Thermal Management of Lithium-Ion Battery Pack Using Equivalent Circuit Model

Abstract

1. Introduction

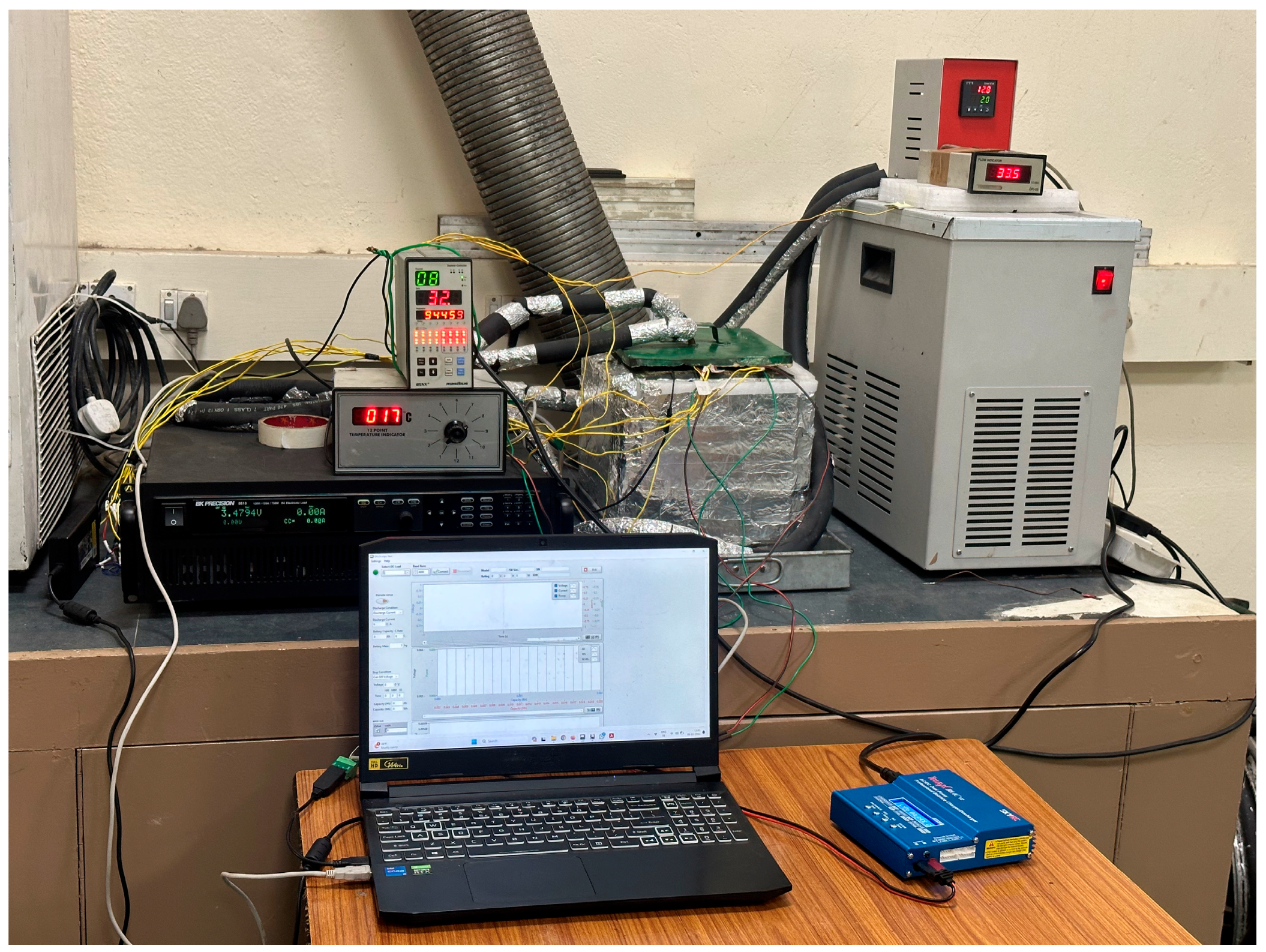

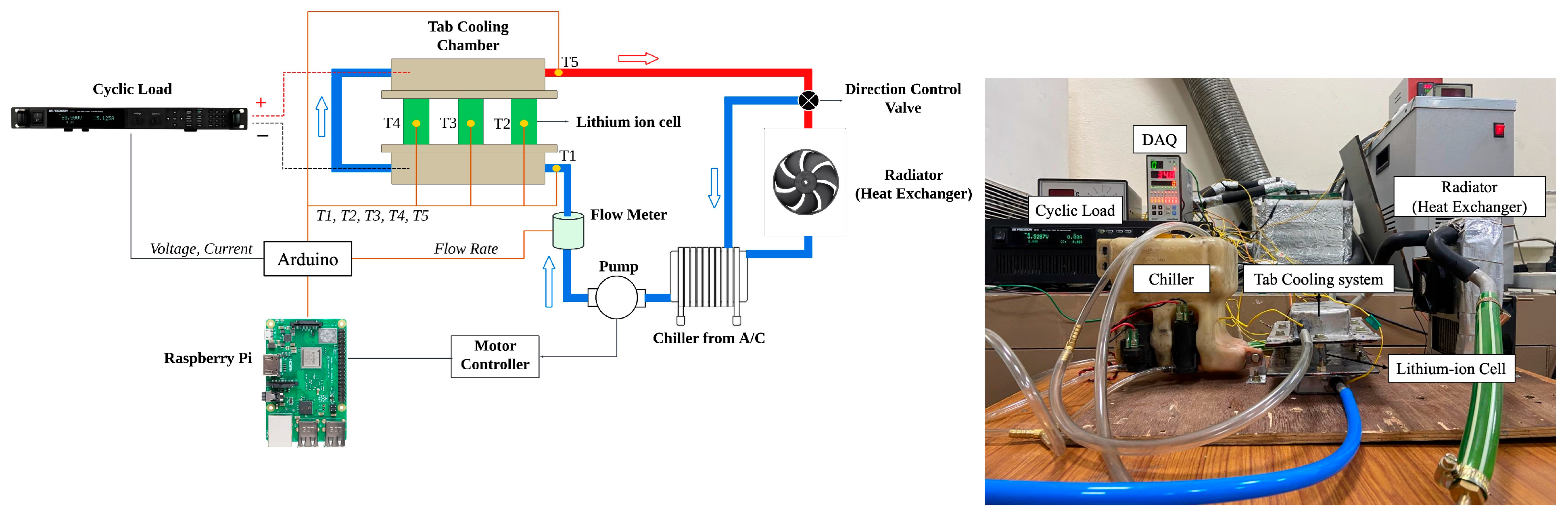

2. Experiment Setup and Methodology

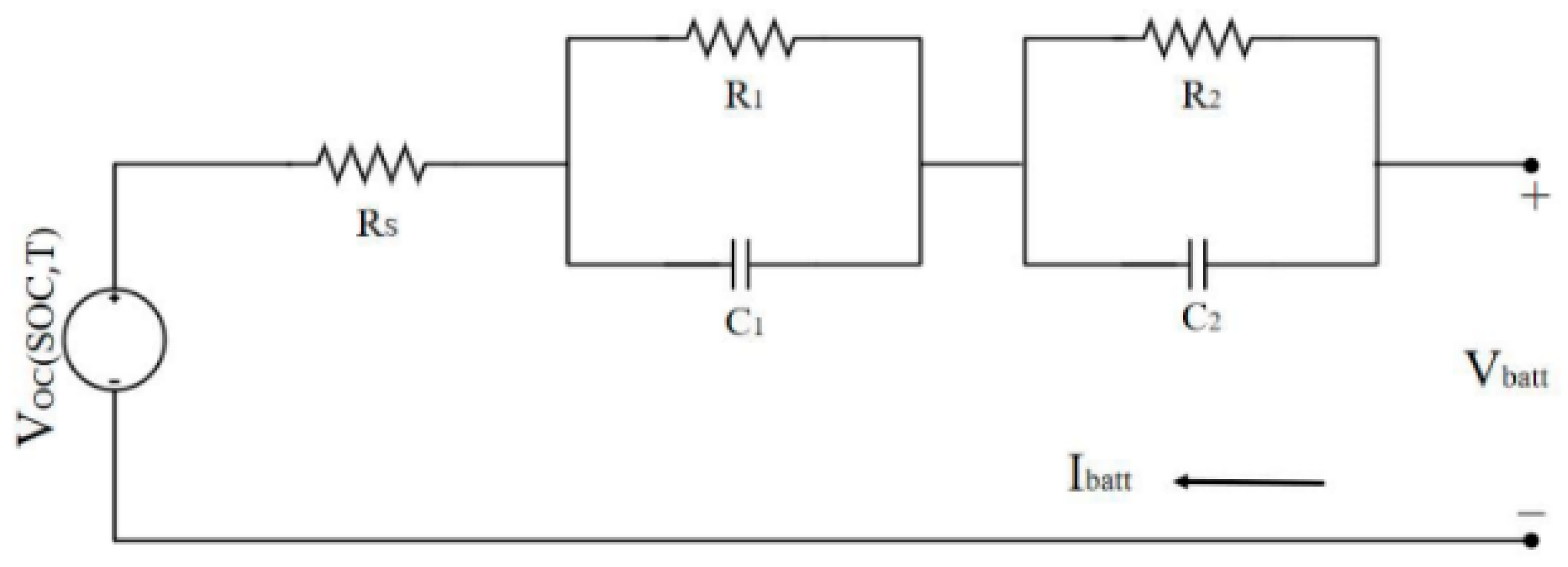

2.1. Equivalent Circuit Model (ECM)

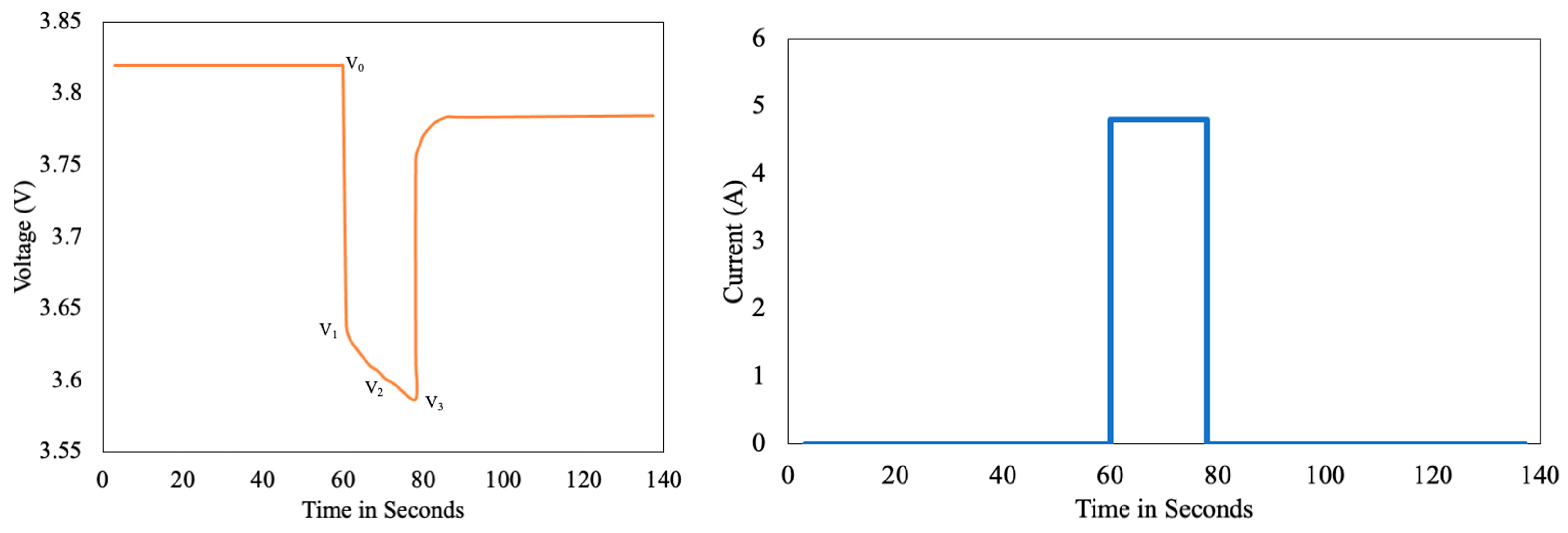

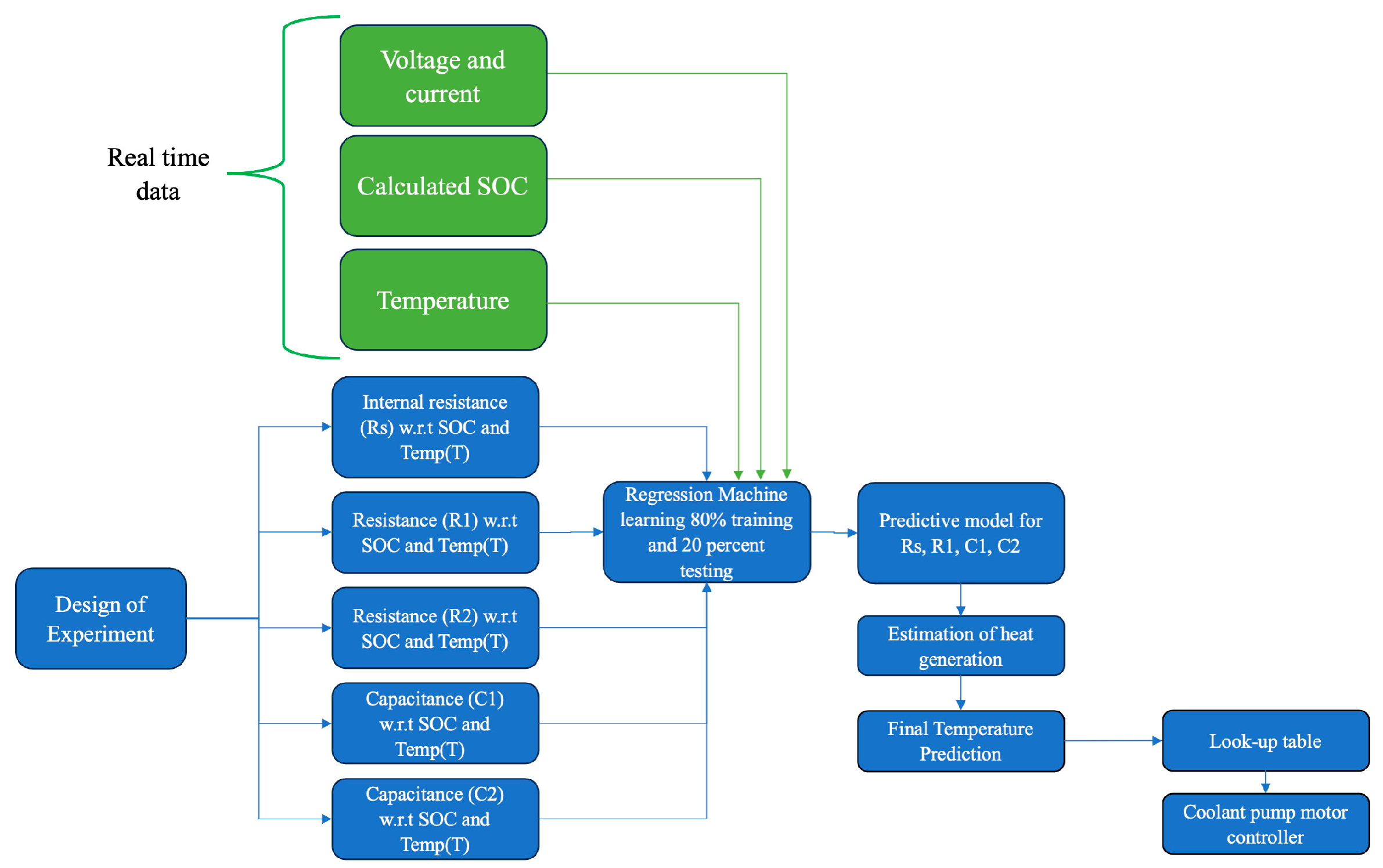

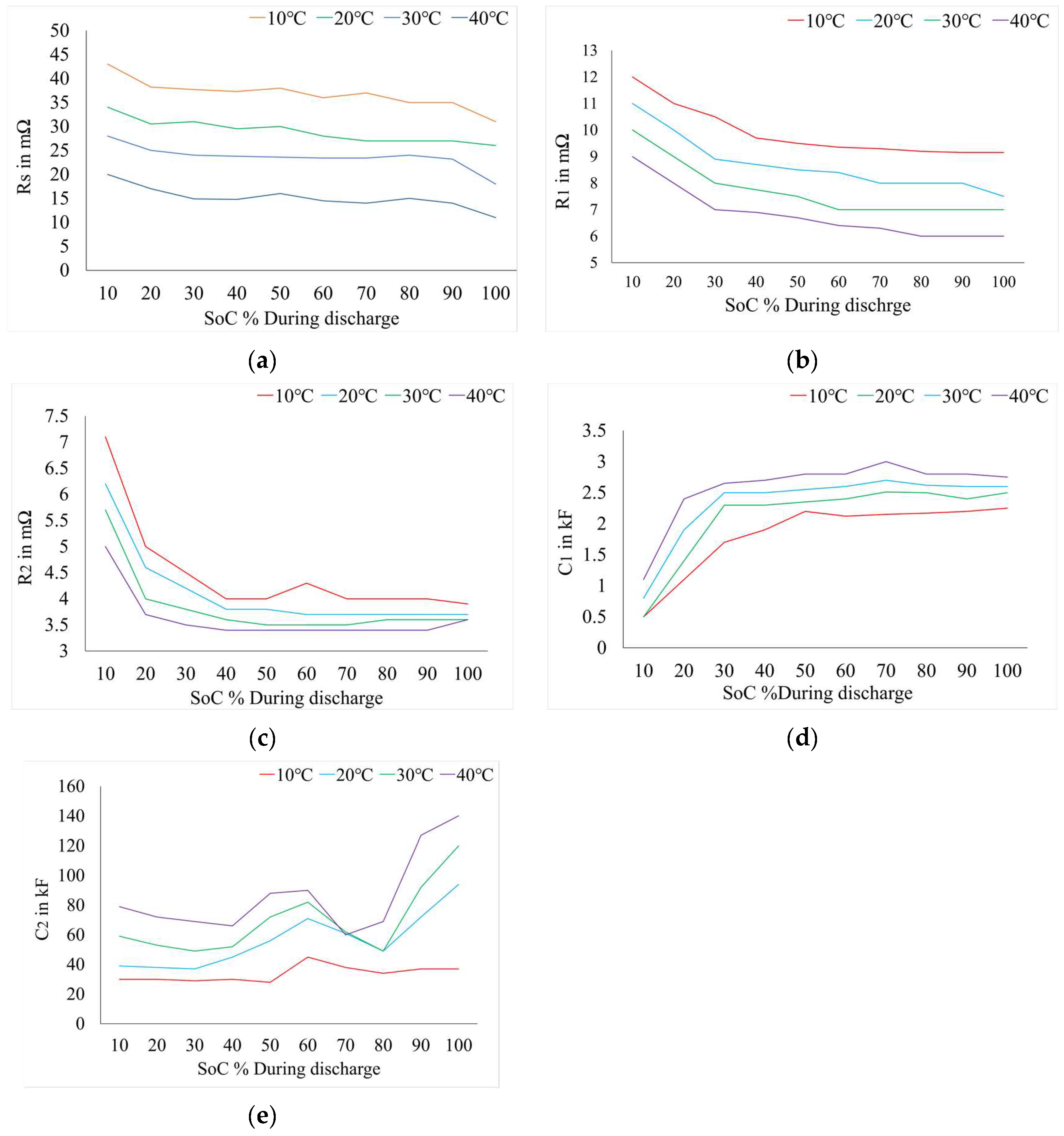

2.2. Model Parameterisation

2.3. Thermal Modeling

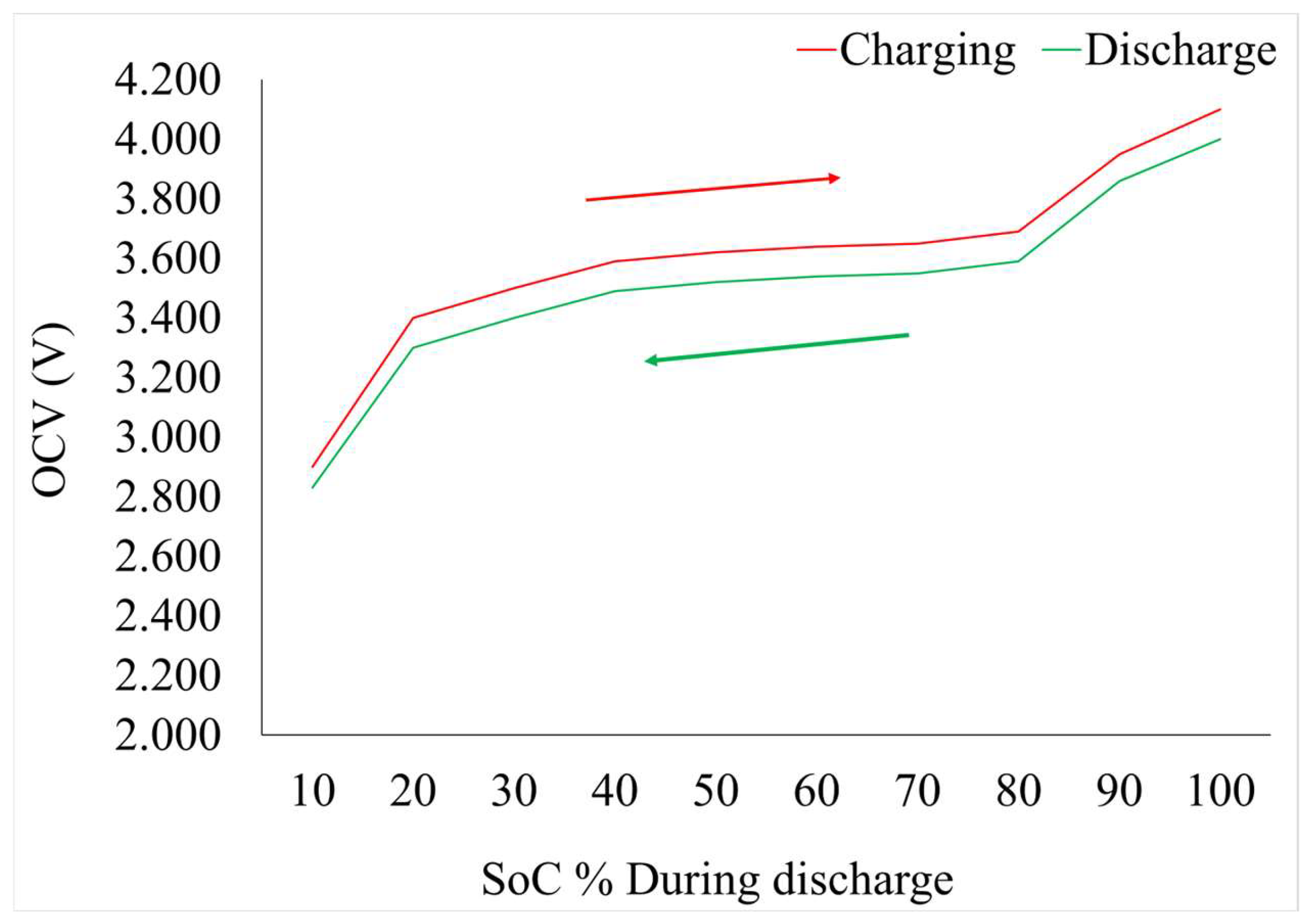

2.4. Open Circuit Voltage

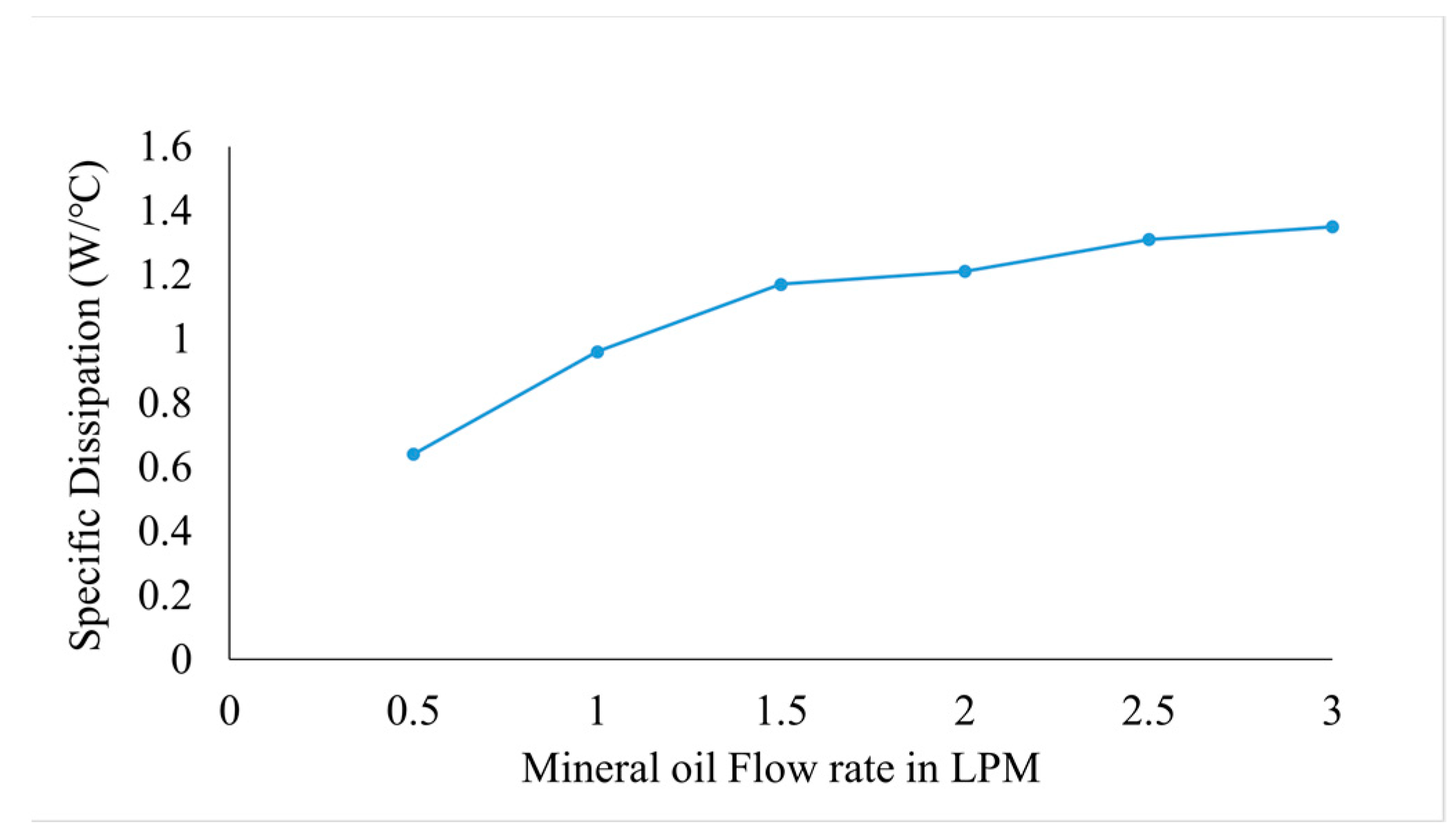

2.5. ECM-Based Tab—Cooling System

3. Results and Discussion

3.1. Cell Parameterization

3.2. Battery Voltage

3.3. Heat Generation Rate

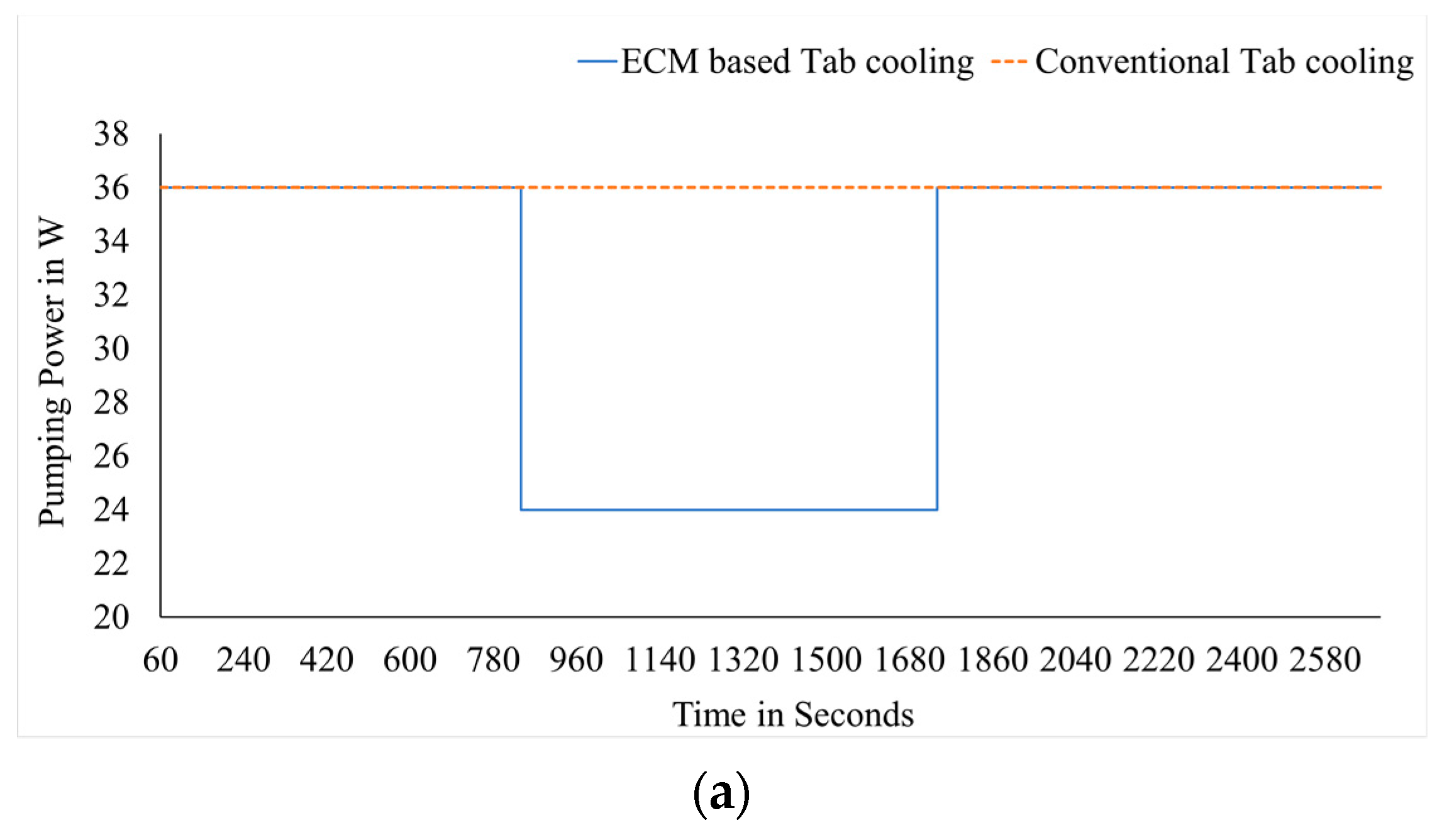

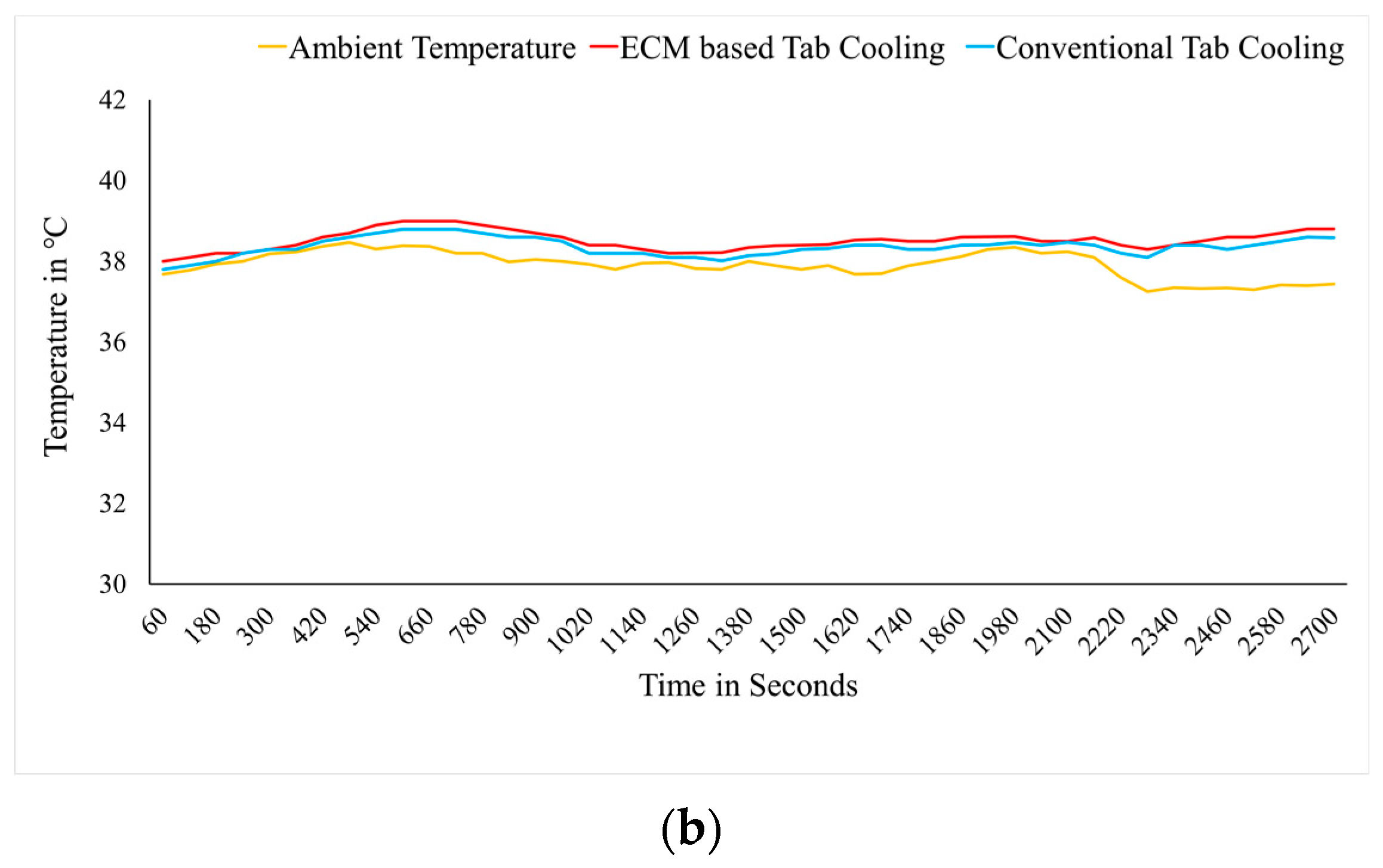

3.4. ECM-Based Thermal Management System

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abatt | Battery surface area (m2) |

| Ah | Ampere-hour |

| AC | Air-conditioning system |

| BTMS | Battery Thermal Management System |

| BTV | Battery terminal voltage |

| CFM | Cubic feet per minute |

| Cp | Specific heat |

| DC | Direct current |

| ECM | Equivalent circuit model |

| EV | Electric vehicle |

| h | Heat transfer coefficient |

| HEV | Hybrid Electric Vehicle |

| HPPC | Hybrid pulse power characteristic |

| Ibatt | Battery current (A) |

| kF | Kilo Farad |

| LIB | Lithium-ion battery |

| LPM | Liter per minute |

| RC | Resistance capacitance |

| Rs | Ohmic resistance |

| T | Surface/skin temperature |

| Tamb | Ambient temperature |

| m | Mass flow rate |

| mAh | Milli ampere |

| mΩ | Milli Ohms |

| NMC | Nickel Manganese Cobalt |

| V | Voltage |

| OCV | Open circuit voltage |

| Q | Heat rejection |

| Convection heat generation rate | |

| QBatt | Battery cell capacity |

| S | SoC value |

| SD | Specific dissipation |

| SoC | State of Charge |

| Vbatt | Battery terminal voltage |

| Vocv | Open circuit voltage |

| a1, a2 | Coefficients for temperature |

| b1, b2 | Coefficient for temperature |

| 0.5 C, 1 C, 2 C | Battery charging rates |

| R1, R2 and Rn | Transient resistance parameters |

| C1, C2 and Cn | Transient capacitance parameters |

| V0, V1, V2, V3 and Vn | Transient voltage parameters |

References

- Jadun, P.; McMillan, C.; Steinberg, D.; Muratori, M.; Vimmerstedt, L.; Mai, T. Electrification Futures Study: End-Use Electric Technology Cost and Performance Projections through 2050; NREL/TP-6A20-70485; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2017; p. 94. [Google Scholar]

- Goodenough, J.B.; Kim, Y. Challenges for Rechargeable Li Batteries. Chem. Mater. Rev. 2010, 22, 587–603. [Google Scholar] [CrossRef]

- Nishi, Y. Lithium ion secondary batteries: Past 10 yearsand the future. J. Power Sources 2001, 100, 101–106. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Iraola, U.; Aizpuru, I.; Gorrotxategi, L.; Segade, J.M.C.; Larrazabal, A.E.; Gil, I. Influence of voltage balancing on the temperature distribution of a Li-ion battery module. IEEE Trans. Energy Convers. 2015, 30, 507–514. [Google Scholar] [CrossRef]

- Hoh, M.; Fuhr, J. Thermal Management of Hybrid Vehicles Battery Systems. In Proceedings of the 24th International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium & Exhibition 2009 (EVS 24), Stavanger, Norway, 13–16 May 2009; pp. 1–10. [Google Scholar]

- Robinson, J.B.; Darr, J.A.; Eastwood, D.S.; Hinds, G.; Lee, P.D.; Shearing, P.R.; Taiwo, O.O.; Brett, D.J. Non-uniform temperature distribution in Li-ion batteries during discharge—A combined thermal imaging, X-ray micro-tomography and electrochemical impedance approach. J. Power Sources 2014, 252, 51–57. [Google Scholar] [CrossRef]

- Liu, H.; Wei, Z.; He, W.; Zhao, J. Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: A review. Energy Convers. Manag. 2017, 150, 304–330. [Google Scholar] [CrossRef]

- Gu, W.B.; Wang, C.Y. Thermal-electrochemical modeling of battery systems. J. Electrochem. Soc. 2000, 147, 2910–2922. [Google Scholar] [CrossRef]

- Newman, J.; Thomas, K.E.; Hafezi, H.; Wheeler, D.R. Modeling of lithium-ion batteries. J. Power Sources 2003, 119–121, 838–843. [Google Scholar] [CrossRef]

- Jiang, J.; Ruan, H.; Sun, B.; Zhang, W.; Gao, W.; Zhang, L. A reduced low-temperature electro-thermal coupled model for lithium-ion batteries. Appl. Energy 2016, 177, 804–816. [Google Scholar] [CrossRef]

- Seaman, A.; Dao, T.S.; McPhee, J. A survey of mathematics-based equivalent-circuit and electrochemical battery models for hybrid and electric vehicle simulation. J. Power Sources 2014, 256, 410–423. [Google Scholar] [CrossRef]

- Chan, H.L.; Sutanto, D. A New Battery Model for use withBattery Energy Storage Systems and Electric Vehicles Power Systems. In Proceedings of the 2000 IEEE Power Engineering Society Winter Meeting, Singapore, 23–27 January 2000; Volume 1, pp. e470–e475. [Google Scholar]

- Buller, S.; Thele, M.; Doncker, R.W.D.; Karden, E. Impedance-based simulation models of supercapacitors and Li-ion batteries for power electronic applications. IEEE Trans. Ind. Appl. 2005, 41, 742–747. [Google Scholar] [CrossRef]

- Rodrigues, S.; Munichandraiah, N.; Shukla, A.K. A review of state-of-charge indication of batteries by means ofac impedance measurements. J. Power Sources 2000, 87, 12–20. [Google Scholar] [CrossRef]

- Benini, L.; Castelli, G.; Macci, A.; Macci, E.; Poncino, M.; Scarsi, R. Discrete-time battery models for system-level low-power design. IEEE Trans. VLSI Syst. 2001, 9, 630–640. [Google Scholar] [CrossRef]

- Baudry, P.; Neri, M.; Gueguen, M.; Lonchampt, G. Electro-thermal modeling of polymer lithium batteries for starting period and pulse power. J. Power Sources 1995, 54, 393–396. [Google Scholar] [CrossRef]

- Saurabh, S.; Raman, S.R.; Saritha, B.; John, V. A Novel Approach for Electrical Circuit Modeling of Li-Ion Battery for Predicting the Steady-State and Dynamic I–V Characteristics. Publication 2016, 41, 479–487. [Google Scholar]

- Hentunen, A.; Lehmuspelto, T.; Suomela, J. Time-Domain Parameter Extraction Method for Thevenin-Equivalent Circuit Battery Models. IEEE Trans. Energy Convers. 2014, 29, 558–566. [Google Scholar] [CrossRef]

- Johnson, V.H. Battery performance models in ADVISOR. J. Power Sources 2002, 110, 321–329. [Google Scholar] [CrossRef]

- Bobobee, E.D.; Wang, S.; Zou, C.; Takyi-Aninakwa, P.; Zhou, H. Emmanuel Appiah State of charge estimation of ternary lithium-ion batteries at variable ambient temperatures. Int. J. Electrochem. Sci. 2023, 18, 100062. [Google Scholar] [CrossRef]

- Chiang, Y.-H.; Sean, W.-Y.; Ke, J.-C. Online estimation of internal resistance and open-circuit voltage of lithium-ion batteries in electric vehicles. J. Power Sources 2011, 196, 3921–3932. [Google Scholar] [CrossRef]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Experimental and simulated temperature variations in a LiFePO4-20 Ah battery during discharge process. Appl. Energy 2016, 180, 504–515. [Google Scholar] [CrossRef]

- Du, J.; Liu, Z.; Wang, Y.; Wen, C. An adaptive sliding mode observer for lithium-ion battery state of charge and state of health estimation in electric vehicles. Control. Eng. Pract. 2016, 54, 81–90. [Google Scholar] [CrossRef]

- Madani, S.S.; Schaltz, E.; Kær, S.K. An Electrical Equivalent Circuit Model of a Lithium Titanate OxideBattery. Batteries 2019, 5, 31. [Google Scholar] [CrossRef]

- Rajchapanupat, N.; Poramapojana, P. A comparative study of equivalent circuit models for a Li-ionbattery pack of an electric Tuk-Tuk. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1137, 012014. [Google Scholar] [CrossRef]

- Jin, Y.; Li, Z.; Liu, B.; Liu, L. Modeling and simulation of lithium ion battery cosidering the effect of charge and discharge rate. J. Phys. Conf. Ser. 2021, 1907, 012003. [Google Scholar] [CrossRef]

- Xia, R.Z.B.; Li, B.; Cao, L.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W.; Wang, M. A Study on the Open Circuit Voltag and State of Charge Characterization of High Capacity Lithium-Ion Battery Under Different Temperature. Energies 2018, 11, 2408. [Google Scholar] [CrossRef]

- Hunt, I.A.; Zhao, Y.; Patel, Y.; Offer, G.J. Surface cooling causes accelerated degradation compared to tab cooling for lithium-ion pouch cells. J. Electrochem. Soc. 2016, 163, A1846. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Ji, Z.; Yang, Z.; Jiang, C.; Lin, H. Cooling the electrode tabs with air to manage the heat transferred through the collectors in traction battery. J. Energy Storage 2022, 48, 103982. [Google Scholar] [CrossRef]

- Muthukrishnan, K.; Kumar, C.R. Study on the effect of tab cooling on the lithium-ion battery pack life cycle. Arch. Thermodyn. 2024, 45, 291–299. [Google Scholar] [CrossRef]

- Hossain, M.; Saha, S.; Haque, M.E.; Arif, M.T.; Oo, A.M.T. A Parameter Extraction Method for the Thevenin Equivalent Circuit Model of Li-ion Batteries. In Proceedings of the 2019 IEEE Industry Applications Society Annual Meeting, Baltimore, MD, USA, 29 September–3 October 2019; ISBN 978-1-5386-4539. [Google Scholar]

- Thanagasundram, S.; Arunachala, R.; Makinejad, K.; Teutsch, T.; Jossen, A. A Cell Level Model for Battery Simulation. In Proceedings of the European Electric Vehicle Congress, Brussels, Belgium, 20–22 November 2012. [Google Scholar]

- He, K.; Xiong, Y.; Zhang, C.; Dou, Z.; Lin, S.; Li, C.; Sun, Y. An Investigation on the Electrochemical and Thermal Characteristics ofLiMn0.6Fe0.4PO4/LiNi0.5Co0.2Mn0.3O2 Composite Cathode Materials for Lithium-Ion Batteries in Different Health States. J. Electrochem. Soc. 2023, 170, 090501. [Google Scholar] [CrossRef]

| Device | Description |

|---|---|

| Cell | BAK 840, 18650 Cylindrical Type |

| Chemistry | NMC |

| Voltage | 4.2 V (peak), 3.6 (nominal) |

| Current capacity | 2.4 Ah |

| Maximum discharge rate | 2 C |

| Recommended charging rate | 1 C |

| Device Name | Instrument Details | Purpose |

|---|---|---|

| DC Electronic load | Precision-BK8610 | Battery loading |

| Battery charger | IMAX B6AC | Charging |

| Flow sensor | Meg Flow 6410 | Measure the mineral oil flow |

| PT 100 sensor | Sensor | To measure the temperatures |

| Data Logger | Masi bus 85XX | Data logging |

| Thermal Bath | Heat exchanger | To maintain the temperature |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaliaperumal, M.; Chidambaram, R.K. Thermal Management of Lithium-Ion Battery Pack Using Equivalent Circuit Model. Vehicles 2024, 6, 1200-1215. https://doi.org/10.3390/vehicles6030057

Kaliaperumal M, Chidambaram RK. Thermal Management of Lithium-Ion Battery Pack Using Equivalent Circuit Model. Vehicles. 2024; 6(3):1200-1215. https://doi.org/10.3390/vehicles6030057

Chicago/Turabian StyleKaliaperumal, Muthukrishnan, and Ramesh Kumar Chidambaram. 2024. "Thermal Management of Lithium-Ion Battery Pack Using Equivalent Circuit Model" Vehicles 6, no. 3: 1200-1215. https://doi.org/10.3390/vehicles6030057

APA StyleKaliaperumal, M., & Chidambaram, R. K. (2024). Thermal Management of Lithium-Ion Battery Pack Using Equivalent Circuit Model. Vehicles, 6(3), 1200-1215. https://doi.org/10.3390/vehicles6030057