1. Introduction

Modern public transport systems play a key role in ensuring population mobility, especially given growing urbanization and the necessity to reduce the negative impact of transport on the environment. One of the promising areas of development is the bus rapid transit (BRT) system, combining the high capacity of rail transport with the flexibility of bus routes. It is characterized by dedicated traffic lanes, optimized stops and effective organization of traffic, ensuring a reduction in delays and an increase in transportation speed. At the same time, classic BRT systems have certain limitations, in particular concerning a single rolling stock capacity [

1].

Considering these challenges, alternative rolling stock options for such systems are being actively considered in Europe and countries worldwide. One possible solution is the usage of trailer bus trains, which can consist of two or three sections, enabling their passenger capacity to vary depending on the transportation intensity throughout the day. A similar scheme has already proven its efficiency in countries such as Germany, Austria and Switzerland, where the use of trailer bus trains contributes to increased flexibility of the route network and resource savings [

2].

The history of using trailer bus trains in Ukraine started at the beginning of the 20th century. In 1913, Benz–Gaggenau SO buses were launched in Kyiv, but due to the poor road conditions and the beginning of World War I, their operation ceased quickly [

3]. In 1959, to increase passenger capacity, bus trains were created based on decommissioned ZIS-155s, but due to difficulties with control and insufficient engine power, they did not become widely used [

4].

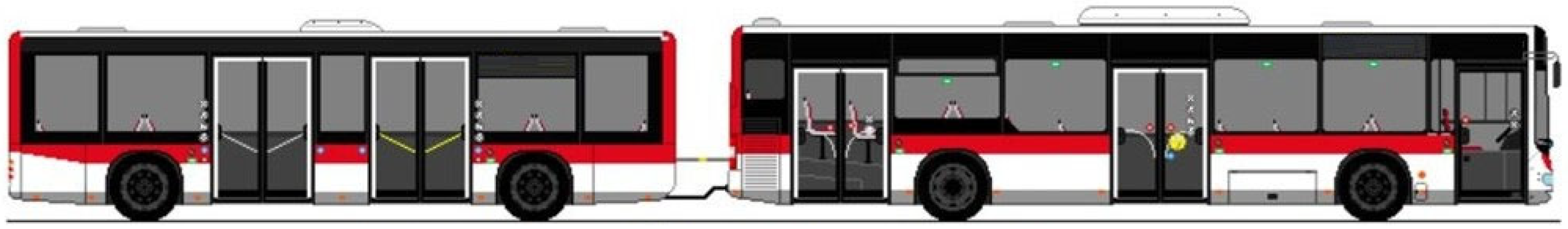

In 1973, an experimental operation of trailer bus trains comprising two LAZ-695M buses (

Figure 1) was carried out in Kyiv, which enabled changing their configuration depending on passenger traffic [

5]. Apart from city routes, trailer buses were actively applied in park areas, exhibition centers, and airports. For example, in 1957, special two-link buses in Kyiv started operations in the territory of VDNH, and RAF-980 platform bus trains, consisting of a tractor and two trailers, operated at Zhulyany airport [

6].

Apart from buses, trolleybus trains were also widely used in Kyiv. Their operation began in 1966 with the use of MTB-82D models, and later, Škoda 9Tr (

Figure 2). In the 1970s, more than 300 such trains were operating in the capital of Ukraine, which significantly increased urban transportation efficiency. However, due to the development of modern articulated buses and trolleybuses, the need for such trains gradually decreased, although operations continued until mid-1994 [

7].

Nowadays, in Europe, trailer bus trains are used in many cities, including Munich, Siegen, Emden, Altenstadt, Gruebenzell, Reutlingen, Grafenberg, Osnabrueck (Germany) [

8], Graz (Austria), and St. Gallen (Switzerland). For instance, in St. Gallen, bus trains consisting of a MAN Lion’s City bus with a Hess passenger trailer (

Figure 3) and with a total passenger capacity of up to 159 people are operated [

9]. The application of such vehicles in BRT systems enables not only an increase in the economic efficiency of transportation, but also ensures rolling stock optimal use depending on the time of day and passenger needs.

The implementation of trailer bus trains in modern BRT systems can be an efficient solution for increasing route capacity, reducing operating costs, and increasing passenger transportation flexibility.

Therefore, this study is aimed at evaluating the fuel efficiency of various configurations of trailer bus trains consisting of single buses and determining the optimal configurations for use in BRT systems. For this purpose, it is necessary to determine how changes in the number of sections and engine operating modes affect the specific fuel consumption per passenger and overall performance. The work is relevant because of the need to develop economically sound and environmentally efficient solutions for urban public transport that can adapt to changing passenger transportation needs.

2. Sources Analysis

Despite a rich history of using trailer bus trains, the issue of researching their performance properties has not received sufficient attention in scientific research.

Thus, ref. [

2] conducted a review of modern road transport with dynamic load capacity. The author identified the main disadvantages of trailer bus trains, in particular, the necessity of a conductor in the trailer due to the driver’s inability to keep order, limited maneuverability on narrow city streets, uncomfortable moving conditions for passengers in the trailer unit, the lack of low-floor trailers, and the lack of heating in the trailer, which complicated operations in the cold season.

The research on the operational properties of a three-link trailer bus train consisting of three single buses was carried out in [

5]. It was established that the power of two engines is sufficient for the movement of such a road train in the entire speed range, that is, one of the buses can be used as a passive trailer, which can lead to improved fuel efficiency. In addition, in terms of maneuverability, such a road train significantly exceeds a three-link articulated bus.

Along with trailer bus trains, modular bus systems (Modular Bus Units) are also being elaborated, which comprise a modern stage in the public transport development, based on the use of autonomous or semi-autonomous modular vehicles. Such modules can be connected and disconnected on the move, adapting to passenger traffic, increasing transportation flexibility and efficiency.

The study considers a flexible dispatching system using modular bus units [

10]. The offered approach enables changing the vehicle configuration according to passenger flow, contributing to cost reduction and improving mobility. In addition, the study confirms that such a system can significantly reduce the average transport waiting time.

In [

11], the operation of shuttle systems under congested conditions is optimized. A discrete control model is developed that enables balancing between operating costs and passenger waiting time. The authors show that the offered method increases the system throughput and reduces delays.

Articles [

12,

13] are devoted to strategies for fighting bus congestion. The application of autonomous modular buses allows for travel interval regulation by dynamically separating or combining modules, improving the regularity of route operation. Studies show that this approach reduces the transport congestion risk and contributes to the even distribution of passenger traffic.

Research [

14] suggests the concept of a modular, adaptive and autonomous transit system (MAATS), where passengers can transfer between hand-held modules without a pause. This approach allows altering the time of dosage and increasing the small transfer efficiency. The MAATS model also favours reduced operating costs and, therefore, optimal transport usage.

Unlike more complex modular systems, trailer bus trains have unique advantages, such as relative ease of implementation, lower costs for adapting existing infrastructure and high flexibility in adapting carrying capacity to changing passenger traffic. They are effective, especially on urban routes with pronounced rush hours, where they allow for significant optimization of rolling stock use and the reduction of operating costs.

The issue of the optimal passenger transport rolling stock due to the indexes of fuel efficiency is also considered in the range of works.

Thus, in [

15], factors influencing bus fuel consumption are investigated using the classification and regression tree (CART) model. Quantitative assessment of these factors helps in selecting the optimal rolling stock in terms of fuel efficiency.

In [

16], a bus motion model was elaborated to evaluate the impact of passenger load, speed, and acceleration on its energy consumption. The results show that increasing passenger load significantly affects fuel consumption, and the authors suggest optimization strategies to reduce energy consumption.

Research [

17] is devoted to comparing the actual fuel consumption, its cost, and harmful substance emissions by buses with different types of power plants, including diesel, hybrid, and compressed natural gas (CNG) buses. The authors found that the choice of power train type significantly affects fuel efficiency and environmental performance, and also provided recommendations for converting diesel bus fleets to other energy sources.

In [

18], the impact of various factors, such as speed, acceleration, the number and duration of stops, and passenger load, on a city bus’s fuel consumption is investigated. Using the VSP (Vehicle Specific Power) method, the authors developed a model for estimating fuel consumption in urban traffic conditions.

The impact of operational factors on the cost of transport service in BRT Curitiba was investigated for four types of buses, including conventional two-section articulated and hybrid-electric buses of different configurations [

19]. The analysis showed that the two-axle plug-in hybrid-electric bus has the lowest fuel consumption, and the conventional two-section articulated bus has the highest. Although a complete fleet replacement significantly increases maintenance costs (reduced waiting time), it significantly improves the quality of passenger transportation.

The fuel consumption and emissions of buses in the BRT Metrobus system in Istanbul are analysed in [

20]. The study showed that driver behaviour significantly affects fuel consumption. Scenarios for reducing fuel consumption by changing acceleration and speed were analysed.

3. The Main Part of the Research

To increase passenger transport service efficiency, BRT (bus rapid transit) systems use various types of rolling stock, in particular buses with increased and especially high passenger capacity (up to 300 people) [

21]. The most common are articulated two- and three-link buses; however, a promising solution is trailer bus trains. They are formed by connecting individual bus units using traction coupling devices or by using tractor buses in combination with passenger trailers.

Trailer bus trains may consist of two or three links, reaching a total length of up to 30 m. This enables significantly increasing the carrying capacity of the transport system without the need to purchase additional rolling stock units or implement large-scale infrastructure projects. So, the capital intensity of the route network modernization is reduced, contributing to operating cost optimization.

One of the key advantages of bus trains is their flexibility in adjusting to changes in passenger traffic. The traditional increase in the number of single buses on a route may lead to stop overloading, increased waiting times and congestion at bottlenecks in the route network. Trailer buses enable more efficient load distribution during peak hours, and also provide the ability to quickly modify the vehicle composition according to current needs. For example, during the off-peak period, a trailer bus train may be disbanded to use individual bus modules on other routes, increasing the overall fleet operational efficiency.

Despite these advantages, the application of trailer bus trains has a number of operational limitations. One of the key disadvantages is reduced maneuverability compared to single buses, although in this respect they are better than three-link articulated buses [

5]. There can also be increased fuel consumption due to the increased weight and the use of multiple power plants. However, the overall costs per passenger carried can be lower, making this type of rolling stock economically reasonable at high occupancy.

An additional factor is the higher purchase and maintenance costs compared to articulated buses. Simultaneously, due to the possibility of optimal rolling stock redistribution of units and increased operational flexibility, trailer bus trains can ensure the vehicle fleet’s more rational use.

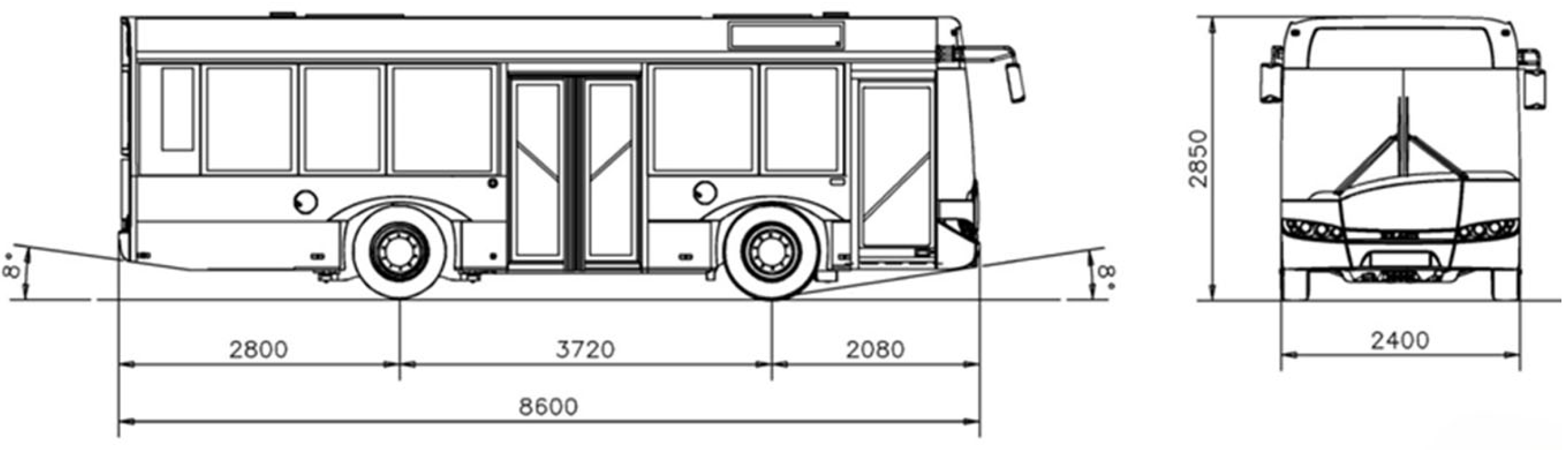

For a BRT system to function effectively, trailer bus trains should consist of two or three modules, providing a passenger capacity of 150–250 people with a maximum length of 28–30 m. Solaris Alpino 8.6 buses (

Figure 4), with a length of 8.6 m and a passenger capacity of up to 70 people, were selected as the basic module of such trains, providing the necessary operational characteristics and meeting modern transport system requirements [

22].

Solaris Alpino 8.6 is a model of a mid-class low-floor city bus, the shortest in the Solaris Urbino family. It is designed for operation on lines with low passenger traffic, running along narrow mountain roads or narrow streets in residential areas or city centers. Brief technical characteristics of the Solaris Alpino 8.6 bus are presented in

Table 1 [

22].

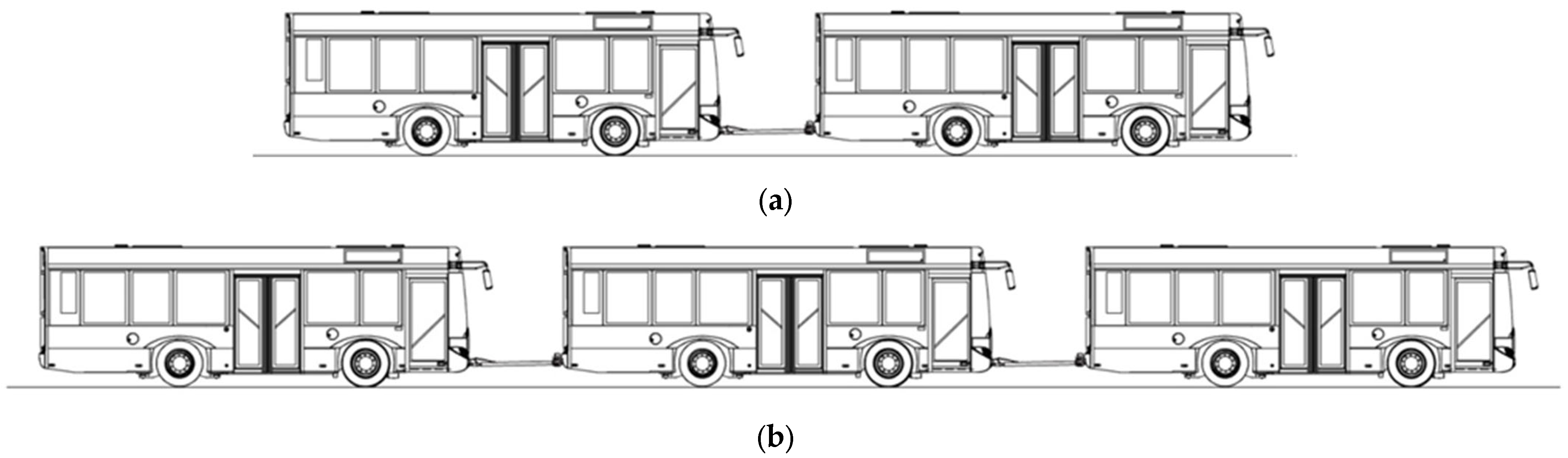

The suggested bus train may consist of two (

Figure 5a) or three (

Figure 5b) sections. Considering that each section is a single bus having its own separate power plant, depending on the traffic conditions and the amount of passenger traffic on the bus train, all engines can be used simultaneously, or some of them can be used. At the same time, if a separate engine section does not work, then this bus is a passive trailer.

As a result, four variants of bus trains with different numbers of sections and working engines were suggested (

Table 2). A single bus was also added for comparison.

Determining the optimal configuration of the proposed trailer bus train demands assessing its fuel efficiency under different operating conditions.

The determination of the optimal configuration of a trailer bus train is based on a multi-criteria assessment, including not only fuel efficiency, but also operational characteristics. Optimality is achieved by finding a compromise between the following key aspects:

- -

Minimum specific fuel consumption per passenger is the main economic indicator of the efficiency of the system.

- -

Sufficient traction and speed properties ensure the ability of the vehicle to maintain a given schedule.

- -

Technological feasibility and operational flexibility provide the ability to quickly change the carrying capacity by coupling or uncoupling sections depending on fluctuations in passenger traffic during the day.

Thus, the optimal configuration is considered to be the one that ensures the best fuel efficiency while maintaining an acceptable level of dynamic characteristics that allow efficient operation according to the conditions of the urban BRT transport system.

Bus fuel efficiency may be determined by various indicators, such as controlling fuel consumption, consumption in urban and highway cycles, fuel characteristics of steady-state traffic, etc.

Taking into consideration the peculiarities of a trailer bus train movement in the BRT system, further analysis of fuel efficiency is based on the following main evaluation indicators: control fuel consumption at a speed of 60 km/h, fuel characteristics of steady-state traffic, and fuel consumption in the urban driving cycle, simulating the real route of buses in the BRT system.

To establish the control of fuel consumption at a speed of 60 km/h, as well as the fuel characteristics of steady-state traffic, it is necessary to determine the fuel consumption during steady-state traffic [

23].

In the steady-state driving mode with a constant speed, fuel consumption is defined by the following dependency:

where

kQ is the fuel consumption correction factor;

Qos is fuel consumption per second, kg/s; and

τy denotes the time the bus is moving at a constant speed, s.

The fuel consumption per second is determined as follows:

where

where

V is the speed of the trailer bus train, m/s;

Ui represents the bus transmission total gear ratio of the i-th gear;

rwr is the wheel rolling radius, m; and

aQ,

bQ, and

cQ are the approximation coefficients of the hourly engine fuel consumption function, as follows:

where

ω represents the rotation angular speed of the engine crankshaft, rad/s.

If there are engines with external speed characteristics, the coefficients

aQ,

bQ,

cQ are defined using the Lagrange interpolation formula on the following condition:

where

ge represents specific fuel consumption and g/kWh;

Ne represents engine power, kW.

The remaining coefficients

aQ,

bQ, and

cQ are calculated as follows:

The most accurate definition of fuel consumption at partial engine load is provided based on two initial dependencies: torque and hourly fuel consumption on the crankshaft angular velocity and the fuel supply control element position. These characteristics enable establishing the relationship between fuel consumption at partial and full feeds in the studied range of engine angular velocities [

24]. However, their determination is possible only experimentally, by obtaining the load characteristics of a particular engine at different operating modes.

While determining fuel consumption, under the condition of engine power partial use, the fuel consumption correction coefficient

kQ is introduced, which is determined as follows:

where,

ki is the engine power utilization factor; and

aki,

bki, and

cki are the function approximation indexes

kQ =

f(

ki).

The engine power application factor for determining fuel efficiency indicators is as follows:

where

Ma is the total mass of the bus, kg;

f0 is the rolling resistance coefficient at low speeds;

Kf is the coefficient considering the change in the rolling resistance coefficient with increasing speed;

F is the frontal area, m

2; and

Ai,

Bi, and

Ci are the approximation coefficients of the circular force equation as follows:

where

ηm is the transmission efficiency;

r∂ and

rwr are the dynamic radius and the rolling radius of the wheel, m, respectively; and

a,

b, and

c are the engine torque curve approximation coefficients [

25], obtained experimentally as follows:

where

ωmin,

MK.min are the minimum angular velocity of the engine crankshaft, s

−1, and the torque, N∙m, at this angular velocity, respectively;

Mk.max is the maximum engine torque, N∙m, and the corresponding angular velocity of the engine crankshaft, s

−1, respectively; and

MN is the torque, N∙m, and the angular velocity of the engine crankshaft, s

−1, corresponding to its maximum power.

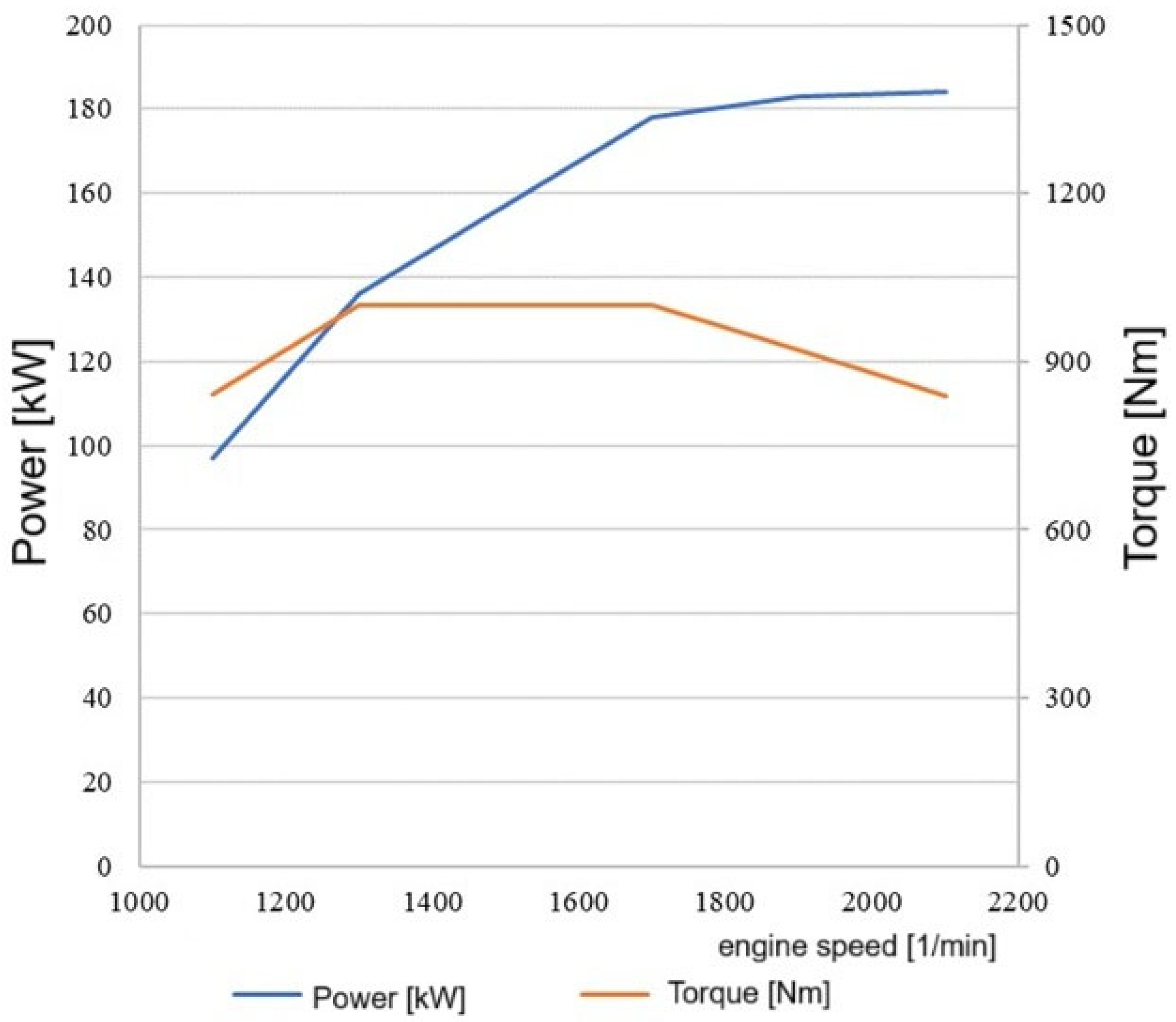

For determining the engine torque curve approximation coefficients, the speed external characteristic of Cummins ISB6.7E6 250B engine was used, shown in

Figure 6 [

26].

The bus travel time τi at a constant speed is the ratio of the difference between the total length of the route section Si and the acceleration path Sai and braking Sbi on this section to the steady-state speed vi.

The bus travel time

τi at a constant speed is calculated as follows

The acceleration path

Sai is determined by the dependency as follows:

where

δrot is the coefficient taking into consideration the rotating masses of the bus;

Vi,

Vf are the initial and final speeds of the bus, m/s, respectively; and

ai,

bi, and

ci are the right-hand side coefficients of the bus motion differential equation as follows:

The braking distance is determined as follows:

where

Vi,

Vf are the initial and final speeds of the bus, m/s, respectively; and

jret is the bus retarding, m/s

2.

Calculations were carried out for a bus train under the conditions of full weight and weight corresponding to half of the passenger capacity. The full weight of the bus train was equal to the sum of the full weight of the individual buses (14,400 kg) included in the bus train, and the weight corresponding to half of the passenger capacity was the sum of the equipped weights (9200 kg) and half of the passengers’ total mass (2600 kg) of a single bus.

The results of calculating fuel consumption while driving at a constant speed by a trailer bus train in different variants for the full weight and the weight corresponding to half the passenger capacity, respectively; see

Table 3 and

Table 4.

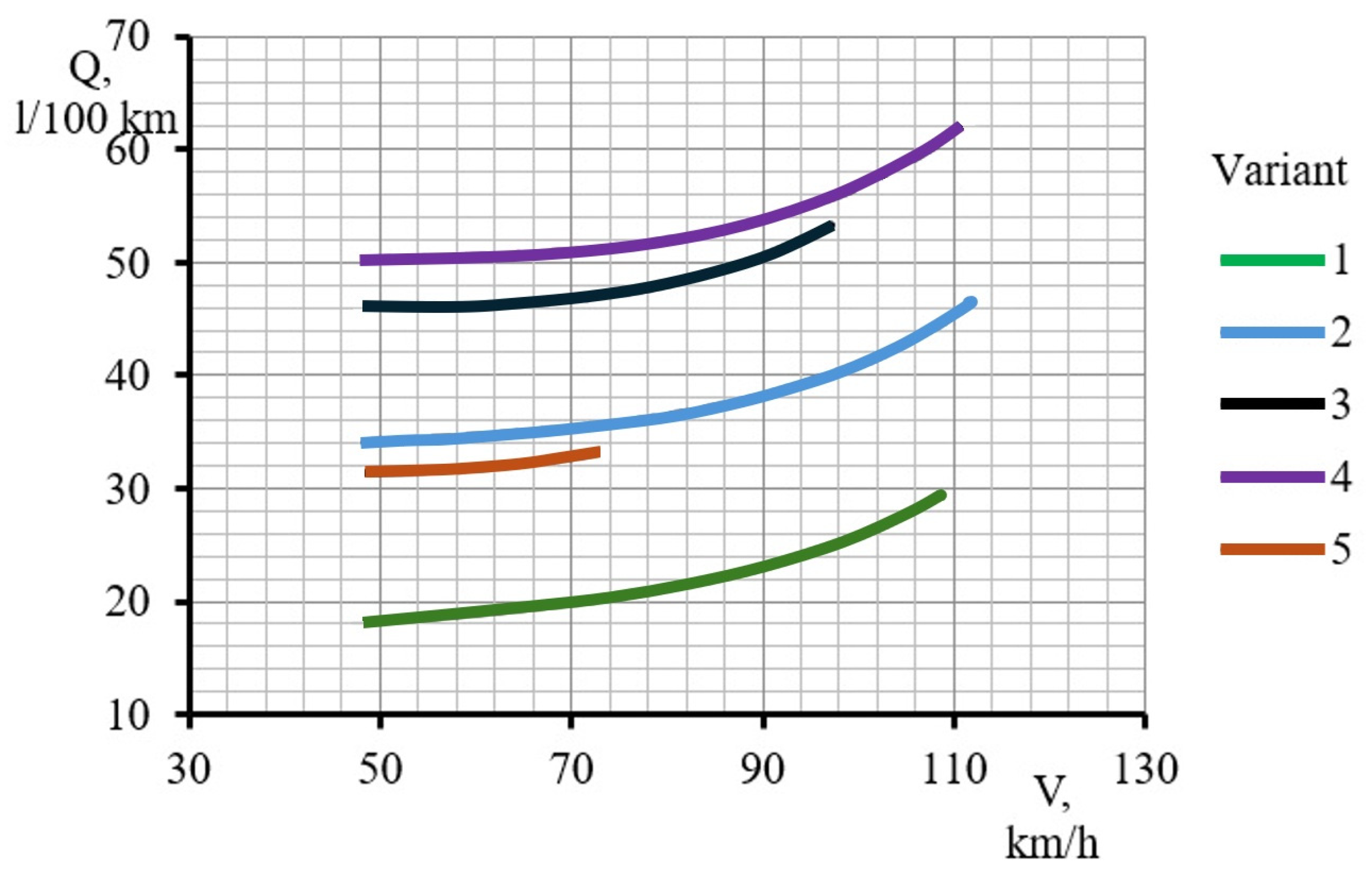

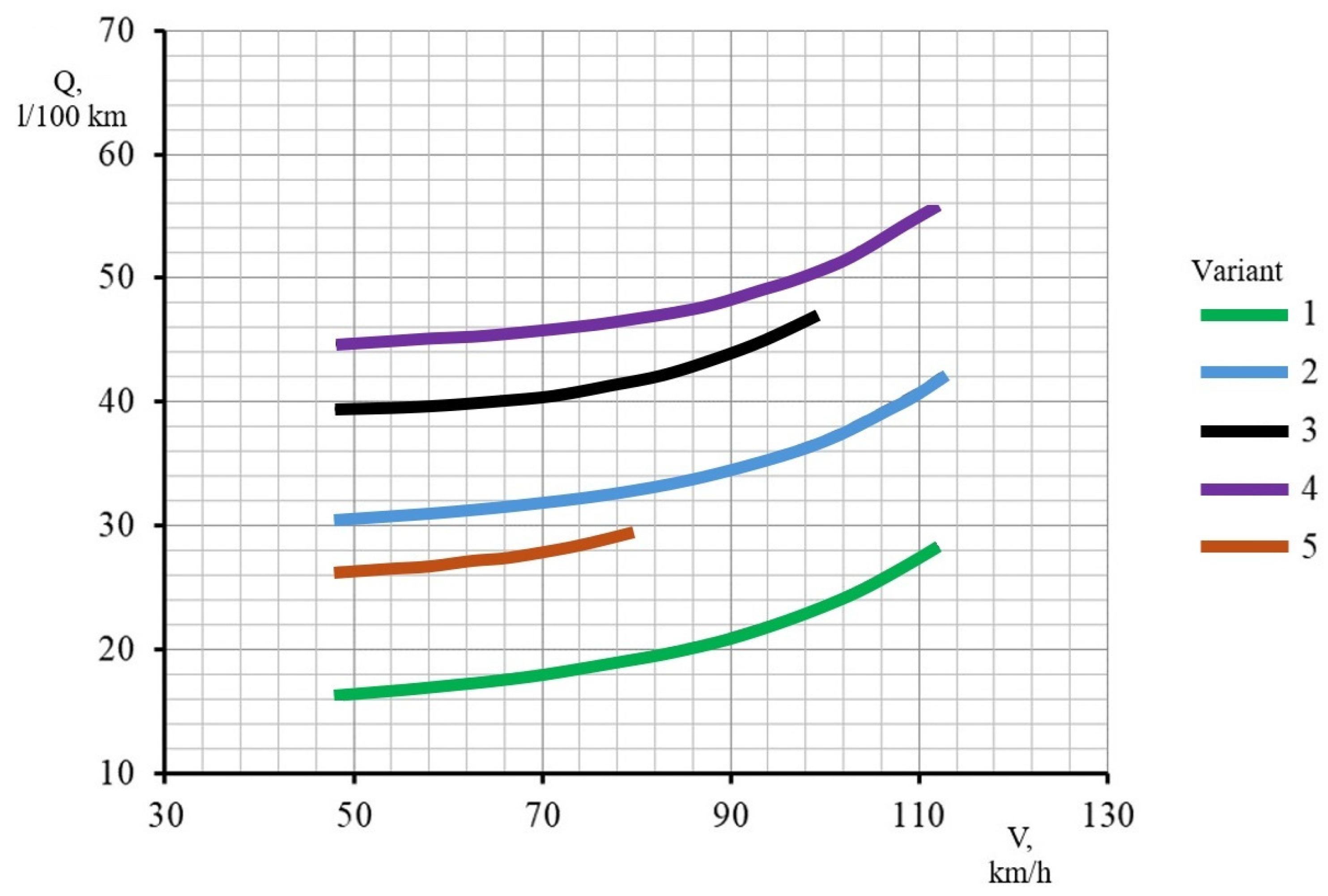

According to the calculation results, the fuel characteristics of the steady-state movement of a trailer bus train were constructed in different variants for the full weight and the weight corresponding to half the passenger capacity, respectively (

Figure 7 and

Figure 8).

Controlling fuel consumption is defined based on the results of fuel consumption calculation when moving at a constant speed of 60 km/h.

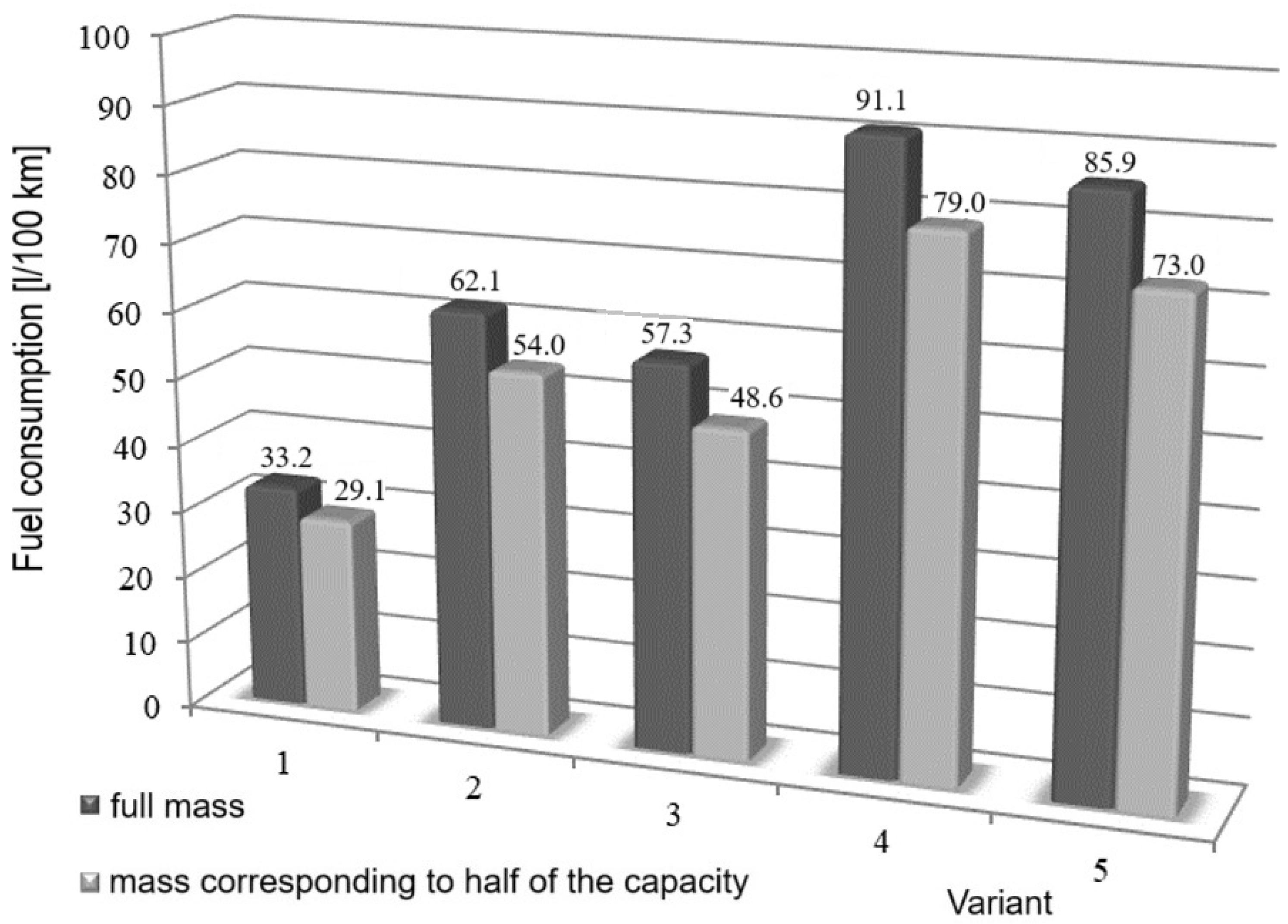

It was established that increasing the number of sections of a trailer bus train leads to an increase in fuel consumption while driving at a constant speed. Thus, controlling fuel consumption (at the speed of 60 km/h) of a trailer bus train with a two-section (Variant 2) and three-section scheme (Variant 4) for the total mass increases by 82.6% and 165.7% in comparison to a single bus (Variant 1), respectively.

Reducing the trailer train mass to a mass corresponding to half the passenger capacity does not significantly influence the difference in fuel consumption between different schemes. Thus, the reference fuel consumption of a trailer bus train with a two-section (Variant 2) and three-section scheme (Variant 4) increases by 82% and 164.2% compared to a single bus (Variant 1), respectively.

Shutting down the engines leads to a reduction in fuel consumption. Thus, the reference fuel consumption of a trailer bus train in a two-section scheme with one running engine (Option 3) compared to two running engines (Option 2) is reduced by 8.2% for the full weight and 13.5% for the weight corresponding to half the passenger capacity. Shutting down one engine (Option 5) in a three-section scheme also leads to a reduction in fuel consumption compared to a bus train with three engines running (Option 4) by 8.7% for the full weight and 11.9% for the weight corresponding to half the passenger capacity.

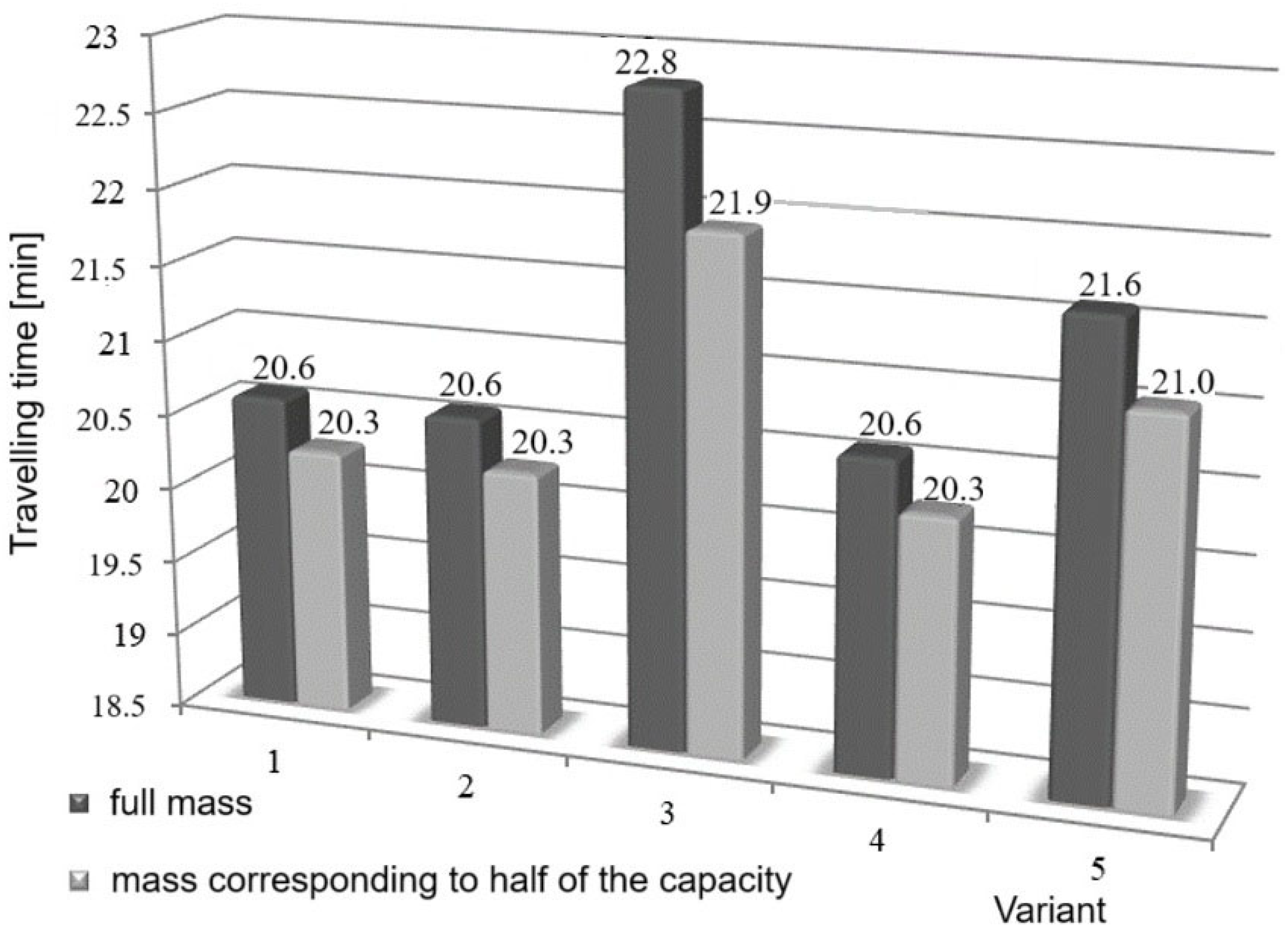

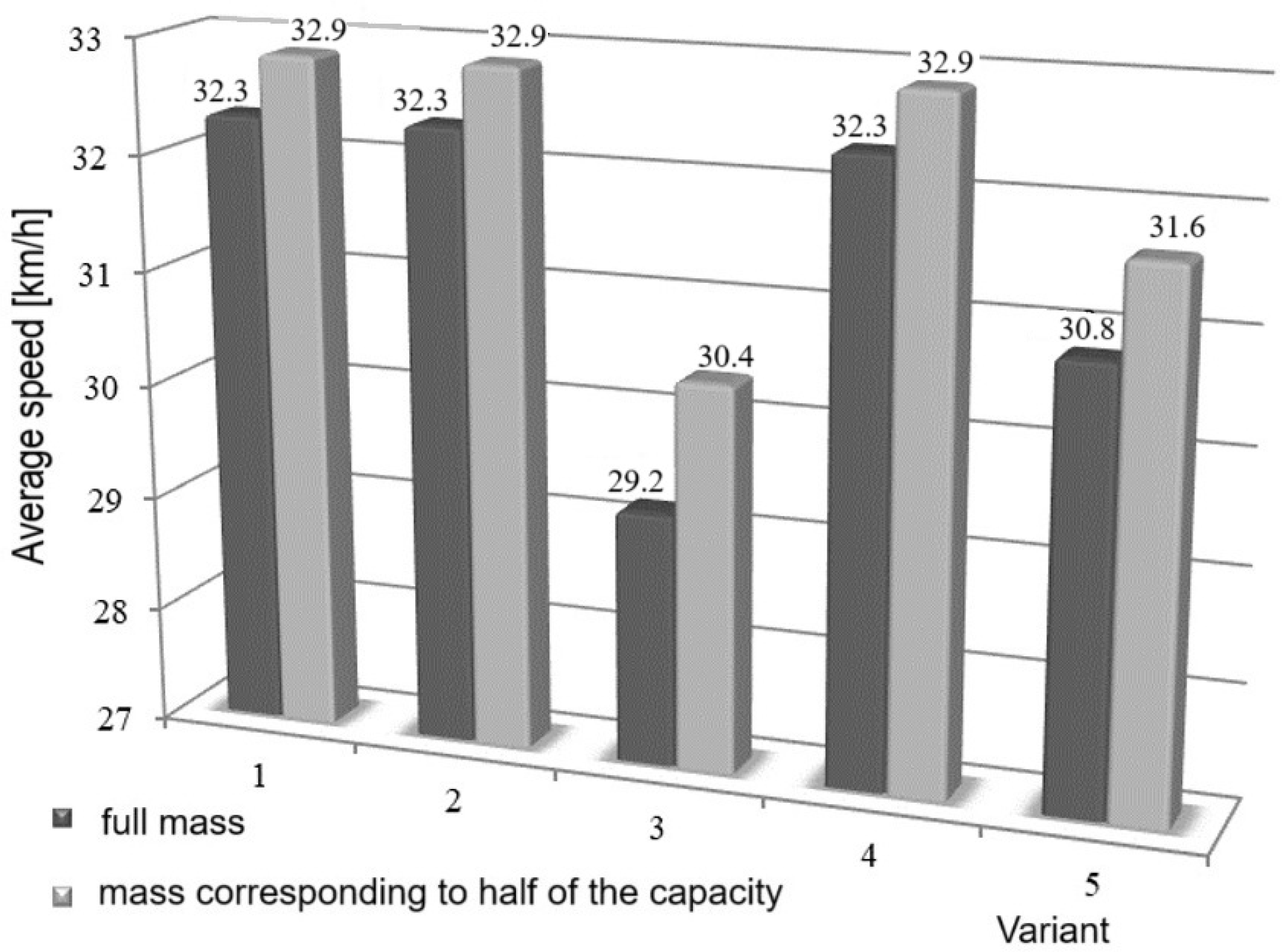

Fuel consumption, as well as driving time and average speed in the urban driving cycle, simulating the real buses’ route in the BRT system, was defined using the method given in [

23] and is shown in

Table 5 and

Figure 9,

Figure 10,

Figure 11 and

Figure 12.

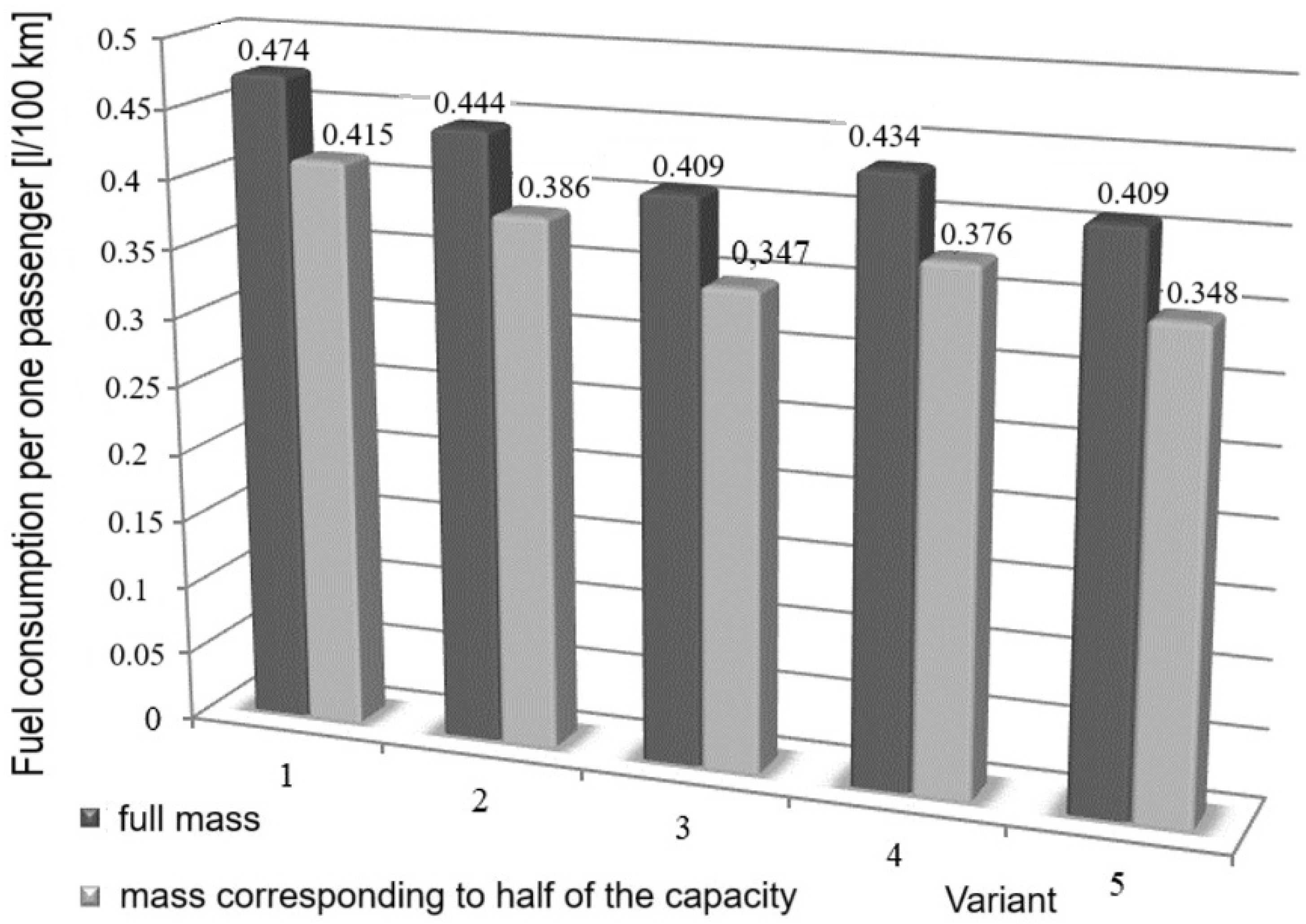

It was established that increasing the number of sections of a trailer bus train, provided that all its engines are operating, causes an increase in fuel consumption in the driving cycle. Thus, fuel consumption in the driving cycle of a trailer bus train with a two-section (Option 2) and three-section scheme (Option 4) increases by 87.2% and 174.6% compared to a single bus (Option 1), respectively.

However, fuel consumption per passenger, at the increase in the number of sections, decreases by 6.3% for a two-section (Variant 2) and 8.4% for a three-section scheme (Variant 4) compared to a single bus (Variant 1).

As in the case of controlling fuel consumption, reducing the bus train mass to a mass corresponding to half the passenger capacity does not significantly affect the difference in fuel consumption in the driving cycle of different variants of the trailer bus train under the condition of all engines running.

Shutting down one of the engines results in a reduction in fuel consumption in the proposed driving cycle with a two-section scheme (Variant 3) by 7.1% for the full weight and 9.9% for the weight corresponding to half the passenger capacity compared to the option with all engines running (Variant 2), and with a three-section scheme (Variant 5) by 5.8% for the gross weight and 7.6% for the weight corresponding to half the passenger capacity compared to the option with all engines running (Variant 4).

Fuel consumption per passenger is also reduced, especially compared to a single bus (Variant 1). In particular, for the two-section scheme (Variant 3), fuel is reduced by 13.7% for the full weight and 16.4% for the weight corresponding to half the passenger capacity, and for the three-section (Variant 5) by 13.7% and 16.1%, respectively.

The cycle performing time and average speed for trailer bus train variants with all engines running (Variants 1, 2, 4) practically do not change. Disabling one engine leads to a deterioration in the traction and speed characteristics, especially for the two-section scheme (Variant 3). Thus, the cycle time increases by 2.2 min for the full weight and 1.7 min for the half-capacity weight, which may lead to the inability to maintain the established schedule on the route. The bus train, according to the three-section scheme (Variant 5), also has a longer travel time on the route by 1 min for the full weight and 0.8 min for the half-capacity weight, and is acceptable for operation on the route.

In general, the use of trailer bus trains is one perspective, as fuel consumption per passenger will be lower than that of single buses. Moreover, increasing the number of sections of such a bus train leads to a decrease in fuel consumption.

Another way to improve fuel efficiency is to turn off one of the engines, especially when the bus train is running with an incomplete load. However, this may significantly worsen its traction and speed characteristics, enabling it to maintain the schedule.

Among the suggested schemes of trailer bus trains, the two-section (Option 2) and three-section (Option 4) schemes with all engines running and the three-section scheme with one engine turned off (Option 5) are appropriate for further use due to improved fuel efficiency indicators with better or acceptable traction and speed properties.

As a result, the following recommendations can be formulated for selecting optimal configurations of trailer bus trains for actual operation in BRT systems. For routes with high and stable passenger traffic, such as rush hours on main lines, the optimal solution is a three-section configuration with all engines running (Option 4), ensuring maximum carrying capacity with the best fuel efficiency. For routes with average or variable passenger traffic, such as during daytime hours or rush hours on less busy routes, a two-section configuration with all engines running (Option 2) and a three-section configuration with one engine switched off (Option 5) are recommended. These options offer significant fuel savings compared to single buses and allow flexible control of carrying capacity, achieving improved or acceptable traction and speed characteristics. In turn, for routes with low passenger traffic, such as late evening hours or on night routes, it is advisable to use single buses, i.e., the first section without a trailer, to minimize operating costs. Decisions about the introduction of trailer bus trains should consider not only fuel efficiency, but also local infrastructure features, such as turning radii and the length of stopping platforms, as well as the specifics of passenger traffic on specific routes. Flexibility in the formation of a train composition is a key advantage, allowing the transport system to adapt to dynamically changing needs.

Compared to articulated buses, which can achieve 15–20% lower fuel consumption [

21], trailer trains offer their own unique advantages. Unlike articulated buses with their fixed capacity, trailer trains allow dynamic adaptation of the carrying capacity to the current passenger flow. This flexibility, including the ability to switch off one of the engines in the train when partially loaded, allows more efficient optimization of the rolling stock use and, as a result, lower overall operating costs in dynamic urban BRT systems where passenger flow fluctuates significantly.

The obtained results on the fuel efficiency of trailer bus trains confirm the general trends observed in studies devoted to the optimization of the operating indicators of large-scale public transport. In particular, the idea of using multi-section vehicles to increase the carrying capacity and reduce the specific cost per passenger-kilometer is confirmed in studies devoted to modular bus systems [

10,

11,

12,

13,

14]. Our work offers a practical assessment of four specific trailer bus train designs, considering real operating cycles and the possibility of switching off engines for additional fuel savings.