Abstract

Air assistance and electrical charge transfer to droplets can optimize pesticide applications and reduce losses in sweet pepper cultivation. The objective of this study was to evaluate the effects of spray rate and pneumatic spraying with and without an electrostatic charge on spray deposition, spray coverage, and ground losses in sweet pepper crops. Four application techniques were employed: standard farmer hydraulics (SFH), reduced volume hydraulics (RVH), pneumatic with air and electrostatic assistance (PAEA), and pneumatic with air assistance (PAA). The effects of the application techniques on spray deposition varied as a function of plant height, canopy depth, and leaf surface. The SFH resulted in the greatest amounts of spray deposition on the adaxial leaf surface. In contrast, PAEA resulted in the greatest amounts of deposition on the abaxial leaves. The PAEA treatment improved spray coverage on abaxial leaves of the external canopy but did not improve spray coverage on the internal canopy. Compared to the SFH treatment, the 50% reduction in the spray rate of the RVH treatment decreased deposition and spray coverage. The pneumatic treatments, regardless of electrostatic charges, resulted in lower spray loss to the ground.

1. Introduction

Brazilian vegetable production has seen a growing demand for pesticide applications to control pests, diseases, and weeds. Compared to other agricultural segments, the sector of pesticide application technology is limited in terms of equipment and technical information [1]. Sweet pepper (Capsicum annuum) is one of the most important vegetable crops grown worldwide for fresh consumption, culinary art, and processing [2]. In Brazil, sweet pepper has a prominent position, ranking third among the most cultivated Solanaceae, behind tomato (Solanum lycopersicum) and potato (Solanum tuberosum) [3]. According to the last Agricultural Brazilian Census published in 2017, 224,286 tons of fruit was harvested in 32,507 production fields. The State of São Paulo was the leading producer (60,176 tons), with 3118 production fields [4].

In vegetable crops grown in protected environments, such as sweet pepper, the difficulties are even more significant due to the greenhouse structures that prevent the displacement and movement of mechanized sprayer systems [5,6,7]. Thus, pesticide spray applications using backpacks and semi-stationary sprayers are widespread [8,9,10], primarily due to their low acquisition, low maintenance costs and easy manipulation. Studies conducted in several countries have shown that application equipment based on vertical boom movement and a lower spray rate result in a low level of deposition on the target and minimal application losses [11,12,13].

Irregular distribution of pesticides on the target also frequently occurs, with the abaxial leaf surface and internal parts of the canopy being the plant structures that are more difficult to reach with spray droplets [1,10,14,15]. Another issue is establishing the spray rate (the volume of spray solution applied per area) without considering crop canopy characteristics at the time of spraying [11]. Without this adjustment, the spray rate applied may exceed what is necessary to ensure application quality, wasting resources and/or contaminating the environment [16].

Given these challenges, alternative pesticide application techniques must be explored for sustainable protected cultivation. The inclusion of air assistance in application equipment increases the penetration of spray droplets into the crop canopy [17], especially in crops with a high leaf density [1]. Benalia et al. [18] compared an automated fixed system, designed specifically for pesticide applications in protected crops positioned at the top inside the greenhouse, with a conventional sprayer equipped with air assistance (model Special Serre 2000) positioned outside the greenhouse. The authors reported variations in the sprayed environment both in the vertical plane (using an automated fixed system) and in the horizontal plane (conventional sprayer with air assistance), over the spray deposit and coverage on the pepper leaves. These findings suggest that, depending on the application technique, air assistance can enhance spray penetration into the crop canopy; however, it may also increase spray deposition variability.

Another promising pesticide spray technology is the electrification of droplets. Electrostatic spraying provides a negative electrical charge to the droplets, and the charged droplets induce an opposite charge on the plant leaves, which attracts the droplets [19]. The electrostatic sprayer can increase deposition, especially in hard-to-reach targets, such as the abaxial leaf surface [15,20,21]. Advances in spraying systems with a reduced spray rate and sensors, such as robot spray systems, have been developed for crops in protected environments. However, many challenges must be overcome [13]. Sánchez-Hermosilla et al. [15] assessed the effectiveness of electrostatic spraying equipment on spray deposition on sweet pepper leaves and the amount lost to the ground. The authors found that using electrostatic equipment increased deposition on the plant canopy by 1.48 times and reduced losses to the ground by 36% compared to a hand-held spray gun.

A key consideration when growing sweet peppers and other vegetables in a greenhouse environment is ensuring that spray droplets reach the internal parts of the plant canopy. Sánchez-Hermosilla et al. [10,15] reported that the droplet deposition on the internal leaves of the sweet pepper canopy was less than half of what was observed on the external leaves. Poor spray coverage in the internal canopy leaves may reduce pesticide performance. A sprayer that combines air assistance with electrostatic spraying could enhance spray deposition in this area.

The lack of information on application technology for sweet peppers grown in greenhouses leads farmers to apply pesticides at excessive spray rates [14], which can result in pesticide waste and environmental contamination [15]. Farmers generally feel more confident in their pesticide application quality when they observe the droplets wetting the leaves after spraying [22], and for these reasons, they apply with a high spray volume.

Considering the above-mentioned issues, this study aimed to evaluate the effects of reducing the spray rate and using pneumatic spraying with and without electrostatic charges on deposition levels, spray coverage, and pesticide losses to the soil in sweet pepper cultivation in a greenhouse.

2. Materials and Methods

2.1. Characterization of the Experimental Area

Two experiments were conducted during the 2019 and 2020 crop seasons in an area of commercial sweet pepper cultivation (22°47′03″ S, 49°30′14″ W) in the municipality of Santa Cruz do Rio Pardo, SP, Brazil. The crops were cultivated in a Londrina model greenhouse, measuring 600 m2 (30 × 20 m), with ceiling heights of 3.8 m (on the higher side) and 3.0 m (on the lower side), covered with a 100 µm polyethylene film.

The cultivated sweet pepper hybrid was Pampa®/HM Clause. The seedlings were transplanted with a spacing of 0.35 m between plants and 1.52 m between rows. The sweet pepper plants were vertically staked and supported by horizontal polyethylene threads fixed to the bamboo stalks.

2.2. Experimental Design and Treatments

The experiment was a completely randomized design with four treatments and five repetitions. Each experimental unit was represented by an 8 m crop row, and only the central 6 m was considered a useful plot. The experimental units were distributed alternately in the greenhouse, with a plant line on both sides as a border.

The treatments used in the trial consisted of the following spray techniques: a standard farmer hydraulics Sprayer (SFH)—a hand spray lance containing two empty conic jet hydraulic spray nozzles (JA-2 at 700 kPa), producing fine droplets and a variable spray rate according to the crop height (Figure 1a); reduced-volume hydraulics (RVH)—a hand spray lance containing two empty conic jet hydraulic spray nozzles (JA-2 at 700 kPa), producing fine droplets and spraying at 50% of the SFH spray rate; pneumatic with air and electrostatic assistance (PAEA)—a pneumatic sprayer with a hand held spray gun containing a nozzle with air assistance plus an electrostatic charge, producing extremely fine droplets (Figure 1b) and spraying at 25% of the SFH spray rate; and pneumatic with air assistance (PAA)—a pneumatic sprayer with a hand-held spray gun containing a nozzle with air assistance and no electrostatic charge, producing extremely fine droplets and spraying at 25% of the SFH spray rate. All devices examined in this study are currently available for purchase.

Figure 1.

Standard Farmer Hydraulics Sprayer (a) and pneumatic with air and electrostatic assistance sprayer (b).

The SFH treatment utilized the spray rate employed by the farmer when the plant reached three specific heights, during which the experiments were performed (Table 1). Thus, the SFH treatment applied the standard spray rate used by farmers in the commercial area. In contrast, the RVH, PAEA, and PAA treatments evaluated for the effect of using lower spray rates compared to using SFH.

Table 1.

Spray rates (L ha−1) obtained at different heights of sweet pepper plants for the different treatments during the 2019 and 2020 crop seasons in a protected environment.

As manual application makes it difficult to obtain a precise displacement speed, the application speed of each treatment was measured individually to determine the actual spray rate (Table 1), considering the operating conditions. For the application of the SFH and RVH treatments, a semi-stationary Yamaho© sprayer equipped with a manual lance with two hydraulic spray nozzles was used. The boom was connected to a three-piston pump with a maximum flow of 18 L min−1, driven by a 3-stroke, 4-stroke Otto cycle engine, via a 40 m hose producing 73 kW of power. The system featured a pressure controller with a manometer at the outlet of the spraying pump, and the solution was returned to a 50 L reservoir. A pressure gauge was installed next to the spray lance to monitor the working pressure with greater precision.

In the applications of the PAEA and PAA treatments, an electrostatic sprayer (MBP 4.0 model, Electrostatic Spraying Systems, Watkinsville, GA, USA) equipped with air assistance and an electrostatic induction system was used. An electric charge was transferred to the droplets by indirect induction. The system voltage was 1 kV, and the rechargeable battery contained in the spray lance was 9 V. The formation and fractionation of the droplets were determined by the pneumatic principle, utilizing air generated by a compressor driven by a four-stroke Otto cycle engine, which produced 4.85 kW of power. The air generated by the compressor was conducted to the handheld spray gun via a 30 m long hose with a ½ inch internal diameter. According to the manufacturer, the volumetric median diameter (VMD) of the droplet spectrum generated was 40 µm, resulting in a charge/mass ratio of 5.3 µC/g. The equipment featured a 15 L spray tank and adjustable shoulder straps for a personalized fit.

2.3. Evaluation of the Leaf Area Index (LAI)

The leaf area index (LAI) was quantified on the evening of each application to evaluate the deposit and soil losses (Table 1). Six plants were randomly selected, and all their leaves were removed. The leaf area was measured with an LI-3100C area meter. Subsequently, the LAI was calculated using Equation (1) adapted from Dario et al. [14].

where is the leaf area index, is the sum of the leaf area of the sampled plants (m2), is the spacing between plants (m), is the plant line spacing (m), and is the number of plants sampled.

2.4. Evaluation of the Deposition and Losses to the Ground

The spraying deposition and ground loss evaluations were performed in three stages of plant growth, corresponding to heights of 0.7, 1.4, and 2.1 m. The spray deposition was measured at two depths in the canopy in the vertical direction (inside and outside the plants) and on both leaf surfaces (abaxial and adaxial). As the canopy had a certain symmetry, only the right side was used as the external part; however, applications were performed on both sides of the crop row, following a practice commonly adopted in commercial crops.

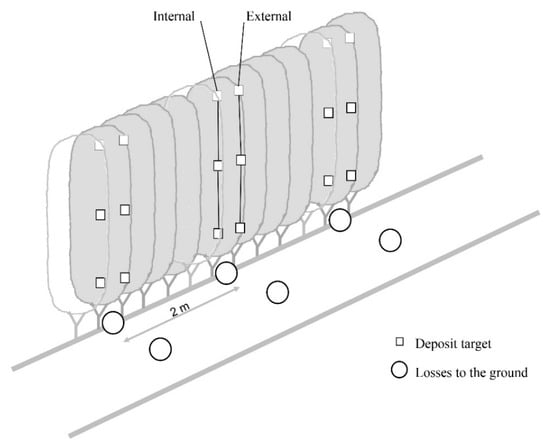

For the experiment performed at a height of 0.7 m, each experimental unit was divided into 6 sampling points on the inside and an equal number of sampling points on the outside of the canopy. For the experiments conducted at plant heights of 1.4 and 2.1 m, each experimental unit was divided into 9 sampling points on the inside and an equal number of sampling points on the outside of the canopy (Figure 2). At each sampling point, a leaf was randomly chosen, and filter paper (3 × 3 cm) was attached to both the adaxial and abaxial surfaces of the same leaf.

Figure 2.

Arrangement of sampling points for evaluating spray deposition in the vertical direction, both external and internal to the canopy, as well as losses to the ground below the plants and between crop rows in the greenhouse.

As a marker, the fungicide Status SC (350 g L−1 copper oxychloride) was added to the spray solution at concentrations of 2.0 mL L−1 for the SFH treatment, 4.0 mL L−1 for the RVH treatment, and 8.0 mL L−1 for the PAEA and PAA treatments. The difference in marker concentration between the treatments was a function of the variation in spray rate, resulting in values close to those of the marker mass per crop area. During the application process, the temperature and relative humidity inside the greenhouse were monitored (Table 2).

Table 2.

Leaf area index (LAI) and weather conditions at the time of application at different heights of the sweet pepper crop in the 2019 and 2020 crop seasons under a protected environment.

After spraying, the filter papers were removed from the leaves and placed individually into 100 mL plastic bottles. Subsequently, 20 mL of 1.0 M L−1 nitric acid solution was added to each flask, which was then shaken on an orbital shaker for 15 min at 220 rpm to remove the marker. The resulting stirring liquid was analyzed using a Shimadzu® atomic absorption spectrophotometer, model AA-6300, to quantify the concentration of copper (Cu) ions, following the methodologies described by Braekman et al. [23] and Christovam et al. [24].

Once the concentration values were obtained, the mass of metallic copper captured per artificial target area (µg cm−2) was determined by Equation (2):

where D is the metallic copper deposit (µg cm−2), [C] is the concentration in the sample (mg L−1), is the volume of the solution used in the removal (mL), and is the surface area of the artificial target (cm2).

Multiplying the actual spray rate (L ha−1) (Table 1) by the concentration of the tracer added to the spray solution (mL L−1), the actual marker mass per area (mg ha−1) was obtained. Then, correction factors were established to normalize the marker mass per area (mg ha−1) across treatments and to correct for differences resulting from minor errors in operator displacement speed. For this, the value of the treatment that applied the highest marker mass per area (mg ha−1) was divided by the mass applied in the respective treatment. Subsequently, each treatment’s deposition data (µg cm−2) were multiplied by their respective correction factors.

Soil losses were evaluated concomitantly with the spray deposition evaluations. Immediately before the treatments were applied, circular filter paper targets (8.5 cm diameter) were placed in Petri dishes, which were positioned on the ground, below the plants (in the crop row) and between crop rows of the greenhouse (Figure 2). In each experimental unit, three Petri dishes were placed below the plants and three were placed between crop rows, spaced 2 m apart in all cases.

In the laboratory, the filter paper was removed from the Petri dish, divided into six equal parts to facilitate the removal of the cupric marker, and placed in 100 mL flasks. Subsequently, 35 mL of 1.0 Mol L−1 nitric acid extractant solution was added to remove the marker. The marker was quantified using the methodology described above for depositing the marker into the canopy.

2.5. Evaluation of Spray Coverage

Spray coverage was evaluated only at the highest plant growth stage (2.1 m) in both seasons, concomitantly with the deposition evaluations. The sampling points were arranged in the same manner for evaluating the deposition.

To evaluate the coverage, the fluorescent yellow marker FD&C Yellow n.5 was added to the spray solution at a concentration of 7.0 g L−1. The evaluation was performed according to the percentage of leaf coverage with the marker. The concentration was established in previous tests, aiming to achieve adequate visualization of the marker in the sprays using the electrostatic equipment, which produces extremely fine droplets that are difficult to visualize.

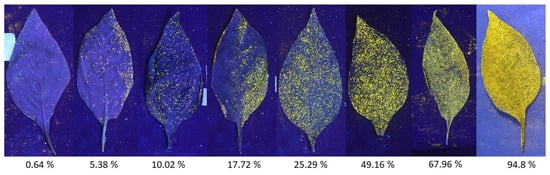

Immediately after applying the treatments, a leaf was randomly collected and stored in a paper bag (10 × 25 cm) at each evaluation point. An environment devoid of natural light was used to visualize the fluorescent marker on the leaves, with a projection of ultraviolet light (BL 15 BLB). Two people (double-blind) visually determined the percentage of the surface covered by the marker by comparing the sprayed leaves with a previously established scale of absolute coverage levels (Figure 3).

Figure 3.

Scale of absolute spray coverage levels in sweet pepper leaves.

To establish this scale, eight sprayed leaves were selected under the same conditions as in the experiment, ensuring they presented different levels of coverage. The selected leaves were photographed in the same visual evaluation environment as the coverage, using a digital camera, model D5100, manufacturer Nikon Corporation, made in Thailand, with an 18–55 mm lens, at a distance of 0.30 m, without flash and with a zoom level defined according to the focus setting, obtaining images in JPEG format at a resolution of 350 dpi. Subsequently, the images were subjected to the software Assess® version 2.0 (Lamari, Department of Plant Science, University of Manitoba, Winnipeg, MB, Canada) to quantify the percentage of the leaf covered by the marker.

2.6. Statistical Analysis

For spray deposition and spray coverage, data were analyzed separately for each canopy depth (internal and external) and leaf surface (abaxial and adaxial). The data for each position (below the plants and corridor) were analyzed separately regarding soil loss. The normality of all data was assessed using the Shapiro–Wilk test (p > 0.05), and the homogeneity of variances was assessed using Levene’s test.

The deposition and soil loss data did not exhibit a normal distribution; therefore, the nonparametric Kruskal–Wallis test (p < 0.05) was applied to verify the differences between the treatments. When significant, the medians were differentiated by a Kruskal–Wallis rank sum test (p < 0.05).

The coverage data were normal with homogeneous variances. Therefore, a combined analysis of variance (p < 0.05) was applied for the 2019 and 2020 crop seasons, following the criteria proposed by Pimentel-Gomes [25]. The combined means of the treatments were compared using the least significant difference (LSD) test at a significance level of p < 0.05.

3. Results and Discussion

3.1. Spray Deposition in the 2019 Crop Season

The effects of the application treatments on spray deposition levels varied among plant heights, canopy depths, and leaf surfaces. Therefore, the results are presented and discussed separately, aiming to elucidate the characteristics of the application treatments at the different plant positions.

On the leaf adaxial surface in the external part of the canopy, the PAA treatment resulted in lower deposition values than the other treatments, except at a plant height of 0.7 m, where the values did not differ from those of the PAEA and RVH treatments. However, they were still lower than those of the SFH treatment (Table 3).

Table 3.

Medians of cupric marker deposit (µg cm−2) according to the different application treatments on both leaf surfaces, canopy positions, and heights of the 2019 sweet pepper crop.

Regarding the adaxial surface, in the internal part of the canopy, treatments with hydraulic sprayers (SFH and RVH) were superior to pneumatic sprayers (PAEA and PAA), resulting in higher spray deposition. This finding was consistent across all plant heights, and this may have occurred because the pneumatic treatments produced smaller droplet sizes. When spraying sweet pepper plants, the droplet is launched horizontally; therefore, it must overcome air resistance to reach the innermost part of the canopy. Smaller droplets have more difficulty overcoming gravitational resistance due to their lower mass, which may hinder their penetration into the canopy, even with the additional energy provided by air assistance in the pneumatic sprayer (Table 3).

According to Holterman [26], when a droplet is projected horizontally, it decelerates, and the total distance traveled horizontally is referred to as the stopping distance. Additionally, the literature reports that smaller droplets have a greater potential for evaporation loss and/or deviation from their trajectory [26,27].

When considering spray deposition on the adaxial surface at both canopy depths (internal and external), it was observed that electrostatic charges increased deposition compared to pneumatic treatments without electrostatic charges on the external part of the canopy. This fact indicated that the pneumatic equipment provided deposition values equivalent to those of the hydraulic equipment at all stages of plant development, using only 25% of the SFH spray rate. In contrast, in the internal part of the canopy, there was no advantage to using electrostatic charges (Table 3). Electrostatic spraying is more efficient at the ends of plants closer to the spray nozzle [28]. Cerqueira et al. [28] reported that electrostatic spraying treatment was more effective in increasing spray deposition in the upper stratum of chrysanthemum plants. In contrast, there was no advantage when electrostatic spraying was used in the middle and lower stratum, which are located internally in the canopy. The increased spray deposition on the canopy outside provided by electrostatic spraying area occurred because an object with an electrical charge tends to discharge into the nearest grounded body [29]. Thus, the droplets were released horizontally toward the sweet peppers plants, as the external part of the canopy, closest to the spray nozzle, allowed for greater deposition with PAEA compared to PAA (Table 3).

Compared to adaxial surface deposition, abaxial surface deposition showed a more significant distinction between the different heights of the canopy. At a height of 0.7 m, treatments did not differ in the external part of the canopy. At 1.4 m, the pneumatic application treatments (PAEA and PAA) were superior to the hydraulic treatments (SFH and RVH). At a height of 2.1 m, the RVH treatment provided the lowest deposition amount, and the deposition amounts of the other treatments did not differ significantly (Table 3).

No differences existed between treatments for plants at 0.7 m within the internal part of the canopy. At 1.4 m, the PAEA treatments resulted in the greatest deposition amount, while the deposition amounts of the other treatments did not differ significantly. At a height of 2.1 m, the SFH treatment performed better than the RVH and PAA treatments but was no different from the PAEA treatment (Table 3).

In summary, the RVH treatment resulted in the smallest deposition amount for the abaxial leaf surface, except at the lowest plant height, where no differences in deposition amounts were observed. Thus, a 50% reduction in the SFH spray rate compromised deposition on this leaf surface, contrasting the results on the adaxial surface, where the lower spray rate had no detrimental effect on deposition.

In contrast, the PAEA treatment resulted in the most significant deposition amounts on the abaxial surface, indicating that electrostatic charges can enhance deposition on this leaf surface. These results agree with those of studies conducted on various crops in the open field, where electrostatic charges increased deposition on the abaxial surface of leaves [15,21]. Studies conducted on pepper and tomato crops in greenhouses have shown that low deposition amounts occur on the abaxial surfaces compared to those on the adaxial surfaces [1,11,12,14]. In this sense, it was expected that the spraying technique that provides higher deposition on this surface could optimize pesticide performance, especially considering that most pests and diseases, which are difficult to control in sweet peppers, occur on the abaxial surface of leaves such as nymphs of the whitefly Bemisia tabaci biotype B [30] and the powdery mildew Oidiopsis taurica [31].

3.2. Spray Deposition in the 2020 Crop Season

The results obtained in 2020 showed some differences compared to those obtained in the 2019 crop season. On the adaxial surface of the leaves, when comparing only the application treatments with the hydraulic sprayer (SFH and RVH), both in the external and internal parts of the canopy, there was no difference in deposition amounts, regardless of plant height, corroborating the results found in the 2019 crop season (Table 4).

Table 4.

Medians of cupric marker deposition (µg cm−2) according to the different application treatments on both leaf surfaces, canopy positions, and heights of sweet pepper in the 2020 crop season.

When comparing only the pneumatic treatments on the adaxial leaf surface, the use of electrostatic charges increased the deposition only at the lowest plant height (0.7 m), on the external position of the canopy, and at the highest plant height (2.1 m), in the internal position of the canopy. In the other situations, the deposition amounts observed in PAEA and PAA were equal (Table 4). These results differ from those obtained in the 2019 crop season, where electrostatic charges increased the deposition amount in the external canopy position compared to that under pneumatic treatments without electrostatic charges, regardless of plant height (Table 3).

Studies have shown that the effect of electrostatic charges on spraying is quite variable under different conditions due to several factors [21,32]. For example, the inclination of leaves towards the horizontal plane can increase deposition on the adaxial surface [33]. Another study demonstrated a positive correlation between the water content of leaves and the deposition of electrically charged droplets [32].

Many variables are involved in the deposition of electrically charged droplets, which may explain the differences between evaluated stages and crop seasons in the present study. Additionally, there was an inconsistency in the results of studies assessing the effect of electrostatic spraying on the qualitative and quantitative parameters of spraying and the biological efficacy of pesticides. Most application technology studies do not typically discuss the variables mentioned above that caused the differences in deposition levels.

Regarding the abaxial leaf surface, consistent with the results for the 2019 crop season, the 2020 crop season’s results showed a greater distinction between plant heights. At a height of 0.7 m, compared to the hydraulic treatments, the pneumatic treatments resulted in significantly greater deposition amounts at both canopy heights. Thus, although pneumatic spraying reduced the deposition amount on the adaxial surface, there was an increase on the abaxial surface (Table 4). Sanches-Hermosilla et al. [15] reported almost twice the spray deposition amount on the underside of sweet pepper leaves when sprayed by an electrostatic sprayer. As previously discussed, increasing deposition on the abaxial leaf surface is necessary when applying pesticides since spray droplets have more difficulty reaching this surface on sweet peppers [12].

At a height of 1.4 m in the external position of the abaxial canopy, the RVH treatment showed the lowest deposition amount. In contrast, the other treatments did not differ significantly from each other. Within the internal position of the canopy, the SFH and PAEA treatments did not differ significantly from each other and yielded superior results compared to the RVH and PAA treatments. At 2.1 m, in the external position of the abaxial leaf surface, the SFH treatment showed the highest deposition amounts, differing significantly from those of the RVH treatment. No significant differences were found on the abaxial surface of the internal canopy position (Table 4).

The differences in the effect of the application treatments at the different plant heights and crop seasons likely occurred because the canopy characteristics were distinct. The LAI was lower in 2020 than in the 2019 crop season for all plant heights (Table 1). In addition to the LAI, other canopy characteristics, such as leaf density and leaf arrangement, may change from one season to another or even between crop development stages, directly influencing spray deposition [34].

Although the experiment was conducted in a protected environment, the greenhouse’s structure did not effectively control meteorological variables, including temperature and air relative humidity. These factors can cause physiological changes in crops, affecting canopy characteristics [35]. The differences mentioned above emphasize the importance of replicating application treatment experiments at various crop stages of development and across different seasons to prevent inconsistent conclusions.

Although differences were detected based on plant heights and crop seasons, some results were consistent. The RVH treatment, despite maintaining a deposition amount equivalent to that under SFH on the adaxial leaf surface, did not perform well on the abaxial surface. The PAEA treatment provided the most significant spray deposition on the abaxial leaf surface. The spray deposition amount under PAA treatment was never superior to that under PAEA treatment, considering the two seasons and canopy positions evaluated, indicating that electrostatic charge is essential for enabling the use of a pneumatic sprayer in sweet pepper cultivation under a greenhouse environment.

3.3. Spray Coverage in the 2019 and 2020 Crop Seasons

According to the combined analysis of variance, there was no difference in coverage between crop seasons, and no interaction was found between seasons and treatments. However, there were differences between the application treatments, except on the abaxial leaf surface in the internal canopy position. On the adaxial leaf surface of the external and internal canopy positions, the SFH treatment resulted in a greater coverage level than those of the other treatments, which did not differ significantly from each other (Table 5).

Table 5.

Mean spray coverage values (%) on the abaxial and adaxial surfaces of leaves at the external and internal canopy positions, obtained through the combined analysis of the 2019 and 2020 crop seasons, under different application treatments.

These results contradict those obtained in the depositions from both crop seasons (2019 and 2020), where no significant difference was found between the treatments using hydraulic sprayers (SFH and RVH). Thus, although the reduction in the spray rate did not affect the amount of deposition on the adaxial leaf surface, the distribution (coverage) was impaired.

Several studies have demonstrated that higher spray rates improve coverage [1,14,36]. Nevertheless, studies show that spraying coverage is related not only to the spray rate but also to other factors, such as spray nozzle, droplet size, work pressure, and the interaction between droplets and the target surface [1,16,36]. Furthermore, techniques such as air assistance and electrostatic charges resulted in changes in coverage levels [1,28,36].

Consistent with the previous information, when comparing only the RVH treatment with the pneumatic treatments (PAEA and PAA) on the adaxial leaf surface, it was observed that although the RVH treatment delivered twice the spray rate, there was no difference in spray coverage between them (Table 5). It is known that air assistance, when appropriately used, can improve target coverage [37,38]. Therefore, the equivalence of coverage between treatments that applied different spray rates can be attributed to air assistance present in pneumatic techniques.

Regarding the abaxial leaf surface in the external canopy position, the PAEA treatment resulted in the highest coverage (42%), followed by the SFH and PAA treatments, which provided moderate coverage amounts. The RVH treatment provided the lowest coverage amount, at 24% (Table 5). Thus, in agreement with the deposition data, the use of pneumatic treatment using electrostatic charges may be an alternative for improving application quality on the abaxial leaf surface, especially in the external canopy position. In line with deposition evaluations, this finding is mainly due to the enveloping effect generated by an electrostatically charged spray that attracts droplets, allowing better coverage on the abaxial leaf surface [3,19,36].

Achieving adequate coverage on the abaxial leaf surface is one of the main challenges of the pesticide application program [14]. Thus, it is suggested that the pneumatic treatment using electrostatic charges be used as an alternative to improve the application quality on the abaxial leaf surface. This approach may significantly contribute to the biological efficacy of pesticides in controlling pests and diseases that are preferentially located on the abaxial surfaces of pepper leaves.

3.4. Spray Losses to the Ground

The effects of the application treatments on ground losses varied among sampling sites, plant heights, and crop seasons. Mainly, in the position below the plants, the median values of the losses were high, these being numerically similar to the deposition amounts in the canopy (Table 6). High losses to the ground have been observed in several studies conducted on crops in protected environments [10,12,13,15]. These results are concerning because pesticides deposited on the ground can lead to environmental contamination and fail to control pests or diseases. In sweet pepper plants, the leaves of the lower plant stratum are close to the ground; therefore, the spray jet must be directed at them to ensure coverage of the entire plant length. This fact contributes to the intensification of the ground deposition, especially for collectors positioned below plants.

Table 6.

Medians of the loss values of the cupric marker (µg cm−2) on the ground in the crop rows and between crop rows of the greenhouse, according to the different application treatments and heights of sweet pepper cultivation, in the 2019 and 2020 crop seasons.

For the application performed at 0.7 m, compared to pneumatic treatments (PAEA and PAA), the SFH treatment results in the greatest losses, regardless of the soil collection site. Regarding the RVH treatment, the losses were equivalent to those in the SFH treatment at the position below the plants but lower between crop rows (Table 6). At a height of 1.4 m, the greatest loss occurred in the RVH treatment, regardless of the collection position on the ground, except for those between crop rows in the 2020 crop season, where no differences were observed between the application treatments. Thus, for the 2020 crop season, compared to the conventional treatment, the hydraulic sprayer with the lowest spray rate resulted in increased soil losses (Table 6).

At a height of 2.1 m, there was a difference in losses only for the crop row in the 2020 crop season, where the SFH and RVH treatments showed higher deposition (losses) than the PAEA and PAA treatments. In general, it was observed that the most significant losses varied between the SFH and/or RVH treatments in all evaluated situations. These results indicate that the pneumatic treatments (PAEA and PAA) resulted in the fewest losses to the ground. The smaller droplet size produced by the pneumatic sprayer treatments was likely the primary factor contributing to lower deposition amounts on the soil. Sánchez-Hermosilla et al. [11,15] also achieved decreased losses to the soil by reducing the droplet size. The authors attributed this fact to the greater evaporation potential of the fine droplets before reaching the soil surface.

When comparing only the pneumatic sprayer treatments with each other, the use of electrostatic charges did not change the amount of losses compared to the treatments without electrostatic charges (PAA), regardless of plant height and position in the soil. In a study by Sánchez-Hermosilla et al. [15], ground losses for sweet pepper crops were not significantly different between electrostatic spray guns and uncharged electrostatic spray guns. However, the electrostatic spray gun demonstrated lower ground deposition losses compared to the hand-held spray gun.

4. Conclusions

This study examined the impact of reducing the spray rate and employing pneumatic spraying, both with and without electrostatic charges, on spray deposition, coverage, and losses to the ground in sweet pepper cultivation within a greenhouse. The key conclusions drawn from this study are as follows:

- The effects of different application treatments on spray deposition depend on factors such as sweet pepper plant height, canopy depth, and leaf surface characteristics.

- Hydraulic spraying with a variable spray rate, adjusted according to crop height (SFH), resulted in the highest spray deposition on the adaxial surface of sweet pepper leaves. In contrast, the pneumatic treatment with electrostatic charges (PAEA) achieved the greatest spray deposition on the abaxial leaf surface.

- The PAEA sprayer improved spray coverage on the abaxial surface of the external sweet pepper canopy but did not enhance coverage inside.

- Reducing the spray rate of the hydraulic sprayer by 50% compared to the SFH led to decreased spray deposition and coverage.

- Pneumatic sprayers, both with and without electrostatic charges (PPA and PAAE), decreased the spray volume lost to the ground.

- Future studies should investigate the effectiveness of pesticides on sweet peppers using the equipment employed in this research to evaluate their impact on biological targets.

Author Contributions

Conceptualization, G.D. and C.G.R.; methodology, G.D., C.G.R. and L.D.B.J.; software, G.D. and M.M.N.; preparation and production of the spray coverage scale, F.N.d.S. and F.A.d.S.e.O.; formal analysis, M.M.P.S.; writing—original draft preparation, G.D. and J.F.V.S.; writing—review and editing, C.G.R. and E.P.P. All authors have read and agreed to the published version of the manuscript.

Funding

Brazilian National Council for Scientific and Technological Development (CNPq).

Data Availability Statement

Data will be made available by request to the corresponding author.

Acknowledgments

To the Higher Education Personnel Improvement Coordination—Brazil (CAPES)—Financing Code 001.

Conflicts of Interest

Author Del Bem Junior, L. was employed by the company Fundação MS. Author da Silva, F.N. was employed by the company Magnojet. Author Negrisoli, M.M. was employed by the company Syngenta Proteção de Cultivos. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SFH | Standard farmer hydraulics |

| RVH | Reduced-volume hydraulics |

| PAEA | Pneumatic with air and electrostatic assistance |

| PAA | Pneumatic with air assistance |

References

- Llop, J.; Gil, E.; Gallart, M.; Contador, F.; Ercilla, M. Spray distribution evaluation of different settings of a hand-held-trolley sprayer used in greenhouse tomato crops. Pest Manag. Sci. 2015, 72, 505–516. [Google Scholar] [CrossRef]

- Krasnow, C.; Ziv, C. Non-chemical approaches to control postharvest gray mold disease in bell peppers. Agronomy 2022, 12, 216. [Google Scholar] [CrossRef]

- Santos, H.C.A.; Lima Junior, J.A.; Silva, A.L.P.; Castro, G.L.S.; Gomes, R.F. Yield of fertigated bell pepper under different soil water tensions and nitrogen fertilization. Rev. Caatinga 2020, 33, 172–183. [Google Scholar] [CrossRef]

- IBGE—Instituto Brasileiro de Geografia e Estatística. Available online: https://www.ibge.gov.br/explica/producao-agropecuaria/pimentao/br (accessed on 28 April 2025).

- Nuyttens, D.; Windey, S.; Sonck, B.A.R.T. Comparison of operator exposure for five different greenhouse spraying applications. J. Agric. Saf. Health 2004, 10, 187. [Google Scholar] [CrossRef] [PubMed]

- González, R.; Rodríguez, F.; Sánchez-Hermosilla, J.; Donaire, J.G. Navigation techniques for mobile robots in greenhouses. Appl. Eng. Agric. 2009, 25, 153–165. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Liu, Y.; Lv, X.; Zheng, W. Comparison of a new knapsack mist sprayer and three traditional sprayers for pesticide application in plastic tunnel greenhouse. Phytoparasitica 2021, 50, 177–190. [Google Scholar] [CrossRef]

- Cerruto, E.; Manetto, G.E.; Santoro, F.; Pascuzzi, S. Operator dermal exposure to pesticides in tomato and strawberry greenhouses from hand-held sprayers. Sustainability 2018, 10, 2273. [Google Scholar] [CrossRef]

- Rincón, V.J.; Páez, F.C.; Sánchez-Hermosilla, J. Potential dermal exposure to operators applying pesticide on greenhouse crops using low-cost equipment. Sci. Total Environ. 2018, 630, 1181–1187. [Google Scholar] [CrossRef]

- Sánchez-Hermosilla, J.; Rincón, V.J.; Páez, F.C.; Pérez-Alonso, J.; Callejón-Ferre, Á.J. Evaluation of the effect of different hand-held sprayer types on a greenhouse pepper crop. Agriculture 2021, 11, 532. [Google Scholar] [CrossRef]

- Sánchez-Hermosilla, J.; Páez, F.; Rincón, V.J.; Callejón, Á.J. Evaluation of a fog cooling system for applying plant-protection products in a greenhouse tomato crop. Crop Prot. 2013, 48, 76–81. [Google Scholar] [CrossRef]

- Rincón, V.J.; Sánchez-Hermosilla, J.; Páez, F.; Pérez-Alonso, J.; Callejón, Á.J. Assessment of the influence of working pressure and application rate on pesticide spray application with a hand-held spray gun on greenhouse pepper crops. Crop Prot. 2017, 96, 7–13. [Google Scholar] [CrossRef]

- Rincón, V.J.; Grella, M.; Marucco, P.; Alcatrão, L.E.; Sánchez-Hermosilla, J.; Balsari, P. Spray performance assessment of a remote-controlled vehicle prototype for pesticide application in greenhouse tomato crops. Sci. Total Environ. 2020, 726, 138509. [Google Scholar] [CrossRef]

- Dario, G.; Precipito, L.M.B.; Oliveira, J.V.D.; Lucilhia, L.V.D.S.; de Oliveira, R.B. Application techniques of pesticides in greenhouse tomato crops. Hortic. Bras. 2020, 38, 146–152. [Google Scholar] [CrossRef]

- Sánchez-Hermosilla, J.; Pérez-Alonso, J.; Martínez-Carricondo, P.; Carvajal-Ramírez, F.; Agüera-Vega, F. Evaluation of electrostatic spraying equipment in a greenhouse pepper crop. Horticulturae 2022, 8, 541. [Google Scholar] [CrossRef]

- Ferguson, J.C.; Chechetto, R.G.; Hewitt, A.J.; Chauhan, B.S.; Adkins, S.W.; Kruger, G.R.; O’Donnell, C.C. Assessing the deposition and canopy penetration of nozzles with different spray qualities in an oat (Avena sativa L.) canopy. Crop Prot. 2016, 81, 14–19. [Google Scholar] [CrossRef]

- Badules, J.; Vidal, M.; Boné, A.; Llop, J.; Salcedo, R.; Gil, E.; García-Ramos, F.J. Comparative study of CFD models of the air flow produced by an air-assisted sprayer adapted to the crop geometry. Comput. Electron. Agric. 2018, 149, 166–174. [Google Scholar] [CrossRef]

- Benalia, S.; Mantella, A.; Sbaglia, M.; Abenavoli, L.M.; Bernardi, B. Automated fixed system specifically designed for agrochemical applications in protected crops. Agriculture 2025, 15, 330. [Google Scholar] [CrossRef]

- Law, S.E. Agricultural electrostatic spray application: A review of significant research and development during the 20th century. J. Electrost. 2001, 51–52, 25–42. [Google Scholar]

- Yanliang, Z.; Qi, L.; Wei, Z. Design and test of a six-rotor unmanned aerial vehicle (UAV) electrostatic spraying system for crop protection. Int. J. Agric. Biol. Eng. 2017, 10, 68–76. [Google Scholar] [CrossRef]

- Appah, S.; Wang, P.; Ou, M.; Gong, C.; Jia, W. Review of electrostatic system parameters, charged droplets characteristics and substrate impact behavior from pesticides spraying. Int. J. Agric. Biol. Eng. 2019, 12, 1–9. [Google Scholar] [CrossRef]

- Derksen, R.C.; Frantz, J.; Ranger, C.; Locke, J.C.; Zhu, H.; Krause, C.R. Comparing greenhouse handgun delivery to poinsettias by spray volume and quality. Trans. ASABE 2008, 51, 27–35. [Google Scholar] [CrossRef]

- Braekman, P.; Foque, D.; Messens, W.; Van Labeke, M.C.; Pieters, J.G.; Nuyttens, D. Effect of spray application technique on spray deposition in greenhouse strawberries and tomatoes. Pest Manag. Sci. 2010, 66, 203–212. [Google Scholar] [CrossRef] [PubMed]

- Christovam, R.S.; Raetano, C.G.; Dal Pogetto, M.H.F.A.; Prado, E.P.; Aguiar Júnior, H.O.; Gimenes, M.J.; Serra, M.E. Effect of nozzle angle and air-jet parameters in air assisted sprayer on biological effect of soybean Asian rust chemical protection. J. Plant Prot. Res. 2010, 50, 347–353. [Google Scholar]

- Pimentel Gomes, F. Experimental Statistic Course, 2nd ed.; Nobel: São Paulo, SP, Brazil, 1985; p. 467. [Google Scholar]

- Holterman, H.J. Kinetics and Evaporation of Water Drops in Air; IMAG Report 2003-12: Wageningen, The Netherlands, 2003; p. 67. [Google Scholar]

- Becce, L.; Mazzi, G.; Ali, A.; Bortolini, M.; Gregoris, E.; Feltracco, M.; Gambaro, A. Wind tunnel evaluation of plant protection products drift using an integrated chemical–physical approach. Atmosphere 2024, 15, 656. [Google Scholar] [CrossRef]

- Cerqueira, D.T.R.D.; Raetano, C.G.; Dal Pogetto, M.H.F.A.; Carvalho, M.M.; Prado, E.P.; Costa, S.Í.D.A.; Moreira, C.A.F. Optimization of spray deposition and Tetranychus urticae control with air assisted and electrostatic sprayer. Sci. Agric. 2017, 74, 32–40. [Google Scholar] [CrossRef]

- Sasaki, R.S.; Teixeira, M.M.; Fernandes, H.C.; Monteiro, P.M.D.B. Deposition and distribution uniformity of spray in coffee plants using electrostatic spraying. Cienc. Rural 2013, 43, 1605–1609. [Google Scholar] [CrossRef]

- Fanela, T.L.M.; Baldin, E.L.L.; Pannuti, L.E.; Cruz, P.L.; Crotti, A.E.M.; Takeara, R.; Kato, M.J. Lethal and inhibitory activities of plant-derived essential oils against Bemisia tabaci Gennadius (Hemiptera: Aleyrodidae) biotype B in tomato. Neotrop. Entomol. 2016, 45, 201–210. [Google Scholar] [CrossRef]

- Guigón López, C.; Muñoz Castellanos, L.N.; Flores Ortiz, N.A.; González González, J.A. Control of powdery mildew (Leveillula taurica) using Trichoderma asperellum and Metarhizium anisopliae in different pepper types. BioControl 2019, 64, 77–89. [Google Scholar] [CrossRef]

- Ma, J.; Liu, K.; Chen, C.; Ahmad, F.; Qiu, B. Influence of plant leaf moisture content on retention of electrostatic-induced droplets. Sustainability 2021, 13, 11685. [Google Scholar] [CrossRef]

- Maski, D.; Durairaj, D. Effects of charging voltage, application speed, target height, and orientation upon charged spray deposition on leaf abaxial and adaxial surfaces. Crop Prot. 2010, 29, 134–141. [Google Scholar] [CrossRef]

- Garcerá, C.; Fonte, A.; Salcedo, R.; Soler, A.; Chueca, P. Dose expression for pesticide application in citrus: Influence of canopy size and sprayer. Agronomy 2020, 10, 1887. [Google Scholar] [CrossRef]

- Schmidt, D.; Zamban, D.T.; Prochnow, D.; Caron, B.O.; Souza, V.Q.; Paula, G.M.; Cocco, C. Phenological characterization, phyllochron and thermal requirement of Italian tomato in two cropping seasons. Hortic. Bras. 2017, 35, 89–96. [Google Scholar] [CrossRef]

- Palma, R.P.; Cunha, J.P.D.; Guimarães, E.C.; Santana, D.G.D.; Assunção, H.H.D. Multivariate analysis applied to spray deposition in ground application of phytosanitary products in coffee plants. Eng. Agric. 2021, 41, 458–467. [Google Scholar] [CrossRef]

- Souza, D.M.; Raetano, C.G.; Moreira, C.A.F.; Bueno, R.C.O.F.; Carvalho, M.M. Effects of news sowing arrangements and air assistance on fungicide spray distribution on soybean crop. Acta Sci. 2024, 41, 42700. [Google Scholar] [CrossRef]

- Ou, M.; Zhang, Y.; Wu, M.; Wang, C.G.; Dai, S.; Wang, M.; Dong, X.; Jiang, L. Development and experiment of an air-assisted sprayer for vineyard pesticide application. Agriculture 2024, 14, 2279. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).