Advancements in Thin-Film Thermoelectric Generator Design for Agricultural Applications

Abstract

1. Introduction

- What are the ideal materials for use in the fabrication of thin film thermoelectric generators? This is answered in Section 3.

- What are the key advancements in thermoelectric generator design on topics such as their substrate characteristics, integration with flexible circuits, co-design with other materials, and their integration with artificial intelligence? This is answered in Section 5.

- A comparative analysis of different thermoelectric materials used in TEGs alongside their fabrication, deposition, and processing techniques.

- A discussion and comparison of different literature showcasing the applications of TEGs in the agricultural setting.

- A technical analysis of the advancements in AI-integration in the field of thermoelectric generators, their general process flow, and a discussion of the various literature, or lack thereof. A discussion on various literature on advancements in thin-film TEG design was provided.

- A scientific elucidation of the general research trends in the field of thermoelectric generators as well as other points of possible development such as AI-integration, material discovery, and other possible applications for TEGs.

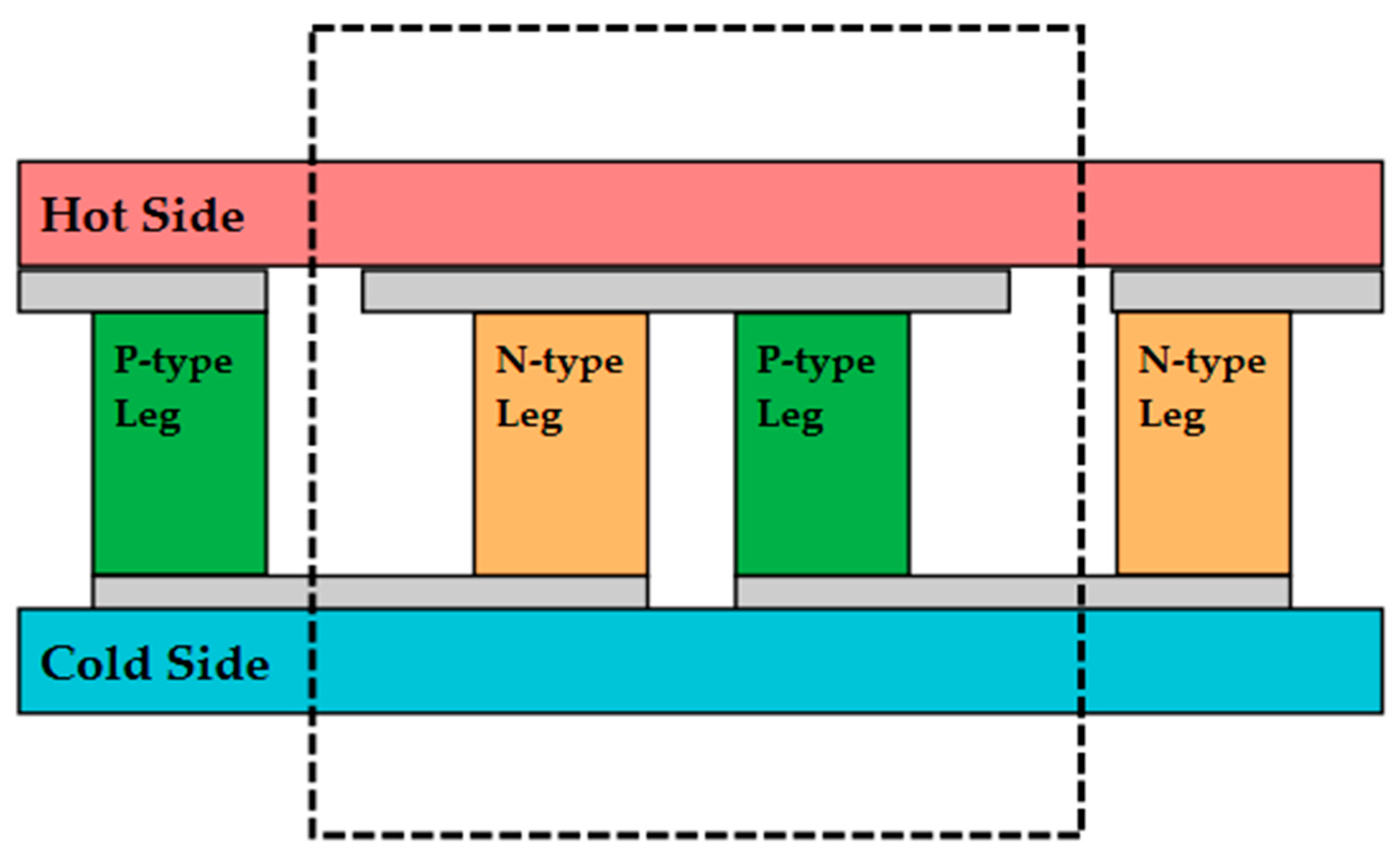

2. Thermoelectric Effect and Thin-Film Thermoelectric Generators

| Property | Formula | Description and Symbols | Reference |

|---|---|---|---|

| Seeback Effect | where S is the Seebeck coefficient, ∆V is the thermal voltage, and ∆T is the temperature difference between the hot and cold sides of the TEG. | [22,27] | |

| Figure of Merit | Where zT is the Figure of Merit, is the electrical conductivity, T is the absolute temperature; and is the thermal conductivity. | [23,28,29] | |

| Thermal Efficiency | is the thermoelectric thermal efficiency, is the Carnot efficiency; and zT is the Figure of merit. | [22,27,28] | |

| Carnot Efficiency | Where is the temperature of the hot side, and is the material of the cold side. | [22,27] | |

| Heat transfer through high temperature contact | Where A is the cross-sectional area, l is the length of the leg, is the resistivity, and I is the current. | [22,27,29] | |

| Heat transfer through low temperature contact | No new term introduced | [22,27,29] | |

| Fill Factor | Where is the cross-sectional area of the p-type leg, is the cross-sectional area of the n-type leg, A is the total device area, And FF should be less than or equal to 1. | [22,28] | |

| Optimized TEG Output power | Where FF is the Fill Factor, and The external load resistance is equal to the internal electrical resistance of the TEG. | [22] |

| Use Case in Agriculture | Application Area | Mode of Integration | Mass per Unit Area (g cm−2) | Advantages | Limitations | References |

|---|---|---|---|---|---|---|

| Plant-wearable TEGs | Leaf and stem monitoring | Laminated to leaf surface or stem | Low (0.002–0.01 g cm−2) | Low-mass, non-invasive, monitors plant physiology, battery-free | Limited by small temperature gradient, sensitive to moisture and adhesion issues | [3,6] |

| Canopy-level TEGs | Microclimate sensing | Suspended or arrayed across canopy levels | Low–Moderate (0.003–0.02 g cm−2) | Enables distributed, energy-autonomous sensing, scalable in deployment | Complexity in installation, shading effects on plants | [3,31] |

| Stem-clipped TEGs | Xylem sap analysis | Clipped to thicker stems or fruit peduncles | Very Low (0.001–0.005 g cm−2) | Close contact with vascular flow, real-time monitoring of plant water transport | Limited stem area for mounting, potential mechanical stress on plant | [3] |

| Soil-embedded TEGs | Soil nutrient and mineral monitoring | Buried in topsoil or exposed to surface air near the soil | Moderate (0.005–0.03 g cm−2) | Applicable to smart irrigation, passive energy from natural thermal gradients | Soil compaction, moisture interference, possible corrosion | [30] |

| Greenhouse TEG arrays | Indoor cultivation environment monitoring | Mounted on panels or heat sources | High (0.01–0.05 g cm−2) | Utilizes controlled gradients, consistent in daily cycles, clean integration | Seasonal variation, need for optimized placement | [2,30] |

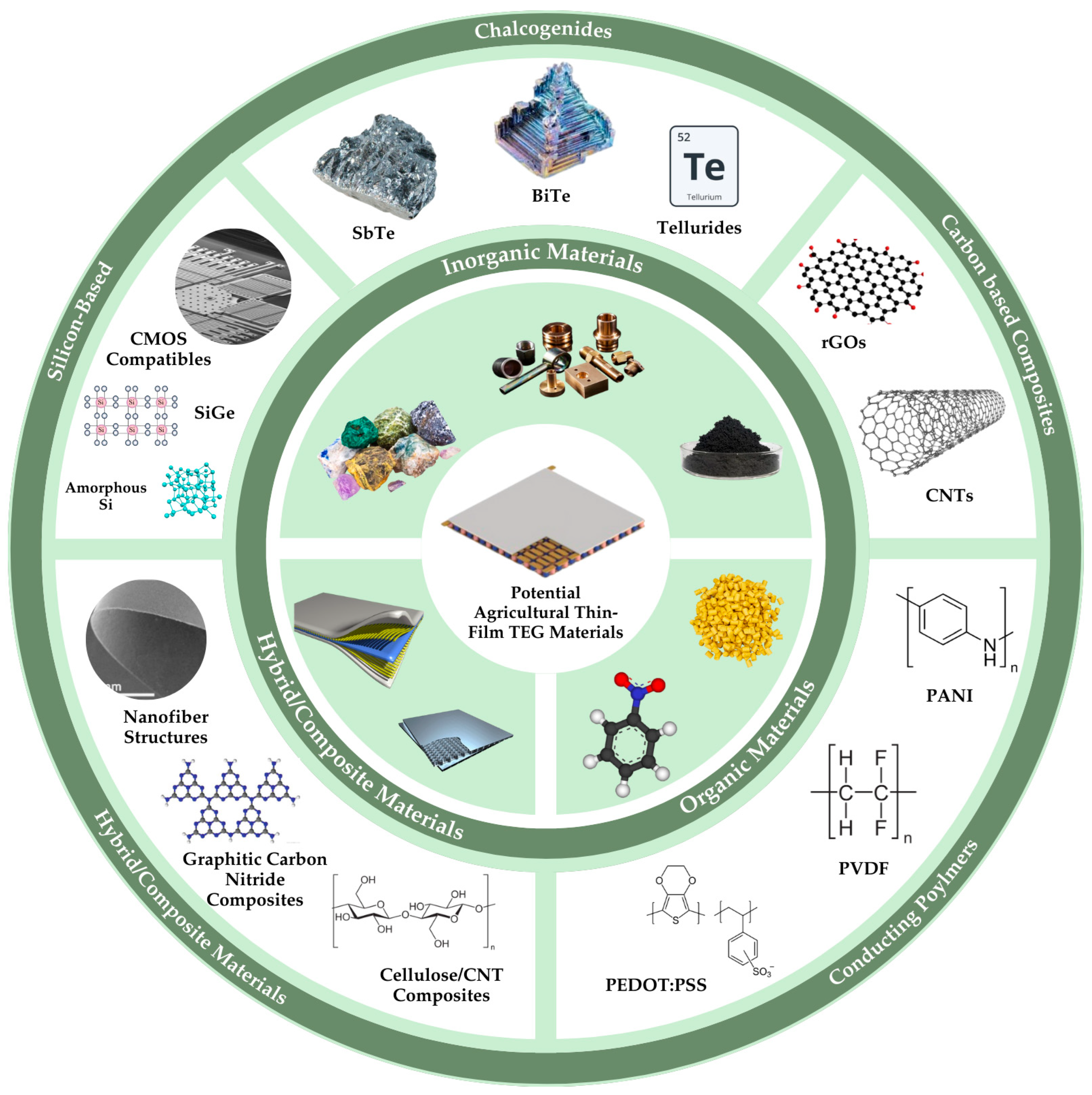

3. Chemistry of Thin-Film TEGs

3.1. Material Classification of Thin-Film TEGs

3.1.1. Inorganic Thin-Films

- Silicon-Based Materials

- Chalcogenide Materials

- Carbon Nanomaterials

- Other Inorganic TF Materials

3.1.2. Organic Thin-Films

- Conducting Polymers

3.1.3. Hybrid Thin-Films

3.2. Thin Film TEG Performance Evaluation and Practical Considerations

3.2.1. Economic and Scalability Considerations

3.2.2. Optical Activity and Light Material Interactions in Thin-Film TEG Materials

3.2.3. Performance Trends and Evaluation

3.3. Fabrication and Processing Techniques

3.3.1. Physical Deposition Techniques

3.3.2. Chemical Deposition Techniques

| Technique | Category | Advantages | Disadvantages | Ref. |

|---|---|---|---|---|

| Sputtering | Physical | Uniformity, adhesion, control over thickness, scalability | Requires high vacuum, expensive equipment, low throughput | [35,41,61] |

| Evaporation | Simple setup, fast deposition, good crystallinity, low cost | Poor Coverage, limited uniformity | [11] | |

| PLD/MBE | Nanostructuring, high control and purity, good interface | Small deposition area, low throughput, high cost | [62] | |

| Spin Coating | Uniformity, ease of control, low-cost and fast | Flat substrates only, solvent waste, Film cracking in thick layers | [64] | |

| Drop-Casting | Simplicity, low-cost, thick film deposition, suitability | Poor thickness control, non-homogeneous morphology | [63] | |

| Printing | Digital, low-waste, scalable, low cost | ink-formulation challenges, resolution-dependence, requires post processing | [53,55,64] | |

| USD/USSC | Uniformity, controlled porosity, waste reduction, scalable, versatile | Liquid delivery challenges, optimization complexity, material limitations, | [65,66] | |

| CVD | Chemical | Conformational coating, good compositional control | High-temp processing, toxic precursors | [36,67] |

| ALD/MLD | High thickness control, excellent uniformity and conformality | slow growth rate, high precursor cost | [68] | |

| Electrodeposition | Low-cost and scalable, compositional and morphological control | Substrate-dependent, film stress and adhesion issues | [69,70] | |

| In-situ Polymerization | Precise molecular ordering, controlled doping | limited choices for monomers, long processing time | [71] |

4. Biocompatibility and Eco-Stability of Thin-Film TEGs in Agricultural Environments

4.1. Interaction with Plant Tissues and Soil

4.2. Environment-Responsive Degradation and Encapsulation

5. Recent Advancements in Thin-Film TEG Design

5.1. Design Advancements in Thin-Film Thermoelectric Generators

5.2. Flexible and Stretchable Substrates for Conformal Applications and Integration with Flexible Printed Circuits and Biodegradable Electronics

5.3. Thin-Film Thermoelectric Generator Co-Design with Sensor Technology

5.4. Artificial Intelligence in the Context of Thermoelectric Generators

5.5. Device Layout, Structural Optimization, and Data-Driven Multiphysics Simulation

5.6. Surrogate Modeling of TEG Device Performance

5.7. AI-Assisted FEM

6. Future Directions and Implications

7. Conclusions and Recommendations

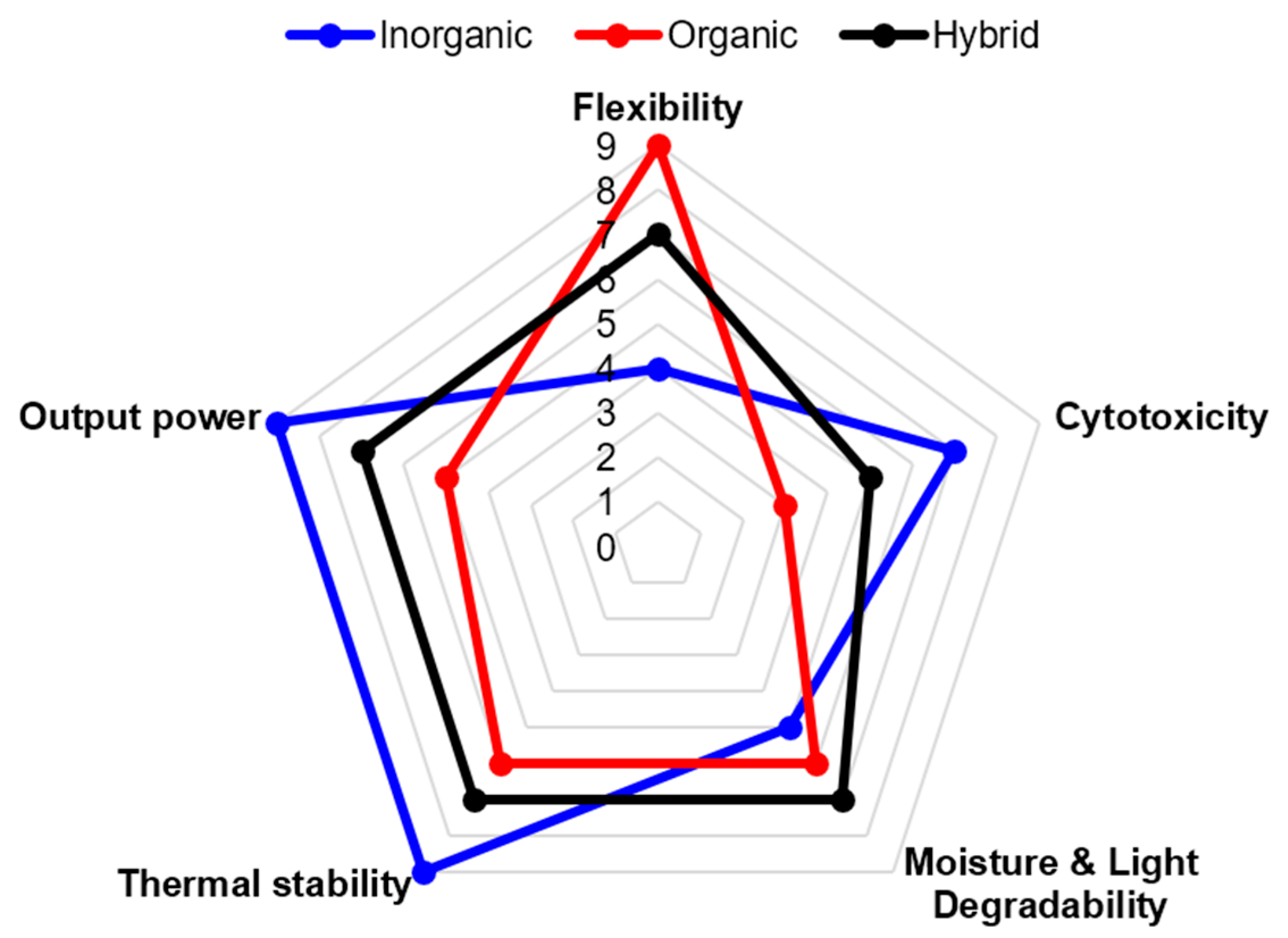

- The complex relationship between the material properties and fabrication strategies primarily governs the application and performance of a thin-film TEG. Inorganic materials deliver superior thermoelectric efficiency but require polishing in flexibility and compatibility with soft substrates. Carbon-based materials, on the other hand, provide enhanced mechanical flexibility, and sustainable processing, but suffer from low power outputs. Hybrid materials bridge these gaps and show promise in agricultural and wearable use-cases. Likewise, fabrication techniques, whether physical or chemical, greatly influence film morphology, interfacial quality, and eventual device performance. In agricultural use-case scenarios, the strategy in aligning the materials and processing methods should encompass the specific tailoring fabrication techniques for low-temperature, flexible substrates, improving power output under ambient and sub-optimal temperature gradients, and establishing durability under real environmental conditions.

- Organic and inorganic thin-film materials were mostly utilized for electrochemical sensing, and crop growth and health monitoring for agricultural applications. Organic materials are generally more biocompatible and conform due to their flexibility. Inorganic TEs, on the other hand, have good power output but suffer from relatively poor mechanical flexibility. It was, however, proven that the choice of materials and fabrication methods may address this drawback. Encapsulating TE devices has been proven to enhance their performance and properties while slowing down their rate of degradation due to different external factors. While inorganic TE materials displayed impressive performance and mechanical flexibility, there is lacking evidence to support their biocompatibility and interaction with plant, soil and microfauna considering their cytotoxicity in their elemental state.

- To overcome common challenges faced by thermoelectric generators, such as miniaturization, ease of integration, and efficiency, solutions are leveraged through the mesh of artificial intelligence, flexible and stretchable substrates, and exploration of design architectures. It was seen that the choice of materials for substrates and design architectures affect the overall performance of thermoelectric generators. Nevertheless, the advantages and improvements presented in current applications can be foundational when implementing these technologies, especially for prolonging the operation of a system in smart agriculture, such as monitoring plant conditions. There have been multiple studies on the implementation of AI in the field of TEGs with most studies focusing on the use of AI in the optimization of TEG parameters through methods such as inverse and multi-objective optimization and with a focus on the use of neural networks. The use of AI tools such as GAI in the initial modelling of the TEG has not been explored however GAI tools have been implemented to assist with optimization using cGANs to generate visual representations and thermal models. The use of AI to assist in other aspects of TEG design such as FEM was explored however there is a lack of literature on the topic to confirm the actual viability in TEG design. Recent studies on the integration of AI in TEG optimization focus more on the improvement brought about in both the optimization process in comparison to traditional methods and the general performance of the TEG itself.

- The field of thin-film thermoelectrics has great potential for development in a variety of research directions. The utilization of TEGs for temperature sensing purposes, the combination of multiple TEGs to improve overall performance, and AI integration are directions for performance improvement of TEGs. There are other directions in terms of the improvement and feasibility analysis of TFTEG performance through the considerations for economic feasibility of widescale production, power supply management considerations for IoT integration, and life cycle assessment for sustainability viability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TEG | Thermoelectric Generator |

| TFTEG | Thin film Thermoelectric Generator |

| ATEG | Annular Thermoelectric Generator |

| AI | Artificial Intelligence |

| ANN | Artificial Neural Network |

| FNN | Feedforward Neural Network |

| CNN | Convolutional Neural Network |

| RNN | Recurrent Neural Network |

| DNN | Deep Neural Network |

| GAI | Generative Artificial Intelligence |

| cGAN | Conditional Generative Adversarial Network |

| PCM | Phase Change Material |

| FEM | Finite Element Modelling |

| NSGA II | Non-dominated Sorting Genetic Algorithm II |

| MOPSO | Multi-Objective Particle Swarm Optimization |

| TOPSIS | Technique for Order Preference by the Ideal Solution |

| EPRCM | Evolutionary Polynomial Regression-based Constitutive Model |

| GRNN | Generalized Regression Neural Network |

| FDO | Fitness Dependent Optimization |

| GMPP | Global Maximum Power Point |

| CSA | Cuckoo-Search Algorithm |

| PandO | Perturb and Observe algorithm |

| PSO | Particle Swarm Optimization |

| GHO | Grasshopper Optimization Algorithm |

| GA | Genetic Algorithm |

| AL | Active Learning |

References

- Xiao, X. Sustainable Agriculture with Self-Powered Wireless Sensing. Agriculture 2025, 15, 234. [Google Scholar] [CrossRef]

- Gui, Y.; Wang, Y.; He, S.; Yang, J. Self-Powered Smart Agriculture Real-Time Sensing Device Based on Hybrid Wind Energy Harvesting Triboelectric-Electromagnetic Nanogenerator. Energy Convers. Manag. 2022, 269, 116098. [Google Scholar] [CrossRef]

- Hsu, H.H.; Zhang, X.; Xu, K.; Wang, Y.; Wang, Q.; Luo, G.; Xing, M.; Zhong, W. Self-Powered and Plant-Wearable Hydrogel as LED Power Supply and Sensor for Promoting and Monitoring Plant Growth in Smart Farming. Chem. Eng. J. 2021, 422, 129499. [Google Scholar] [CrossRef]

- Grzybek, D.; Micek, P. Piezoelectric Beam Generator Based on MFC as a Self-Powered Vibration Sensor. Sens. Actuators Phys. 2017, 267, 417–423. [Google Scholar] [CrossRef]

- Baskaran, P.; Rajasekar, M. Recent Progress in Thermoelectric Devices and Applications. Chem. Eng. J. 2025, 506, 159929. [Google Scholar] [CrossRef]

- Bancik, K.; Konecny, J.; Konecny, J.; Mikus, M.; Choutka, J.; Hercik, R.; Koziorek, J.; Navikas, D.; Andriukaitis, D.; Prauzek, M. Powering Agriculture IoT Sensors Using Natural Temperature Differences Between Air and Soil: Measurement and Evaluation. Sensors 2024, 24, 7687. [Google Scholar] [CrossRef]

- Xia, Z.; Zhang, Z.; Meng, Z.; Yu, Z. A 24-Hour Thermoelectric Generator Simultaneous Using Solar Heat Energy and Space Cold Energy. J. Quant. Spectrosc. Radiat. Transf. 2020, 251, 107038. [Google Scholar] [CrossRef]

- Saharun, I.F.; Saudin, N.; Mohamed, M.A.; Jamel, N.; Mohamed, H. Comparative Study of Thermal Energy Harvesting on Agricultural Soils Using Thermoelectric Generator (TEG). J. Phys. Conf. Ser. 2021, 1878, 012043. [Google Scholar] [CrossRef]

- Masoumi, S.; Xiong, R.; Caffrey, E.; Gatensby, R.; Ilhan, C.; Coleman, J.N.; Pakdel, A. Flexible Thermoelectric Generators from Spray-Printed PEDOT:PSS/Bi0.5Sb1.5Te3 Composites. RSC Adv. 2025, 15, 6574–6584. [Google Scholar] [CrossRef]

- Song, Y.; Yu, H.; Ran, Y.; Zeng, H.; Li, W.; He, J.; Tai, K.; Yu, Z. High-Performance Flexible Wavy-Structure Thermoelectric Generator Based on (Bi,Sb)2Te3 Films for Energy Harvesting. J. Power Sources 2024, 600, 234260. [Google Scholar] [CrossRef]

- Karthikeyan, V.; Surjadi, J.U.; Wong, J.C.K.; Kannan, V.; Lam, K.-H.; Chen, X.; Lu, Y.; Roy, V.A.L. Wearable and Flexible Thin Film Thermoelectric Module for Multi-Scale Energy Harvesting. J. Power Sources 2020, 455, 227983. [Google Scholar] [CrossRef]

- Yahya, A.E.M.; Sarreb, R.D.; Yahya, K.; Attar, H.; Aldababsa, M.; Hafez, M. Analyzing the Impact of Temperature Variations on the Performance of Thermoelectric Generators. In Proceedings of the 2023 2nd International Engineering Conference on Electrical, Energy, and Artificial Intelligence (EICEEAI), Zarqa, Jordan, 27–28 December 2023; pp. 1–6. [Google Scholar]

- Skipidarov, S.; Nikitin, M. (Eds.) Thin Film and Flexible Thermoelectric Generators, Devices and Sensors; Springer International Publishing: Cham, Switzerland, 2021; ISBN 978-3-030-45861-4. [Google Scholar]

- Schmidt, R.; Fan, X.; Case, E.; Sarac, P.B. Mechanical properties of Mg2Si thermoelectric materials with the addition of 0–4 vol% silicon carbide nanoparticles (SiCNP). J. Mater. Sci. 2015, 50, 4034–4046. [Google Scholar] [CrossRef]

- Toral, V.; Gómez-Gijón, S.; Romero, F.J.; Morales, D.P.; Castillo, E.; Rodríguez, N.; Rojas, S.; Molina-Lopez, F.; Rivadeneyra, A. Future Trends in Alternative Sustainable Materials for Low-Temperature Thermoelectric Applications. ACS Appl. Electron. Mater. 2024, 6, 8640–8654. [Google Scholar] [CrossRef]

- Fan, P.; Zheng, Z.; Cai, Z.; Chen, T.; Liu, P.; Cai, X.; Zhang, D.; Liang, G.; Luo, J. The High Performance of a Thin Film Thermoelectric Generator with Heat Flow Running Parallel to Film Surface. Appl. Phys. Lett. 2013, 102, 033904. [Google Scholar] [CrossRef]

- Yu, Y.; Zhu, W.; Wang, Y.; Zhu, P.; Peng, K.; Deng, Y. Towards High Integration and Power Density: Zigzag-Type Thin-Film Thermoelectric Generator Assisted by Rapid Pulse Laser Patterning Technique. Appl. Energy 2020, 275, 115404. [Google Scholar] [CrossRef]

- Klochko, N.P.; Zhadan, D.O.; Klepikova, K.S.; Petrushenko, S.I.; Kopach, V.R.; Khrypunov, G.S.; Lyubov, V.M.; Dukarov, S.V.; Khrypunova, A.L. Semi-Transparent Copper Iodide Thin Films on Flexible Substrates as p-Type Thermolegs for a Wearable Thermoelectric Generator. Thin Solid. Film. 2019, 683, 34–41. [Google Scholar] [CrossRef]

- Cai, Y.; Ding, N.; Rezania, A.; Deng, F.; Rosendahl, L.; Chen, J. A Multi-Objective Optimization in System Level for Thermoelectric Generation System. Energy 2023, 281, 128194. [Google Scholar] [CrossRef]

- Xu, A.; Xie, C.; Xie, L.; Zhu, W.; Xiong, B.; Gooi, H.B. Performance Prediction and Optimization of Annular Thermoelectric Generators Based on a Comprehensive Surrogate Model. Energy 2024, 290, 130195. [Google Scholar] [CrossRef]

- Jouhara, H.; Żabnieńska-Góra, A.; Khordehgah, N.; Doraghi, Q.; Ahmad, L.; Norman, L.; Axcell, B.; Wrobel, L.; Dai, S. Thermoelectric Generator (TEG) Technologies and Applications. Int. J. Thermofluids 2021, 9, 100063. [Google Scholar] [CrossRef]

- Eryilmaz, I.H.; Chen, Y.-F.; Mattana, G.; Orgiu, E. Flexible Organic Thermoelectric Generators. In Organic Flexible Electronics; Elsevier: Amsterdam, The Netherlands, 2021; pp. 335–351. ISBN 978-0-12-818890-3. [Google Scholar]

- Wang, F.; Wu, J. Applications in Thermoelectric Thin Films. In Modern Ion Plating Technology; Elsevier: Amsterdam, The Netherlands, 2023; pp. 459–473. ISBN 978-0-323-90833-7. [Google Scholar]

- Ghosh, M.; Paul, A.; Mandal, R. Thin Film Fabrication for Wearable Electronics: Journey so Far. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2024; pp. 39–60. ISBN 978-0-323-96021-2. [Google Scholar]

- Akbi, H.; Rafai, S.; Riou, O.; Mekki, A.; Durastani, J.-F.; Bekkar Djeloul Sayeh, Z.; Touidjine, S. Flexible and Lightweight Thermoelectric Generator Based on Chemically and Thermally Prepared Reduced Graphene Oxide Films. Mater. Chem. Phys. 2025, 344, 131071. [Google Scholar] [CrossRef]

- Acar, C. Thermoelectric Materials. In Comprehensive Energy Systems; Elsevier: Amsterdam, The Netherlands, 2025; pp. 498–523. ISBN 978-0-443-34108-3. [Google Scholar]

- Hussein, H.A.; Wang, Z.; Alani, W.K.; Zheng, J.; Fayad, M.A. A Novel Experimental Design for Free Energy from the Heat-Gaining Panel Using Multi-Thermoelectric Generators (TEGs) Panel. Case Stud. Therm. Eng. 2023, 50, 103431. [Google Scholar] [CrossRef]

- Pang, D.; Zhang, A.; Wang, B.; Li, G.; Lou, J. A Three-Dimensional Analytical Model for Performance Evaluation of Thermoelectric Generators. Case Stud. Therm. Eng. 2024, 64, 105579. [Google Scholar] [CrossRef]

- Qureshi, T.; Sheikh, K.A.; Khan, M.M.; Pali, H.S.; Tasnim, M. Exploring TEG Parameters for Optimal Body Heat Harvesting in Wearable Devices. Solid-State Electron. 2025, 227, 109122. [Google Scholar] [CrossRef]

- Dias, P.C.; Cadavid, D.; Ortega, S.; Ruiz, A.; França, M.B.M.; Morais, F.J.O.; Ferreira, E.C.; Cabot, A. Autonomous Soil Moisture Sensor Based on Nanostructured Thermosensitive Resistors Powered by an Integrated Thermoelectric Generator. Sens. Actuators Phys. 2016, 239, 1–7. [Google Scholar] [CrossRef]

- Wang, S.; Edupulapati, B.; Hagel, J.M.; Kwok, J.J.; Quebedeaux, J.C.; Khasbaatar, A.; Baek, J.M.; Davies, D.W.; Ella Elangovan, K.; Wheeler, R.M.; et al. Highly Stretchable, Robust, and Resilient Wearable Electronics for Remote, Autonomous Plant Growth Monitoring. Device 2024, 2, 100322. [Google Scholar] [CrossRef]

- Nandihalli, N. Thermoelectric Films and Periodic Structures and Spin Seebeck Effect Systems: Facets of Performance Optimization. Mater. Today Energy 2022, 25, 100965. [Google Scholar] [CrossRef]

- Narducci, D.; Giulio, F. Recent Advances on Thermoelectric Silicon for Low-Temperature Applications. Materials 2022, 15, 1214. [Google Scholar] [CrossRef]

- Ascencio-Hurtado, C.R.; Ambrosio Lázaro, R.C.; Estrada-López, J.J.; Torres Jacome, A. Review of Si-Based Thin Films and Materials for Thermoelectric Energy Harvesting and Their Integration into Electronic Devices for Energy Management Systems. Eng 2023, 4, 1409–1431. [Google Scholar] [CrossRef]

- Pham, N.H.; Vallin, Ö.; Panda, J.; Kam, V.; Ozawa, T.; Murata, M.; Suemasu, T.; Toko, K. Flexible Thermoelectric Generator Based on Polycrystalline SiGe Thin Films. Materials 2022, 15, 608. [Google Scholar] [CrossRef]

- Pham, N.H.; Vallin, Ö.; Panda, J.; Venkata Kamalakar, M.; Guo, J.; Luo, J.; Wen, C.; Zhang, S.-L.; Zhang, Z.-B. High Thermoelectric Power Factor of P-Type Amorphous Silicon Thin Films Dispersed with Ultrafine Silicon Nanocrystals. J. Appl. Phys. 2020, 127, 245304. [Google Scholar] [CrossRef]

- Ziouche, K.; Yuan, Z.; Lejeune, P.; Lasri, T.; Leclercq, D.; Bougrioua, Z. Silicon-Based Monolithic Planar Micro Thermoelectric Generator Using Bonding Technology. J. Microelectromechanical Syst. 2016, 26, 45–47. [Google Scholar] [CrossRef]

- Shi, Y.; Sturm, C.; Kleinke, H. Chalcogenides as Thermoelectric Materials. J. Solid. State Chem. 2019, 270, 273–279. [Google Scholar] [CrossRef]

- Tan, M.; Shi, X.-L.; Liu, W.-D.; Jiang, Y.; Liu, S.-Q.; Cao, T.; Chen, W.; Li, M.; Lin, T.; Deng, Y.; et al. Enabling Ultra-Flexible Inorganic Thin-Film-Based Thermoelectric Devices by Introducing Nanoscale Titanium Layers. Nat. Commun. 2025, 16, 633. [Google Scholar] [CrossRef]

- Chien, S.-Y.; Hou, L.-C.; Li, C.-C.; Liao, C.-N. Flexible Thermoelectric Generators Prepared by Dispenser Printing Technology. Mater. Chem. Phys. 2022, 287, 126269. [Google Scholar] [CrossRef]

- Kobayashi, A.; Konagaya, R.; Tanaka, S.; Takashiri, M. Optimized Structure of Tubular Thermoelectric Generators Using N-Type Bi2Te3 and P-Type Sb2Te3 Thin Films on Flexible Substrate for Energy Harvesting. Sens. Actuators A Phys. 2020, 313, 112199. [Google Scholar] [CrossRef]

- Abol-Fotouh, D.; Dörling, B.; Zapata-Arteaga, O.; Rodríguez-Martínez, X.; Gómez, A.; Reparaz, J.S.; Laromaine, A.; Roig, A.; Campoy-Quiles, M. Farming Thermoelectric Paper. Energy Environ. Sci. 2019, 12, 716–726. [Google Scholar] [CrossRef] [PubMed]

- Ascencio-Hurtado, C.R.; Torres, A.; Ambrosio, R.; Moreno, M.; Álvarez-Quintana, J.; Hurtado-Macías, A. N-Type Amorphous Silicon-Germanium Thin Films with Embedded Nanocrystals as a Novel Thermoelectric Material of Elevated ZT. J. Alloys Compd. 2021, 890, 161843. [Google Scholar] [CrossRef]

- Nayak, R.; Shetty, P.; Selvakumar, M.; Shivamurthy, B.; Rao, A.; Sriram, K.V.; Murari, M.S.; Kompa, A.; Deepika Shanubhogue, U. Influence of Microstructure and Thermoelectric Properties on the Power Density of Multi-Walled Carbon Nanotube/Metal Oxide Hybrid Flexible Thermoelectric Generators. Ceram. Int. 2023, 49, 39307–39328. [Google Scholar] [CrossRef]

- Ugraskan, V.; Karaman, F. Enhanced Thermoelectric Properties of Highly Conductive Poly(3,4-Ethylenedioxy Thiophene)/Exfoliated Graphitic Carbon Nitride Composites. Synth. Met. 2022, 287, 117070. [Google Scholar] [CrossRef]

- Masoumi, S.; O’Shaughnessy, S.; Pakdel, A. Organic-Based Flexible Thermoelectric Generators: From Materials to Devices. Nano Energy 2022, 92, 106774. [Google Scholar] [CrossRef]

- Bahk, J.-H.; Fang, H.; Yazawa, K.; Shakouri, A. Flexible Thermoelectric Materials and Device Optimization for Wearable Energy Harvesting. J. Mater. Chem. C 2015, 3, 10362–10374. [Google Scholar] [CrossRef]

- Culebras, M.; Gómez, C.; Cantarero, A. Review on Polymers for Thermoelectric Applications. Materials 2014, 7, 6701–6732. [Google Scholar] [CrossRef]

- Kadam, M.D.; Gore, P.M.; Kandasubramanian, B. Fiber-Based Thermoelectric Generators and Their Substrate Materials. Hybrid. Adv. 2024, 5, 100177. [Google Scholar] [CrossRef]

- Cao, T.; Shi, X.-L.; Zou, J.; Chen, Z.-G. Advances in Conducting Polymer-Based Thermoelectric Materials and Devices. Microstructures 2021, 1, 1–33. [Google Scholar] [CrossRef]

- Du, Y.; Cai, K.; Chen, S.; Wang, H.; Shen, S.Z.; Donelson, R.; Lin, T. Thermoelectric Fabrics: Toward Power Generating Clothing. Sci. Rep. 2015, 5, 6411. [Google Scholar] [CrossRef]

- Du, Y.; Cai, K.F.; Shen, S.Z.; Donelsonand, R.; Xu, J.Y.; Wang, H.X.; Lin, T. Multifold Enhancement of the Output Power of Flexible Thermoelectric Generators Made from Cotton Fabrics Coated with Conducting Polymer. RSC Adv. 2017, 7, 43737–43742. [Google Scholar] [CrossRef]

- Dun, C.; Hewitt, C.A.; Huang, H.; Xu, J.; Zhou, C.; Huang, W.; Cui, Y.; Zhou, W.; Jiang, Q.; Carroll, D.L. Flexible N-Type Thermoelectric Films Based on Cu-Doped Bi2Se3 Nanoplate and Polyvinylidene Fluoride Composite with Decoupled Seebeck Coefficient and Electrical Conductivity. Nano Energy 2015, 18, 306–314. [Google Scholar] [CrossRef]

- Zhao, X.; Han, W.; Jiang, Y.; Zhao, C.; Ji, X.; Kong, F.; Xu, W.; Zhang, X. A Honeycomb-like Paper-Based Thermoelectric Generator Based on a Bi2Te3/Bacterial Cellulose Nanofiber Coating. Nanoscale 2019, 11, 17725–17735. [Google Scholar] [CrossRef]

- Park, D.; Kim, M.; Kim, J. High-Performance PANI-Coated Ag2Se Nanowire and PVDF Thermoelectric Composite Film for Flexible Energy Harvesting. J. Alloys Compd. 2021, 884, 161098. [Google Scholar] [CrossRef]

- Shah, S.Z.H. Organic Inorganic Hybrid Thermoelectric Materials for Energy Harvesting Applications. Ph.D. Thesis, University of Southhampton, Southampton, UK, 2024; pp. 1–165. [Google Scholar]

- Jeong, M.H. Study on High-Efficiency Wearable TEG through Heat and Light Management. Ph.D. Thesis, Ulsan National Institute of Science and Technology, Ulsan, Republic of Korea, 2022; pp. 1–95. [Google Scholar]

- Xin, B.; Wang, L.; Le Febvrier, A.; Elsukova, A.; Paul, B.; Solin, N.; Eklund, P. Mechanically Flexible Thermoelectric Hybrid Thin Films by Introduction of PEDOT:PSS in Nanoporous Ca3Co4O9. ACS Omega 2022, 7, 23988–23994. [Google Scholar] [CrossRef]

- Massetti, M.; Jiao, F.; Ferguson, A.J.; Zhao, D.; Wijeratne, K.; Würger, A.; Blackburn, J.L.; Crispin, X.; Fabiano, S. Unconventional Thermoelectric Materials for Energy Harvesting and Sensing Applications. Chem. Rev. 2021, 121, 12465–12547. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Zhu, W.; Deng, Y. An Overview of Thermoelectric Films: Fabrication Techniques, Classification, and Regulation Methods. Chin. Phys. B 2018, 27, 047210. [Google Scholar] [CrossRef]

- Morgan, K.A.; Tang, T.; Zeimpekis, I.; Ravagli, A.; Craig, C.; Yao, J.; Feng, Z.; Yarmolich, D.; Barker, C.; Assender, H.; et al. High-Throughput Physical Vapour Deposition Flexible Thermoelectric Generators. Sci. Rep. 2019, 9, 4393. [Google Scholar] [CrossRef] [PubMed]

- Fan, P.; Zhang, P.; Liang, G.; Li, F.; Chen, Y.; Luo, J.; Zhang, X.; Chen, S.; Zheng, Z. High-Performance Bismuth Telluride Thermoelectric Thin Films Fabricated by Using the Two-Step Single-Source Thermal Evaporation. J. Alloys Compd. 2019, 819, 153027. [Google Scholar] [CrossRef]

- Orrill, M.; LeBlanc, S. Printed Thermoelectric Materials and Devices: Fabrication Techniques, Advantages, and Challenges. J. Appl. Polym. Sci. 2017, 134, 44256. [Google Scholar] [CrossRef]

- Abbasi, M.S.; Sultana, R.; Ahmed, I.; Adnan, M.; Shah, U.A.; Irshad, M.S.; Vu, H.N.; Do, L.T.; Ha, H.; Pham, T.-D.; et al. Contemporary Advances in Organic Thermoelectric Materials: Fundamentals, Properties, Optimization Strategies, and Applications. Renew. Sustain. Energy Rev. 2024, 200, 114579. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, X.; Zhang, L.; Xie, W. Ultrasonic Spray Coating Polymer and Small Molecular Organic Film for Organic Light-Emitting Devices. Sci. Rep. 2016, 6, 37042. [Google Scholar] [CrossRef]

- Kumar, R.S.N.; Ramirez, A.V.; Verding, P.; Nivelle, P.; Renner, F.; D’Haen, J.; Deferme, W. Deposition of Ultra-Thin Coatings by a Nature-Inspired Spray-On-Screen Technology. Commun. Eng. 2023, 2, 42. [Google Scholar] [CrossRef]

- Newbrook, D.W.; Richards, S.P.; Greenacre, V.K.; Hector, A.L.; Levason, W.; Reid, G.; de Groot, C.H.K.; Huang, R. Selective Chemical Vapor Deposition Approach for Sb2Te3 Thin Film Micro-Thermoelectric Generators. ACS Appl. Energy Mater. 2020, 3, 5840–5846. [Google Scholar] [CrossRef]

- DeCoster, M.E.; Chen, X.; Zhang, K.; Rost, C.M.; Hoglund, E.R.; Howe, J.M.; Beechem, T.E.; Baumgart, H.; Hopkins, P.E. Thermal Conductivity and Phonon Scattering Processes of ALD Grown PbTe–PbSe Thermoelectric Thin Films. Adv. Funct. Mater. 2019, 29, 1904073. [Google Scholar] [CrossRef]

- Saha, S.; Johnson, M.; Altayaran, F.; Wang, Y.; Wang, D.; Zhang, Q. Electrodeposition Fabrication of Chalcogenide Thin Films for Photovoltaic Applications. Electrochem 2020, 1, 286–321. [Google Scholar] [CrossRef]

- Gurav, K.V.; Kim, Y.K.; Shin, S.W.; Suryawanshi, M.P.; Tarwal, N.L.; Ghorpade, U.V.; Pawar, S.M.; Vanalakar, S.A.; Kim, I.Y.; Yun, J.H.; et al. Pulsed Electrodeposition of Cu2ZnSnS4 Thin Films: Effect of Pulse Potentials. Appl. Surf. Sci. 2014, 334, 192–196. [Google Scholar] [CrossRef]

- Pudzs, K.; Vembris, A.; Rutkis, M.; Woodward, S. Thin Film Organic Thermoelectric Generator Based on Tetrathiotetracene. Adv. Electron. Mater. 2017, 3, 1600429. [Google Scholar] [CrossRef]

- Lew, T.T.S.; Koman, V.B.; Silmore, K.S.; Seo, J.S.; Gordiichuk, P.; Kwak, S.-Y.; Park, M.; Ang, M.C.-Y.; Khong, D.T.; Lee, M.A.; et al. Real-Time Detection of Wound-Induced H2O2 Signalling Waves in Plants with Optical Nanosensors. Nat. Plants 2020, 6, 404–415. [Google Scholar] [CrossRef]

- Elsherbiny, A.S.; Galal, A.; Ghoneem, K.M.; Salahuddin, N.A. Novel Chitosan-Based Nanocomposites as Ecofriendly Pesticide Carriers: Synthesis, Root Rot Inhibition and Growth Management of Tomato Plants. Carbohydr. Polym. 2022, 282, 119111. [Google Scholar] [CrossRef]

- Fan, C.-X.; Wang, Z.; Wang, Z.-H.; Wang, A.-W.; Wang, Z.-Y.; Huang, L. A Microneedle Sensor for In-Vivo Sodium Ion Detection in Plants. Anal. Chim. Acta 2025, 1352, 343892. [Google Scholar] [CrossRef]

- Jaishankar, M.; Tseten, T.; Anbalagan, N.; Mathew, B.B.; Beeregowda, K.N. Toxicity, Mechanism and Health Effects of Some Heavy Metals. Interdiscip. Toxicol. 2014, 7, 60–72. [Google Scholar] [CrossRef]

- Ren, W.; Sun, Y.; Zhao, D.; Aili, A.; Zhang, S.; Shi, C.; Zhang, J.; Geng, H.; Zhang, J.; Zhang, L.; et al. High-Performance Wearable Thermoelectric Generator with Self-Healing, Recycling, and Lego-like Reconfiguring Capabilities. Sci. Adv. 2021, 7, eabe0586. [Google Scholar] [CrossRef]

- Brostow, W.; Datashvili, T.; Hagg Lobland, H.E.; Hilbig, T.; Su, L.; Vinado, C.; White, J. Bismuth Telluride-Based Thermoelectric Materials: Coatings as Protection against Thermal Cycling Effects. J. Mater. Res. 2012, 27, 2930–2936. [Google Scholar] [CrossRef]

- Abdallah, F.; Ciammaruchi, L.; Jiménez-Arguijo, A.; Duraia, E.M.; Ragab, H.S.; Dörling, B.; Campoy-Quiles, M. Investigating Thermoelectric Stability under Encapsulation Using PEI-Doped CNT Films as a Model System. Adv. Mater. Technol. 2020, 5, 2000256. [Google Scholar] [CrossRef]

- Hou, S.; Huang, J.; Liu, Y.; Luo, Y.; Wang, X.; Yin, L.; Sun, X.; Wu, Z.; Wang, J.; Sui, J.; et al. Encapsulated Ag2Se-Based Flexible Thermoelectric Generator with Remarkable Performance. Mater. Today Phys. 2023, 38, 101276. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Koh, S.C.L.; Mustapha, K.B.; Smith, L.; Acquaye, A.; Iyasara, A.C.; Hussain, F.; Morley, N.; Sinclair, D.C.; Randall, C.A.; et al. Techno-Environmental Analysis of Material Substitution in Thermoelectric Modules: Non-Oxide (Bismuth Telluride Alloys) vs. Oxide-Based (Lanthanum-Doped Strontium Titanate and Calcium Cobaltite) Materials. Energy Convers. Manag. X 2023, 19, 100395. [Google Scholar] [CrossRef]

- Rai, J.; Kumar Verma, M.; Sharma, M.; Kumar, R. Bismuth Chalcogenide Assisted Nanomaterials: A Versatile Platform against Harmful Bacteria and Toxic Organic Moieties. Environ. Nanotechnol. Monit. Manag. 2024, 22, 101010. [Google Scholar] [CrossRef]

- Klochko, N.P.; Barbash, V.A.; Klepikova, K.S.; Kopach, V.R.; Tyukhov, I.I.; Yashchenko, O.V.; Zhadan, D.O.; Petrushenko, S.I.; Dukarov, S.V.; Sukhov, V.M.; et al. Efficient Biodegradable Flexible Hydrophobic Thermoelectric Material Based on Biomass-Derived Nanocellulose Film and Copper Iodide Thin Nanostructured Layer. Sol. Energy 2020, 212, 231–240. [Google Scholar] [CrossRef]

- Hasan, M.B.; Parvez, M.M.; Abir, A.Y.; Ahmad, M.F. A Review on Conducting Organic Polymers: Concepts, Applications, and Potential Environmental Benefits. Heliyon 2025, 11, e42375. [Google Scholar] [CrossRef] [PubMed]

- Maskey, B.B.; Shrestha, K.; Sun, J.; Park, H.; Park, J.; Parajuli, S.; Shrestha, S.; Jung, Y.; Ramasundaram, S.; Koirala, G.R.; et al. Proving the Robustness of a PEDOT:PSS-Based Thermistor via Functionalized Graphene Oxide–Poly(Vinylidene Fluoride) Composite Encapsulation for Food Logistics. RSC Adv. 2020, 10, 12407–12414. [Google Scholar] [CrossRef] [PubMed]

- Figueira, J.; Peixoto, M.; Gaspar, C.; Loureiro, J.; Martins, R.; Carlos, E.; Pereira, L. Cellulose-Based Encapsulation for All-Printed Flexible Thermoelectric Touch Detectors. J. Mater. Sci. Mater. Electron. 2025, 36, 10. [Google Scholar] [CrossRef]

- Tayebi, L.; Zamanipour, Z.; Vashaee, D. Design Optimization of Micro-Fabricated Thermoelectric Devices for Solar Power Generation. Renew. Energy 2014, 69, 166–173. [Google Scholar] [CrossRef]

- Yamamuro, H.; Hatsuta, N.; Wachi, M.; Takei, Y.; Takashiri, M. Combination of Electrodeposition and Transfer Processes for Flexible Thin-Film Thermoelectric Generators. Coatings 2018, 8, 22. [Google Scholar] [CrossRef]

- Klochko, N.P.; Barbash, V.A.; Klepikova, K.S.; Kopach, V.R.; Tyukhov, I.I.; Yashchenko, O.V.; Zhadan, D.O.; Petrushenko, S.I.; Dukarov, S.V.; Lyubov, V.M.; et al. Use of Biomass for a Development of Nanocellulose-Based Biodegradable Flexible Thin Film Thermoelectric Material. Sol. Energy 2020, 201, 21–27. [Google Scholar] [CrossRef]

- Zhu, W.; Deng, Y.; Cao, L. Light-Concentrated Solar Generator and Sensor Based on Flexible Thin-Film Thermoelectric Device. Nano Energy 2017, 34, 463–471. [Google Scholar] [CrossRef]

- Sajjad, U.; Ali, A.; Ali, H.M.; Hamid, K. A Review on Machine Learning Driven next Generation Thermoelectric Generators. Energy Convers. Manag. X 2025, 27, 101092. [Google Scholar] [CrossRef]

- Cui, Z.; Hung, A.J. What Is Artificial Intelligence, Machine Learning, and Deep Learning: Terminologies Explained. In Artificial Intelligence in Urology; Academic Press: Cambridge, MA, USA, 2025; pp. 3–17. ISBN 978-0-443-22132-3. [Google Scholar]

- Saglik, K.; Srinivasan, S.; Victor, V.; Wang, X.; Zhang, W.; Yan, Q. Machine Learning for Next-Generation Thermoelectrics. Mater. Today Energy 2024, 46, 101700. [Google Scholar] [CrossRef]

- Alghamdi, H.; Maduabuchi, C.; Okoli, K.; Albaker, A.; Alanazi, M.; Alghassab, M.; Makki, E.; Alkhedher, M. From Sunlight to Power: Enhancing 4E Performance with Two-Stage Segmented Thermoelectric Generators in Concentrated Solar Applications. J. Clean. Prod. 2023, 429, 139314. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, B.; Tian, J.; Song, Q.; Chen, Y.; Zhang, W.; Wang, C.; Sun, H.; Zhang, Z. A Thermal Conductivity Varying 3D Numerical Model for Parametric Study of a Silicon-Based Nano Thermoelectric Generator. Energy 2024, 293, 130574. [Google Scholar] [CrossRef]

- Shen, L.; Wang, Y.; Tong, X.; Xu, S.; Sun, Y. Inverse Optimization Investigation for Thermoelectric Material from Device Level. Energy Convers. Manag. 2021, 228, 113669. [Google Scholar] [CrossRef]

- Zhao, R.; Zhu, N.; Zhao, X.; Luo, Z.; Chang, J. Multi-Objective Optimization of a Novel Photovoltaic-Thermoelectric Generator System Based on Hybrid Enhanced Algorithm. Energy 2025, 319, 135046. [Google Scholar] [CrossRef]

- Javadi, A.A.; Mehravar, M.; Faramarzi, A.; Ahangar-Asr, A. An Artificial Intelligence Based Finite Element Method. ISAST Trans. Comput. Intell. Syst. 2009, 1, 1–7. [Google Scholar]

- Awal, R.; Naznin, M.; Faisal, T.R. Machine Learning Based Finite Element Analysis (FEA) Surrogate for Hip Fracture Risk Assessment and Visualization. Expert. Syst. Appl. 2025, 264, 125916. [Google Scholar] [CrossRef]

- Mirza, A.F.; Haider, S.K.; Ahmed, A.; Rehman, A.U.; Shafiq, M.; Bajaj, M.; Zawbaa, H.M.; Szczepankowski, P.; Kamel, S. Generalized Regression Neural Network and Fitness Dependent Optimization: Application to Energy Harvesting of Centralized TEG Systems. Energy Rep. 2022, 8, 6332–6346. [Google Scholar] [CrossRef]

- Zhu, Y.; Newbrook, D.W.; Dai, P.; De Groot, C.H.K.; Huang, R. Artificial Neural Network Enabled Accurate Geometrical Design and Optimisation of Thermoelectric Generator. Appl. Energy 2022, 305, 117800. [Google Scholar] [CrossRef]

- Zhu, Y.; Newbrook, D.W.; Dai, P.; Liu, J.; De Groot, C.H.K.; Huang, R. Segmented Thermoelectric Generator Modelling and Optimization Using Artificial Neural Networks by Iterative Training. Energy AI 2023, 12, 100225. [Google Scholar] [CrossRef]

- Demeke, W.; Ryu, B.; Ryu, S. Machine Learning-Based Optimization of Segmented Thermoelectric Power Generators Using Temperature-Dependent Performance Properties. Appl. Energy 2024, 355, 122216. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Y.; Deng, Y.; Gao, H.; Lin, Z.; Zhu, W.; Ye, H. A Novel Self-Powered Wireless Temperature Sensor Based on Thermoelectric Generators. Energy Convers. Manag. 2014, 80, 110–116. [Google Scholar] [CrossRef]

- Hassanzadeh, A.; Baghestani, S. A New Self-Powered Temperature Sensor Based on Thermoelectric Generators. IEEE Sensors J. 2022, 22, 22421–22427. [Google Scholar] [CrossRef]

- Baba, T.; Janairo, L.G.; Maging, N.; Tañedo, H.S.; Concepcion, R., II; Magdaong, J.J.; Bantang, J.P.; Del-amen, J.; Culaba, A. Advancements in Chemiresistive and Electrochemical Sensing Materials for Detecting Volatile Organic Compounds in Potato and Tomato Plants. AgriEngineering 2025, 7, 166. [Google Scholar] [CrossRef]

- Anas, S.; Roy, K.; Varghese, H.; Chandran, A.; Lee, C. Thermoelectric Power Generators and Hybrid Energy Harvesters. In Comprehensive Microsystems; Elsevier: Amsterdam, The Netherlands, 2025; pp. 561–598. ISBN 978-0-323-95479-2. [Google Scholar]

- Kulkarni, N.; Tawade, J.V.; Sampathi, S.; Hanumagowda, B.N.; Abdelmohsen, S.A.M.; Khan, M.I.; Saidani, T.; Batool, N. Sustainability and Feasibility of Low-Grade Heat Utilization for Thermoelectric Systems in Geothermal Micro-Seepages. Energy Rep. 2025, 13, 4769–4780. [Google Scholar] [CrossRef]

- Kargaran, M. Advanced Nanofluid-Assisted OHP–TEG Integration for Next-Generation Photovoltaic Thermal Management. Energy 2025, 335, 138024. [Google Scholar] [CrossRef]

| Website | Keywords and Limiting Term | Search Count |

|---|---|---|

| Science Direct | “Generative AI tools” AND “Design” Subject Areas: “Medicine and Dentistry”, “Computer Science”, “Engineering”, “Nursing and Health Professions”, “Biochemistry, Genetics and Molecular Biology” | 307 |

| Scopus | “Generative” AND “AI” AND “Tools” AND “Design” | 1331 |

| Scopus | “Generative” AND “AI” AND “Tools” AND “Design” AND “Optimization” | 93 |

| Science Direct | Generative AI Design; Limitations: Book Chapters, 2024–2025 | 592 |

| Science Direct | Generative Design AND Thin-film | 37 |

| Science Direct | “Thin film” and “Thermoelectric generator”; Limiting term: Book chapters | 222 |

| Science Direct | “Thermoelectric Generator” AND “Optimization” AND “Thin film” AND “Simulation” AND “ Modelling” AND “Artificial Intelligence” | 155 |

| Science Direct | (“Thermoelectric generator” OR “Teg”) AND (“Generative Artificial Intelligence” OR “Generative AI” or “GAI”) and (“Thin film” OR “Thin-film”) | 63 |

| Scopus | (“Thermoelectric generator” OR “Teg”) AND (“Generative Artificial Intelligence” OR “Generative AI” or “GAI”) and (“Thin film” OR “Thin-film”) | 0 |

| Material Classification | p/n Materials | Substrate | Number of Pairs | Treatment | Operating Temperature (K) | Temperature Gradient (ΔT) | Output Power (μW) | PF (μW/cm·K2) | Fabrication Method | Tuning/Doping | Morphology and Thickness | Stability | Flexibility and Robustness | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Silicon-Based | Si0.4Ge0.6/Si0.85Ge0.15 | Polyimide (PI) | 2 p-type, 1 n-type | SiO2 | Room Temperature | 30 K | 0.45 | 560/390 | Ag-induced Layer Exchange, Magnetron Sputtering | As-doped Ag for n-type | ∼1000 nm | High | High | [35] |

| Amorphous Silicon | None | None | dispersion with ultrafine crystals by annealing | Room Temperature | None | None | 1000 | Low pressure chemical vapor deposition | Boron ion implantation | None | None | None | [36] | |

| Si | None | None | None | 313 K | 31.5 K | 12.3 | None | deep reactive ion etching | None | None | None | None | [37] | |

| Chalcogenide | Bi0.5Sb1.5Te3/ Bi2Te2.7Se0.3 | Polyimide (PI) | 162 | None | Room Temperature | 5 K | 225.4 | 108.7 | Masked Magnetron Sputtering, Flip-Chip Bonding Technique | None | 2.5 μm | High | High | [39] |

| Bi0.45Sb1.55Te3 Se0.034/ Bi2Te2.7Se0.3 | Polyimide (PI) | 8 | Sintering treatment | Room Temperature | 33 K | 68 | 23.2/19.1 | Dispenser Printing | None | 100 μm | High | High | [40] | |

| Bi0.5Sb1.5Te3/Bi2Te3 | Polyimide (PI) | 15 | None | Room Temperature | 11 | 10.6 | 37.8 | Magnetron Sputtering | None | 1.4 mm | High | High | [10] | |

| Bi2Te3/Sb2Te3 | Polyimide (PI) | 16 | None | 353 K | 20 K | 0.3068 | 4.7 | RF Magnetron Sputtering | None | 1.5 μm | none | High | [41] | |

| Conducting Polymer | PEDOT:PSS-coated polyester/Silver wires | polyester | None | None | 300 K | 75.2 K | 12.29 nW | 0.045 | PEDOT:PSS coating of polyester fabric | None | 520 μm | High | High | [51] |

| PEDOT:PSS-coated cotton/Constantan | cotton | 5 strips | None | 300 K | 74.3 K | 0.2126 | 0.057 | PEDOT:PSS coating of commercial cotton fabric | None | none | High | High | [52] | |

| Carbon Nanocomposites | Bacterial Cellulose/Carbon Nanotube | Bacterial Cellulose | 6 | None | Room Temperature | 20 K | 0.0145 | 20 | Bacterial Cellulose inoculation with K. xylinus | n-doping with polyethyleneimine (PEI), or tetramethyl-ammonium hydroxuide (TMAOH) | 10 μm | High | High | [42] |

| MWCNT-NH2/NiO | PET | 15 | None | Room Temperature | 100 K | 1.44 nW | 0.48 nW | Screen Printing | Amine-Functionalization | 49 μm | High | High | [44] | |

| MWCNT-NH2/CuO | 15 | None | Room Temperature | 100 K | 1.06 nW | none | Screen Printing | Amine-Functionalization | 54 μm | High | ||||

| MWCNT-NH2/Fe2O3 | 15 | None | Room Temperature | 100 K | 0.32 nW | none | Screen Printing | Amine-Functionalization | 52 μm | High | ||||

| Hybrid | PEDOT:PSS/Cu intercalated Bi2Se3:PVDF | Glass | None | None | Room Temperature | 15 K | None | 103 | Drop-Casting | Cu-doping | 10 μm | High | High | [53] |

| Bi2Te3/Bacterial Cellulose Nanofiber Coating | paper | 96 | heat treatment | 310 K | 55 K | 0.596 | 25.5 | Printing | None | 500 μm | HIgh | High | [54] | |

| PEDOT:PSS/Exfoliated g-C3N4 composites | glass | None | Ultrasonic homogenization | Room Temperature | 70 K | none | 419.7 | Oxidative chemical polymerizaiton | none | none | High | None | [45] | |

| PEDOT:PSS/Bi0.5Sb1.5Te3 composite | Kapton Sheet | 40 | Post treatment processes | 25 | 2–50 | 0.23–378 pW | 0.23 | Spray Printing | DMSO doping/NaOH dedoping | 227 nm | High | High | [9] | |

| PANI/Ag2Se | PVDF | 6 | None | 300 K | 30 | 0.835 | 196.6 | Solution Mixing and Drop Casting | Camphosulphonic acid (CSA), dodecyl benzene sulfonic acid (DBSA) | 10 μm | High | High | [55] |

| Software Used | AI Algorithms/Tools Used | Boundary Conditions/Input Parameters | Parameters to Be Optimized | Optimization Results | Reference |

|---|---|---|---|---|---|

| ANSYS 2023 R1; Autodesk Inventor Professional | No AI tools implemented | 1. Defined heat flux to hot junction. 2. Defined heat transfer coefficient at cold junction. 3. Ground at n-type semiconductor and terminal voltage determined at p-type semiconductor. | 1. Dollar per Watt Value 2. Maximum power output 3. CO2 savings 4. Exergy efficiency 5. Thermoelectric height 6. Thermoelectric cross-sectional area 7. Skutterudite Content | 1. Economic Optimal operation attained at a Dollar per Watt Value of 0.16 US$/W at Skutterudite composition of 92.59% and a concentrated solar flux of 40 kW/m2. 2. Optimal power generation of 41.12 W and maximum CO2 savings of 19.5 kg/yr attained at a concentrated solar flux of 95 kW/m2 and heat transfer coefficient of 4 kW/(m2K). 3. Peak exergy efficiency of 9.52% attained at a concentrated solar flux of 20 kW/m2 at a cross-sectional area of 0.1 mm2 and concentrated solar flux of 10 and 20 kW/m2. 4. Optimal leg height and cross-sectional area varies based on ideal parameters to be optimized with a leg height of 7.5 mm ideal for 2.18 W power output. | [93] |

| COMSOL Multiphysics | No AI tools implemented | Model considerations: 1. Seebeck coefficient, p- and n-type doping concentrations, contact resistance, and temperature applied to both ends specified. 2. Thermal conductivity and electrical resistance to be calculated. | 1. Power density 2. Geometric parameters (Length, width, and height of blade thermocouples) | Maximum power density of 16.2 μw/(cm2K2) achieved with a thermocouple thickness of 2 μw and a width of 60 nm. | [95] |

| Unspecified | No AI tools implemented | 1 Constant heat flow at the hot side. 2. Constant temperature on the cold side. | 1. Maximum power generation 2. Optimal matching external load. Impact of the following parameters considered: 1. Thermal conductivity 2. Seebeck coefficient 3. Electrical conductivity | A range of parameters for specific figure of merit values was identified with the key result focused on a flowchart of the TE inverse optimization process at the device level. Formulas for identifying maximum power were generated based on thermal conductivity which varied based on the figure of merit. | [96] |

| COMSOL Multiphysics | 1. ANN (Matlab Neural Network toolbox) 2. cGAN Trained using PyTorch in Python | Value ranges and resolutions for the following geometric parameters were identified: 1. Twist ratio = 30–110 with a resolution of 20. 2. Radius = 0.01–0.03 m with a resolution of 0.005 m. 3. Length = 0.017–0.097 m with a resolution of 0.016 m. 4. Inlet temperature 5. Inlet velocity | 1. Maximum power output 2. TEG efficiency | 1. Prediction accuracy = 97% 2. SSIM of pressure distribution = 0.954 3. SSIM of heat flux distribution = 0.934 4. Net power increase = 22.07% 5. Efficiency increase = 59.11% Computational efficiency achieved = 99.97% | [20] |

| Unspecified however a multi-objective optimization software was used with response surface methodology. | No AI tools implemented | 1. Function of amplitude and frequency as input heat. 2. Heat transfer coefficient as input at cold end. 3. Seebeck effect, Peltier effect, and Thomson effect considered. | 1. Maximum output power 2. TEG system efficiency 3. Investment | 1. Maximum output power loss of 1%. 2. Efficiency loss of 1%. 3. TEG investment reduction of 30–50% | [19] |

| MATLAB | NSGA II-MOPSO algorithm alongside other analysis tools such as the TOPSIS method | Sensitivity parameters: 1. PV reference efficiency 2. TEG module quantity 3. Thickness of each of the two PCM plates 4. Melting temperature of each off the two PCM plates. | 1. Electrical Efficiency 2. Minimum life cycle cost | 1. Average annual efficiency increased by 52.4% 2. Total life cycle costs decreased by 98.4% Optimal configuration identified 1. Electrical efficiency of 25.6% 2. Total life cycle cost of 335.4 CNY Parameters for optimal configuration: 1. PV reference efficiency of 26.4% 2. TEG module quantity of 25.6% 3. Optimal thickness of 21.6 mm and 2.8 mm for external and internal PCM plates respectively. 4. Melting temperatures of 30.8 °C and 11.4 °C for external and internal PCM plates respectively. | [96] |

| MATLAB/SIMULINK | Generalized Regression Neural Network (GRNN) combined with FDO | 1. Hot side temp = 250 K at matched load 2. Cold side temp = 50 K at matched load TEG module parameters: 1. Power output = 24.3 W 2. Open-circuit voltage = 10.8 V 3. Load voltage = 5.4 V 4. TEG internal resistance = 1.2 Ω 5. Load current = 4.5 A | Global Maximum Power Point (GMPP) | Global Maxima tracking efficiency > 99%. Time taken to trace true GMPP = 110.1 ms. GRNN with FDO compared to other methods such as Cuckoo-search algorithm (CSA), Perturb and observe algorithm (PandO), Particle swarm optimization (PSO), and Grasshopper optimization algorithm (GHO) and was found to display the finest results with minimal tracking time. | [99] |

| ANSYS COMSOL Multiphysics | ANN Genetic Algorithms (GA) | 1. Cold side temperature = 300 K 2. Convectional heat flux on all open internal surfaces with heat transfer coefficient of 1 mW/(cm2K). 3. TEG model connected to external load. 4. Inlet and outlet of metal substrate as terminal voltage and ground respectively. | 1. Fill Factor 2. Maximum output power density 3. Thermoelectric height 4. Interconnect height 5. Width of n-type leg 6. Width of p-type leg | Values achieved at operating conditions of heat flux density = 300 mW/cm2 and contact resistivity = 10−8 Ωm2 1. FF = 0.11. 2. PDMAX = approx. 3 mW/cm2 3. HTE = 4.81 mm 4. HIC = 0.5 mm 5. Wn = 2.27 mm 6. Wp = 2.25 mm Geometrical Optimization time = 40 s. Neural network optimization is 1000 times more effective than COMSOL simulation optimization. | [100] |

| COMSOL multiphysics | ANN GA | 1. Constant heat flux conditions. 2. Insulation thickness and electrode thickness set to 0.5 mm. 3. TEG device area = 1 cm2 4. Cold side temperature = 293.15 K 5. External temperature = 293.15 K 6. Convectional heat flux on open internal surfaces with heat transfer coefficient = 1 mW/(cm2K) Ranges and resolution of geometric parameters and operating conditions 1. TE leg height with a range of 1–10 mm at a resolution of 0.1 mm. 2. FF with a range of 0.05–0.95 and resolution of 0.01. 3. High temperature n-type and p-type TE leg height ratio both with a range of 0.05–0.95 and a resolution of 0.01. 4. Heat flux with a range of 100–2000 mW/cm2 and a resolution of 1 mW/cm2. 5. Top and bottom side contact resistivities both with a range of 10−9–10−7 Ωm2. with a resolution of 10−9 Ωm2. | Optimization time and performance. | Prediction accuracy of iterative trained ANN increased from 94 to 98%. Average ANN optimization time = 6.3 s Proposed optimization method over 5000 times faster than FEM optimization methods | [101] |

| COMSOL multiphysics | DNN GA Active Learning (AL) | Boundary conditions: 1. Hot end temperature = 670 K 2. Cold end temperature = 350 K 3. All other boundaries are thermally insulated. 4. Heat convection and heat radiation are neglected. 5. Material properties are assumed homogeneous and isotropic. 6. Thermal and electrical contact resistance at interfaces between any two sections are not considered. 7. External load resistance is considered a thermal insulator. Input parameters: 1. TE leg length = 10 mm 2. P-type and n-type segment length both with a range of 0.1–9.7 mm. 3. Height of aluminum oxide and copper electrode = 1 mm. 4. Radius of external load resistance = 1.5 mm 5. Horizontal bar length = 8 mm. 6. External load resistivity with a range of 10−7–10−2 Ωm. 7. TE area of both legs = 3 × 3 mm2 Five weight factors considered with values of 0, 0.25, 0.5, 0.75, and 1.0. | 1. Max power output 2. TEG efficiency | The optimization process resulted in an improvement of 1,91 and 1.5 times in terms of power output and TEG efficiency respectively in comparison to the designs in the initial dataset. Values calculated for each weight factor with a sample power output of 0.1710 W and efficiency of 12.450% at a weight factor of 0 in comparison to actual power of 0.1695 and efficiency of 12.459%. | [102] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baba, T.; Janairo, L.G.; Maging, N.; Tañedo, H.S.; Concepcion, R., II; Magdaong, J.J.; Bantang, J.P.; Del-amen, J.; Ronquillo, C.J.; Bandala, A.; et al. Advancements in Thin-Film Thermoelectric Generator Design for Agricultural Applications. AgriEngineering 2025, 7, 291. https://doi.org/10.3390/agriengineering7090291

Baba T, Janairo LG, Maging N, Tañedo HS, Concepcion R II, Magdaong JJ, Bantang JP, Del-amen J, Ronquillo CJ, Bandala A, et al. Advancements in Thin-Film Thermoelectric Generator Design for Agricultural Applications. AgriEngineering. 2025; 7(9):291. https://doi.org/10.3390/agriengineering7090291

Chicago/Turabian StyleBaba, Toshiou, Lorenzo Gabriel Janairo, Novelyn Maging, Hoshea Sophia Tañedo, Ronnie Concepcion, II, Jeremy Jay Magdaong, Jose Paolo Bantang, Jesson Del-amen, Christian Joseph Ronquillo, Argel Bandala, and et al. 2025. "Advancements in Thin-Film Thermoelectric Generator Design for Agricultural Applications" AgriEngineering 7, no. 9: 291. https://doi.org/10.3390/agriengineering7090291

APA StyleBaba, T., Janairo, L. G., Maging, N., Tañedo, H. S., Concepcion, R., II, Magdaong, J. J., Bantang, J. P., Del-amen, J., Ronquillo, C. J., Bandala, A., & Culaba, A. (2025). Advancements in Thin-Film Thermoelectric Generator Design for Agricultural Applications. AgriEngineering, 7(9), 291. https://doi.org/10.3390/agriengineering7090291