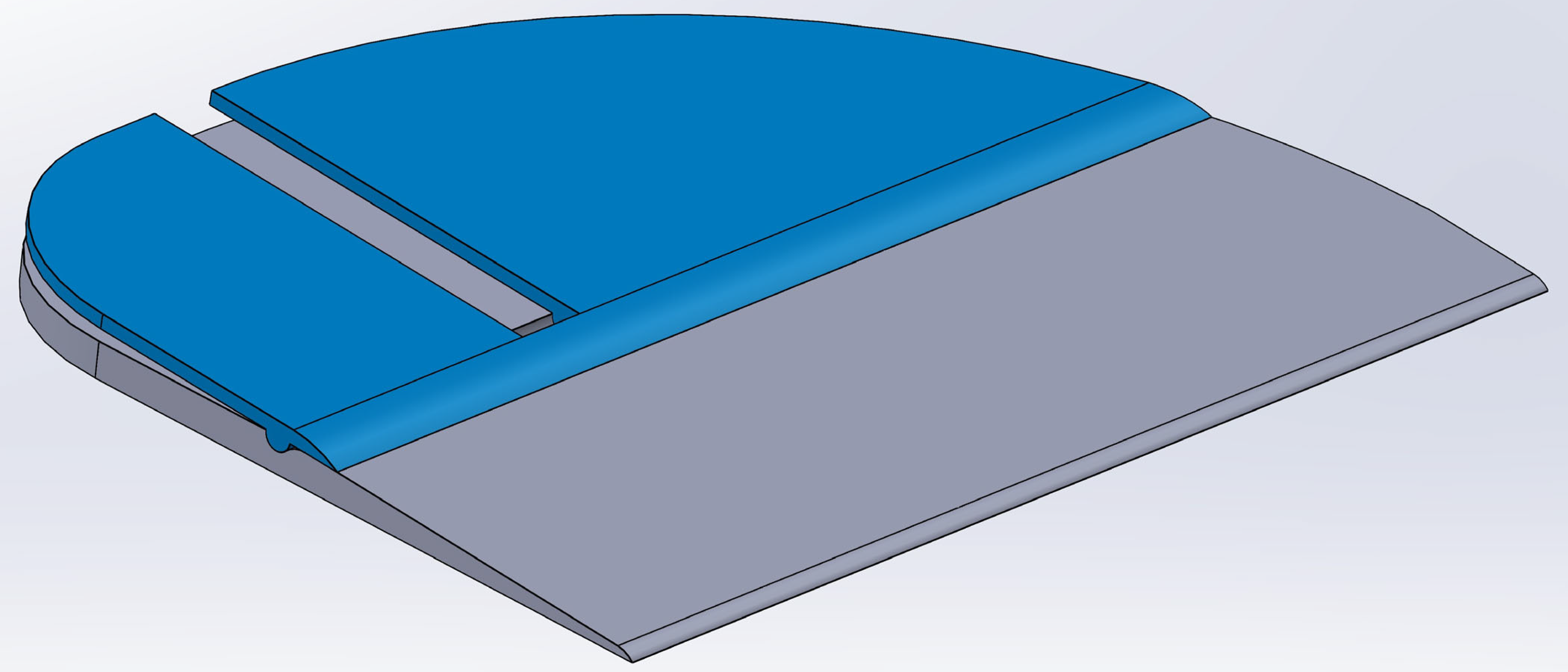

2.1. Infinity Foot Controller Design

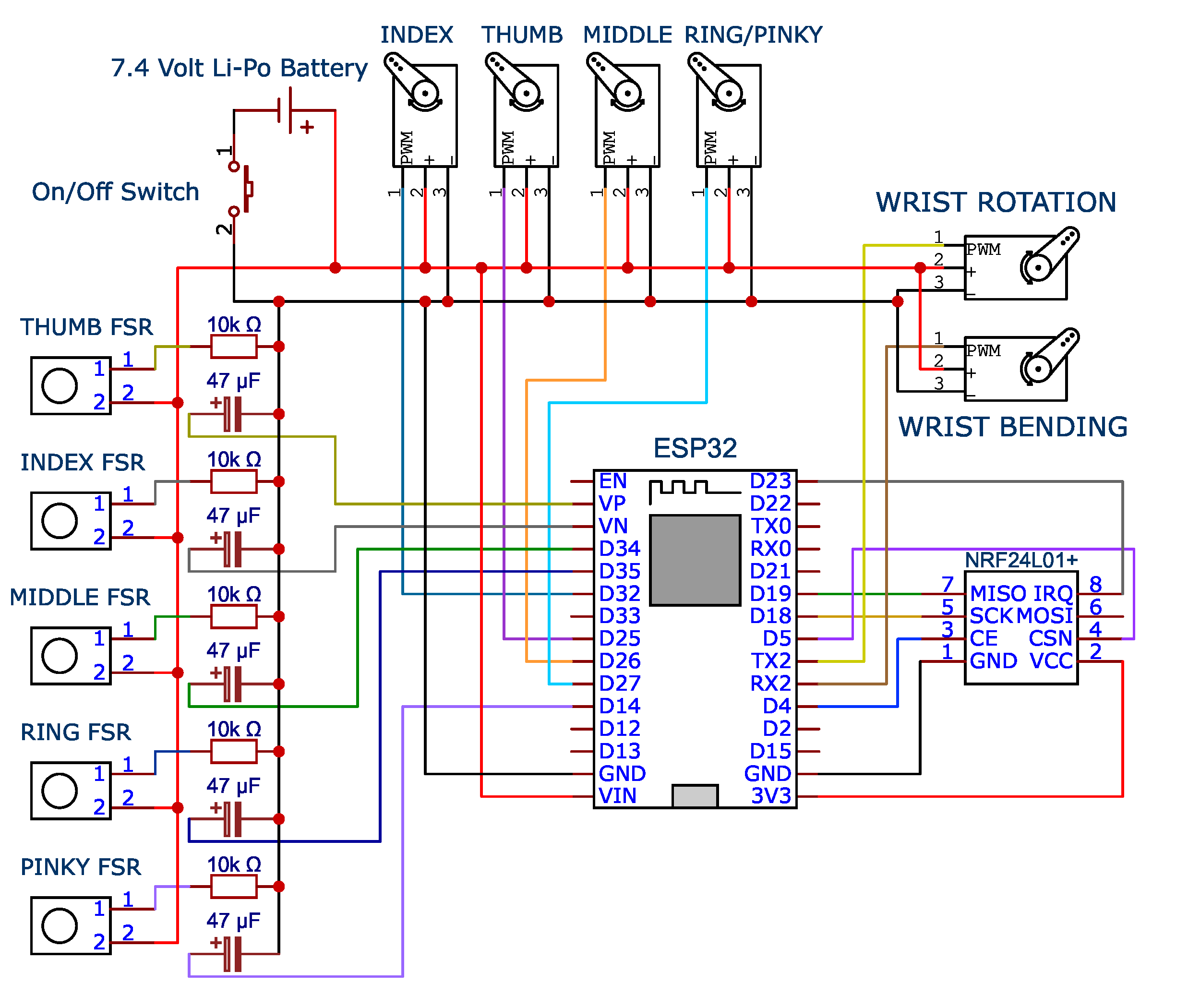

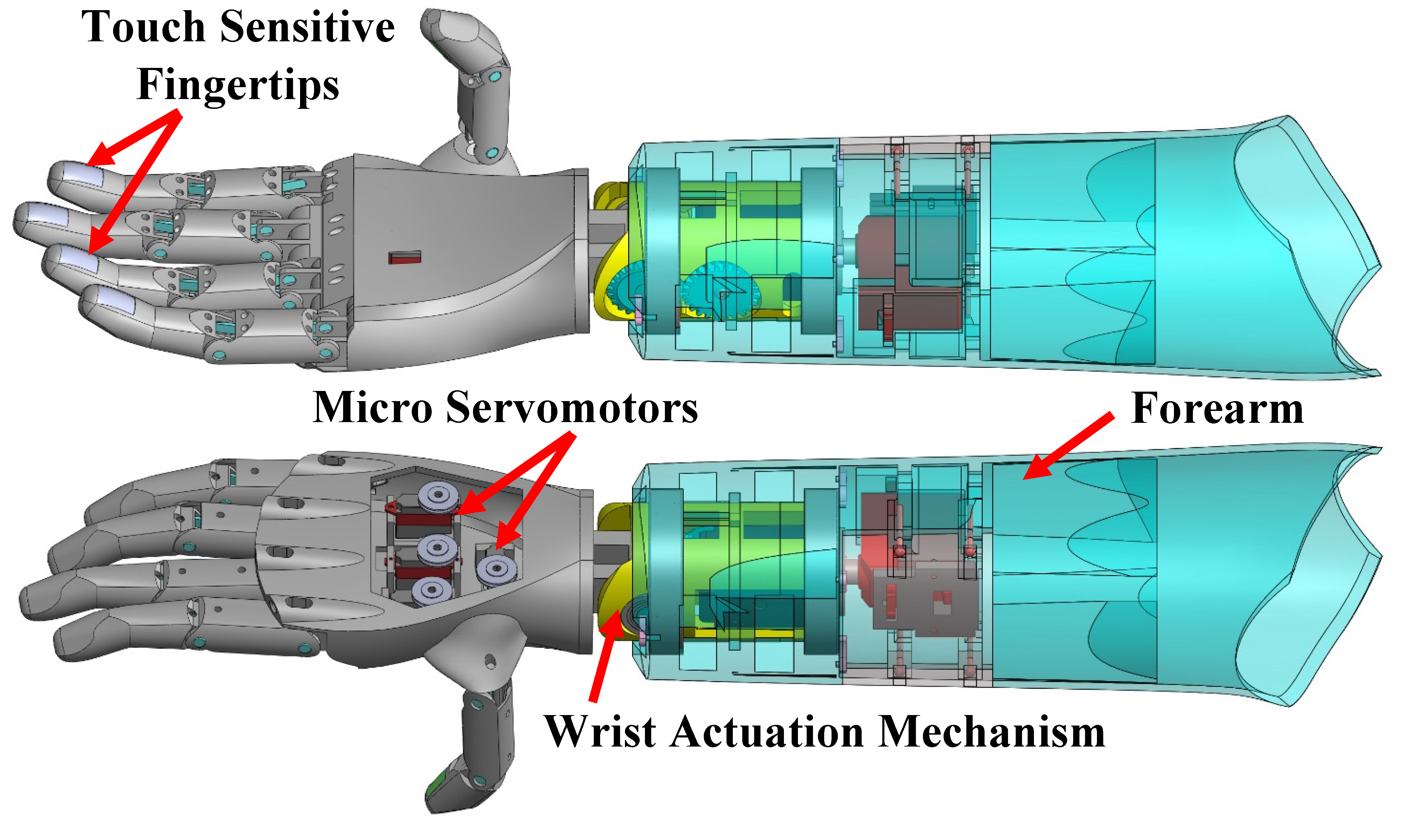

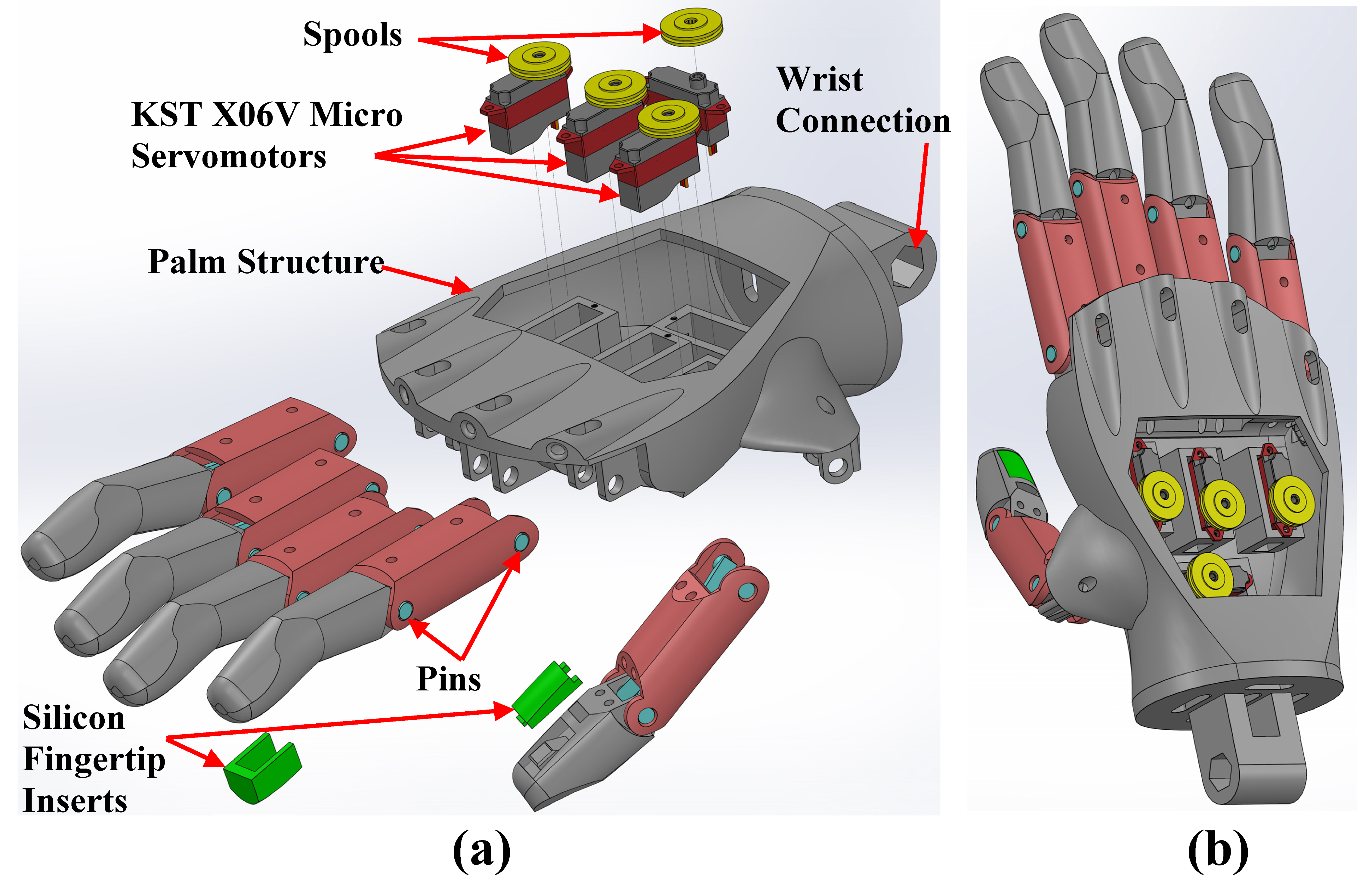

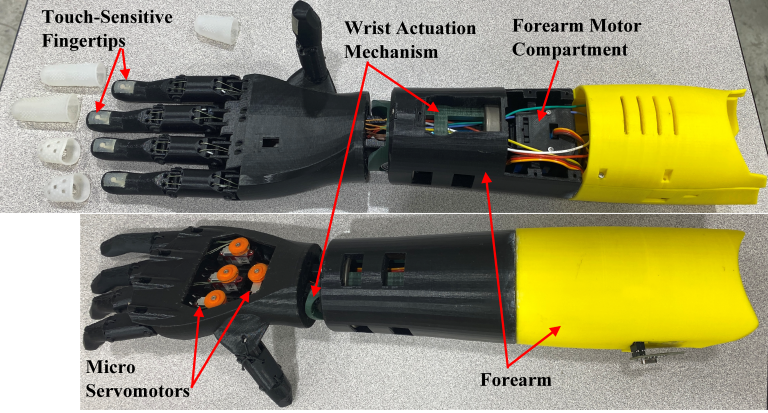

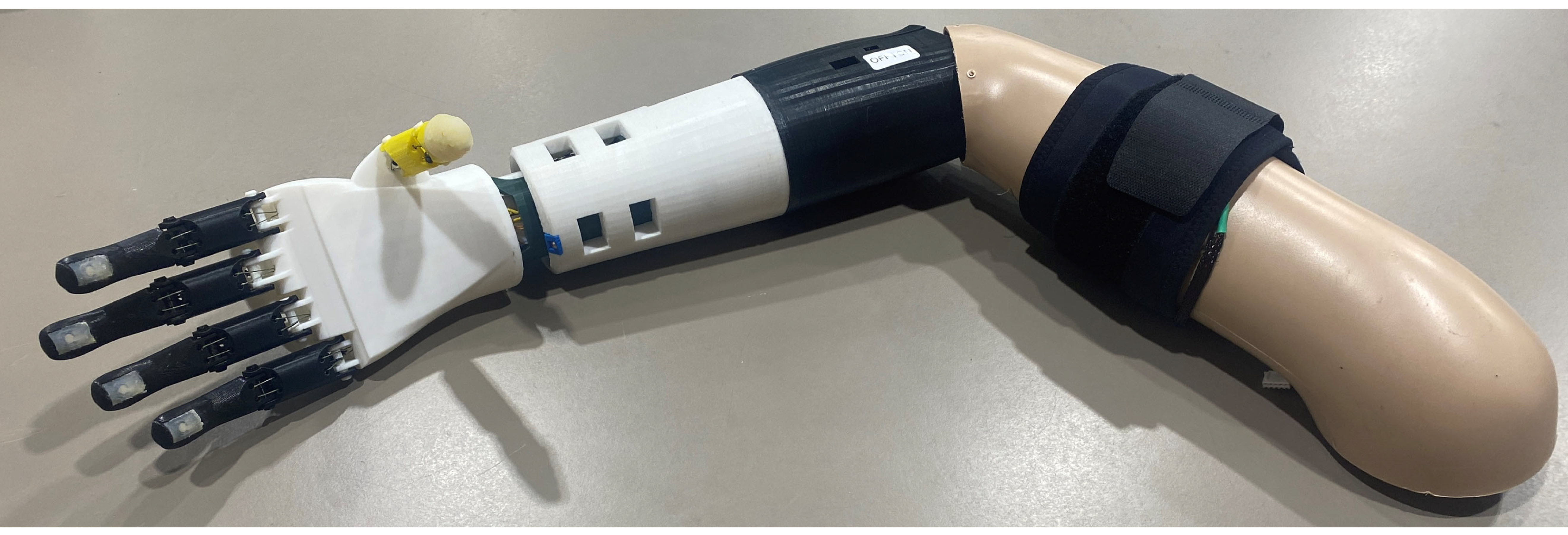

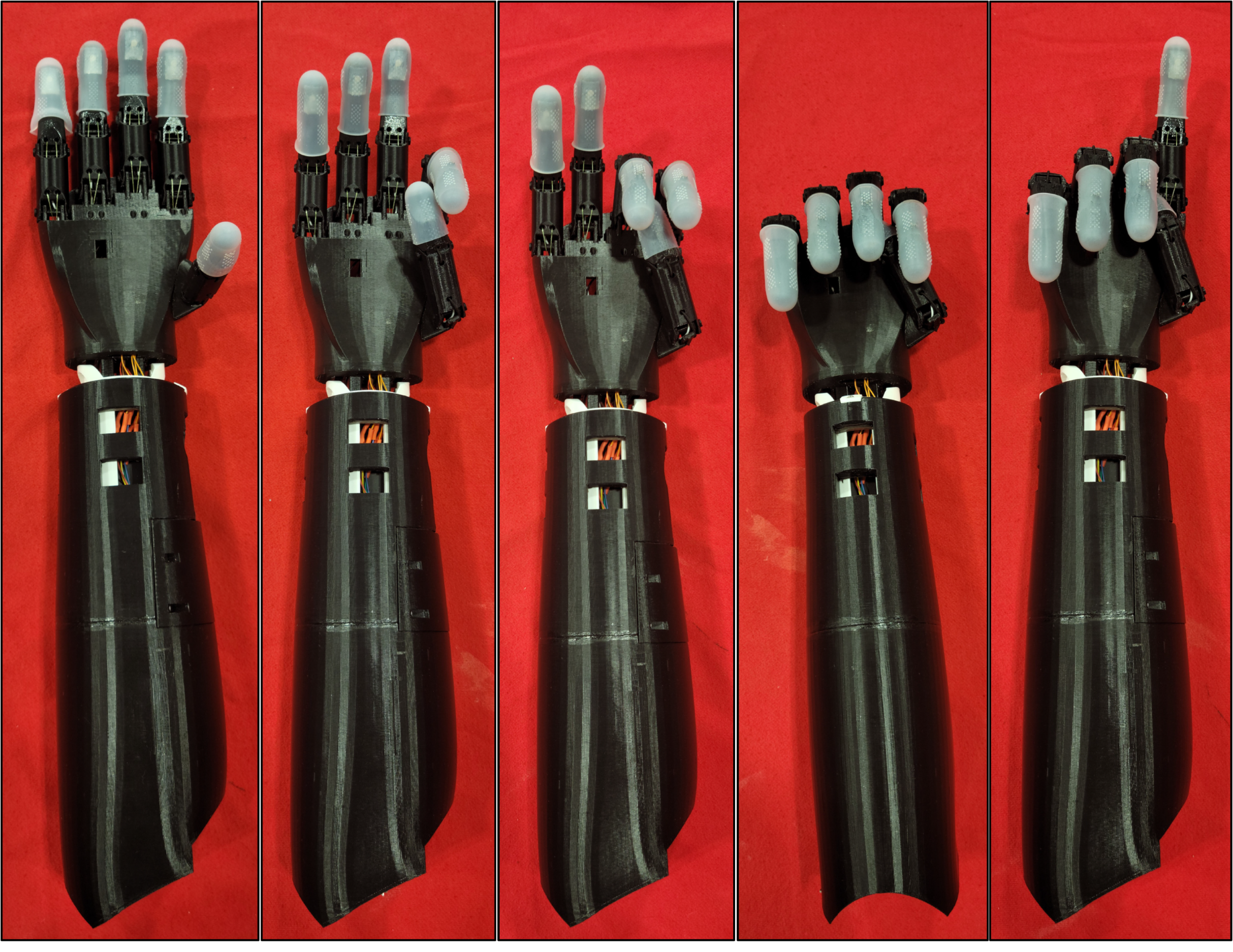

2.2. Infinity Arm Design

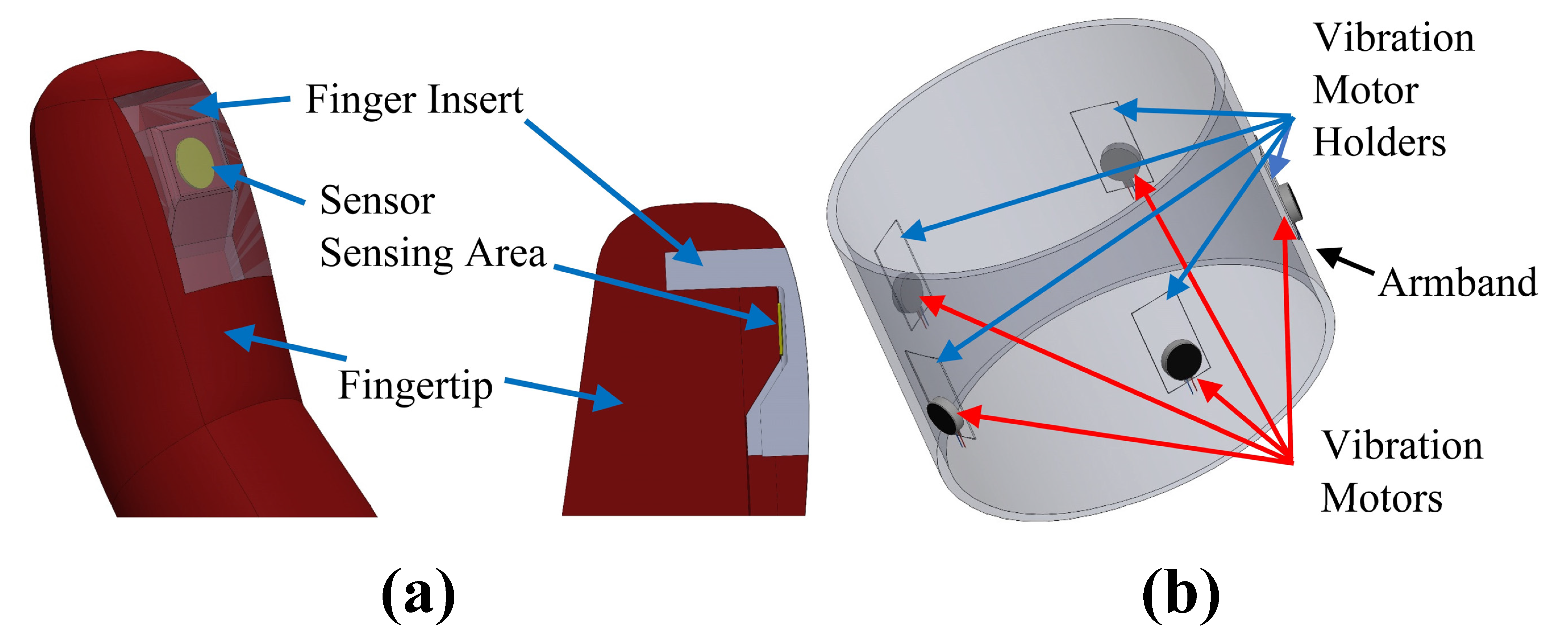

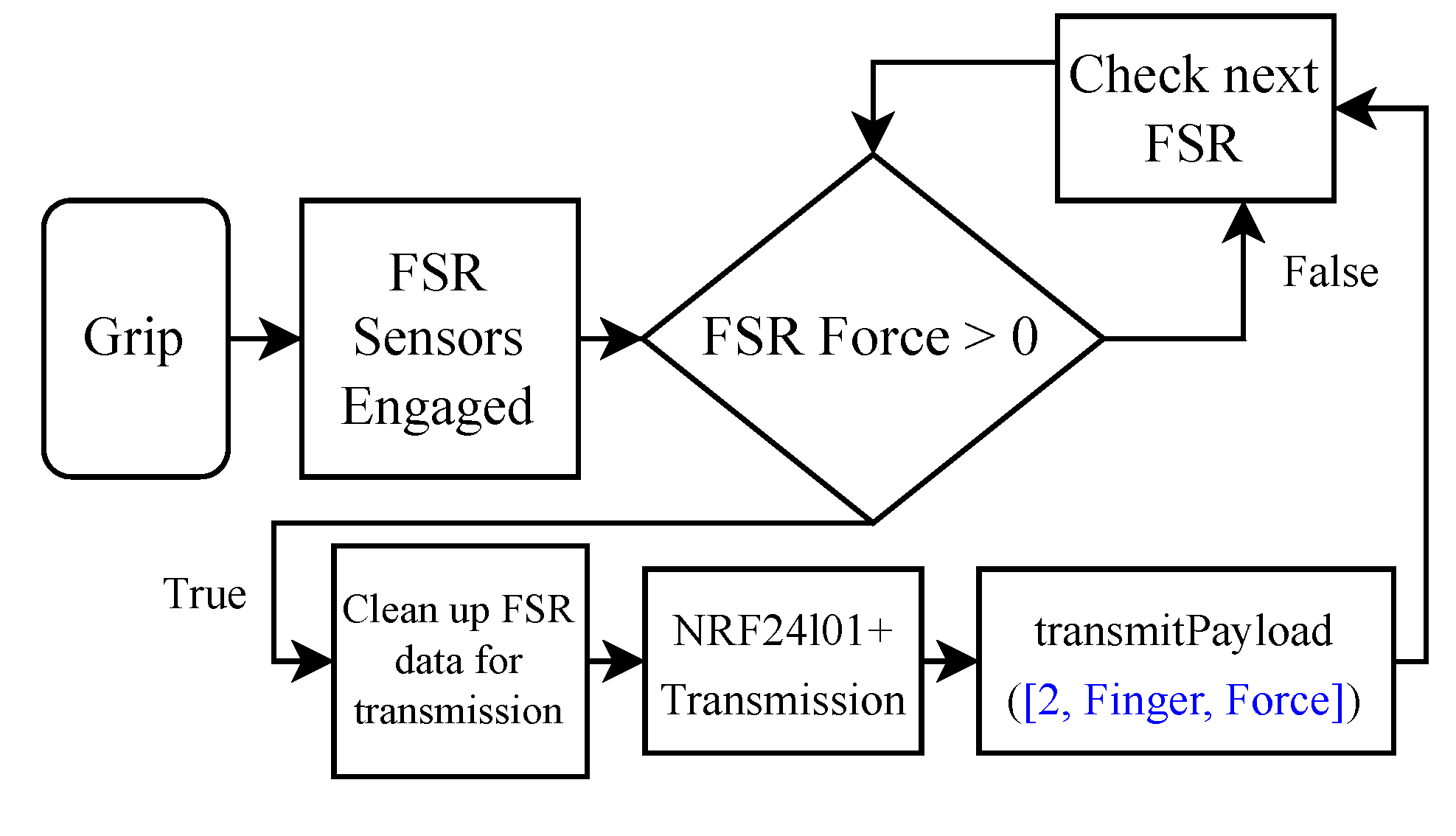

2.3. Infinity Haptic Feedback System Design

3. Results

3.1. Manufacturing and Assembly

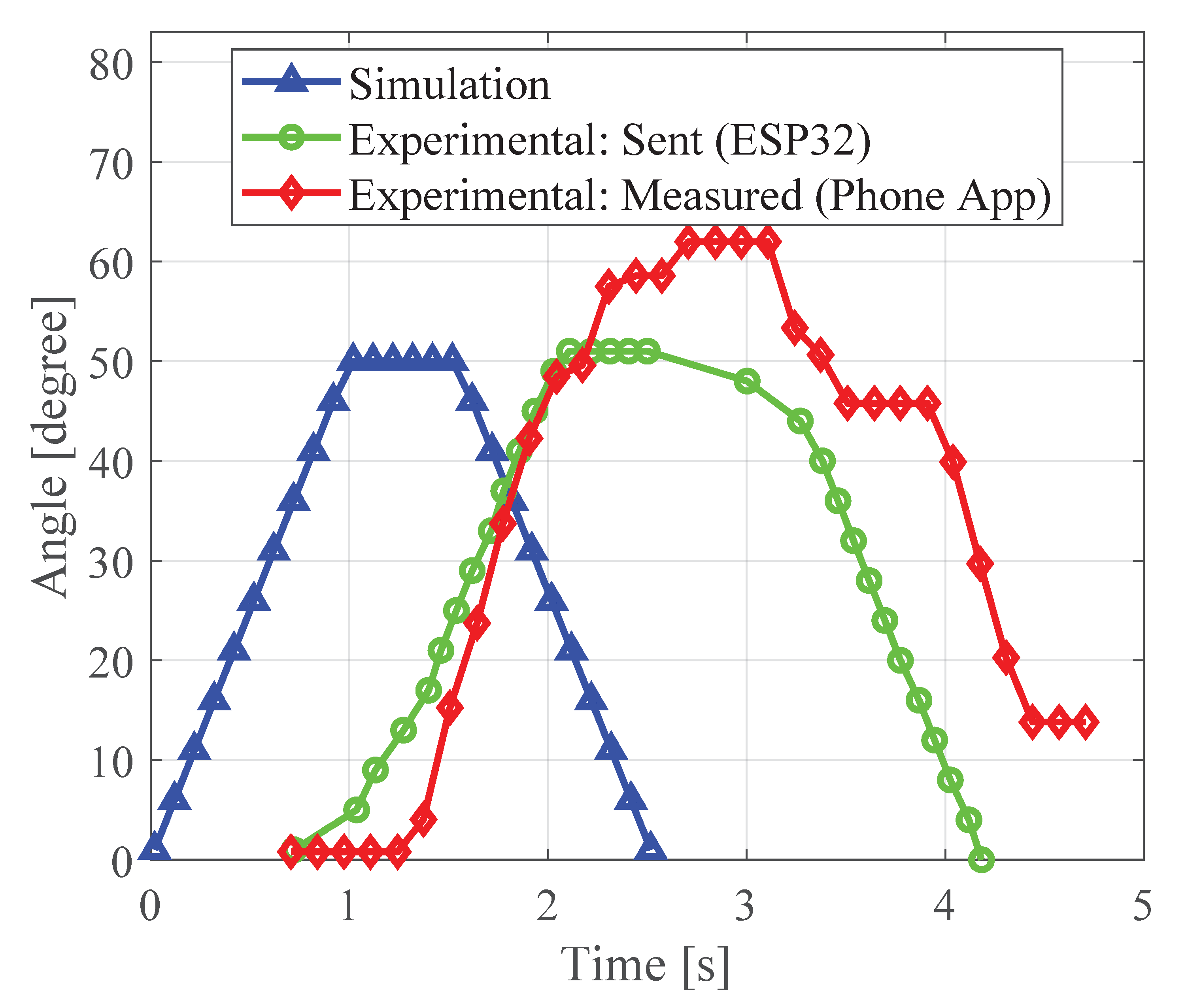

3.2. Actuation and Gripping Tests

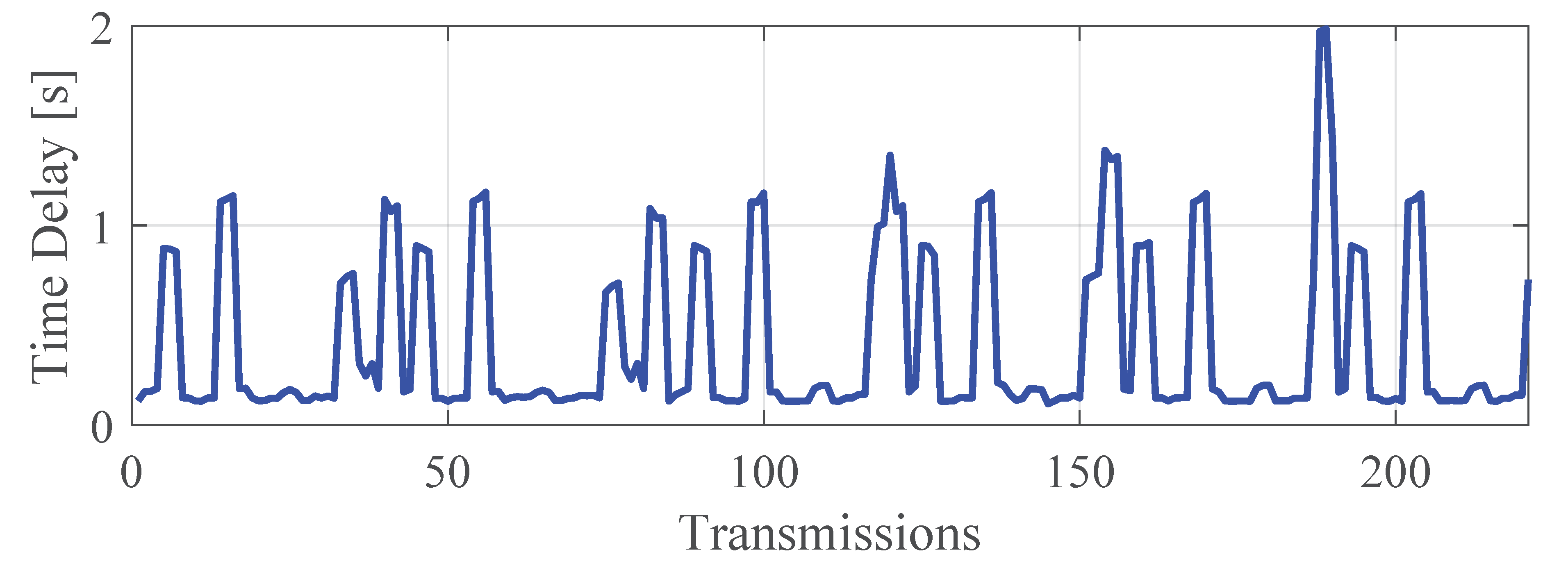

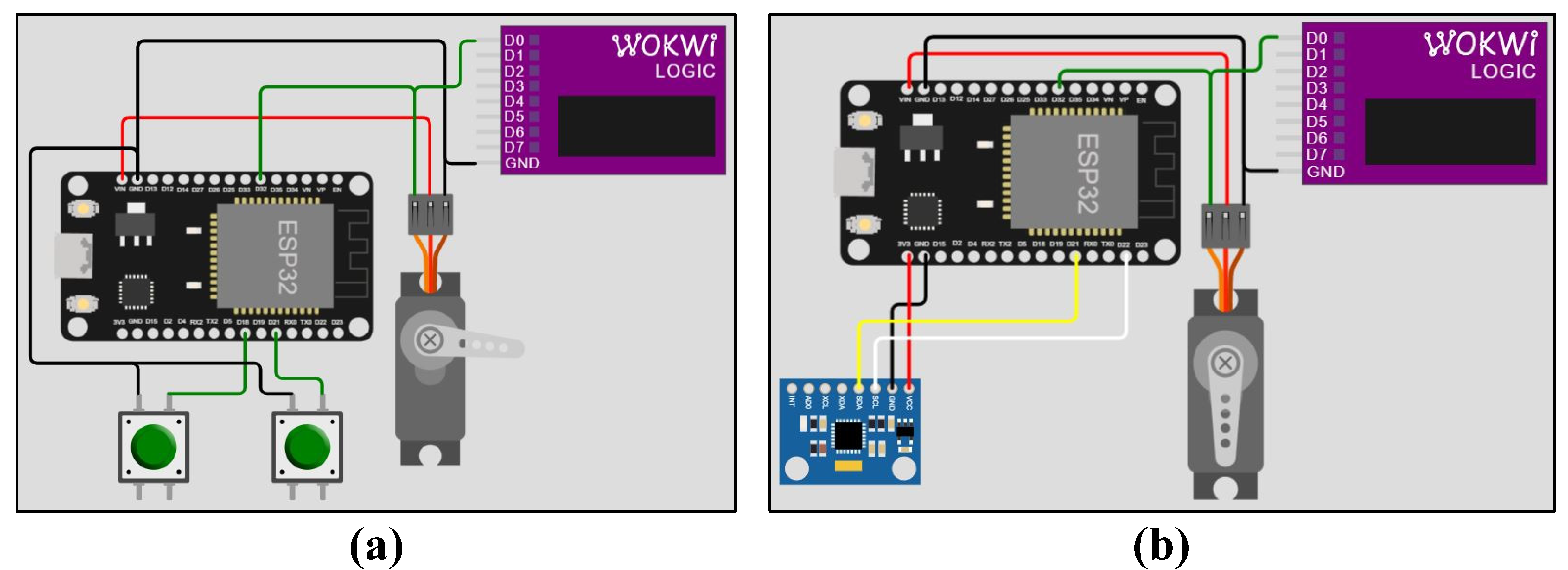

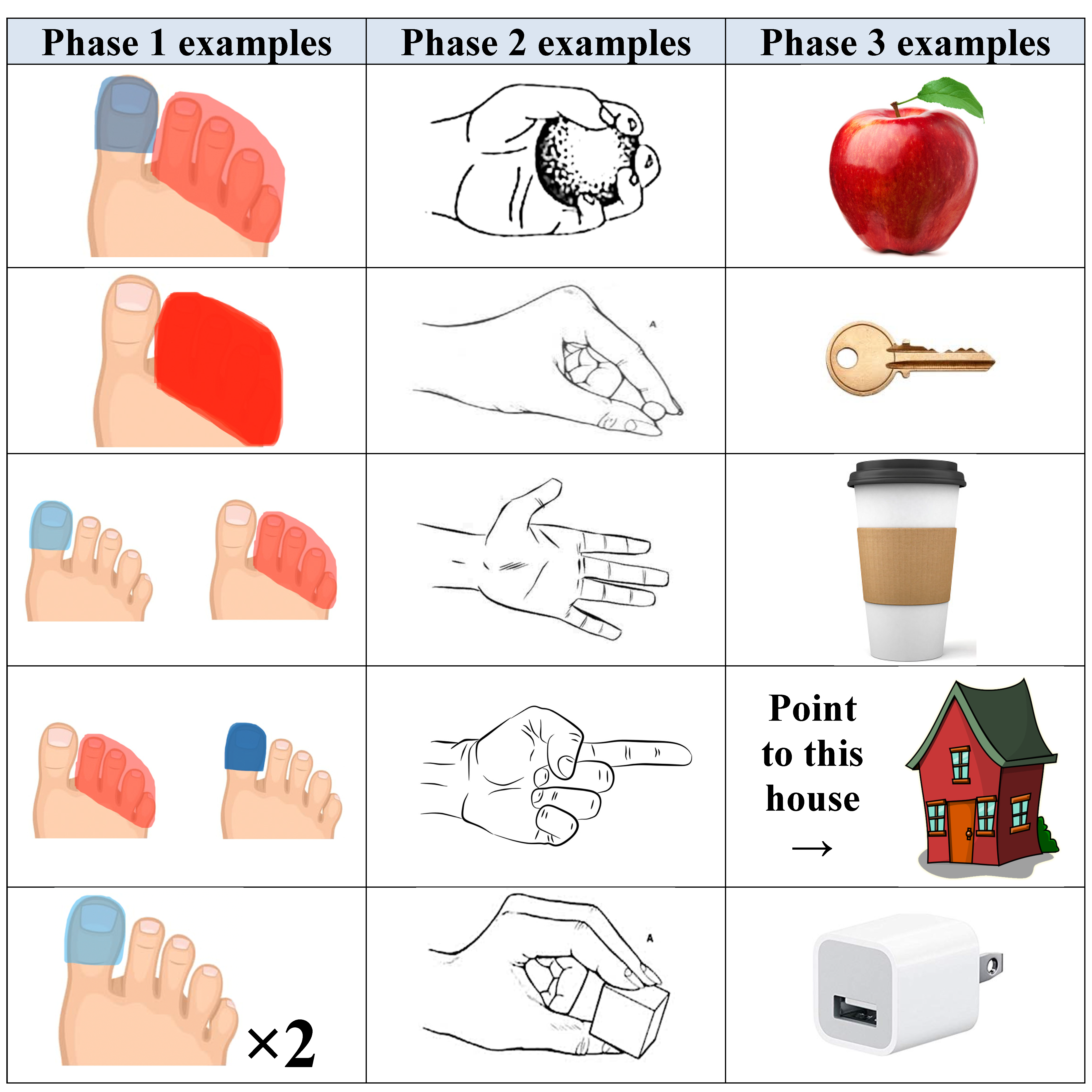

3.3. Foot Control Training System

4. Discussion

4.1. Comparison between Infinity and DEKA Foot Controllers

- DEKA’s foot control design is intended to be implemented underneath the insole of a shoe whereas Infinity’s insole controller is placed on top of the insole or as a replacement of the user’s shoe insole.

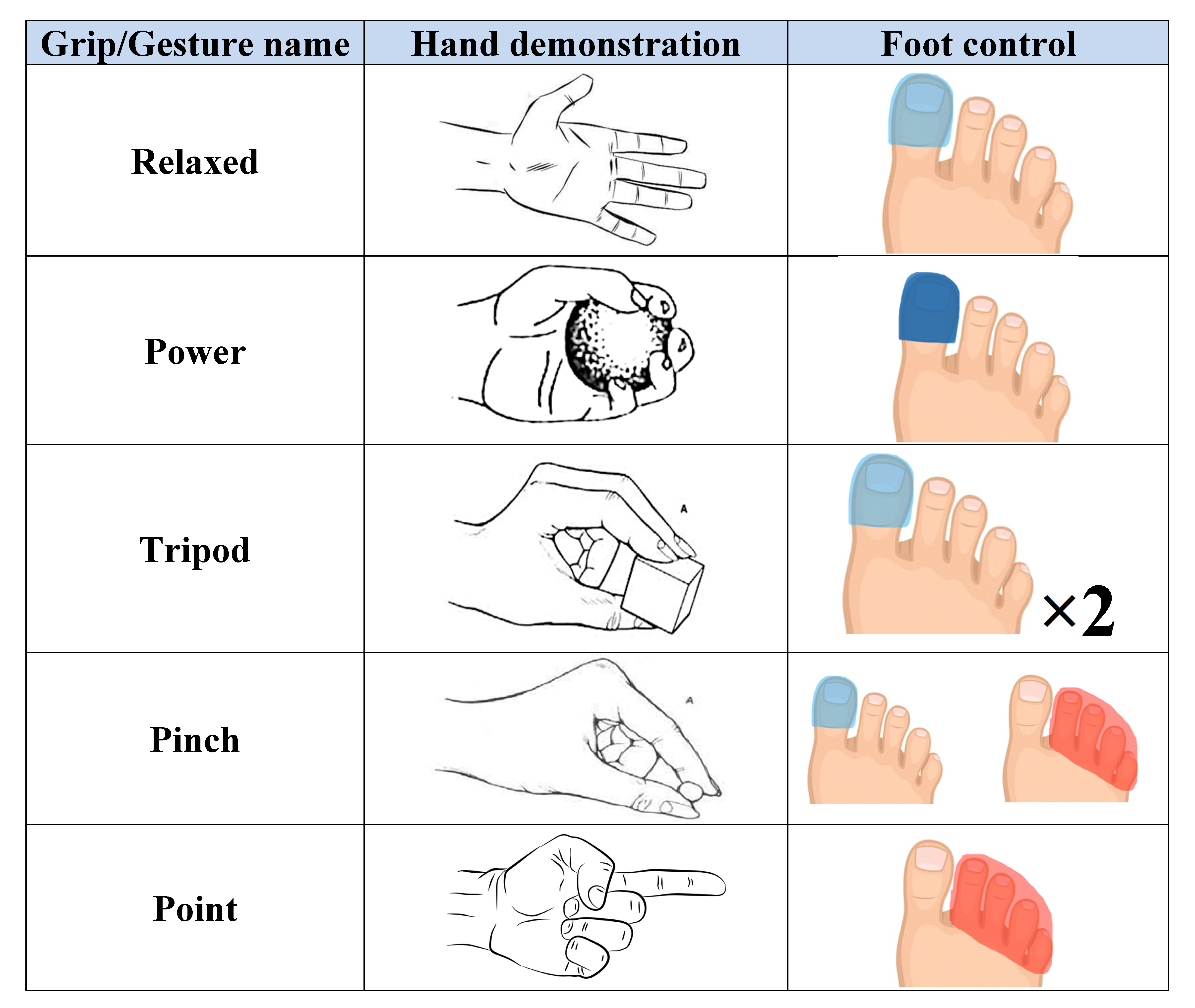

- Infinity design uses two push buttons strategically placed underneath the big toe and the four lesser toes. Paddles are placed above these push buttons to increase the surface area of the push buttons for easier control by the user. In addition, the combination of the push buttons and paddles allows for audible feedback to the user as well as haptic feedback to the user’s toes. This allows the user to gain instant feedback of the commands they are sending to the prosthetic arm. On the other hand, DEKA’s design has only pressure sensors that give no audible or haptic feedback.

- In DEKA’s foot control system, motions of the prosthetic arm are solely based on differences in force or pressure of the user’s foot, whereas Infinity’s design focuses on different commands implemented by the two push buttons under the toes, such as single click, double click, long click, and combination clicks.

- In Infinity, control of the prosthetic arm gripping actions is localized under the toes which are the body parts that humans can control the most and easiest in their foot. On the other hand, DEKA’s control has force sensors spread all over the place under the foot, which might be more challenging to press.

- Both systems include IMU functionality (which contains a gyroscope and an accelerometer) to measure the orientation of the user’s foot or its acceleration. These signals can be used to bend or rotate the wrist of the prosthetic arm if such degrees of freedom are available. The system is programmed to disengage when the user starts walking. However, the placement of the IMU is different in these two designs: in DEKA’s design, the IMU is placed on top of the user’s shoe, while in Infinity, it is placed on the side of the user’s shoe. Accordingly, the translation of data to different functions varies between the two designs. The authors believe that the side of the shoe is a better location for the IMU than the top, because it will not be as noticeable as it is on the top of the shoe.

- DEKA patents state that there may be at least one or more CPU within the system to translate input data from the sensors to the prosthetic arm. The CPU can communicate with the prosthetic arm via wired connection or wirelessly. Infinity includes a compact 3D-printed sensor-controller unit that includes the IMU integrated in a microcontroller, a rechargeable battery with its charging unit, an On/Off power switch, and a wireless transmitter. The structure of this unit has been designed to house all these components in the smallest possible footprint that clips on the side of the user’s shoe.

4.2. Foot Controller Limitations

- (1)

- The user should be able to move their toes to click with the big toe or the four lesser toes;

- (2)

- The user should be sitting or standing to control the arm. Walking can result in unintended pressing on the push buttons, so once detected, the arm will go to a “freeze” mode and stays on its posture, whether gripping an object or not, until the “rest” state is retrieved;

- (3)

- The battery needs to be recharged regularly depending on the usage (a replacement battery can be used while recharging the replaced one);

- (4)

- Regular wear-and-tear can happen to the foot controller or the SCU depending on the usage, and replacement units can be used;

- (5)

- The distance between the foot controller and the arm should not exceed 5 m to maintain reliable connection. Given that both wearables are supposed to be on the body of the user, this distance would not be reached in normal operation.

4.3. Infinity Arm Design Limitations

5. Summary and Conclusions

6. Patents

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| Foot Control | Prosthetic Arm | ||||

|---|---|---|---|---|---|

| Item | Manufacturer | Qty | Item | Manufacturer | Qty |

| 3.7 V 400 mAh LiPo Battery | YDL | 1 | DRS-0201 HerkuleX servomotor | HYULIM ROBOT | 1 |

| Seeeduino XIAO BLE Sense | Seeed Studio | 1 | DS3235 35 kg Servomotor | TYEUIRZO | 1 |

| 4 Pin JST Connectors | Qibaok | 1 | KST X06V Micro Servomotor | KST Servos | 4 |

| SS-12D00 Slide Switch | HiLetGo | 1 | 2000 mah 7.4 V Li-ion battery | URGENEX | 1 |

| NRF24L01+ RF Transceiver module (2.4 GHz) | Deegoo-FPV | 1 | NRF24L01+ RF Transceiver module (2.4 GHz) | Deegoo-FPV | 1 |

| 2 Pin Micro Switch | Liyafy | 2 | Arduino Nano | LAFVIN | 1 |

| ESP-WROOM-32 ESP-32S | ESPRESSIF | 1 | Deep groove Ball Bearing (3/8”) | NICE | 1 |

| ESP32S Breakout Board | AIDEEEPEN | 1 | Needle Roller Bearing 2” INA SCE328 | INA (Schaeffler) | 2 |

| TP4056 Charging Module | MakerFocus | 1 | ESP-WROOM-32 ESP-32S | ESPRESSIF | 1 |

| ESP32S Breakout Board | AIDEEEPEN | 1 | |||

| Haptic Feedback | |||||

| FlexiForce A101 Sensor | Tekscan | 5 | E-Tronic Arm Band | E Tronic Edge | 1 |

| Mini Vibration Motors (12K rpm) | DZS Elec | 5 | NRF24L01+ RF Transceiver module (2.4 GHz) | Deegoo-FPV | 1 |

| Arduino Nano | LAFVIN | 1 | |||

References

- Geethanjali, P. Myoelectric Control of Prosthetic Hands: State-of-the-Art Review. MDER 2016, 9, 247–255. [Google Scholar] [CrossRef] [PubMed]

- Bishay, P.; Aguilar, C.; Amirbekyan, A.; Vartanian, K.; Arjon-Ramirez, M.; Pucio, D. Design of a Lightweight Shape Memory Alloy Stroke-Amplification and Locking System in a Transradial Prosthetic Arm. In Proceedings of the ASME 2021 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, American Society of Mechanical Engineers, Virtual, 14 September 2021; p. V001T05A015. [Google Scholar]

- Hargrove, L.; Englehart, K.; Hudgins, B. A Training Strategy to Reduce Classification Degradation Due to Electrode Displacements in Pattern Recognition Based Myoelectric Control. Biomed. Signal Process. Control. 2008, 3, 175–180. [Google Scholar] [CrossRef]

- Young, A.J.; Hargrove, L.J.; Kuiken, T.A. The Effects of Electrode Size and Orientation on the Sensitivity of Myoelectric Pattern Recognition Systems to Electrode Shift. IEEE Trans. Biomed. Eng. 2011, 58, 2537–2544. [Google Scholar] [CrossRef] [PubMed]

- Stango, A.; Negro, F.; Farina, D. Spatial Correlation of High Density EMG Signals Provides Features Robust to Electrode Number and Shift in Pattern Recognition for Myocontrol. IEEE Trans. Neural Syst. Rehabil. Eng. 2015, 23, 189–198. [Google Scholar] [CrossRef]

- Jiang, N.; Dosen, S.; Muller, K.-R.; Farina, D. Myoelectric Control of Artificial Limbs—Is There a Need to Change Focus? [In the Spotlight]. IEEE Signal Process. Mag. 2012, 29, 150–152. [Google Scholar] [CrossRef]

- Beyrouthy, T.; Al Kork, S.K.; Korbane, J.A.; Abdulmonem, A. EEG Mind Controlled Smart Prosthetic Arm. In Proceedings of the 2016 IEEE International Conference on Emerging Technologies and Innovative Business Practices for the Transformation of Societies (EmergiTech), IEEE, Balaclava, Mauritius, 3–6 August 2016; pp. 404–409. [Google Scholar]

- Bright, D.; Nair, A.; Salvekar, D.; Bhisikar, S. EEG-Based Brain Controlled Prosthetic Arm. In Proceedings of the 2016 Conference on Advances in Signal Processing (CASP), Pune, India, 9–11 June 2016; pp. 479–483. [Google Scholar]

- Bishay, P.L.; Fontana, J.; Raquipiso, B.; Rodriguez, J.; Borreta, M.J.; Enos, B.; Gay, T.; Mauricio, K. Development of a Biomimetic Transradial Prosthetic Arm with Shape Memory Alloy Muscle Wires. Eng. Res. Express 2020, 2, 035041. [Google Scholar] [CrossRef]

- Pradeep, J.; Jamna, A.; Sasikumar, R. Low-Cost Voice-Controlled Prosthetic Arm with Five Degrees of Freedom. IETE J. Res. 2021, 69, 4047–4052. [Google Scholar] [CrossRef]

- Hazubski, S.; Hoppe, H.; Otte, A. Electrode-Free Visual Prosthesis/Exoskeleton Control Using Augmented Reality Glasses in a First Proof-of-Technical-Concept Study. Sci. Rep. 2020, 10, 16279. [Google Scholar] [CrossRef]

- Nagaraja, V.H.; da Ponte Lopes, J.; Bergmann, J.H.M. Reimagining Prosthetic Control: A Novel Body-Powered Prosthetic System for Simultaneous Control and Actuation. Prosthesis 2022, 4, 394–413. [Google Scholar] [CrossRef]

- Baker, C.A.; Akhlaghi, N.; Rangwala, H.; Kosecka, J.; Sikdar, S. Real-Time, Ultrasound-Based Control of a Virtual Hand by a Trans-Radial Amputee. In Proceedings of the 2016 38th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Orlando, FL, USA, 16–20 August 2016; pp. 3219–3222. [Google Scholar]

- Engdahl, S.; Dhawan, A.; Bashatah, A.; Diao, G.; Mukherjee, B.; Monroe, B.; Holley, R.; Sikdar, S. Classification Performance and Feature Space Characteristics in Individuals with Upper Limb Loss Using Sonomyography. IEEE J. Transl. Eng. Health Med. 2022, 10, 1–11. [Google Scholar] [CrossRef]

- Patwardhan, S.; Schofield, J.; Joiner, W.M.; Sikdar, S. Sonomyography Shows Feasibility as a Tool to Quantify Joint Movement at the Muscle Level. In Proceedings of the 2022 International Conference on Rehabilitation Robotics (ICORR), Rotterdam, The Netherlands, 25 July 2022; pp. 1–5. [Google Scholar]

- Nazari, V.; Zheng, Y.-P. Controlling Upper Limb Prostheses Using Sonomyography (SMG): A Review. Sensors 2023, 23, 1885. [Google Scholar] [CrossRef] [PubMed]

- Lyons, K.R.; Joshi, S.S. Real-Time Evaluation of a Myoelectric Control Method for High-Level Upper Limb Amputees Based on Homologous Leg Movements. In Proceedings of the 2016 38th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Orlando, FL, USA, 16–20 August 2016; pp. 6365–6368. [Google Scholar]

- Lyons, K.R.; Joshi, S.S. Upper Limb Prosthesis Control for High-Level Amputees via Myoelectric Recognition of Leg Gestures. IEEE Trans. Neural Syst. Rehabil. Eng. 2018, 26, 1056–1066. [Google Scholar] [CrossRef] [PubMed]

- Lyons, K.R.; Joshi, S.S. A Case Study on Classification of FOOT Gestures via Surface Electromyography. In Proceedings of the Annual Conference of Rehabilitation Engineering and Assistive Technology Society of America (RESNA), Denver, CO, USA, 11–14 June 2015; pp. 1–5. [Google Scholar]

- Maragliulo, S.; Lopes, P.F.A.; Osorio, L.B.; De Almeida, A.T.; Tavakoli, M. Foot Gesture Recognition through Dual Channel Wearable EMG System. IEEE Sens. J. 2019, 19, 10187–10197. [Google Scholar] [CrossRef]

- Lee, S.; Sung, M.; Choi, Y. Wearable Fabric Sensor for Controlling Myoelectric Hand Prosthesis via Classification of Foot Postures. Smart Mater. Struct. 2020, 29, 035004. [Google Scholar] [CrossRef]

- Resnik, L.; Klinger, S.L.; Etter, K. The DEKA Arm: Its Features, Functionality, and Evolution during the Veterans Affairs Study to Optimize the DEKA Arm. Prosthet. Orthot. Int. 2014, 38, 492–504. [Google Scholar] [CrossRef]

- Resnik, L.; Klinger, S.L.; Etter, K.; Fantini, C. Controlling a Multi-Degree of Freedom Upper Limb Prosthesis Using Foot Controls: User Experience. Disabil. Rehabil. Assist. Technol. 2014, 9, 318–329. [Google Scholar] [CrossRef]

- ten Kate, J.; Smit, G.; Breedveld, P. 3D-Printed Upper Limb Prostheses: A Review. Disabil. Rehabil. Assist. Technol. 2017, 12, 300–314. [Google Scholar] [CrossRef]

- Andrés, F.J.; Pérez-González, A.; Rubert, C.; Fuentes, J.; Sospedra, B. Comparison of Grasping Performance of Tendon and Linkage Transmission Systems in an Electric-Powered Low-Cost Hand Prosthesis. J. Mech. Robot. 2019, 11, 011018. [Google Scholar] [CrossRef]

- Bajaj, N.M.; Spiers, A.J.; Dollar, A.M. State of the Art in Artificial Wrists: A Review of Prosthetic and Robotic Wrist Design. IEEE Trans. Robot. 2019, 35, 261–277. [Google Scholar] [CrossRef]

- Montagnani, F.; Controzzi, M.; Cipriani, C. Is It Finger or Wrist Dexterity That Is Missing in Current Hand Prostheses? IEEE Trans. Neural Syst. Rehabil. Eng. 2015, 23, 600–609. [Google Scholar] [CrossRef]

- Fan, H.; Wei, G.; Ren, L. Prosthetic and Robotic Wrists Comparing with the Intelligently Evolved Human Wrist: A Review. Robotica 2022, 40, 4169–4191. [Google Scholar] [CrossRef]

- Belter, J.T.; Segil, J.L.; Dollar, A.M.; Weir, R.F. Mechanical Design and Performance Specifications of Anthropomorphic Prosthetic Hands: A Review. JRRD 2013, 50, 599. [Google Scholar] [CrossRef]

- Biddiss, E.; Beaton, D.; Chau, T. Consumer Design Priorities for Upper Limb Prosthetics. Disabil. Rehabil. Assist. Technol. 2007, 2, 346–357. [Google Scholar] [CrossRef]

- Biddiss, E.A.; Chau, T.T. Upper Limb Prosthesis Use and Abandonment: A Survey of the Last 25 Years. Prosthet. Orthot. Int. 2007, 31, 236–257. [Google Scholar] [CrossRef] [PubMed]

- Nemah, M.N.; Low, C.Y.; Aldulaymi, O.H.; Ong, P.; Ismail, A.E.; Qasim, A.A. A Review of Non-Invasive Haptic Feedback Stimulation Techniques for Upper Extremity Prostheses. Int. J. Integr. Eng. 2019, 11, 299–326. [Google Scholar] [CrossRef]

- Rosenbaum-Chou, T.; Daly, W.; Austin, R.; Chaubey, P.; Boone, D.A. Development and Real World Use of a Vibratory Haptic Feedback System for Upper-Limb Prosthetic Users. J. Prosthet. Orthot. 2016, 28, 136–144. [Google Scholar] [CrossRef]

- Kim, K.; Colgate, J.E. Haptic Feedback Enhances Grip Force Control of SEMG-Controlled Prosthetic Hands in Targeted Reinnervation Amputees. IEEE Trans. Neural Syst. Rehabil. Eng. 2012, 20, 798–805. [Google Scholar] [CrossRef] [PubMed]

- Seneviratne, S.; Hu, Y.; Nguyen, T.; Lan, G.; Khalifa, S.; Thilakarathna, K.; Hassan, M.; Seneviratne, A. A Survey of Wearable Devices and Challenges. IEEE Commun. Surv. Tutor. 2017, 19, 2573–2620. [Google Scholar] [CrossRef]

- Controzzi, M.; Cipriani, C.; Carrozza, M.C. Design of Artificial Hands: A Review. In The Human Hand as an Inspiration for Robot Hand Development; Balasubramanian, R., Santos, V.J., Eds.; Springer Tracts in Advanced Robotics; Springer International Publishing: Cham, Switzerland, 2014; Volume 95, pp. 219–246. ISBN 978-3-319-03016-6. [Google Scholar]

- Napier, J.R. The prehensile movements of the human hand. J. Bone Jt. Surgery. Br. Vol. 1956, 38, 902–913. [Google Scholar] [CrossRef]

- Barrios-Muriel, J.; Romero-Sánchez, F.; Alonso-Sánchez, F.J.; Rodríguez Salgado, D. Advances in Orthotic and Prosthetic Manufacturing: A Technology Review. Materials 2020, 13, 295. [Google Scholar] [CrossRef]

| Foot Control Action | Resulting Prosthetic Hand Reaction | |

|---|---|---|

| 1 | Big toe single-click | Relax all fingers |

| 2 | Big toe double-click | Tripod |

| 3 | Big toe long-click | Power |

| 4 | Four-toe single-click | Point |

| 5 | Big toe then four-toe single-clicks | Pinch |

| 6 | Foot dorsiflexion | Wrist extension |

| 7 | Foot plantarflexion | Wrist flexion |

| 8 | Foot inversion | Forearm supination |

| 9 | Foot eversion | Forearm pronation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bishay, P.L.; Wilgus, J.; Chen, R.; Valenzuela, D.; Medina, V.; Tan, C.; Ittner, T.; Caldera, M.; Rubalcava, C.; Safarian, S.; et al. Controlling a Below-the-Elbow Prosthetic Arm Using the Infinity Foot Controller. Prosthesis 2023, 5, 1206-1231. https://doi.org/10.3390/prosthesis5040084

Bishay PL, Wilgus J, Chen R, Valenzuela D, Medina V, Tan C, Ittner T, Caldera M, Rubalcava C, Safarian S, et al. Controlling a Below-the-Elbow Prosthetic Arm Using the Infinity Foot Controller. Prosthesis. 2023; 5(4):1206-1231. https://doi.org/10.3390/prosthesis5040084

Chicago/Turabian StyleBishay, Peter L., Jack Wilgus, RunRun Chen, Diego Valenzuela, Victor Medina, Calvin Tan, Taylor Ittner, Miguel Caldera, Cristina Rubalcava, Shaghik Safarian, and et al. 2023. "Controlling a Below-the-Elbow Prosthetic Arm Using the Infinity Foot Controller" Prosthesis 5, no. 4: 1206-1231. https://doi.org/10.3390/prosthesis5040084

APA StyleBishay, P. L., Wilgus, J., Chen, R., Valenzuela, D., Medina, V., Tan, C., Ittner, T., Caldera, M., Rubalcava, C., Safarian, S., Alfaro, G. F., Gonzalez-Martinez, A., Gosparini, M., Fuentes-Perez, J., Lima, A., Villalobos, J., & Solis, A. (2023). Controlling a Below-the-Elbow Prosthetic Arm Using the Infinity Foot Controller. Prosthesis, 5(4), 1206-1231. https://doi.org/10.3390/prosthesis5040084