Abstract

Sustainable water desalination and purification membrane processes require new practical pathways to improve their efficiency. To this end, the inclusion of two-dimensional materials in membrane structure has proven to have a significant impact in various applications. In particular, in processes such as membrane distillation and crystallization, these materials, thanks to their characteristics, help to increase the recovery of clean water and, at the same time, to improve the quality and the production of the recovered salts. Therefore, a fundamental aspect of obtaining 2D materials with certain characteristics is the technique used for the preparation. This review provides a broad discussion on the preparation and proprieties of 2D materials, including examples of organic structures (such as graphene and structures containing transition metals and organic metals). Finally, the critical challenges, future research directions, and the opportunities for developing advanced membranes based on 2D materials are outlined.

1. Introduction

Agricultural expansion, industrial development, population growth, and climate change have led to increased water withdrawals and water shortages in many regions of the world. The need to solve the water crisis is becoming so urgent that freshwater has taken the role of a strategic resource. Because oceans constitute nearly 97% of the world’s water, desalination has garnered significant attention as an effective method to extract freshwater from seawater, wastewater, or brackish water.

Commercial desalination technologies can be divided into two main categories: thermal distillation (multi-effect distillation (MED) and first multi-stage flash (MSF) distillation) and membrane separation (reverse osmosis (RO) and nanofiltration (NF)). The former involves phase change processes, whilst the latter involves semipermeable membrane systems [1]. RO technology is used in >90% of the current desalination plants and contributes to 69% of annual desalinated water production [2]. However, RO can recover max 50% due to the osmotic phenomena.

Recently, among the different emerging technologies, membrane distillation (MD) has received considerable attention both from an industrial and academic perspective. MD is a thermally driven separation process that uses a microporous hydrophobic membrane to separate dissolved molecules from a liquid stream [3]. Its advantages include a lower operating pressure compared to RO process which allows for the use of low-grade thermal energy and renewable energy for its operation. In addition, many efforts to further reduce MD energy consumption have been reported in recent years, including photothermal membrane distillation [4] and hybrid membrane distillation systems [5].

One of the most interesting and promising extension of MD concept is represented by the membrane crystallization (MCr) process which provides the possibility of recovering simultaneously pure water and high-quality salt products using the logic of zero liquid discharge (ZLD) [6].

Nevertheless, despite their great potential, MD and MCr have some drawbacks such as flux lowering due to poor hydrodynamics and inefficient module design, and distillate contamination due to membrane wetting; the latter is one of the main obstacles to the wider application of MD. Therefore, developing new advanced membrane materials with good performance and low cost has become essential to intensify the MD process. Ideal MD membranes are expected to exhibit features such as high liquid entry pressure (LEP), high permeability, low fouling rate, low thermal conductivity, excellent chemical and thermal stability and excellent mechanical strength.

Polymeric membranes have long been considered for MD applications due to their good processability, intrinsic hydrophobicity, and low cost.

However, they present disadvantages such as limited chemical stability, fouling, and short lifetime. In contrast, inorganic membranes (zeolite, silica, zeolite, carbon, and hybrid inorganic–organic one) exhibit higher chemical, thermal, and mechanical stabilities that make them potential candidates for MD applications. In particular, zeolites [7,8,9] and carbon nanotubes [10,11] were suitable for water desalination due to their subnanometer pores/channels. However, the high cost- and time-consuming process of preparing perfectly ordered subnanometer arrays of zeolites and carbon nanotubes hinder their commercialization [12].

Since the discovery of single-layer graphene, two-dimensional (2D) materials have garnered notable interest in many fields of science and technology including MD processes. In the last decade, research on the role of 2D materials in membrane science has grown as they have a high potential of providing new solutions to significant problems. Two-dimensional materials are suitable for the fabrication of high-performance membranes in terms of specificity, selectivity, high flux, chemical and mechanical resistance [13]. Members of the family of 2D materials include graphene-based materials, transition metal dichalcogenides (TMDs), 2D zeolites, metal organic frameworks (MOFs) and carbides (MXenes) [7,14,15,16,17].

This review discusses the state of the art of 2D materials embedded in polymeric membranes. The preparation of these membranes was carried out to increase the performance of desalination processes such as membrane distillation. Among the 2D materials investigated, particular focus is laid on graphene and chalcogenide materials. The first section presents the materials and some techniques used for their peeling and preparation. The second part presents the experimental results derived from the application of 2D materials in MD. Finally, future application prospects and potential of these membranes functionalized with two-dimensional materials are addressed.

1.1. The Advent of 2D Materials

Two-dimensional materials are crystalline solids with a high ratio between their lateral size (∼1–10,000 μm) and thickness (<1 nm) [18]. They consist of single- or few-layer atoms in which the in-plane interatomic interactions are much stronger than those along the staking direction [19]. Being ultrathin, 2D materials exhibit exceptional physical, electrical, chemical, and optical properties [20,21,22].

Two-dimensional materials have garnered great interest in seawater treatment applications because ion-sieving, either via in-plane pores or stacked nanosheet channels, can be achieved and both can be economically produced on a large scale. The hyper-thinness of 2D monolayers makes it possible to fabricate ultra-thin membranes with excellent mass transport and high transmembrane fluxes [23]. Furthermore, 2D materials can significantly improve the selectivity of solutes due to their structural and chemical homogeneity [24]. Currently, nanofiltration is the membrane process where 2D materials are most commonly used.

In 2004, graphene was the first 2D material discovered, becoming the most representative of 2D materials [25,26]. The possibility of cheaper synthesis of large-area graphene sheets makes this material very interesting for large-scale applications [27]. Furthermore, graphene has shown great potential as filler for composite materials, giving it outstanding mechanical and thermal properties [28,29].

The early successes of graphene have inspired much research on the use of 2D materials for next-generation membranes [13]. As a result, a variety of new 2D materials have been discovered. Examples include 2D boron nitride (BN), 2D transition metal dicalcogenides (e.g., molybdenum disulfide (MoS2), tungsten chalcogenides (WS2)), monoelemental 2D materials (such as borophene or phosphorene) and carbides or transition metal carbonitrides (MXenes) [4,30,31,32,33]. Some of them (MoS2, BN and MXenes) were already extensively studied in membrane technologies for water purification. Two-dimensional transition metal dichalcogenides (TMDCs), in recent years, were mainly investigated as an alternative route to replace the metal oxide-based photocatalyst, thanks to their suitable bandgap (1.6–2.03 eV) for the collection of visible light. Bidimensional TMDCs are endowed with high mobility of charge carriers which provide large active surface for dye degradation [34,35,36,37].

1.1.1. Graphene

Graphene is a single layer of carbon atoms arranged in a flat honeycomb lattice. Over the years, graphene and its derivatives have found application in many fields, from water treatment to electronic and optics, due to its peculiarity such as excellent electronic conductivity, hydrophobic and anti-wetting nature, anti-fouling properties, great mechanical strength, low density and selective absorption of water vapors [38]. The introduction of graphene in membrane science is a promising approach to support sustainable growth in industrial development and research [39]. Few-layers graphene membranes exhibit ideal characteristics for the membrane contactor process, such as narrow pore size, high performance in terms of permeability and selectivity [40,41,42]. Generally, graphene is produced via exfoliation of graphite sheets. The exfoliation technique is fundamental for the quality of graphene in terms of the number of layers, lateral dimension and thickness of the graphene flakes. Various techniques for graphene exfoliation are reported in the literature such as mechanical exfoliation [43,44], epitaxial graphene in silicon carbide (SiC) [45], direct growth of graphene on thin nickel [46], chemical vapor deposition (CVD) [47,48], etc. The most used method is liquid phase exfoliation (LPE), which (in a liquid environment) allows ultrasound or shear forces to break the van der Waals bond between the graphite layers, thereby causing the exfoliation of graphite [49]. In recent years, an innovative and advanced technique known as wet jet milling (MJW) was developed for high-quality graphene exfoliation. In particular, this technique allows to prepare grapheme films with well-controlled thickness and lateral dimension in an easy and scalable way [44].

When chemical oxidation occurs on the graphene, several oxygen-containing groups, such as carboxylic, hydroxyl, and epoxide functional groups are formed on the carbon surface. This is called graphene oxide (GO), which is usually prepared using the Hummers method [50]. This method consists of the addition of potassium permanganate to a solution of graphite, sodium nitrate, and sulfuric acid. GO is a nonstoichiometric compound that varies in compositions depending on the synthesis conditions (oxidizing agent, solvents, time, exfoliation, etc.). The exact composition and structure of chemically synthesized GO are still being discussed [51]. Li et al. [52] prepared graphene membranes to study the ripple of GO nanosheets and found that GO nanosheets could be successfully used in the nanofiltration process with a 67% rejection rate for direct yellow (i.e., a dye molecule that is often used as a model molecule in the characterization of separation membranes).

1.1.2. Transition Metal Dichalcogenides

Transition metal dichalcogenides are layered metal oxides classified as two-dimensional (2D) materials. Their intrinsic properties make them interesting materials for energy storage [13], catalysis [53], sensors [15] and biomedical applications [54]. Two-dimensional transition metal dichalcogenides include different materials such as molybdenum sulphide (MoS2), tungsten disulfide (WS2), MXene, boron nitride (BN), carbon nitride g-(C3N4), metal–organic framework (MOF) and covalent–organic framework (COF) [55]. Recently, single-layer or few-layer TMDs were used in the field of membranes due to their excellent molecular sieve [56] and high flux and antifouling proprieties in water treatment. They have strong covalent bonds in the plane and weak van der Waals bonds outside the plane [57]. TMD nanosheets, depending on the coordination environment of the transition metal and chalcogen, can be found in the two different polymorphic states. These two polymorphs are the stable 2H trigonal prism polymorph (semiconducting) and the 1T metastable octahedral polymorph (metallic) [58]. Lithium interception predominantly produces the 1T phase, but exfoliation into the liquid phase produces the 2H phase.

The use of 2D materials in membranes has shown promising results in gas separation processes, especially for MXene membranes [59], demonstrating high separation performance. In the case of layered TMD, there are limited reports on the use of MoS2 as an additive for the preparation of composite membrane for gas separation. For example, Coleman et al. [60] prepared MoS2 membranes with different thicknesses after exfoliation with butyllithium, which showed an H2/CO2 separation factor of 4.4–3.4 and an H2 permeability in the range of 2454–27,400 GPU [60]. Chari and Eswaramoorthy prepared MoS2 nanosheets [61] in 1T phase using butyllithium and converted them to 2H phase by heating the membrane [62]. The 2H phase showed better perselectivity than the 1T phase (H2/CO2 selectivity of 6.2 and 8.2 with an H2 permeability of 1740 and 1175 barrers, respectively).

The following section focuses on the main 2D materials exfoliation techniques, highlighting both the advantages and disadvantages of each. In addition, the performance of membranes with 2D materials in the field of water treatment will be discussed.

1.2. Exfoliation of 2D Materials

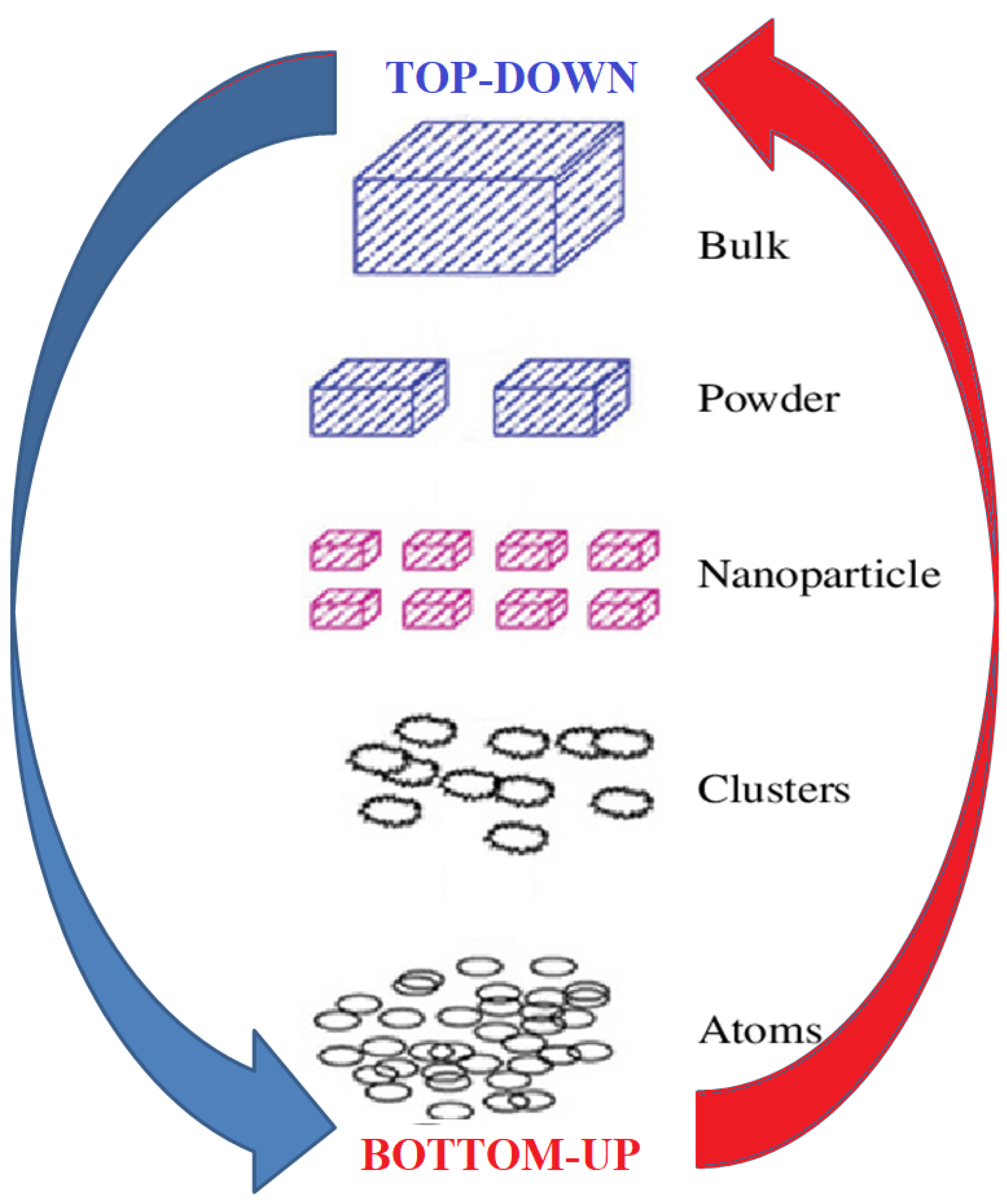

Exfoliation consists of separating the individual layers more or less regularly to obtain materials with few layers. Nanofabrication methods can be classified into two groups: top-down and bottom-up approach [63,64] (Figure 1).

Figure 1.

Top-down and bottom-up approaches for materials exfoliation.

The top-down method allows for the formation of 2D or nanometric materials starting from the raw material, reducing its size until the desired nanometric particle size is reached. Although top-down approaches are relatively simple to use, they are unsuitable for producing irregularly shaped and extremely small particles. The difficulty in obtaining the correct particle size and shape is the main drawback of this approach. The top-down method can be achieved through several techniques including tape exfoliation, metal exfoliation, intercalation and liquid-mediated exfoliation [65,66]. The exfoliation of layered bulk crystals into single- or few-layer sheets is generally achieved using chemical/physical driving forces to overcome the weak van der Waals interactions between the layers. Tape exfoliation of thin metal film is a very simple technique which mechanically strips loose crystals and produces single crystal flakes [44]. The single crystal flakes produced are often of high purity and clean lines, mainly suitable for the production of main devices and the characterization of new 2D systems. Regarding intercalation strategies, ionic species are interdispersed in the spaces between the layers. Intercalation creates expansion forces through the reaction and allows for the separation of layers in the liquid. Ultrasound, or liquid-mediated exfoliation, is used to produce a high local temperature and extreme pressure, which tends to break the bonds between the various layers [43]. Liquid phase preparations are considered more suitable for obtaining large production, although submicrometric scales with high defects and modified chemical or physical properties are often obtained. Monolayers prepared via fluid mediation are particularly useful for catalysis or other chemical applications [38].

The bottom-up approach is based on the direct construction of 2D nanomaterials with precursor atoms via the growth or self-assembly of atoms and molecules. The nanomaterials (NMs) produced using these techniques have a well-defined shape, size and chemical composition depending on the constituent elements. During deposition, nucleation at different local positions leads to continuous growth of individual domains, which subsequently coalesce into a continuous monolayer thin film constituting a polycrystalline film [67]. With tuned growth conditions, isolated single-crystalline flakes, down to a few hundred µm in the lateral dimension, can be obtained. Controlling the number of layers through targeted growth is particularly difficult due to the high barrier of nucleation [68].

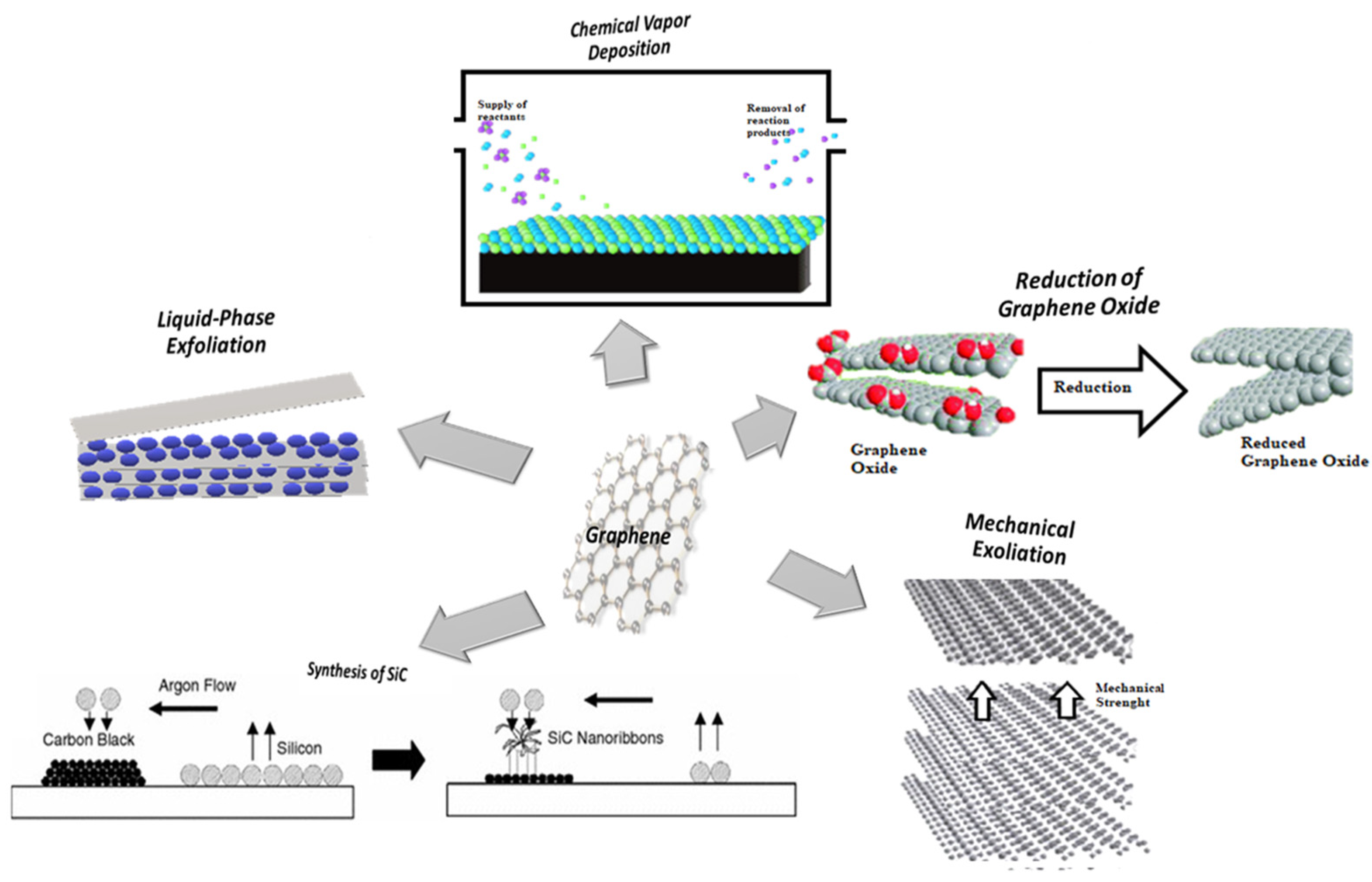

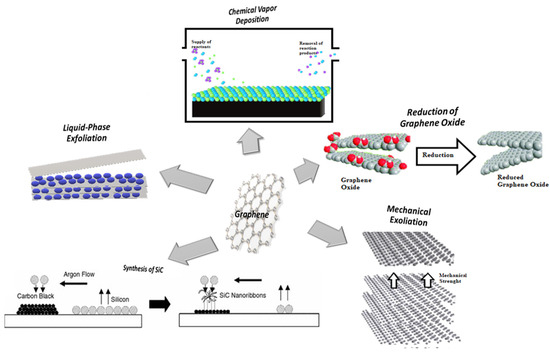

Figure 2 illustrates the main exfoliation techniques discussed in the literature, while Table 1 provides an overview of the corresponding pros and cons [69,70]. The illustrated techniques were utilized especially for graphene production. In some cases, several techniques were also utilized with other materials (such as carbon-based nanomaterials, silicate clays, TMDs, MOFs layered double hydroxides (LDHs), titanium dioxide (TiO2), Tetramethyl orthosilicate (TMOs), BN, black phosphorous (BP), etc.) [71,72]. High production costs are still the major barrier hindering commercial adoption. For example, in the case of graphene, on average, the cost is USD 550 per square centimeter; however, it could also drop down to between USD 100 and USD 200 when demand is expected to increase [73,74].

Figure 2.

Main exfoliation methods used for the graphene production.

Table 1.

Main exfoliation methods with an overall production process in terms of quality, cost aspect (a low value corresponds to high cost of production), scalability, purity and yield. Modified from [69].

Due to low scalability and high manufacturing costs, methods such as mechanical exfoliation and SiC synthesis are no longer the forerunners to produce graphene for niche applications such as touch screens and high transistors frequency. Likewise, chemical vapor deposition of hydrocarbons, although an established technique in industry, appears to be generally unsuitable for mass production of graphene for electrochemical energy storage due to moderate product purity and rather low yields. Currently, the most popular production method for obtaining good quality graphene at reasonable cost is the chemical vapor deposition, in which the gaseous reactants form a graphene film on a metal substrate (usually a copper foil).

Reduced graphene oxide (rGO) is an alternative form of graphene oxide (GO) with a reduced amount of oxygen (as the latter makes GO unstable [40]). Typically, the reduction process can be achieved via electrochemical reduction, chemical reduction and thermal reduction [75,76,77,78]. rGO exhibits high conductivity, stability and also has the presence of defective sites that are chemically active, making it a potential candidate for application as an active material in biosensors [79]. rGO was commonly used to prepare composite membranes with various materials, such as metal and metal oxides, using different techniques to improve the performance of the supercapacitor.

Chemical vapor deposition (CVD) process is a gas-phase chemical methodology for the formation of thin layers (with thicknesses generally between 0.1 and 10 μm) of various materials [80,81]. The respective films or structures are formed as a result of the elimination of the volatile by-products produced during the thermally induced decomposition process. The operational requirements are as follows: controlled delivery of reagents in the gas phase, availability of a closed reaction chamber, gas discharge, regulation of the reaction pressure, supply of an energy source for chemical reactions, cleaning of the exhaust gases to achieve safe and non-toxic levels and control of the automation process to increase the stability of the deposition process [63,81].

Liquid phase exfoliation (LPE) is one of the main methods for producing two-dimensional (2D) materials in large quantities with a good balance between quality and cost. This technique is widely adopted by both the academic and industrial sectors. Liquid phase exfoliation can be applied in several ways. Based on the type of exfoliation used, different techniques can be distinguished. For example, a fragmentation or high-pressure mechanism can be used. The mechanisms involved in fragmentation and exfoliation are usually attributed to the interaction of ultrasound-induced forces with solvent molecules. The principal liquid phase exfoliation techniques are as follows [44]:

- Wet-jet milling (WJM) [44,82,83,84];

- Ultra-sonication (UW) [49,85,86,87];

- Ball-milling (BM) [84,88,89,90,91];

- Micro fluidization [73,92,93,94,95,96];

- Electrochemical exfoliation [97,98,99,100,101].

Graphene is produced in large quantities mainly through liquid phase exfoliation and reduction of graphene oxide. In the first process, the particles of uncontaminated or expanded graphite (obtained from the thermal expansion of graphite intercalation compounds) are first dispersed in a solvent and subsequently, through an applied driving force (ultrasound, electric field or cutting), the graphite exfoliates into high quality graphene sheets. Dispersion in a solvent is necessary to reduce the strength of the van der Waals attraction between the graphene layers. A drawback of this process is the necessity to remove the non-exfoliated graphite residue. On the contrary, the advantages of this process are very the high scalability and the low cost of liquid phase exfoliation, which make it suitable for the production of graphene in large quantities. In the second process, graphene is produced via the reduction of graphene oxide (GO), a highly defective form of graphene with a disrupted sp2 bond network. Graphite, through a process of strong oxidation followed by stirring or ultrasound in liquid media, is transformed into graphene oxide. The reduction of the latter serves to restore the π network, which is characteristic of conductive graphene. To conduct this, chemical, thermal or electrochemical processes are commonly employed. Despite the medium-low quality of the material obtained due to the presence of both intrinsic defects (edges and deformations) and extrinsic defects (groups containing O and H), these methods allow for the production of large quantities of graphene with high yield and low costs. In addition to liquid phase exfoliation and GO reduction, other exfoliation techniques are available, such as carbon nanotube decompression or direct arc discharge. However, these techniques have higher costs, and therefore, they are unsuitable for large productions.

Mechanical exfoliation (ME) is one of the commonly used exfoliation techniques. It can be implemented according to both top-down and bottom up approaches [101]. Top-down method allows for the exfoliation of a single-layer from spout crystals VDW (van der Waals heterostructures). Usually, a shear force is applied (for this reason, it is often called Shear-Exfoliation (SE)) to separate the sheets of the material to be exfoliated (e.g., graphene). The shear mixer has emerged as a new tool for the exfoliation of layered crystals [102,103,104]. The turbulence and shear forces produced by the reciprocal rotor/stator movement exfoliate the dispersed stratified crystals. To date, shear exfoliation appears to be a technique that still needs to be improved to meet the demands at an industrial scale. The scalable method of high shear exfoliation has not yet been fully explored, and there are only few reports focused on shear mixing in environmentally friendly aqueous media to produce low-layer graphene dispersions. The highest concentrations recorded to date are approximately 1 mg/mL using processing times of up to 4 h [104]. Therefore, high shear exfoliation is quite a new technique and despite the apparent simplicity, many aspects influence the outcome of exfoliation in terms of quantity and quality [104,105].

These aspects include the properties of the graphite source material such as flake size, type of surfactant and its concentration, as well as mixing parameters (such as rotor speed and mixing time). Some of these aspects, such as the mixing parameters, have been studied more thoroughly, while other parameters have received less attention. In particular, the effect of flake size on the outcome of exfoliation has not received much attention and its effect is unclear. It is interesting to study it as large graphite flakes with high crystallinity are typically used to obtain high-quality, low-layer graphene. Furthermore, it is of great interest to reduce the amount of solvent and surfactant residues since they limit the applicability of the material produced by decreasing, for example, the conductivity of the subsequent films [106].

2. Preparation of Membranes Functionalized with 2D Materials

Several kinds of manufacturing techniques are proposed for the development of nanostructured membranes. Here, particular attention has been paid to the preparation techniques with a high degree of geometric order through two-dimensional (2D) and tridimensional (3D) space. Each approach has advantages and limitations, and endows certain characteristics to the membranes produced. Over the years, researchers have been trying to improve each technique in order to obtain increasingly efficient membranes [106].

The techniques based on traditional phase inversion allows to easily control the morphology of the membrane. These techniques require the polymer to be soluble in a suitable solvent or in a mixture of solvents. Two-dimensional materials are usually dispersed in the solvent or a mixture of solvent as described in Frappa et al. [23,107,108]. In principle, all the main phase inversion techniques can prepare membranes containing 2D materials (non-solvent-induced phase inversion (NIPS), vapor-induced phase separation (VIPS), thermally induced phase separation (TIPS) and evaporation of the solvent, (EIPS)). Phase inversion techniques have various advantages such as low formation of defects, possibility to use green solvents, high possibility to control the final morphology (pore size, thickness, etc.) and symmetric structures. At an industrial level, the membranes are commonly prepared with phase inversion techniques [109].

A second category of membranes is realized according to more sophisticated manufacturing strategies. These breakthrough methodologies include the following:

- (a)

- Lithographic technique is proposed especially for creating polymeric surfaces with a regular structure and a precise geometric order. The main feature of lithography is the mechanical reproduction of certain images. At the nanometer level (lateral size between the size of a single atom and about 100 nm), lithography can be used in the fabrication of advanced semiconductor integrated circuits or nano electromechanical systems (NEMS). Lithography can also be performed using a support [110] on which the polymer solution is placed, making the final product exhibit certain structures and properties. Patterns are created with mechanical deformation of the impression strength and subsequent processes. The main disadvantages of this process are the high cost of making molds with dimensions of the nano order and the difficulty in obtaining a large resolution. On a larger scale, the creation of well-made surfaces turns out to be more efficient and easier.

- (b)

- Phase separation micro-molding (PSμM) is a highly specialized manufacturing process that produces extremely small, high-precision thermoplastic parts and components with micron tolerances [111]. The process begins in a tooling department where a mold is created that has a cavity shaped like the desired part. Thermoplastic or resin is rapidly injected into the cavity, creating the component or part at high speed. The combination of micro-molding and phase separation techniques is another approach to create nanostructures with hierarchical ordered morphology. It can be seen as an evolution of the traditional phase reversal. A polymer is precipitated from a solution assuming a desired configuration similar to traditional phase inversion. The final configuration can be flat, cylindrical or spherical. The solidification process begins with the transition from a liquid to two liquid phases: one rich in polymer, the other rich in solvent. The first solidifies forming a solid network; the second generates pores or voids in the matrix [112].

- (c)

- Colloidal templates use polymeric nanocapsules composed of a shell or membrane, which is mechanically very strong and separates the internal cavity from the outside medium, thus creating a barrier for various substances that can be encapsulated therein [113]. Scientists found that monodisperse colloidal spheres can self-assemble into arrays of periodic spheres, called colloidal crystals, in a hexagonal arrangement under well-controlled experimental conditions using drop coating, spin coating, dip coating, electrophoretic deposition and self-assembly at the liquid/gas interface. Moreover, in the large hollow spaces, substances such as drugs and biomolecules can be encapsulated and released in a controlled manner, which make the polymeric nanocapsules attractive devices for drug delivery, cancer and gene therapy, protecting enzymes, etc. [114]. The synthesis of monodisperse colloidal spheres offers an opportunity to extend their applications. Membranes with morphological features of high structural order at the nanometric scale may be achieved according to the colloidal template method. Colloid crystalline particles are three-dimensional close-packed crystals of sub-micrometer spheres working as imprinting agents, whose long-ranged ordered structure is replicated in a solid matrix, thus yielding materials with ordered pores. Colloidal crystal structures with this ordered architecture are of great interest for tissue engineering wherein the availability of arrays for cellular proliferation is requested to promote the optimum environment for a good adhesion and consequent cells proliferation [115].

- (d)

- Self-assembly copolymers exploit the ability of some materials to spontaneously form ordered aggregates [116]. This allows to obtain nanostructures, even complex ones, depending on the intrinsic structure and chemistry of the molecules involved. The components most present in these types of assemblies are as follows:

- Lipids, proteins, carbohydrates and nucleic acids;

- Molecular crystals;

- Liquid crystals;

- Semi-crystalline and separate phase polymers.

In the case of membranes, the ability of polymers to self-assemble on a nanometric scale is exploited. Different techniques are used in these processes. The two main strategies that have been used by the researchers are as follows:

- -

- The use of block polymers which give rise to a cylindrical morphology;

- -

- The use of a block polymer with a bi-continuous morphology which obviates the need for alignment [117].

- (e)

- Breath figure (BF) for bio-inspired high-defined membranes has been developed in the context of bio, innovative and bio processes in the preparation of micro-porous membranes [118]. This technique allows to obtain membranes with ordered pore geometry. The basic idea for using BF has been developed from the observation of the common phenomenon of fog formation which originates when water vapor comes into contact with a cold surface. During this event, the condensed water droplets tend to rearrange themselves into an ordered geometry that resembles honeycomb patterns. The condensation of water droplets on the surface of dilute polymeric solutions containing immiscible or partially miscible solvents also allows for an easier recovery of the solvent at the end of the process. Furthermore, water is a widely available non-toxic templating agent, so the general approach can be considered as an environmentally friendly production technology. Despite the simplicity with which droplets can be formed, the mechanism that controls the formation of BF geometry can be very complex and not perfectly unique. This may depend on the polymeric materials and solvents used, but also on changes in the surrounding experimental conditions, which make the management of water droplet dynamics somewhat difficult [119].

- (f)

- Deposition for filtration is one of the most common and effective deposition methods. The vertical downtown force, supplied with pressure/vacuum filtration, drives the 2D nanosheets group in a layered interlocking structure on the substrate. The thickness is provided by the membrane that is supported, though it can slightly vary with deposition. Furthermore, other ions, molecules or nanoparticles can be easily mixed and interspersed in the strikers, providing additional flexibility on the tuning of the membrane structure [120].

- (g)

- Coating: Coating is the creation of a thin layer on the surface of the membrane. Various coating methods have been reported to assemble 2D nanosheets on membranes, including drop coating, sterile coating, spin coating and casting, etc. The success of a uniform coating is based on the smoothness of the substrate, the surface tension of the coating solutions, as well as the process of evaporation applied. Among the methods, spin coating could provide centrifugal and cutting forces to control the assembly of nanosheets, producing a well-interloped ordered laminated structure. At present, this technique is also applied to prepare highly ordered labeled membranes [79,121].

- (h)

- Layer-by-layer self-assembly (LBL) refers to the deposition process of different materials on the surface of the substrate. This approach is mainly based on the interactions between adjacent layers, including electrostatic bonding, hydrogen or even covalent interactions. The LBL method can accurately check the thickness of the selective layer by varying the number of deposition cycles and is useful for introducing the intercalary stabilization forces. Therefore, the resulting membranes can remain stable in aqueous or organic media. However, the implementation of this method requires the presence of material interactions and the preparation process takes time [122,123].

- (i)

- Honeycomb membranes possess a specific distribution of the pores on the surface of the partition walls and an enlarged porosity in addition to subtle dividing walls of a prescribed value. The preparation of these particular structures is based on the preparation of lithographic precision membranes according to a BF biospirated process [119]. The condensation waterdrops act as the imprinting agents on the polymer surface and with the balance between solvent evaporation and humid air condensation in a 3D construction, bee nest membranes can be obtained in a single pass. After condensation, the dripping water drills grow and self-assemble in ordered arrays, producing a highly defined hexagonal geometry as a result of their imprinting action, different from what is observed for the separation techniques of conventional phases. The main limitation is using this process to produce commercially large-scale films is the lack of control over the long-range structural order through the surface of the films created [124].

3. Application of 2D Materials in Membrane Distillation

Membrane distillation is a thermally driven technology for removing volatile components from solutions, and therefore useful for desalting highly saline waters. The driving force is the difference of vapor pressure between the two membrane surfaces [125]. The mass transport takes place inside the pores, and the trans-membrane flux is directly proportional to vapor pressure difference across the membrane:

where is the membrane distillation coefficient, which depends on the membrane morphology such pore size, porosity, membrane thickness, etc. The membrane distillation coefficient can be calculated with the following:

where is the nominal pore size of membrane, is the exponent of in the range of 1 to 2 ( for Knudsen diffusion, for viscous flux), is the pore tortuosity and is the membrane thickness.

Typically, membranes with two-dimensional material allow water to permeate, and this can happen through three distinct paths: one is given by the nanopores in the plane (through defects), the second path is given by the interplanar tunnels (with slit pores) and the third is given by the voids generated by the least ordered stack of nanoflakes [126]. So these 2D mixed composites have potential for future applications in membrane filtration. Discussing the performance competition offered by the types of membrane structures, mainly membranes involving stacked laminar pathways have shown better scalability than those involving porous pathways [126]. In the field of membrane distillation, Liu et al. [41] report that the 2D channels between stacked GO nanosheets allow molecules to pass through differently from nanosheet membranes where in-plane nanopores provide the transport channels. The oxygen-containing functional groups on GO nanosheets, besides making GO dispersible in water, also provide convenient sites for enhancing specific interactions (for example, hydrogen bonds, and electrostatic) with transport components (water, CO2, and ions).

More and more 2D materials are being explored for the fabrication of membrane distillation (MD) membranes [42]. The main applications of these materials in MD are illustrated below.

3.1. Graphene in Membrane Distillation

Recently, graphene became one of the most attractive materials to be used in membrane systems, especially in MD. An example of graphene-based membranes was conducted by Gontarek et al. [127,128] in which graphene nanoplatelets were dispersed in solvent and confined in a membrane matrix at different concentrations. The prepared membranes were experimentally tested in MD. The results indicate that composite membranes perform well in terms of trans-membrane fluxes and rejection (of about 100%), without the wetting, fouling and thermal polarization phenomena.

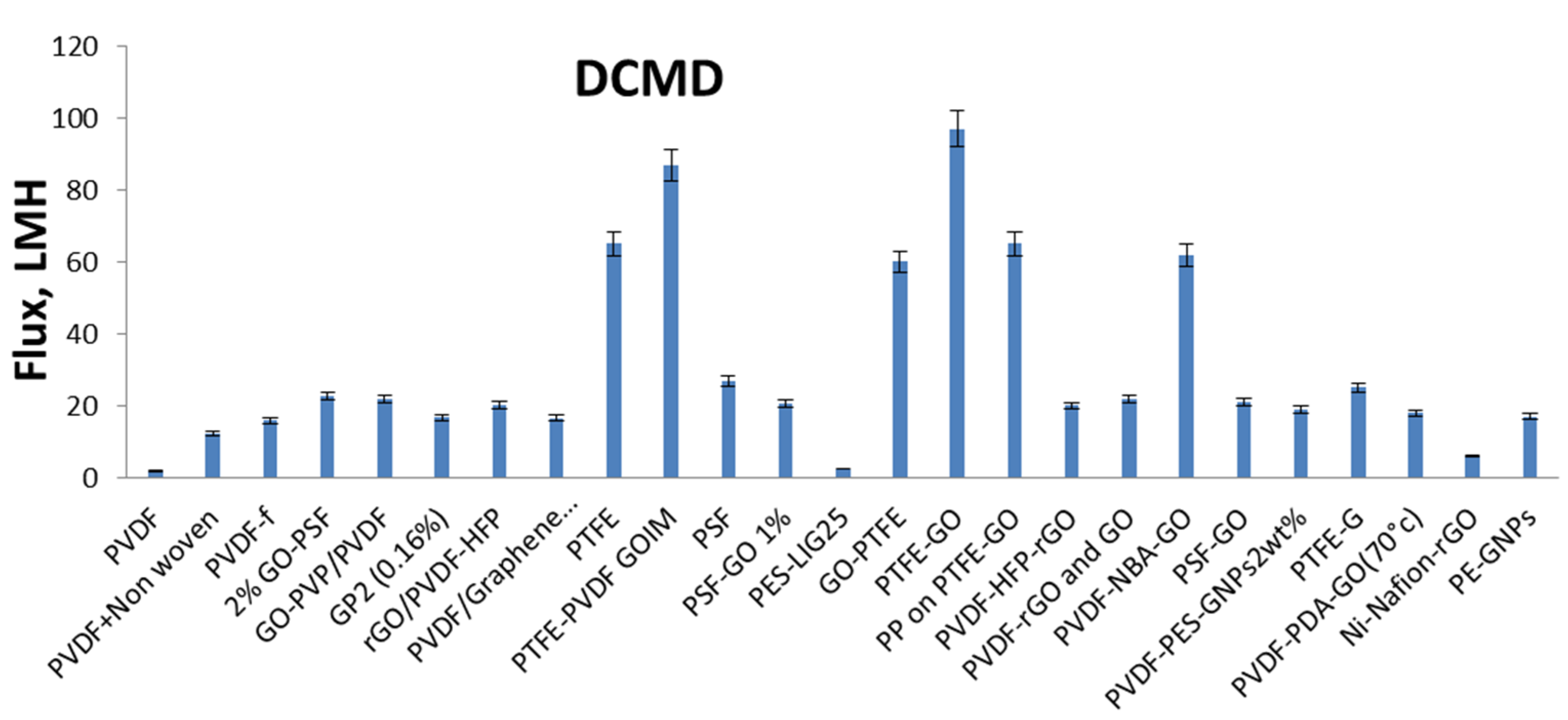

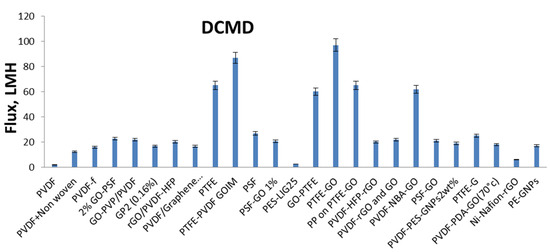

In Figure 3, trans-membrane flux of different kinds of graphene-based membranes tested in direct contact membrane distillation is shown. Table 2 reports on the main characteristics of the graphene-based membranes considered for the comparison in Figure 3. All the membranes with graphene and graphene oxide present a rejection rate of over the 99.9%. In general, graphene is chemically anchored on membrane surface, exploiting the π-π interactions created with the PVDF surface. A recent study of graphene oxide functionalization for MD application was carried out by Zahirifar et al. [129].

Figure 3.

Trans-membrane flux of graphene-based membrane in DCMD.

Table 2.

Main characteristics of graphene-based membranes.

In particular, graphene oxide was functionalized chemically with octadecylamine (ODA) in order to exploit the long hydrocarbon chain of ODA for reducing the surface energy and increasing membrane hydrophobicity. The ODA-functionalized was carried out with a coating of GO on PVDF membrane surface. The prepared membrane was then applied for desalination in air gap membrane distillation (AGMD), and its performance was evaluated in terms of water permeability and salt rejection. The results showed how a suitable amount of GO-ODA coated on PVDF membrane significantly enhances MD performance. This improvement was attributed to the increase in hydrophobicity and roughness, reduced pore wetting, as well as low thermal conductivity of GO-ODA. Moreover, a decline in temperature polarization and heat diffusion across the membrane was also observed. Another example of graphene application in direct contact membrane distillation (DCMD) process was proposed by Bhadra et al. [137]. They prepared the membrane via immobilization of GO on a PTFE (polytetrafluoroethylene) matrix with an improvement in trans-membrane flux and high salt rejection. The cause of this improvement can be many, including selective absorption, non-capillary effects, reduced temperature polarization and the introduction of functional groups by graphene oxide. The potential of novel graphene quantum dots (GQDs)/polyvinylidene fluoride (PVDF) nanofibrous membranes for AGMD was studied by Jafari et al. [140]. In their work, AGMD experiments were conducted with 3.5 wt% NaCl solution for 8 h, showing how the graphene may prevent the wetting and fouling in a long-time experiment. Moreover, the tests indicated a water flux of 17.6 kg/m2h and salt rejection of about 99.7% for the membrane containing 0.25 wt% GQDs compared to neat PVDF nanofibrous where partial wetting occurred after 4 h. A study of rGO on hydrophobic PVDF membranes was successfully performed by Abdel-Karim et al. [141]. In their work, different degrees of rGO nanoplatelets were incorporated as fillers in PVDF matrices in order to evaluate the effect of the oxygen content of the fillers in the MD performance. The MD results show how 0.5 wt% rGO in the mixed matrix membrane can enhance the performance of PVDF membranes by about 169%. Furthermore, continuous testing for up to 96 h showed a stable performance of the developed mixed matrix membranes (MMMs), without compromising the MD performance. Hongbin li et al. [142] prepared composite membrane for vacuum membrane distillation (VMD) with a hydrophobic PVDF nanofibrous layer and a hydrophobic polypropylene (PP) nonwoven fabric (NWF) as substrate. The PVDF layers were directly fabricated on the surface of the PP substrate using the electrospinning technique and functionalized with GO. The GO functionalization allows for enhancing the hydrophobicity and permeation water flux for vacuum membrane distillation (VMD) and endows the membrane with anti-wetting properties. A similar work, where GO was used to functionalize the surface of a PVDF membrane, was developed by Qiu et al. [133]. The surface modification was conducted by dispersing graphene oxide (GO) on the channel surface, forming a functional layer with the possibility of blockage of bulk pores. This may increase the mass transfer resistance and reduce the permeability. The membrane was tested in direct-contact membrane distillation with anionic and cationic surfactants as foulants, and they showed an improved antifouling behavior and distillated flux compared to the pristine PVDF membrane. Qiu et al. [133] attributed the enhanced results to the oxygen containing functional groups in GO and healing of the membrane pore defects. This method guarantees an effective way to functionalize the membrane for anti-fouling separation without increasing the mass transfer resistance.

More recently, Lou et al. [139] developed an MOF-wrapped graphene-based bifunctional photothermal membrane with high thermal efficiency. It was used for the photothermal MD (PMD) process. The hierarchical porous structure and the low thermal conductivity of ZIF-67 (zeolitic imidazolate framework-67) provided the ZGM (ZIF-67 graphene membrane) with a greater ability to absorb light and localize heat. The experiment was conducted using simulated solar illumination. The ZGM recorded a flux increase of 183.2% compared to the pristine membrane corresponding to a photothermal efficiency of 62.1%.

Luque-Alled et al. [143] fabricated two types of PVDF-based MMMs with hydrophobic GOs. The first MMM contains reduced GO functionalized with octylamine (OA-rGO), while the second has reduced GO functionalized with perfluorooctylamine (PFOA-rGO). Although OA and PFOA have some chemical differences, in both cases PVDF membranes achieve a higher water flux and rejection compared to pure PVDF (a water flux of 8.8 and 9.1 Lm−2h −1 for 0.7% PFOA-rGO and 0.7% OA-rGO with an increase in flux of 76% and 82%, respectively, compared to pure PVDF membranes with a flux of 5 Lm −2h−1).

3.2. TMDC in Membrane Processes

Since membrane desalination requires high productivity and high thermal efficiency, other classes of atomically thick materials, including TMDC and layered metal oxides were tested in MD. The competitive thermal conductivity of these materials would make them a likely suitable alternative to graphene, particularly for the implementation of MD processes. Some authors have examined the challenges and opportunities of two-dimensional materials in liquid phase separations, water purification, and ion conducting membranes. However, contributions on this topic are still scarce and further studies are needed. A recent desalination study was conducted with thin MoS2 layers [143]. The Mo-only pore architecture provides the highest water permeation rate, while the hydrophilicity of S-terminated single cell MoS2 causes high affinity for water and some gases, such as CO2 and NO2.

Heiranian et al. [145] conducted a study with MoS2 laminar membranes (pores of 20–60 Å) in nanofiltration. The MoS2 laminar membranes retain more than 88% of ions, producing a water flow of 2–5 orders of magnitude higher than traditional nanoporous membranes and 70% higher than graphene-based membranes. Experimentally, the joint effect of steric hindrance, compatibility with the two-dimensional hydrogen bonding network of water and electrostatic interactions were hypothesized to be responsible for the diffusion of aqueous ions through lamellar membranes containing Mo2S, while a property of molecular sieving for organic vapor was recently demonstrated for the first time. This kind of material can add their property at the membranes such as atomic thickness, antibacterial property, uniform pore diameter and surface charge characteristics. Hexagonal boron nitride (h-BN) and novel molybdenum disulfide (MoS2) are other two-dimensional materials enclosed in a polymer membrane matrix. The first shows good mechanical stability, and is expected to improve the permeability of the membrane [146]. A modified interfacial polymerization (IP) reaction was carried out to fabricate fouling-resistant membranes with few-layered amine functionalized-boron nitride BN(NH2) nanosheets [147]. Membranes with BN(NH2) nanosheets tested in nanofiltration to separate NOM from water revealed a 59% enhancement in flux and a 50% improvement in total fouling resistance, long-term operational stability and enhanced recoverability with no-leaching during filtration. For what concerns MoS2, it was found promising in the field of membrane technology for displaying smooth surface without any oxygenated functional group, reducing the resistance of water molecules to transport [148]. The pore structure of MoS2 allows to achieve a superior separation performance with a flux 3–5 times higher compared to GO when prepared under the same conditions [149]. The exfoliated few-layers MoS2 incorporated into polysulfone (PSF) membrane with negative charged show a good hydrophilicity that improve the permeability and selectivity of the NF and RO membranes. Similar to the oxidization of graphene nanosheets, the oxidation and exfoliation of molybdenum disulfide (O–MoS2) allow to improve its proprieties and to enhance the NF performance [144]. Compared to the MoS2-TFN membrane, the O–MoS2 TFN membrane has an unprecedented enhancement in permeability and selectivity with an excellent antifouling performance. MoS2 materials are used in membrane distillation as well. An example is the work developed from Yan et al. [150] in which self-cleaning and photothermal membrane containing Co-MoS2/CNT were prepared. Results showed that the permeate flux maintains at 2.43 Lm−2h−1 with an initial feed temperature of 35℃. In addition, the flux of the Co-MoS2/CNT/PTFE membrane can be maintained above 95% after three fouling-cleaning cycles, indicating that the modified membrane has a good self-cleaning performance.

In a recent study, Frappa et al. [107] prepared and tested MD membranes with bismuth telluride exfoliated and trapped in the polymeric matrix. They proved that Bi2Te3-enabled membranes are suitable for ultrafast and energy-saving freshwater recovery. Bismuth compounds are second-generation topological insulators with a metal surface and an insulating footprint [151]. They are considered among the most widely used thermoelectric materials given their high crystalline organization, thermal stability and negligible surface reactivity towards oxygen and water. All this makes them extremely attractive for future preparations, manipulations and applications of electronics, photonics, sensors and optics. A part of the bismuth chalcogenide family, bismuth telluride (Bi2Te3) is proposed for the frontier field of water desalination [144,145,146,147,148,149,150,151,152,153,154,155,156,157].

3.3. MXenes in Membrane Processes

Mxene is another two-dimensional material applied in order to optimize the membrane performance [158]. This material (with formula Mn + 1XnTx) is usually produced by selectively etching mainly the group IIIA or IVA elements layers from Mn + 1AXn phases (n = 1, 2, or 3), where M is a transition metal and X is carbon and/or nitrogen. The MXenes have garnered the interest of the scientific community due to their particular characteristics, such as high electronic conductivity, hydrophilicity, high surface area, active sites on the surface, metallic and antibacterial properties, and processability. These characteristics make them suitable for use in the biomedical, energy, biosensor and catalysis fields. Some peculiar qualities such as low toxicity of degradation products, antibacterial properties and chemical functions have made them interesting to be used in membrane processes of water purification [159,160]. Several studies have shown their effectiveness in removing metal ions, salts, dyes and radionuclides, killing E. coli and B. subtilis [161,162]. Furthermore, surface chemistry makes them variously functionalized to impart further capacities. The morphologies of the membranes present a narrow nanochannel between the neighboring MXene nanosheets, which makes MXene an ideal and promising material for water treatment and more. In general, MXene membranes exhibit good removal rates, maintaining exceptional water permeance (>1000 Lm−2h–1bar−1). This is due to the properties of water transport pathways and interlayer nanoparticles separating slit pores between MXene nanosheets, resulting in an increased interlayer distance and the formation of abundant nanochannels [158]. A study conducted by Tan et al. 2018 [4] in DCMD configuration on a PDVF-coated membrane with Ti3C2Tx Mxene conferred a 56–64% reduction in flux decline compared to the uncoated membrane after 21 h, showing strong antifouling properties. The MXene membrane exhibited interesting photothermal properties which conferred a 12% decrease in the energy consumed by the heater per unit volume distillate [4].

3.4. Silica Nanoparticles and MOFs in Membrane Processes

Silica nanoparticles are another material widely used for constructing membranes for several applications. Wu et al. [151] introduced a novel thin layer of mesoporous silica nanoparticles (MSN) into polyamide membranes via interfacial polymerization of trimesoyl chloride (TMC) and piperazine (PIP) in the presence of mMSN. To prevent the reaction of amino groups with the acid chloride group of TMC during polymerization, silica nanoparticles were chemically incorporated into the nanocomposite membrane in situ. This can improve the compatibility and the loading of silica nanoparticles with the polymer. The influence of the mMSN amount on the membrane performance allowed for improving the anti-fouling proprieties and a good long-term stability with an enhanced water flux. Feng et al. [156] used hollow silica nanoparticles (SiNPs) with different sizes to construct omniphobic MD membranes. Compared with the commercial PVDF membrane, which showed a rapid flux decline in the MD experiment with NaCl hypersaline water, the presence of silica nanoparticles resulted in a 20–50% improvement compared with the commercial PVDF membrane.

Other interesting materials utilized for water treatment are represented by the metal organic frameworks (MOFs). By incorporating them into the polymeric membranes, it is possible to exploit the MOFs proprieties, such as high porosity and surface area for entrapping the contaminants present in drinking water. MOFs-based membrane were utilized to remove arsenic, fluoride, and iron from drinking water [163]. MOF-based membrane include continuous growth process where the membranes are formed via layer-by-layer deposition of MOF, electro-deposition, thin-film nano-composite and solvothermal [164]. The applications of MOFs allow good stabilities under various conditions, large-scale production and cost-effective synthesis route. It is observed that the stability of the MOFs can be enhanced by using carbon nano-tubes (CNTs) for water purification from arsenic and fluoride [165].

The use of MOF materials in MD is, however, still little explored in the literature [161,162,163,164]. Table 3 reports on a comparative analysis; it has to be stressed that the use of different operating conditions affect the final result.

Table 3.

Membranes functionalized with MOF tested in MD with related operating conditions.

4. Conclusions

Some of the recent advancements achieved in the field of major exfoliation techniques for preparing two-dimensional materials have been addressed in this paper. A special focus was laid on the use of these materials in membrane systems for the production of clean water and salt crystallization using the logics of eco-sustainability and global social growth. As discussed in this review, there is a wide variety of preparation processes for two-dimensional materials, each of which has its own set of advantages and limitations. Therefore, suitable methodologies must be employed which can be adapted according to their target application and respective composition. Furthermore, in this way, their costs, impurities and their characteristics can also be regulated in detail.

The unique physical and chemical properties and versatility in structural assembly with other nanomaterials make two-dimensional materials very interesting to obtain high-performing polymer membranes in various processes. In particular, the use of two-dimensional materials in membrane distillation and crystallization was analyzed. As described, the introduction of two-dimensional materials into these processes appears to be still in its infancy and further research is needed. This could help to solve one of the main problems of MD/MCr processes such as low productivity on an industrial scale in terms of transmembrane flux and low thermal efficiency. This problem occurs mainly due to the temperature polarization phenomena. The key factors that must be taken into account to improve the membrane process in the treatment of water are the reduction in energy consumption and cost, and the decrease in the simultaneous risk of wetting, reduction and dirtying of the membranes.

In this regard, several two-dimensional materials, including covalent, zeolites, mixed organic structures, molybdenum, MOF, graphene and its family, were proposed for the desalinization of water. The possibility of a cheaper synthesis of a large area of graphene, as recently reported, makes it more interesting for modern use. In addition to graphene, two-dimensional (2D) materials with atomic thickness are other materials of the new generation membranes with extraordinarily high permeability. The 2D membranes with well-defined transport channels and ultra-low thicknesses have shown exceptional performance for the separation of liquids and gas applications. However, along with the many advantages, there are some disadvantages and risks. In the case of food, the migration of nanomaterials from the packaging to the food product was studied. However, the migration is insignificant in minor quantities. Finally, being new materials, a greater understanding of their properties and applications is still necessary. Despite much progress in this field, several research areas require further attention. In addition to the development of innovative and scalable methods to tune and fix the distances between the layers of 2D materials, we should take into consideration the development of 2D materials with anti-swelling properties and layer sizes lower than the hydration radius of cations. Finally, the combination of nanoporous membranes and several 2D materials must be extensively studied. In this scenario, the different chemical and physical properties of the materials could be exploited by improving the selectivity and performance of the individual processes. Another important feature that could make 2D materials even more interesting for MD is their photothermal properties. This could help to convert sunlight into heat, thereby equipping MD with solar energy in an eco-sustainable way and reducing costs [171,172,173]. The dispersion of 2D materials in the membrane has demonstrated the higher performance of interface evaporation, leading to the mitigation or retreat of the polarization of the temperature. However, even if the efficiency of these materials is demonstrated in solar energy MD on a laboratory scale, long-term stability of these materials is still questionable.

An interesting and promising scenario for 2D-based membranes is their possible application in membrane crystallization. Membrane crystallization is an emerging intensive technique for the recovery of raw materials from high-concentrated brine. MCr may be considered as an extension of MD where the continuous evaporation of volatile components from the feed (with a high concentration of solute) generates a supersaturation of the solute. Unlike MD, the introduction of 2D materials in MCr is still underused. The few works present in the literature are particularly focused on the use of graphene. Perrotta et al. [172] studied the influence of graphene loading in PVDF flat sheet membranes and concluded that a graphene loading leads to a more uniform crystal size distribution (CSD) of NaCl and a lower coefficient of variation (CV) than pristine PVDF, thanks to the assisted water exclusion. Frappa et al. [108] studied how the presence of graphene and bismuth telluride in PVDF-based membranes help to obtain purer NaCl crystals. Macedonio et al. [56] studied the effect of Bi2Se3 introduced in PVDF membranes as fillers. The confinement of Bi2Se3 in polymeric hydrophobic membrane has produced an unexpected increase in the growth rate and uniform dispersion of NaCl crystals with respect to the PVDF-pristine membrane. The dispersion of CSD reaches the lowest CV (36%) when a consecutive measurement is performed on a third sample of crystals. On contrary, the CV values reached with PVDF-pristine membrane range from 40 to 63%, indicating a worsened quality of the NaCl crystals. Shahi et al. [173] investigated the influence of TiO2 nanoparticles morphologies on membrane performance (salt rejection and water flux). To evaluate the advancement of 2D materials in membranes-assisted crystallization beyond the state of the art, a comparison in terms of CV and flux was proposed (Table 4). All of the fluxes are comparable with each other, except for PVDF–GP5 which shows the highest trans-membrane flux (6 Lm−2h−1). Considering the CV values, the membranes (PVDF/G (0.5%) and PVDF/BT (7%)) show a coefficient of variation which, in general, is lower than the other membranes. The only exception is 26.7%, achieved for the membrane with graphene powder PVDF GP 5, prepared using the same procedure described in this article but with 10 times higher graphene concentration. Santoro et al. [174] have highlighted the potential of PMCr, derived from the hybridization of MCr and photothermal materials, in the crystallization of inorganic salts. Specifically, graphene-based membranes have been tested for the recovery of salt from seawater and brines, and found to have improved the efficiency of the process.

Table 4.

Membrane-assisted crystallization performances in literature. Membrane code.

Author Contributions

Conceptualization, methodology, original draft preparation, writing—review and editing, M.F.; conceptualization, methodology, writing—review and editing, F.M.; writing—review and editing, F.A.; conceptualization, supervision, E.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mezher, T.; Fath, H.; Abbas, Z.; Khaled, A. Techno-economic assessment and environmental impacts of desalination technologies. Desalination 2011, 266, 263–273. [Google Scholar] [CrossRef]

- Naseer, M.N.; Zaidi, A.A.; Khan, H.; Kumar, S.; Bin Owais, M.T.; Wahab, Y.A.; Dutta, K.; Jaafar, J.; Uzair, M.; Johan, M.R.; et al. Desalination technology for energy-efficient and low-cost water production: A bibliometric analysis. Green Process. Synth. 2022, 11, 306–315. [Google Scholar] [CrossRef]

- Naidu, G.; Tijing, L.; Johir, M.A.H.; Shon, H.; Vigneswaran, S. Hybrid membrane distillation: Resource, nutrient and energy recovery. J. Membr. Sci. 2020, 599, 117832. [Google Scholar] [CrossRef]

- Tan, Y.Z.; Wang, H.; Han, L.; Tanis-Kanbur, M.B.; Pranav, M.V.; Chew, J.W. Photothermal-enhanced and fouling-resistant membrane for solar-assisted membrane distillation. J. Membr. Sci. 2018, 565, 254–265. [Google Scholar] [CrossRef]

- Xie, M.; Nghiem, L.D.; Price, W.E.; Elimelech, M. A Forward Osmosis–Membrane Distillation Hybrid Process for Direct Sewer Mining: System Performance and Limitations. Environ. Sci. Technol. 2013, 47, 13486–13493. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.; Labhasetwar, P.K.; Shahi, V.K. Membrane distillation crystallization technology for zero liquid discharge and resource recovery: Opportunities, challenges and futuristic perspectives. Sci. Total. Environ. 2021, 806, 150692. [Google Scholar] [CrossRef]

- Ananthoji, R.; Eubank, J.F.; Nouar, F.; Mouttaki, H.; Eddaoudi, M.; Harmon, J.P. Symbiosis of zeolite-like metal–organic frameworks (rho-ZMOF) and hydrogels: Composites for controlled drug release. J. Mater. Chem. 2011, 21, 9587–9594. [Google Scholar] [CrossRef]

- Hayashi, H.; Côté, A.P.; Furukawa, H.; O’keeffe, M.; Yaghi, O.M. Zeolite A imidazolate frameworks. Nat. Mater. 2007, 6, 501–506. [Google Scholar] [CrossRef]

- Teow, Y.H.; Mohammad, A.W. New generation nanomaterials for water desalination: A review. Desalination 2019, 451, 2–17. [Google Scholar] [CrossRef]

- Jhaveri, J.H.; Murthy, Z. A comprehensive review on anti-fouling nanocomposite membranes for pressure driven membrane separation processes. Desalination 2016, 379, 137–154. [Google Scholar] [CrossRef]

- Daer, S.; Kharraz, J.; Giwa, A.; Hasan, S.W. Recent applications of nanomaterials in water desalination: A critical review and future opportunities. Desalination 2015, 367, 37–48. [Google Scholar] [CrossRef]

- Eykens, L.; De Sitter, K.; Dotremont, C.; Pinoy, L.; Van der Bruggen, B. Membrane synthesis for membrane distillation: A review. Sep. Purif. Technol. 2017, 182, 36–51. [Google Scholar] [CrossRef]

- Xiong, P.; Ma, R.; Wang, G.; Sasaki, T. Progress and perspective on two-dimensional unilamellar metal oxide nanosheets and tailored nanostructures from them for electrochemical energy storage. Energy Storage Mater. 2018, 19, 281–298. [Google Scholar] [CrossRef]

- Wu, X.; Ding, M.; Xu, H.; Yang, W.; Zhang, K.; Tian, H.; Wang, H.; Xie, Z. Scalable Ti3C2Tx MXene Interlayered Forward Osmosis Membranes for Enhanced Water Purification and Organic Solvent Recovery. ACS Nano 2020, 14, 9125–9135. [Google Scholar] [CrossRef]

- Voiry, D.; Mohite, A.; Chhowalla, M. Phase engineering of transition metal dichalcogenides. Chem. Soc. Rev. 2015, 44, 2702–2712. [Google Scholar] [CrossRef] [PubMed]

- Shafie, Z.M.H.M.; Ahmad, A.L. Juxtaposition of PES based hollow fiber membrane: Antifouling and antibacterial potential of LiCl mediated PVA–ZnO blend. J. Ind. Eng. Chem. 2018, 62, 273–283. [Google Scholar] [CrossRef]

- Gude, V.G. Desalination and water reuse to address global water scarcity. Rev. Environ. Sci. Bio/Technol. 2017, 16, 591–609. [Google Scholar] [CrossRef]

- Kumar, C.; Das, S.; Jit, S. Device physics and device integration of two-dimensional heterostructures. In 2D Nanoscale Heterostructured Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 195–214. [Google Scholar] [CrossRef]

- Song, C.; Huang, S.; Wang, C.; Luo, J.; Yan, H. The optical properties of few-layer InSe. J. Appl. Phys. 2020, 128, 060901. [Google Scholar] [CrossRef]

- Er, D.; Ghatak, K. Atomistic modeling by density functional theory of two-dimensional materials. In Synthesis, Modeling, and Characterization of 2D Materials, and Their Heterostructures; Elsevier: Amsterdam, The Netherlands, 2020; pp. 113–123. [Google Scholar] [CrossRef]

- Senapati, S.; Maiti, P. Emerging bio-applications of two-dimensional nanoheterostructure materials. In 2D Nanoscale Heterostructured Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 243–255. [Google Scholar] [CrossRef]

- Hasan, M.N.; Nafiujjaman, M.; Lee, Y.-K. 2D Nanomaterials for Gene Delivery. In Biomedical Applications of Graphene and 2D Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 87–104. [Google Scholar] [CrossRef]

- Frappa, M.; Castillo, A.E.D.R.; Macedonio, F.; Politano, A.; Drioli, E.; Bonaccorso, F.; Pellegrini, V.; Gugliuzza, A. A few-layer graphene for advanced composite PVDF membranes dedicated to water desalination: A comparative study. Nanoscale Adv. 2020, 2, 4728–4739. [Google Scholar] [CrossRef]

- Gugliuzza, A.; Politano, A.; Drioli, E. The advent of graphene and other two-dimensional materials in membrane science and technology. Curr. Opin. Chem. Eng. 2017, 16, 78–85. [Google Scholar] [CrossRef]

- Zhao, L.; Lu, X.; Wu, C.; Zhang, Q. Flux enhancement in membrane distillation by incorporating AC particles into PVDF polymer matrix. J. Membr. Sci. 2016, 500, 46–54. [Google Scholar] [CrossRef]

- Attia, H.; Osman, M.S.; Johnson, D.J.; Wright, C.; Hilal, N. Modelling of air gap membrane distillation and its application in heavy metals removal. Desalination 2017, 424, 27–36. [Google Scholar] [CrossRef]

- Attia, H.; Alexander, S.; Wright, C.J.; Hilal, N. Superhydrophobic electrospun membrane for heavy metals removal by air gap membrane distillation (AGMD). Desalination 2017, 420, 318–329. [Google Scholar] [CrossRef]

- Li, J.; Gunister, E.; Barsoum, I. Effect of graphene oxide as a filler material on the mechanical properties of LLDPE nanocomposites. J. Compos. Mater. 2019, 53, 2761–2773. [Google Scholar] [CrossRef]

- Tang, B.; Hu, G.; Gao, H.; Hai, L. Application of graphene as filler to improve thermal transport property of epoxy resin for thermal interface materials. Int. J. Heat Mass Transf. 2015, 85, 420–429. [Google Scholar] [CrossRef]

- Xu, Y.; Cao, H.; Xue, Y.; Li, B.; Cai, W. Liquid-Phase Exfoliation of Graphene: An Overview on Exfoliation Media, Techniques, and Challenges. Nanomaterials 2018, 8, 942. [Google Scholar] [CrossRef] [PubMed]

- Miró, P.; Audiffred, M.; Heine, T. An atlas of two-dimensional materials. Chem. Soc. Rev. 2014, 43, 6537–6554. [Google Scholar] [CrossRef]

- Dervin, S.; Dionysiou, D.D.; Pillai, S.C. 2D nanostructures for water purification: Graphene and beyond. Nanoscale 2016, 8, 15115–15131. [Google Scholar] [CrossRef] [PubMed]

- Mas-Ballesté, R.; Gómez-Navarro, C.; Gómez-Herrero, J.; Zamora, F. 2D materials: To graphene and beyond. Nanoscale 2011, 3, 20–30. [Google Scholar] [CrossRef]

- Gusakova, J.; Wang, X.; Shiau, L.L.; Krivosheeva, A.; Shaposhnikov, V.; Borisenko, V.; Gusakov, V.; Tay, B.K. Electronic Properties of Bulk and Monolayer TMDs: Theoretical Study within DFT Framework (GVJ-2e Method). Phys. Status Solidi. 2017, 214, 1700218. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Q.; Zheng, Y.; Peng, T.; Yao, K.; Xie, S.; Zhang, X.; Xia, X.; Li, J.; Jiang, H. Development of a quantitative fluorescence-based lateral flow immunoassay for determination of chloramphenicol, thiamphenicol and florfenicol in milk. Food Agric. Immunol. 2018, 29, 56–66. [Google Scholar] [CrossRef]

- Dai, H.; Feng, N.; Li, J.; Zhang, J.; Li, W. Chemiresistive humidity sensor based on chitosan/zinc oxide/single-walled carbon nanotube composite film. Sens. Actuators B Chem. 2019, 283, 786–792. [Google Scholar] [CrossRef]

- Zhang, T.; Xiao, C.; Zhao, J.; Liu, X.; Ji, D.; Zhang, H. One-step facile fabrication of PVDF/graphene composite nanofibrous membrane with enhanced oil affinity for highly efficient gravity-driven emulsified oil/water separation and selective oil absorption. Sep. Purif. Technol. 2021, 254, 117576. [Google Scholar] [CrossRef]

- Chhowalla, M.; Shin, H.S.; Eda, G.; Li, L.-J.; Loh, K.P.; Zhang, H. The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat. Chem. 2013, 5, 263–275. [Google Scholar] [CrossRef] [PubMed]

- Subramani, A.; Jacangelo, J.G. Emerging desalination technologies for water treatment: A critical review. Water Res. 2015, 75, 164–187. [Google Scholar] [CrossRef]

- Cranford, S.W.; Brommer, D.B.; Buehler, M.J. Extended graphynes: Simple scaling laws for stiffness, strength and fracture. Nanoscale 2012, 4, 7797–7809. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Jin, W.; Xu, N. Two-Dimensional-Material Membranes: A New Family of High-Performance Separation Membranes. Angew. Chem. Int. Ed. 2016, 55, 13384–13397. [Google Scholar] [CrossRef]

- Gugliuzza, A.; Macedonio, F.; Politano, A.; Drioli, E. Prospects of 2D materials-based membranes in water desalination. Chem. Eng. Trans. 2019, 73, 265–270. [Google Scholar] [CrossRef]

- Kauling, A.P.; Seefeldt, A.T.; Pisoni, D.P.; Pradeep, R.C.; Bentini, R.; Oliveira, R.V.B.; Novoselov, K.S.; Neto, A.H.C. The Worldwide Graphene Flake Production. Adv. Mater. 2018, 30, e1803784. [Google Scholar] [CrossRef]

- Castillo, A.E.D.R.; Pellegrini, V.; Ansaldo, A.; Ricciardella, F.; Sun, H.; Marasco, L.; Buha, J.; Dang, Z.; Gagliani, L.; Lago, E.; et al. High-yield production of 2D crystals by wet-jet milling. Mater. Horizons. 2018, 5, 890–904. [Google Scholar] [CrossRef]

- Dawlaty, J.M.; Shivaraman, S.; Chandrashekhar, M.; Rana, F.; Spencer, M.G. Measurement of ultrafast carrier dynamics in epitaxial graphene. Appl. Phys. Lett. 2008, 92, 042116. [Google Scholar] [CrossRef]

- Kim, K.S.; Zhao, Y.; Jang, H.; Lee, S.Y.; Kim, J.M.; Kim, K.S.; Ahn, J.-H.; Kim, P.; Choi, J.-Y.; Hong, B.H. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 2009, 457, 706–710. [Google Scholar] [CrossRef] [PubMed]

- Nikkho, S.; Mirzaei, M.; Sabet, J.K.; Moosavian, M.A.; Hedayat, S.M. Enhanced quality of transfer-free graphene membrane for He/CH4 separation. Sep. Purif. Technol. 2020, 232, 115972. [Google Scholar] [CrossRef]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E.; et al. Large-Area Synthesis of High-Quality and Uniform Graphene Films on Copper Foils. Science 2009, 324, 1312–1314. [Google Scholar] [CrossRef]

- Gu, X.; Zhao, Y.; Sun, K.; Vieira, C.L.; Jia, Z.; Cui, C.; Wang, Z.; Walsh, A.; Huang, S. Method of ultrasound-assisted liquid-phase exfoliation to prepare graphene. Ultrason. Sonochem. 2019, 58, 104630. [Google Scholar] [CrossRef]

- Sitko, R.; Zawisza, B.; Malicka, E. Graphene and Derivatives: Sample Handling. In Reference Module in Chemistry, Molecular Sciences and Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Woo, Y.C.; Kim, S.-H.; Shon, H.K.; Tijing, L.D. Introduction: Membrane Desalination Today, Past, and Future. In Current Trends and Future Developments on (Bio-) Membranes; Elsevier: Amsterdam, The Netherlands, 2019; pp. xxv–xlvi. [Google Scholar] [CrossRef]

- Qiu, L.; Zhang, X.; Yang, W.; Wang, Y.; Simon, G.P.; Li, D. Controllable corrugation of chemically converted graphene sheets in water and potential application for nanofiltration. Chem. Commun. 2011, 47, 5810–5812. [Google Scholar] [CrossRef]

- Park, K.S.; Ni, Z.; Côté, A.P.; Choi, J.Y.; Huang, R.; Uribe-Romo, F.J.; Chae, H.K.; O’Keeffe, M.; Yaghi, O.M. Exceptional chemical and thermal stability of zeolitic imidazolate frameworks. Proc. Natl. Acad. Sci. USA 2006, 103, 10186–10191. [Google Scholar] [CrossRef]

- Farrusseng, D. Metal-Organic Frameworks: Applications from Catalysis to Gas Storage; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Raza, A.; Hassan, J.Z.; Mahmood, A.; Nabgan, W.; Ikram, M. Recent advances in membrane-enabled water desalination by 2D frameworks: Graphene and beyond. Desalination 2022, 531, 115684. [Google Scholar] [CrossRef]

- Macedonio, F.; Politano, A.; Drioli, E.; Gugliuzza, A. Bi2Se3-assisted membrane crystallization. Mater. Horizons 2018, 5, 912–919. [Google Scholar] [CrossRef]

- Ajayan, P.; Kim, P.; Banerjee, K. Two-dimensional van der Waals materials. Phys. Today 2016, 69, 38–44. [Google Scholar] [CrossRef]

- Zhang, X.; Lai, Z.; Ma, Q.; Zhang, H. Novel structured transition metal dichalcogenide nanosheets. Chem. Soc. Rev. 2018, 47, 3301–3338. [Google Scholar] [CrossRef]

- Li, L.; Zhang, T.; Duan, Y.; Wei, Y.; Dong, C.; Ding, L.; Qiao, Z.; Wang, H. Selective gas diffusion in two-dimensional MXene lamellar membranes: Insights from molecular dynamics simulations. J. Mater. Chem. A 2018, 6, 11734–11742. [Google Scholar] [CrossRef]

- Coleman, J.N.; Lotya, M.; O’Neill, A.; Bergin, S.D.; King, P.J.; Khan, U.; Young, K.; Gaucher, A.; De, S.; Smith, R.J.; et al. Two-Dimensional Nanosheets Produced by Liquid Exfoliation of Layered Materials. Science 2011, 331, 568–571. [Google Scholar] [CrossRef] [PubMed]

- Achari, A.; Sahana, S.; Eswaramoorthy, M. High performance MoS2 membranes: Effects of thermally driven phase transition on CO2 separation efficiency. Energy Environ. Sci. 2016, 9, 1224–1228. [Google Scholar] [CrossRef]

- Keshebo, D.L.; Hu, C.-P.; Hu, C.-C.; Hung, W.-S.; Wang, C.-F.; Tsai, H.-C.; Lee, K.-R.; Lai, J.-Y. Effect of composition of few-layered transition metal dichalcogenide nanosheets on separation mechanism of hydrogen selective membranes. J. Membr. Sci. 2021, 634, 119419. [Google Scholar] [CrossRef]

- Abid, N.; Khan, A.M.; Shujait, S.; Chaudhary, K.; Ikram, M.; Imran, M.; Haider, J.; Khan, M.; Khan, Q.; Maqbool, M. Synthesis of nanomaterials using various top-down and bottom-up approaches, influencing factors, advantages, and disadvantages: A review. Adv. Colloid Interface Sci. 2022, 300, 102597. [Google Scholar] [CrossRef] [PubMed]

- Kolahalam, L.A.; Viswanath, I.K.; Diwakar, B.S.; Govindh, B.; Reddy, V.; Murthy, Y. Review on nanomaterials: Synthesis and applications. Mater. Today: Proc. 2019, 18, 2182–2190. [Google Scholar] [CrossRef]

- Liu, F. Mechanical exfoliation of large area 2D materials from vdW crystals. Prog. Surf. Sci. 2021, 96, 100626. [Google Scholar] [CrossRef]

- Castillo, A.E.D.R.; Reyes-Vazquez, C.D.; Rojas-Martinez, L.E.; Thorat, S.B.; Serri, M.; Martinez-Hernandez, A.L.; Velasco-Santos, C.; Pellegrini, V.; Bonaccorso, F. Single-step exfoliation and functionalization of few-layers black phosphorus and its application for polymer composites. FlatChem 2019, 18, 100131. [Google Scholar] [CrossRef]

- Murphy, G.W. Desalination by Photoelectrodialysis. II. J. Electrochem. Soc. 1981, 128, 1819–1821. [Google Scholar] [CrossRef]

- Peng, Y.-H.; Kashale, A.A.; Lai, Y.; Hsu, F.-C.; Chen, I.-W.P. Exfoliation of 2D materials by saponin in water: Aerogel adsorption/photodegradation organic dye. Chemosphere 2021, 274, 129795. [Google Scholar] [CrossRef] [PubMed]

- Raccichini, R.; Varzi, A.; Passerini, S.; Scrosati, B. The role of graphene for electrochemical energy storage. Nat. Mater. 2015, 14, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.; Cao, X.; Wu, X.-J.; He, Q.; Yang, J.; Zhang, X.; Chen, J.; Zhao, W.; Han, S.; Nam, G.-H.; et al. Recent Advances in Ultrathin Two-Dimensional Nanomaterials. Chem. Rev. 2017, 117, 6225–6331. [Google Scholar] [CrossRef]

- Sakthivel, R.; Keerthi, M.; Chung, R.-J.; He, J.-H. Heterostructures of 2D materials and their applications in biosensing. Prog. Mater. Sci. 2023, 132, 101024. [Google Scholar] [CrossRef]

- Foller, T.; Wang, H.; Joshi, R. Rise of 2D materials-based membranes for desalination. Desalination 2022, 536, 115851. [Google Scholar] [CrossRef]

- Karagiannidis, P.G.; Hodge, S.A.; Lombardi, L.; Tomarchio, F.; Decorde, N.; Milana, S.; Goykhman, I.; Su, Y.; Mesite, S.V.; Johnstone, D.N.; et al. Microfluidization of Graphite and Formulation of Graphene-Based Conductive Inks. ACS Nano 2017, 11, 2742–2755. [Google Scholar] [CrossRef]

- Elessawy, N.A.; Rafea, M.A.; Roushdy, N.; Youssef, M.E.; Gouda, M.H. Development and evaluation of cost-effective and green Bi-functional nickel oxide decorated graphene electrocatalysts for alkaline fuel cells. Results Eng. 2023, 17, 100871. [Google Scholar] [CrossRef]

- Huang, H.-H.; Joshi, R.K.; De Silva, K.K.H.; Badam, R.; Yoshimura, M. Fabrication of reduced graphene oxide membranes for water desalination. J. Membr. Sci. 2019, 572, 12–19. [Google Scholar] [CrossRef]

- Stobinski, L.; Lesiak, B.; Malolepszy, A.; Mazurkiewicz, M.; Mierzwa, B.; Zemek, J.; Jiricek, P.; Bieloshapka, I. Graphene oxide and reduced graphene oxide studied by the XRD, TEM and electron spectroscopy methods. J. Electron Spectrosc. Relat. Phenom. 2014, 195, 145–154. [Google Scholar] [CrossRef]

- Yuan, S.; Li, Y.; Xia, Y.; Kang, Y.; Yang, J.; Uddin, H.; Liu, H.; Selomulya, C.; Zhang, X. Minimizing Non-selective Nanowrinkles of Reduced Graphene Oxide Laminar Membranes for Enhanced NaCl Rejection. Environ. Sci. Technol. Lett. 2020, 7, 273–279. [Google Scholar] [CrossRef]

- Buha, J.; Gaspari, R.; Castillo, A.E.D.R.; Bonaccorso, F.; Manna, L. Thermal Stability and Anisotropic Sublimation of Two-Dimensional Colloidal Bi2Te3 and Bi2Se3 Nanocrystals. Nano Lett. 2016, 16, 4217–4223. [Google Scholar] [CrossRef]

- Huang, X.; Marsh, K.L.; McVerry, B.T.; Hoek, E.M.V.; Kaner, R.B. Low-Fouling Antibacterial Reverse Osmosis Membranes via Surface Grafting of Graphene Oxide. ACS Appl. Mater. Interfaces 2016, 8, 14334–14338. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Zhang, H.; Yan, Y. Catalytic oxidation of ethyl acetate over CuO/ZSM-5 zeolite membrane coated on stainless steel fibers by chemical vapor deposition. Chem. Eng. Res. Des. 2020, 157, 13–24. [Google Scholar] [CrossRef]

- Lang, H.; Dietrich, S. Metals—Gas-Phase Deposition and Applications. In Comprehensive Inorganic Chemistry II.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 211–269. [Google Scholar] [CrossRef]

- JOKOH. Available online: https://jokoh.com/en/ (accessed on 1 February 2011).

- Loh, Z.H.; Samanta, A.K.; Heng, P.W.S. Overview of milling techniques for improving the solubility of poorly water-soluble drugs. Asian J. Pharm. Sci. 2015, 10, 255–274. [Google Scholar] [CrossRef]