Performance Assessment of a Vibratory-Enhanced Plowing System for Improved Energy Efficiency and Tillage Quality on Compacted Soils

Abstract

1. Introduction

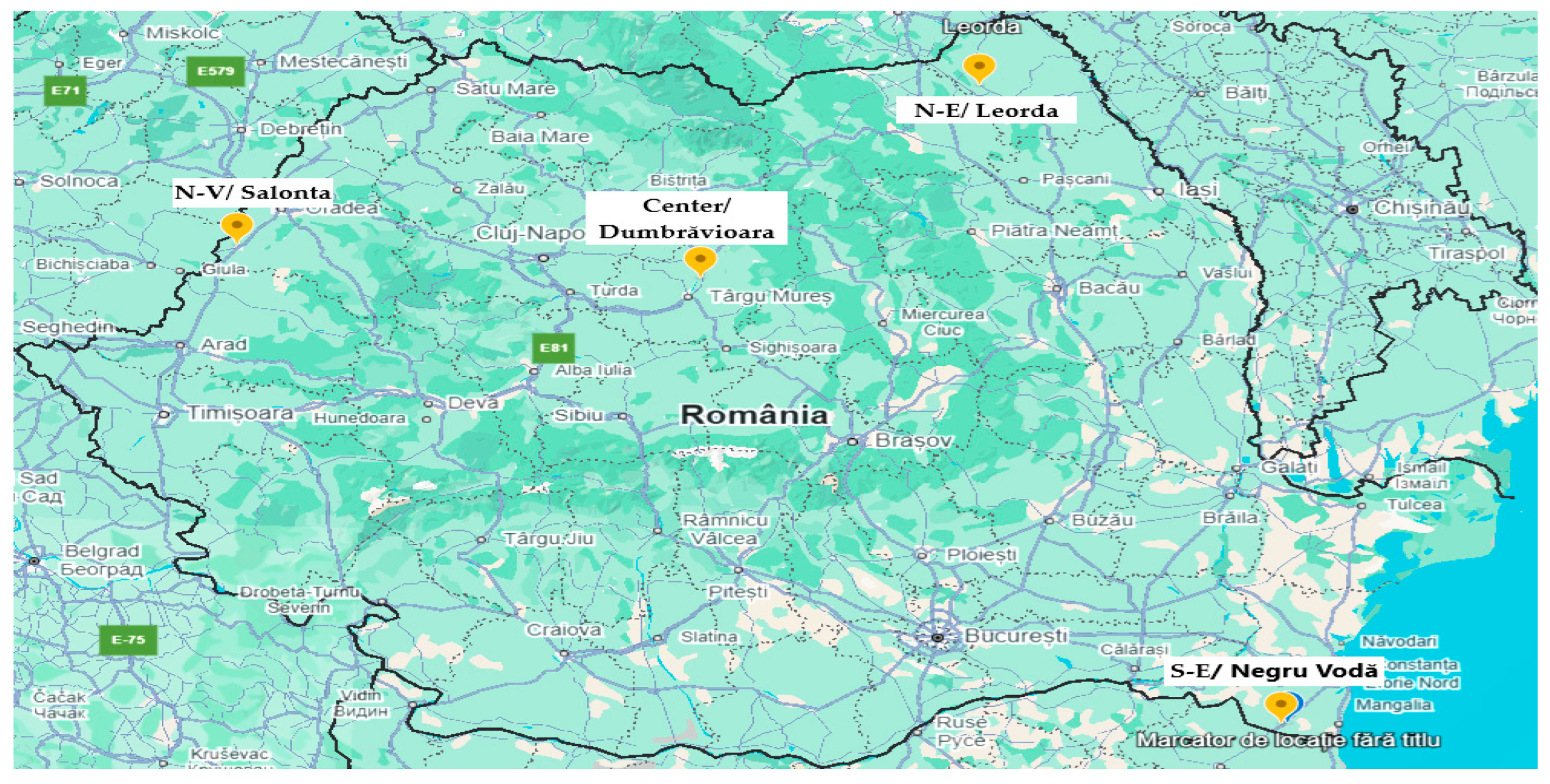

2. Materials and Methods

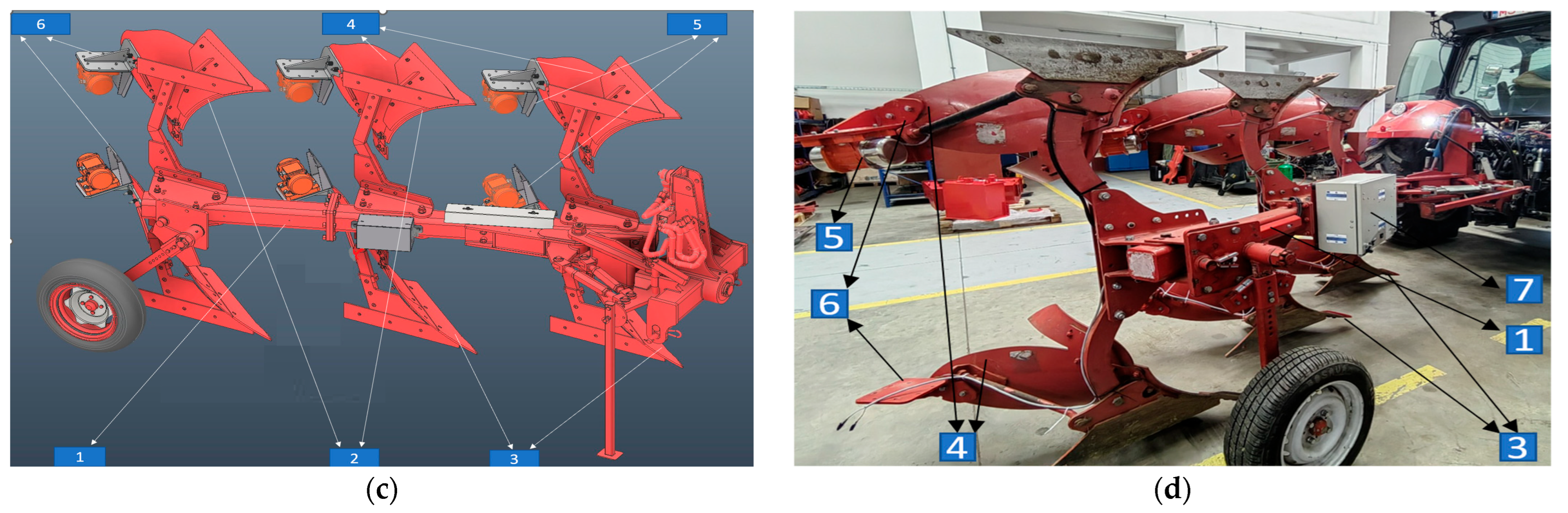

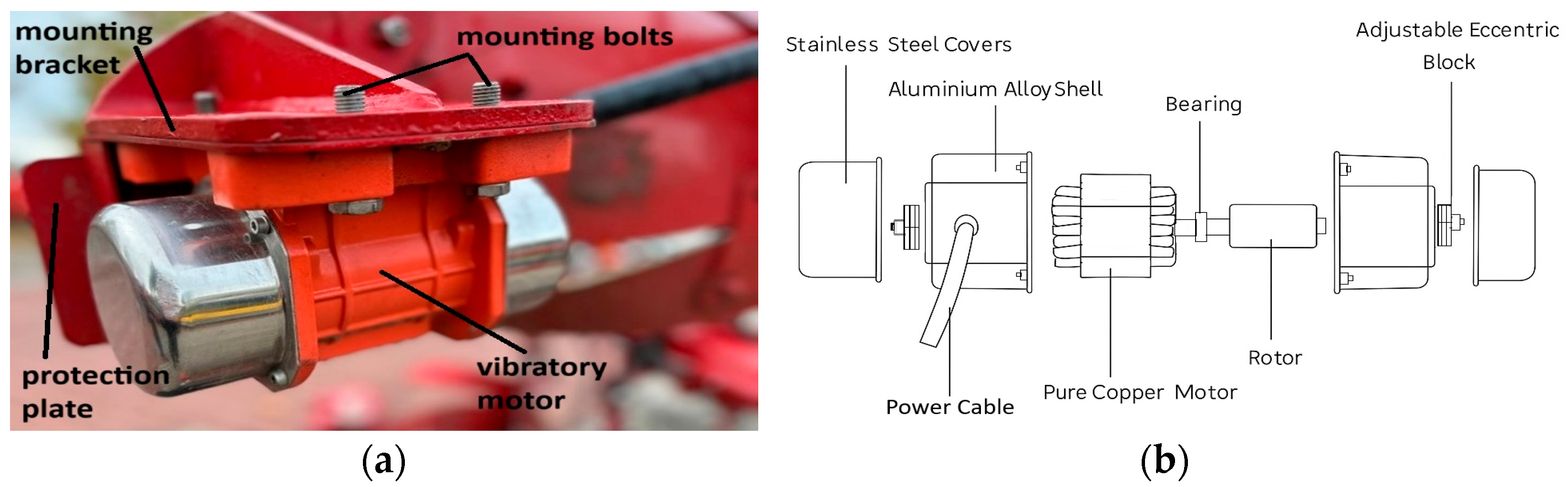

2.1. Design and Functional Description of the Proposed Vibrotillage Technology

2.2. Experimental Setup: Instrumentation and Control Tools Employed in Field Testing

2.3. Statistical Analysis

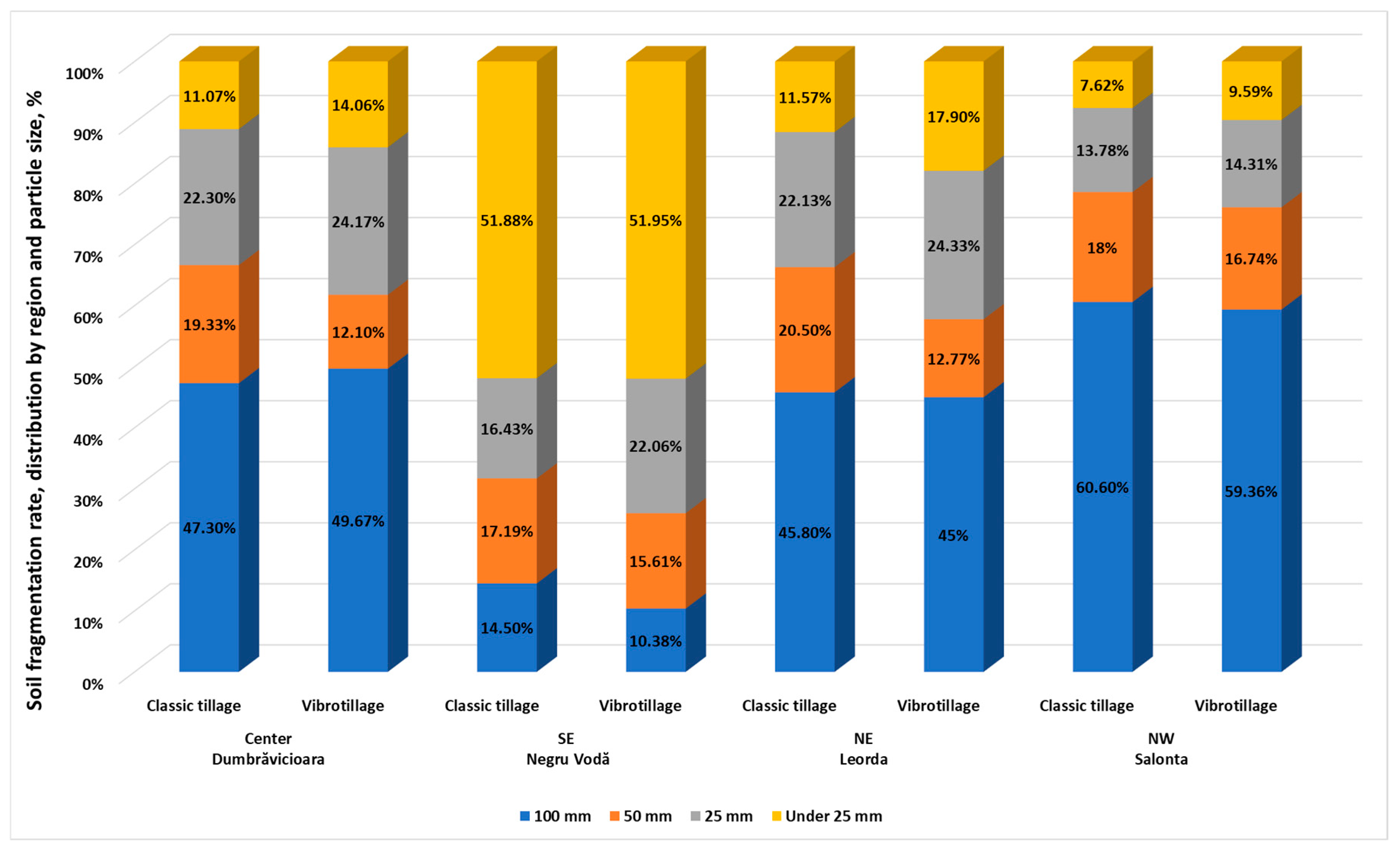

3. Results

3.1. Determining Soil Characteristics

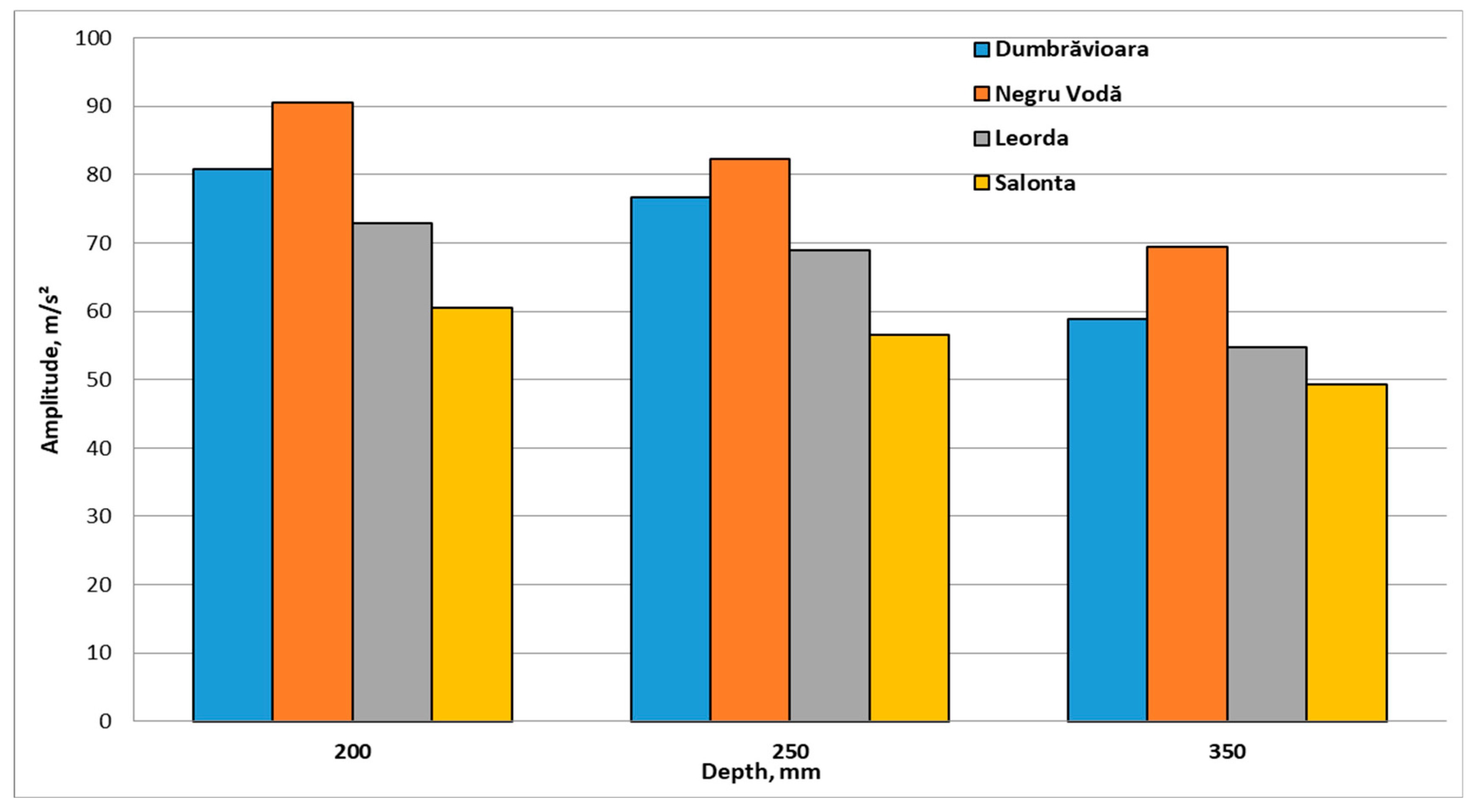

3.2. Average Amplitude as a Function of Phase Shift and Plow Body

4. Discussion

4.1. Vibration Efficiency and Equipment Protection

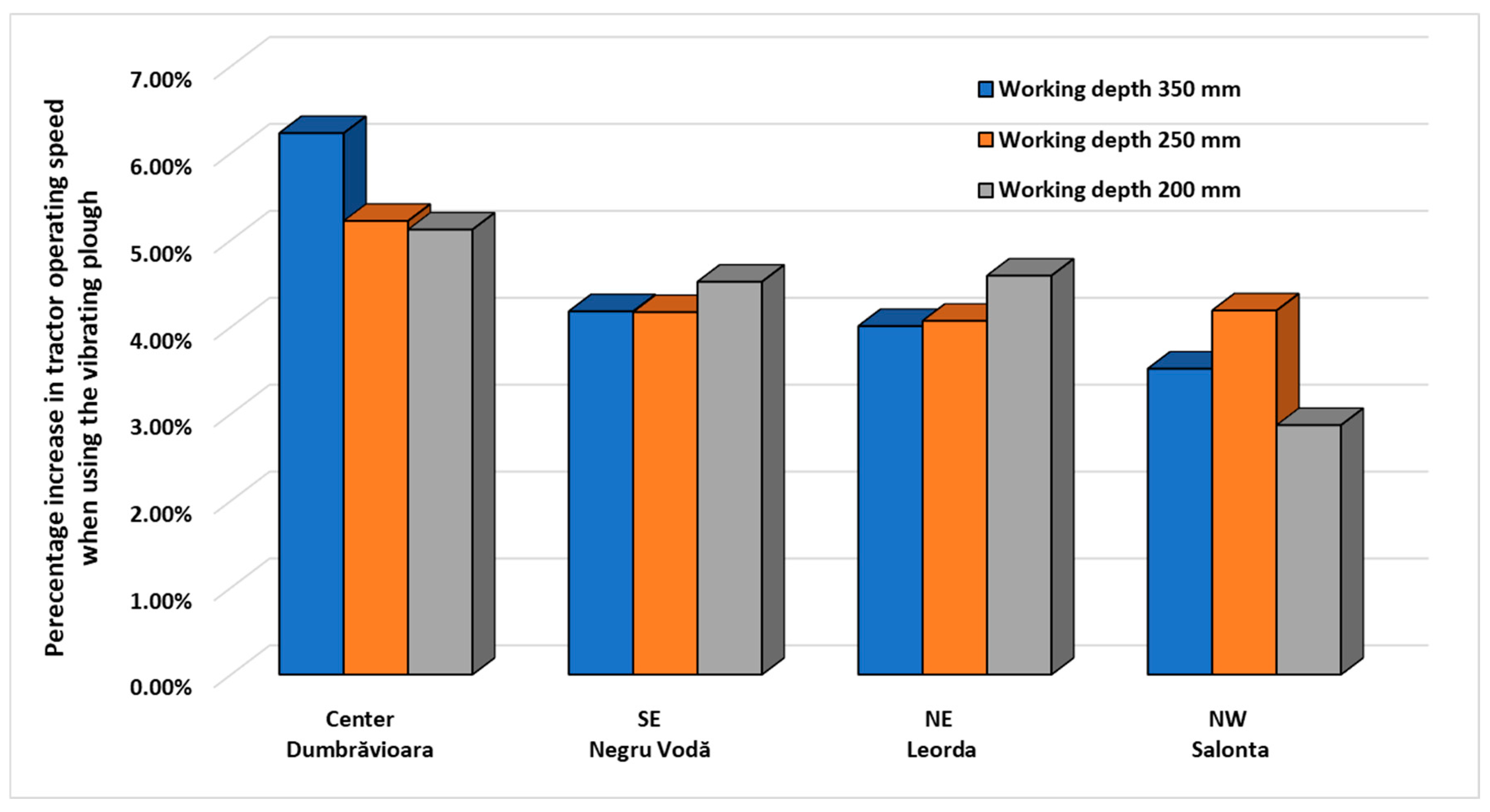

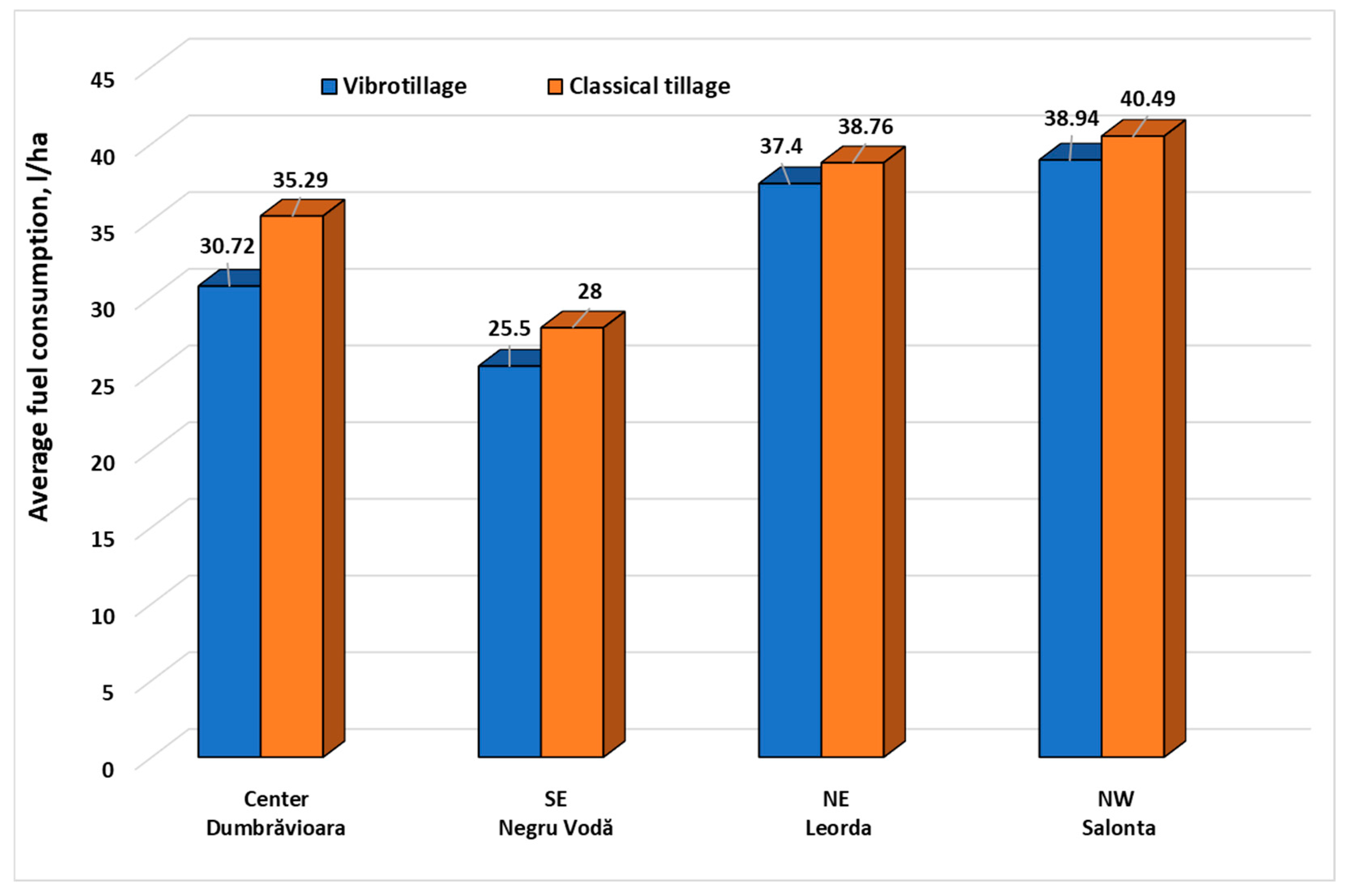

4.2. Analysis of Increasing Tractor Work Efficiency on Difficult Soils by Using Vibrotillage

4.3. Research Perspectives and Technological Challenges

5. Conclusions

5.1. Influence of Vibrotillage on Soil and Fauna

5.2. Research Recommendations and Limitations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manuwa, S. Performance evaluation of tillage tines operating under different depths in a sandy clay loam soil. Soil Tillage Res. 2009, 103, 399–405. [Google Scholar] [CrossRef]

- Ucgul, M.; Chang, C.-L. Design and Application of Agricultural Equipment in Tillage Systems. Agriculture 2023, 13, 790. [Google Scholar] [CrossRef]

- Oprescu, M.R.; Biris, S.-S.; Nenciu, F. Novel Furrow Diking Equipment-Design Aimed at Increasing Water Consumption Efficiency in Vineyards. Sustainability 2023, 15, 2861. [Google Scholar] [CrossRef]

- Romaneckas, K. Sustainable Tillage and Sowing Technologies. Agronomy 2022, 12, 2467. [Google Scholar] [CrossRef]

- Xu, G.; Xie, Y.; Peng, S.; Liang, L.; Ding, Q. Performance Evaluation of Vertical Discs and Disc Coulters for Conservation Tillage in an Intensive Rice–Wheat Rotation System. Agronomy 2023, 13, 1336. [Google Scholar] [CrossRef]

- Nenciu, F.; Oprescu, M.R.; Biris, S.-S. Improve the Constructive Design of a Furrow Diking Rotor Aimed at Increasing Water Consumption Efficiency in Sunflower Farming Systems. Agriculture 2022, 12, 846. [Google Scholar] [CrossRef]

- Popescu, E.; Nenciu, F.; Vladut, V. A new strategic approach used for the regeneration of soil fertility, in order to improve the productivity in ecological systems. Sci. Pap.-Ser. E-Land Reclam. Earth Obs. Surv. Environ. Eng. 2022, 11, 277–284. [Google Scholar]

- Hettiaratchi, D. Theoretical Soil Mechanics and Implement Design. Soil Tillage Res. 1988, 11, 325–347. [Google Scholar] [CrossRef]

- Mouazen, A.M.; Neményi, M.; Schwanghart, H.; Rempfer, M. Tillage tool design by the finite element method: Part 2. Experimental validation of the finite element results with soil bin test. J. Agric. Eng. Res. 1999, 72, 53–58. [Google Scholar] [CrossRef]

- Nenciu, F.; Fatu, V.; Arsenoaia, V.; Persu, C.; Voicea, I.; Vladut, N.-V.; Matache, M.G.; Gageanu, I.; Marin, E.; Biris, S.-S.; et al. Bioactive Compounds Extraction Using a Hybrid Ultrasound and High-Pressure Technology for Sustainable Farming Systems. Agriculture 2023, 13, 899. [Google Scholar] [CrossRef]

- Shahgoli, G.; Saunders, C.; Desbiolles, J.; Fielke, J. The effect of oscillation angle on the performance of oscillatory tillage. Soil Tillage Res. 2009, 104, 97–105. [Google Scholar] [CrossRef]

- Rao, G.; Chaudhary, H. A review on effect of vibration in tillage application. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012030. [Google Scholar] [CrossRef]

- Sahay, C.S.; Thomas, E.V.; Satapathy, K.K. Performance evaluation of a novel powertiller-operated oscillatory tillage implement for dry land tillage. Biosyst. Eng. 2009, 102, 385–391. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, D.; Yang, L.; Cui, T.; Jing, H.; Zhong, X. Modeling the Interaction of Soil and a Vibrating Subsoiler Using the Discrete Element Method. Comput. Electron. Agric. 2020, 174, 105518. [Google Scholar] [CrossRef]

- Bandalan, E.; Salokhe, V.; Gupta, C.; Niyamapa, T. Performance of an oscillating subsoiler in breaking a hardpan. J. Terramech. 1999, 36, 117–125. [Google Scholar] [CrossRef]

- Niyamapa, T.; Salokhe, V. Force and Pressure Distribution under Vibratory Tillage tool. J. Terramech. 2000, 37, 139–150. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, Y.; Hu, Y.; Han, X.; Feng, K.; Li, P.; Wei, X.; Zhai, C. Study on Operating Vibration Characteristics of Different No-Tillage Planter Row Units in Wheat Stubble Fields. Agriculture 2024, 14, 1878. [Google Scholar] [CrossRef]

- Marín-Cabrera, L.O.; García de la Figal-Costales, A.E.; Martínez-Rodríguez, A. Effect of Vibrations and Operational Parameters on the Frequency and Amplitude of a Vibratory Subsoiler. Rev. Cienc. Técnicas Agropecu. 2021, 30, e03. [Google Scholar]

- Li, Y.; Yu, M.; Liu, H.; Wang, J.; Guo, Q. Analysis of Vibration Characteristics of Tractor–Rotary Cultivator. Agriculture 2024, 14, 1139. [Google Scholar] [CrossRef]

- Soltani, M.; Hemmat, A.; Alimardani, R. Evaluation and Analysis of Whole-Body Vibration Exposure during Soil Tillage Operation. Environments 2020, 7, 61. [Google Scholar]

- Krause, A.; Wróbel, M.; Słowiński, M. Field Evaluation of a Vibrating Dual Bent-Share Cultivator. Res. Agric. Eng. 2020, 66, 123–130. [Google Scholar] [CrossRef]

- Gupta, C.P.; Rajput, D.S. Effect of amplitude and frequency on soil break-up by an oscillating tillage tool in a soil bin experiment. Soil Tillage Res. 1993, 25, 329–338. [Google Scholar] [CrossRef]

- Available online: https://www.proconsilgrup.ro/vibratoare-electrice-industriale/ (accessed on 25 August 2025).

- Hettiaratchi, D.R.P.; Witney, B.D.; Reece, A.R. The calculation of passive pressure in two-dimensional soil failure. J. Agric. Eng. Res. 1966, 11, 89–107. [Google Scholar] [CrossRef]

- Mouazen, A.M.; Neményi, M. Tillage tool design by the finite element method: Part 1. Finite element modelling of soil plastic behaviour. J. Agric. Eng. Res. 1999, 72, 37–51. [Google Scholar] [CrossRef]

| Evaluated Site | Design Type | Compared Treatments | Parcels per Block | Replicates per Treatment | Total Raw Values per Treatment per Region 3 × No. of Blocks |

|---|---|---|---|---|---|

| Dumbrăvioara | Randomized complete block design | Conventional plowing (classic) vs. vibrotillage | 2 (parallel parcels per treatment) | 3 | ≥9 |

| Negru Vodă | Randomized complete block design | Conventional plowing (classic) vs. vibrotillage | 2 (parallel parcels per treatment) | 3 | ≥9 |

| Leorda | Randomized complete block design | Conventional plowing (classic) vs. vibrotillage | 2 (parallel parcels per treatment) | 3 | ≥9 |

| Salonta | Randomized complete block design | Conventional plowing (classic) vs. vibrotillage | 2 (parallel parcels per treatment) | 3 | ≥9 |

| Region Center Dumbrăvioara | The predominant soils in the hilly plateau and intra-montane depression regions are reddish-brown, exhibiting a pH range from weakly acidic to neutral. These soils are susceptible to erosion and waterlogging. The climate in these areas is relatively cooler compared to other regions of Romania, with an average annual temperature ranging between 8.5 °C and 9 °C and annual precipitation levels of 600–750 mm. At the time of the experiment, the soil exhibited a high degree of compaction, while the vegetation had a density of 760 g/m2 and a height between 9 and 12 cm. The previous crop cultivated was wheat, managed under a conventional agricultural system. |

| Region SE Negru Vodă | The soils of the arid plateau are predominantly sandy soils, exhibiting neutral to slightly acidic pH values. These soils are vulnerable to wind erosion and drought conditions. The climate in this region is warmer compared to other parts of Romania, with an average annual temperature ranging from 11 °C to 11.5 °C and annual precipitation between 350 and 450 mm. At the time of the experiment, the vegetation showed a density of 550 g/m2 and a height up to 23 cm. The previous crop culture was barley, managed under a conventional farming system. |

| Region NE Leorda | Predominantly found in the plateau region are Chernozem soils, characterized by acidic pH values. These soils are susceptible to erosion processes. The local climate is relatively warmer compared to other Romanian regions and an average annual precipitation ranging from 500 to 600 mm. At the time of the experiment, the soil exhibited high compaction, while the vegetation presented a density of 820 g/m2 and a height between 7 and 14 cm. The preceding crop cultivated was peas, managed under a conventional agricultural system. |

| Region NW Salonta | The predominant soils in the lowland areas are Chernozems, exhibiting a weakly alkaline to neutral pH. These soils are susceptible to waterlogging. The climate in this region is warmer compared to other parts of Romania, with an average annual precipitation between 550 and 650 mm. At the time of the experiment, the soil was heavily compacted, and the vegetation displayed a density of 410 g/m2 with heights ranging from 10 to 15 cm. The previous crop cultivated was corn, managed under a conventional farming system. |

| Region/ Locality | Soil Resistance to Penetration (kPa) | Soil Moisture (%) |

|---|---|---|

| Center/Dumbrăvioara | 2528 | 19.0 |

| SE/Negru Vodă | 1724 | 11.05 |

| NE/Leorda | 2505 | 10.1 |

| NW/Salonta | 3155 | 10.73 |

| Region/ Location | System | Working Depth (mm) | Plant Mass Residue on Soil Surface (%) | |||

|---|---|---|---|---|---|---|

| Measured | Established | Plot 1 | Plot 2 | Plot 3 | ||

| Center/ Dumbrăvioara | Classic tillage | 340 | 350 | 6.6 | 6.6 | 13.2 |

| Vibrotillage | 6.6 | 3.3 | 3.3 | |||

| Classic tillage | 245 | 250 | 13.2 | 13.2 | 16.45 | |

| Vibrotillage | 3.3 | 6.6 | 13.2 | |||

| Classic tillage | 203 | 200 | 5.25 | 9.85 | 6.6 | |

| Vibrotillage | 3.3 | 3.95 | 4.6 | |||

| SE/ Negru Vodă | Classic tillage | 337 | 350 | 9.1 | 10.9 | 14.5 |

| Vibrotillage | 5.5 | 4.5 | 4.5 | |||

| Classic tillage | 248 | 250 | 12.7 | 14.5 | 16.4 | |

| Vibrotillage | 10.9 | 10.9 | 12.7 | |||

| Classic tillage | 205 | 200 | 18.2 | 22.7 | 27.3 | |

| Vibrotillage | 16.4 | 18.2 | 18.2 | |||

| NE/ Leorda | Classic tillage | 305 | 350 | 8.5 | 9.8 | 8.5 |

| Vibrotillage | 7.3 | 7.3 | 6.1 | |||

| Classic tillage | 246 | 250 | 9.8 | 8.5 | 6.1 | |

| Vibrotillage | 7.3 | 6.1 | 8.5 | |||

| Classic tillage | 197 | 200 | 4.9 | 7.3 | 4.9 | |

| Vibrotillage | 3.7 | 4.9 | 4.9 | |||

| NW/ Salonta | Classic tillage | 346 | 350 | 14.6 | 17.1 | 14.6 |

| Vibrotillage | 14.6 | 14.6 | 14. 6 | |||

| Classic tillage | 295 | 250 | 22 | 19.6 | 19.6 | |

| Vibrotillage | 17.1 | 17.1 | 19.6 | |||

| Classic tillage | 249 | 200 | 24.4 | 26.8 | 24.4 | |

| Vibrotillage | 22 | 22 | 22 | |||

| Center Dumbrăvioara | SE Negru Vodă | NE Leorda | NW Salonta | |||||

|---|---|---|---|---|---|---|---|---|

| Average Working Depth (mm) | Average Travel Speed (km/h) | Average Working Depth (mm) | Average Travel Speed (km/h) | Average Working Depth (mm) | Average Travel Speed (km/h) | Average Working Depth (mm) | Average Travel Speed (km/h) | |

| Classic tillage | 350 | 3.61 | 350 | 5.04 | 350 | 2.63 | 350 | 3.29 |

| Vibrotillage | 3.85 | 5.26 | 2.74 | 3.41 | ||||

| Classic tillage | 250 | 3.99 | 250 | 5.05 | 250 | 2.12 | 250 | 3.43 |

| Vibrotillage | 4.21 | 5.27 | 2.21 | 3.58 | ||||

| Classic tillage | 200 | 4.05 | 200 | 5.07 | 200 | 2.08 | 200 | 3.38 |

| Vibrotillage | 4.27 | 5.31 | 2.18 | 3.48 | ||||

| Gear | System | Average Working Depth (mm) | Tractor Wheel Slippage (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Center Dumbrăvioara | SE Negru Vodă | NE Leorda | NW Salonta | |||||||

| Left Wheel | Right Wheel | Left Wheel | Right Wheel | Left Wheel | Right Wheel | Left Wheel | Right Wheel | |||

| V1 | Classic tillage | 350 | 22.67 | 29.29 | 10.32 | 10.32 | 16.17 | 16.17 | 26.26 | 26.26 |

| Vibrotillage | 20.8 | 22.67 | 7.33 | 10.32 | 16.17 | 11.12 | 26.26 | 26.26 | ||

| V2 | Classic tillage | 22.67 | 23.85 | 13.13 | 13.13 | 21.21 | 21.21 | 23.74 | 23.74 | |

| Vibrotillage | 20.8 | 20.8 | 10.32 | 13.13 | 13.64 | 16.17 | 23.74 | 23.74 | ||

| V3 | Classic tillage | 22.67 | 23.85 | 10.32 | 7.33 | 6.01 | 11.12 | 28.79 | 26.26 | |

| Vibrotillage | 20.8 | 20.8 | 7.33 | 10.32 | 6.01 | 11.12 | 26.26 | 26.26 | ||

| V1 | Classic tillage | 250 | 22.67 | 23.85 | 10.32 | 13.13 | 6.01 | 6.01 | 26.26 | 26.26 |

| Vibrotillage | 20.8 | 20.8 | 10.32 | 10.32 | 1.01 | 6.01 | 23.74 | 26.26 | ||

| V2 | Classic tillage | 17.5 | 20.8 | 10.32 | 13.13 | 11.12 | 11.12 | 26.26 | 26.26 | |

| Vibrotillage | 12 | 13.91 | 7.33 | 10.32 | 11.12 | 6.01 | 23.74 | 23.74 | ||

| V3 | Classic tillage | 17.5 | 20.8 | 15.76 | 15.76 | 6.01 | 1.01 | 26.26 | 23.74 | |

| Vibrotillage | 10 | 13.91 | 13.13 | 15.76 | 1.01 | 1.01 | 26.26 | 26.26 | ||

| V1 | Classic tillage | 200 | 10 | 13.91 | 10.32 | 13.13 | 6.01 | 6.01 | 23.74 | 23.74 |

| Vibrotillage | 5.71 | 10 | 10.32 | 13.13 | 1.01 | 1.01 | 18.69 | 21.21 | ||

| V2 | Classic tillage | 7.91 | 13.91 | 10.32 | 13.13 | 11.12 | 11.12 | 21.21 | 23.74 | |

| Vibrotillage | 10 | 10 | 10.32 | 10.32 | 6.01 | 11.12 | 21.21 | 21.21 | ||

| V3 | Classic tillage | 5.71 | 10 | 10.32 | 13.13 | 6.01 | 6.01 | 21.21 | 21.21 | |

| Vibrotillage | 5.71 | 10 | 7.33 | 10.32 | 6.01 | 6.01 | 16.16 | 16.16 | ||

| Average Traction Force (daN) | ||||||

|---|---|---|---|---|---|---|

| Gear | System | Average Working Depth (mm) | Center Dumbrăvioara | SE Negru Vodă | NE Leorda | NW Salonta |

| V1 | Classic tillage | 350 | 3178.3 | 2444.67 | 2718.91 | 2607.83 |

| Vibrotillage | 3022.1 | 1971.20 | 2597.92 | 2399.49 | ||

| V2 | Classic tillage | 3199.1 | 2856.09 | 2701.35 | 2587.77 | |

| Vibrotillage | 3106.1 | 2587.41 | 2657.43 | 2381.70 | ||

| V3 | Classic tillage | 3202.7 | 2920.22 | 2737.12 | 2524.13 | |

| Vibrotillage | 3028.96 | 2745.35 | 2568.22 | 2464.10 | ||

| V1 | Classic tillage | 250 | 2696.7 | 2478.09 | 2181.65 | 2417.08 |

| Vibrotillage | 2583.3 | 2297.68 | 2100.72 | 2345.90 | ||

| V2 | Classic tillage | 2505.7 | 2280.89 | 2387.69 | 2431.33 | |

| Vibrotillage | 2101.7 | 1912.29 | 1915.18 | 2289.81 | ||

| V3 | Classic tillage | 2785.9 | 2544.18 | 2567.81 | 2349.59 | |

| Vibrotillage | 2692.6 | 2439.93 | 2413.10 | 2110.93 | ||

| V1 | Classic tillage | 200 | 2123.6 | 2181.98 | 1878.60 | 2005.41 |

| Vibrotillage | 1966.2 | 1939.87 | 1741.77 | 1850.87 | ||

| V2 | Classic tillage | 2031.3 | 2160.42 | 1602.29 | 2014.02 | |

| Vibrotillage | 2123.2 | 1862.68 | 1555.87 | 1899.82 | ||

| V3 | Classic tillage | 2245.4 | 2032.15 | 1792.60 | 2029.27 | |

| Vibrotillage | 2091.9 | 1789.14 | 1715.39 | 1869.71 | ||

| Region/ Locality | Vibrotillage | Classic Tillage | Fuel Gain (L/ha) | ||

|---|---|---|---|---|---|

| Average Operating Speed (km/h) | Average Fuel Consumption (L/ha) | Average Operating Speed (km/h) | Average Fuel Consumption (L/ha) | ||

| Center/Dumbrăvioara | 3.85 | 30.72 | 3.61 | 35.29 | 4.57 |

| SE/Negru Vodă | 5.26 | 25.5 | 5.04 | 28 | 2.5 |

| NE/Leorda | 2.74 | 37.40 | 2.63 | 38.76 | 1.36 |

| NW/Salonta | 3.41 | 38.94 | 3.29 | 40.49 | 1.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vlădutoiu, L.C.; Marin, E.; Nenciu, F.; Lateș, D.; Persu, I.C.; Cristea, M.; Manea, D. Performance Assessment of a Vibratory-Enhanced Plowing System for Improved Energy Efficiency and Tillage Quality on Compacted Soils. AgriEngineering 2025, 7, 304. https://doi.org/10.3390/agriengineering7090304

Vlădutoiu LC, Marin E, Nenciu F, Lateș D, Persu IC, Cristea M, Manea D. Performance Assessment of a Vibratory-Enhanced Plowing System for Improved Energy Efficiency and Tillage Quality on Compacted Soils. AgriEngineering. 2025; 7(9):304. https://doi.org/10.3390/agriengineering7090304

Chicago/Turabian StyleVlădutoiu, Laurentiu Constantin, Eugen Marin, Florin Nenciu, Daniel Lateș, Ioan Catalin Persu, Mario Cristea, and Dragoș Manea. 2025. "Performance Assessment of a Vibratory-Enhanced Plowing System for Improved Energy Efficiency and Tillage Quality on Compacted Soils" AgriEngineering 7, no. 9: 304. https://doi.org/10.3390/agriengineering7090304

APA StyleVlădutoiu, L. C., Marin, E., Nenciu, F., Lateș, D., Persu, I. C., Cristea, M., & Manea, D. (2025). Performance Assessment of a Vibratory-Enhanced Plowing System for Improved Energy Efficiency and Tillage Quality on Compacted Soils. AgriEngineering, 7(9), 304. https://doi.org/10.3390/agriengineering7090304