A Systematic Review for Ammonia Monitoring Systems Based on the Internet of Things

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Questions

- Query 1: What types of sensors are employed for the detection and monitoring of ammonia gas?

- Query 2: Which microcontrollers are typically utilized to interface with ammonia gas sensors and facilitate data acquisition?

- Query 3: What communication technologies are commonly implemented to transmit data from these sensor systems?

- Query 4: What IoT platforms are predominantly used for the visualization and analysis of data collected from ammonia gas sensor systems?

- Query 5: What are the primary applications of ammonia gas sensors integrated with IoT technologies?

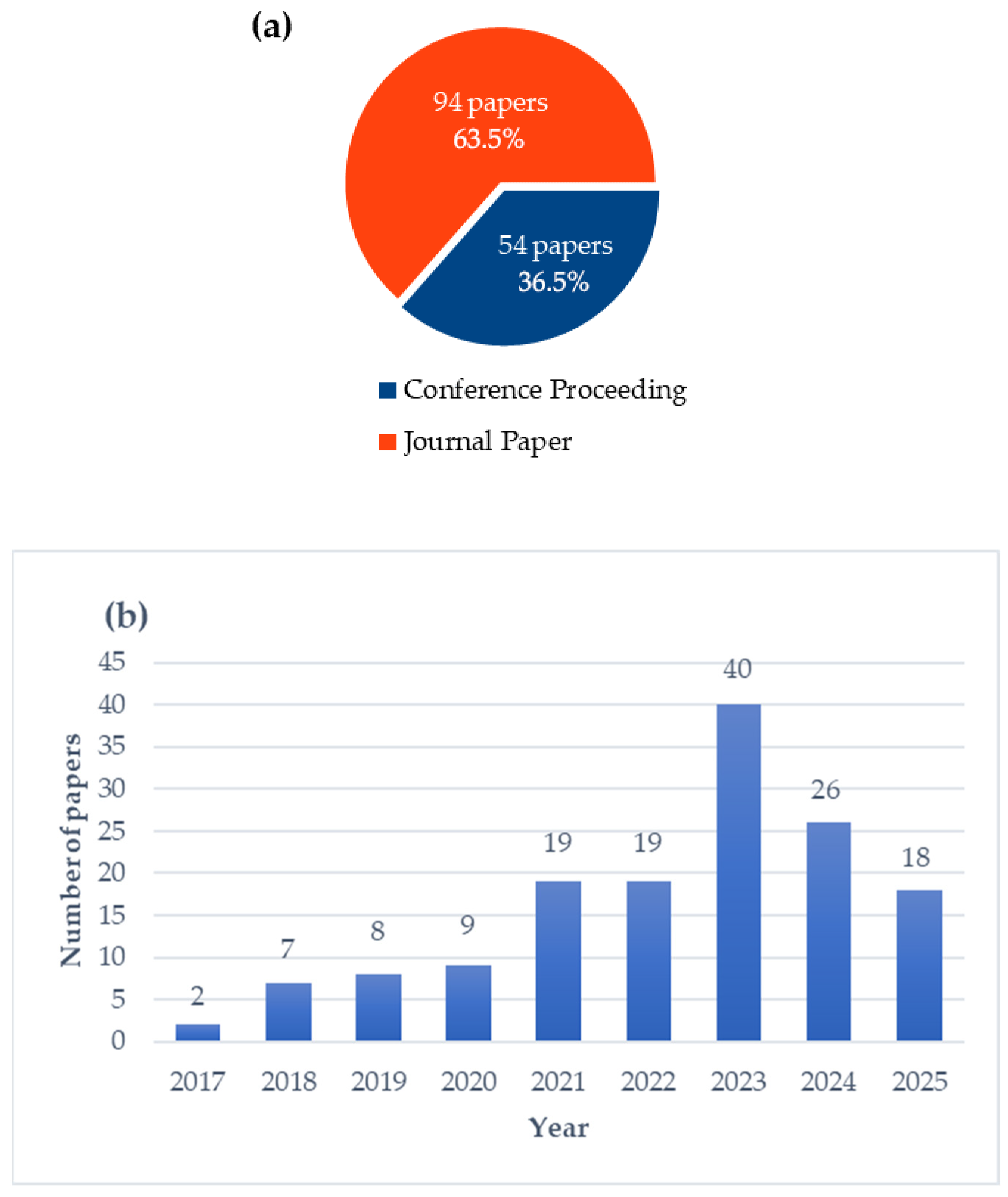

2.2. Search Process

2.3. Inclusion and Exclusion Criteria

2.4. Study Selection

2.5. Risk of Bias

2.6. Data Extraction and Synthesis

3. Results and Discussion

3.1. Types of Sensors

| Sensor Name (Qty of References) | Type | Datasheet | References |

|---|---|---|---|

| MQ-135 (70) | Metal Oxide SnO2 | [36] | [46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115] |

| MQ-137 (32) | Metal Oxide SnO2 | [37] | [62,116,117,118,119,120,121,122,123,124,125,126,127,128,129,130,131,132,133,134,135,136,137,138,139,140,141,142,143,144,145,146] |

| MQ-2 (3) | Metal Oxide SnO2 | [147] | [49,148,149] |

| MQ (4) | [150,151,152,153] | ||

| MiCS-6814 (6) | Metal oxide | [154] | [116,155,156,157,158,159] |

| MiCS-5524 (2) | Metal Oxide | [160] | [161,162] |

| TGS 2602 (3) | Metal Oxide | [163] | [164,165,166] |

| TGS-2444 (1) | Metal Oxide SnO2 | [167] | [168] |

| ZE03 (1) | Electrochemical | [38] | [169] |

| ME3-NH3 (1) | Electrochemical | [40] | [73] |

| MIX8415 (1) | Electrochemical | [170] | |

| N11 board. NH3 sensor GS +4NH3100 (2) | Electrochemical | [39] | [171,172] |

| Self developed (8) | [28,29,30,31,32,33,34,35] | ||

| N/A (18) | [173,174,175,176,177,178,179,180,181,182,183,184,185,186,187,188,189,190] |

3.2. Microcontrollers

3.3. Communication Technology

3.4. IoT Platforms

3.5. Applications

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pearson, A. Refrigeration with Ammonia. Int. J. Refrig. 2008, 31, 545–551. [Google Scholar] [CrossRef]

- Abas, N.; Kalair, A.R.; Khan, N.; Haider, A.; Saleem, Z.; Saleem, M.S. Natural and Synthetic Refrigerants, Global Warming: A Review. Renew. Sustain. Energy Rev. 2018, 90, 557–569. [Google Scholar] [CrossRef]

- Hocking, M.B. Ammonia, Nitric Acid and Their Derivatives. In Modern Chemical Technology and Emission Control; Springer: Berlin/Heidelberg, Germany, 1985; pp. 205–233. [Google Scholar] [CrossRef]

- Huang, J.; Liu, Q.; Wu, W.; Ma, Y.; Huang, J. Industrial Process and Modern Technical Adaptations for Nylon 6 Monomer Caprolactam: A Mini Review. Mater. Sci. 2024, 30, 47–52. [Google Scholar] [CrossRef]

- Busca, G. Bases and Basic Materials in Industrial and Environmental Chemistry: A Review of Commercial Processes. Ind. Eng. Chem. Res. 2009, 48, 6486–6511. [Google Scholar] [CrossRef]

- Karri, R.R.; Sahu, J.N.; Chimmiri, V. Critical Review of Abatement of Ammonia from Wastewater. J. Mol. Liq. 2018, 261, 21–31. [Google Scholar] [CrossRef]

- Khudhur, D.A.; Tuan Abdullah, T.A.; Norazahar, N. A Review of Safety Issues and Risk Assessment of Industrial Ammonia Refrigeration System. ACS Chem. Health Saf. 2022, 29, 394–404. [Google Scholar] [CrossRef]

- ANSI/ASHRAE Standard 34-2007; Designation and Safety Classification of Refrigerants. ASHRAE—American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2007.

- Pfahl, U.J.; Ross, M.C.; Shepherd, J.E.; Pasamehmetoglu, K.O.; Unal, C. Flammability Limits, Ignition Energy, and Flame Speeds in H2–CH4–NH3–N2O–O2–N2 Mixtures. Combust. Flame 2000, 123, 140–158. [Google Scholar] [CrossRef]

- Occupational Safety and Health Administration. Ammonia. 2024. Available online: https://www.osha.gov/chemicaldata/623 (accessed on 14 April 2025).

- National Center for Biotechnology Information. PubChem Compound Summary for CID 222, Ammonia. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Ammonia (accessed on 17 April 2025).

- Liu, X.; Elgowainy, A.; Wang, M. Life Cycle Energy Use and Greenhouse Gas Emissions of Ammonia Production from Renewable Resources and Industrial By-Products. Green Chem. 2020, 22, 5751–5761. [Google Scholar] [CrossRef]

- ASHRAE Standard 15-2013; Safety Standard for Refrigeration Systems. ASHRAE—American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2013.

- Alsamrai, O.; Redel-Macias, M.D.; Pinzi, S.; Dorado, M.P. A Systematic Review for Indoor and Outdoor Air Pollution Monitoring Systems Based on Internet of Things. Sustainability 2024, 16, 4353. [Google Scholar] [CrossRef]

- Timmer, B.; Olthuis, W.; Berg, A.V.D. Ammonia Sensors and Their Applications—A Review. Sens. Actuators B Chem. 2005, 107, 666–677. [Google Scholar] [CrossRef]

- Kwak, D.; Lei, Y.; Maric, R. Ammonia Gas Sensors: A Comprehensive Review. Talanta 2019, 204, 713–730. [Google Scholar] [CrossRef]

- Bielecki, Z.; Stacewicz, T.; Smulko, J.; Wojtas, J. Ammonia Gas Sensors: Comparison of Solid-State and Optical Methods. Appl. Sci. 2020, 10, 5111. [Google Scholar] [CrossRef]

- Aarya, S.; Kumar, Y.; Chahota, R.K. Recent Advances in Materials, Parameters, Performance and Technology in Ammonia Sensors: A Review. J. Inorg. Organomet. Polym. Mater. 2020, 30, 269–290. [Google Scholar] [CrossRef]

- Bannov, A.G.; Popov, M.V.; Brester, A.E.; Kurmashov, P.B. Recent Advances in Ammonia Gas Sensors Based on Carbon Nanomaterials. Micromachines 2021, 12, 186. [Google Scholar] [CrossRef]

- Norizan, M.N.; Siti Zulaikha, N.D.; Norhana, A.B.; Syakir, M.I.; Norli, A. Carbon Nanotubes-Based Sensor for Ammonia Gas Detection—An Overview. Polimery 2021, 66, 175–186. [Google Scholar] [CrossRef]

- Hizam, S.M.M.; Al-Dhahebi, A.M.; Mohamed Saheed, M.S. Recent Advances in Graphene-Based Nanocomposites for Ammonia Detection. Polymers 2022, 14, 5125. [Google Scholar] [CrossRef] [PubMed]

- Insausti, M.; Timmis, R.; Kinnersley, R.; Rufino, M.C. Advances in Sensing Ammonia from Agricultural Sources. Sci. Total Environ. 2020, 706, 135124. [Google Scholar] [CrossRef]

- Ni, J.-Q.; Heber, A.J. Sampling and Measurement of Ammonia at Animal Facilities. Adv. Agron. 2008, 98, 201–269. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef]

- Sorri, K.; Mustafee, N.; Seppänen, M. Revisiting IoT Definitions: A Framework towards Comprehensive Use. Technol. Forecast. Soc. Change 2022, 179, 121623. [Google Scholar] [CrossRef]

- Ryu, H.; Thompson, D.; Huang, Y.; Li, B.; Lei, Y. Electrochemical Sensors for Nitrogen Species: A Review. Sens. Actuators Rep. 2020, 2, 100022. [Google Scholar] [CrossRef]

- Guo, X.; Chen, J.; Shen, Y.; Li, H.; Zhu, Y. Evolution of the Fluorometric Method for the Measurement of Ammonium/Ammonia in Natural Waters: A Review. TrAC Trends Anal. Chem. 2024, 171, 117519. [Google Scholar] [CrossRef]

- Li, Y.; Guo, S.; Wang, B.; Sun, J.; Zhao, L.; Wang, T.; Yan, X.; Liu, F.; Sun, P.; Wang, J.; et al. Machine Learning-assisted Wearable Sensor Array for Comprehensive Ammonia and Nitrogen Dioxide Detection in Wide Relative Humidity Range. InfoMat 2024, 6, e12544. [Google Scholar] [CrossRef]

- Dargie, W.; Wen, J.; Panes-Ruiz, L.A.; Riemenschneider, L.; Ibarlucea, B.; Cuniberti, G. Monitoring Toxic Gases Using Nanotechnology and Wireless Sensor Networks. IEEE Sens. J. 2023, 23, 12274–12283. [Google Scholar] [CrossRef]

- Alure, S.M.; Tonpe, R.V.; Jadhav, A.D.; Sambare, S.T.; Pagare, J.D. Drainage Toxic Gas Detection System Using IoT. Adv. Intell. Syst. Comput. 2020, 1077, 161–167. [Google Scholar] [CrossRef]

- Gupta, K.; Kishore, K.; Jain, S.C. Quality Assessment and Drift Analysis of IoT Enabled Ammonia Sensor. In Proceedings of the 2017 6th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions) (ICRITO), Noida, India, 20–22 September 2017; pp. 171–176. [Google Scholar] [CrossRef]

- Santos-Betancourt, A.; Carlos Santos-Ceballos, J.; Salehnia, F.; Ayoub Alouani, M.; Romero, A.; LuisRamirez, J.; Vilanova, X. IoT Platform Enhanced with Neural Network for Air Pollutant Monitoring. IEEE Trans. Instrum. Meas. 2024, 73, 1–11. [Google Scholar] [CrossRef]

- George, J.; Vikraman, H.K.; Ghuge, R.S.; Reji, R.P.; Jayaraman, S.V.; Magna, G.; Paolesse, R.; Sivalingam, Y.; Di Natale, C.; Mangalampalli, K.S.R.N. Self-Powered, Photovoltaic-Driven NH3 Sensor: Ultra-High Selectivity, High Sensitivity, and IoT-Enabled Real-Time Monitoring with Novel Organic Molecule Functionalized TiZnN2/p-Si Heterostructure. Small 2025, 21, 2502324. [Google Scholar] [CrossRef]

- Agir, I.; Yildirim, R.; Nigde, M.; Isildak, I. Internet of Things Implementation of Nitrate and Ammonium Sensors for Online Water Monitoring. Anal. Sci. 2021, 37, 971–976. [Google Scholar] [CrossRef]

- Deepak, K.S.; Balapure, A.; Priya, P.R.; Kumar, P.; Saiand Dubey, S.K.; Javed, A.; Chattopadhyay, S.; Goel, S. Development of a Microfluidic Device for the Dual Detection and Quantification of Ammonia and Urea from the Blood Serum. Sens. Actuators Phys. 2024, 369, 115174. [Google Scholar] [CrossRef]

- Datasheet MQ-135. Available online: https://www.winsen-sensor.com/d/files/PDF/Semiconductor%20Gas%20Sensor/MQ135%20(Ver1.4)%20-%20Manual.pdf (accessed on 6 March 2025).

- Datasheet MQ-137. Available online: https://www.winsen-sensor.com/d/files/semiconductor/mq137.pdf (accessed on 6 March 2025).

- Datasheet ZE03. Available online: https://www.winsen-sensor.com/d/files/ze03-electrochemical-module-manualv2_5.pdf (accessed on 6 March 2025).

- Datasheet GS +4NH3100. Available online: https://ddscientific.com/products/gs-4nh3-100-electrochemical-sensor-ammonia-nh3?srsltid=AfmBOorVXwlTqBlA4q7pbFzt-NEj-RL1LjAHjGG_7lysQNfKmnrieTeR (accessed on 6 March 2025).

- Datasheet ME3-NH3. Available online: https://www.winsen-sensor.com/d/files/me3-nh3-0-100ppm(ver1_3)-manual.pdf (accessed on 6 March 2025).

- Lee, D.; Yun, M.J.; Kim, K.H.; Kim, S.; Kim, H.-D. Advanced Recovery and High-Sensitive Properties of Memristor-Based Gas Sensor Devices Operated at Room Temperature. ACS Sens. 2021, 6, 4217–4224. [Google Scholar] [CrossRef]

- Ali, M.; Lee, D.; Ahmad, I.; Kim, H.-D. Recent Progress in Memristor-Based Gas Sensors (Gasistor; Gas Sensor + Memristor): Device Modeling, Mechanisms, Performance, and Prospects. Sens. Actuators Rep. 2025, 9, 100269. [Google Scholar] [CrossRef]

- Chae, M.; Lee, D.; Kim, H. Dynamic Response and Swift Recovery of Filament Heater-Integrated Low-Power Transparent CNT Gas Sensor. Adv. Funct. Mater. 2024, 34, 2405260. [Google Scholar] [CrossRef]

- Khorramifar, A.; Karami, H.; Lvova, L.; Kolouri, A.; Łazuka, E.; Piłat-Rożek, M.; Łagód, G.; Ramos, J.; Lozano, J.; Kaveh, M.; et al. Environmental Engineering Applications of Electronic Nose Systems Based on MOX Gas Sensors. Sensors 2023, 23, 5716. [Google Scholar] [CrossRef] [PubMed]

- Yadav, V.; Arkoti, N.K.; Gautam, S.K.; Kuppireddy, S.; Yendrapati, T.P.; Modem, S.; Narayana, C.; Lee, H.-D.; Siddhanta, S.; Jayarmaulu, K. Recent Advances in Nanoporous NOx Gas Sensors: Synergizing Raman Spectroscopy, IoT, and Machine Learning for High-Performance Detection. Nanoscale 2025, 17, 20704–20733. [Google Scholar] [CrossRef] [PubMed]

- Siregar, G.A.W.; Sofina, D.; Hayatunnufus; Harahap, L.A.; Ramadhani, R. Implementation of Rabbit Urine Ammonia Level Detection System with Internet of Things. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Medan, Indonesia, 25–26 July 2024; IOP Publishing: Bristol, UK, 2024; Volume 1413, p. 012052. [Google Scholar] [CrossRef]

- Aubakirov, A.; Makhanov, K.; Issainova, A.; Glazyrina, N.; Razkhova, B.; Satybaldina, D. An IoT-Based Air Pollution Monitoring System for Smart City. In Proceedings of the 2024 4th International Conference on Computer Systems, ICCS 2024, Hangzhou, China, 20–22 September 2024; pp. 156–161. [Google Scholar] [CrossRef]

- Ahmareza, D.; Widiyanto, A.; Nugroho, S. Automatic Odor Control System in Broiler Chicken Coops Using MQ-135 and DHT 11 Sensors. E3S Web Conf. 2024, 500, 03017. [Google Scholar] [CrossRef]

- Nagrale, N.K.; Nagrale, V.N.; Nagrale, A.N. Modern Food Grain Storage with RFID Security Cover and Innovative Technology Using IoT. In Proceedings of the 2024 International Conference on Innovations and Challenges in Emerging Technologies (ICICET), Nagpur, India, 7–8 June 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Bachewar, B.; Gadiya, A.; Badagandi, H.; Ahuja, M.; Kadu, A. ChemiRover—Integrated IoT and ML for Hazardous Area Monitoring. In Proceedings of the 2024 15th International Conference on Computing Communication and Networking Technologies (ICCCNT), Kamand, India, 24–28 June 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Abid, M.A.; Amjad, M.; Munir, K.; Siddique, H.U.R.; Jurcut, A.D. IoT-Based Smart Biofloc Monitoring System for Fish Farming Using Machine Learning. IEEE Access 2024, 12, 86333–86345. [Google Scholar] [CrossRef]

- Prasad, R.; Raj, S.; Akash, M.; Shashni, H.; Subeesh, A.; Chauhan, N. Implementation of IoT and Fuzzy Logic Driven Real-Time Smart Storage Monitoring System. In Proceedings of the 2024 15th International Conference on Computing Communication and Networking Technologies (ICCCNT), Kamand, India, 24–28 June 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Soliman-Cuevas, H. ZamPen Chick Monitoring Using Wireless Sensor Network. In Proceedings of the 2024 Conference on Information Communications Technology and Society (ICTAS), Durban, South Africa, 7–8 March 2024; pp. 232–236. [Google Scholar] [CrossRef]

- Islam, M.D.S.; Saha, T.; Mir, M.D.S.; Ankon, M.H.; Chisty, N.A. Design and Implementation of IoT-Based Manhole Monitoring System. In Proceedings of the 2024 IEEE International Conference on Power, Electrical, Electronics and Industrial Applications (PEEIACON), Rajshahi, Bangladesh, 12–13 September 2024; pp. 502–507. [Google Scholar] [CrossRef]

- Johar, G.M.; Adha, F.J.; Hajamydeen, A.I.; Raya, L.; Alkawaz, M.H. The Efficiency in Controlling and Monitoring a Poultry Farm Based on Internet of Things (IoT). In Proceedings of the 2024 IEEE International Conference on Automatic Control and Intelligent Systems, I2CACIS 2024, Shah Alam, Malaysia, 29 June 2024; pp. 303–307. [Google Scholar] [CrossRef]

- Bhuiyan, Z.W.; Haider, S.A.R.; Haque, A.; Uddin, M.R.; Hasan, M. IoT Based Meat Freshness Classification Using Deep Learning. IEEE ACCESS 2024, 12, 196047–196069. [Google Scholar] [CrossRef]

- Sundar Ganesh, C.S.; Akshaya Prasaath, V.; Arun, A.; Bharath, M.; Kanagasabapathy, E. Internet of Things Enabled Air Quality Monitoring System. In Proceedings of the International Conference on Sustainable Computing and Smart Systems, ICSCSS 2023—Proceedings, Coimbatore, India, 14–16 June 2023; pp. 934–937. [Google Scholar] [CrossRef]

- Karuna, G.; Ram Kumar, R.P.; Gopaldas, S.; Parvathaneni, V.; Lokesh, T. Air Quality and Hazardous Gas Detection Using IoT for Household and Industrial Areas. E3S Web Conf. 2023, 391, 01146. [Google Scholar] [CrossRef]

- Rai, A.; Rai, A.; Upadhyay, A. Smart Wearables for Coal Mine Workers. In Proceedings of the ViTECoN 2023—2nd IEEE International Conference on Vision Towards Emerging Trends in Communication and Networking Technologies, Vellore, India, 5–6 May 2023. [Google Scholar] [CrossRef]

- Alekhya, K.; Sravya, P.D.; Naik, N.C.; Lakshminarayana, B.J. Ambient Air Quality Monitoring System. In Proceedings of the 2023 International Conference for Advancement in Technology, ICONAT 2023, Goa, India, 24–26 January 2023. [Google Scholar] [CrossRef]

- Zhang, H.; Luo, Q.; Chen, X.; Deng, X.; Zou, J.; Han, H.; Liu, Y. Development of a Programmable and Scalable Smart IoT Cultivation Apparatus. In Proceedings of the International Conference on Internet of Things and Machine Learning (IoTML 2023), Singapore, 15–17 September 2023; Volume 12937, p. 1293704. [Google Scholar] [CrossRef]

- Jebari, H.; Mechkouri, M.H.; Rekiek, S.; Reklaoui, K. Poultry-Edge-AI-IoT System for Real-Time Monitoring and Predicting by Using Artificial Intelligence. Int. J. Interact. Mob. Technol. 2023, 17, 149–170. [Google Scholar] [CrossRef]

- Srinivasan, C.; Sridhar, P.; Pradeepa, J.; Thulasiragavan, P.V.; Yuvaraj, R. Internet of Things Towards the Implementation of a Smart City. In Proceedings of the 2023 3rd International Conference on Pervasive Computing and Social Networking (ICPCSN), Salem, India, 19–20 June 2023; pp. 984–988. [Google Scholar] [CrossRef]

- Fathurohman, M.A.A.; Sumitra, I.D.; Daud, A.R. Integration of Wireless Sensor Network and IoT for Enhanced Broiler Closed-House Monitoring: A Case Study at Broiler Teaching Farm. In Proceedings of the 2023 9th International Conference on Signal Processing and Intelligent Systems (ICSPIS), Bali, Indonesia, 14–15 December 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Sai Prasad, M.V.; Sumalatha, A.; Rani, K.S.; Nicy, M.; Meenakshi, C.; Babu, D.C. IoT Based Smart Poultry Management System. In Proceedings of the 2023 International Conference on Innovative Computing, Intelligent Communication and Smart Electrical Systems (ICSES), Chennai, India, 14–15 December 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Valov, N. Project-Based Teaching of Students with Development of a Smart Control of the Free Range Chicken House. In Proceedings of the 2023 5th International Congress on Human-Computer Interaction, Optimization and Robotic Applications (HORA), Istanbul, Turkiye, 8–10 June 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Dhanalakshmi, K.S.; Jeyanathan, J.S.; Anjineyulu, K.C.; Babu, K.M.; Mahendra, M.; Reddy, N.P. Cloud IoT Based Poultry Environment Analysis System. In Proceedings of the 2023 Third International Conference on Artificial Intelligence and Smart Energy (ICAIS), Coimbatore, India, 2–4 February 2023; pp. 76–81. [Google Scholar] [CrossRef]

- Chaganti, P.C.V.; Sukesh, K.S. Smart IoT Solutions for Subsurface Gas Monitoring and Safety in Critical Infrastructures. In Proceedings of the 2023 2nd International Conference on Automation, Computing and Renewable Systems (ICACRS), Pudukkottai, India, 11–13 December 2023; pp. 303–308. [Google Scholar] [CrossRef]

- Banupriya, N.; Gokul, G.; Naveen, K.S.; Narayani, S.; Mohamed, A.A. Wearable IoT Gas Monitoring for Sewers Safety. In Proceedings of the 2023 2nd International Conference on Automation, Computing and Renewable Systems (ICACRS), Pudukkottai, India, 11–13 December 2023; pp. 268–272. [Google Scholar] [CrossRef]

- Malik, P.K.; Duggal, A.S.; Aluvala, S.; Sahithi, R.; Geetanjali; Gehlot, A. Development of a Low-Cost IoT Device Using ESP8266 and Atmega328 for Real-Time Monitoring of Outdoor Air Quality with Alert. In Proceedings of the 2023 3rd International Conference on Advancement in Electronics & Communication Engineering (AECE), Ghaziabad, India, 23–24 November 2023; pp. 125–129. [Google Scholar] [CrossRef]

- Pramono, T.B.; Qothrunnada, N.I.; Asadi, F.; Cenggoro, T.W.; Pardamean, B. Water Quality Monitoring System for Aquaponic Technology Using the Internet of Things (IoT). Commun. Math. Biol. Neurosci. 2023, 2023, 120. [Google Scholar] [CrossRef]

- Santos, R.C.; Lopes, A.L.N.; Sanches, A.C.; Gomes, E.P.; da Silva, E.A.S.; da Silva, J.L.B. Intelligent Automated Monitoring Integrated with Animal Production Facilities. Eng. Agric. 2023, 43, e20220225. [Google Scholar] [CrossRef]

- Lashari, M.H.; Karim, S.; Alhussein, M.; Hoshu, A.A.; Aurangzeb, K.; Anwar, M.S. Internet of Things-Based Sustainable Environment Management for Large Indoor Facilities. PEERJ Comput. Sci. 2023, 9, e1623. [Google Scholar] [CrossRef]

- Murugeswari, R.; Jegadeesh, P.; Kumar, G.N.; Babu, S.N.; Samar, B. Revolutionizing Poultry Farming with IoT: An Automated Management System. In Proceedings of the 2023 4th International Conference on Signal Processing and Communication (ICSPC), Coimbatore, India, 23–24 March 2023; pp. 22–27. [Google Scholar] [CrossRef]

- Charieth, F.M.; Parengal, H.; Ashifa, K.M.; Prabhakaran, S.; Arya, C.F. Air Purification by Chemical Photocatalysis by Means of Titanium Dioxide: A Smart Air Purification System. Eur. Chem. Bull. 2022, 11, 146–152. [Google Scholar] [CrossRef]

- Rakib, M.; Haq, S.; Hossain, M.I.; Rahman, T. IoT Based Air Pollution Monitoring & Prediction System. In Proceedings of the 2022 International Conference on Innovations in Science, Engineering and Technology (ICISET), Chittagong, Bangladesh, 26–27 February 2022; pp. 184–189. [Google Scholar] [CrossRef]

- Islam, R.; Hossain, M.I.; Rahman, M.S.; Kabir, S.; Sohan, M.S.R.; Shufian, A. Smart IoT System for Automatic Detection and Protection from Indoor Hazards: An Experimental Study. In Proceedings of the 2022 IEEE 10th Region 10 Humanitarian Technology Conference (R10-HTC), Hyderabad, India, 16–18 September 2022; pp. 112–117. [Google Scholar] [CrossRef]

- Siddika, A.; Hossen Faysal, M.A.; Rasel Ahmed, M.; Rahaman, M.M.; Ali, M.; Ahmed Foysal, M.F. A Data Analysis Technique to Find the Environmental Effect on Egg Production in the Poultry Farm Using ML and IOT. In Proceedings of the 2022 IEEE 8th International Conference on Computing, Engineering and Design (ICCED), Sukabumi, Indonesia, 28–29 July 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Gkogkidis, A.; Tsoukas, V.; Papafotikas, S.; Boumpa, E.; Kakarountas, A. A TinyML-Based System for Gas Leakage Detection. In Proceedings of the 2022 11th International Conference on Modern Circuits and Systems Technologies (MOCAST), Bremen, Germany, 8–10 June 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Naik, A.; Koushik, K.A.; Poorna Vikas, A.S.; Reddy, S.; Manjunatha, N.M.; Sooda, K. A Poultry Farm Monitoring and Control System. In Proceedings of the 2022 IEEE 2nd Mysore Sub Section International Conference (MysuruCon), Mysuru, India, 16–17 October 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Mani, G.; Viswanadhapalli, J.K.; Sriramalakshmi, P. AI Powered IoT Based Real-Time Air Pollution Monitoring and Forecasting. In Proceedings of the Journal of Physics: Conference Series, Chennai, India, 23–25 September 2021; Volume 2115, p. 012016. [Google Scholar] [CrossRef]

- Megantoro, P.; Aldhama, S.A.; Prihandana, G.S.; Vigneshwaran, P. IoT-Based Weather Station with Air Quality Measurement Using ESP32 for Environmental Aerial Condition Study. Telkomnika Telecommun. Comput. Electron. Control. 2021, 19, 1316–1325. [Google Scholar] [CrossRef]

- Ahuja, V.K.; Kotamraju, S.K.; Kavya, K.C.S.; Dangi, M.; Ahammad, S.H. Implementation of an Energy Efficient Framework for Air Quality Monitoring in the Cremation Center Based on Improved Chacha20 Stream Cipher for Secure Data Transmission. In Proceedings of the 2021 3rd International Conference on Advances in Computing, Communication Control and Networking (ICAC3N), Greater Noida, India, 17–18 December 2021; pp. 1146–1153. [Google Scholar] [CrossRef]

- Shyamalaprasanna, A.; Velnath, R.; Dhivya, K.T.; Aishwarya, S.; Saravana, G.; Srimathi, R. Monitoring and Controlling of Industrial Sewage Outlet Using IoT. In Proceedings of the 2021 International Conference on Advancements in Electrical, Electronics, Communication, Computing and Automation (ICAECA), Coimbatore, India, 8–9 October 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Korlepara, N.S.D.P.; Chandra, G.P.; Seshagiri, B.; Raju, V.S.N.N.; Veeraiah, N.; Pragaspathy, S. ¬Novel Freshness Indication Packaging Technology for Frozen Shrimps. In Proceedings of the 2021 International Conference on Advancements in Electrical, Electronics, Communication, Computing and Automation (ICAECA), Coimbatore, India, 8–9 October 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Gomes, J.B.A.; Rodrigues, J.J.P.C.; Rabêlo, R.A.L.; Tanwar, S.; Al-Muhtadi, J.; Kozlov, S. A Novel Internet of Things-Based Plug-and-Play Multigas Sensor for Environmental Monitoring. Trans. Emerg. Telecommun. Technol. 2021, 32, e3967. [Google Scholar] [CrossRef]

- Shobha, R.; Sadiq Mafas, S.; Karthic Raja, B.; Sangeeth Ajay, M.B.; Elavarasi, R. IoT Based Air Quality Monitoring and Poisonous Gas Detection System. Int. J. Electr. Eng. Technol. IJEET 2021, 12, 143–151. [Google Scholar]

- Ullas, S.; Upadhyay, S.; Chandran, V.; Pradeep, S.; Mohankumar, T.M. Control Console of Sewage Treatment Plant with Sensors as Application of IOT. In Proceedings of the 2020 11th International Conference on Computing, Communication and Networking Technologies, ICCCNT 2020, Kharagpur, India, 1–3 July 2020. [Google Scholar] [CrossRef]

- Rozie, F.; Syarif, I.; Al Rasyid, M.U.H. Design and Implementation of Intelligent Aquaponics Monitoring System Based on IoT. In Proceedings of the 2020 International Electronics Symposium (IES), Surabaya, Indonesia, 29–30 September 2020; pp. 534–540. [Google Scholar] [CrossRef]

- Kodali, R.K.; Pathuri, S.; Rajnarayanan, S.C. Smart Indoor Air Pollution Monitoring Station. In Proceedings of the 2020 International Conference on Computer Communication and Informatics (ICCCI-2020), Coimbatore, India, 22–24 January 2020; pp. 535–539. [Google Scholar] [CrossRef]

- Syahrorini, S.; Rifai, A.; Saputra, D.H.R.; Ahfas, A. Design Smart Chicken Cage Based on Internet of Things. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Lumpur, Malaysia, 7–8 November 2020; Volume 519. [Google Scholar] [CrossRef]

- Boppana, L.; Lalasa, K.; Vandana, S.; Kodali, R.K. Mongoose OS Based Air Quality Monitoring System. In Proceedings of the IEEE Region 10 Annual International Conference, Proceedings/TENCON, Kochi, India, 17–20 October 2019; pp. 1247–1252. [Google Scholar] [CrossRef]

- Budiman, F.; Rivai, M.; Nugroho, M.A. Monitoring and Control System for Ammonia and pH Levels for Fish Cultivation Implemented on Raspberry Pi 3B. In Proceedings of the 2019 International Seminar on Intelligent Technology and Its Applications (ISITIA), Surabaya, Indonesia, 28–29 August 2019; pp. 68–73. [Google Scholar] [CrossRef]

- Vijayalakshmi, J.; Puthilibhai, G.; Siddarth, S.R.L. Implementation of Ammonia Gas Leakage Detection & Monitoring System Using Internet of Things. In Proceedings of the 2019 Third International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud) (I-SMAC), Palladam, India, 12–14 December 2019; pp. 778–781. [Google Scholar] [CrossRef]

- Gunawan, T.S.; Sabar, M.F.; Nasir, H.; Kartiwi, M.; Motakabber, S.M.A. Development of Smart Chicken Poultry Farm Using RTOS on Arduino. In Proceedings of the 2019 IEEE International Conference on Smart Instrumentation, Measurement and Application (ICSIMA), Kuala Lumpur, Malaysia, 27–29 August 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Sai, K.B.K.; Mukherjee, S.; Sultana, P.H. Low Cost IoT Based Air Quality Monitoring Setup Using Arduino and MQ Series Sensors with Dataset Analysis. Procedia Comput. Sci. 2019, 165, 322–327. [Google Scholar] [CrossRef]

- Muladi, M.; Sendari, S.; Widiyaningtyas, T. Real Time Indoor Air Quality Monitoring Using Internet of Things at University. In Proceedings of the 2018 2nd Borneo International Conference on Applied Mathematics and Engineering, BICAME 2018, Balikpapan, Indonesia, 10–11 December 2018; pp. 169–173. [Google Scholar] [CrossRef]

- Sitaram, K.A.; Ankush, K.R.; Anant, K.N.; Raghunath, B.R. IoT Based Smart Management of Poultry Farm and Electricity Generation. In Proceedings of the 2018 IEEE International Conference on Computational Intelligence and Computing Research (ICCIC), Madurai, India, 13–15 December 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Hamadi, H.; Satrio, K.A.; Harsono, D. Design and Development of CO, CO2, CH4, and NH3 Gas Detection Equipment Based on Iot. Res Mil. 2023, 13, 5295–5304. [Google Scholar]

- Tsoukas, V.; Gkogkidis, A.; Boumpa, E.; Papafotikas, S.; Kakarountas, A. A Gas Leakage Detection Device Based on the Technology of TinyML. Technologies 2023, 11, 45. [Google Scholar] [CrossRef]

- Brito, R.C.; Ferrareze, C.V.; Favarim, F.; Oliva, J.T.; Todt, E. A Novel System for Ammonia Gas Control in Broiler Production Environment. In Proceedings of the 2020 3rd International Conference on Information and Computer Technologies (ICICT), San Jose, CA, USA, 9–12 March 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 336–340. [Google Scholar] [CrossRef]

- Zakaria, N.A.; Zainal, Z.; Harum, N.; Chen, L.; Saleh, N.; Azni, F. Wireless Internet of Things-Based Air Quality Device for Smart Pollution Monitoring. Int. J. Adv. Comput. Sci. Appl. 2018, 9, 65–69. [Google Scholar] [CrossRef]

- Srinivas, C.S.; Mohan Kumar, C. Toxic Gas Detection and Monitoring Utilizing Internet of Things. Int. J. Civ. Eng. Technol. 2017, 8, 614–622. [Google Scholar]

- Demetillo, A.T.; Tudio, N.J.G.; Solite, J.C.; Dagsa, L.M.; Sajonia, E.R.B.; Balamad, A.D.B. IoT-Enabled Aquaculture Surveillance System for Enhanced Fisheries Resource Management. In Proceedings of the 2023 Second International Conference on Advances in Computational Intelligence and Communication (ICACIC), Puducherry, India, 7–8 December 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Chakraborty, A.; Gupta, R.D.; Roy, D.; Kabir, Z.; Bablu, S.I.; Gupta, R.D. Radiation Monitoring and Environmental Assessment in Precision Agriculture: Development of an Integrated IoT Device with Comprehensive Data Analysis Capabilities. In Proceedings of the 2023 26th International Conference on Computer and Information Technology (ICCIT), Cox’s Bazar, Bangladesh, 13–15 December 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Hambali, M.F.H.; Patchmuthu, R.K.; Wan, A.T. IoT Based Smart Poultry Farm in Brunei. In Proceedings of the 2020 8th International Conference on Information and Communication Technology (ICoICT), Yogyakarta, Indonesia, 24–26 June 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Megantoro, P.; Pramudita, B.A.; Vigneshwaran, P.; Yurianta, A.; Winarno, H.A. Real-Time Monitoring System for Weather and Air Pollutant Measurement with Html-Based Ui Application. Bull. Electr. Eng. Inform. 2021, 10, 1669–1677. [Google Scholar] [CrossRef]

- Godinho, A.; Vicente, R.; Silva, S.; Coelho, P.J. Wireless Environmental Monitoring and Control in Poultry Houses: A Concetual Study. IoT 2025, 6, 32. [Google Scholar] [CrossRef]

- Rosmiati, M.; Wijaya, R.; Hanifa, F.H.; Hidayat, R.; Winata, A.Y.; Maulana, M.A. IoT-Based Cattle Pen Monitoring and Mobile App.lication Interface for WS Farm: Enhancing Livestock Management Through Real-Time Data. Instrum. Mes. Métrologie 2025, 24, 161–169. [Google Scholar] [CrossRef]

- Antad, S.; Giri, V.; Bachewar, B.; Barsude, S.; Gadiya, A.; Badagandi, H. Real-Time Gas Monitoring and Anomaly Detection in Petroleum Industry Using IoT and Machine Learning. Int. J. Comput. Digit. Syst. 2025, 17, 1–17. [Google Scholar] [CrossRef]

- Rajendrakumar, P.M.; Shwetha, P.; Reddy, P.; Tejasri, T.; Piruthiviraj, P. IoT Cloud-Based Air Quality Monitoring System with Arduino. In Proceedings of the 2025 International Conference on Knowledge Engineering and Communication Systems (ICKECS), Karnataka, India, 23–24 April 2025; IEEE: Piscataway, NJ, USA, 2025; pp. 1–6. [Google Scholar] [CrossRef]

- Ullas, S.; Maheswari, B.U.; Ponnekanti, S.; Kumar, T.M.M. Automated System to Optimize the Process and Energy Consumption for Sewage Treatment Plant Based on Gas Emission by Using Sensors and IoT. IEEE Access 2025, 13, 115972–115989. [Google Scholar] [CrossRef]

- Singh, K.; Momin, K.; Nishal, M.; Sultania, C.; Rao, M. Agri-Guard: IoT-Based Network for Agricultural Health Monitoring with Fault Detection. In Proceedings of the 10th International Conference on Internet of Things, Big Data and Security, Porto, Portugal, 6–8 April 2025; SCITEPRESS-Science and Technology Publications: Setúbal, Portugal, 2025; pp. 223–230. [Google Scholar] [CrossRef]

- Wang, L.; Li, K. Design and Implementation of Intelligent Pet House Environment Monitoring System Based on IoT. In Proceedings of the 2025 6th International Conference on Electrical, Electronic Information and Communication Engineering (EEICE), Shenzhen, China, 18–20 April 2025; pp. 694–699. [Google Scholar] [CrossRef]

- Raja, G.B.; Vigneashwaran, R.; Rohan, M.; Praveen, N.B.; Vijay, N.P. IoT-Based Sewage Atmosphere and Health Monitoring for Sanitation Workers with Alerting System. In Proceedings of the 2025 7th International Conference on Inventive Material Science and Applications (ICIMA), Shenzhen, China, 18–20 April 2025; pp. 855–860. [Google Scholar] [CrossRef]

- Khadim, H.J.; Obaed, F.K.; Ajeel, N.S. Wireless Sensing Network for Implementation of Air Quality Monitoring System and Indoor Air Quality Index Application. Iraqi Geol. J. 2024, 57, 210–220. [Google Scholar] [CrossRef]

- Fahrurrozi, I.; Wahyono; Sari, Y.; Sari, A.K.; Usuman, I.; Ariyadi, B. Integrating Random Forest Model and Internet of Things-Based Sensor for Smart Poultry Farm Monitoring System. Indones. J. Electr. Eng. Comput. Sci. 2024, 33, 1283–1292. [Google Scholar] [CrossRef]

- Singh, A.; Banerjee, A.; Chatterjee, S.; Das, H.; Das, N.; Saha, S.; Mandal, H. Sustainable Smart Trash Bin Based Waste Segregation and Collection System. In Proceedings of the 2024 4th International Conference on Computer, Communication, Control & Information Technology (C3IT), Hooghly, India, 28–29 September 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Saad, H.; Zaidi, N.F.N.; Isa, N.M.; Shahbudin, S.; Othman, N.; Masrie, M. Incorporating IoT into STEM Education through PBL-Chicken Farming Issues. In Proceedings of the 2024 IEEE 15th Control and System Graduate Research Colloquium, ICSGRC 2024, Shah Alam, Malaysia, 17 August 2024; pp. 187–192. [Google Scholar] [CrossRef]

- Singh, H.; Kajla, A.K. Optimizing Ammonia Concentration in Poultry Houses Through Random Forest Prediction and Lora-Wan Monitoring & Controlling System. SSRN 2024. [Google Scholar] [CrossRef]

- Sridhar, K.; Radhakrishnan, P.; Swapna, G.; Kesavamoorthy, R.; Pallavi, L.; Thiagarajan, R. A Modular IOT Sensing Platform Using Hybrid Learning Ability for Air Quality Prediction. Meas. Sens. 2023, 25, 100609. [Google Scholar] [CrossRef]

- Dequilla-Pabiania, M.; Marasigan, J.A.; Mercado, N.P.; Rivera, L. A Low-Cost Electronic Food Nose IoT-Based Fish Quality Monitoring System. Chem. Eng. Trans. 2023, 106, 487–492. [Google Scholar] [CrossRef]

- Rahman Alvi, K.M.; Mondal, S. Ammonia & CO2 Gas Detection of Poultry Farms and Compost Plants by Low-Cost Smart Sensing System. In Proceedings of the 2023 26th International Conference on Computer and Information Technology (ICCIT), Cox’s Bazar, Bangladesh, 13–15 December 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Azman, F.I.; Fazdli, M.S.F.M.; Saleh, N.L.; Noor, A.S.M.; Ali, A.M. Residential College’s Smart Restroom Monitoring System. In Proceedings of the 2023 International Conference on Smart Applications, Communications and Networking (SmartNets), Istanbul, Turkiye, 25–27 July 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Bashyam, S.; Pramodini, V.; Ashik, A.; Prasanth, V.S. IoT-Based Garbage Gas Detection System. In Proceedings of the 2023 4th International Conference for Emerging Technology (INCET), Belgaum, India, 26–28 May 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Srinuanjan, K.; Kruakuanphet, A.; Phongwisit, P.; Yindeesuk, W.; Kamoldilok, S. Electronic Nose Ammonia Gas Monitoring via IoT System for Chlorella sp. Cultivation. In Proceedings of the SPIE Future Sensing Technologies 2023, Yokohama, Japan, 18–21 April 2023; p. 123271F. [Google Scholar] [CrossRef]

- Perdanasari, L.; Etikasari, B.; Rukmi, D.L. Control System for Temperature, Humidity, and Ammonia Levels in Laying Hens Farms Based on Internet of Things. IOP Conf. Ser. Earth Environ. Sci. 2023, 1168, 012053. [Google Scholar] [CrossRef]

- Lukman, L. Early Detection of Ammonia Gas Levels in the Air Using IoT-Based SVM. J. Pendidik. Tambusai 2023, 7, 3750–3757. [Google Scholar] [CrossRef]

- Mia, M.H.; Mahfuz, N.; Habib, R.; Hossain, R. An Internet of Things Application on Continuous Remote Patient Monitoring and Diagnosis. In Proceedings of the 2021 4th International Conference on Bio-Engineering for Smart Technologies (BioSMART), Paris/Créteil, France, 8–10 December 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Listyarini, S.; Warlina, L.; Sambas, A. The Air Quality Monitoring Tool Based on Internet of Things to Monitor Pollution Emissions Continuously. Environ. Ecol. Res. 2022, 10, 824–829. [Google Scholar] [CrossRef]

- Zamzari, N.Z.; Kassim, M.; Yusoff, M. Analysis and Development of IoT-Based Aqua Fish Monitoring System. Int. J. Emerg. Technol. Adv. Eng. 2022, 12, 191–197. [Google Scholar] [CrossRef] [PubMed]

- Azman, F.I.; Saleh, N.L.; Ali, A.M.; Sali, A.; Noor, A.S.M. Restroom Hygiene Smart Monitoring System Incorporating Lora Technology. In Proceedings of the TENCON 2022 IEEE Region 10 Conference (TENCON), Hong Kong, China, 1–4 November 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, C.; Liu, H. Design and Implementation of Animal Laboratory Environmental Monitoring System Based on Internet of Things. In Proceedings of the 2022 2nd International Conference on Electrical Engineering and Control Science (IC2ECS), Nanjing, China, 16–18 December 2022; pp. 1235–1238. [Google Scholar] [CrossRef]

- Sangeetha, K.; Kanthimathi, M.; Monisha, S.R.; Reethika, M.; Amirthabowmiya, M. Poultry Farm Control and Management System Using Wireless Sensor Networks. In Proceedings of the 2022 1st International Conference on Computational Science and Technology (ICCST), Chennai, India, 9–10 November 2022; pp. 712–715. [Google Scholar] [CrossRef]

- Udanor, C.N.; Ossai, N.I.; Nweke, E.O.; Ogbuokiri, B.O.; Eneh, A.H.; Ugwuishiwu, C.H.; Aneke, S.O.; Ezuwgu, A.O.; Ugwoke, P.O.; Christiana, A. An Internet of Things Labelled Dataset for Aquaponics Fish Pond Water Quality Monitoring System. Data Brief 2022, 43, 108400. [Google Scholar] [CrossRef]

- Dinesh, D.; Mowshik, A.N.; Meyyappan, M.; Kowtham, M. Analysis of Universal Gas Leak Detector of Hazardous Gases Using IOT. Mater. Today-Proc. 2022, 66, 1044–1050. [Google Scholar] [CrossRef]

- Kruakuanphet, A.; Phongwisit, P.; Yindeesuk, W.; Kamoldilok, S.; Srinuanjan, K. Multi-Range Ammonia Gas Sensor Control and Monitor via IoT System. In Proceedings of the 2022 26th International Computer Science and Engineering Conference (ICSEC), Sakon Nakhon, Thailand, 21–23 December 2022; pp. 182–185. [Google Scholar] [CrossRef]

- Onibonoje, M.O. IoT-Based Synergistic Approach for Poultry Management System. In Proceedings of the 2021 IEEE International IOT, Electronics and Mechatronics Conference (IEMTRONICS), Toronto, ON, Canada, 21–24 April 2021; pp. 572–576. [Google Scholar] [CrossRef]

- Lukman; Achmad, A.; Syarif, S. Prediction of Ammonia Contamination Levels in Wastewater Management Plant Using the SVM Method. In Proceedings of the 2021 International Seminar on Intelligent Technology and Its Applications (ISITIA), Surabaya, Indonesia, 21–22 July 2021; pp. 250–255. [Google Scholar] [CrossRef]

- Sanger, J.B.; Sitanayah, L.; Ahmad, I. A Sensor-Based Garbage Gas Detection System. In Proceedings of the 2021 IEEE 11th Annual Computing and Communication Workshop and Conference (CCWC), Las Vegas, NV, USA, 27–30 January 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1347–1353. [Google Scholar] [CrossRef]

- Pereira, W.F.; Fonseca, L.d.S.; Putti, F.F.; Goes, B.C.; Naves, L.d.P. Environmental Monitoring in a Poultry Farm Using an Instrument Developed with the Internet of Things Concept. Comput. Electron. Agric. 2020, 170, 105257. [Google Scholar] [CrossRef]

- Zaini, A.; Kurniawan, A.; Herdhiyanto, A.D. Internet of Things for Monitoring and Controlling Nutrient Film Technique (NFT) Aquaponic. In Proceedings of the 2018 International Conference on Computer Engineering, Network and Intelligent Multimedia (CENIM), Surabaya, Indonesia, 26–27 November 2018; pp. 167–171. [Google Scholar] [CrossRef]

- Khaowdang, S.; Suriyachai, N.; Imman, S.; Suwannahong, K.; Wongcharee, S.; Kreetachat, T. Application of Internet of Things Technology for Ventilation and Environmental Control in Conventional Open-Air Pig Housing Systems in Thailand. AgriEngineering 2025, 7, 165. [Google Scholar] [CrossRef]

- Febriana, S.D.; Mutiara, G.A.; Erfianto, B. E-Sniffer: Raw Meat Freshness Detection Tool Based on Odor Classification and Fuzzy Logic Utilizing Gas Fusion Sensor. Instrum. Mes. Métrologie 2025, 24, 97–109. [Google Scholar] [CrossRef]

- Azman, F.I.; Saleh, N.L.; Hashim, F.; Sali, A.; Ali, A.M.; Noor, A.S.M. An IoT-Based Hygiene Monitoring System in the Restroom. IEEE Access 2025, 13, 119348–119361. [Google Scholar] [CrossRef]

- Traya, M.A.; Azucena, E.T.; Budok, J.G.F.; Guanzon, G.S.; Naputol, A.T.; Ituriaga, J.I. Development of an IoT-Based System with AI-Driven Robotic Feeder and Rice Hull Management for Chickens. In Proceedings of the 2025 IEEE International Conference on Robotics and Technologies for Industrial Automation (ROBOTHIA), Kuala Lumpur, Malaysia, 12 April 2025; IEEE: Piscataway, NJ, USA, 2015; pp. 1–7. [Google Scholar] [CrossRef]

- Datasheet MQ-2. Available online: https://www.winsen-sensor.com/d/files/PDF/Semiconductor%20Gas%20Sensor/MQ-2%20(Ver1.4)%20-%20Manual.pdf (accessed on 6 March 2025).

- Krishnamurthy, K.T.; Managuli, M.; Malipatil, S.; Bagyalakshmi, K.; Salake, S.V.; Kadalagi, P.S.; Patil, S.B. IoT Based Poultry Farm Smart Management System. In Proceedings of the 2024 International Conference on Knowledge Engineering and Communication Systems (ICKECS), Chikkaballapur, India, 18–19 April 2024. [Google Scholar] [CrossRef]

- Chigwada, J.; Mazunga, F.; Nyamhere, C.; Mazheke, V.; Taruvinga, N. Remote Poultry Management System for Small to Medium Scale Producers Using IoT. Sci. Afr. 2022, 18, e01398. [Google Scholar] [CrossRef]

- Lehaa, T.; Dhanasekaran, D.; Kumar, P.; Murali Prasad, A.; Samyuktha, P.R. Smart Poultry Farm: An IoT-Based Environmental Monitoring and Control System. In Proceedings of the 2025 7th International Conference on Inventive Material Science and Applications (ICIMA), Namakkal, India, 28–30 May 2025; IEEE: Piscataway, NJ, USA, 2025; pp. 1083–1090. [Google Scholar] [CrossRef]

- Indrawati, E.M.; Munawi, H.A.; Suwardono, A.; Santoso, R.; Maulana, F.I. Smart Technology Intervention for Integrated Gurami Fish Cultivation Based on IoT*. In Proceedings of the 2024 IEEE International Conference on Internet of Things and Intelligence Systems (IoTaIS), Bali, Indonesia, 28–30 November 2024; pp. 198–202. [Google Scholar] [CrossRef]

- Sai Prasad, M.V.; Sumalatha, A.; Rani, K.S.; Meenakshi, C.; Nicy, M.; Babu, D.C. Cloud-Based IoT Solution for Enhanced Poultry Farm Management. In Proceedings of the 2024 4th International Conference on Innovative Practices in Technology and Management (ICIPTM), Noida, India, 21–23 February 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Islam, S. An Intelligent System on Environment Quality Remote Monitoring and Cloud Data Logging Using Internet of Things (IoT). In Proceedings of the International Conference on Computer, Communication, Chemical, Material and Electronic Engineering, IC4ME2 2018, Rajshahi, Bangladesh, 8–9 February 2018. [Google Scholar] [CrossRef]

- Datasheet MiCS-6814. Available online: https://www.sgxsensortech.com/content/uploads/2015/02/1143_Datasheet-MiCS-6814-rev-8.pdf (accessed on 6 March 2025).

- Aserkar, A.A.; Godla, S.R.; Baker El-Ebiary, Y.A.; Krishnamoorthy; Ramesh, J.V.N. Real-Time Air Quality Monitoring in Smart Cities Using IoT-Enabled Advanced Optical Sensors. Int. J. Adv. Comput. Sci. Appl. 2024, 15, 840–848. [Google Scholar] [CrossRef]

- Mulling, L.F.; Lindino, C.; Oyamada, M.S. Calibration of a Metal Oxide Sensor for Ammonia Detection Targeting IoT Solutions. In Proceedings of the 2023 XIII Brazilian Symposium on Computing Systems Engineering, SBESC, Porto Alegre, Brazil, 21–24 November 2023. [Google Scholar] [CrossRef]

- Mapili, M.G.A.; Rodriguez, K.A.D.; Sese, J.T. Smart Air Filtration System Using IoT and Kalman Filter Algorithm for Indoor Air Quality and Plant Monitoring. In Proceedings of the 2021 IEEE 11th International Conference on System Engineering and Technology (ICSET), Shah Alam, Malaysia, 6 November 2021; pp. 309–314. [Google Scholar] [CrossRef]

- Nasution, T.H.; Hizriadi, A.; Tanjung, K.; Nurmayadi, F. Design of Indoor Air Quality Monitoring Systems. In Proceedings of the 2020 4th International Conference on Electrical, Telecommunication and Computer Engineering, ELTICOM 2020—Proceedings, Medan, Indonesia, 3–4 September 2020; pp. 238–241. [Google Scholar] [CrossRef]

- Marques, G.; Pitarma, R. A Cost-Effective Air Quality Supervision Solution for Enhanced Living Environments through the Internet of Things. Electronics 2019, 8, 170. [Google Scholar] [CrossRef]

- Datasheet MiCS-5524. Available online: https://www.sgxsensortech.com/content/uploads/2014/07/1084_Datasheet-MiCS-5524-rev-8.pdf (accessed on 6 March 2025).

- Fatkhurrahman, J.A.; Sari, I.R.J. Affordable Metal Oxide Gas Sensor as Environmental Friendly Method for Ammonia Gas Measurement. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Yogyakarta, Indonesia, 29–30 October 2019; Volume 366. [Google Scholar] [CrossRef]

- Prafanto, A.; Firdaus, M.B. Implementation of Naïve Bayes Gaussian Algorithm for Real-Time Classification of Broiler Cage Conditions. J. App.l. Data Sci. 2025, 6, 1551–1562. [Google Scholar] [CrossRef]

- Datasheet TGS2602. Available online: https://www.figarosensor.com/product/docs/TGS2602-B00%20%280615%29.pdf (accessed on 6 March 2025).

- Suhud, A.; Hanafi, N.; Purnomo, D.S. Smart Cat Litter Box with Ammonia Gas Level Controller Using IoT-Based Fuzzy Logic. In Proceedings of the 2024 International Electronics Symposium, IES 2024, Denpasar, Indonesia, 6–8 August 2024; pp. 317–321. [Google Scholar] [CrossRef]

- Eriyadi, M.; Notosudjono, D.; Setiana, H.; Yakin, M.A.A.A. Low-Cost Mobile Air Quality Monitoring Based on Internet of Things for Factory Area. Indones. J. Electr. Eng. Comput. Sci. 2023, 32, 545–554. [Google Scholar] [CrossRef]

- Panjagal, S.B.; Ramaiah, G.N.K. Odorsense: Measuring, Assessment and Alerting the Health Effects of Odor Pollution. 3C Tecnol. 2021, Special Issue, 97–113. [Google Scholar] [CrossRef]

- Datasheet TGS-2444. Available online: https://www.figaro.co.jp/en/product/docs/tgs2444_product_infomation_rev02.pdf (accessed on 6 March 2025).

- Kumar, M.; Mini, S.; Panigrahi, T. A Scalable Approach to Monitoring Air Pollution Using IoT. In Proceedings of the 2018 2nd International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud) (I-SMAC)I-SMAC (IoT in Social, Mobile, Analytics and Cloud) (I-SMAC), Palladam, India, 30–31 August 2018; pp. 42–47. [Google Scholar] [CrossRef]

- Damdam, A.N.; Ozay, L.O.; Ozcan, C.K.; Alzahrani, A.; Helabi, R.; Salama, K.N. IoT-Enabled Electronic Nose System for Beef Quality Monitoring and Spoilage Detection. Foods 2023, 12, 2227. [Google Scholar] [CrossRef]

- Yoon, S.U.; Choi, S.M.; Lee, J.H. A Study on the Development of Livestock Odor (Ammonia) Monitoring System Using ICT (Information and Communication Technology). Agriculture 2021, 12, 46. [Google Scholar] [CrossRef]

- Provolo, G.; Brandolese, C.; Grotto, M.; Marinucci, A.; Fossati, N.; Ferrari, O.; Beretta, E.; Riva, E. An Internet of Things Framework for Monitoring Environmental Conditions in Livestock Housing to Improve Animal Welfare and Assess Environmental Impact. Animals 2025, 15, 644. [Google Scholar] [CrossRef] [PubMed]

- Bordignon, F.; Pravato, M.; Trocino, A.; Xiccato, G.; Marinello, F.; Pezzuolo, A. Environmental Gradients and Hen Spatial Distribution in a Cage-Free Aviary System: Internet of Things-Based Real-Time Monitoring for Proactive Management. Animals 2025, 15, 1225. [Google Scholar] [CrossRef] [PubMed]

- Abinaya, T.; Lshwarya, J.; Maheswari, M. A Novel Methodology for Monitoring and Controlling of Water Quality in Aquaculture Using Internet of Things (IoT). In Proceedings of the 2019 International Conference on Computer Communication and Informatics (ICCCI-2019), Coimbatore, India, 23–25 January 2019. [Google Scholar] [CrossRef]

- Suriasni, P.A.; Faizal, F.; Hermawan, W.; Subhan, U.; Panatarani, C.; Joni, I.M. IoT Water Quality Monitoring and Control System in Moving Bed Biofilm Reactor to Reduce Total Ammonia Nitrogen. Sensors 2024, 24, 494. [Google Scholar] [CrossRef]

- Rahul, S.G.; Rajkumar, R.; Reddy, Y.K.; Koushik, N.; Manikannta, V.S.; Subitha, D. Integrating IoT and Deep Learning for Smart Aquaculture Management in Freshwater Aquariums. In Proceedings of the 2nd International Conference on Sustainable Computing and Smart Systems, ICSCSS 2024, Coimbatore, India, 10–12 July 2024; pp. 321–326. [Google Scholar] [CrossRef]

- Xu, Y.; Wu, L.; Fan, Y.; Guo, Q. Intelligent Space Disinfection System Based on Microcontroller. In Proceedings of the International Conference on Electronic Information Engineering and Data Processing (EIEDP 2023), Nanchang, China, 17–19 March 2023; Volume 12700. [Google Scholar] [CrossRef]

- Xinyu, S.; Liangzhe, C.; Jinxiang, W.; Yaya, X.; Xijia, H.; Qing, Y. Research on Intelligent Ammonia Detection System Based on NB-IOT Networking Technology. In Proceedings of the 2023 IEEE 3rd International Conference on Data Science and Computer Application (ICDSCA), Dalian, China, 27–29 October 2023; pp. 460–464. [Google Scholar] [CrossRef]

- Shafkat, A.; Islam, E. Iot Based Biofloc Automation and Monitoring for Smart Fish Production. In Proceedings of the 2023 3rd International Conference on Electronic and Electrical Engineering and Intelligent System (ICE3IS), Yogyakarta, Indonesia, 9–10 August 2023; pp. 158–162. [Google Scholar] [CrossRef]

- Benhmad, T.; Ben Abdennour, A.; Darghouthi, A.; Belgacem Rhaimi, C. Remote Control of Environmental Parameters in Rabbitry Based on IoT. Internet Things Cyber-Phys. Syst. 2022, 2, 111–119. [Google Scholar] [CrossRef]

- Wang, Y.; Ho, I.W.-H.; Chen, Y.; Wang, Y.; Lin, Y. Real-Time Water Quality Monitoring and Estimation in AIoT for Freshwater Biodiversity Conservation. IEEE Internet Things J. 2022, 9, 14366–14374. [Google Scholar] [CrossRef]

- Jayarajan, P.; Annamalai, M.; Jannifer, V.A.; Prakash, A.A. IOT Based Automated Poultry Farm for Layer Chicken. In Proceedings of the 2021 7th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 19–20 March 2021; Volume 1, pp. 733–737. [Google Scholar] [CrossRef]

- Mohd Redzuan, A.A.A.; Saparudin, F.A.; Mohd Shah, N.S.; Noor Azeb, M.M.A.; Shamsuddin, M.K.A. Wireless Ammonia Sensor System for Distributed Wireless Monitoring Platform Using Heltec Wifi LoRa 32 (V2). Prog. Eng. Appl. Technol. 2021, 2, 502–513. [Google Scholar]

- Lashari, M.H.; Memon, A.A.; Shah, S.A.A.; Nenwani, K.; Shafqat, F. IoT Based Poultry Environment Monitoring System. In Proceedings of the 2018 IEEE International Conference on Internet of Things and Intelligence System, IOTAIS 2018, Bali, Indonesia, 1–3 November 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Kalamaras, S.D.; Tsitsimpikou, M.-A.; Tzenos, C.A.; Lithourgidis, A.A.; Pitsikoglou Dimitra, S.; Kotsopoulos, T.A. A Low-Cost IoT System Based on the ESP32 Microcontroller for Efficient Monitoring of a Pilot Anaerobic Biogas Reactor. Appl. Sci. 2025, 15, 34. [Google Scholar] [CrossRef]

- Xu, Y.; Jin, J.; Zeng, S.; Zhang, Y.; Xiao, Q. Development and Evaluation of an Iot-Based Portable Water Quality Monitoring System for Aquaculture. Inmateh-Agric. Eng. 2023, 70, 359–368. [Google Scholar] [CrossRef]

- Kamruzzaman, S.M.; Sakib, F.S.; Rahman, L.M.; Ahmed, T.; Alam, M.D.S.; Shakir, M.B.; Pavel, M.I. Sense-IT: An Aquaculture-Specific Autonomous Data Acquisition and Monitoring System. In Proceedings of the 2022 International Electronics Symposium (IES), Surabaya, Indonesia, 9–11 August 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 404–409. [Google Scholar] [CrossRef]

- Tamim, A.T.; Begum, H.; Shachcho, S.A.; Khan, M.M.; Yeboah-Akowuah, B.; Masud, M.; Al-Amri, J.F. Development of IoT Based Fish Monitoring System for Aquaculture. Intell. Autom. Soft Comput. 2022, 32, 55–71. [Google Scholar] [CrossRef]

- Shandikiri, R.; Erfianto, B. Internet of Things: Water Quality Classiffication Based on Estimation of Dissolved Oxygen Solubility and Unionized Ammonia for Smallscales Freshwater Aquaculture. Kinet. Game Technol. Inf. Syst. Comput. Netw. Comput. Electron. Control J. 2021, 6, 259–268. [Google Scholar] [CrossRef]

- Khaoula, T.; Abdelouahid, R.A.; Ezzahoui, I.; Marzak, A. Architecture Design of Monitoring and Controlling of IoT-Based Aquaponics System Powered by Solar Energy. Procedia Comput. Sci. 2021, 191, 493–498. [Google Scholar] [CrossRef]

- Chang, C.-C.; Wei, C.-H.; Lin, M.-T.; Hwang, S.-C.J. Machine Learning Approach to IoT- Based Water Quality Monitoring. In Proceedings of the 2023 IEEE 5th Eurasia Conference on Biomedical Engineering, Healthcare and Sustainability, ECBIOS 2023, Tainan, Taiwan, 2–4 June 2023; pp. 182–186. [Google Scholar] [CrossRef]

- Opta. Available online: https://docs.arduino.cc/hardware/opta/ (accessed on 19 October 2025).

- NORVI IIoT ESP32 Industrial Controller. Available online: https://norvi.io/norvi-iiot-esp32-industrial-controller/ (accessed on 19 October 2025).

- ESP32-S3 HMI with LVGL Support. Available online: https://norvi.io/esp32-s3-hmi-with-lvgl-support/ (accessed on 19 October 2025).

- Arduino’s Series of High-Performance Industry-Rated Boards. Available online: https://www.arduino.cc/pro/hardware-product-family-portenta-family/ (accessed on 19 October 2025).

- ESP32-S3 Designed for AIoT Applications. Available online: https://www.espressif.com/en/products/socs/esp32-s3 (accessed on 19 October 2025).

- STM32 Wireless MCUs. Available online: https://www.st.com/en/microcontrollers-microprocessors/stm32-wireless-mcus.html (accessed on 19 October 2025).

- Patchmuthu, R.K.; Wan, A.T.; Suhaili, W.S. Exploring Data Security and Privacy Issues in Internet of Things Based on Five-Layer Architecture. Int. J. Commun. Netw. Inf. Secur. IJCNIS 2022, 12. [Google Scholar] [CrossRef]

- Ferro, E.; Potorti, F. Bluetooth and Wi-Fi Wireless Protocols: A Survey and a Comparison. IEEE Wirel. Commun. 2005, 12, 12–26. [Google Scholar] [CrossRef]

- Reyneke, M.; Mullins, B.; Reith, M. LoRaWAN & The Helium Blockchain: A Study on Military IoT Deployment. Int. Conf. Cyber Warf. Secur. 2023, 18, 327–337. [Google Scholar] [CrossRef]

- Shilpa, B.; Radha, R.; Movva, P. Comparative Analysis of Wireless Communication Technologies for IoT Applications. In Artificial Intelligence and Technologies; Raje, R.R., Hussain, F., Kannan, R.J., Eds.; Lecture Notes in Electrical Engineering; Springer: Singapore, 2022; Volume 806, pp. 383–394. [Google Scholar] [CrossRef]

- Yadav, V.; Kumar, L.; Kumar, P. Evolution and Development of Wireless Communication System. In Proceedings of the 2019 International Conference on Computing, Power and Communication Technologies (GUCON), New Delhi, India, 27–28 September 2019; pp. 53–57. [Google Scholar]

- Poursafar, N.; Alahi, M.E.E.; Mukhopadhyay, S. Long-Range Wireless Technologies for IoT Applications: A Review. In Proceedings of the 2017 Eleventh International Conference on Sensing Technology (ICST), Sydney, NSW, Australia, 4–6 December 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Asemani, M.; Abdollahei, F.; Jabbari, F. Understanding IoT Platforms: Towards a Comprehensive Definition and Main Characteristic Description. In Proceedings of the 2019 5th International Conference on Web Research (ICWR), Tehran, Iran, 24–25 April 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 172–177. [Google Scholar] [CrossRef]

- Shwe, T.; Aritsugi, M. Optimizing Data Processing: A Comparative Study of Big Data Platforms in Edge, Fog, and Cloud Layers. Appl. Sci. 2024, 14, 452. [Google Scholar] [CrossRef]

- Jamshed, M.A.; Ali, K.; Abbasi, Q.H.; Imran, M.A.; Ur-Rehman, M. Challenges, Applications, and Future of Wireless Sensors in Internet of Things: A Review. IEEE Sens. J. 2022, 22, 5482–5494. [Google Scholar] [CrossRef]

- Panda, S.; Mehlawat, S.; Dhariwal, N.; Kumar, A.; Sanger, A. Comprehensive Review on Gas Sensors: Unveiling Recent Developments and Addressing Challenges. Mater. Sci. Eng. B 2024, 308, 117616. [Google Scholar] [CrossRef]

- Chowdhury, M.A.Z.; Oehlschlaeger, M.A. Artificial Intelligence in Gas Sensing: A Review. ACS Sens. 2025, 10, 1538–1563. [Google Scholar] [CrossRef] [PubMed]

- Narkhede, P.; Walambe, R.; Mandaokar, S.; Chandel, P.; Kotecha, K.; Ghinea, G. Gas Detection and Identification Using Multimodal Artificial Intelligence Based Sensor Fusion. Appl. Syst. Innov. 2021, 4, 3. [Google Scholar] [CrossRef]

- Singh, S.; S, S.; Varma, P.; Sreelekha, G.; Adak, C.; Shukla, R.P.; Kamble, V.B. Metal Oxide-Based Gas Sensor Array for VOCs Determination in Complex Mixtures Using Machine Learning. Microchim. Acta 2024, 191, 196. [Google Scholar] [CrossRef]

- Peng, S.; Zhu, J.; Liu, Z.; Hu, B.; Wang, M.; Pu, S. Prediction of Ammonia Concentration in a Pig House Based on Machine Learning Models and Environmental Parameters. Animals 2022, 13, 165. [Google Scholar] [CrossRef]

- Li, X.; Guo, J.; Xu, W.; Cao, J. Optimization of the Mixed Gas Detection Method Based on Neural Network Algorithm. ACS Sens. 2023, 8, 822–828. [Google Scholar] [CrossRef]

- Ferrer-Cid, P.; Barcelo-Ordinas, J.M.; Garcia-Vidal, J.; Ripoll, A.; Viana, M. Multisensor Data Fusion Calibration in IoT Air Pollution Platforms. IEEE Internet Things J. 2020, 7, 3124–3132. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, X.; Li, E.; Zeng, L.; Luo, K.; Zhang, J. Edge Intelligence: Paving the Last Mile of Artificial Intelligence With Edge Computing. Proc. IEEE 2019, 107, 1738–1762. [Google Scholar] [CrossRef]

- Nayak, S.; Misra, S.; Basu Majumder, S. Machine Learning-Based Edge Intelligence for Reliable Gas Monitoring Networks. IEEE Sens. J. 2025, 25, 35268–35277. [Google Scholar] [CrossRef]

| Inclusion Criteria | Exclusion Criteria |

|---|---|

| Publications from 2015–2025 | Duplicates |

| Research manuscripts published in journals or conference proceedings | Books, book chapters, reviews, magazines, abstracts |

| Written in English | Written in other languages |

| Within the scope of the research queries | Out of the scope of the research questions |

| Group (Qty of References) | Microcontrollers Identified | Native Wireless (Qty of References) | References |

|---|---|---|---|

| Xtensa (Espressif) (99) | ESP32: ESP-32 CAM, WROOM-32, Mappi 32, TTGO, Heltec Lora. ESP 8266: Wemos D1 Mini, ESP 12E/F, NodeMCU. | Yes (99) | [29,33,35,46,48,49,50,51,53,54,55,56,57,58,60,61,62,63,64,65,66,67,68,69,70,71,72,74,77,80,82,83,84,85,86,89,90,91,92,96,97,101,103,104,105,106,107,108,109,110,111,113,114,115,116,117,119,120,121,122,123,124,125,126,128,129,131,134,135,137,139,140,141,142,144,145,148,149,150,151,152,155,156,158,159,161,162,164,165,169,174,177,179,180,182,184,185,186,187,189] |

| ARM Cortex-M (14) | STM32: STM32F103C8T6, STM32F103RCT6, STM32L431RCT6, F401RE, B-L072Z-LRWAN1. GD32F303RGT6 Arduino Nano 33 BLE | No (11) Yes (3) B-L072Z-LRWAN1/Nano 33 BLE | [18,28,47,61,67,79,100,114,121,124,132,133,176,177] |

| AVR (8-bit) (61) | ATmega328P: Arduino UNO/Nano. ATmega2560 (Mega), ATmega1281, Arduino Pro Mini | No (61) | [30,34,48,49,51,53,57,59,60,62,63,65,68,69,70,71,73,75,76,77,78,80,81,87,89,93,94,95,96,97,98,103,104,105,106,111,112,116,122,128,129,130,134,136,138,139,140,142,150,152,153,162,165,166,173,174,175,177,179,181,190] |

| ARM Cortex-A (27) | Raspberry Pi 5/4/4B/3B+/2/Zero/pico W NVIDIA Jetson AGX Xavier | Yes (15) (Raspberry Pi 3B+/4/5) No (12) | [31,32,52,55,56,62,73,81,83,88,89,93,99,102,110,112,113,118,121,124,127,146,157,178,182,183,188] |

| MSP430 (16-bit) (1) | MSP430G2553 | No (1) | [86] |

| Hybrid/Special (2) | Waspmote Gases PRO v3 Zolertia RE-Motes | Yes (2) | [29,168] |

| N/A (4) | [143,170,171,172] |

| Parameter | Wi-Fi * [197,198,199] | Bluetooth [198] | ZigBee [200] | LoRaWAN ** [200] | 2G (GSM/GPRS) *** [201] | 4G (LTE ****) [202] |

|---|---|---|---|---|---|---|

| Range | 100 m | 10 m | 10–100 m | 5 km (Urban) 15 km (rural) | 500 m–25 km | 15 km |

| Data Rate | 31.4 Mbps | 732 kbps | 20, 40, 250 Kbps | 250 bps-50 kbps | 64 kbps | 100 Mbps-1 Gbps |

| Operating Frequency | 2.4 GHz, 5 GHz | 2.4 GHz | 2.4 GHz, 868 MHz, 915 MHz | 868 MHz, 915 MHz, 430 MHz | 1.8 GHz | 2–8 GHz |

| Communication Technology (Qty of References) | References |

|---|---|

| Wi-Fi (89) | [30,31,32,33,34,48,49,51,53,54,55,57,58,59,61,64,65,66,67,68,69,70,71,72,74,76,77,80,81,82,84,85,86,87,89,90,91,92,95,96,97,99,101,102,103,105,106,108,109,110,111,113,114,115,116,119,123,126,128,129,131,133,134,137,139,140,141,143,145,146,148,149,151,152,158,159,161,165,166,169,174,175,178,179,180,184,185,187,189] |

| Bluetooth (7) | [28,75,79,100,144,156,188] |

| Lorawan (4) | [120,132,136,182] |

| Zigbee (1) | [29] |

| Cellular technologies 2G (GSM/GPRS) and 4G. (7) | [98,104,130,153,168,176,183] |

| Cellular technologies 2G (GSM/GPRS) and 4G coupled to other technologies (Wi-Fi, zigbee, lorawan, bluetooth, ethernet) (12) | Cellular technologies + Wi-Fi: [60,107,173,181,186] Cellular technologies + zigbee: [138,170] Cellular technologies + lorawan or RF868: [73,171,172] Cellular technologies + lorawan + ethernet: [47] Cellular technologies + Wi-Fi + bluetooth: [63] |

| Wi-Fi coupled to others (bluetooth, zigbee, lorawan, ethernet) (5) | Wi-Fi + ethernet: [121] Wi-Fi + bluetooth: [125,155] Wi-Fi + lorawan: [124] Wi-Fi + zigbee + ethernet: [62] |

| Ethernet (2) | [78,94] |

| N/A (21) | [35,46,50,52,56,83,88,93,112,117,118,122,127,135,142,150,157,162,164,177,190] |

| Category (Qty of References) | Tool | References |

|---|---|---|

| Cloud platform (74) | Alibaba | [61,114,176] |

| Aliyun | [133] | |

| AWS | [73,106,155] | |

| Firebase | [30,53,81,84,101,107,127,178,187] | |

| Losant | [92] | |

| Blynk | [33,49,50,54,57,58,66,69,70,71,74,80,91,110,119,126,131,137,169] | |

| Blynk/ThingSpeak | [67,129,157] | |

| Blynk/Thingspeak/AWS | [105,111] | |

| ThingSpeak | [34,35,48,51,59,60,72,76,77,83,87,90,96,102,104,116,122,128,139,146,148,158,159,168,175,179,181] | |

| VK Cloud | [47] | |

| Ubidot | [134] | |

| Google Cloud | [62] | |

| In.IoT | [86] | |

| Kaggle | [135] | |

| oneNET | [185] | |

| Self-hosted (11) | Grafana | [123] |

| Thingsboard | [143,171,174,180] | |

| NodeRed | [32,99,124,132,145] | |

| Thinger.io | [165] | |

| Other (1) | GoDaddy | [120] |

| N/A (62) | [28,29,31,46,52,55,56,63,64,68,75,78,79,82,85,88,89,93,94,95,97,98,100,103,108,109,112,113,115,117,118,121,125,130,136,138,140,141,142,144,148,149,150,151,152,153,156,161,162,164,166,170,172,173,177,182,183,184,186,188,189,190] |

| Category (Qty of References) | Applications | References |

|---|---|---|

| Agriculture (45) | Animal farming: chicken farming, poultry farming, rabbitry farming. Agroindustry, onion farming, livestock odor. | [48,52,53,55,61,62,64,65,66,67,72,74,78,80,91,95,98,101,105,106,108,109,113,117,119,120,123,127,134,137,138,141,143,146,148,149,150,152,162,170,171,172,179,181,183] |

| Environmental (46) | Air and water quality, odor pollution, landfill, sewage and biogas facilities, wastewater management, sewage treatment plant. | [32,34,46,47,57,58,60,70,75,81,82,83,86,87,88,90,92,96,97,102,107,111,116,121,125,128,130,136,139,140,145,153,155,157,158,159,164,165,166,168,174,180,182,184,188,190] |

| Industrial Safety (16) | Hazardous area, gas leakage, industrial ambient, mines, industrial sewage outlet. | [28,29,50,59,73,76,77,79,84,94,100,103,110,112,115,132] |

| Aquaculture (17) | Aquaculture, aquaponics. | [51,71,89,93,104,122,131,135,142,151,173,175,178,185,186,187,189] |

| Smart Cities (7) | Smart Trash Bin, smart room, manhole, sewers, Subsurface, gas drainage. | [30,54,63,68,69,118,124] |

| Healthcare (5) | Medicine, Animal laboratory, Space disinfection, Pet house | [35,114,129,133,176] |

| Food Industry (5) | Freshness food, Food industry. | [49,56,85,144,169] |

| Research & Labs (7) | Laboratory, quality assessment. | [31,33,99,126,156,161,177] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva, A.H.M.C.; da Silva, M.K.; Santos, A.; Gómez-Malagón, L.A. A Systematic Review for Ammonia Monitoring Systems Based on the Internet of Things. IoT 2025, 6, 66. https://doi.org/10.3390/iot6040066

da Silva AHMC, da Silva MK, Santos A, Gómez-Malagón LA. A Systematic Review for Ammonia Monitoring Systems Based on the Internet of Things. IoT. 2025; 6(4):66. https://doi.org/10.3390/iot6040066

Chicago/Turabian Styleda Silva, Adriel Henrique Monte Claro, Mikaelle Karoline da Silva, Augusto Santos, and Luis Arturo Gómez-Malagón. 2025. "A Systematic Review for Ammonia Monitoring Systems Based on the Internet of Things" IoT 6, no. 4: 66. https://doi.org/10.3390/iot6040066

APA Styleda Silva, A. H. M. C., da Silva, M. K., Santos, A., & Gómez-Malagón, L. A. (2025). A Systematic Review for Ammonia Monitoring Systems Based on the Internet of Things. IoT, 6(4), 66. https://doi.org/10.3390/iot6040066