2. Doce de Leite

Chemically, doce de leite is defined as a mixture of milk and sucrose in which Maillard reactions (MR) occur during thermal and evaporative treatment. These reactions are responsible for the characteristic flavor, color, texture, and aroma of doce de leite. It is a primary dairy product concentrated by heat energy, produced predominantly by small to mid-sized dairy companies in South American countries. The product can be tailored to different consumer needs, offering “lactose-free” versions for those with lactose intolerance or reduced-sugar options for a diet-friendly alternative. Additionally, it can be customized in terms of texture (pasty or solid), color (darker or lighter), and the degree of caramelization to cater to varying taste preferences [

7,

8,

9,

10].

Depending on the Latin American country, doce de leite can have different names: doce de leite (Brazil), dulce de leche (Argentina, Uruguay, Bolivia, Paraguay, Puerto Rico, Dominican Republic, Ecuador, and some regions in Colombia and Venezuela), cajeta (Mexico), arequipe (Venezuela, Guatemala, and some regions in Colombia), cajeta de manjar de leche (Nicaragua), manjar (Chile and Ecuador), manjar blanco (Bolivia, Peru, and Panama), and fanguito (Cuba). Similar products can be found in other countries, where they are called milk jam (in English), confiture de lait (in France), süt reçeli (in Turkish), and kajmak (Poland).

Like condensed milk, evaporated milk, milk powder, and whey powder, doce de leite undergoes an evaporation process. This process involves removing water from milk at atmospheric or reduced pressure by transferring energy as heat, typically using indirect steam, although gas flames are an alternative method. The evaporation process is employed to enhance the product ’s shelf life and flavor, as well as to decrease transportation and storage costs, thereby rendering the product more appealing to consumers [

11,

12,

13,

14].

According to the Technical Regulation for Doce de Leite Identity and Quality, approved by Ordinance No. 354 on 4 September 1997, of the Brazilian the Ministry of Agriculture, Livestock, and Supply, doce de leite is defined as a product obtained by concentrating and heating milk or reconstituted milk at normal or reduced pressure, with or without the addition of milk and/or cream-origin solids, and with sucrose, which may be partially replaced by monosaccharides and/or other disaccharides. The regulation also specifies centesimal composition parameters, including a minimum of 6.0 g/100 g for fat, a minimum of 5.0 g/100 g for protein, a maximum of 2.0 g/100 g for ash, and a maximum of 30.0 g/100 g for moisture, as well as the maximum permitted quantities of ingredients. This regulation aligns with Mercosur Resolution GMC 137/96, which establishes the identity and minimum requirements for doce de leite across all member countries, irrespective of regional characteristics [

15].

The heat-induced reaction, one of the primary reactions occurring during doce de leite production, begins with the condensation of a reducing sugar, such as lactose, with an amino group from a protein, peptide, or amino acid, such as lysine. This reaction forms a Schiff base, which then rearranges into Amadori products, marking the initial stage. Subsequently, advanced glycation end products (AGEs) are formed, producing reactive intermediates in the intermediate stage, and ultimately leading to the creation of melanoidins. These melanoidins are responsible for the brown coloration in food, characterizing the final stage. The RM is a complex and competitive chain reaction that generates numerous reactive intermediates both consecutively and simultaneously. Factors such as pH, heating temperature, and the presence of various reducing sugars and amino groups significantly influence the MR [

16,

17,

18,

19,

20].

3. Manufacturing Processes

Doce de leite technology is closely associated with the type of equipment utilized by each company. Frequently, the factor limiting the enhancement of doce de leite technology is not cost nor the industry’s technical skills, but rather the available equipment (process) for product manufacturing. Doce de leite can be produced with a concentration time varying from 30 min to 6 h using the same volume of milk. This variability indicates that equipment can significantly impact the competitiveness of the doce de leite production industry.

Doce de leite is produced in facilities varying from small artisanal factories to large industrial dairies (

Table 1). The quality of raw materials, formulation types, and technological challenges associated with non-standardized times and temperatures during manufacturing have hindered brand standardization in the Brazilian market. Therefore, it is crucial to analyze, study, and prioritize the impact of various ingredients, manufacturing technologies, and heat treatment intensities on the product’s quality and consistency [

21].

Most manufacturers initiated their operations with small production runs that expanded over time. This growth inevitably compelled each manufacturer to acquire new equipment, develop processes, and establish production lines. Consequently, there is no standardized process for producing doce de leite. This variability is undoubtedly a primary reason for the wide diversity of products available, despite the well-established mandatory initial ingredients.

Two types of evaporators are commonly employed in the manufacture of doce de leite: the atmospheric pressure evaporator, also known as a pan, and the reduced pressure evaporator, commonly referred to in the industry as a vacuum evaporator. Vacuum evaporators facilitate lower water evaporation costs compared to pans and also allow for the processing of large volumes of milk. Additionally, these two types of equipment can be combined.

The basic equipment required for producing doce de leite is the pan, an evaporation unit that heats the mixture of ingredients to the water’s evaporation temperature. It consists of a main vat with a double wall (double-jacketed) designed to circulate heating fluid (steam, oil, or high-pressure hot water). Open pans are simple in both function and maintenance; however, they are unsuitable for processing large volumes of milk (typically less than 2000 L).

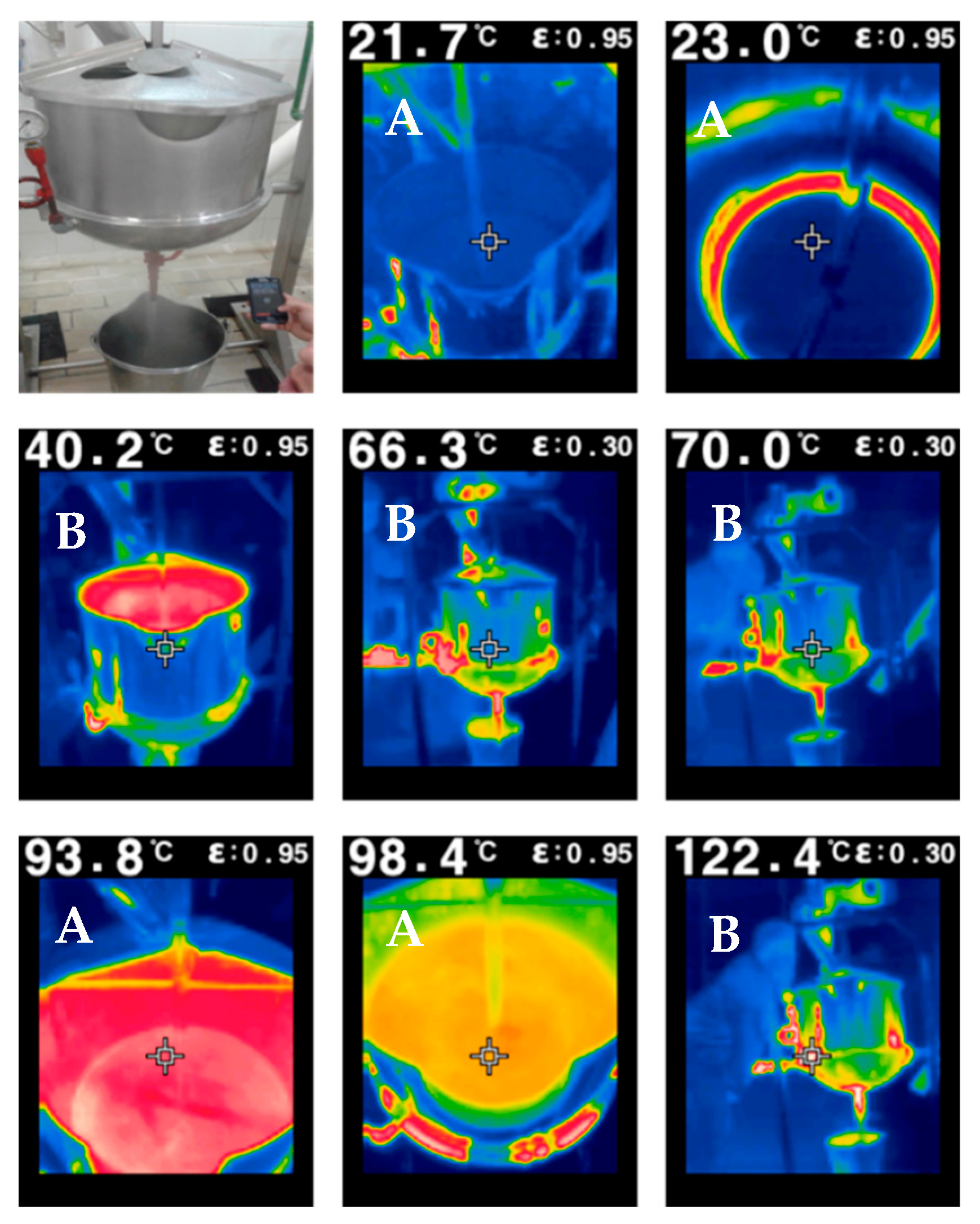

Figure 1 shows a series of heat mapping images of an open pan construction (at atmospheric pressure) along with temperature readings during doce de leite production. This figure shows the heating phases of the open pan process from the beginning to the end of production, in which images with the letter A are inside the pan, while those with the letter B are images of the outside of the pan. All images were captured using a FLIR TG165 Imaging IR Thermometer.

The temperature ranges from 20 °C to 125 °C, and the colors are dark blue: colder areas; light blue/green: moderately cold temperatures; yellow: temperatures near the middle of the range; orange: hot areas; red: areas with high temperatures. The ε indicates the emissivity index and varies with each material, with 0.95 being the most used for common surfaces.

The mixture of milk, sugar, and other ingredients and additives is referred to as syrup. This mixture must undergo a continuous water evaporation process, where energy is transferred indirectly in the form of vapor originating from boilers. The water from the milk, which remains in a vapor state, is termed “evaporated”. It is essential to promptly remove this vapor from the equipment to prevent its reintegration into the syrup through condensation.

Our research group mapped nine distinct doce de leite production modes, categorized based on their main features (

Table 1). This review describes the primary characteristics of each process, without delving into minor variations that may occur between different companies.

3.1. Total Batch System

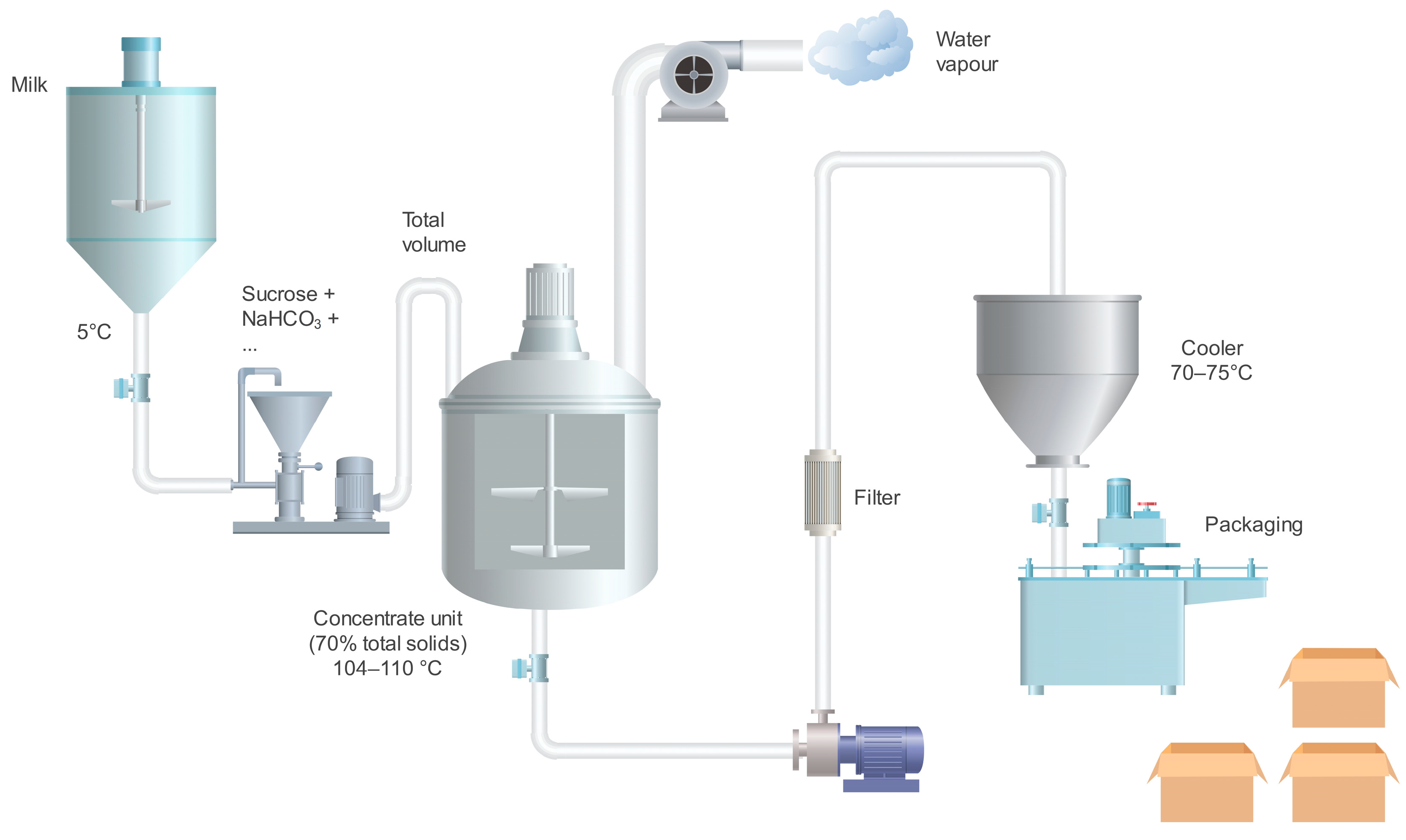

The milk/sugar mixture used in a traditional doce de leite production–total batch system (Process 1), as depicted in

Figure 2, is prepared directly in a stainless-steel pan featuring double walls in which steam circulates. Once the mixture (syrup) is ready, it is gradually heated with constant stirring. This agitation prevents the portion in direct contact with the pan walls from burning and reduces excessive foam formation, facilitating the evaporation process until the product achieves the desired consistency. Moreover, this stirring process also avoids high temperatures inside doce de leite dough during the cooling step (temperature close to 75 °C), since high temperatures would affect color and texture uniformity in the product.

Generally, an indirect cooking method is employed using a jacketed pan evaporator through which a hot vapor stream flows. Fluid milk and sugar are added to the pan, along with sodium bicarbonate and glucose syrup. These ingredients are continuously stirred as the mixture cooks, caramelizing and concentrating to the desired viscosity and quality. It is noteworthy that the process begins with a substantially liquid mixture, which undergoes various steps to gradually thickens into a pasty consistency with varying humidity levels. For instance, the product used by confectioners and alfajor manufacturers (traditional Latin American dessert made with two or three layers of soft cookies filled with doce de leite or other fillings and covered with chocolate) typically has a humidity value of approximately 23%, whereas doce de leite spreads for domestic use generally have a humidity of around 27%. Conventional methods can take several hours, as the initial humidity values may be as high as 60%, depending on the formula, and the concentration rate is kept low to prevent excessive “burning” due to high temperatures [

21,

22].

3.2. Doce de Leite Manufacturing Based on the Batch System with Gradual Mix Addition

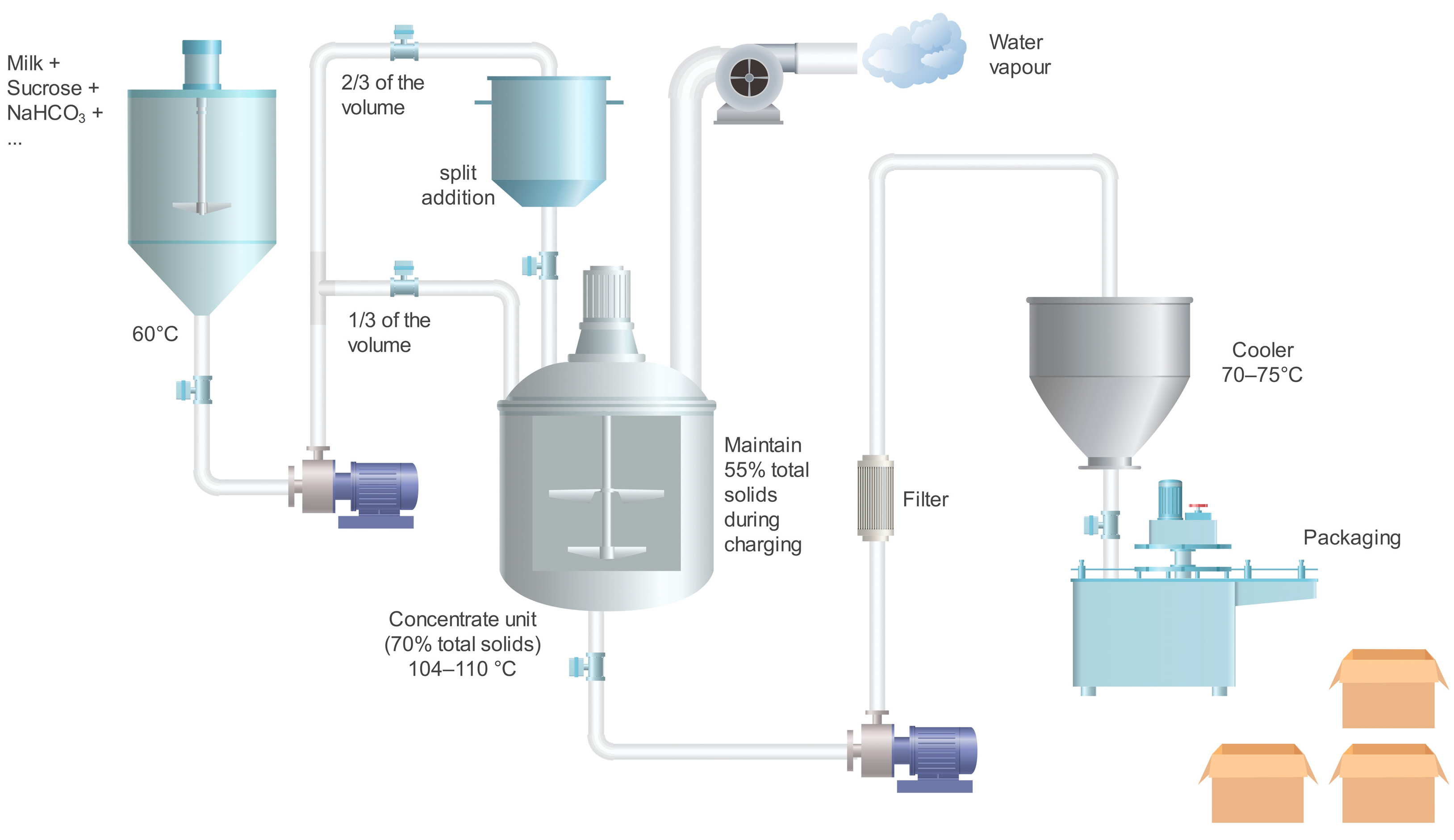

Another method for producing doce de leite, similar to the one previously described, is the batch system with fractionated mix addition. In this approach, (Process 1), evaporation occurs because the entire volume of milk and sugar is added at the start of the production process. However, some companies add only a portion of the milk and sugar required by the formulation to the mixture initially; the remaining fraction is then gradually incorporated throughout the production time. This method, based on a batch process with fractionated addition (Process 2), allows for the processing of a larger volume of milk than the pan’s initial nominal capacity, as depicted in

Figure 3. Therefore, the primary distinction between Process 1 and Process 2 is the stage at which ingredients are added. Manufacturers achieve improved control over the final product’s consistency by gradually adding milk, allowing for adjustments to the recipe as needed.

This method also prevents problems such as excessive foaming during the initial boiling phase of the syrup (a mixture of milk, sugar, and other ingredients) and reduces the risk of overflow during evaporation. This occurs because adding a small initial volume of syrup to the open pan rapidly increases the concentration of solids and changes its properties, particularly viscosity. In some plants, the entire sugar volume of a production batch is combined with one-third of the total milk volume, and only this mixture is initially evaporated. As the concentration of solids increases, the risk of spillage decreases, and the remaining milk can be added gradually. However, there is no industry-wide standard for the initial milk-to-sugar ratio or solids concentration required before the rest of the milk is added. In more modern plants, this process is automated using level sensors installed in the open pans.

The incremental addition of milk is particularly advantageous in industrial environments, where it facilitates the management of consistency and quality in high-volume production. This approach optimizes the performance of the equipment and guarantees a more uniform doce de leite, as manufacturing is not based on constantly maintaining the doce de leite. The incremental addition of milk is particularly advantageous in industrial settings, where it facilitates the management of consistency and quality in large-volume production. This approach optimizes equipment performance and ensures a more uniform doce de leite by keeping a constant feed/heating vapor pressure.

The specific details of the process may vary depending on the production needs and the desired characteristics of the doce de leite. This flexibility in formulation is advantageous for tailoring the product to meet standards of taste, texture, and production volume.

In addition to increasing the equipment’s nominal capacity, fractionated addition of the mix to the pan during the cooking process often alters the processing time, shortening the period and resulting in doce de leite with distinctive color (lighter), taste, and aroma characteristics, which have not yet been scientifically characterized. This method is particularly intriguing from a scientific perspective, as it intensifies the thermal treatment each milk fraction receives due to its incremental addition. Consequently, milk proteins exhibit unique properties (such as their voluminosity—not only casein and whey proteins but also fat and carbohydrates—which changes with concentration, increasing their volume fractions), which affords this production method gradual viscosity and texture development. It is common for such products to exhibit high moisture content (exceeding the 30% threshold set by doce de leite’s RTIQ), yet they still satisfy the sensory expectations of consumers. In essence, this process yields a product that does not comply with legal standards but is highly valued by consumers for its lower sugar concentration, reduced sweetness, and overall improved palatability.

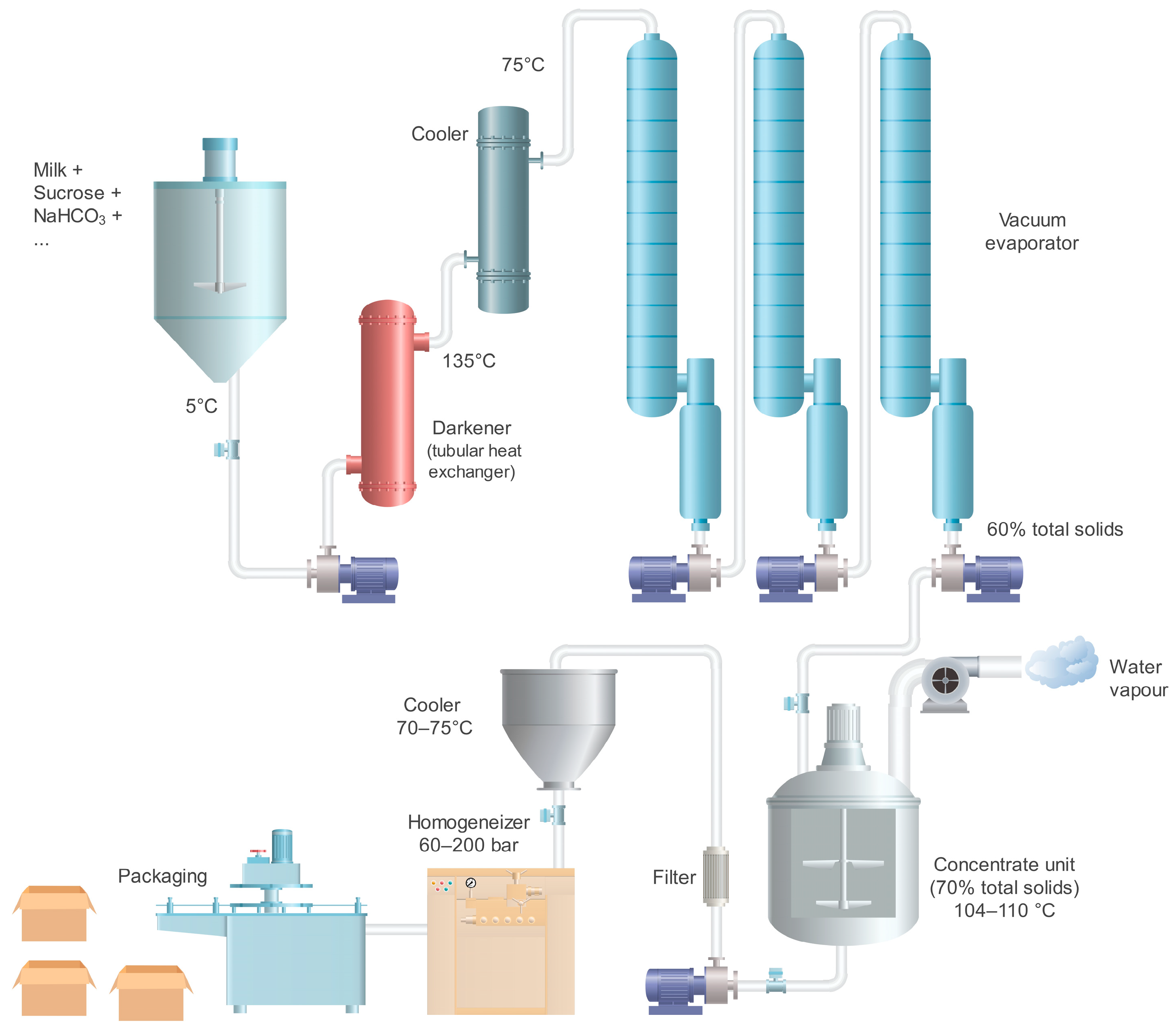

3.3. Manufacturing Doce de Leite with Pre-Concentration in a Vacuum Evaporator Followed by Finishing in an Open Pan

The third process involves pre-concentration in a vacuum evaporator followed by finishing in an open pan. The vacuum evaporator significantly reduces vapor consumption in the industry and greatly enhances production capacity. While an open pan uses approximately 1.1–1.3 kg of steam to evaporate 1.0 kg of milk water, an evaporator requires only 0.1–0.3 kg of steam to evaporate the same amount. However, the vacuum evaporator’s drawback is that it cannot be the sole piece of equipment for doce de leite production, as it does not facilitate the necessary development of MR and sensory physical–chemical changes in milk. Consequently, milk is vacuum-concentrated with sugar to approximately 62–66°Brix; this syrup is then further concentrated in the pan for an additional 20–40 min, allowing for the mixture to develop the viscosity, texture, and color characteristics expected of doce de leite [

6].

Concentration at low temperatures (48–70 °C), compared to the conventional open pan process, does not result in intense MR or a significant increase in product viscosity, both of which are key characteristics of doce de leite. Consequently, the manufacturing process must conclude with an open pan process to impart the desired organoleptic properties onto the product (

Figure 4).

Concentration using multi-stage evaporators is prevalent in dairy companies that handle powdered milk, condensed milk, and concentrated milk. However, due to the high initial costs associated with equipment acquisition, it is only viable for companies processing large volumes of milk. An evaporator operates under partial vacuum to lower the boiling point, thereby minimizing the effects of temperature on milk protein structure and lactose alterations.

Each stage functions as an evaporator; however, stages subsequent to the first utilize the vapor produced from the preceding stage as a thermal source. Vapor generated in the first effect of the multiple-effect system, along with the partially concentrated liquid, flows to the vapor separator, where they are separated by centrifugal force. The product is propelled into the vaporization chamber of the subsequent effect due to a pressure differential. In this chamber, it condenses by transferring energy in the form of vapor to the liquid that is to be concentrated.

3.4. Production of Doce de Leite with Pre-Concentration in a Vacuum Evaporator and Finishing in an Open Pan, Accompanied by Lactose Micro-Crystallization

The fourth process involves pre-concentration in a vacuum evaporator, followed by finishing in an open pan, and includes lactose micro-crystallization. In this method, the product is obtained similarly to Process 3, excluding homogenization, and is further subjected to an additional stage of lactose micro-crystallization.

In partially dehydrated products, lactose exhibits a distinct behavior owing to its lower solubility compared to other sugars, such as sucrose and glucose. With reduced water content and product temperature, lactose becomes prone to crystallization. Two critical events for lactose crystallization are nucleation, the formation of new crystals, and the subsequent growth of these crystals. Nucleation can be either primary or secondary. Primary nucleation necessitates a supersaturated solution, whereas secondary nucleation relies on pre-existing crystals in the solution to initiate the formation of new crystals [

23,

24,

25].

In the literature and industry, various terms describe the intentional addition of powdered lactose crystals to control or induce crystallization in doce de leite. The temperature is lowered to between 30 °C and 35 °C. This reduction in temperature decreases the solubility of lactose, consequently promoting the formation of nuclei [

26].

The crystallization of lactose induced in doce de leite at varying temperatures does not significantly alter the physicochemical properties of the product, but it does change its interaction with light, resulting in a color change (noticeable in the L* and b* values). The addition of lactose crystals to doce de leite influences the crystallization process, promoting the formation of several smaller crystals. For example, the two-stage cooling process (at 35 °C for 30 min and at 25 °C for 60 min) results in a higher number of crystals and limits their growth, according to a study by Netto and collaborators (2022) [

27].

Controlled and rapid cooling of doce de leite intensifies the energy driving the crystallization stage and promotes the formation of nuclei within the product. The addition of lactose powder (nuclei) is crucial for doce de leite production, yielding a large number of small crystals. This profile is desirable as it diminishes the sensory detection of crystals by consumers (

Figure 5). Unlike Process 3, there is no homogenization stage before packaging in this process because lactose crystals hinder the implementation of this operation. Conversely, crystallization alters the rheological properties of doce de leite, often increasing its viscosity and reducing its luster.

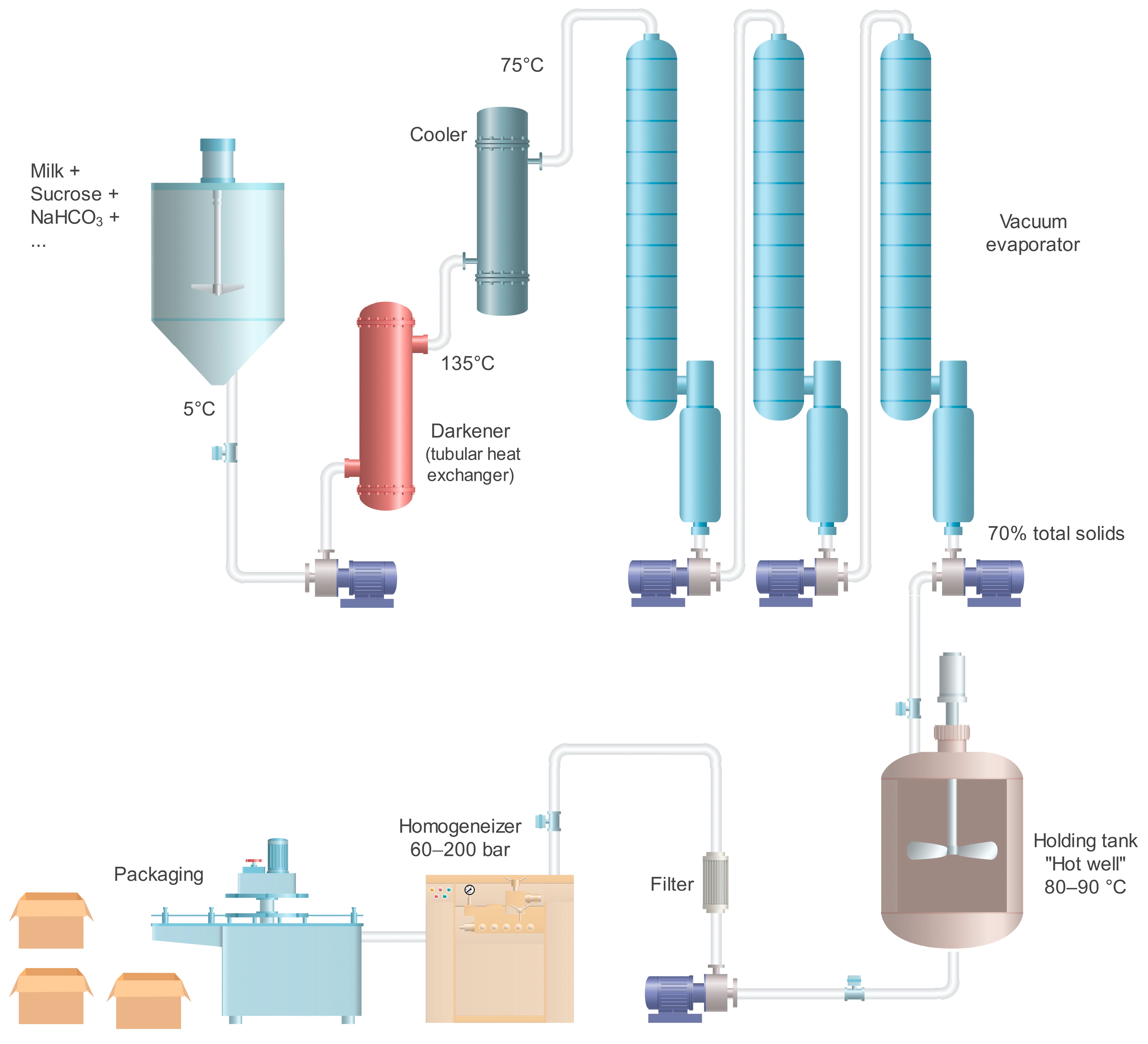

3.5. Production of Doce de Leite Under Constant Flow, Employing a Vacuum Evaporator for Total Concentration and a Holding Tank (Hot Well) for Viscosity Control

When the production volume is high and the goal is a continuous production line, Process 5 (

Figure 6) appears to be an attractive option to produce doce de leite in continuous flow, using a tubular heat exchanger with a temperature of around 135 °C for subsequent total concentration in a vacuum evaporator and viscosity control in a holding tank (hot well), which keeps the product temperature between 80 and 90 °C. The heat treatment that precedes vacuum evaporation must be intensified; control of the consistency and viscosity of the doce de leite takes place in the hot well, where the product is kept at a warm temperature until the desired characteristics are acquired. Normally, the difference between the inlet and outlet of the product determines the residence time (in addition to the temperature, volume, and stirring speed), guaranteeing a constant flow of product.

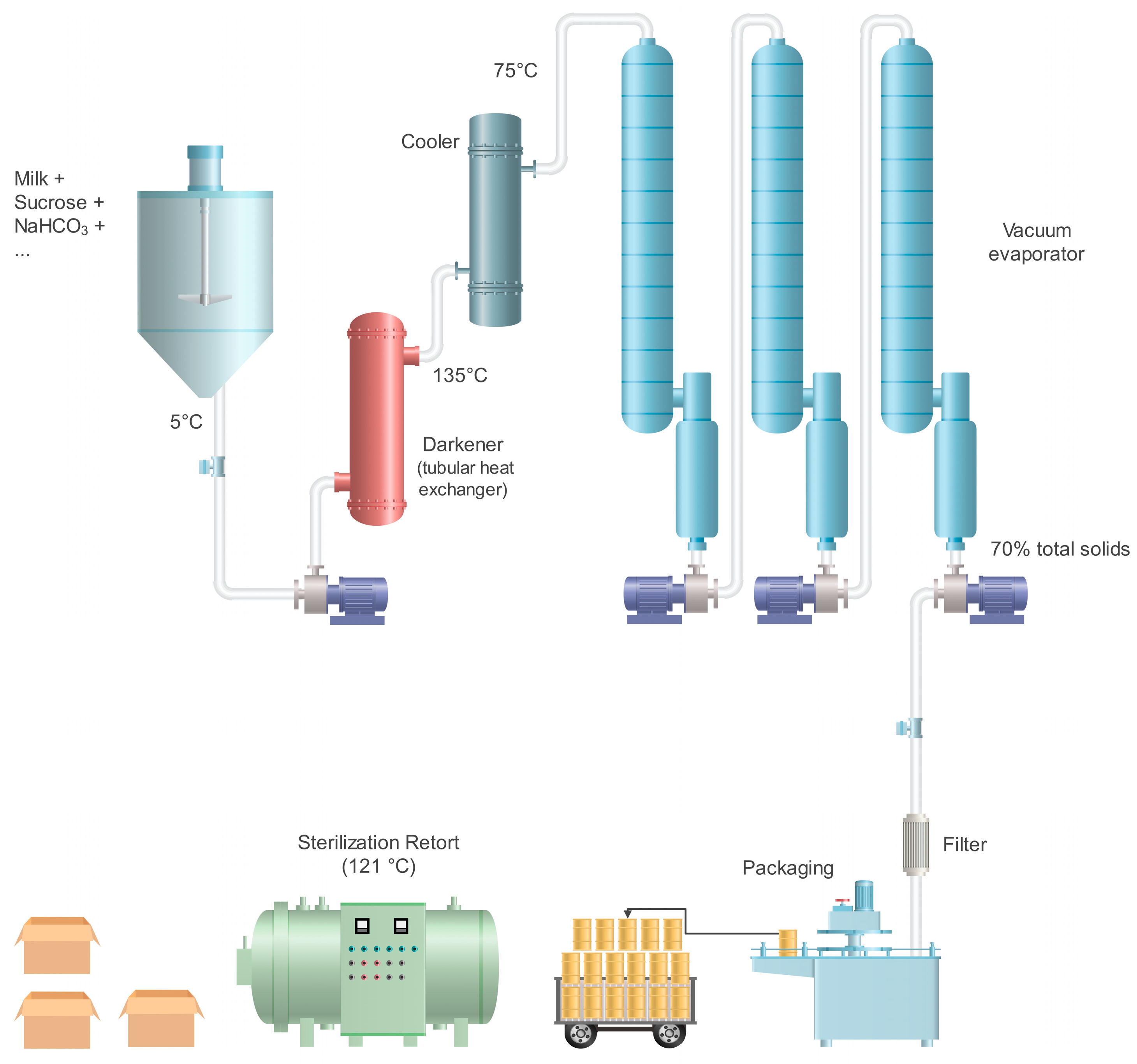

3.6. Production of Doce de Leite with Total Concentration Under Vacuum Vapor and Sterilization via an Autoclave System

The manufacturing process of doce de leite involves complete concentration in a vacuum evaporator, followed by sterilization in an autoclave system. This type of technology is commonly employed to produce high-viscosity products that require intense thermal treatment to ensure microbiological safety (

Figure 7). Although this technology often raises the product cost, it is utilized to establish special product lines. In this context, MR is developed at elevated temperatures, operating between 95 °C and 121 °C, for varying durations that can be optimized through the use of appropriate physical–chemical indicators. MR indicators, such as 5-hydroxymethylfurfural, 2-furaldehyde (F), 2-furyl-methyl ketone (FMC), and 5-methyl-2-furaldehyde (MF) have recently been suggested for the control of doce de leite [

28].

The use of an autoclave system to produce doce de leite presents several benefits, particularly regarding food safety, preservation, and product uniformity. The equipment employs high temperatures and pressure to sterilize doce de leite, effectively eliminating bacteria, viruses, and other harmful microorganisms. Consequently, the product is safer and has an extended shelf life. Autoclave sterilization is vital for large-scale production and distribution to remote areas. Moreover, the autoclave enables precise control over processing conditions, ensuring a consistently high-quality final product with uniform taste, texture, and appearance.

Autoclave production, particularly in an industrial context, can be more efficient and scalable than manual or small-batch processing methods. It is crucial to note that while the autoclave presents significant advantages, its implementation must adhere to strict safety standards and comply with specific food regulations. Quality control, process monitoring, and proper equipment maintenance are essential to ensure the anticipated benefits.

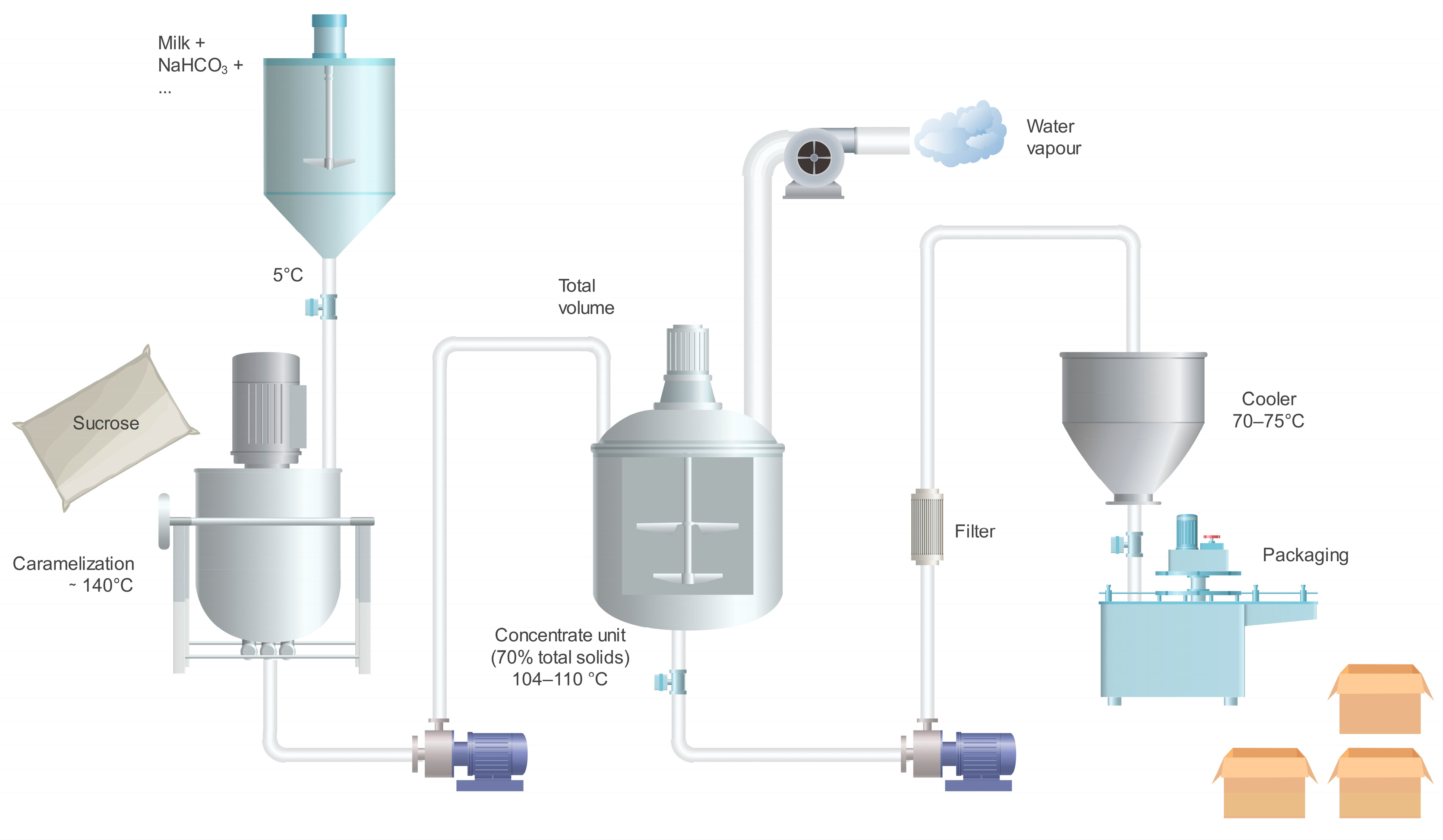

3.7. Doce de Leite Manufacturing with Sugar Pre-Caramelization and a Total Batch System

Process 7 (

Figure 8) employs various strategies to create the sensory attributes of the products. Initially, sucrose undergoes pre-caramelization (up to 140 °C), resulting in the production of doce de leite in a total batch system. Consequently, the product exhibits both MR and caramelization characteristics. Although this process is not utilized in Brazil, some small companies adopt it to differentiate their products in the market. The primary challenge of this process is the precise control of the sugar caramelization temperature to prevent an overly intense burnt syrup flavor. Furthermore, no scientific literature has been found that discusses chemical markers for either MR or caramelization in this type of product.

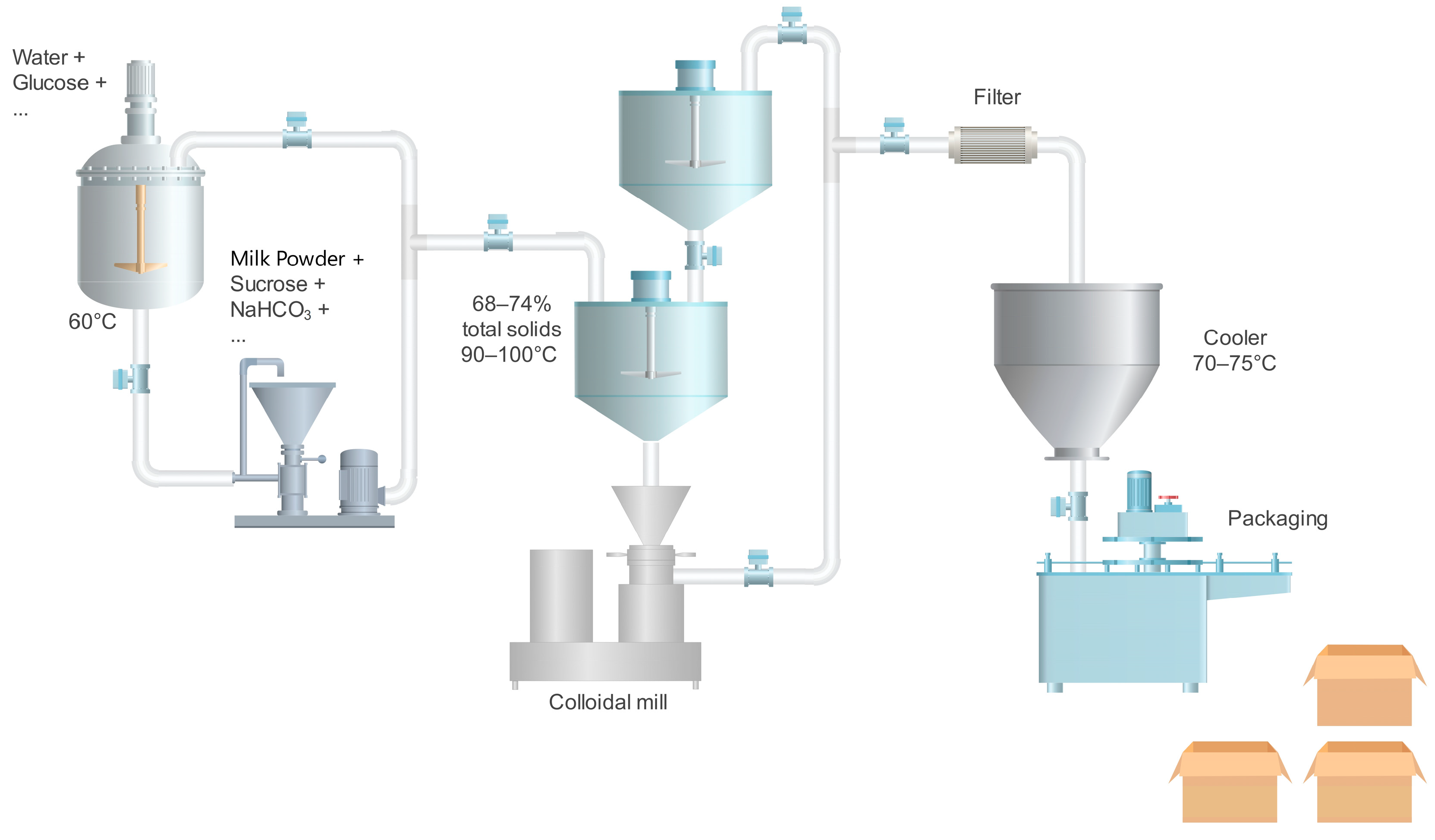

3.8. Doce de Leite Production with Colloidal Mill Without an Evaporation Process

In 2016, inventors Carlos Arcusin, Gustavo Alfredo Garcia, and Claudio Schena applied to receive a patent for a process and device designed to prepare creamy food products (WO 2016/062348 A1), which can be utilized in the production of doce de leite [

22].

According to this patent, the process entails several stages for processing a batch featuring a mix with relatively low moisture content (below 20%). The mix is repeatedly passed through a colloidal mill or across multiple cycle stations connected by pipes to regulate flow pressure. The final stages include adding liquid to achieve the desired density for the mix batch. The device facilitates the recirculation of product batches through a single colloidal mill or through multiple cycle stations, each with its respective colloidal mill. This technology is depicted as Process 8 in

Figure 9. A colloidal mill is an industrial device designed to reduce the size of solid particles in suspension or emulsion, proving particularly effective in producing emulsions, dispersions, and colloidal suspensions where particle size reduction is crucial.

3.9. Manufacturing a Doce de Leite Bar Using the Sucrose Crystallization Stage

The final production mode, Process 9 (

Figure 10), targets the doce de leite bar, which crystallizes into blocks of uniform color and texture. It is often consumed in pieces. The distinction between types of doce de leite rests on the total solids and sucrose content, which is significantly higher in the doce de leite bar compared to the creamy variety. Additionally, the manufacturing process differs, as the doce de leite bar undergoes “beating” to induce lactose and sucrose crystallization within the product [

6].

The sucrose and lactose content in doce de leite bar solution is higher than that in creamy doce de leite. Consequently, the doce de leite bar is more prone to crystallization. This product type exhibits crystals within its matrix, a characteristic that contributes to the desired texture and consistency of this particular doce de leite variety. To achieve this effect, the doce de leite undergoes a controlled crystallization process or beating, which may be performed manually or mechanically. During this process, the doce de leite is intensely stirred under controlled conditions or beaten, while concurrently being slowly cooled. This method promotes the formation of numerous lactose and sugar crystals, thereby altering the product’s texture.

Milk drop doce de leite is a variation of the doce de leite in a bar format, sold in small pieces, characterized by a hard and crystallized crust with a soft and creamy interior. This texture results from rapid cooling and partial, superficial dehydration that occurs when the doce de leite is spread in thin layers on an appropriate tray. Typically, these trays bear stamps (company name or logo) that imprint such images onto the product.

The choice between doce de leite bars and pastes depends on the manufacturer’s preferences and the target market. Each variant possesses unique characteristics, catering to diverse tastes and consumer preferences.

4. Conclusions

The different doce de leite production processes vary significantly in terms of costs, energy efficiency, and suitability for production scale. Simple batch processes and those with fractionated addition, such as Processes 1 and 2, are more accessible and popular among small and medium producers due to their lower initial investment and ease of operation. In contrast, processes using vacuum evaporators, like Process 3 (pre-concentration with open pan finishing) and Process 5 (continuous production), require higher equipment investments but are more energy-efficient and offer better quality control, making them widely adopted by large industries.

The availability of diverse technologies enables manufacturers to tailor the process to achieve specific desired characteristics in doce de leite, such as texture, flavor, and ingredient concentration. More advanced processes, like lactose micro-crystallization, help control crystal perception, creating pasty products with refined texture. The pre-caramelization process, meanwhile, intensifies the caramelized flavor, differentiating the product. Therefore, the decision on the most suitable process should consider investment capacity, market demand, and the desired product profile, balancing cost, sustainability, and quality.

Combining different technologies provides more precise control over variables like temperature, processing time, and ingredient concentration, yielding a more consistent product. Utilizing a range of technologies places manufacturers in a competitive position, allowing for them to provide differentiated products that meet market demands.