Physical–Mechanical Properties of Tomato Seedlings for the Design and Optimization of Automatic Transplanters

Abstract

1. Introduction

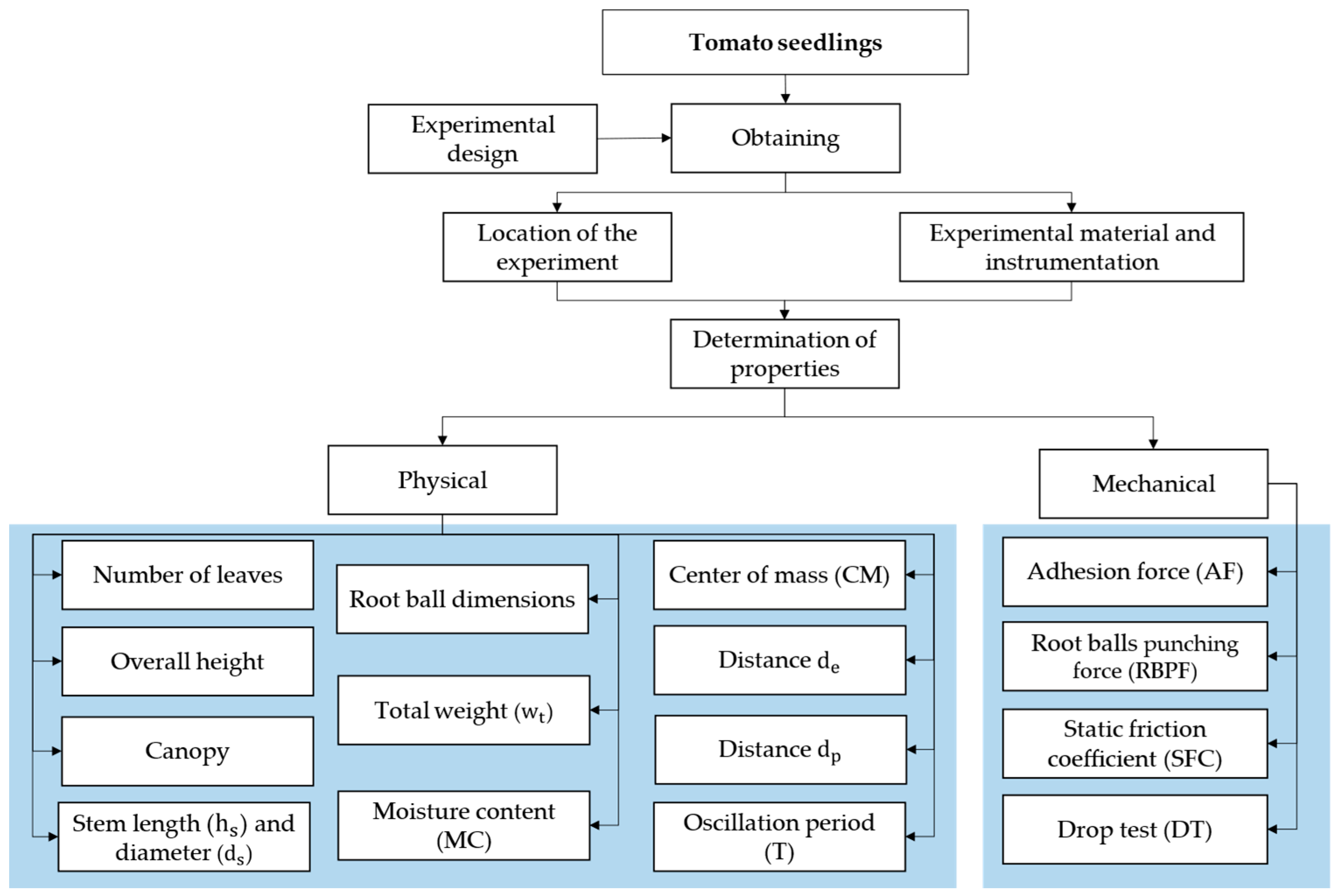

2. Materials and Methods

2.1. Location and Experimental Material

2.2. Determination of Physical Characteristics

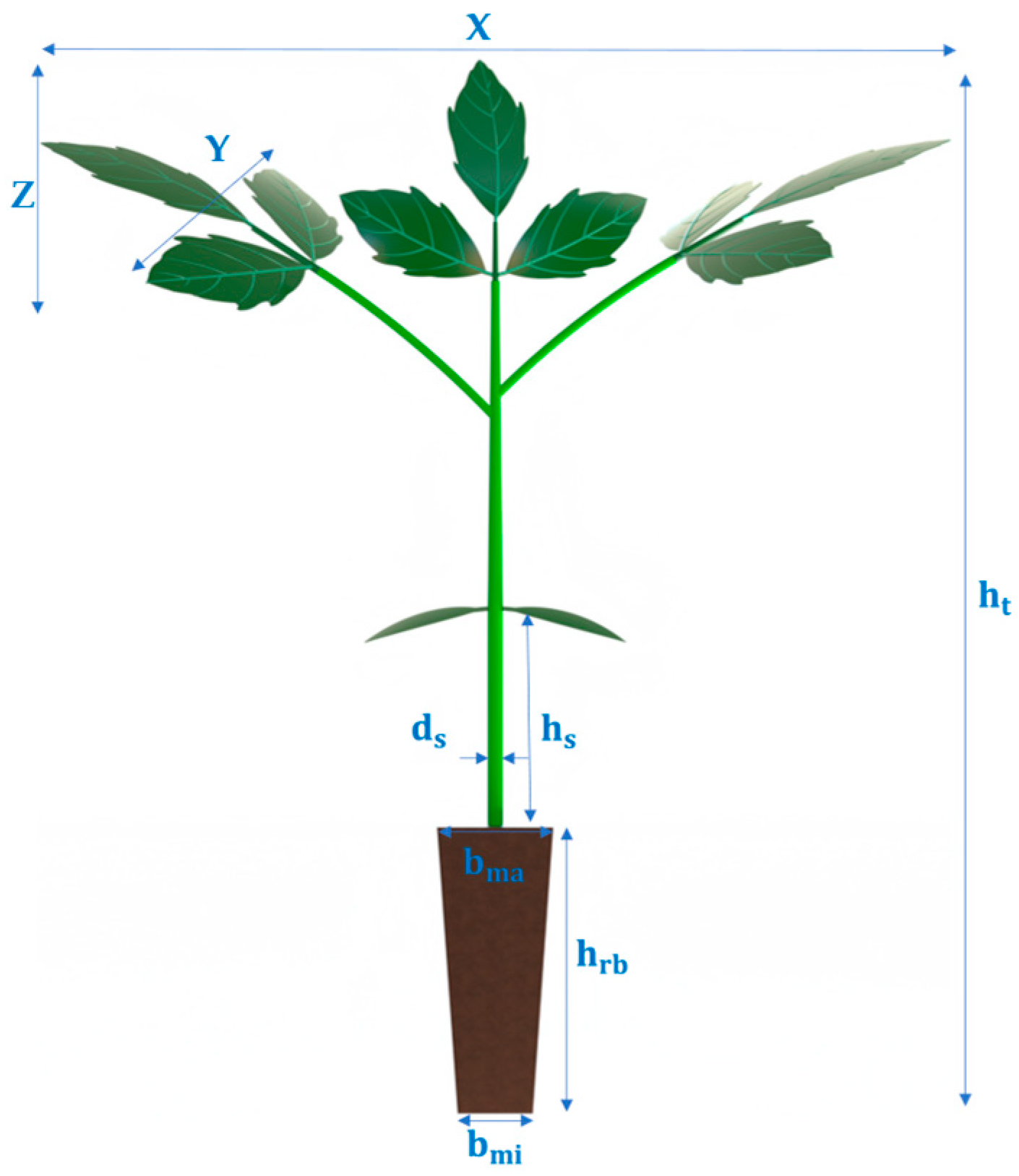

2.2.1. Number of Leaves, Total Height, and Canopy

2.2.2. Root Ball and Stem Dimensions

2.2.3. Weight and Moisture Content

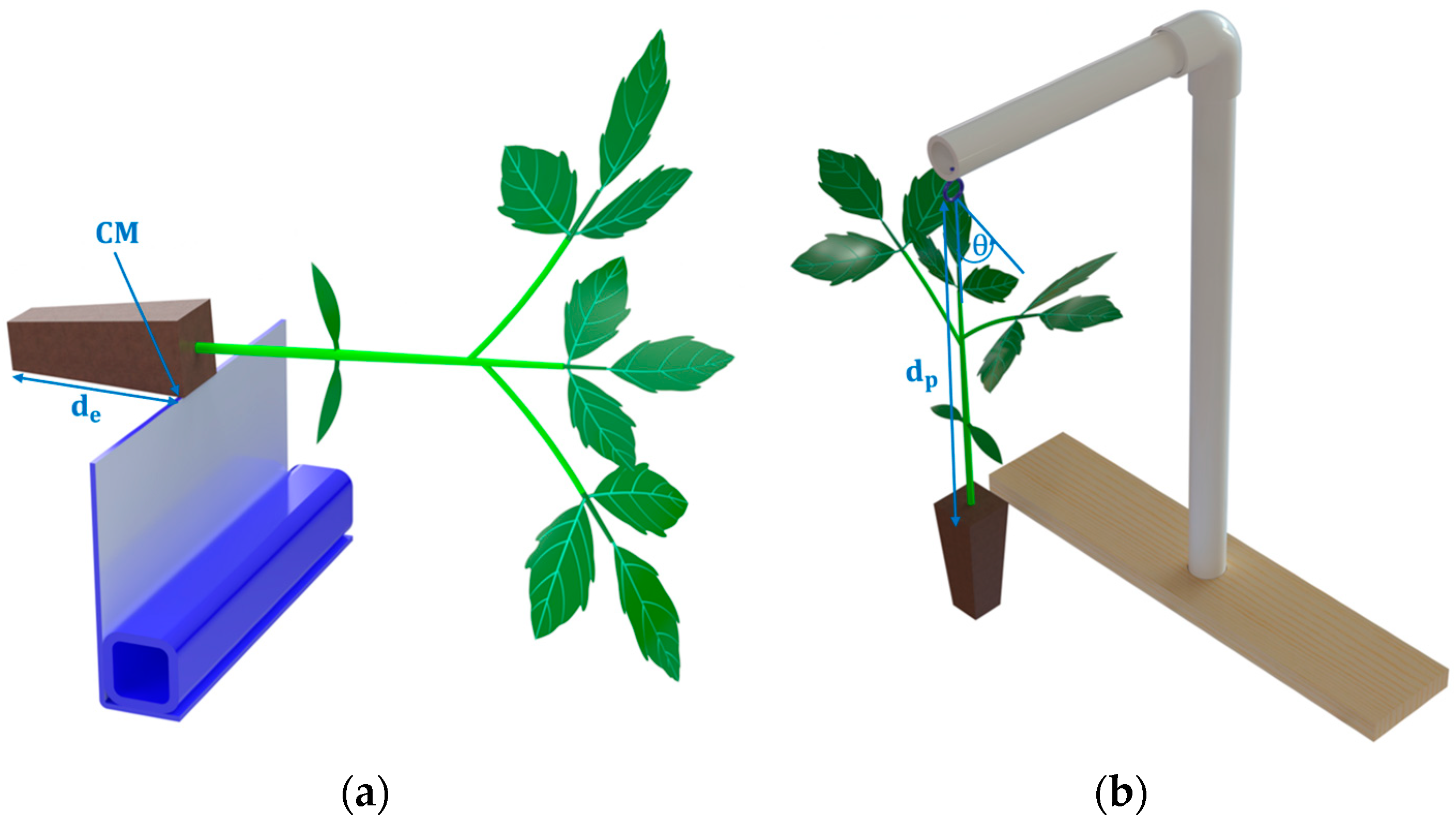

2.2.4. Center of Mass and Oscillation Period

2.3. Mechanical Test

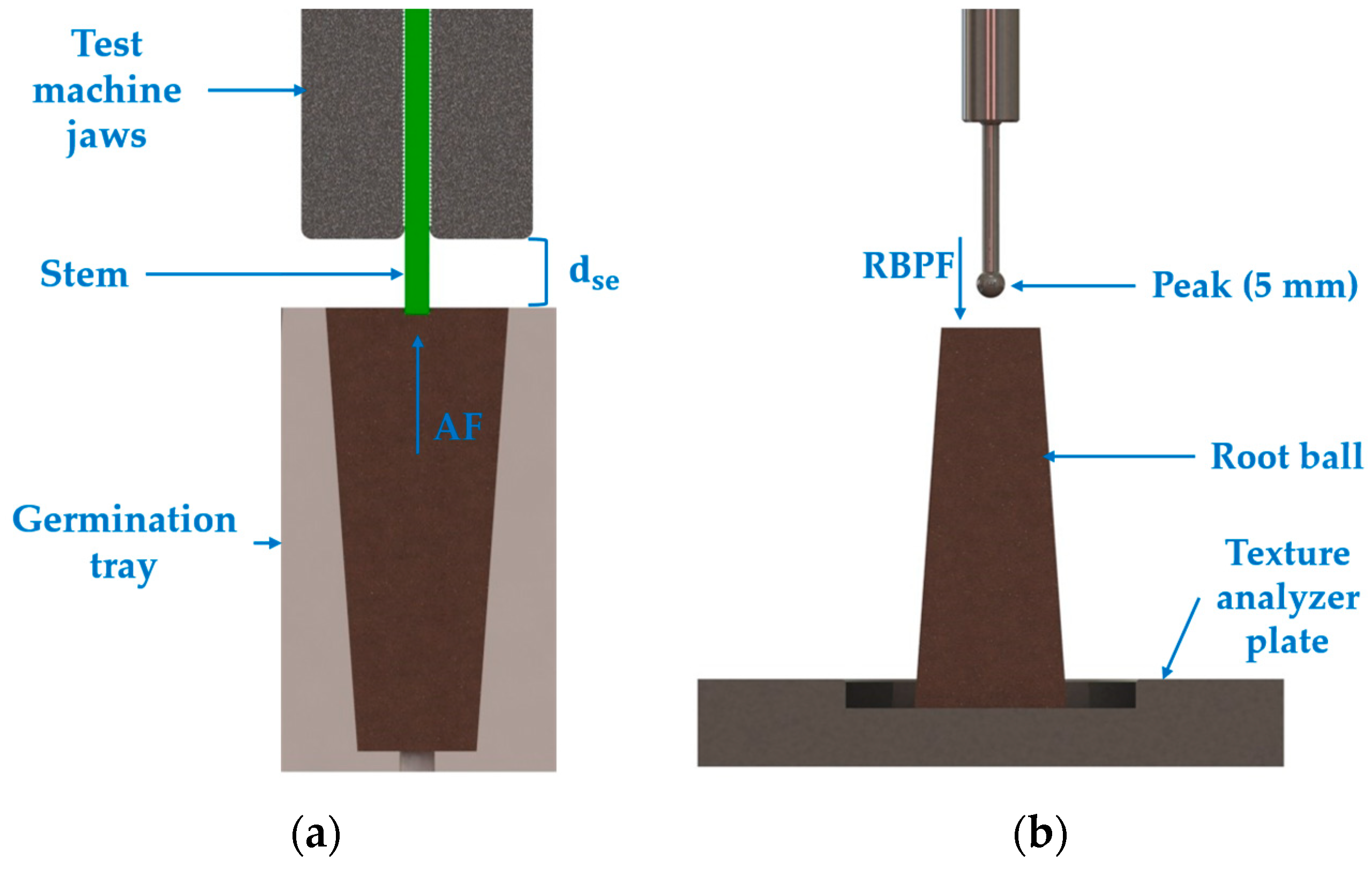

2.3.1. Adhesion Force

2.3.2. Root Ball Punching Force

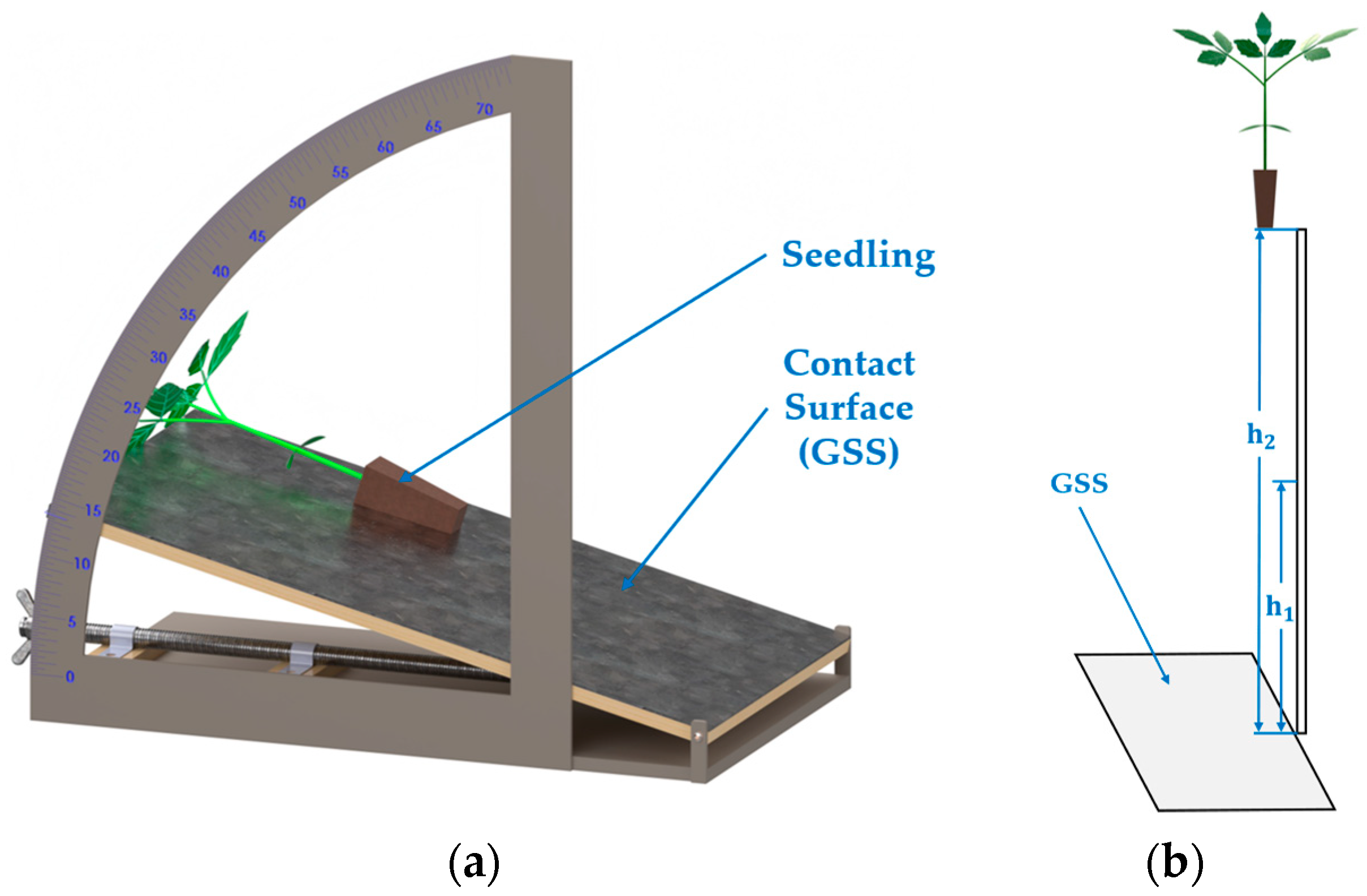

2.3.3. Static Friction Coefficient

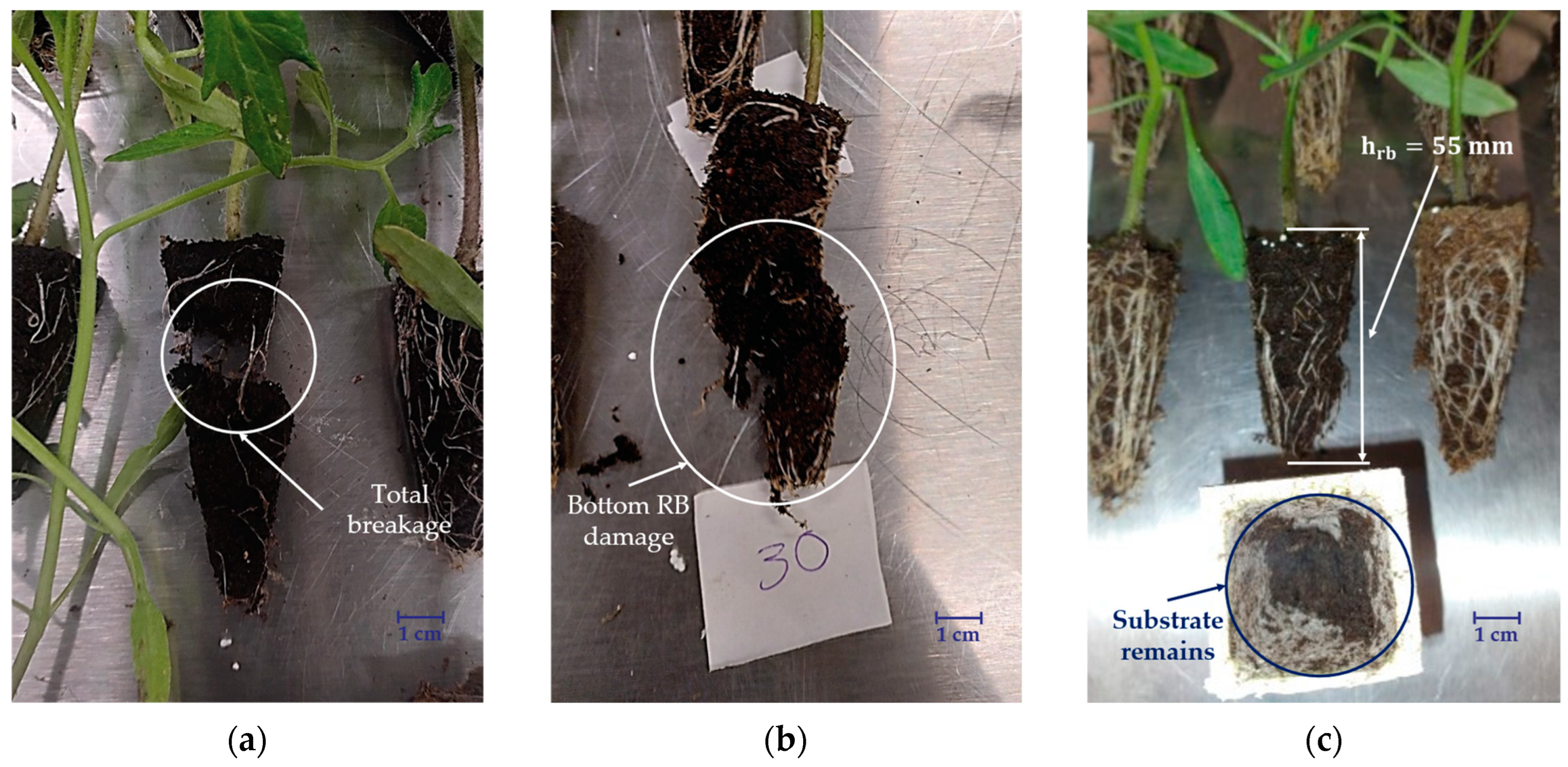

2.3.4. Drop Test

2.4. Statistical Analysis

3. Results

3.1. Physical Characteristics

3.1.1. Number of Leaves, Total Height, and Canopy

3.1.2. Stem and Root Ball Dimensions

3.1.3. Mass and Moisture Content

3.1.4. Center of Mass and Oscillation Period

3.2. Mechanical Tests

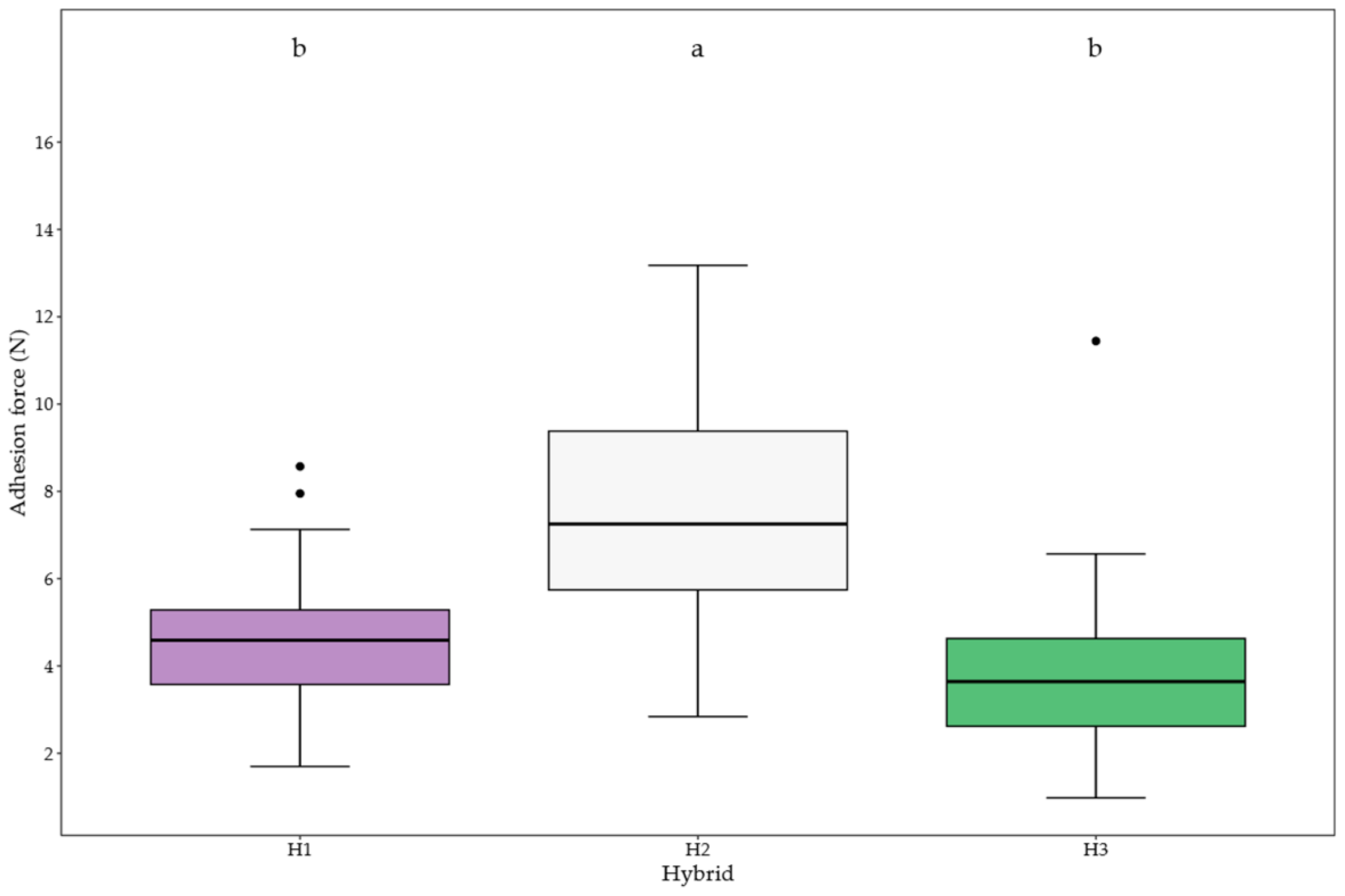

3.2.1. Adhesion Force

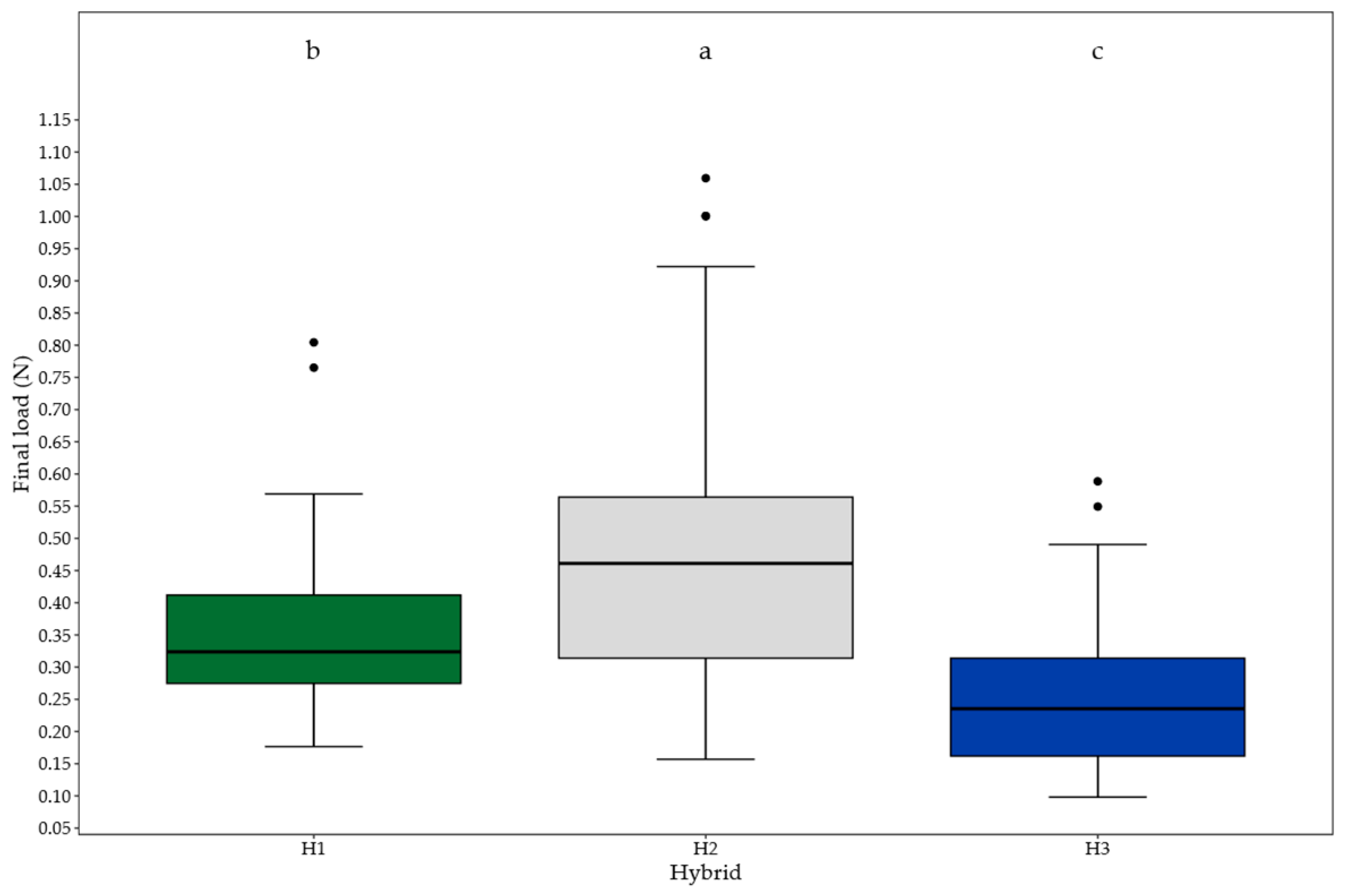

3.2.2. Root Ball Punching Force

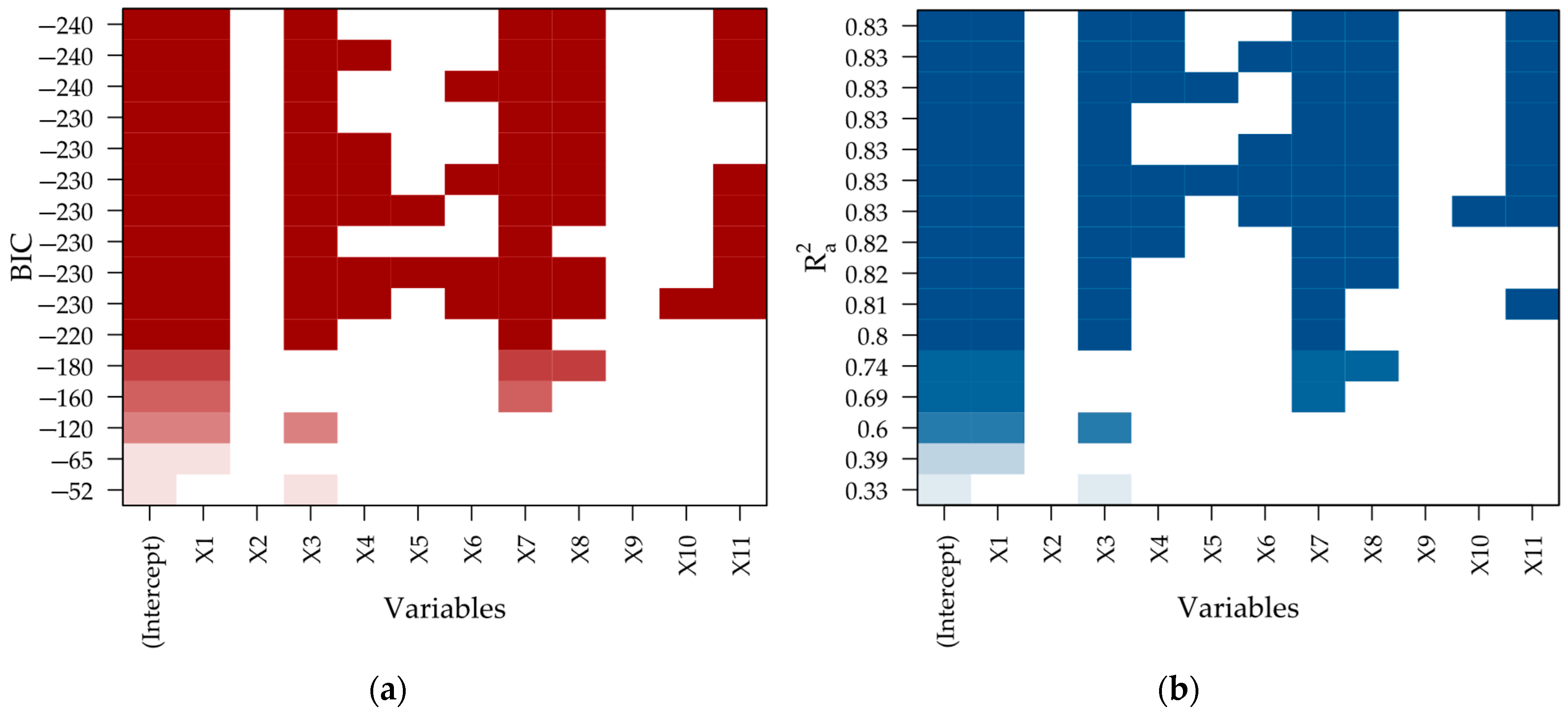

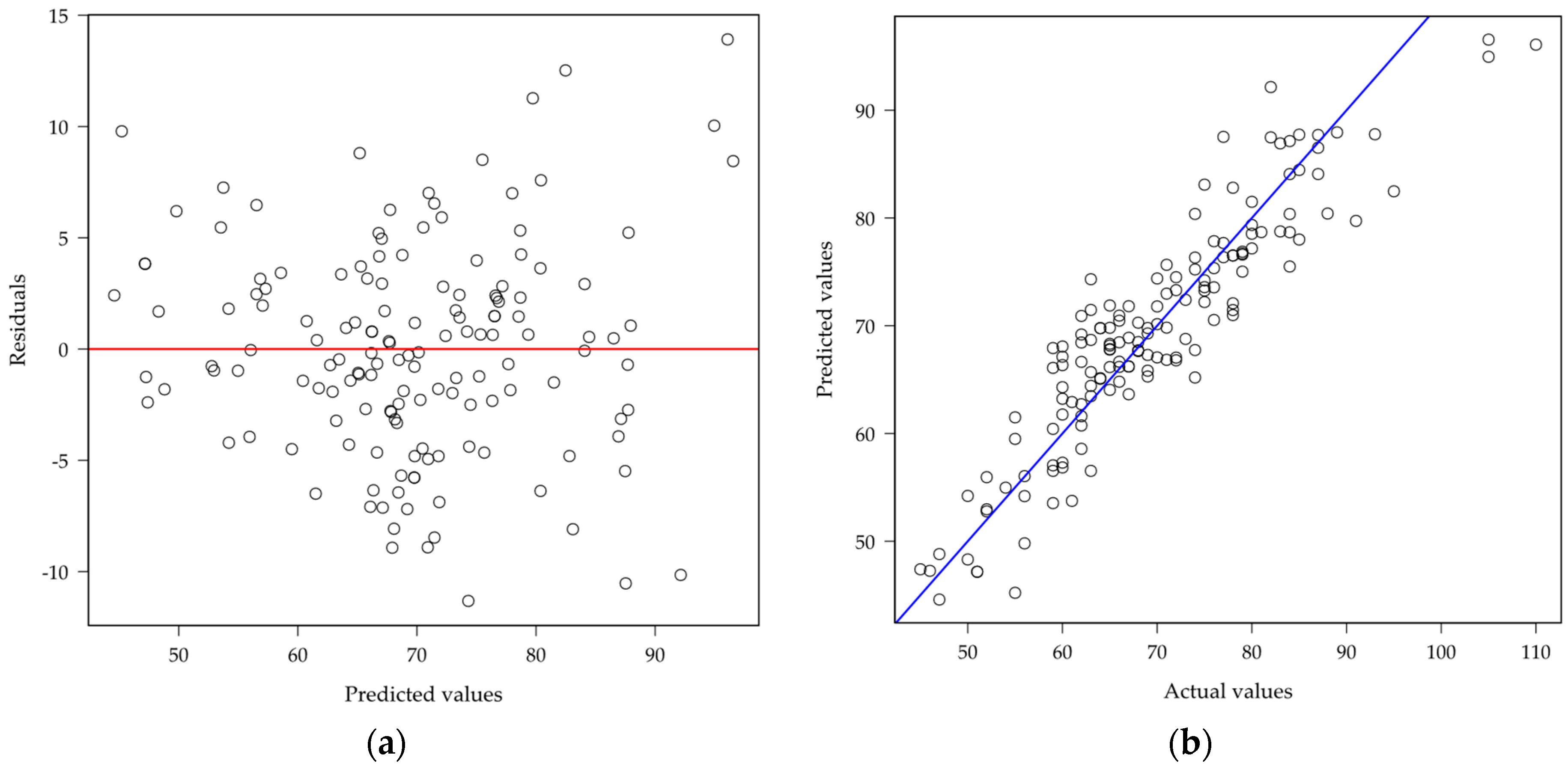

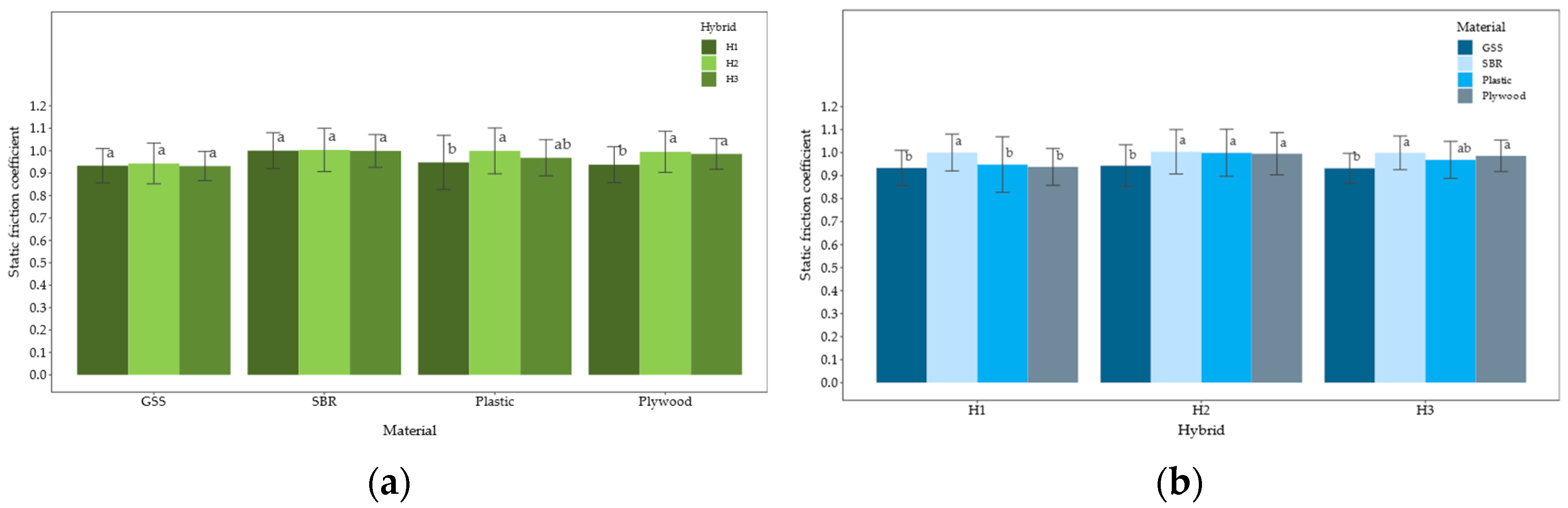

3.2.3. Static Friction Coefficient

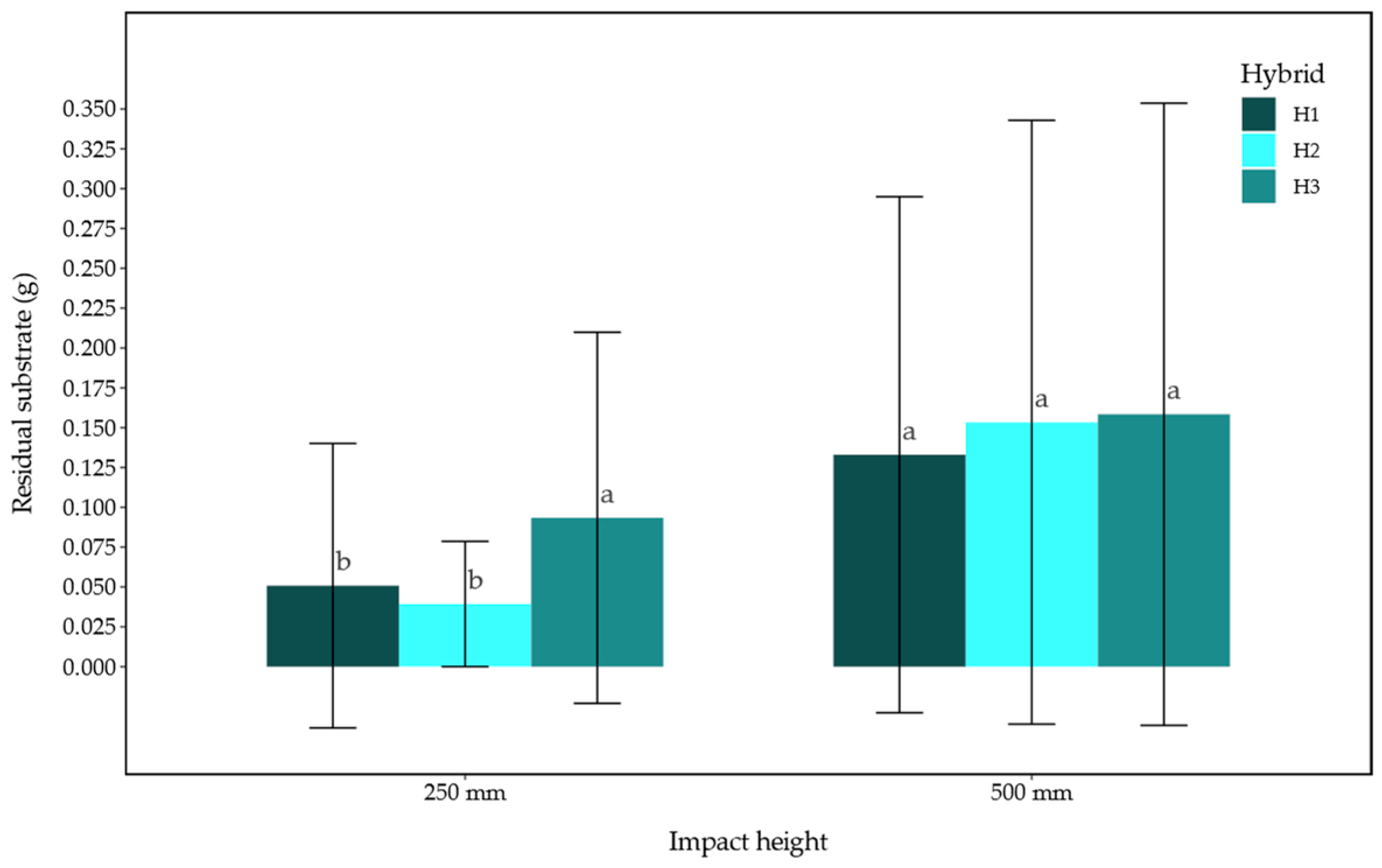

3.2.4. Drop Test

4. Discussion

4.1. Physical Characteristics

4.1.1. Number of Leaves, Total Height and Canopy

4.1.2. Stem and Root Ball Dimensions

4.1.3. Weight and Moisture Content

4.1.4. Center of Mass and Oscillation Period

4.2. Mechanical Tests

4.2.1. Adhesion Force

4.2.2. Root Ball Punching Force

4.2.3. Static Friction Coefficient

4.2.4. Drop Test

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AF | Adhesion force |

| ANOVA | Analysis of variance |

| ASNS | American Standard for Nursery Stock |

| ASAE | American Society of Association Executives |

| BIC | Bayesian Information Criterion |

| CM | Center of mass |

| SECIHTI | Secretaría de Ciencia, Humanidades, Tecnología e Innovación |

| CV | Coefficient of variation |

| DT | Drop test |

| GSS | Galvanized steel sheet |

| H1 | Natalie F1 hybrid |

| H2 | CID F1 hybrid |

| H3 | Gavilán F1 hybrid |

| MA | Massachusetts |

| MC | Moisture content |

| Adjusted coefficient of determination | |

| RB | Root ball |

| RBPF | Root ball punching force |

| SBR | Commercial neoprene |

| SD | Standard Deviation |

| SFC | Static friction coefficient |

| T | Oscillation period |

| USA | United States American |

| VIF | Variance inflation factors |

| Mean |

References

- Global Alliance for Improved Nutrition (GAIN). Tomatoes: The World’s Most Popular Vegetable. Available online: https://www.gainhealth.org/resources/reports-and-publications/tomatoes-worlds-most-popular-vegetable (accessed on 3 October 2024).

- Akotowanou, O.; Adjou, E.; Olubi, A.; Kougblenou, S.; Ahoussi, E.; Sohounhloué, D. The Tomato (Solanum lycopersicum L.) in Community Development: An Overview Focused on Nutritional Properties, Agronomic Constraints, Recent Achievements and Future Prospective. Int. J. Front. Biol. Pharm. Res. 2022, 3, 8–16. [Google Scholar] [CrossRef]

- Padmanabhan, P.; Cheema, A.; Paliyath, G. Solanaceous Fruits Including Tomato, Eggplant, and Peppers. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 24–32. [Google Scholar] [CrossRef]

- Shahbandeh, M. Global Production of Vegetables in 2022, by Type; Statista: Hamburg, Germany, 2022. [Google Scholar]

- SIAP. Panorama Agroalimentario 2018–2024; SIAP: Ciudad de México, Mexico, 2024; Available online: https://www.gob.mx/siap/acciones-y-programas/panorama-agroalimentario-258035 (accessed on 5 October 2024).

- Javanmardi, J.; Moradiani, M. Tomato Transplant Production Method Affects Plant Development and Field Performance. Int. J. Veg. Sci. 2017, 23, 31–41. [Google Scholar] [CrossRef]

- Nage, S.M.; Mathur, S.M.; Meena, S.S. Vegetable Transplanters for India: A Review. Agric. Sci. Dig. 2023, 43, 129–134. [Google Scholar] [CrossRef]

- Grande, G.; Hidalgo-Reyes, M.; Cruz, P.; Velázquez, N. Evolution and Technological Development of Automatic Transplanters for Vegetables: A Review. INMATEH-Agric. Eng. 2024, 72, 830–847. [Google Scholar] [CrossRef]

- Pandirwar, A.; Kumar, A.; Mani, I.; Islam, S. Biometric Properties of Onion Seedlings Relevant to the Development of Onion Seedling Transplanter. J. Appl. Nat. Sci. 2015, 7, 768–773. [Google Scholar] [CrossRef]

- Zeng, F.; Li, X.; Bai, H.; Cui, J.; Liu, X.; Zhang, Y. Experimental Study on Pot Damage and Contact Stress Distribution Characteristics of Oil Sunflower Plug Seedlings. Appl. Sci. 2022, 12, 10889. [Google Scholar] [CrossRef]

- Pagare, V.; Din, M.; Mehta, C.R.; Nandede, B.M.; Kumar, M. Morphological and Mechanical Characteristics of Onion Seedlings Insight to Mechanized Transplantation. Indian J. Agric. Res. 2022, 58, 1235–1243. [Google Scholar] [CrossRef]

- Khadatkar, A.; Gaikwad, B.; Pandirwar, A. Biometric Properties of Plug Vegetable Seedlings Relevant to the Design of Vegetable Transplanter. J. Agric. Eng. 2020, 57, 16–24. [Google Scholar]

- Hu, S.; Hu, M.; Zhang, W.; Jiang, Z. Experimental and Simulation Study on Mechanical Properties of Stem of Pepper Hole Seedlings. J. Chin. Agric. Mech. 2022, 43, 9–18. [Google Scholar] [CrossRef]

- Magar, A.P.; Nalawade, S.M.; Walunj, A.A.; Khadatkar, A.; Bhangare, S.C.; Bhalekar, M.N.; Nimbalkar, C.A.; Gaikwad, B.B. Engineering Properties of Some Plug-Type Vegetable Seedlings for Development of Automatic Vegetable Transplanter. J. Agric. Eng. 2023, 60, 1–13. [Google Scholar] [CrossRef]

- Abubakar, A.J.; Iya, S.A.; Aliyu, B.; Tashiwa, Y.I. Determination of Physico-Mechanical Properties of Tomato Seedlings for Design of a Tomato Transplanter. J. Agric. Eng. Technol. 2020, 25, 106–122. [Google Scholar]

- Sharma, A.; Khar, S.; Chaudhary, D.; Thakur, P. Study of Biometric Attributes of Plug Type Tomato Seedlings Pertinent to Transplanter Design. Indian J. Ecol. 2023, 50, 503–507. [Google Scholar] [CrossRef]

- Han, L.; Mao, H.; Hu, J.; Miao, X.; Tian, K.; Yang, X. Experiment on Mechanical Property of Seedling Pot for Automatic Transplanter. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2013, 29, 24–29. [Google Scholar]

- Tian, Z.; Gao, A.; Ma, W.; Jiang, H.; Cao, D.; Wang, W.; Qian, J.; Xu, L. Modeling the Mechanical Properties of Root–Substrate Interaction with a Transplanter Using Artificial Neural Networks. Agriculture 2024, 14, 651. [Google Scholar] [CrossRef]

- Cui, J.; Li, X.; Zeng, F.; Bai, H. Study on Contact Stress Distribution Characteristics and Damage of Plug Seedlings Based on Flexible Fressure Sensor. Sensors 2023, 23, 8175. [Google Scholar] [CrossRef] [PubMed]

- Zeng, F.; Cui, J.; Li, X.; Bai, H. Establishment of the Interaction Simulation Model between Plug Seedlings and Soil. Agronomy 2024, 14, 4. [Google Scholar] [CrossRef]

- Cui, J.; Li, X.; Zeng, F.; Bai, H.; Zhang, Y. Parameter Calibration and Optimization of a Discrete Element Model of Plug Seedling Pots Based on a Collision Impact Force. Appl. Sci. 2023, 13, 6278. [Google Scholar] [CrossRef]

- American Horticultural Industry Association d/b/a American Hort an ANSI Accredited Standard Developing Organization. American Standard for Nursery Stock (ASNS); AmericanHort: Columbus, OH, USA, 2014. [Google Scholar]

- ASAE S358.3; Moisture Measurement Forages. American Society and Biological Engineers Standards: St. Joseph, MI, USA, 2012.

- Paneque, P.P.; López, G.; Mayans, P.R.; Muñoz, F.; Gaytán, J.G. Fundamentos Teóricos y Análisis de Máquinas Agrícolas, 1st ed.; Universidad Autónoma Chapingo: Texcoco, Mexico, 2017. [Google Scholar]

- Muñoz, F.; Gaytán, J.G.; Serwatowsky, R.; Gracia, C. Trasplante Mecanizado de Hortalizas Mechanized Transplant of Vegetables. Rev. Cienc. Técnicas Agropecu. 2006, 15, 5–11. [Google Scholar]

- Cruz, P.; García, S.; Márquez, C.; López, G. Determinación de Las Propiedades Físico-Mecánicas Para El Descascarado de Las Cápsulas de La Higuerilla (Ricinus communis L.). Rev. Mex. Ciencias Agrícolas 2012, 3, 644–649. [Google Scholar]

- Onwe, D.N.; Umani, K.C.; Olosunde, W.A.; Ossom, I.S. Comparative Analysis of Moisture-Dependent Physical and Mechanical Properties of Two Varieties of African Star Apple (Chrysophyllum Albidum) Seeds Relevant in Engineering Design. Sci. Afr. 2020, 8, e00303. [Google Scholar] [CrossRef]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials, 2nd ed.; Gordon and Breach Science Publishers, Inc.: New York, NY, USA, 1986. [Google Scholar]

- Gallegos-Cedillo, V.M.; Nájera, C.; Gruda, N.S.; Signore, A.; Gallegos, J.; Rodríguez, R.; Ochoa, J.; Egea-Gilabert, C.; Fernández, J.A. An In-Depth Analysis of Sustainable Practices in Vegetable Seedlings Nurseries: A Review. Sci. Hortic. 2024, 334, 113342. [Google Scholar] [CrossRef]

- Xu, X.; Yang, F.; Song, J.; Zhang, R.; Cai, W. Does the Daily Light Integral Influence the Sowing Density of Tomato Plug Seedlings in a Controlled Environment? Horticulturae 2024, 10, 730. [Google Scholar] [CrossRef]

- Bebre, I.; Riebl, H.; Annighöfer, P. Seedling Growth and Biomass Production under Different Light Availability Levels and Competition Types. Forests 2021, 12, 1376. [Google Scholar] [CrossRef]

- Bauer, S.; Wyszomirski, T.; Berger, U.; Hildenbrandt, H.; Grimm, V. Asymmetric Competition as a Natural Outcome of Neighbour Interactions among Plants: Results from the Field-of-Neighbourhood Modelling Approach. Plant Ecol. 2004, 170, 135–145. [Google Scholar] [CrossRef]

- Huber, M.; Nieuwendijk, N.M.; Pantazopoulou, C.K.; Pierik, R. Light Signalling Shapes Plant–Plant Interactions in Dense Canopies. Plant Cell Environ. 2021, 44, 1014–1029. [Google Scholar] [CrossRef]

- Maynard, E.T.; Guan, W.; Langenhoven, P.; Hoagland, L. Tomato Seedling Performance in Commercial Organic Growing Media. Horttechnology 2024, 34, 80–91. [Google Scholar] [CrossRef]

- Han, L.; Xiang, D.; Xu, Q.; Du, X.; Ma, G.; Mao, H. Development of Simplified Seedling Transplanting Device for Supporting Efficient Production of Vegetable Raw Materials. Appl. Sci. 2023, 13, 10022. [Google Scholar] [CrossRef]

- Jin, X.; Li, D.Y.; Ma, H.; Ji, J.T.; Zhao, K.X.; Pang, J. Development of Single Row Automatic Transplanting Device for Potted Vegetable Seedlings. Int. J. Agric. Biol. Eng. 2018, 11, 67–75. [Google Scholar] [CrossRef]

- Han, L.; Ma, H.; Mo, M.; Kumi, F.K.; Hu, J.; Mao, H. Design and Test of an Efficient Seedling Pick-up Device with a Combination of Air Jet Ejection and Mechanical Action. J. Agric. Eng. 2024, 55, 1575. [Google Scholar] [CrossRef]

- Ji, D.; Liu, L.; Zeng, F.; Zhang, G.; Liu, Y.; Diao, H.; Tian, S.; Zhao, Z. Design and Experimental Study of a Traction Double-Row Automatic Transplanter for Solanum Lycopersicum Seedlings. Horticulturae 2024, 10, 692. [Google Scholar] [CrossRef]

- Jiang, Z.; Hu, Y.; Jiang, H.; Tong, J. Design and Force Analysis of End-Effector for Plug Seedling Transplanter. PLoS Comput. Biol. 2017, 12, e0180229. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhou, H.; Che, H.; Liu, Y.; Li, P. Optimal Design of Ejector Belt Seedling Collecting Mechanism Based on Edem. INMATEH Agric. Eng. 2023, 69, 109–120. [Google Scholar] [CrossRef]

- Bai, H.; Li, X.; Zeng, F.; Cui, J.; Zhang, Y. Study on the Impact Damage Characteristics of Transplanting Seedlings Based on Pressure Distribution Measurement System. Horticulturae 2022, 8, 1080. [Google Scholar] [CrossRef]

| Hybrid | ) (mm) | Canopy (mm) | |||

|---|---|---|---|---|---|

| X | Y | Z | |||

| H1 | Max. | 336 | 232 | 231 | 147 |

| Min. | 180 | 91 | 22 | 32 | |

| 260.58 ± 36.88 b | 142.01 ± 26.93 b | 91.34 ± 28.74 b | 75.28 ± 23.08 b | ||

| CV | 0.14 | 0.19 | 0.31 | 0.31 | |

| H2 | Max. | 358 | 229 | 188 | 174 |

| Min. | 234 | 114 | 48 | 56 | |

| 311.76 ± 26.80 a | 170.24 ± 29.74 a | 106.84 ± 23.66 a | 98.14 ± 27.39 a | ||

| CV | 0.08 | 0.17 | 0.22 | 0.28 | |

| H3 | Max. | 302 | 208 | 174 | 144 |

| Min. | 185 | 60 | 47 | 29 | |

| 233.52 ± 26.05 c | 141.18 ± 31.61 b | 93.14 ± 25.24 b | 83.46 ± 24.93 b | ||

| CV | 0.11 | 0.22 | 0.27 | 0.30 | |

| p-value | <2 × 10−16 *** | 6.45 × 10−7 *** | 0.00584 ** | 5.16 × 10−5 *** | |

| Hybrid | RB (mm) | Stem (mm) | ||||

|---|---|---|---|---|---|---|

| ) | ) | ) | ) | ) | ||

| H1 | Max. | 62.73 | 25.98 | 12.61 | 86.23 | 3.78 |

| Min. | 54.10 | 23.8 | 10.44 | 36.81 | 2.73 | |

| 59.58 ± 1.87 a | 24.94 ± 0.57 ab | 11.66 ± 0.41 ab | 53.18 ± 8.23 a | 3.26 ± 0.25 b | ||

| CV | 0.03 | 0.02 | 0.03 | 0.15 | 0.08 | |

| H2 | Max. | 64.06 | 26.55 | 14.61 | 63.53 | 4.62 |

| Min. | 51.9 | 23.35 | 10.61 | 35.48 | 2.95 | |

| 58.56 ± 2.70 a | 25.03 ± 0.76 a | 11.97 ± 0.75 a | 47.41 ± 6.31 b | 3.65 ± 0.38 a | ||

| CV | 0.04 | 0.03 | 0.06 | 0.13 | 0.10 | |

| H3 | Max. | 62.39 | 26.41 | 12.62 | 75.36 | 4.49 |

| Min. | 54.45 | 23.35 | 8.77 | 39.30 | 2.70 | |

| 59.15 ± 1.89 a | 24.65 ± 0.59 b | 11.42 ± 0.79 b | 49.51 ± 7.70 b | 3.70 ± 0.42 a | ||

| CV | 0.03 | 0.02 | 0.07 | 0.16 | 0.11 | |

| p-value | 0.0684 · | 0.00931 ** | 0.000353 *** | 0.000687 *** | 2.35 × 10−9 *** | |

| Hybrid | (g) | MC (%) | |||

|---|---|---|---|---|---|

| RB | Stem | Remaining Foliage | |||

| H1 | Max. | 16.14 | 83.99 | 95.83 | 93.75 |

| Min. | 6.37 | 58.26 | 86.21 | 85.22 | |

| 11.76 ± 2.00 a | 77.37 ± 6.84 a | 91.94 ± 2.34 c | 91.40 ± 1.58 b | ||

| CV | 0.17 | 0.09 | 0.03 | 0.02 | |

| H2 | Max. | 18.14 | 83.02 | 95.83 | 94.97 |

| Min. | 7.85 | 55.92 | 90.00 | 91.76 | |

| 11.92 ± 2.12 a | 74.31 ± 6.68 b | 93.24 ± 1.36 b | 93.41 ± 1.20 a | ||

| CV | 0.18 | 0.09 | 0.01 | 0.01 | |

| H3 | Max. | 13.7 | 81.45 | 98.04 | 94.95 |

| Min. | 7.19 | 57.92 | 90.91 | 90.53 | |

| 10.71 ± 1.58 b | 74.75 ± 5.34 ab | 94.51 ± 1.39 a | 92.92 ± 0.93 a | ||

| CV | 0.15 | 0.07 | 0.01 | 0.01 | |

| p-value | 0.00322 ** | 0.0351 * | 1.25 × 10−10 *** | 4.6 × 10−15 *** | |

| Hybrid | (mm) | (mm) | T (s) | |

|---|---|---|---|---|

| H1 | Max. | 88 | 265.4 | 0.95 |

| Min. | 50 | 125.48 | 0.72 | |

| 64.20 ± 8.56 b | 196.38 ± 34.02 b | 0.85 ± 0.06 b | ||

| CV | 0.13 | 0.17 | 0.07 | |

| H2 | Max. | 110 | 279 | 0.96 |

| Min. | 61 | 169 | 0.73 | |

| 78.36 ± 10.87 a | 233.4 ± 23.72 a | 0.88 ± 0.04 a | ||

| CV | 0.14 | 0.10 | 0.05 | |

| H3 | Max. | 93 | 210 | 0.86 |

| Min. | 45 | 125 | 0.62 | |

| 66.48 ± 10.48 b | 167.04 ± 20.84 c | 0.78 ± 0.04 c | ||

| CV | 0.16 | 0.12 | 0.06 | |

| p-value | 2.85 × 10−11 *** | <2 × 10−16 *** | <2 × 10−16 *** | |

| Variable | DF | Sum of Squares | Mean Square | F-Value | p-Value | VIF |

|---|---|---|---|---|---|---|

| 1 | 8094.7 | 8094.7 | 344.8738 | <2.2 × 10−16 *** | 1.2716 | |

| 1 | 4362.1 | 4362.1 | 185.8451 | <2.2 × 10−16 *** | 1.3485 | |

| 1 | 103.5 | 103.5 | 4.4089 | 0.037509 * | 1.0451 | |

| 1 | 4050.8 | 4050.8 | 172.5820 | <2.2 × 10−16 *** | 1.1268 | |

| 1 | 378.3 | 378.3 | 16.1171 | 9.574 × 10−5 *** | 1.3473 | |

| 1 | 200.9 | 200.9 | 8.5596 | 0.003999 ** | 1.2198 | |

| Residuals | 143 | 3356.4 | 23.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grande, G.; Hidalgo-Reyes, M.; Cruz, P.; Velázquez-López, N. Physical–Mechanical Properties of Tomato Seedlings for the Design and Optimization of Automatic Transplanters. AgriEngineering 2025, 7, 138. https://doi.org/10.3390/agriengineering7050138

Grande G, Hidalgo-Reyes M, Cruz P, Velázquez-López N. Physical–Mechanical Properties of Tomato Seedlings for the Design and Optimization of Automatic Transplanters. AgriEngineering. 2025; 7(5):138. https://doi.org/10.3390/agriengineering7050138

Chicago/Turabian StyleGrande, Gaudencio, Martín Hidalgo-Reyes, Pedro Cruz, and Noé Velázquez-López. 2025. "Physical–Mechanical Properties of Tomato Seedlings for the Design and Optimization of Automatic Transplanters" AgriEngineering 7, no. 5: 138. https://doi.org/10.3390/agriengineering7050138

APA StyleGrande, G., Hidalgo-Reyes, M., Cruz, P., & Velázquez-López, N. (2025). Physical–Mechanical Properties of Tomato Seedlings for the Design and Optimization of Automatic Transplanters. AgriEngineering, 7(5), 138. https://doi.org/10.3390/agriengineering7050138