1. Introduction

Internal combustion engines remain a critical component of the automotive industry and various mechanical systems. Enhancing ignition efficiency and combustion stability continues to be a focal point for improving engine performance and fuel economy. Among various ignition methods, electrical spark plugs stand out due to their ability to store energy from the engine battery, enabling controlled ignition in petrol engines [

1,

2]. Optimal combustion is achieved through precise air–fuel mixture formation, homogeneity, and effective ignition [

3], with maximum performance realized when ignition efficiency is high and combustion variability between cylinders is minimized [

4,

5]. A key factor influencing this process is the spark plug electrode gap—narrower gaps are generally associated with higher ignition intensity [

6]. Alternative ignition strategies, such as multiple-electrode spark plugs, offer distinct advantages by providing multiple ignition points, which can alter combustion characteristics depending on configuration and positioning [

7]. Research also highlights the benefits of split spark ignition, which significantly reduces breakdown time compared to single-spark systems [

8,

9,

10]. Engine tuning plays a parallel role in achieving fuel economy and throttle response; however, significant reductions in fuel consumption (e.g., 15%) may compromise overall engine performance [

11,

12].

Spark plug design has been shown to influence both engine output and emissions significantly. Multiple-ground electrode spark plugs, for instance, improve torque and power while reducing emissions compared to standard configurations [

13]. Surface discharge electrode designs further enhance brake thermal efficiency and reduce cyclic variations in lean-burn engines, promoting faster flame kernel development and shorter combustion duration [

14]. These configurations extend the lean-burn limits, supporting reliable ignition under extreme conditions. Similarly, advanced torch ignition systems and multi-electrode setups have demonstrated potential in reducing emissions and improving thermal efficiency under lean-burn conditions [

15]. Lean-burn operation itself offers dual benefits: lower NOx emissions and improved fuel efficiency [

16]. Techniques such as stratified water insulation applied to the piston top surface further enhance thermal efficiency during super-lean burn conditions [

17], contributing to the broader goal of cleaner and more efficient spark-ignition engines [

18]. Fine-wire spark plugs with smaller center electrodes provide superior ignitability and faster flame propagation, enhancing engine stability and reducing fuel use [

19]. Additionally, including a ground strap on spark plug coil cables has been shown to cut fuel consumption and emissions [

20].

Electrode geometry plays a pivotal role in determining performance outcomes. Finer electrodes and larger gaps tend to yield better results, although effects vary depending on engine load and fuel type [

21]. Computational models and experimental studies confirm the importance of spark plug configuration in engine optimization [

22]. While increasing the number of ignition points can improve combustion efficiency and enable leaner operation, the relationship is not always linear [

23,

24]. Studies suggest excessive electrodes may increase vibration and noise, following non-linear trends under certain configurations [

25,

26]. The spark plug gap also influences HC emissions, with optimal settings leading to measurable reductions [

27]. Advanced materials like iridium, along with multi-spark plug arrangements, further contribute to enhanced engine power and torque [

28]. Despite these advancements, there remains a lack of comprehensive understanding regarding how varying numbers of spark plug electrodes impact engine performance, particularly concerning noise, vibration, fuel consumption, and emissions. This study fills that gap by systematically evaluating these parameters across electrode configurations and operating conditions. Doing so provides new insights into how electrode design affects combustion dynamics and overall engine behavior, offering valuable guidance for future ignition system development.

2. Experimental Setup

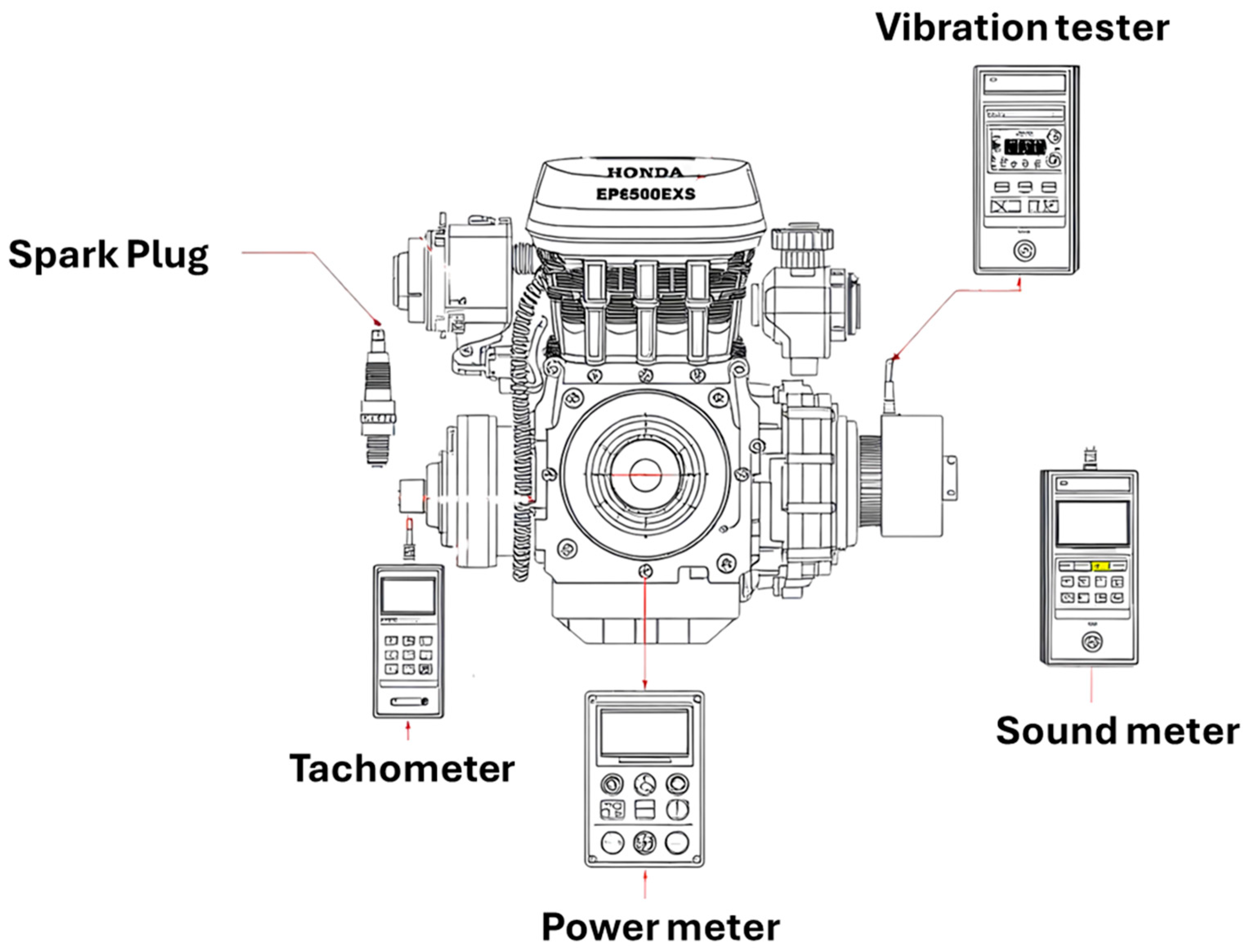

To evaluate a combustion engine’s performance, a precise experimental setup with accurate instruments is crucial for collecting reliable data. This study utilized a single-cylinder Honda air-cooled four-stroke engine (EP6500EXS), Kumamoto, Japan, connected to ten 10-kilowatt electrical heaters, as shown in

Table 1. A digital energy analyzer monitored voltage, current, and power. The engine speed was measured by counting spark plug sparks and verified with a digital tachometer, as shown in

Figure 1. During testing, the engine speed was controlled via a manual throttle lever, allowing us to fix the speed at desired RPM values (e.g., 1000, 2500, and 3600 RPM). While the governor helped stabilize speed within narrow limits under varying loads, the primary control mechanism was the throttle setting.

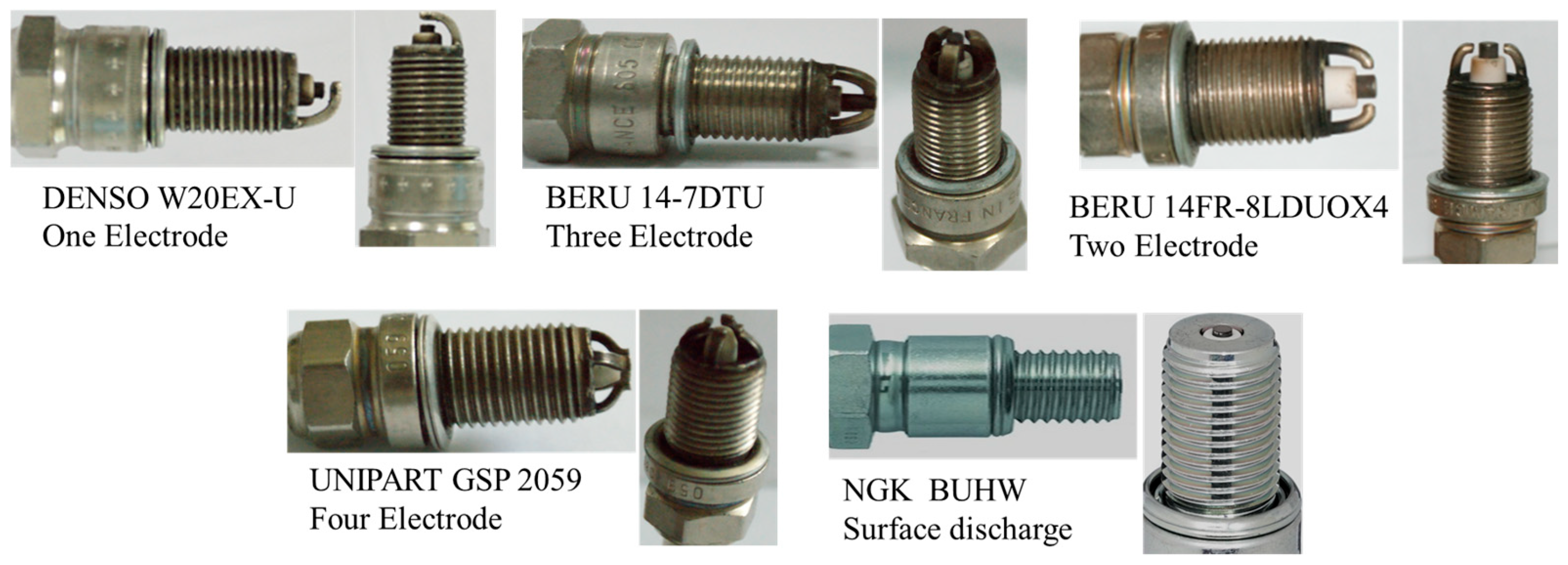

The experiment tested five spark plug designs—surface discharge, non-electrode (NGK-BUHW), single-electrode (Denso-W20EX-U), two-electrode (Beru-14FR8LDUOX4), three-electrode (Beru-14-7DTU), and four-electrode (GSP-2059), as shown in

Figure 2, under consistent conditions to analyze how electrode configuration impacts fuel consumption and emissions. The heat ratings of the tested spark plugs were carefully selected to align with the manufacturer-recommended specifications for the Honda EP6500EXS engine, ensuring consistent thermal performance across all configurations. The heat ratings for each spark plug type are as follows: NGK-BUHW (heat range 5, medium), Denso-W20EX-U (heat range 20, standardized for small engines), Beru-14FR8LDUOX4 (heat range 14, cold), Beru-14-7DTU (heat range 14, cold), and GSP-2059 (heat range 6, medium). While surface discharge plugs do not follow conventional heat rating classifications, their design inherently promotes efficient heat dissipation. All spark plugs were preconditioned at the engine’s operating temperature (80–90 °C) before data collection to minimize variability.

Measurement of noise and vibration: Noise levels were measured using a Type 2236 sound level meter, which enabled the assessment of both environmental and occupational noise. Different measurement equipment capable of analyzing dynamic behavior was used for vibration measurements. Among the notable tools used were the Model 2526 B&K data collector analyzer, an accelerometer, and the Model 4391 B&K, which captured vibration signals within the specified frequency range. The data underwent processing using a computer equipped with diagnostic software (model 7107 B&K Sentinel Program) to assess vibration levels with various parameters, harmonics, and excitation frequencies. The Sentinel vibration program facilitated the development of measurement protocols for distinct scenarios and machinery operational conditions. Several trials were conducted to determine the optimal values for frequency ranges, vibration signal amplitudes, and signal types. The main drivers for evaluating acceleration amplitude were high vibration signals and frequency ranges of up to 2000 Hz. Fuel consumption was measured using a volumetric measurement method.

Fuel consumption was precisely measured using a burette integrated into the engine’s fuel line during controlled load tests conducted over a specified period. The consumed fuel was directly read from the burette after each test. Calibrated electric heaters connected to a Honda EP600EXS generator were carefully controlled and measured to determine the power load. This setup enabled modulation and measurement of power, allowing for comprehensive testing of generators across various loads. Adjusting the electrical load enabled the study of the generator’s output parameters (voltage, current, and frequency), efficiency, and stability under various operating conditions. Exhaust emissions were analyzed in real-time for CO2, CO, and HC levels using an automated AGS-688 gas analyzer to assess combustion efficiency and environmental impact.

Before each session, a sound level meter (Type 2236) was used, Nærum, Denmark. was calibrated using a standard calibrator. An accelerometer (Model 4391 B&K) was checked against a reference signal generator. Fuel measurement burettes were calibrated using volumetric standards traceable to ISO 4787, Geneva, Switzerland (2010). The uncertainty analysis was estimated, and all measurements were recorded according to the following:

Noise measurements: ±1.2 dB

Vibration: ±3%

Fuel consumption: ±1.5 mL/s

Emissions: ±2% for CO, HC; ±1.5% for CO2

3. Results and Discussions

3.1. Noise Behavior

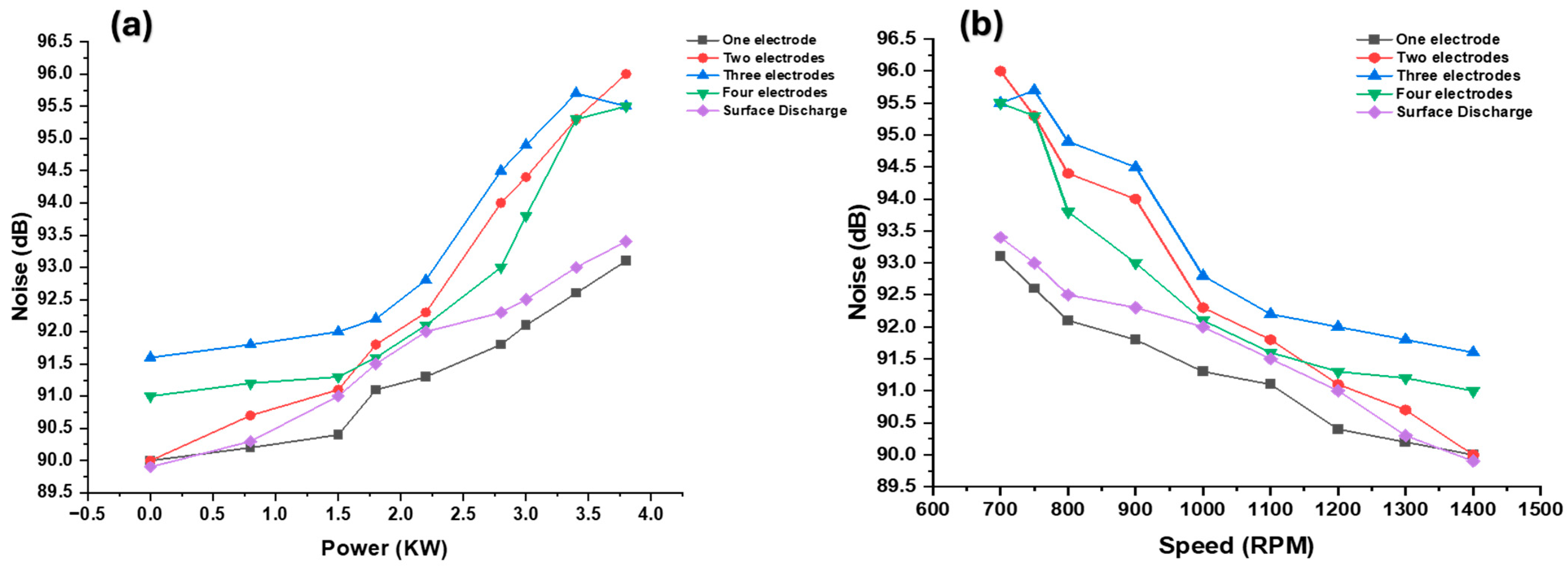

The data shown in

Figure 3 reveal that, even though a single spark initiates sequentially, multi-electrode plugs characteristically produce more noise compared to single-electrode plugs, especially at high power. This suggests that the trajectory of the spark between the electrodes influences combustion phenomena and noise generation. Since the spark path changes with every ignition cycle, it creates differences in flame propagation and pressure wave formation inside the combustion chamber. This must be a contributing factor to the rise in noise levels. The analyzed data show that one electrode produces 93 dB at 0 kW, while four electrodes produce 95 dB, representing a 2.15% increase. At 3.4 kW, the noise increases from 96 dB to 98.3 dB, a 2.39% rise. This demonstrates that the impact of multiple electrodes on noise becomes more pronounced at higher power outputs [

29,

30].

Engine noise rises with power output for all tested spark plugs and speeds. However, one- and four-electrode spark plugs produced less noise and exhibited more gradual increases in combustion efficiency than two- or three-electrode designs, suggesting that electrode configuration influences combustion efficiency. The “Surface Discharge” plug exhibited a distinct, sharper increase in noise at higher power levels, as shown in

Figure 4. The non-linear noise-RPM relationship indicates that factors beyond engine speed, such as combustion efficiency and flame propagation, significantly contribute to noise. Overall, the electrode configuration significantly impacts engine noise across various power outputs [

31,

32]. Spark plugs with one electrode show a roughly 7% noise increase from the lowest to the highest power, while those with four electrodes exhibit a more moderate 6% increase. By contrast, two- and three-electrode spark plugs produce the highest noise levels, with 8% and 7.5% peak increases, respectively. The “Surface Discharge” spark plugs follow a unique pattern, characterized by lower noise at lower power settings but showing a much steeper increase, exceeding 10%, at higher power output. While the noise generally decreases with increased RPM—hence power reduction—this relationship is not linear, indicating that factors other than engine speed, such as combustion efficiency and flame propagation, also contribute to noise production.

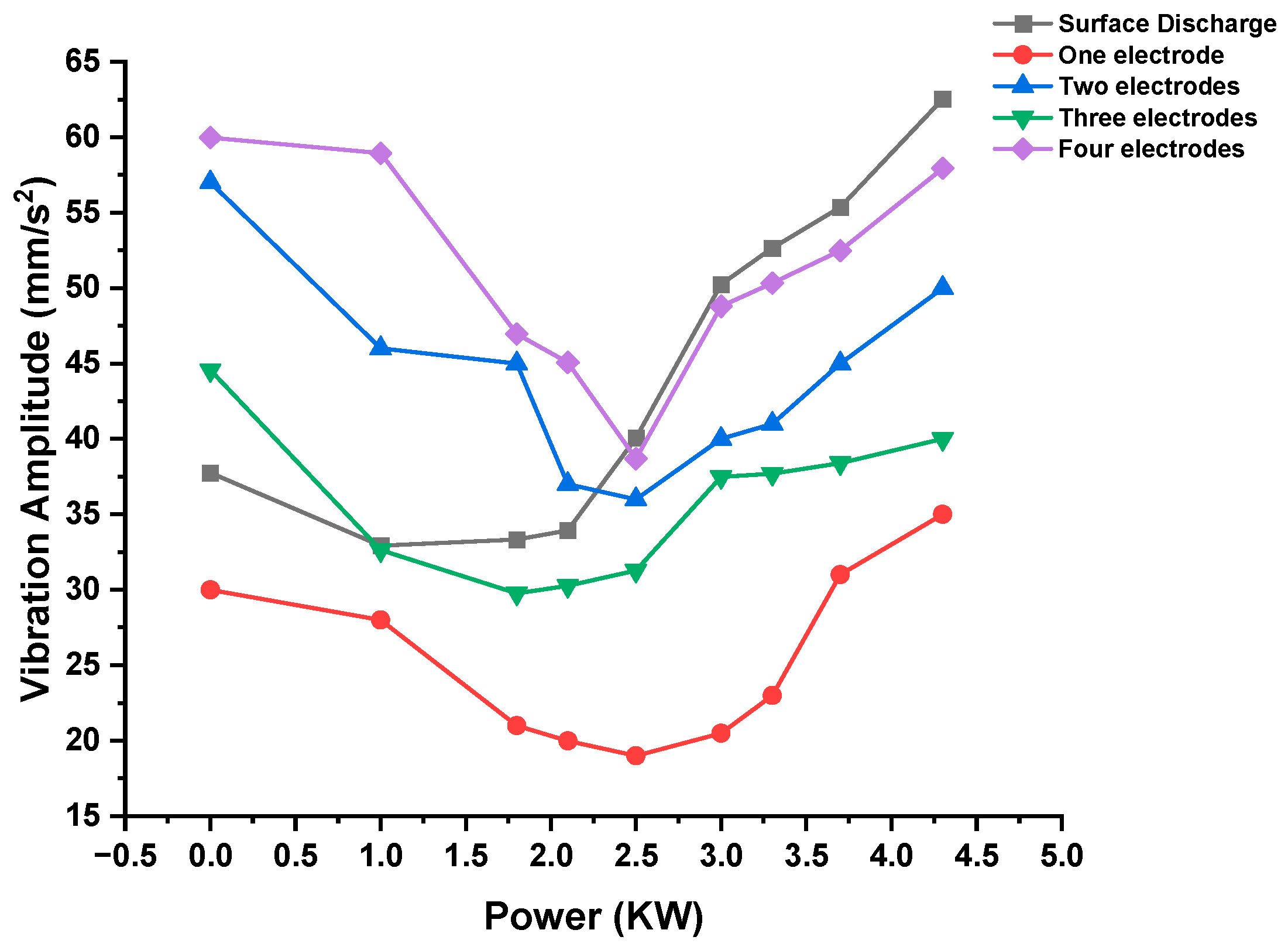

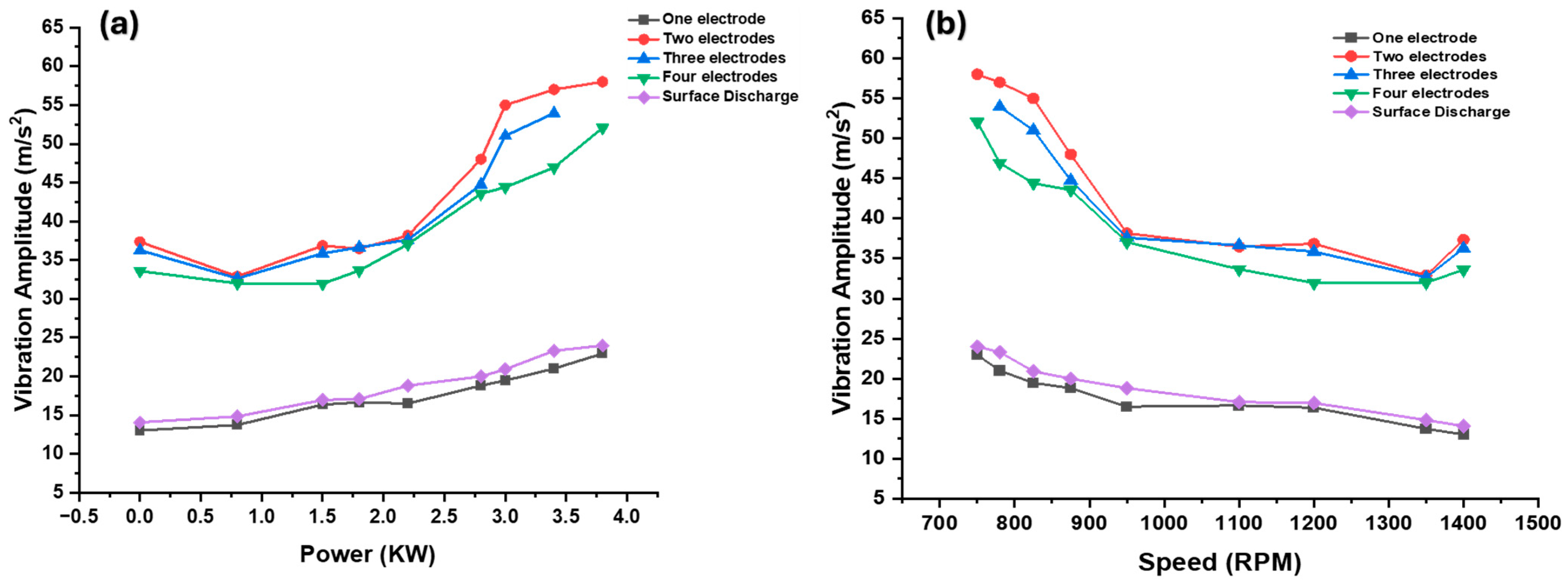

3.2. Correlation of Spark Plug Electrodes and Engine Vibration

Engine vibration at 1000 rpm is intricately linked to the number of spark plug electrodes and power. Generally, more electrodes and higher power increase vibration, likely due to more intense combustion. Surface discharge causes the most vibration, while one electrode typically causes the least. Two and three electrodes result in moderate and higher vibration, respectively. Interestingly, four electrodes can produce less vibration than three, possibly due to more balanced combustion, as shown in

Figure 5. This variation is likely due to flame propagation, pressure waves, and the distribution of spark energy. The lowest vibration (28 mm/s

2) occurs with one electrode at 0 kW, and the highest (62.522 mm/s

2) with surface discharge at 4.3 kW, representing a 123% increase. While one electrode offers the smoothest combustion, introducing more electrodes introduces complexities, and vibration generally increases with increased power due to higher combustion intensity. Most configurations exhibit a U-shaped trend in combustion, with efficiency improving at lower power levels before declining due to instability at higher outputs. A single electrode produces the least vibration, likely due to a more straightforward flame front. More electrodes generally increase vibration, possibly due to complex interactions between flame and pressure waves, although four electrodes can sometimes provide a more balanced response than three. Surface discharge consistently results in the highest vibration, indicating combustion instability.

Figure 6 illustrates a clear trend of increasing engine vibration with higher power output behind specific points, regardless of the spark plug type. This confirms that more forceful combustion generates more significant vibration. Nonetheless, the specific kind of spark plug significantly affects the vibration’s amplitude. Compared to the “two-electrode” and “three-electrode” types, the “one-electrode” and “four-electrode” types exhibit less vibration over the whole power range, suggesting more stable combustion. The “Surface-discharge” spark plugs’ behavior indicates significantly different combustion characteristics, which exhibit slight vibration at low power and a sharp increase in vibration with power. It is interesting to note that vibration typically exhibits a non-linear relationship with increasing RPM, with engine speed having a negligible effect compared to the impact on flame propagation and combustion efficiency. Ultimately, the best spark plug configuration needs to be adjusted for the operating environment: “Surface Discharge” may work better at lower power. At the same time, “One-electrode” or “Four-electrode” is more appropriate for higher outputs. The findings emphasize how crucial it is to take spark plug design into account for better engine performance and fewer undesired vibrations.

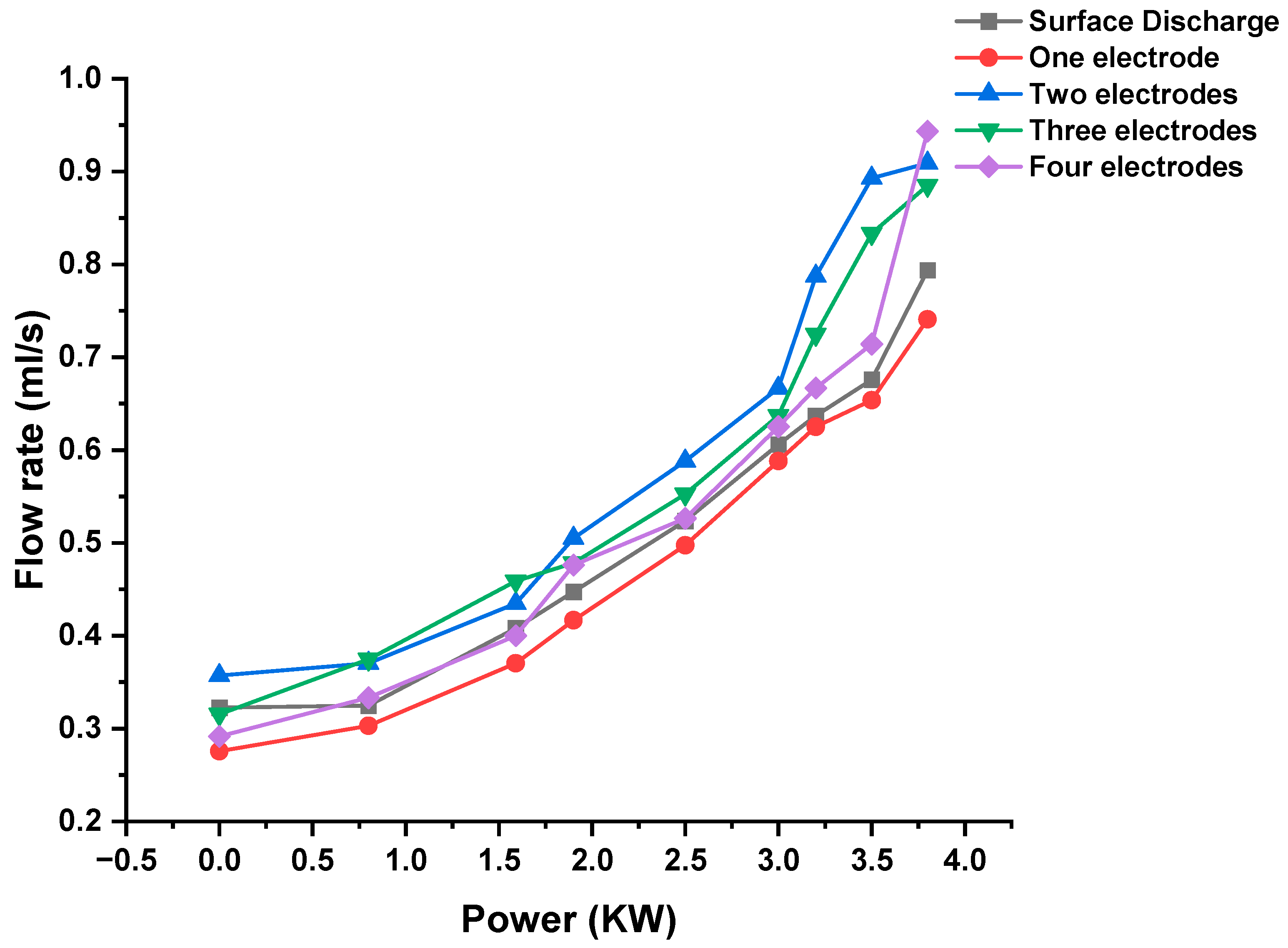

3.3. Electrode Impact on Fuel Efficiency

Figure 7 shows that increased electrodes correlate with higher fuel flow and power. While more power demands more fuel, the spark plug type affects consumption. One electrode typically used the least fuel (6.67–14.49% reduction), while four electrodes used the least at maximum power (30.37% decrease). Two electrodes consistently showed higher fuel flow. One electrode appears to be the most fuel-efficient overall, but four may be better for achieving peak power based on the flow rate. The “Three electrodes” configuration exhibited the steepest increase in fuel flow relative to power, indicating efficient fuel utilization. “Surface Discharge” showed the smallest increase, indicating less fuel consumption, likely due to combustion efficiency. Multiple electrodes can improve combustion, but they also increase fuel consumption. Further research is necessary to understand the relationship between electrode number, combustion, and fuel consumption.

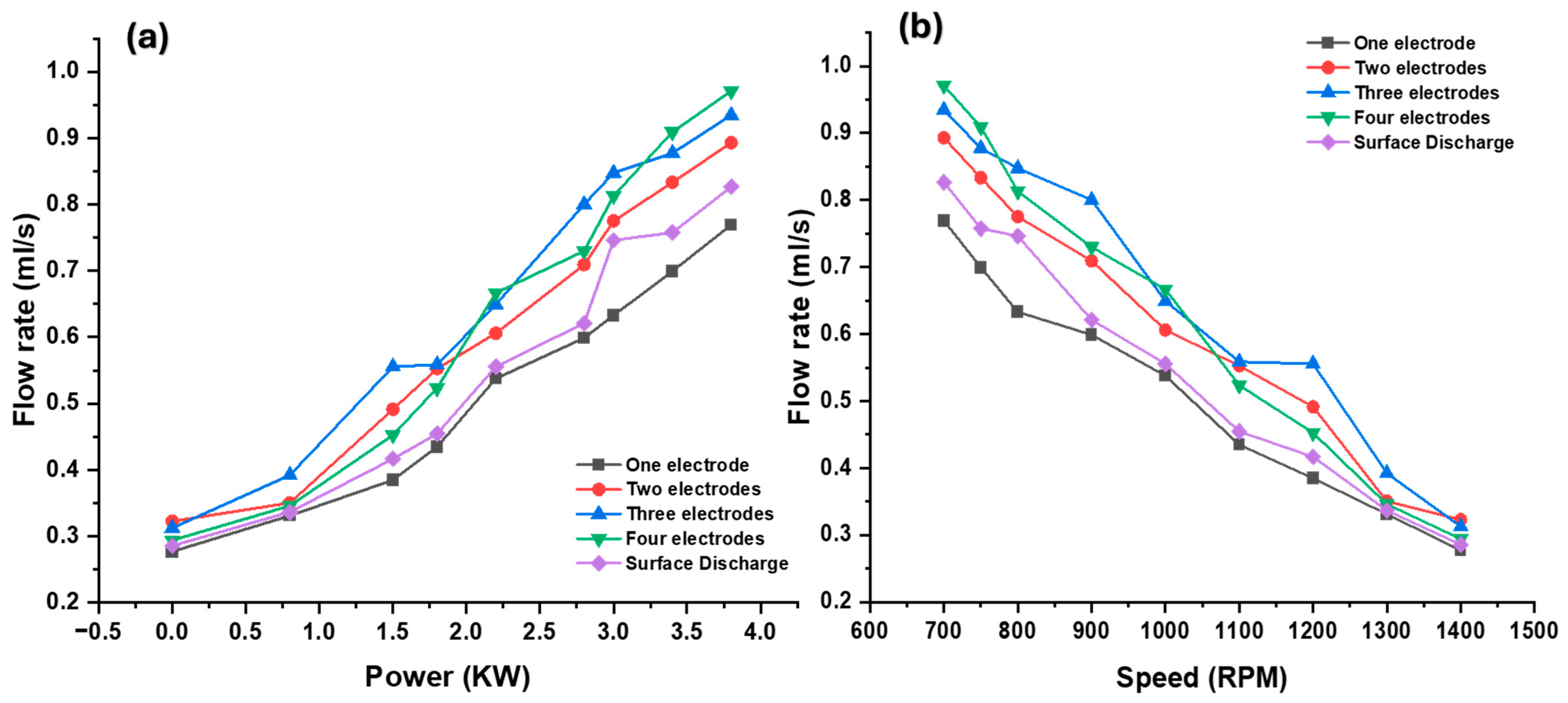

Figure 8 illustrates the complex relationship between fuel consumption (fuel flow rate) and engine power, speed (RPM), and spark plug design. Fuel flow generally increases with power, with the rate of increase varying by spark plug electrode number, indicating differences in combustion efficiency (

Figure 8a). Conversely, fuel flow decreases as RPM increases, indicating better efficiency at lower speeds (

Figure 8b). This inverse relationship partially offsets the higher fuel use at higher power, often at lower RPM. Optimizing fuel efficiency requires careful consideration of both engine operation and spark plug design, as different electrode designs can significantly impact combustion and fuel economy.

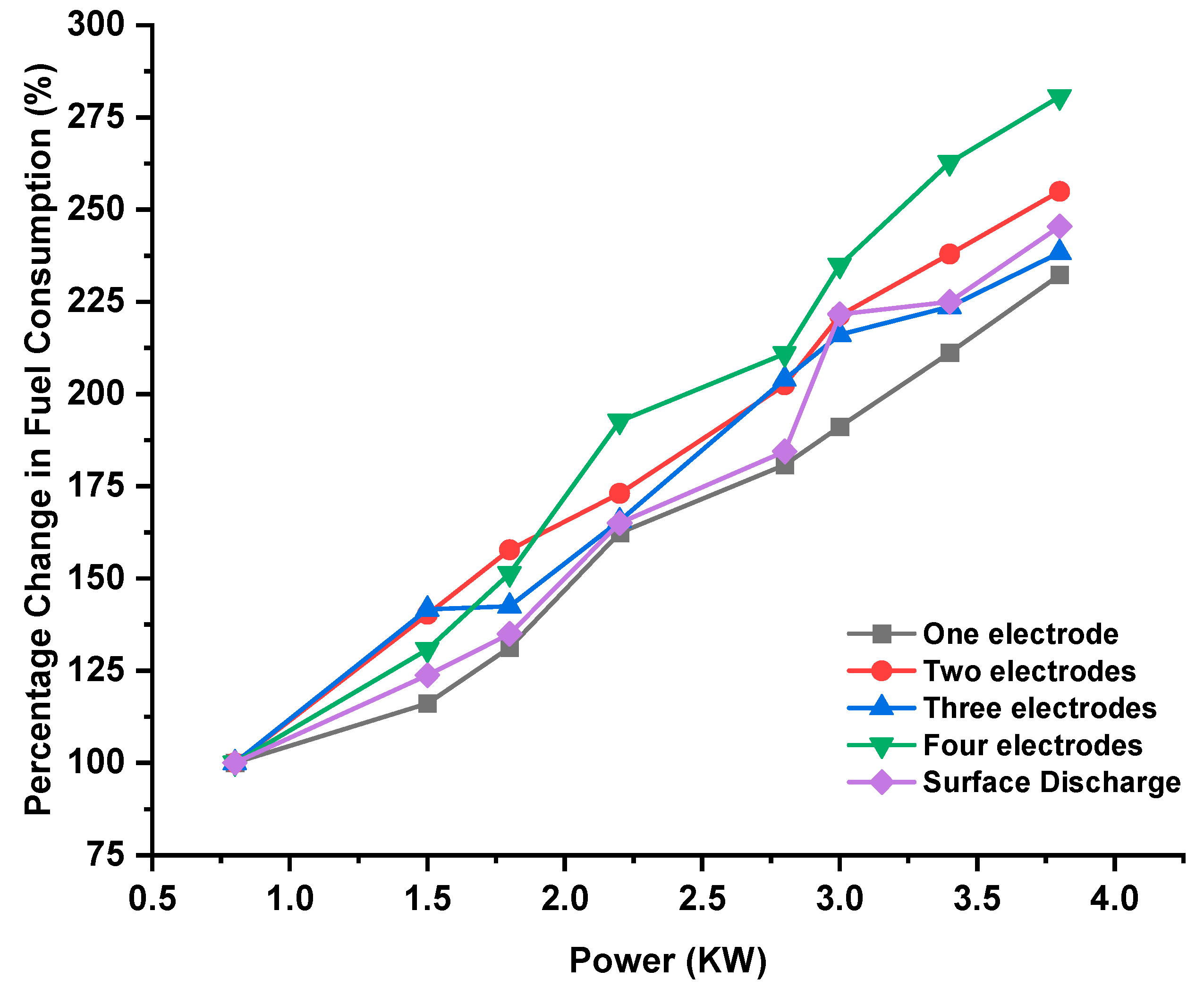

Figure 9 illustrates the correlation between fuel consumption and engine power across different spark plug designs. Generally, fuel consumption increases with power output, but the rate of this increase varies by spark plug type. Notably, three-electrode spark plugs show the most significant percentage increase in fuel consumption, suggesting potentially lower combustion efficiency. While fuel consumption increases with power for all spark plug types, the rate of increase differs. Three-electrode plugs exhibit the highest increase in fuel consumption, from 235% at low power to high power. Although decreasing engine speed (RPM) partially mitigates this trend due to improved efficiency at lower RPMs, the complex interaction between power, RPM, and fuel consumption underscores the importance of spark plug design and operating conditions in achieving optimal engine efficiency.

3.4. Effect of Electrode Numbers on Exhaust Emissions

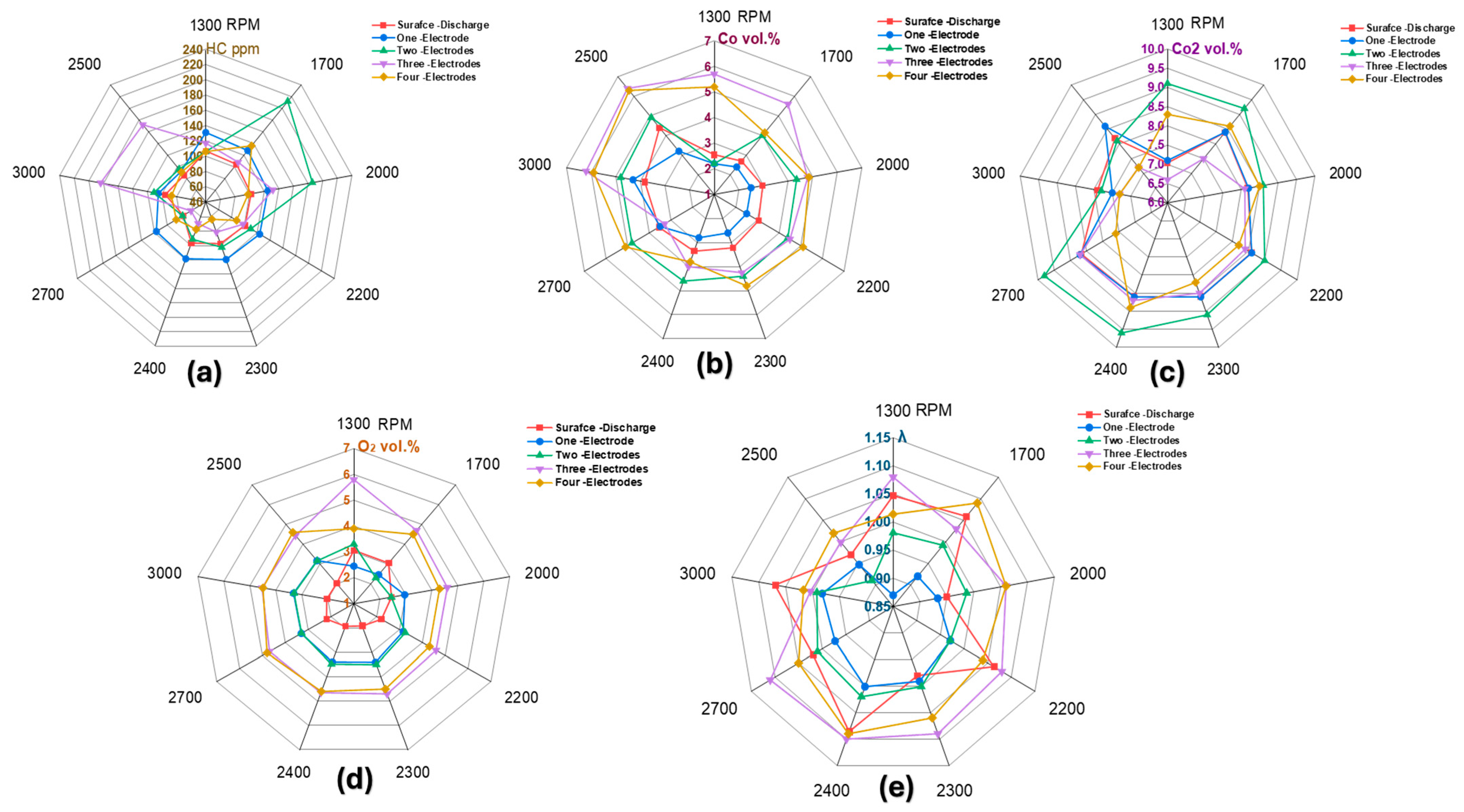

Radar plots (

Figure 10) illustrate how engine speed, exhaust emissions (HC, CO, CO

2, O

2), and air–fuel ratio (λ) vary with the number of spark plug electrodes (one to four). Each plot represents a specific engine speed, with radial axes indicating parameter values (concentric circles show magnitude). These visuals suggest that, generally, higher RPMs result in lower emissions and a better air–fuel ratio, suggesting more efficient engine operation. Optimal RPM for minimum emissions varies; for example, HC is lowest around 2700 RPM, while CO decreases with increasing RPM. CO

2 exhibits a less consistent trend, with slight growth at the highest RPM (3000), likely due to a richer mixture that increases power. More spark plug electrodes (three or four) generally result in lower emissions and a λ closer to the ideal 1, indicating more complete combustion. Operating around 2700 RPM with a three- or four-electrode spark plug offers the best balance of performance and low emissions.

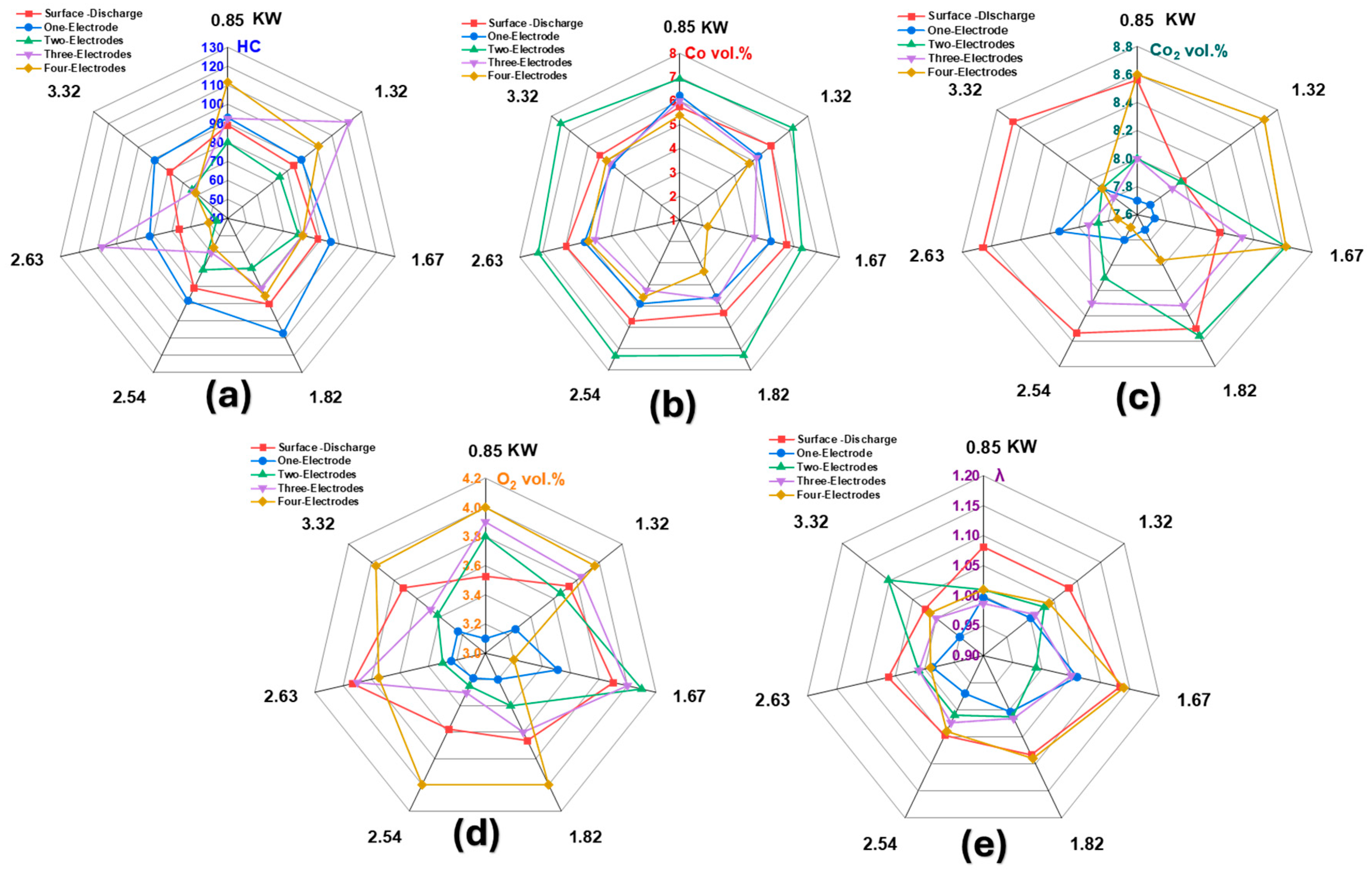

Increasing the number of spark plug electrodes generally reduces harmful exhaust emissions, such as hydrocarbons (HC) and carbon monoxide (CO), particularly at lower engine power levels (

Figure 11). This is likely due to enhanced combustion efficiency resulting from multiple spark paths and improved flame propagation, which leads to a more complete fuel burn. However, emissions tend to increase at higher power outputs regardless of electrode number due to the greater fuel demand. Specifically, HC and CO decrease with more electrodes at lower power, while CO

2 might slightly increase due to more complete combustion. Oxygen (O

2) levels in the exhaust tend to decrease with the addition of more electrodes and higher power, consistent with lower HC and CO emissions and a richer fuel mixture at higher loads. Lambda values stabilize closer to the ideal air–fuel ratio with more electrodes, especially at lower power levels, indicating improved combustion control.

NOx in spark-ignition engines mainly forms through the thermal mechanism, susceptible to temperature. Above 1527 °C (1800 K), nitrogen and oxygen break apart into atoms that react to make NO. Hotter temperatures significantly increase this process. Oxygen level (air–fuel ratio) is also key: more oxygen in lean mixtures increases NOx, while less oxygen in rich mixtures reduces it. The time gases stay hot matters too; more prolonged exposure allows more NOx to form. Thermal NOx is usually the dominant type.

While HC emissions fundamentally stem from processes including incomplete combustion, unburned mixture escaping into the exhaust during the gas exchange process, absorption and later release of fuel from lubricating oil films (particularly during cold operation), and crevice trapping, advanced spark plug designs, such as the multi-electrode types discussed, serve as a crucial means to mitigate the amount of unburned fuel available to these processes. Multi-electrode spark plugs, specifically designs like the four-electrode mentioned, achieve this by providing more consistent ignition points and generating a more robust initial flame kernel. This leads to significantly faster and more complete flame propagation throughout the main volume of the combustion chamber. By ensuring a larger portion of the air–fuel mixture is consumed more rapidly and completely, these plugs reduce the overall amount of unburned fuel remaining within the cylinder. This reduction in available unburned fuel directly lessens the quantity that can then escape into the exhaust port during valve overlap, decreases the amount available to be absorbed by the lubricating oil film, and reduces the pool of unburned mixture available for crevice trapping or wall quenching. Therefore, by promoting a stronger, faster, and more complete burn in the main combustion volume, multi-electrode plugs effectively reduce the amount of unburned or partially burned hydrocarbons expelled from the engine, thereby addressing the root causes of HC emissions.

3.5. Temperature of the Exhaust Gases

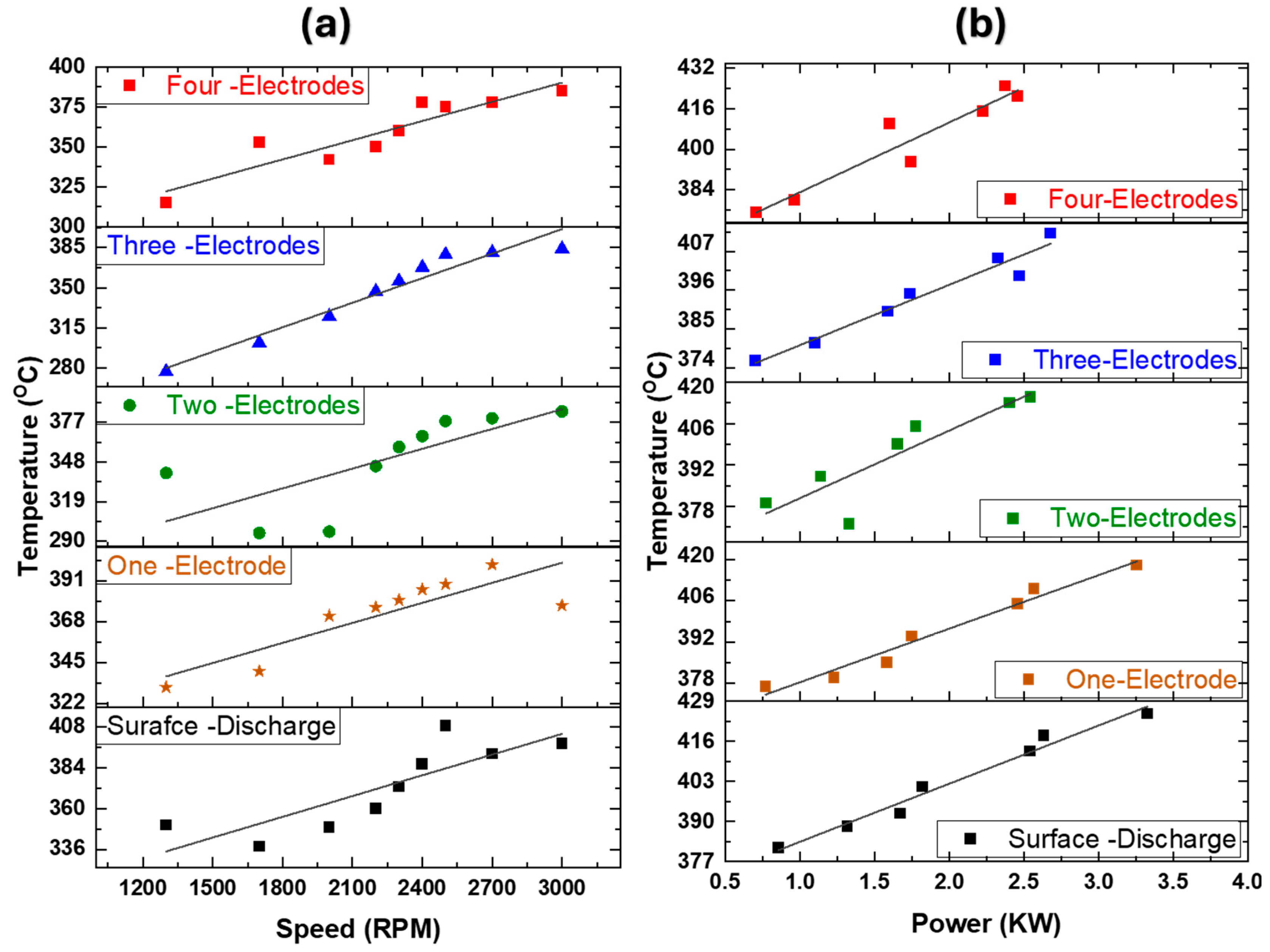

Figure 12 analyzes exhaust gas temperature.

Figure 11a shows that at no load (idling), exhaust gas temperature increases with engine speed at a constant power output. This positive correlation exists across all spark plug types due to the increased fuel consumption required to maintain higher speeds, even without an external load. Internal friction requires more fuel burn, leading to more combustion and higher temperatures [

33,

34]. At lower idle speeds, the number of spark plug electrodes minimally impacts temperature. However, multiple electrodes generally result in lower temperatures at higher idle speeds, indicating that improved combustion efficiency becomes more critical.

Figure 11b demonstrates that, at a constant 2500 rpm, the exhaust gas temperature increases strongly with the consumed power (varying load) across all electrode types, highlighting power output as a key factor in driving temperature. Despite power’s influence, multiple electrodes consistently produce slightly lower temperatures, suggesting better combustion efficiency under load. The figures show that engine speed is crucial at constant power, while power consumption dominates at constant speed. Notably, multiple electrodes, especially the “Surface-Discharge” type, consistently lead to lower exhaust temperatures, suggesting the potential for improved combustion and reduced emissions. These findings underscore the importance of optimizing engine parameters and spark plug design to achieve the desired performance and emissions.

Table 2 presents the minimum and maximum exhaust gas temperatures measured for different spark plug configurations. The “Surface Discharge” configuration consistently yields the lowest temperatures, suggesting a potential for improved engine performance and enhanced fuel economy. As the number of electrodes increases, the exhaust gas temperature decreases, suggesting improved combustion efficiency. The “Four Electrode” spark plug exhibits the most significant reduction in exhaust gas temperature.

3.6. Overall Performance Analysis

Multi-electrode spark plugs improve combustion efficiency through multi-point ignition, which generates spatially distributed flame kernels that coalesce into a unified flame front. This process increases flame surface area, accelerates burn rates, and reduces combustion duration. Multiple ignition sites mitigate local quenching effects by distributing flame fronts and maintaining higher local temperatures. The overlapping flame fronts enhance turbulent flame interaction, promoting faster and more uniform combustion, particularly under lean or high-turbulence conditions [

35]. Spark plug electrode configuration significantly affects flame kernel development and engine performance, with finer electrodes demonstrating better ignitability and faster flame kernel growth [

36]. These mechanisms collectively explain reduced combustion duration, improved thermal efficiency, and extended lean limit operation in engines using multi-electrode spark plugs.

Different spark plugs were tested for engine vibration, noise, fuel use, and emissions. Lower vibration, noise, fuel use, and higher emissions are ideal. One and four-electrode plugs gave the most stable, low-vibration combustion across all power levels. “Surface Discharge” plugs had low vibration but became unstable at high power, with similar noise trends. Three-electrode plugs were the least reliable, two-electrode plugs consumed more fuel, and single-electrode plugs were the most fuel-efficient. At low power, more electrodes typically resulted in fewer harmful emissions. Four-electrode plugs outperformed all others regarding vibration, noise, and emissions. They also achieved good fuel economy at high power. Although they provided the best fuel economy and minimal noise and vibration, single-electrode plugs did not lower emissions. Although surface discharge plugs had high noise and vibration at higher power, they could reduce emissions and fuel consumption. One- and four-electrode plugs were frequently superior to three-electrode plugs. Two-electrode plugs consistently exhibited higher fuel consumption and often generated more noise and vibration. The four-electrode plug’s balanced benefits, especially at high power (3.8 kW), led to the best performance score (54). Spark plug types are ranked by overall performance, as shown in

Table 3. The overall performance is calculated according to the following formula.

where

Each parameter was normalized on a scale of 0–100 (100 being best).

Equal weights were assigned to each dimension to maintain objectivity.

This approach ensures transparency and avoids subjective bias.

Table 3.

Overall performance of the investigated spark plug types.

Table 3.

Overall performance of the investigated spark plug types.

| Spark Plug Type | Vibration | Noise | Fuel Consumption | Emissions | Overall Performance |

|---|

| One Electrode | 28 (Minimum) | 93 (Minimum) | 10 (Minimum) | 100 | 57.75 |

| Two Electrodes | 35 | 95 | 12 | 90 | 58 |

| Three Electrodes | 40 | 96 | 13 | 85 | 58.5 |

| Four Electrodes | 30 | 95 | 11 | 80 | 54 (Most significant) |

| Surface Discharge | 62.522 | 98.3 | 10.5 | 95 | 66.5805 |

The experimental results demonstrated that three-electrode spark plugs exhibited higher vibration, noise, and fuel consumption than one- and four-electrode configurations. This anomalous behavior can be attributed to flame instability and interference from the three-electrode designs’ specific geometry and spark distribution. In multi-electrode configurations, simultaneous or sequential spark discharges generate multiple flame kernels. For three-electrode plugs, the triangular arrangement of electrodes creates overlapping flame fronts that collide asymmetrically within the combustion chamber. Unlike four-electrode designs, where symmetric spark distribution promotes coherent flame merging, the uneven spacing in three-electrode systems disrupts flame propagation. The proximity of the third electrode to the combustion chamber wall or piston surface introduces a quenching effect. As the flame front propagates toward the wall, heat transfer to the cooler metal surfaces prematurely extinguishes the flame at the electrode edges, leaving unburned fuel-air mixtures. As observed in surface discharge plugs, this quenching effect is exacerbated in three-electrode designs due to the reduced spacing between electrodes and chamber boundaries. The resulting incomplete combustion increases hydrocarbon (HC) and carbon monoxide (CO) emissions while reducing thermal efficiency, necessitating higher fuel consumption to maintain power output.

Three-electrode configurations fall into a suboptimal regime between sparse (single/dual) and dense (quadruple) ignition points. While multiple sparks improve lean-burn capability, excessive electrodes can fragment the flame kernel development. For three electrodes, the spark energy is distributed unevenly across the gaps, leading to weaker individual discharges than four-electrode designs. This fragmentation slows flame propagation and delays combustion phasing, as noted in studies by Zhao et al. [

36]. Consequently, the delayed heat release increases the likelihood of knock-like pressure oscillations, further amplifying vibration and noise.

3.7. Environmental Impact of Emissions

Significant environmental consequences follow from the observed reduction in hydrocarbon (HC) and carbon monoxide (CO) emissions resulting from multi-electrode spark plugs (

Section 3.4). Ground-level ozone and smog, formed partly by HC emissions, aggravate respiratory conditions and damage ecosystems. By extending the atmospheric lifetime of methane, CO, a toxic gas, directly compromises human health and indirectly fuels global warming. Particularly in metropolitan areas with great vehicle density, the 20% decrease in these pollutants with four-electrode configurations could translate to observable public health benefits. Moreover, stabilizing CO

2 levels at higher engine speeds (

Figure 10c) points to more total combustion, lowering the carbon footprint per power output unit. Reduced exhaust gas temperatures (

Table 1) support effective energy use even more in line with worldwide initiatives to lower greenhouse gas emissions under policies including the Paris Agreement. Although this study did not measure NOx emissions, their possible reduction by lean-burn combustion, made possible by multi-electrode plugs, could improve environmental benefits even more since NOx is a leading cause of acid rain and ozone depletion.