Abstract

In the bioenergy industry, highway hauling cost is typically 30%, or more, of the average cost of feedstock delivered to a biorefinery. Thus, truck productivity, in terms of Mg/d/truck, is a key issue in the design of a logistics system. One possible solution to this problem that is being explored is the utilization of modular pellet depots. In such a logistics system, raw biomass (i.e., low-bulk-density product) is converted into pellets (i.e., high-bulk-density product) by several smaller-scale modular pellet depots instead of by a single larger-capacity pellet depot. A truckload of raw biomass (e.g., round bales) is 16 Mg and a load of pellets is 34 Mg. The distribution of depots across a feedstock production area can potentially have an impact on the total truck operating hours (i.e., raw biomass hauling to a depot + pellet hauling from the depot to the biorefinery) required to deliver feedstock for annual operation of a biorefinery. This study examined three different distributions of depots across five feedstock production areas. The numbers of depots were one, two, and four per production area for totals of five, ten, and twenty depots. Increasing the number of depots from five to ten reduced raw biomass hauling hours by 12%, and increasing from five to twenty reduced these hours by 30%. Total hauling hours (raw biomass + pellets) were reduced by less than 1% with an increase from five to ten and by about 11% with an increase from five to twenty. The modular pellet depot concept demonstrated potential for providing improvements to biorefinery logistics systems, but more research is needed to optimize this balance.

Keywords:

herbaceous; feedstock; logistics; modeling; spatial analysis; depots; biorefinery; transporting 1. Introduction

The southeastern region of the United States has the potential to be a significant contributor to the national biorefinery industry. One challenge is posed by low feedstock density, defined as the amount (in Mg) of potential feedstock production available per square km within a given radius of any proposed biorefinery location. As the radius of the feedstock production area for the biorefinery increases, the per-Mg feedstock delivery cost increases, because the average cycle time for truck delivery increases. Thus, truck productivity (in Mg per day) decreases and truck cost (in USD per Mg) increases. A round-bale system for feedstock is the best option for the Piedmont, a 166-county physiographic region across five southeastern states, due to this region consisting of small, irregular-shaped fields over rolling terrain [1]. Work has been done to eliminate single-bale handling for loading and unloading, which is an important operational parameter in the logistics system [2,3,4].

It is common for biorefineries to require a high capacity of feedstock to take advantage of economies of scale. It is often not feasible to satisfy necessary feedstock demand using low-bulk-density raw biomass from the production area. As a result of this limitation, the US DOE is exploring the utilization of depot networks to support biorefinery logistics. These depots would be designed to produce an intermediate feedstock (i.e., material at higher bulk density, such as pellets), which would then be delivered to a biorefinery [5,6]. While researchers have studied the influence of depot distributions on average delivered feedstock cost [7,8,9], more research is needed on this topic for the Piedmont region to explore the impact of its unique environment on the logistics system.

As specific examples applicable to this study, a load of 40 round bales is 16 Mg and a load of pellets is 34 Mg. For each load, the cost to operate the truck (USD/h) is approximately the same, with only small differences in fuel consumption. The question then emerges: what impact does the distribution of pellet depots have on the total truck operating hours (raw biomass hauling + pellet hauling) required to deliver biomass to a biorefinery for annual operation? A modular, or containerized, pellet plant design has been developed [10]. This technology provides an opportunity to include smaller-scale depots in the logistics system. Thus, it is possible to consider a larger number of widely dispersed, smaller-capacity depots, as opposed to a smaller number of more centrally located, larger-capacity depots.

For implementation of the concept, it is envisioned that each farmgate contract holder owns their own pellet depot. This means that farmgate contracts are limited to those who can secure the capitalization required to purchase and install the modular plant. There would also be a requirement for essential expertise to operate the pellet depot, as well as a requirement that the system of depots operate to provide a year-round supply of pellets. All three of these issues, namely, capitalization, operational expertise, and continuous year-round supply to the biorefinery, argue against a “farm-level” implementation of the concept, and in favor of the “community-level” implementation proposed in this study.

There are over 200,000 trucking companies in the USA; thus, truck cost (USD/h) is well defined for the heavy truck industry. However, a business plan is needed which will minimize the truck operating hours required to deliver feedstock for year-round operation of the biorefinery. The total truck cost includes the cost to deliver the raw biomass to a pellet depot, plus the subsequent cost to deliver pellets to the biorefinery. A single depot at the center of a production area requires an increased number of truck operating hours for the delivery of raw biomass. Consequently, a wider distribution of depots reduces the raw biomass trucking hours, but may increase the operating hours required to deliver the pellets.

This study simulated a modular pellet depot network in the Piedmont and compared the total truck operating hours, raw biomass hauling + pellet hauling, for several depot distributions across five production areas, each having a different feedstock density. Total truck operating hours were calculated for three depot distributions within a 48 km radius production area: (1) a single depot at the center of the area pelleting 100% of the stored biomass; (2) two depots, each pelleting approximately 50% of the stored biomass; and (3) four depots, each pelleting approximately 25% of the stored biomass.

2. Methodology

2.1. Study Area

As defined for previous studies [11,12], three production areas were selected from Virginia (VA5, VA6, VA7) and two production areas were selected from North Carolina (NC2, NC3). Each of these five production areas was assigned the same three depot distributions, defined as Depot-1 (one depot per area), Depot-2 (two depots per area), and Depot-4 (four depots per area). Thus, the total numbers of depots for the five production areas supplying the biorefinery were five for Depot-1, ten for Depot-2, and twenty for Depot-4.

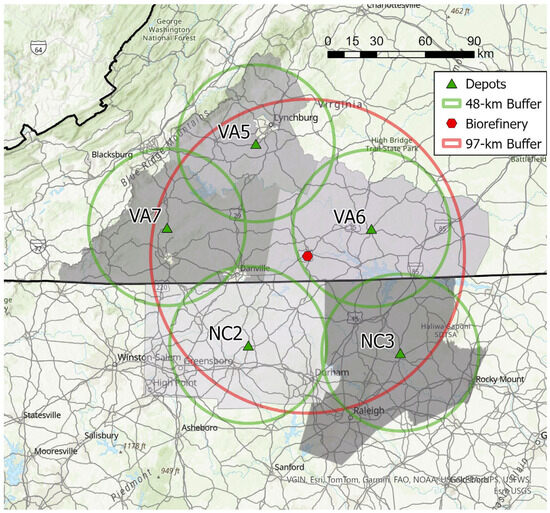

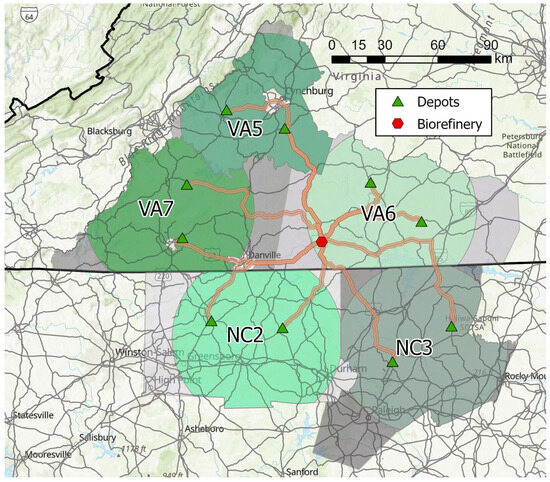

Previous studies have used a range of parameters to define the feedstock supply radius for a potential biorefinery. Gustafson et al. [13] used a 161 km (100 mi) radius for wheat straw and corn stover. Holder et al. [14] used an 80 km (50 mi) radius for corn feedstock. Lynch and Satrio [15] used a 97 km (60 mi) radius for switchgrass feedstock. For this study, a biorefinery location was chosen near South Boston, VA with convenient access to a four-lane highway and an existing rail siding [11]. The radius encompassing the depots for each of the three distributions was 97 km. The Depot-1 distribution, with one depot per production area, is shown in Figure 1.

Figure 1.

Sites of biorefinery, three production areas in Virginia (VA), and two production areas in North Carolina (NC), for the Depot-1 analysis, adapted from Resop and Cundiff [11].

2.2. Raw Biomass Available for Each Production Area

The potential switchgrass feedstock production was estimated from available land cover (i.e., scrubland and grassland) within a 48 km (30 mi) radius of each depot (Figure 1), the same as used by previous studies in this region [4,11,12]. The buffered areas were clipped to the multi-county production zones to prevent overlapping between the production areas. All spatial analyses, such as geoprocessing, as well as network analyses, such as calculating highway travel distances and routing, were performed using ArcGIS Pro 3.1 (Redlands, CA, USA), as described by Resop and Cundiff [11] and by Resop et al. [12].

Switchgrass (Panicum virgatum L.) was selected as the feedstock to be utilized by the biorefinery. Switchgrass is a perennial warm-season grass that has shown potential as a feedstock for biorefineries in the Piedmont region. It was assumed that switchgrass would be harvested from fields and stored in satellite storage locations (SSLs) in round bales with an average moisture content (MC) of 15%. An average switchgrass yield of 6.7 Mg/ha was assumed [16]. The annual production for each production area was

where

Qn = the total annual production (Mg) for the nth production area (n = 1 VA5, n = 2 VA6, n = 3 VA7, n = 4 NC2, and n = 5 NC3);

An = the total feedstock production area (ha) within a 48 km radius;

yld = the average switchgrass yield across the entire production area (Mg/ha).

The available land cover area for each production area was multiplied by 40%, which represented the land proportion anticipated to be attracted into switchgrass production, and then multiplied by the average yield (6.7 Mg/ha) to estimate the annual production for each production area (Table 1). The potential annual production ranged from 80,840 Mg (VA5) to 170,830 Mg (VA6). Over all five production areas, a total raw biomass production of 553,250 Mg could potentially be supplied annually to the biorefinery.

Table 1.

Total feedstock (Mg), at 15% moisture content (MC), stored in the five production areas, adapted from Resop and Cundiff [11].

2.3. Satellite Storage Location (SSL) Databases for Each Production Area

The SSL database for each production area was assigned the same SSL distribution developed by Resop et al. [17], identified here as the “Gretna” database. The road distance to each SSL, relative to the proposed centrally located depot location, was defined in the Gretna database. This same database was used for all five production areas in this study. The only difference among the five production areas was the quantity of biomass harvested and stored in each SSL, which was defined as the feedstock density factor (Fn):

where

Qb = the total annual production defined in the Gretna database (152,526 Mg).

The same load-out methodology described by Resop and Cundiff [11] was used for each of the five production-area databases in this study. As in the previous studies, a truckload was two 20-bale handling units per truck [2]. Modern balers can produce 5 ft × 4 ft round bales (1.5 m dia. × 1.2 m long) of switchgrass that weigh about 0.4 Mg (at 15% MC), resulting in 16 Mg of raw biomass per 40-bale truckload.

2.4. Hauling Distance Databases for Each Depot Distribution

Three analyses were performed for this study, based on different distributions of depots. The Depot-1 analysis assumed a single depot located at the center of each 48 km radius production area. This analysis used the same depot location and 199 SSLs, based on the Gretna database, as used by Resop et al. [4] to study central control optimization of herbaceous feedstock delivery in the Piedmont. There were a total of five depots, one per production area, which supplied the biorefinery for the Depot-1 analysis.

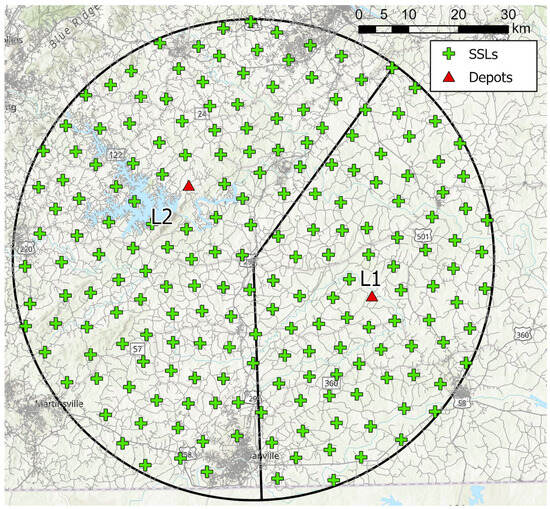

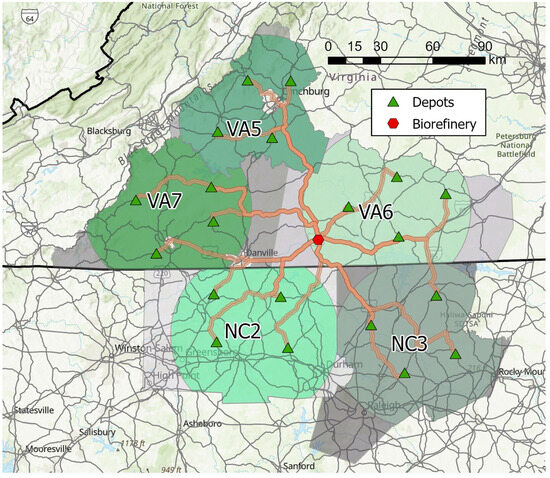

The Depot-2 analysis assumed two depots in each production area. To locate these depots, the production area was divided so that approximately 50% of the total stored biomass was allocated to each depot. These areas were defined as L1 and L2 (Figure 2). The two depots were positioned to minimize the mass-distance parameter, defined as the weighted average distance (in km) traveled by a unit of biomass, for raw biomass hauling from the SSLs to the depots. There were a total of ten depots, two depots for each of the five production areas, which supplied the biorefinery for the Depot-2 analysis.

Figure 2.

Locations of depots and satellite storage locations (SSLs) for the Depot-2 analysis.

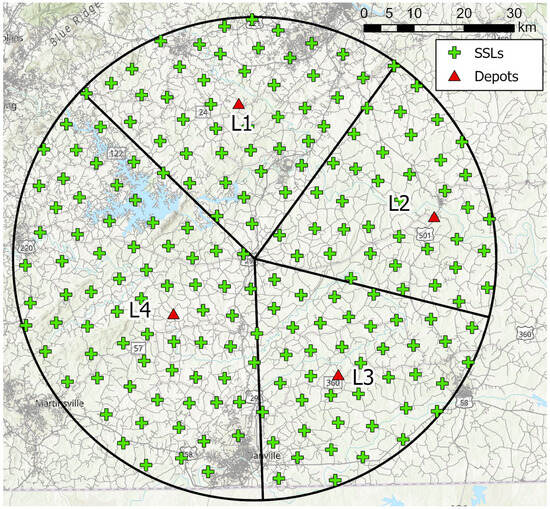

The Depot-4 analysis assumed four depots in each production area. The area was divided so that approximately 25% of the total stored biomass was allocated to each depot. These zones were defined as L1, L2, L3, and L4 (Figure 3). As with the Depot-2 analysis, the depots were positioned so that the mass-distance parameter was minimized for all four subareas. There were a total of twenty depots, four for each of the five production areas, which supplied the biorefinery for the Depot-4 analysis.

Figure 3.

Locations of depots and satellite storage locations (SSLs) for the Depot-4 analysis.

A database was created with the road distance from each SSL to its assigned depot, which defined the haul distance for raw biomass to that depot. The number of load-out operations for each database was the same as described by Resop and Cundiff [11] (Table 2). Each load-out moved through the same sequence of SSLs as in the previous studies; the only difference was the truck scheduling. Rather than delivering to a single centrally located depot, the trucks hauled to their new depot assignment (Figure 2 and Figure 3).

Table 2.

Assigned load-outs for each production area, adapted from Resop and Cundiff [11].

The capacity of the pellet depots was calculated using the following parameters: average moisture content of raw biomass = 15% (wet basis); ratio of raw biomass to pellets = 1.1 dry matter basis; moisture content of shipped pellets = 6% (wet basis). This gave a conversion factor of 0.822. The depots were expected to operate 7 d/wk for 48 wk/y (i.e., 336 d/y). The resulting capacities (Mg pellets/d) are given in Table 3, Table 4 and Table 5 for the Depot-1, Depot-2, and Depot-4 distributions, respectively. The smallest depot was 47.7 Mg/d and the largest was 417.9 Mg/d, giving a 10:1 ratio in depot capacity across the entire study.

Table 3.

Depot capacity (Mg pellets/d) for the Depot-1 analysis.

Table 4.

Depot capacity (Mg pellets/d) for the Depot-2 analysis.

Table 5.

Depot capacity (Mg pellets/d) for the Depot-4 analysis.

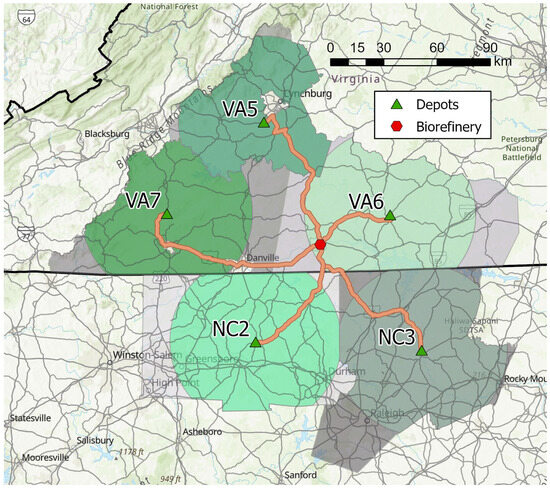

The highway route used to haul pellets from each of the five depots in the Depot-1 analysis is shown in Figure 4 and the distances are given in Table 6. Similarly, the highway routes from each of the ten depots in the Depot-2 analysis are shown in Figure 5 and the distances are given in Table 7. In like manner, the highway routes from each of the twenty depots in the Depot-4 analysis are shown in Figure 6 and the distances are given in Table 8.

Figure 4.

Highway routes for delivery of pellets from the five depots in the Depot-1 analysis.

Table 6.

Highway travel (km) for delivery of pellets from five depots in the Depot-1 analysis.

Figure 5.

Highway routes for delivery of pellets from ten depots in the Depot-2 analysis.

Table 7.

Highway travel (km) for delivery of pellets from ten depots in the Depot-2 analysis.

Figure 6.

Highway routes for delivery of pellets from twenty depots in the Depot-4 analysis.

Table 8.

Highway travel (km) for delivery of pellets from twenty depots in the Depot-4 analysis.

2.5. Truck Operating Hours Required to Haul Raw Biomass to Depots

The truck operating hours required to haul raw biomass were determined using the following procedure: the ideal truck cycle time (i.e., from the depot to an SSL and back) was calculated based on a set of parameters, adapted from Resop et al. [4], representing the following optimistic, not average, conditions:

- Load time (Lt) was assumed to be 15 min.

- Unload time (Ut) was assumed to be 20 min.

- Travel speed was assumed to average 70 km/h.

The ideal truck cycle time (Tcycj) (i.e., assuming no delays) for hauls from the jth SSL located at a distance hdj from the assigned depot was computed as:

A multiplier of 1.4 was used to estimate the achieved average truck cycle time (Taj), defined as:

This multiplier accounted for delays in loading (e.g., waiting at SSL) and unloading (e.g., waiting at the depot receiving facility), plus delays due to traffic. While this was an optimistic achieved cycle time, it defined the necessary “baseline” truck fleet size.

Number of loads was based on a load of 40 bales equal to 16 Mg. This defined the number of loads (nlj) hauled from the jth SSL. No partial loads were considered. Typically, there will be some remaining bales, and there is potential for a mobile pelleting unit to travel from SSL to SSL to process these bales into pellets [18]. This option was not explored here. The total truck operating hours (Tohj) required to haul all loads from the jth SSL was given by:

The total truck operating hours for each of the three distributions were calculated as follows: The operating hours were first summed for all SSLs assigned to a given depot. This calculation was straightforward for the Depot-1 simulation because all SSLs within a given production area (i.e., all 199) supply biomass to one centrally located depot. This total was designated Tohn for the nth production area.

The total for all five production areas was calculated as

For the Depot-2 simulation, the SSLs assigned to the two depots were not sequential. It may be recalled that the decision was made to use the same load-out procedure (i.e., the same sequence of SSLs) for all three distributions. Thus, a matrix was created to list the SSL numbers in the needed sequence. Summation was then carried out for this number of SSLs to obtain TohL1n for the L1 depot and TohL2n for the L2 depot. The total for the Depot-2 simulation was

The same procedure was used for the Depot-4 simulation. The Toh values for the SSLs assigned to a given depot in the nth production area were summed to obtain TohL1n, TohL2n, TohL3n, and TohL4n for the L1, L2, L3, and L4 depots, respectively. The total for the Depot-4 simulation was

The total haul distance required to haul all loads of raw biomass from the jth SSL (Tdj) was given by:

The same summation procedure was used for Td as that described for Toh to obtain haul distance totals for each of the three different depot distributions.

2.6. Truck Operating Hours Required to Haul Pellets to Biorefinery

The decision was made not to maintain the identification of the depots with the production area. For the Depot-1 analysis, a fleet of trucks hauled from five depots, i = 1–5. For the Depot-2 analysis, a fleet of trucks hauled from ten depots, i = 1–10. Finally, in like manner, a fleet of trucks hauled from twenty depots, i = 1–20, for the Depot-4 analysis.

The raw biomass mass delivered to each depot was converted to pellet mass for the pellet shipment calculation. The ruck operating hours required for hauling pellets were determined using the following procedure. Like before, the ideal truck cycle time (i.e., from the biorefinery to a depot and back) was calculated based on the following parameters:

- Load time (Lt) was assumed to be 20 min.

- Unload time (Ut) was assumed to be 20 min.

- Travel speed was assumed to average 70 km/h.

The ideal cycle time for hauling pellets from the ith depot, located a distance hdpi from the biorefinery, is

Assuming an aluminum grain trailer was used, a load of pellets was 34 Mg. This load size defined the number of pellet loads produced at the ith depot (nlpi). Using the same 1.4 multiplier to obtain Tai, the value for total truck operating hours required to haul all pellet loads from the ith depot was given by:

The truck operating hours per depot was summed over the total depots to obtain a total Tohp for all depots. The pellet hauling trucks were expected to operate 24 h/d for 6 d/week for 48 weeks; thus, the total hours were 8064/y. The hours-per-truck total was divided into Tohp to obtain the size of the truck fleet required for the Depot-1, Depot-2, and Depot-4 analyses.

Total haul distance required to haul all loads of pellets from the ith depot (Tdpi) was given by:

The total travel distance divided by the number of trucks in the pellet hauling fleet provided the average travel distance per truck.

3. Results

3.1. Results for Delivery of Raw Biomass to Depots

The total truck operating hours required to haul raw biomass to the depots over the 48-week season are given in Table 9. Percentage decreases in truck hours, relative to the Depot-1 analysis, are given in Table 10. The decrease was about 12% for the Depot-2 distribution and 30% for the Depot-4 distribution. Because all five production areas had approximately the same spatial distribution of stored raw biomass, i.e., different quantities but similar distributions, it was not surprising that the percentage decreases in truck operating hours were similar.

Table 9.

Total truck operating hours required to haul all raw biomass from satellite storage locations (SSLs) to depots for the three depot distributions.

Table 10.

Percentage decreases in truck operating hours (i.e., raw biomass hauling to the depots), relative to the Depot-1 distribution.

The total haul distance required to deliver raw biomass to the depots was calculated for the three depot distributions (Table 11). The total haul distance decreased by 18% when the number of depots increased from five to ten, and by 34% when the number of depots increased from five to twenty.

Table 11.

Total haul distance (km) required to deliver all raw biomass from satellite storage locations (SSLs) to depots for the three depot distributions.

The mass-distance parameter for raw biomass hauling for all depot distributions was approximately equal for all production areas because a similar spatial distribution of feedstock production was assumed. The difference was the quantity of raw biomass stored in each SSL. As the number of depots increased, the distance from a given SSL to the nearest depot decreased. Thus, the mass-distance parameter decreased from 41.4 to 34.0 to 22.7 km as the number of depots increased from five to ten to twenty.

3.2. Results for Delivery of Pellets to Biorefinery

The total truck operating hours, as well as the total haul distances required to haul pellets to the biorefinery over the 48-week season are given in Table 12.

Table 12.

Total truck operating hours and total haul distances required to deliver pellets to the biorefinery.

A key result was the increase in pellet hauling hours as the number of depots increased from five to ten; this increase was about 19% (Table 12). When the number of depots was doubled again, from ten to twenty, the increase was only about 2%, which suggests that increasing the number of depots has a diminishing impact on the required truck operating hours to haul pellets.

The increase in total truck travel (Table 12) with increases in the number of depots is partly explained by the fact that the mass-distance parameter increased from 87.9 km for the Depot-1 distribution to 89.0 km and 90.6 km for the Depot-2 and Depot-4 distributions, respectively. The increase in total truck travel (i.e., pellet hauling to the biorefinery) was 19% from Depot-1 to Depot-2 and 22% from Depot-1 to Depot-4.

The total truck operating hours to haul both raw biomass and pellets is given in Table 13. As previously mentioned, the hourly cost to operate the truck, based on ownership and operating costs (including labor), was about the same whether the load was 16 Mg of round bales or 34 Mg of pellets. Thus, total truck operating hours was a key parameter in the comparison of different logistics systems, i.e., different distributions of depots.

Table 13.

Total truck operating hours, raw biomass hauling + pellet hauling, required to supply biorefinery annual operation.

Increasing the number of depots reduced the truck cycle time for many of the individual loads; thus, the total truck operating hours was expected to decrease, and this was observed. This decrease was less than 1% as the number of depots increased from five to ten. More significantly, an increase from five to twenty depots resulted in a decrease in total truck operating hours of about 11%.

4. Conclusions

A truck tractor can pull a load of high-value products or a load of low-value raw biomass; the cost in USD per day is approximately the same. The heavy truck industry in the US is huge; thus, this cost is well defined for all locations. The goal of any feedstock logistics system is to maximize Mg per day per truck. This minimizes the average feedstock hauling cost in USD per Mg. A truckload of pellets is 34 Mg and a truckload of raw biomass (i.e., round bales) is 16 Mg. The distance that raw biomass is hauled before converting to pellets is an important issue in the logistics system design.

The reduction in total truck operating hours was minor, less than 1%, when the number of depots was increased from five to ten. The reduction in raw biomass hauling hours was mostly offset by an increase in pellet hauling hours. An increase from five to twenty resulted in a reduction of about 11%. This was less than might be expected, given that a truckload of raw biomass was assumed to carry less biomass than a truckload of pellets. The number of trips required to haul the raw biomass was greater, but the haul distance for each trip was lower. Conversely, fewer trips were required to haul pellets from a given depot, but the haul distance for this depot was often greater.

Another possibility for improving biorefinery logistics systems that is still in development is the concept of mobile pelleting mills [18]. It may be practical in the future to use this technology to move from SSL to SSL and convert the raw biomass to pellets, thus eliminating all truck hauling of raw biomass from an SSL to a pelleting location. A mobile pelleting option would require that pellet storage bins, in a range of different capacities, be built at each of the SSLs. The cost comparison is a subject of future research.

Author Contributions

Conceptualization, J.S.C.; methodology, J.S.C. and S.S.; software, J.S.C. and J.P.R.; validation, J.S.C. and S.S.; formal analysis, J.S.C. and S.S.; investigation, J.S.C.; resources, J.S.C. and J.P.R.; data curation, J.P.R.; writing—original draft preparation, J.S.C. and J.P.R.; writing—review and editing, J.S.C., J.P.R. and S.S.; visualization, J.P.R.; supervision, J.S.C.; project administration, J.S.C.; funding acquisition, J.S.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data is contained within the article.

Acknowledgments

Appreciation is expressed to the University of Maryland Department of Geographical Sciences for access to their GIS computing resources.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Resop, J.P.; Cundiff, J.S. Assessment of Herbaceous Feedstock Supply for Locating Biorefineries in the Piedmont, USA. Biofuels Bioprod. Biorefining 2022, 16, 43–53. [Google Scholar] [CrossRef]

- Grisso, R.D.; Cundiff, J.S.; Comer, K. Multi-Bale Handling Unit for Efficient Logistics. AgriEngineering 2020, 2, 336–349. [Google Scholar] [CrossRef]

- Grisso, R.D.; Cundiff, J.S.; Sarin, S.C. Rapid Truck Loading for Efficient Feedstock Logistics. AgriEngineering 2021, 3, 158–167. [Google Scholar] [CrossRef]

- Resop, J.P.; Cundiff, J.S.; Grisso, R.D. Central Control for Optimized Herbaceous Feedstock Delivery to a Biorefinery from Satellite Storage Locations. AgriEngineering 2022, 4, 544–565. [Google Scholar] [CrossRef]

- Hess, J.R.; Kenney, K.L.; Ovard, L.P.; Searcy, E.M.; Wright, C.T. Commodity-Scale Production of an Infrastructure-Compatible Bulk Solid from Herbaceous Lignocellulosic Biomass; Idaho National Laboratory (INL): Idaho Falls, ID, USA, 2009; Volume 6, p. 163. [Google Scholar]

- Hess, J.R.; Wright, C.T.; Kenney, K.L.; Searcy, E.M. Uniform-Format Solid Feedstock Supply System: A Commodity-Scale Design to Produce an Infrastructure-Compatible Bulk Solid from Lignocellulosic Biomass—Executive Summary; Idaho National Laboratory (INL): Idaho Falls, ID, USA, 2009. [Google Scholar]

- Lamers, P.; Roni, M.S.; Tumuluru, J.S.; Jacobson, J.J.; Cafferty, K.G.; Hansen, J.K.; Kenney, K.; Teymouri, F.; Bals, B. Techno-Economic Analysis of Decentralized Biomass Processing Depots. Bioresour. Technol. 2015, 194, 205–213. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Dale, B.E. A Distributed Cellulosic Biorefinery System in the US Midwest Based on Corn Stover. Biofuels Bioprod. Biorefining 2016, 10, 819–832. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E.; Basso, B.; Thelen, K.; Maravelias, C.T. Supply Chain System for a Centralized Biorefinery System Based on Switchgrass Grown on Marginal Land in Michigan. Biofuels Bioprod. Biorefining 2023, 17, 1502–1514. [Google Scholar] [CrossRef]

- Simet, A. Thinking Inside the Box. Biomass Magazine, 29 November 2021. Available online: https://biomassmagazine.com/articles/thinking-inside-the-box-18500 (accessed on 16 May 2025).

- Resop, J.P.; Cundiff, J.S. Optimization of Herbaceous Feedstock Delivery to a Network of Supply Depots for a Biorefinery in the Piedmont, USA. Biofuels Bioprod. Biorefining 2023, 17, 1528–1540. [Google Scholar] [CrossRef]

- Resop, J.P.; Cundiff, J.S.; Sokhansanj, S. Delivered Cost for Switchgrass Pellets from Depots to a Biorefinery in the Piedmont, USA. Biofuels Bioprod. Biorefining 2025, in press. [Google Scholar] [CrossRef]

- Gustafson, C.; Maung, T.; Saxowsky, D.; Nowatzki, J.; Miljkovic, T. Economics of Sourcing Cellulosic Feedstock for Energy Production. In Proceedings of the Agricultural and Applied Economics Association (AAEA) Conferences, Pittsburgh, PA, USA, 24–26 July 2011. [Google Scholar]

- Holder, C.T.; Cleland, J.C.; LeDuc, S.D.; Andereck, Z.; Martin, K.M. Generating a Geospatial Database of U.S. Regional Feedstock Production for Use in Evaluating the Environmental Footprint of Biofuels. J. Air Waste Manag. Assoc. 2016, 66, 356–365. [Google Scholar] [CrossRef] [PubMed]

- Lynch, M.N.; Satrio, J.A. Utilization of Grassy Biomass Grown in Heavy-Metal Contaminated Soil as Feedstock for Bioenergy Production—An LCA Study. IOP Conf. Ser. Earth Environ. Sci. 2022, 1034, 012022. [Google Scholar] [CrossRef]

- Fike, J.H.; Parrish, D.J.; Wolf, D.D.; Balasko, J.A.; Green, J.T.; Raske, M. Long-term Yield Potential of Switchgrass-for-Biofuel Systems. Biomass Bioenergy 2006, 30, 198–206. [Google Scholar] [CrossRef]

- Resop, J.P.; Cundiff, J.S.; Heatwole, C.D. Spatial Analysis to Site Satellite Storage Locations for Herbaceous Biomass in the Piedmont of the Southeast. Appl. Eng. Agric. 2011, 27, 25–32. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Ebadian, M.; Rezaei, H.; Yazdanpanah, F. The Logistics of Production and Supply of Ag Pellets for Industrial Applications in Canada. J. Sustain. Bioenergy Syst. 2023, 13, 40–55. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).