An Approach for Estimating the Reliability of IGBT Power Modules in Electrified Vehicle Traction Inverters

Abstract

1. Introduction

1.1. Background Literature of Inverter Reliability Estimation

1.2. Contribution of This Paper

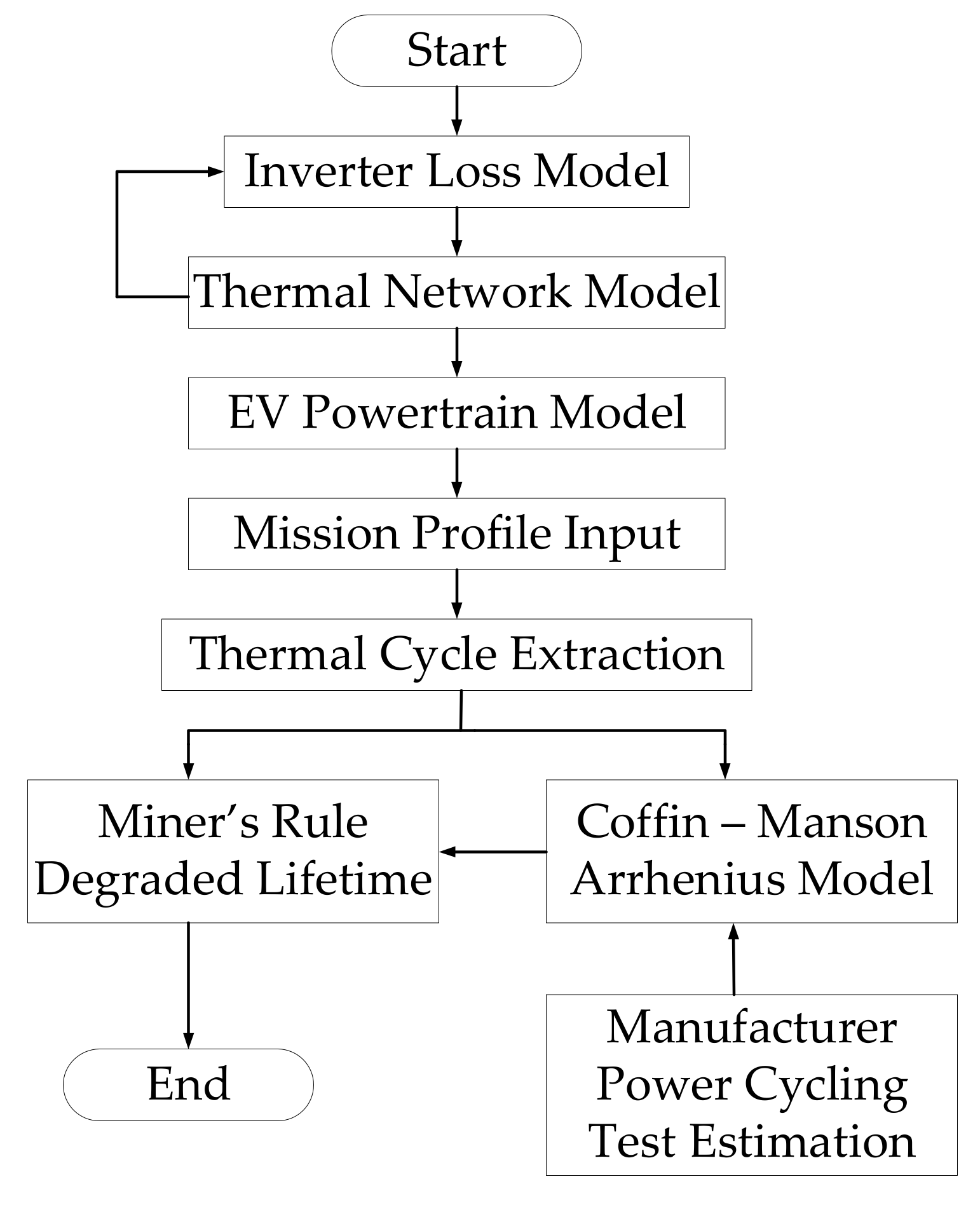

2. Electro—Thermal Model of 3-Phase VSI for Traction Application

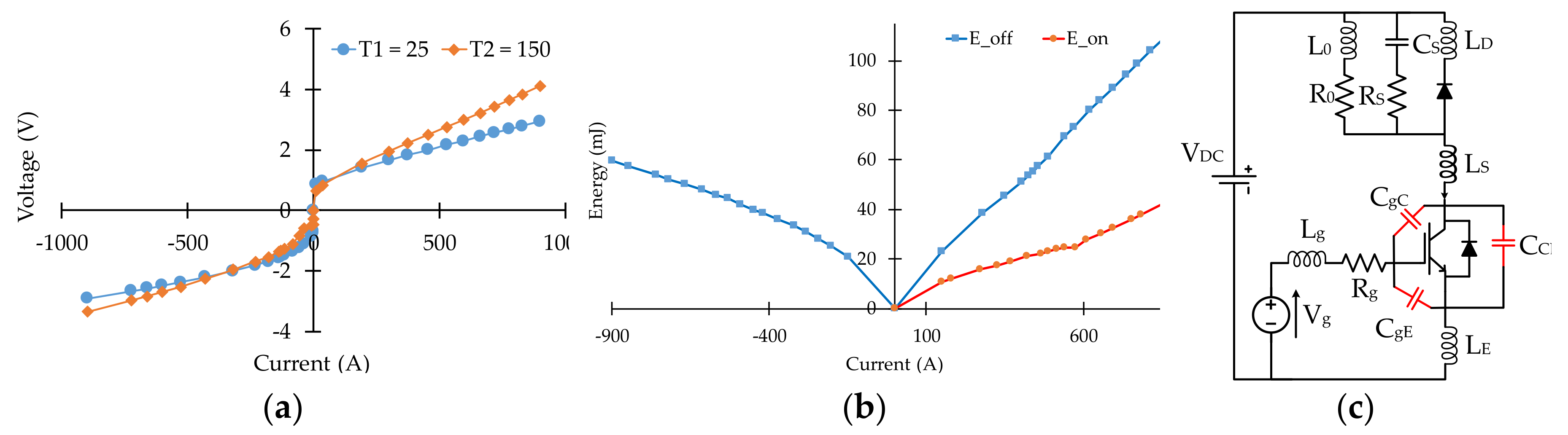

2.1. Improved Power Loss Model Considering Dynamic and Transient Effects

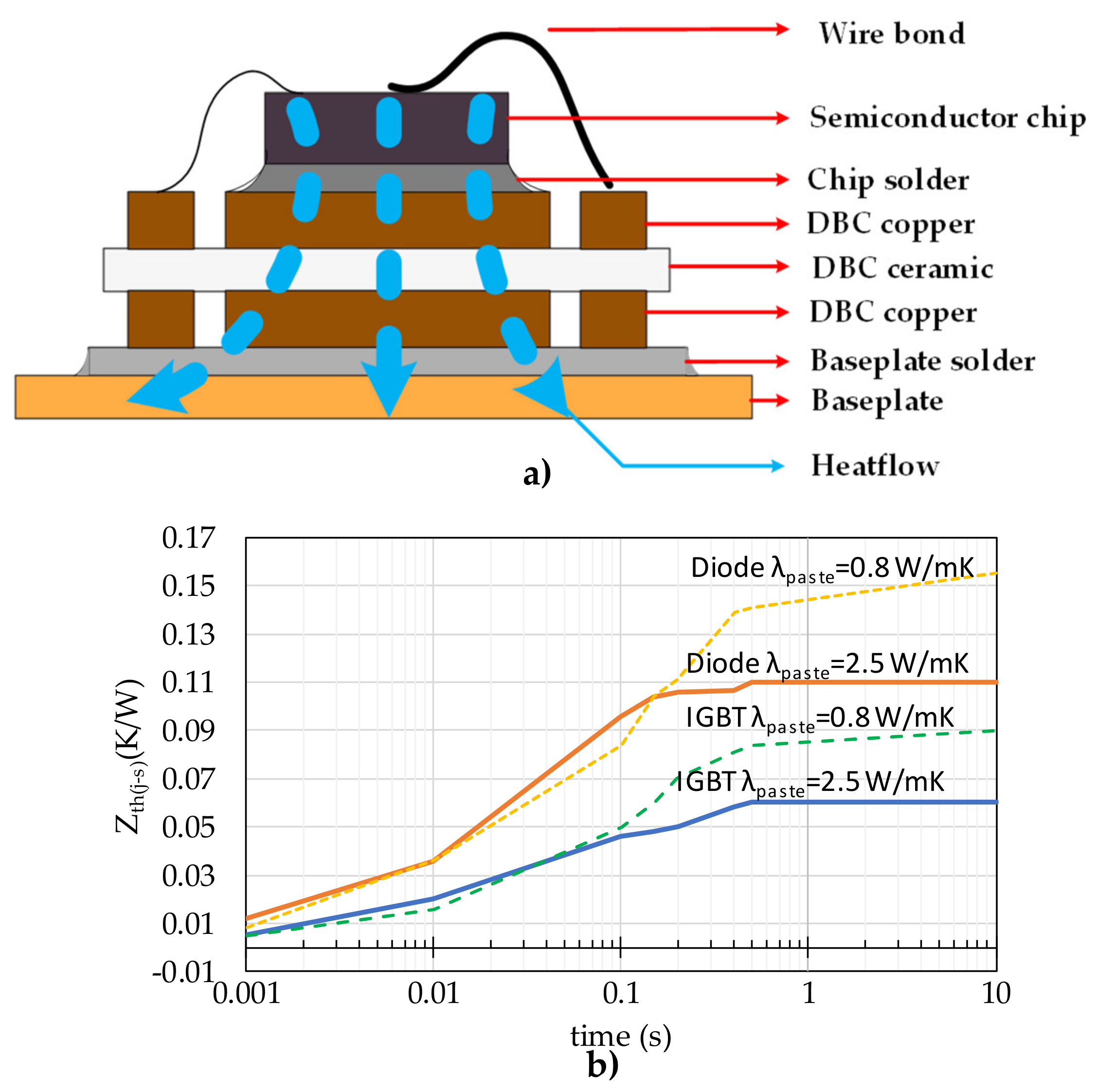

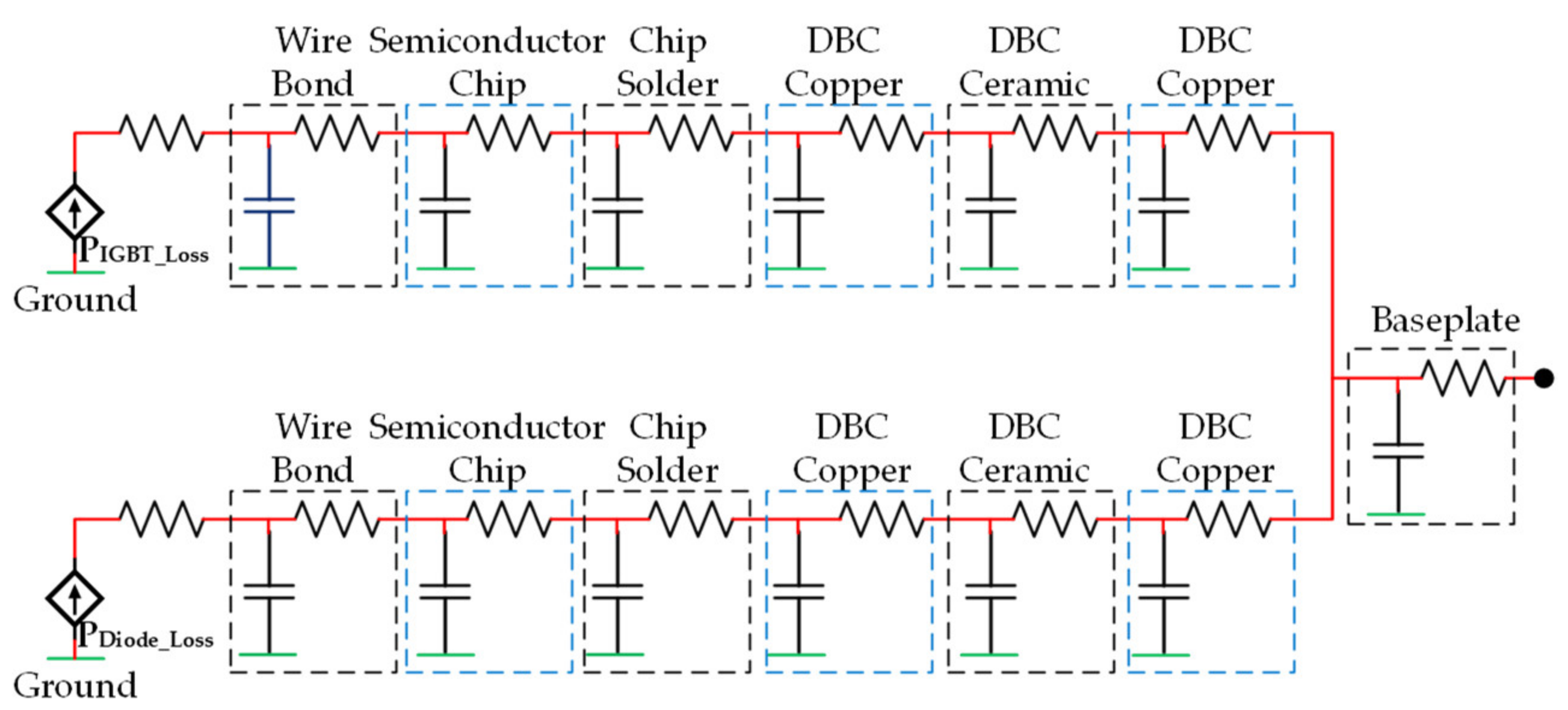

2.2. Derivation of Electro—Thermal Model Parameters Considering Inverter Material Information

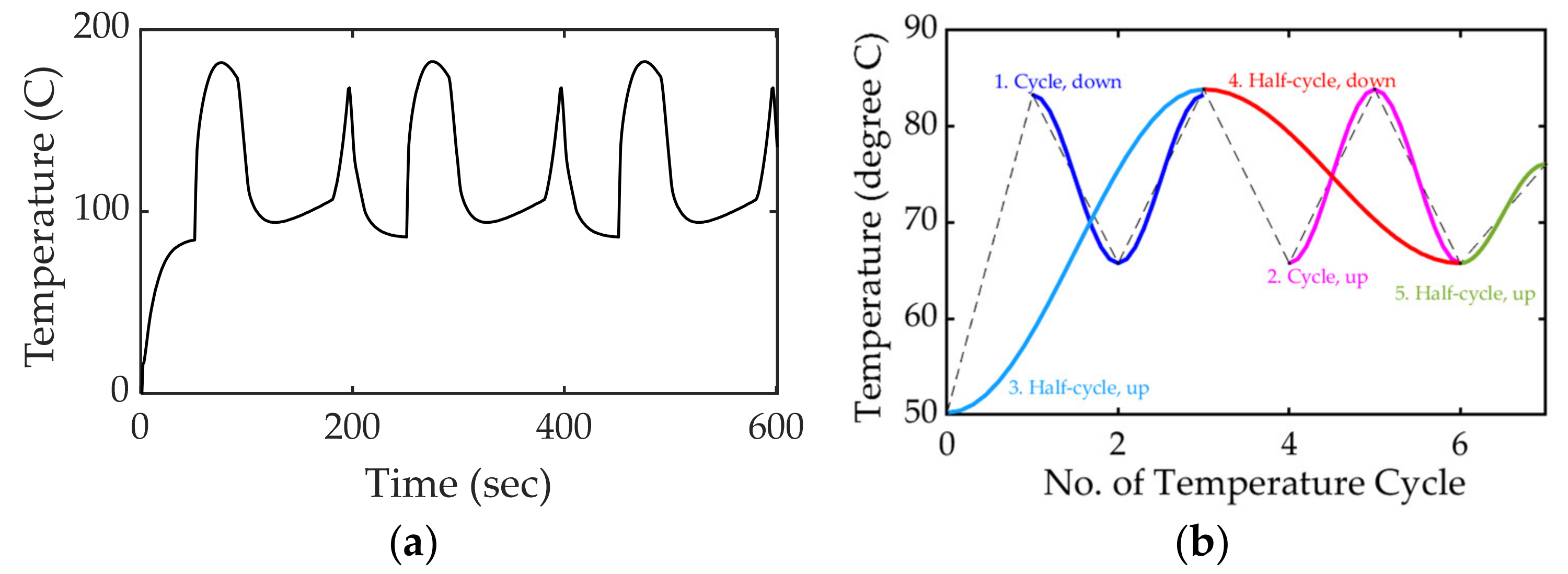

3. Reliability Performance of VSI under Different Mission Profile

3.1. Rainflow Algorithm-Based Inverter Reliability Estimation

3.2. Impact of Mission Profile on Inverter Remaining Useful Lifetime Estimation

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Ni, Z.; Lyu, X.; Yadav, O.P.; Singh, B.N.; Zheng, S.; Cao, D. Overview of Real-Time Lifetime Prediction and Extension for SiC Power Converters. IEEE Trans. Power Electron. 2020, 35, 7765–7794. [Google Scholar] [CrossRef]

- Sangwongwanich, A.; Yang, Y.; Sera, D.; Blaabjerg, F. Mission Profile-Oriented Control for Reliability and Lifetime of Photovoltaic Inverters. IEEE Trans. Ind. Appl. 2018, 56, 2512–2518. [Google Scholar]

- Musallam, M.; Yin, C.; Bailey, C.; Johnson, M. Mission profile-based reliability design and real-time life consumption estimation in power electronics. IEEE Trans. Power Electron. 2015, 30, 2601–2613. [Google Scholar] [CrossRef]

- Sangwongwanich, A.; Yang, Y.; Sera, D.; Blaabjerg, F.; Zhou, D. On the Impacts of PV Array Sizing on the Inverter Reliability and Lifetime. IEEE Trans. Ind. Appl. 2018, 54, 3656–3667. [Google Scholar] [CrossRef]

- Ma, K.; Liserre, M.; Blaabjerg, F.; Kerekes, T. Thermal loading and lifetime estimation for power device considering mission profiles in wind power converter. IEEE Trans. Power Electron. 2015, 30, 590–602. [Google Scholar] [CrossRef]

- Wei, L.; McGuire, J.; Lukaszewski, R.A. Analysis of PWM frequency control to improve the lifetime of PWM inverter. IEEE Trans. Ind. Appl. 2011, 47, 922–929. [Google Scholar]

- Yang, K.; Guo, J.; Ge, H.; Bilgin, B.; Loukanov, V.; Emadi, A. Transient electro-thermal analysis for a MOSFET based Traction Inverter. In Proceedings of the 2014 IEEE Transportation Electrification Conference and Expo, Detroit, MI, USA, 15–18 June 2014; pp. 1–6. [Google Scholar]

- Li, X.; Jiang, J.; Huang, A.Q.; Guo, S.; Deng, X.; Zhang, B.; She, X. A SiC Power MOSFET Loss Model Suitable for High-Frequency Applications. IEEE Trans. Ind. Electron. 2017, 64, 8268–8276. [Google Scholar] [CrossRef]

- Xu, Y.; Ho, C.N.M.; Ghosh, A.; Muthumuni, D. A Datasheet-Based Behavioral Model of SiC MOSFET for Power Loss Prediction in Electromagnetic Transient Simulation. In Proceedings of the 2019 IEEE Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 17–21 March 2019; pp. 521–526. [Google Scholar]

- Roy, S.K.; Basu, K. Analytical Estimation of Turn on Switching Loss of SiC mosfet and Schottky Diode Pair From Datasheet Parameters. IEEE Trans. Power Electron. 2018, 34, 9118–9130. [Google Scholar] [CrossRef]

- Peng, H.; Chen, J.; Cheng, Z.; Kang, Y.; Wu, J.; Chu, X. Accuracy-Enhanced Miller Capacitor Modeling and Switching Performance Prediction for Efficient SiC Design in High-Frequency X-Ray High-Voltage Generators. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 179–194. [Google Scholar] [CrossRef]

- Ye, J.; Yang, K.; Ye, H.; Emadi, A. A Fast Electro-Thermal Model of Traction Inverters for Electrified Vehicles. IEEE Trans. Power Electron. 2017, 32, 3920–3934. [Google Scholar] [CrossRef]

- An, N.; Du, M.; Hu, Z.; Wei, K. A High-Precision Adaptive Thermal Network Model for Monitoring of Temperature Variations in Insulated Gate Bipolar Transistor (IGBT) Modules. Energies 2018, 11, 595. [Google Scholar] [CrossRef]

- Tsibizov, A.; Kovačević-Badstübner, I.; Kakarla, B.; Grossner, U. Accurate Temperature Estimation of SiC Power mosfets Under Extreme Operating Conditions. IEEE Trans. Power Electron. 2020, 35, 1855–1865. [Google Scholar] [CrossRef]

- Nakamura, Y.; Evans, T.M.; Kuroda, N.; Sakairi, H.; Nakakohara, Y.; Otake, H.; Nakahara, K. Electrothermal Cosimulation for Predicting the Power Loss and Temperature of SiC MOSFET Dies Assembled in a Power Module. IEEE Trans. Power Electron. 2020, 35, 2950–2958. [Google Scholar] [CrossRef]

- Zheng, S.; Du, X.; Zhang, J.; Yu, Y.; Sun, P. Measurement of Thermal Parameters of SiC MOSFET Module by Case Temperature. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 311–322. [Google Scholar] [CrossRef]

- Ceccarelli, L.; Kotecha, R.M.; Bahman, A.S.; Iannuzzo, F.; Mantooth, H.A. Mission-Profile-Based Lifetime Prediction for a SiC mosfet Power Module Using a Multi-Step Condition-Mapping Simulation Strategy. IEEE Trans. Power Electron. 2019, 34, 9698–9708. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, H.; Zhang, Y.; Blaabjerg, F. A Viable Mission Profile Emulator for Power Modules in Modular Multilevel Converters. IEEE Trans. Power Electron. 2019, 34, 11580–11593. [Google Scholar] [CrossRef]

- Choi, U.; Jørgensen, S.; Blaabjerg, F. Advanced Accelerated Power Cycling Test for Reliability Investigation of Power Device Modules. IEEE Trans. Power Electron. 2016, 31, 8371–8386. [Google Scholar] [CrossRef]

- Xiang, D.; Ran, L.; Tavner, P.; Bryant, A.; Yang, S.; Mawby, P. Monitoring Solder Fatigue in a Power Module Using Case-Above-Ambient Temperature Rise. IEEE Trans. Ind. Appl. 2011, 47, 2578–2591. [Google Scholar] [CrossRef]

| Model | Device Parameters |

|---|---|

| Vce | 1200 V |

| Ic | 556 A |

| Max. Tj | 175 °C |

| IF | 438 A |

| Rce | 2.3 mΩ |

| Vge(th) | 5.8 V |

| ton | 276 ns |

| toff | 538 ns |

| Model | Device Parameters |

|---|---|

| cies | 26.4 nF |

| coes | 1.74 nF |

| cres | 1.41 nF |

| Ls/p | 15 nH |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kundu, A.; Balamurali, A.; Korta, P.; Iyer, K.L.V.; Kar, N.C. An Approach for Estimating the Reliability of IGBT Power Modules in Electrified Vehicle Traction Inverters. Vehicles 2020, 2, 413-423. https://doi.org/10.3390/vehicles2030022

Kundu A, Balamurali A, Korta P, Iyer KLV, Kar NC. An Approach for Estimating the Reliability of IGBT Power Modules in Electrified Vehicle Traction Inverters. Vehicles. 2020; 2(3):413-423. https://doi.org/10.3390/vehicles2030022

Chicago/Turabian StyleKundu, Animesh, Aiswarya Balamurali, Philip Korta, K. Lakshmi Varaha Iyer, and Narayan C. Kar. 2020. "An Approach for Estimating the Reliability of IGBT Power Modules in Electrified Vehicle Traction Inverters" Vehicles 2, no. 3: 413-423. https://doi.org/10.3390/vehicles2030022

APA StyleKundu, A., Balamurali, A., Korta, P., Iyer, K. L. V., & Kar, N. C. (2020). An Approach for Estimating the Reliability of IGBT Power Modules in Electrified Vehicle Traction Inverters. Vehicles, 2(3), 413-423. https://doi.org/10.3390/vehicles2030022