Spatial Distribution of Greenhouse Gas Emissions and Environmental Variables in Compost Barn Dairy Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Location Description

2.2. Acquisition of Evaluated Variables

2.3. Geostatistical Analysis of Data

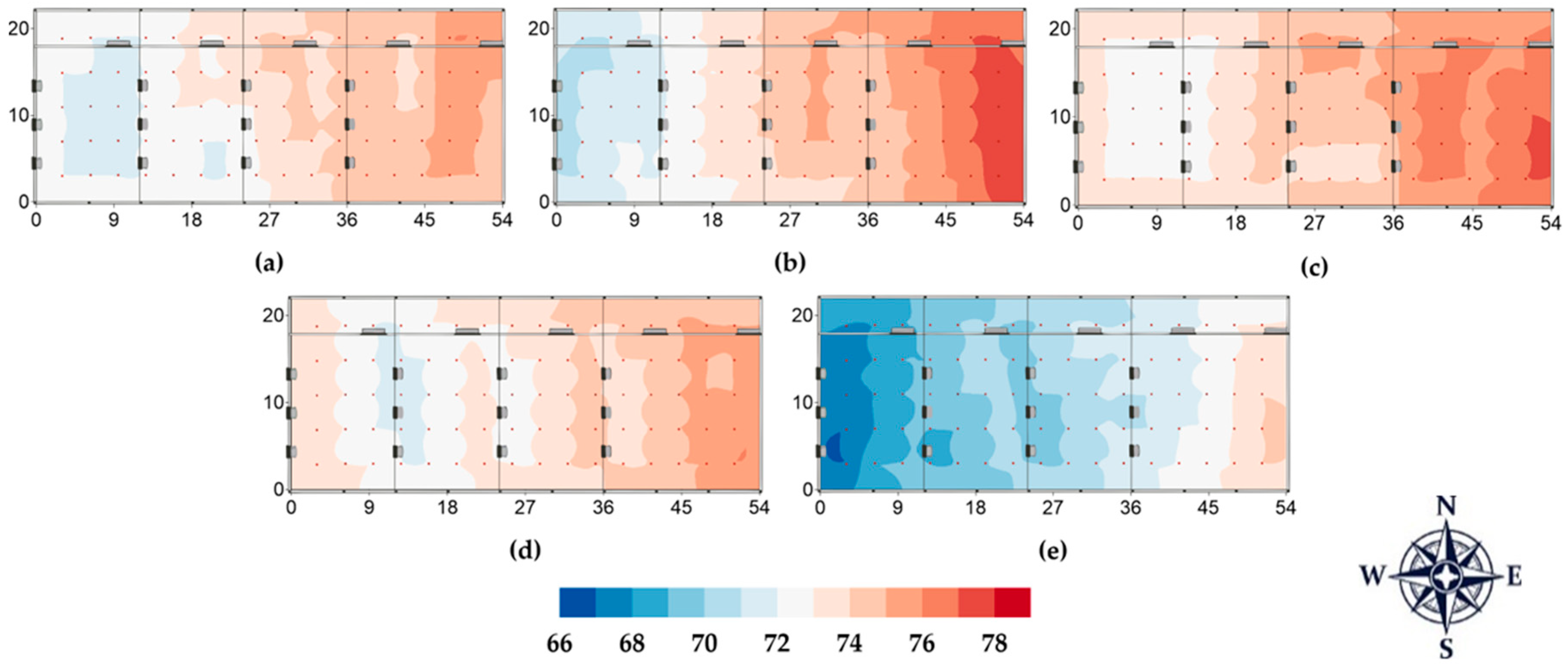

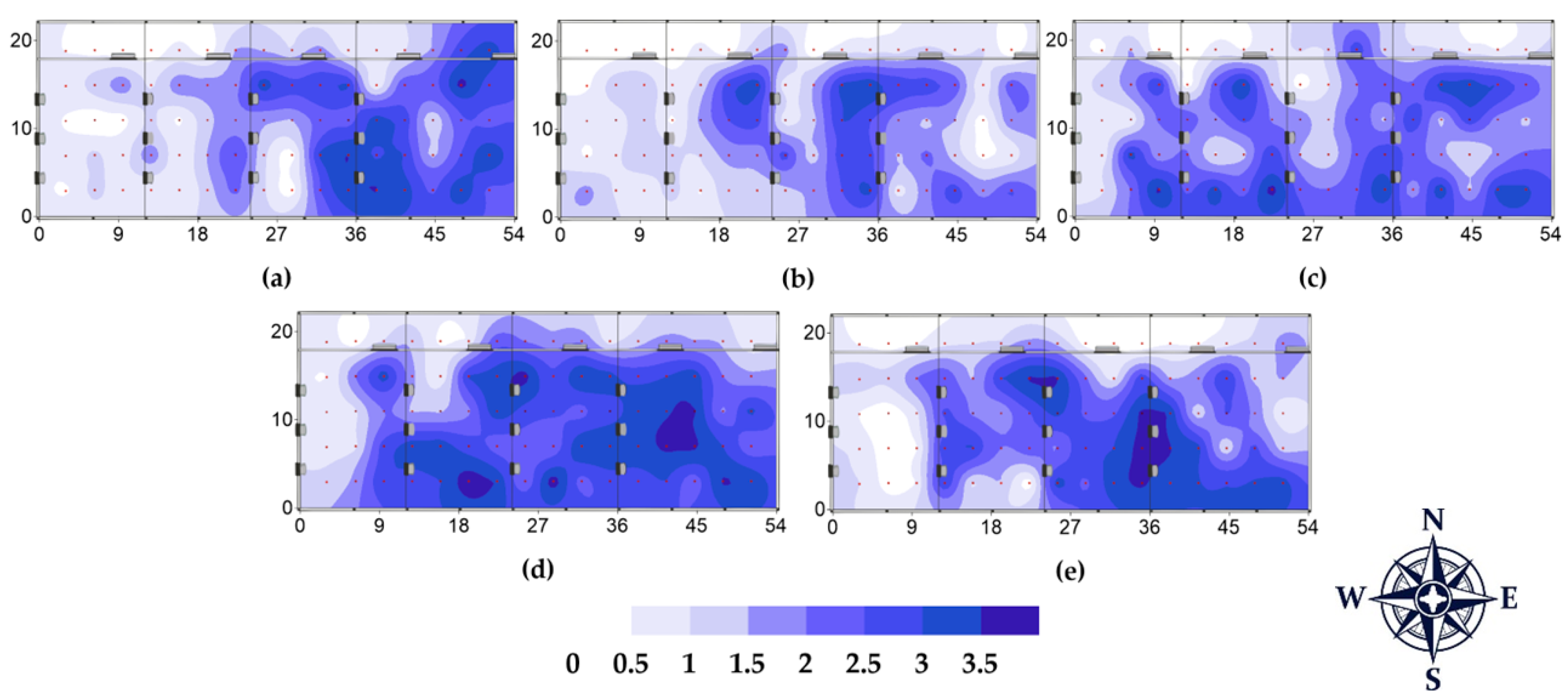

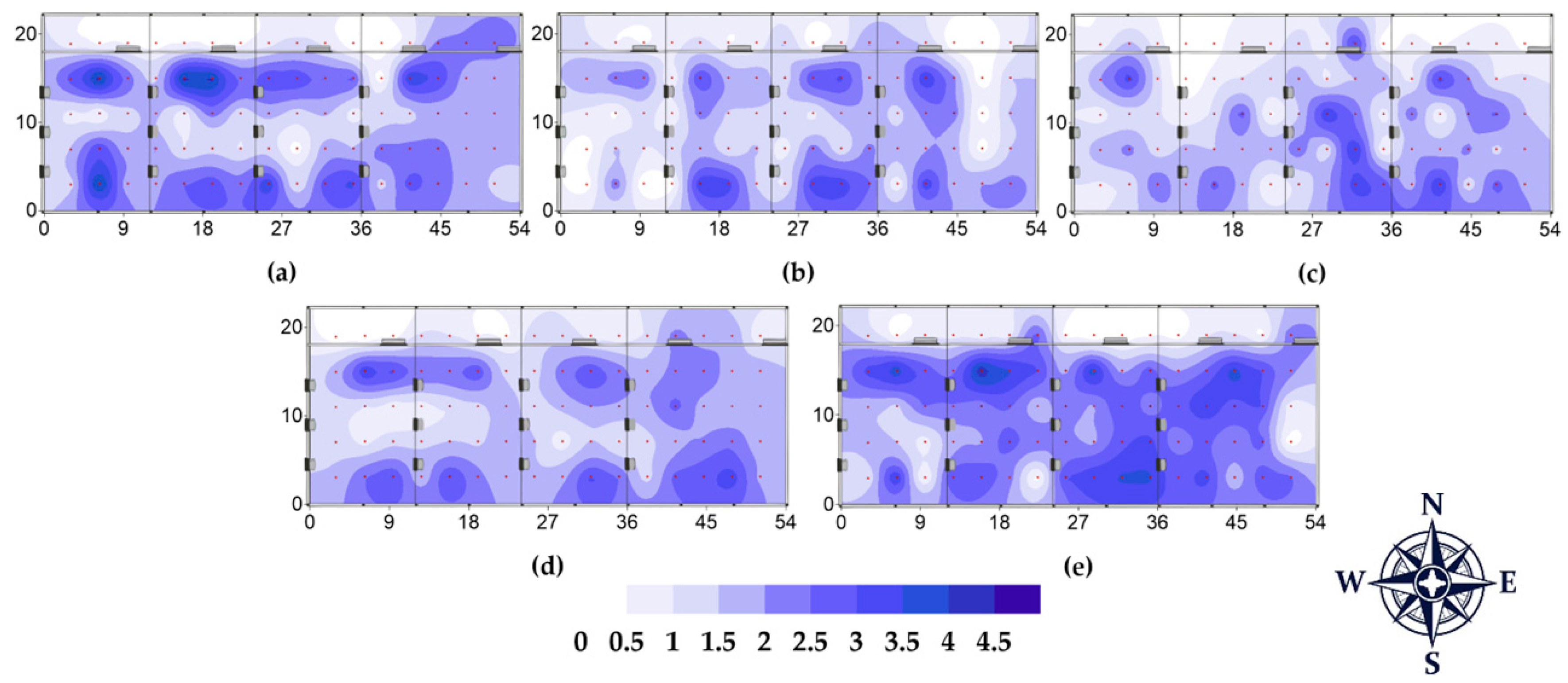

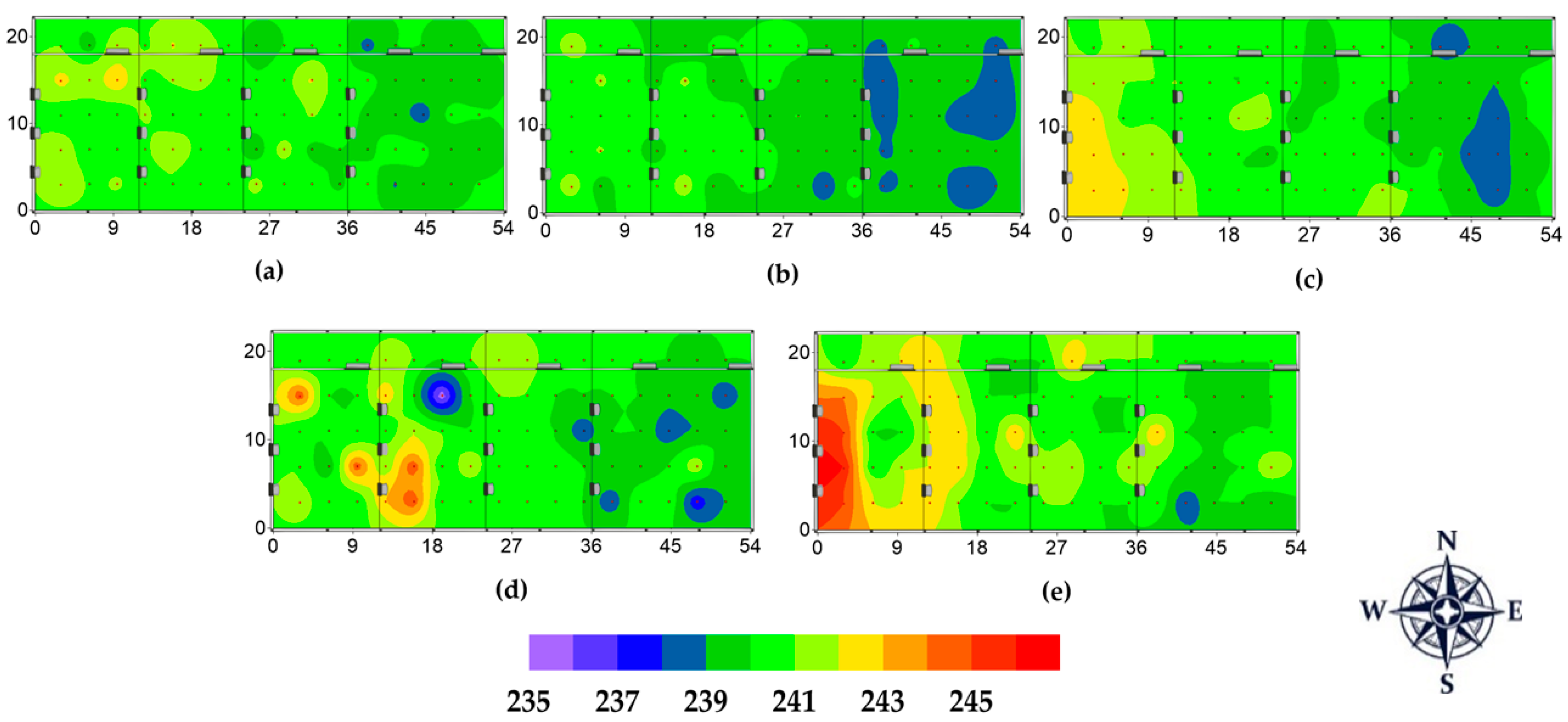

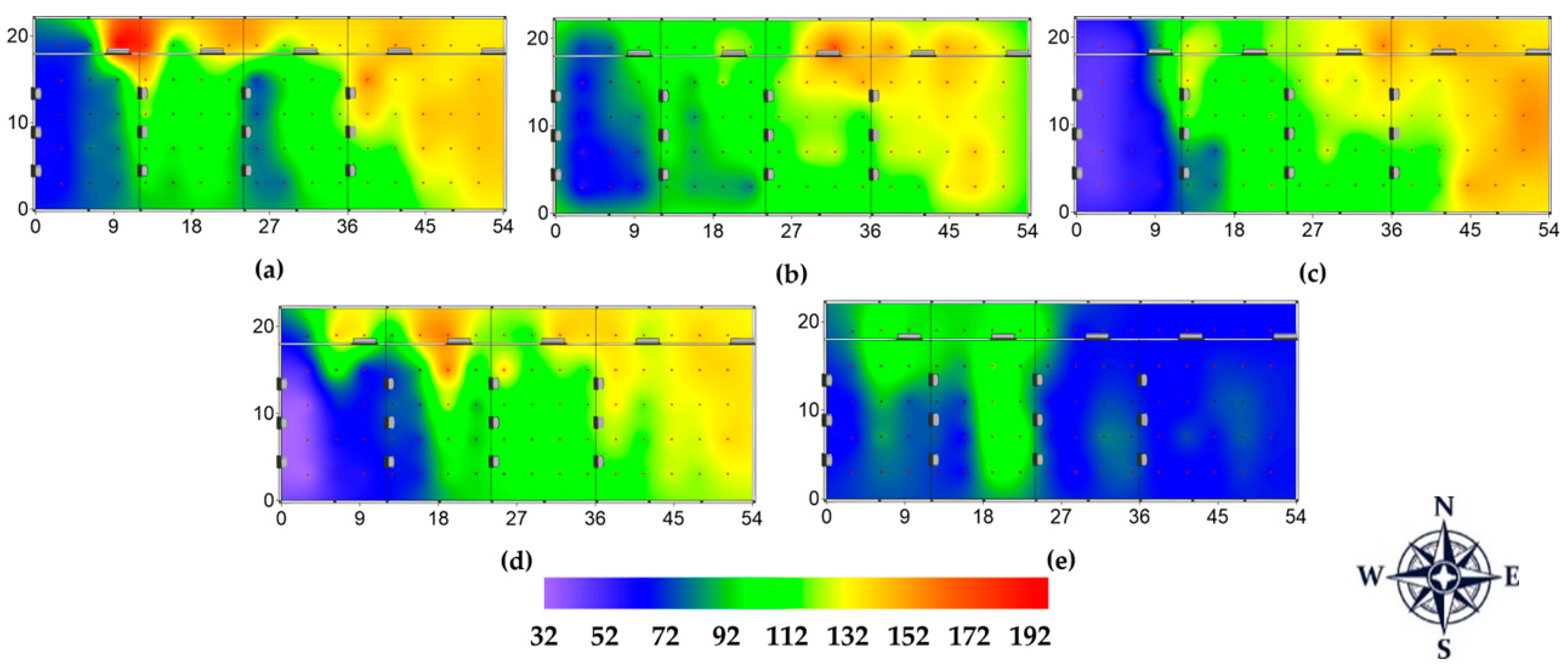

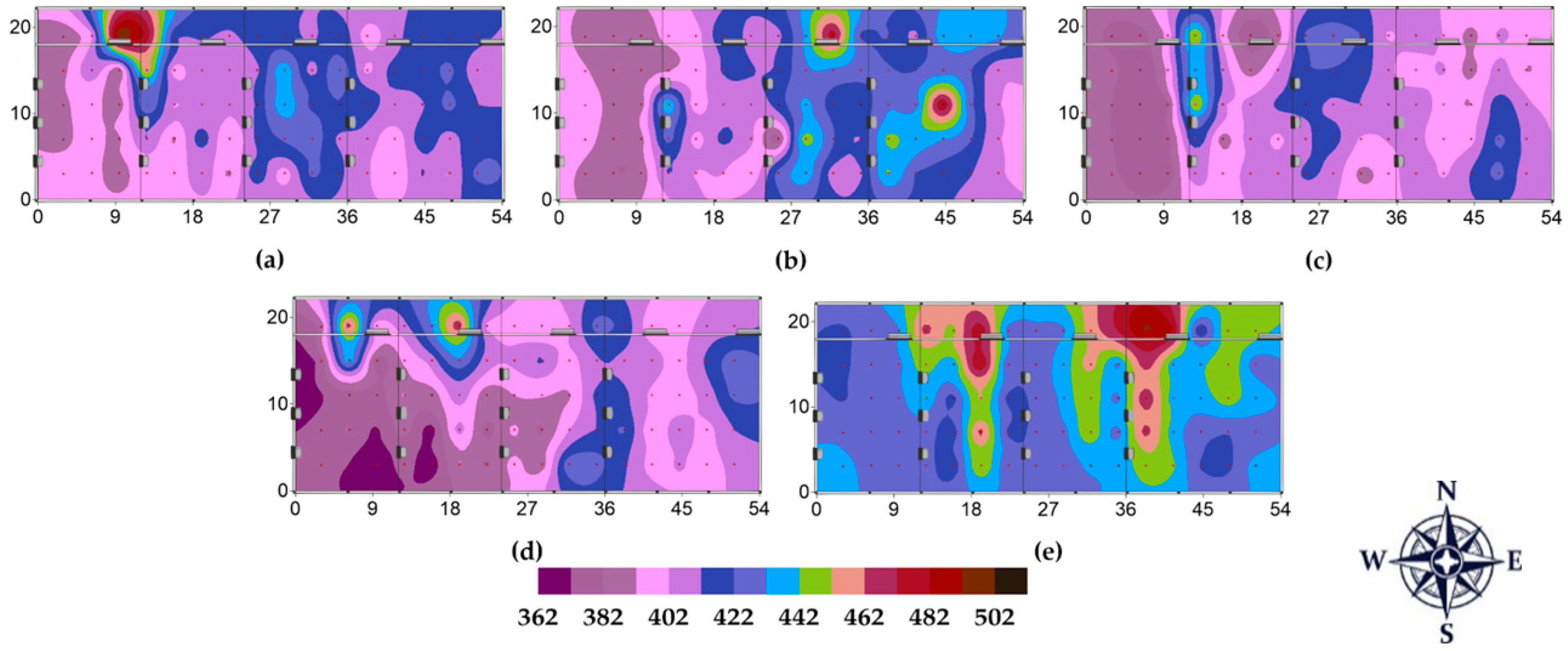

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Min, B.R.; Lee, S.; Jung, H.; Miller, D.N.; Chen, R. Enteric Methane Emissions and Animal Performance in Dairy and Beef Cattle Production: Strategies, Opportunities, and Impact of Reducing Emissions. Animals 2022, 12, 948. [Google Scholar] [CrossRef]

- de L. Santos, G.C.; Neto, S.G.; Bezerra, L.R.; de Medeiros, A.N. Use of cakes to feed dairy cows: A review. Braz. J. Anim. Environ. Res. 2020, 3, 89–113. [Google Scholar]

- Biasato, I.; D’Angelo, A.; Bertone, I.; Odore, R.; Bellino, C. Compost bedded-pack barn as an alternative housing system for dairy cattle in Italy: Effects on animal health and welfare and milk and milk product quality. Ital. J. Anim. Sci. 2019, 18, 1142–1153. [Google Scholar] [CrossRef]

- da Silva, M.V.; Pandorfi, H.; de Almeida, G.L.P.; da Silva, R.A.B.; Morales, K.R.M.; Guiselini, C.; Santana, T.C.; de Cangela, G.L.C.; Filho, J.A.D.B.; Moraes, A.S.; et al. Spatial Modeling via Geostatistics and Infrared Thermography of the Skin Temperature of Dairy Cows in a Compost Barn System in the Brazilian Semiarid Region. Smart Agr. Technol. 2023, 3, 100078. [Google Scholar] [CrossRef]

- Shi, Z.; Xi, L.; Zhao, X. Measurement of ammonia and hydrogen sulfide emission from three typical dairy barns and estimation of total ammonia emission for the Chinese dairy industry. Animals 2023, 13, 2301. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro-Filho, H.M.N.; Civiero, M.; Kebreab, E. Potential to reduce greenhouse gas emissions through different dairy cattle systems in subtropical regions. PLoS ONE 2020, 15, e0234687. [Google Scholar] [CrossRef] [PubMed]

- da Silva, M.V.; Pandorfi, H.; de Almeida, G.L.P.; da Rosa Ferraz Jardim, A.M.; Batista, P.H.D.; da Silva, R.A.B.; Lopes, I.; de Oliveira, M.E.G.; de Silva, J.L.B.; Moraes, A.S. Spatial variability and exploratory inference of abiotic factors in barn compost confinement for cattle in the semiarid. J. Therm. Biol. 2020, 94, 102782. [Google Scholar] [CrossRef]

- Peixoto, M.S.M.; Barbosa Filho, J.A.D.; Machado, N.A.F.; De Sena Sales Viana, V.; Costa, J.F.M. Thermoregulatory behavior of dairy cows submitted to bedding temperature variations in Compost barn systems. Biol. Rhythm Res. 2019, 52, 1120–1129. [Google Scholar] [CrossRef]

- Fuertes, E.; Balcells, J.; Maynegre, J.; Fuente, G.; Sarri, L.; Seradj, A.R. Measurement of methane and ammonia emissions from compost-bedded pack systems in dairy barns: Tilling effect and seasonal variations. Animals 2023, 13, 1871. [Google Scholar] [CrossRef]

- Džermeikaitė, K.; Krištolaitytė, J.; Antanaitis, R. Relationship between Dairy Cow Health and Intensity of Greenhouse Gas Emissions. Animals 2024, 14, 829. [Google Scholar] [CrossRef]

- Zhuang, M.; Shan, N.; Wang, Y.; Caro, D.; Fleming, R.M.; Wang, L. Different Characteristics of Greenhouse Gases and Ammonia Emissions from Conventional Stored Dairy Cattle and Swine Manure in China. Sci. Total Environ. 2020, 722, 137693. [Google Scholar] [CrossRef]

- Grossi, G.; Goglio, P.; Vitali, A.; Williams, A.G. Livestock and climate change: Impact of livestock on climate and mitigation strategies. Anim. Front. 2019, 9, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Singaravadivelan, A.; Sachin, P.B.; Harikumar, S.; Vijayakumar, P.; Vindhya, M.V.; Farhana, F.M.B.; Rameesa, K.K.; Mathew, J. Life cycle assessment of greenhouse gas emission from the dairy production system—Review. Trop. Anim. Health Prod. 2023, 55, 320. [Google Scholar] [CrossRef] [PubMed]

- Forster, P.; Storelvmo, T.; Armour, K.; Collins, W.; Dufresne, J.L.; Frame, D.; Lunt, D.J.; Mauritsen, T.; Palmer, M.D.; Watanabe, M.; et al. The Earth’s Energy Budget, Climate Feedbacks, and Climate Sensitivity. In Climate Change 2021: The Physical Science Basis.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021; pp. 923–1054. [Google Scholar]

- Signor, D.; Cerri, C.E.P. Nitrous oxide emissions in agricultural soils: A review. Pesqui. Agropecu. Trop. 2013, 43, 322–338. [Google Scholar] [CrossRef]

- de Oliveira, V.C.; da Silva, L.F.; Oliveira, C.E.A.; Franco, J.R.; Rodrigues, S.A.; de Souza, C.M.A.; Andrade, R.R.; Damasceno, F.A.; de Fátima Ferreira Tinôco, I.; Bambi, G. Characterization and Mitigation Measures for Carbon Dioxide, Methane, and Ammonia Emissions in Dairy Barns. Livest. Sci. 2024, 290, 105595. [Google Scholar] [CrossRef]

- Ferraz, P.F.P.; Ferraz, G.A.e.S.; Ferreira, J.C.; Aguiar, J.V.; Santana, L.S.; Norton, T. Assessment of Ammonia Emissions and Greenhouse Gases in Dairy Cattle Facilities: A Bibliometric Analysis. Animals 2024, 14, 1721. [Google Scholar] [CrossRef]

- Zanon, T.; Fichter, G.; Mittermair, P.; Nocker, L.; Gauly, M.; Peratoner, G. Quantifying methane emissions under field conditions under 2 different dairy production scenarios: Low-input versus high-input milk production. J. Dairy Sci. 2023, 106, 4711–4724. [Google Scholar] [CrossRef]

- Pragna, P.; Chauhan, S.S.; Sejian, V.; Leury, B.J.; Dunshea, F.R. Climate change and goat production: Enteric methane emission and its mitigation. Animals 2018, 8, 235. [Google Scholar] [CrossRef]

- Lôbo, A.M.B.O.; Lôbo, R.N.B.; Facó, O.; Souza, V.; Alves, A.A.C.; Costa, A.C.; Albuquerque, M.A.M. Characterization of milk production and composition of four exotic goat breeds in Brazil. Small Rumin. Res. 2017, 153, 9–16. [Google Scholar] [CrossRef]

- Bell, M.J.; Wall, E.; Simm, G.; Russel, G. Effects of genetic line and feeding system on methane from dairy systems. Anim. Feed Sci. Technol. 2011, 166–167, 699–707. [Google Scholar] [CrossRef]

- Johnson, K.A.; Johnson, D.E. Methane emissions from cattle. J. Anim. Sci. 1995, 73, 2483–2492. [Google Scholar] [CrossRef] [PubMed]

- Damasceno, F.A. Compost Barn as an Alternative for Dairy Farming, 3rd ed.; Gulliver: João Pessoa, Brazil, 2020; p. 396. [Google Scholar]

- Hindrichsen, I.K.; Wettstein, H.R.; Machmüller, A.; Jorg, B.; Kreuzer, M. Effect of the Carbohydrate Composition of feed Concentratates on Methane Emission from dairy Cows and Their Slurry. Environ. Monit. Assess. 2005, 107, 329–350. [Google Scholar] [CrossRef]

- Stokstad, M.; Klem, T.B.; Myrmel, M.; Oma, V.S.; Toftaker, I.; Osteras, O.; Nodtvedt, A. Using biosecurity measures to combat respiratory disease in cattle: The Norwegian control program for bovine respiratory syncytial virus and bovine Coronavirus. Front. Vet. Sci. 2020, 7, 167. [Google Scholar] [CrossRef]

- Pereira, M.H.C.; Rodrigues, A.D.P.; Martins, T.; Oliveira, W.V.C.; Silveira, P.S.A.; Wiltbank, M.C.; Vasconcelos, J.L.M. Timed artificial insemination programs during the summer in lactating dairy cows: Comparison of the 5-d Cosynch protocol with an estrogen/progesterone-based protocol. J. Dairy. Sci. 2013, 96, 6904–6914. [Google Scholar] [CrossRef] [PubMed]

- Furst, L.; Feliciano, M.; Frare, L.; Igrejas, G. A Portable Device for Methane Measurement Using a Low-Cost Semiconductor Sensor: Development, Calibration and Environmental Applications. Sensors 2021, 21, 7456. [Google Scholar] [CrossRef]

- Butturini, A.; Fonollosa, J. Use of Metal Oxide Semiconductor Sensors to Measure Methane in Aquatic Ecosystems in the Presence of Cross-Interfering Compounds. Limnol. Oceanogr. Methods 2022, 20, 710–720. [Google Scholar] [CrossRef]

- Fakra, D.A.H.; Andriatoavina, D.A.S.; Razafindralambo, N.A.M.N.; Amarillis, K.A.; Andriamampianina, J.M.M. A Simple and Low-Cost Integrative Sensor System for Methane and Hydrogen Measurement. Sens. Int. 2020, 1, 100032. [Google Scholar] [CrossRef]

- Oliaee, S.N.; Khodadadi, A.; Mortazavi, Y.; Alipour, S. Highly Selective Pt/SnO2 Sensor to Propane or Methane in Presence of CO and Ethanol, Using Gold Nanoparticles on Fe2O3 Catalytic Filter. Sens. Actuators B Chem. 2010, 147, 400–405. [Google Scholar] [CrossRef]

- Riddick, S.N.; Mauzerall, D.L.; Celia, M.; Allen, G.; Pitt, J.; Kang, M.; Riddick, J.C. The Calibration and Deployment of a Low-Cost Methane Sensor. Atmos. Environ. 2020, 230, 117440. [Google Scholar] [CrossRef]

- Van den Bossche, M.; Rose, N.T.; De Wekker, S.F.J. Potential of a Low-Cost Gas Sensor for Atmospheric Methane Monitoring. Sens. Actuators B Chem. 2017, 238, 501–509. [Google Scholar] [CrossRef]

- Fu, L.; You, S.; Li, G.; Li, X.; Fan, Z. Application of Semiconductor Metal Oxide in Chemiresistive Methane Gas Sensor: Recent Developments and Future Perspectives. Molecules 2023, 28, 6710. [Google Scholar] [CrossRef] [PubMed]

- Massari, J.M.; Moura, D.J.; Curi, T.M.R.C.; Vercellino, R.A.; Medeiros, B.B.L. Zoning of environmental conditions inside a wean-to-finish pig facility. Energ. Agric. Botucatu. 2016, 36, 739–748. [Google Scholar] [CrossRef]

- Ribeiro, P.A.P.; Yanagi Junior, T.; Oliveira, D.D.; Ferraz, G.A.S.; Lourençone, D. Análise geoestatística das iluminâncias em aviários para poedeiras equipados com lâmpadas fluorescents compactas e de led. Energ. Agric. Botucatu. 2016, 36, 11–21. [Google Scholar]

- Ferreira, J.C.; Ferraz, P.F.P.; Ferraz, G.A.S.; Oliveira, F.M.; Cadavid, V.G.; Rossi, G.; Becciolini, V. Spatial variability of methane and carbon dioxide gases in a Compost-Bedded Pack Barn system. Agron. Res. 2024, 22, 110–126. [Google Scholar]

- Oliveira, C.E.A.; Tinôco, I.F.F.; Damasceno, F.A.; Oliveira, V.C.; Rodrigues, P.H.M.; Ferraz, G.A.S.; Sousa, F.C.; Andrade, R.R.; Nascimento, J.A.C.; Silva, L.F. Air velocity spatial variability in open Compost-Bedded Pack Barn system with positive pressure ventilation. An. Acad. Bras Cienc. 2023, 95, e20220415. [Google Scholar]

- Dantas, A.A.A.; de Carvalho, L.G.; Ferreira, E. Climatic classification and tendencies in Lavras region, MG. Ciênc. Agrotec. 2007, 31, 1862–1866. [Google Scholar] [CrossRef]

- Becciolini, V.; Conti, L.; Rossi, G.; Marin, D.B.; Merlini, M.; Coletti, G.; Barbari, M. Real-Time Measurements of Gaseous and Particulate Emissions from Livestock Buildings and Manure Stores with Novel UAV-Based System. In Proceedings of the Conference of the Italian Society of Agricultural Engineering, Turin, Italy, 19–22 September 2022. [Google Scholar]

- Thom, E.C. The discomfort index. Weatherwise 1959, 12, 57–61. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2024; Available online: https://www.R-project.org/ (accessed on 27 April 2024).

- Ribeiro, P.J., Jr.; Diggle, P.; Christensen, O.; Schlather, M.; Bivand, R.; Ripley, B. geoR: Analysis of Geostatistical Data, R package version 1.9-4; 2024. Available online: http://www.leg.ufpr.br/geoR/ (accessed on 29 April 2024).

- Oliveira, R.A.; Souza, C.F.; Silva, R.C.; Lima, R.R. Spatial variability of environmental variables in a free-stall barn. Rev. Bras. Eng. Agríc. Ambient. 2017, 21, 410–414. [Google Scholar]

- Bachmaier, M.; Backers, M. Variogram or semivariogram? understanding the variances in a variogram. Prec. Agric. 2008, 9, 173–175. [Google Scholar] [CrossRef]

- Ferraz, P.F.P.; Ferraz, G.A.S.; Schiassi, L.; Nogueira, V.H.B.; Barbari, M.; Damasceno, F.A. Spatial variability of litter temperature, relative air humidity and skin temperature of chicks in a commercial broiler house. Agron. Res. 2019, 17, 408–417. [Google Scholar]

- Cambardella, C.A.; Moorman, T.B.; Novak, J.M.; Parkin, T.B.; Karlen, D.L.; Turco, R.F.; Konopka, A.E. Field-scale variability of soil properties in central Iowa soils. Soil Science Society of America journal. Soil Sci. Soc. Am. J. 1994, 58, 1501–1511. [Google Scholar] [CrossRef]

- Ferraz, G.A.S.; Silva, F.M.; Oliveira, M.S.; Custódio, A.A.P.; Ferraz, P.F.P. Spatial variability of plant attributes in a coffee plantation. Ver. Ciênc. Agron. 2017, 48, 81–91. [Google Scholar] [CrossRef]

- Golden Software, L.L.C. Surfer (Version 13.4.553) Computer Software. Golden Software: Golden, CO, USA, 2016. Available online: https://www.goldensoftware.com/products/surfer (accessed on 28 April 2023).

- Frigeri, K.D.M.; Deniz, M.; Damasceno, F.A.; Barbari, M.; Herbut, P.; Vieira, F.M.C. Effect of Heat Stress on the Behavior of Lactating Cows Housed in Compost Barns: A Systematic Review. Appl. Sci. 2023, 13, 2044. [Google Scholar] [CrossRef]

- Rosanova, C.; Rebouças, G.F.; da Silva, M.D.M.P.; Rezende, D.M.L.C.; da Rocha, A.S.; Pereira Junior, A.; da Silva, E.W. Determinação do ITU–índice de temperatura e umidade da região de Araguaína-TO para avaliação do conforto térmico de bovinos leiteiros. Braz. J. Dev. 2020, 6, 69254–69258. [Google Scholar] [CrossRef]

- Mader, T.L.; Davis, M.S.; Brown-Brandl, T. Environmental factors influencing heat stress in feedlot cattle. J. Anim. Sci. 2006, 84, 712–719. [Google Scholar] [CrossRef] [PubMed]

- da Silva, M.V.; de Almeida, G.L.P.; Pandorfi, H.; Moraes, A.S.; de Almeida Macêdo, G.A.P.; Batista, P.H.D.; da Silva, R.A.B.; Quiselini, C. Influence of meteorological elements on behavioral responses of gir cows and effects on milk quality. Acta scientiarum. Anim. Sci. 2021, 43, e52604. [Google Scholar] [CrossRef]

- Nogara, K.F.; Bill Kaelle, G.C.; Gouveia Tavares, Q.; Marcon, T.R.; Gopinger, E.; Zopollatto, M.; Debortoli, E.d.C. Influência das estações do ano sobre a qualidade microbiológica do leite de fazendas leiteiras da região norte do Rio Grande do Sul, Brasil. Braz. Anim. Sci. 2022, 23, e-72795P. [Google Scholar] [CrossRef]

- Almeida, J.V.N.; Marques, L.R.; Marques, T.C.; Guimarães, K.C.; Leão, K.M. Influence of thermal stress on the productive and reproductive aspects of cattle—Review. Res. Soc. Dev. 2020, 9, e230973837. [Google Scholar] [CrossRef]

- Baumgard, L.H.; Rhoads, R.P., Jr. Effects of heat stress on postabsorptive metabolism and energetics. Annu. Rev. Anim. Biosci. 2013, 1, 311–337. [Google Scholar] [CrossRef]

- Hansen, P.J.; Fuquay, J.W. Stress in Dairy Animals Heat Stress: Effects on Reproduction. In Reference Module in Food Science; Academic Press: Cambridge, MA, USA, 2016. [Google Scholar] [CrossRef]

- Tao, S.; Orellana, R.M.; Weng, X.; Marins, T.N.; Dahl, G.E.; Bernard, J.K. Symposium Review: The Influences of Heat Stress on Bovine Mammary Gland Function. J. Dairy Sci. 2018, 101, 5642–5654. [Google Scholar] [CrossRef]

- Staples, C.R.; Thatcher, W.W. Heat Stress: Effects on Milk Production and Composition, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2011; pp. 561–566. [Google Scholar]

- Soriani, N.; Panella, G.; Calamari, L. Rumination Time during the Summer Season and Its Relationships with Metabolic Conditions and Milk Production. J. Dairy Sci. 2013, 96, 5082–5094. [Google Scholar] [CrossRef] [PubMed]

- de Almeida Neto, L.A.; Pandorfi, H.; de Almeida, G.L.; Guiselini, C. Pre-milking acclimatization of ‘Girolando’ cows during the winter in the semiarid region. Rev. Bras. Eng. Agríc. Ambient. 2014, 18, 1072–1078. [Google Scholar]

- Danieli, B.; Barreta, D.A.; Schogor, A.L.B. Características e recomendações de gerenciamento no confinamento de vacas de leite em compost barn: Revisão. Sci. Agrar. 2018, 19, 249–255. [Google Scholar] [CrossRef]

- Dal Más, F.E.; Debiage, R.R.; Schuh, B.R.F.; Guirro, E.C.B.P. Estresse térmico em bovinos leiteiros—Impactos, avaliação e medidas de controle. Rev. Vet. Foco 2020, 17, 2. [Google Scholar]

- Lobeck, K.M.; Endres, M.I.; Shane, E.M.; Godden, S.M.; Fetrow, J. Animal Welfare in Cross-Ventilated, Compost-Bedded Pack, and Naturally Ventilated Dairy Barns in the Upper Midwest. J. Dairy Sci. 2011, 94, 5469–5479. [Google Scholar] [CrossRef] [PubMed]

- Janni, K.A.; Endreas, M.I.; Reneau, J.K.; Schoper, W.W. Compost Dairy Barn Layout and Management Recommendations. Appl. Eng. Agric. 2007, 23, 97–102. [Google Scholar] [CrossRef]

- Leso, L.; Barbari, M.; Lopes, M.A.; Damasceno, F.A.; Galama, P.; Taraba, J.L.; Kuipers, A. Invited Review: Compost-Bedded Pack Barns for Dairy Cows. J. Dairy Sci. 2020, 103, 1072–1099. [Google Scholar] [CrossRef]

- Eckelkamp, E.A.; Taraba, J.L.; Akers, K.A.; Harmon, R.J.; Bewley, J.M. Understanding Compost Bedded Pack Barns: Interactions among Environmental Factors, Bedding Characteristics, and Udder Health. Livest. Sci. 2016, 190, 35–42. [Google Scholar] [CrossRef]

- Llonch, L.; Castillejos, L.; Mainau, E.; Manteca, X.; Ferret, A. Effect of Forest Biomass as Bedding Material on Compost-Bedded Pack Performance, Microbial Content, and Behavior of Nonlactating Dairy Cows. J. Dairy Sci. 2020, 103, 10676–10688. [Google Scholar] [CrossRef]

- Radavelli, W.M.; Danieli, B.; Zotti, M.L.A.N.; Gomes, F.J.; Endres, M.I.; Schogor, A.L.B. Compost barns in Brazilian Subtropical region (Part 1): Facility, barn management and herd characteristics. Res. Soc. Dev. 2020, 9, e445985198. [Google Scholar] [CrossRef]

- Gaughan, J.B.; Mader, T.L.; Holt, S.M.; Lisle, A. A New Heat Load Index for Feedlot Cattle. J. Anim. Sci. 2008, 86, 226–234. [Google Scholar] [CrossRef] [PubMed]

- Bewley, J.M.; Taraba, J.L.; Day, G.B.; Black, R.A. Compost Bedded Pack Barn Design Features and Management Considerations. In Cooperative Extension Publ. ID-206; Cooperative Extension Service, University of Kentucky College of Agriculture: Lexington, KY, USA, 2012; p. 150. [Google Scholar]

- Berman, A. Invited review: Are adaptations present to support dairy cattle productivity in warm climates? J. Dairy Sci. 2011, 94, 2147–2158. [Google Scholar] [CrossRef]

- Ding, L.; Cao, W.; Shi, Z.; Li, B.; Wang, C.; Zhang, G.; Kristensen, S. Carbon Dioxide and Methane Emissions from the Scale Model of Open Dairy Lots. J. Air Waste Manag. Assoc. 2016, 66, 715–725. [Google Scholar] [CrossRef]

- Hempel, S.; Saha, C.K.; Fiedler, M.; Berg, W.; Hansen, C.; Amon, B.; Amon, T. Non-Linear Temperature Dependency of Ammonia and Methane Emissions from a Naturally Ventilated Dairy Barn. Biosyst. Eng. 2016, 145, 10–21. [Google Scholar] [CrossRef]

- Jungbluth, T.; Hartung, E.; Brose, G. Greenhouse Gas Emissions from Animal Houses and Manure Stores. Nutr. Cycl. Agroecosyst. 2001, 60, 133–145. [Google Scholar] [CrossRef]

- Negussie, E.; Lehtinen, J.; Mäntysaari, P.; Bayat, A.R.; Liinamo, A.E.; Mäntysaari, E.A.; Lisauer, M.H. Non-invasive individual methane measurement in dairy cows. Animal 2017, 11, 890–899. [Google Scholar] [CrossRef] [PubMed]

- Niero, G.; Cendron, F.; Penasa, M.; Marchi, M.; Cozzi, G.; Cassandro, M. Repeatability and Reproducibility of Measures of Bovine Methane Emissions Recorded Using a Laser Detector. Animals 2020, 10, 606. [Google Scholar] [CrossRef]

- Sejian, V.; Bhatta, R.; Soren, N.M.; Malik, P.K.; Ravindra, J.P.; Prasad, C.S.; Lal, R. Introduction to Concepts of Climate Change Impact on Livestock and Its Adaptation and Mitigation. Clim. Risk Manag. 2017, 16, 145–163. [Google Scholar]

- Fiedler, N.C.; Ramalho, A.H.C.; Falcão, R.S.; Menezes, R.A.S.; Biazatti, L.D. Emissão de Gases Tóxicos em Incêndios Florestais. Cienc. Florest. 2023, 33, e62965. [Google Scholar] [CrossRef]

- Bewley, J.M.; Robertson, L.M.; Eckelkamp, E.A. A 100-Year Review: Lactating Dairy Cattle Housing Management. J. Dairy Sci. 2017, 100, 10418–10431. [Google Scholar] [CrossRef]

| E.V | h | Day | (C0) | (C1) | (C0 + C1) | a | DSD | ME | SDm | RE | SDR | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| THI | 0.25 | 1 | 0.00 | 1.00 | 1.00 | 20.45 | 0.00 | Strong | 0.002 | 0.459 | 0.001 | 0.990 |

| 2 | 0.00 | 1.45 | 1.45 | 31.86 | 0.00 | Strong | 0.002 | 0.457 | 0.002 | 0.995 | ||

| 3 | 0.00 | 0.88 | 0.88 | 30.77 | 0.38 | Strong | 0.003 | 0.360 | 0.004 | 1.002 | ||

| 4 | 0.00 | 0.57 | 0.57 | 24.81 | 0.00 | Strong | 0.002 | 0.308 | 0.004 | 0.963 | ||

| 5 | 0.00 | 1.17 | 1.17 | 31.64 | 0.00 | Strong | −0.002 | 0.397 | −0.002 | 0.957 | ||

| 1.5 | 1 | 0.00 | 1.52 | 1.52 | 3.00 | 0.00 | Strong | 0.000 | 1.247 | −4.5 × 1016 | 1.006 | |

| 2 | 0.00 | 0.67 | 0.67 | 31.88 | 0.00 | Strong | −0.002 | 0.266 | −0.004 | 0.845 | ||

| 3 | 0.00 | 0.68 | 0.68 | 36.80 | 0.00 | Strong | 0.003 | 0.276 | 0.005 | 0.963 | ||

| 4 | 0.00 | 0.55 | 0.55 | 23.44 | 0.00 | Strong | 0.003 | 0.288 | 0.004 | 0.887 | ||

| 5 | 0.00 | 1.17 | 1.17 | 31.64 | 0.00 | Strong | −0.001 | 0.290 | −0.001 | 0.685 | ||

| V | 0.25 | 1 | 0.09 | 1.01 | 1.10 | 9.08 | 8.25 | Strong | −0.007 | 0.778 | −0.004 | 0.996 |

| 2 | 0.02 | 0.93 | 0.94 | 7.97 | 1.94 | Strong | −0.003 | 0.761 | −0.002 | 1.012 | ||

| 3 | 0.49 | 0.55 | 1.04 | 8.38 | 47.22 | Moderate | −0.004 | 0.955 | −0.002 | 1.006 | ||

| 4 | 0.12 | 0.99 | 1.12 | 11.43 | 11.12 | Strong | −0.007 | 0.744 | −0.005 | 1.006 | ||

| 5 | 0.24 | 1.10 | 1.34 | 12.67 | 17.74 | Strong | −0.004 | 0.826 | −0.003 | 1.000 | ||

| 1.5 | 1 | 0.00 | 1.08 | 1.08 | 5.38 | 0.00 | Strong | −0.002 | 0.960 | −0.001 | 0.977 | |

| 2 | 0.00 | 0.94 | 0.94 | 5.40 | 0.00 | Strong | −0.002 | 0.924 | −0.001 | 1.004 | ||

| 3 | 0.69 | 0.26 | 0.95 | 38.39 | 72.62 | Moderate | −0.002 | 0.884 | −0.001 | 1.005 | ||

| 4 | 0.00 | 0.66 | 0.66 | 7.59 | 0.00 | Strong | −0.007 | 0.612 | −0.006 | 0.955 | ||

| 5 | 0.00 | 1.21 | 1.21 | 5.50 | 0.00 | Strong | −0.005 | 1.024 | −0.002 | 0.991 | ||

| Gasses | h | Day | (C0) | (C1) | (C0 + C1) | a | DSD | ME | SDm | RE | SDR | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CH4 | 0.25 | 1 | 0.00 | 0.88 | 0.88 | 3.00 | 0.00 | Strong | −1.1 × 10−14 | 0.951 | −1.1 × 10−14 | 1.006 |

| 2 | 0.00 | 0.72 | 0.72 | 3.00 | 0.00 | Strong | −6.6 × 10−14 | 0.858 | −7.7 × 10−14 | 1.006 | ||

| 3 | 0.28 | 0.67 | 0.95 | 29.61 | 29.70 | Moderate | 0.004 | 0.668 | 0.003 | 1.006 | ||

| 4 | 0.00 | 2.59 | 2.59 | 3.00 | 0.00 | Strong | 7.1 × 10−15 | 1.629 | 4.4 × 10−15 | 1.006 | ||

| 5 | 1.20 | 1.22 | 2.43 | 34.37 | 49.61 | Moderate | 0.002 | 1.253 | 0.001 | 1.011 | ||

| 1.5 | 1 | 93.85 | 949.26 | 1043.11 | 24.20 | 9.00 | Strong | 0.040 | 17.164 | 0.001 | 1.004 | |

| 2 | 0.00 | 673.90 | 673.90 | 3.00 | 0.00 | Strong | −1.4 × 10−14 | 26.288 | −5.4 × 10−16 | 1.006 | ||

| 3 | 0.00 | 624.32 | 624.32 | 22.21 | 0.00 | Strong | −0.079 | 10.678 | −0.003 | 0.971 | ||

| 4 | 85.24 | 702.07 | 787.31 | 19.15 | 10.83 | Strong | −0.179 | 16.522 | −0.005 | 1.004 | ||

| 5 | 0.00 | 706.37 | 706.37 | 18.54 | 0.00 | Strong | 0.060 | 13.047 | 0.002 | 0.997 | ||

| CO2 | 0.25 | 1 | 149.79 | 1044.15 | 1193.94 | 7.68 | 12.55 | Strong | −0.096 | 28.706 | −0.002 | 1.000 |

| 2 | 407.62 | 983.48 | 1391.10 | 7.74 | 29.30 | Moderate | −0.174 | 33.393 | −0.003 | 1.004 | ||

| 3 | 0.00 | 1143.54 | 1143.54 | 9.091 | 0.00 | Strong | −0.257 | 23.803 | −0.005 | 1.001 | ||

| 4 | 128.99 | 777.12 | 906.11 | 8.21 | 14.24 | Strong | 0.048 | 24.977 | 0.001 | 1.010 | ||

| 5 | 674.02 | 1368.08 | 2042.10 | 10.47 | 33.01 | Moderate | 0.205 | 38.937 | 0.003 | 1.017 | ||

| 1.5 | 1 | 224.57 | 192.05 | 416.62 | 12.85 | 53.90 | Moderate | −0.025 | 18.347 | −0.001 | 1.007 | |

| 2 | 157.66 | 312.47 | 470.13 | 14.46 | 33.54 | Moderate | −0.017 | 16.903 | 0.000 | 1.000 | ||

| 3 | 69.60 | 240.83 | 310.43 | 9.73 | 22.42 | Strong | −0.089 | 14.111 | −0.003 | 1.000 | ||

| 4 | 205.87 | 261.11 | 466.98 | 19.06 | 44.09 | Moderate | −0.032 | 17.717 | −0.001 | 1.012 | ||

| 5 | 212.32 | 160.55 | 372.87 | 17.84 | 56.94 | Moderate | 0.017 | 16.899 | 0.001 | 1.004 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

André, A.L.G.; Ferraz, P.F.P.; Ferraz, G.A.e.S.; Ferreira, J.C.; de Oliveira, F.M.; Reis, E.M.B.; Barbari, M.; Rossi, G. Spatial Distribution of Greenhouse Gas Emissions and Environmental Variables in Compost Barn Dairy Systems. AgriEngineering 2025, 7, 158. https://doi.org/10.3390/agriengineering7050158

André ALG, Ferraz PFP, Ferraz GAeS, Ferreira JC, de Oliveira FM, Reis EMB, Barbari M, Rossi G. Spatial Distribution of Greenhouse Gas Emissions and Environmental Variables in Compost Barn Dairy Systems. AgriEngineering. 2025; 7(5):158. https://doi.org/10.3390/agriengineering7050158

Chicago/Turabian StyleAndré, Ana Luíza Guimarães, Patrícia Ferreira Ponciano Ferraz, Gabriel Araujo e Silva Ferraz, Jacqueline Cardoso Ferreira, Franck Morais de Oliveira, Eduardo Mitke Brandão Reis, Matteo Barbari, and Giuseppe Rossi. 2025. "Spatial Distribution of Greenhouse Gas Emissions and Environmental Variables in Compost Barn Dairy Systems" AgriEngineering 7, no. 5: 158. https://doi.org/10.3390/agriengineering7050158

APA StyleAndré, A. L. G., Ferraz, P. F. P., Ferraz, G. A. e. S., Ferreira, J. C., de Oliveira, F. M., Reis, E. M. B., Barbari, M., & Rossi, G. (2025). Spatial Distribution of Greenhouse Gas Emissions and Environmental Variables in Compost Barn Dairy Systems. AgriEngineering, 7(5), 158. https://doi.org/10.3390/agriengineering7050158