2.2. Working Principle

Based on the gill bleeding process in manual fish killing and combined with the external characteristics of fish, an impact-triggered limited bleeding method is proposed, as shown in

Figure 2. The line segment ab is an inclined plane, and bod forms a rigid limiting trigger mechanism, with o as the pivot. The bleeding knife, connecting rod, and cam constitute a crank-slider mechanism. The implementation process of this method is as follows: The fish slides down from point a to point b with its head facing forward. Utilizing the characteristic that the gravitational potential energy of the fish is converted into kinetic energy during the sliding process, the fish impacts point b, triggering the rotation of bod to b’od’. Under the resistance of the bod mechanism, the fish is ultimately limited to point b’. At this time, the cam releases the limit and begins to rotate in a clockwise direction. Under the action of the crank connecting rod mechanism, the bleeding knife makes a reciprocating kinematics in the direction of the dashed line, achieving the action of piercing the gills and then resetting. Subsequently, the inclined plane ab rotates counterclockwise around point a by a certain angle, releasing the fish from the limit at point b and allowing it to continue sliding down, thus discharging the bled fish. After the fish is discharged, b’od’ returns to bod, and the cam, after completing one full rotation, is limited by od and stops rotating, completing one bleeding cycle.

The fish bleeding device is designed based on the impact-triggered limited bleeding method. The specific working process is as follows: Before the device is started, the working parameters of the bleeding device are adjusted according to the fish size. The position of the adjustment handle is manually adjusted to make the cutting position and the size of the feeding port suitable for the current fish size. Then, the motor is started and the transmission mechanism is in a locked state. The fish is fed into the fish entrance passage with its head facing forward. The fish slides along the channel-supporting plate to the front end. The channel-supporting plate and the pre-channel adjustment plate constrain the fish head and body, and the positioning blade applies adaptive pressure to the fish body to keep the front and rear positions of the fish fixed. Under the action of the sliding kinetic energy of the fish, the fish head pushes the bleeding trigger mechanism to move, releasing the locked state of the transmission mechanism and initiating the bleeding action. Under the driving force of the motor, the crank-slider mechanism begins to move. The blade slides down, inserts into the gills, and then moves upward to reset. Then, the channel-supporting plate rotates downward, the front end outlet of the fish entrance passage opens, the fish body constraint is released, and the fish slides out from the outlet and enters the bleeding pool. Subsequently, driven by the transmission mechanism, the channel-supporting plate rotates back to its original position. After the transmission mechanism completes one working cycle, it returns to the locked state, waiting for the next bleeding action to start.

2.4. Fish Body Shape Feature Parameters

Based on the commonly used fish species in freshwater fish processing enterprises, spindle-shaped fish such as snakehead (Channa argus), grass carp (Ctenopharyngodon idellus), silver carp (Hypophthalmichthys molitrix), and tilapia (Oreochromis mossambicus) are selected as the research objects. The external structure of the fish body is shown in

Figure 3, which is mainly divided into three parts: the head, the trunk, and the tail.

D1 is the total length of the fish body along the head–tail axis,

D2 is the length of the head, and

D3 is the maximum height of the fish head along the ventral–dorsal axis [

21].

According to the actual needs of freshwater fish processing, the commonly used fish size range is between 250 g and 2500 g. Thirty fish of each species were randomly selected as measurement samples. In accordance with the design requirements of the fish bleeding device, the fish head is the key part for bleeding operations. Therefore, the main measurements include the fish body weight, the total length of the fish body along the head–tail axis, the length of the head, the maximum height of the fish head along the ventral–dorsal axis, the maximum width of the fish head along the left–right axis, and the sliding friction angle between the fish body and 304 stainless steel plate. The results of the main body shape measurement parameters of fish are shown in

Table 2.

2.5. Design of Fish Entrance Passage

The fish entrance passage is the main component that supports and constrains the fish body, enabling the fish to slide in and be supported, thus creating stable conditions for the bleeding action. The fish entrance passage is inclined and mounted on the frame, mainly consisting of the feeding port, upper channel plate, channel-supporting plate, channel side plates, and the front channel arc plate, as shown in

Figure 4. The channel-supporting plate, channel side plates, and front channel arc plate together form a space that envelops the fish head, which is conducive to the stable constraint of the fish body. Based on the measurement data of the sliding friction angle of fish, the angle between the upper channel plate of the fish entrance passage and the horizontal direction is determined to be 30°, which is considered appropriate.

The channel-supporting plate is the main contact component for the fish to slide down, and its structure directly affects the stability of the fish body support during the bleeding process. The channel-supporting plate includes a support plate, side wing plates, a supporting plate, and hinges. The schematic diagram of the channel-supporting plate supporting the fish head is shown in

Figure 5. The channel-supporting plate is designed based on the external contour of the fish head, with the support plate achieving a fit and support for the fish head, and two symmetrical side wing plates supporting the sides of the fish body. When the channel-supporting plate rotates downward, the fish inlet channel opens, allowing the fish being bled to slide out from the channel.

Analysis of the head shape characteristics of three types of spindle-shaped fish shows that the fish head can be approximated as an elliptical cone. Combining the measurement parameters of the fish head’s external dimensions, it can be determined that within the measured fish size range, the fish head is located within an enveloping space of an elliptical cone. The model parameters of this elliptical cone are a base long axis of 120 mm, a base short axis of 70 mm, and a height of 158 mm. Based on the schematic diagram of the channel-supporting plate supporting the fish head shown in

Figure 5, the support plate is designed according to the elliptical cone fish head enveloping model. The spatial coordinate schematic diagram of the support plate is shown in

Figure 6.

Based on the elliptical cone fish head enveloping model, according to the effective length parameter of the fish head, a height of 125 mm of the elliptical cone is taken as the design parameter for the contour of the support plate. Therefore, the external contour of the support plate is obtained as the curved surface abcd, and the equation of this curved surface model is as follows:

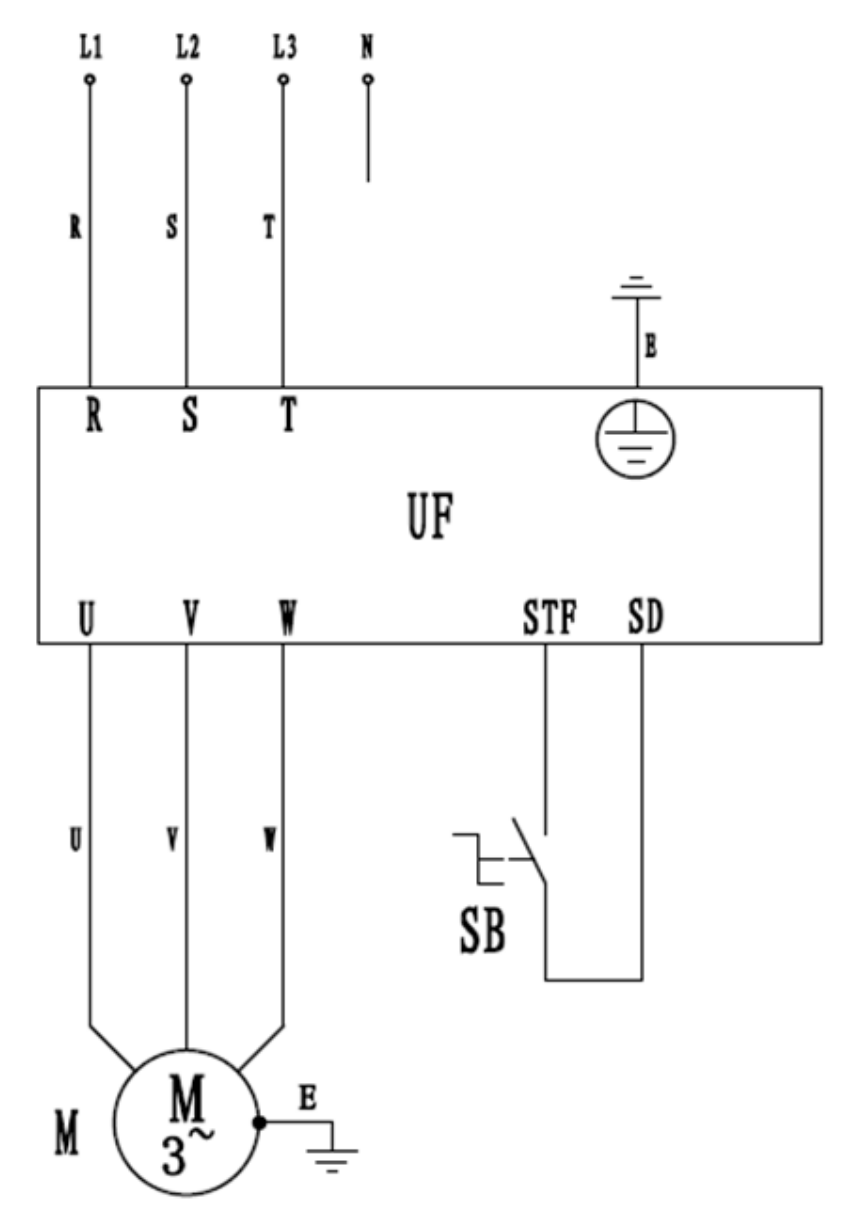

2.7. Design of Transmission Mechanism

The transmission requirements of the bleeding machine mainly come from the reciprocating motion of the bleeding mechanism and the opening and closing motion of the channel-supporting plate. The bleeding operation process indicates that the bleeding mechanism moves first, and after the bleeding is completed, the channel-supporting plate performs the opening and closing motion. Without the next trigger start, both motion mechanisms stop moving after completing one action cycle. Therefore, the transmission of this machine has the characteristics of sequentiality and intermittence. To meet the transmission requirements, the transmission mechanism adopts a design combining chain transmission structure with a clutch mechanism. The structure of the transmission mechanism is shown in

Figure 10, mainly consisting of a clutch assembly, bleeding drive wheel, transmission chain, channel-supporting plate drive wheel, tension wheel, driving wheel, transmission rod, and trigger rotating arm. When the bleeding mechanism’s positional lock is disengaged, the trigger rotating arm synchronizes its rotation with the clutch of the bleeding mechanism. After the trigger rotating arm rotates by a certain angle, it begins to contact the triangular-structured transmission rod. The transmission rod undergoes a slight clockwise rotation under force, thereby disengaging the limit of the corresponding clutch for the channel-supporting plate. Driven by the channel-supporting plate drive wheel, the channel-supporting plate initiates the opening–closing motion. The transmission phase difference between the bleeding mechanism and the channel-supporting plate is 225°.

Two limit clutch mechanisms are installed on the bleeding drive wheel and the channel-supporting plate drive wheel, respectively. The bleeding drive wheel can drive the main shaft of the bleeding mechanism to rotate through the limit clutch mechanism, and the channel-supporting plate drive wheel can drive the drive shaft of the channel-supporting plate to rotate through the limit clutch mechanism. The driving wheel is installed on the motor shaft and continuously transmits power through the chain. When the clutch assembly releases the limit and is in the engaged state, the shaft rotates synchronously with the sprocket, achieving the rotation of the main shaft of the bleeding mechanism and the drive shaft of the channel-supporting plate. When the clutch assembly reaches the limit position and is in the disengaged state, the sprocket rotates but the shaft does not move, realizing the disconnection of the transmission.

As shown in

Figure 10, the bleeding drive wheel and the channel-supporting plate drive wheel are driven wheels. The transmission ratio

i2 between the driving wheel and the bleeding drive wheel and

i3 between the driving wheel and the channel-supporting plate drive wheel are mainly designed according to the operation efficiency of the bleeding machine. The relationship between the operation efficiency of the bleeding machine and the feeding sliding time of the fish and the movement time of the transmission mechanism satisfies Equation (3):

where

tz—the total time for the bleeding machine to perform a bleeding cycle, s;

t0—feeding redundancy time, s;

t1—the sliding time of fish on the channel-supporting plate, s;

t2—the time from the beginning of the bleeding mechanism to the beginning of the movement of the channel-supporting plate, s;

t3—the time for the channel-supporting plate drive wheel to rotate for one revolution, s;

—design parameters of working efficiency of bleeding machine, fish/hour;

—dynamic friction coefficient between fish and the channel-supporting plate;

lab—the distance from the vertex of the channel-supporting plate to the initial position of the trigger baffle plate, m;

a1—the acceleration of the fish sliding, m/s2;

β —the angle between the channel-supporting plate and the horizontal direction, °;

—the transmission phase difference between the bleeding mechanism and the channel-supporting plate, °;

n1—speed of driving wheel, r/min;

n2—speed of bleeding drive wheel, r/min;

n3—speed of channel-supporting plate drive wheel, r/min.

According to the technical parameters and design requirements of the bleeding machine,

is 1000 fish/hour,

t0 is set as 1 s, and

n1 is 90 r/min. Therefore, according to Equation (3), the relationship between

i2 and

i3 can satisfy

Therefore, combined with the design requirements of the chain transmission mechanism and the overall size of the transmission mechanism, i2 is finally determined to be 1.5 and i3 to be 2.

Clutch Assembly

The clutch assembly is the key to intermittent transmission and mainly consists of a return spring, a rotating sleeve, a cam roller frame, rollers, a passive star wheel, and an active hub, as shown in

Figure 11. Eleven rollers are evenly nested in the cam roller frame and placed between the passive star wheel and the active hub, achieving power transmission from the active hub to the passive star wheel. The return spring connects the rotating sleeve and the cam roller frame, and the stretched return spring provides the torque for the cam roller frame to rotate back to its original position.

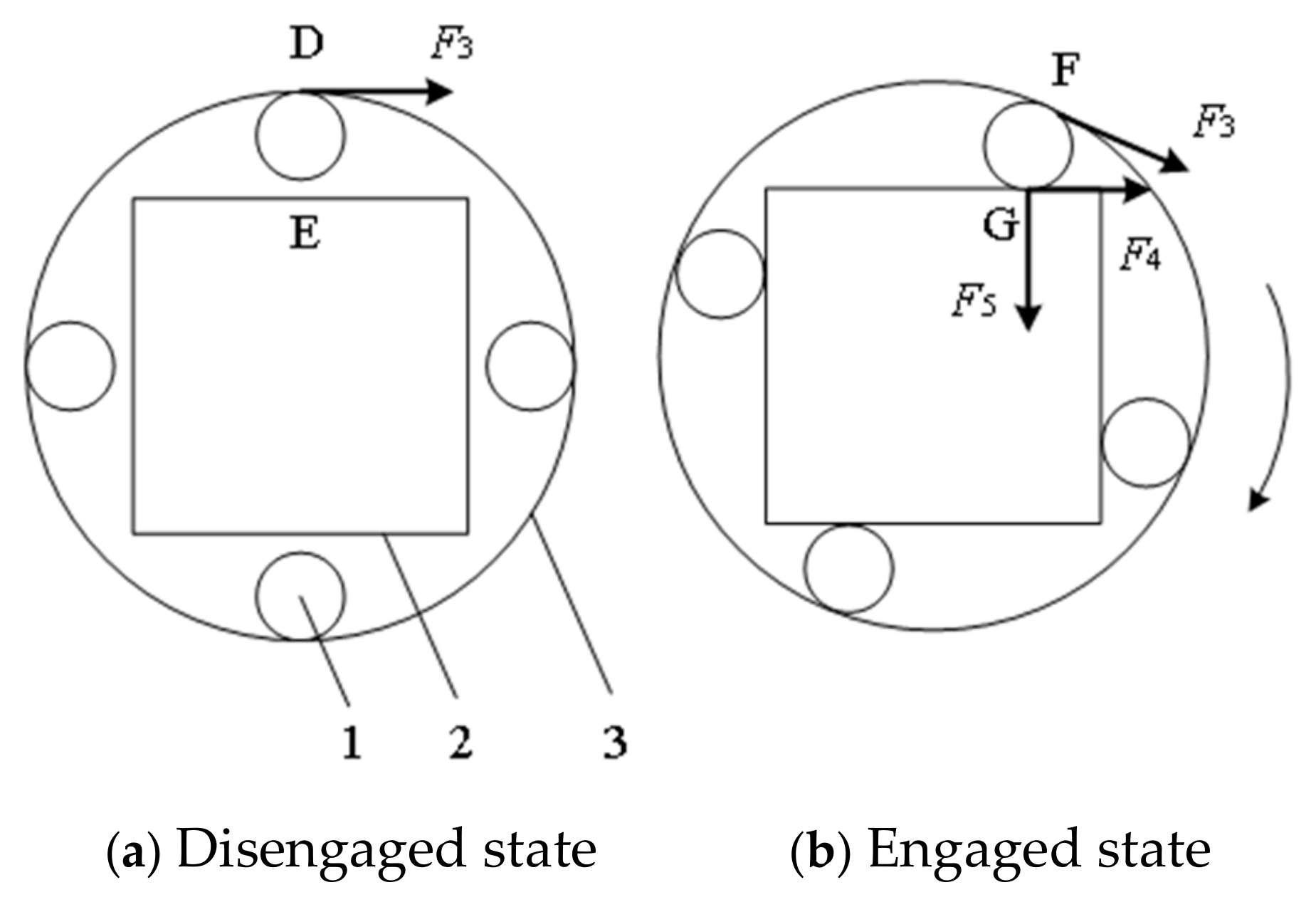

When the clutch assembly is in the limited position, its position state is shown in

Figure 12a. Under the action of the limiting mechanism, the cam roller frame causes the rollers to be tangent to the active hub. Since the distance DE is greater than the diameter of the rollers, the rollers do not come into contact with the passive star wheel. Driven by the chain transmission mechanism, the active hub rotates uniformly in a clockwise direction. Due to the friction force F3 exerted by the active hub on the rollers, the rollers rotate on their own axis, while the passive star wheel remains stationary. Therefore, when the clutch assembly is in the disengaged state, the active hub rotates, but the passive star wheel does not.

After the limit on the cam roller frame is released, under the pull of the return spring, the rollers rotate clockwise with the cam roller frame. Since the distance between the active hub and the passive star wheel decreases in the clockwise direction, when the rollers move to point F, they begin to contact the passive star wheel at point G, as shown in

Figure 12b. At this moment, the rollers start to exert pressure F

5 and friction force F

4 on the passive star wheel.

Analyzing

Figure 12b, the total torque M of the passive star wheel can be obtained as follows:

where n—the number of passive star wheel edges;

M0—the maximum resistance torque of the passive star wheel, N.m;

lEG—the distance between point E and point G, m;

lOE—the distance between point E and the center O of the passive star wheel, m;

μ1—the friction coefficient between the roller and the passive star wheel.

According to Equation (5), when M ≤ 0, the passive star wheel remains stationary. Under the drive of F3, the roller tends to rotate clockwise. Since the space between points F and G is the minimum space to accommodate the roller, the roller cannot continue to move. At this point, the active hub, roller, and passive star wheel are in a relatively stationary state. Due to the continuous torque output from the motor, F3 continues to increase, which in turn causes F5 to increase. As F5 increases, when M > 0, the passive star wheel overcomes the resistance and begins to rotate clockwise. When the rotational speed of the passive star wheel accelerates to match that of the active hub, the passive star wheel reaches a new torque balance and rotates synchronously with the active hub, and the clutch assembly enters the engaged state.

2.8. Design of Trigger Mechanism

2.8.1. Structure of Trigger Mechanism

The trigger mechanism is the switch that initiates the bleeding action of the bleeding mechanism. The trigger mechanism mainly consists of a trigger baffle plate, a trigger arm, a pillow block bearing, a trigger shaft, a spring, and a trigger rod, as shown in

Figure 13. The working process of the trigger mechanism is as follows: The fish body, through the kinetic energy generated by sliding down, collides with the trigger baffle plate, causing the trigger rod to rotate a certain angle. The movement of the end of the trigger rod releases the cam from the limit and starts its rotation, driving the bleeding knife to move up and down reciprocally once. After the cam completes one full rotation, the trigger rod resets under the pull of the spring, limiting the cam from further rotation, thus completing the start–stop cycle.

To address the potential issue of trigger failure in automatic trigger mode, a manual trigger mechanism is added to the trigger mechanism, mainly consisting of a trigger link and a trigger handle, as shown in

Figure 14. By rotating the trigger handle, the trigger rod is pushed to initiate the bleeding action, enhancing the reliability of the operation.

2.8.2. Mechanical Analysis

The simplified motion diagram of the trigger mechanism is shown in

Figure 15. In the absence of a fish trigger, the trigger mechanism is in the

bod position. The tension of the spring keeps the trigger rod at point

d, where the trigger rod

od is perpendicular to the straight edge

de of the cam. The resistance force exerted by the trigger rod

od on the cam can counteract the inertial force when the cam, in its counterclockwise rotation state, initially contacts the trigger rod, thus keeping the cam in a limited stop state.

In the state without fish triggering, to prevent the initial trigger torque from being too small and causing accidental triggering, an initial trigger torque constant C is introduced. At this time, the trigger mechanism is in a torque balance state, and the torque relationship satisfies Equation (6):

where

G1—the gravitational force of the trigger baffle plate and the trigger arm, N;

l1—the distance from point o to the direction of G1, m;

G2—the gravitational force of the trigger rod, N;

l2—the distance from point o to the direction of G2, m;

F2—the support force exerted by the cam on the trigger rod, N;

lod—the length of the trigger rod od, m.

In the state of fish triggering, when the fish slides from point

a to point

b, the trigger mechanism rotates from the

bod position to the

b’od’ position. When the fish reaches point b, its speed decreases to 0. According to the law of conservation of energy, the gravitational potential energy of the fish is ultimately converted into the elastic potential energy of the spring and the thermal energy produced by friction. Therefore, for the normal operation of the trigger mechanism, the following conditions must be met:

where

ldd’—the moving distance of point d on the trigger rod, m;

lde—the distance from point d to point e on the cam, m;

lob—the length from the trigger rotation shaft to the trigger baffle plate, m;

lbb’—the moving distance of point b on the trigger baffle plate, m;

E—the change in potential energy of the fish body, J;

Ep—the increase in elastic potential energy of the spring caused by the fish body impacting the trigger baffle plate, J.

By combining Equations (6) and (7), the elastic coefficient of the spring required for both the no-fish trigger and fish-trigger states can be obtained as 0.7 N/mm ≤ k ≤ 1.8 N/mm.

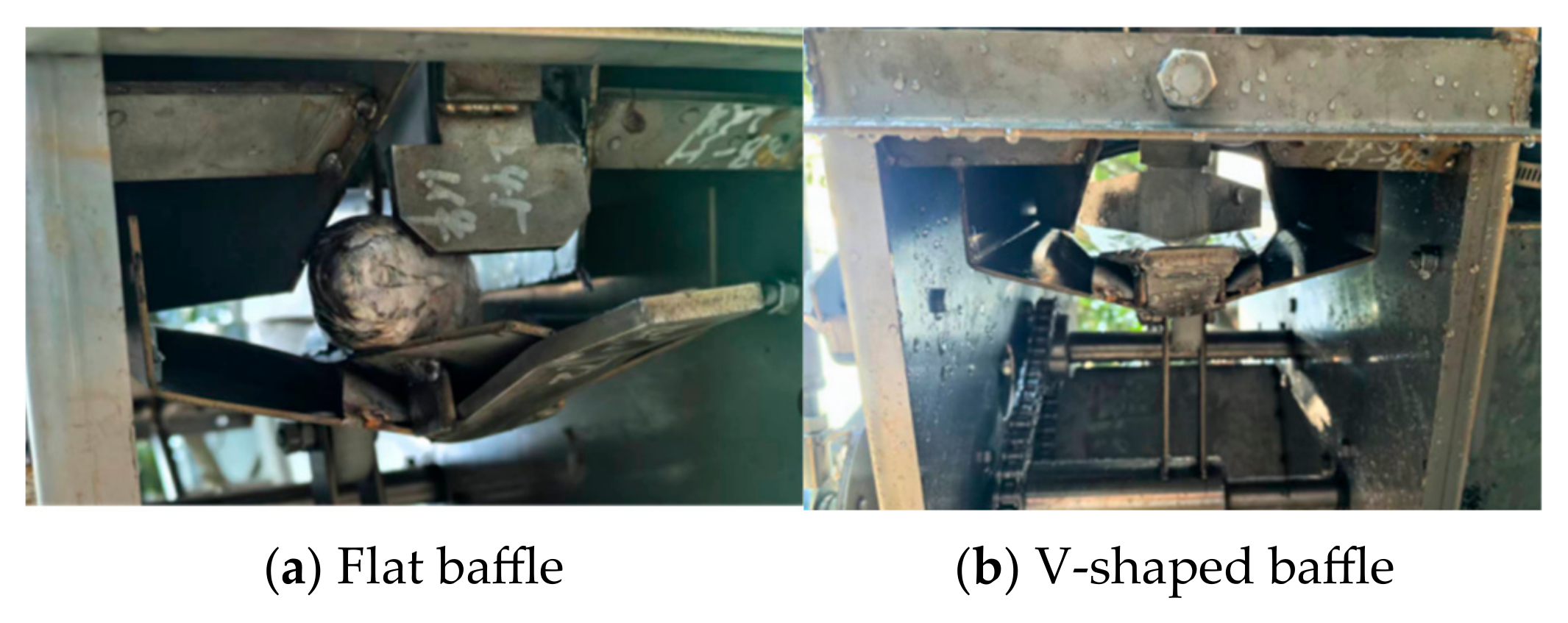

2.8.3. Design of the Trigger Baffle Plate

The trigger baffle plate is the key component of the trigger mechanism that withstands the impact force of the fish body, and its shape structure affects the stability of the contact between the fish body and the trigger baffle plate. Based on the characteristics of the impact force generated by the fish sliding down and the shape of the fish head, two structurally simple trigger baffle plates have been designed, as shown in

Figure 16.

According to the characteristic of the fish body impacting at an oblique vertical angle, a rectangular flat plate with dimensions of 60 mm×30 mm is designed to withstand the force from the vertical direction. Based on the fish head’s shape, which is approximately an elliptical cone, a V-shaped plate with an opening angle of 70° is designed to achieve multi-point support for the fish head and absorb the collision force of the fish body. Both types of trigger baffle plates have their own characteristics, and subsequent comparative experiments will be conducted to test the triggering effects.

2.10. Fish Bleeding Test

2.10.1. Experimental Materials and Apparatus

Fresh and live snakehead (

Channa argus), grass carp (

Ctenopharyngodon dellus), and tilapia (

Oreochromis mossambicus) were selected as experimental subjects. The body mass of all three fish species ranged from 250 g to 2500 g, with 100 individuals prepared for each species. The fish were harvested from aquaculture ponds and transported under refrigeration to the experimental site. A self-developed automated fish bleeding machine served as the experimental platform (

Figure 18). Additional equipment included an electronic balance (accuracy: 0.1 g) and a stopwatch (accuracy: 0.1 s).

2.10.2. Experimental Conditions

The experiment was conducted in November 2024 at the Product Performance Testing Center of Guangdong Hongke Agricultural Machinery Research and Development Co., Ltd. (Guangzhou, China). The ambient temperature during testing was maintained at 25–28 °C. Fish of each species were separately stored in three aquaculture tanks, each equipped with a small aerator to ensure fish vitality during the experiment.

2.10.3. Sensory Evaluation of Bloodletting Efficacy

To assess the bloodletting performance of the automated machine, sensory evaluations were conducted based on fillet color and residual blood content in the muscle tissue to determine the cleanliness of mechanized bloodletting and its impact on fillet quality.

Twenty individuals of each species (snakehead, grass carp, and tilapia) were sequentially fed into the bloodletting machine in a head-first orientation. Fish that completed the bloodletting process were transferred to a clean water pool for free swimming to facilitate further bleeding. Ten minutes later, 10 fish from each species were sampled and filleted into fish fillets. A five-member evaluation panel performed sensory assessments of the bloodletting efficacy for each fillet, following the criteria outlined in

Table 3. The sensory scores for each species were used as evaluation indicators, and the comprehensive average score calculated from the panel’s assessments determined the machine’s bloodletting efficacy for each species.

2.10.4. Comparative Test

To test the impact of the trigger baffle plate on the bleeding effect of the automatic fish bleeding machine, a comparative test was conducted using two types of trigger baffle plate designs: the flat plate and the V-shaped plate.

The test method is as follows:

- a.

First, install the flat plate on the prototype of the automatic fish bleeding machine, then prepare a batch of live fish and record the total number of fish; press the start button to activate the bleeding machine;

- b.

Feed the fish into the machine with their heads facing forward. Once a fish slides out of the exit, feed in the next one until all fish have been processed. For each fish tested, observe whether the bleeding action is successfully triggered and examine the fish after bleeding. If there is a cut on the gill area of the fish head and blood flows out, it is considered a successful bleeding; otherwise, it is a failure. Record the number of successfully bled fish and note the condition of the fish that failed to bleed;

- c.

Calculate the trigger success rate and the bleeding success rate for each test.

The formula for calculating the bleeding success rate is

The formula for calculating the trigger success rate is as follows.

where

M—the bleeding success rate;

V—the trigger success rate;

N—the total number of fish, in pieces;

N1—the number of fish that were successfully bled, in pieces;

N2—the number of fish for which the trigger was successful, in pieces;

- d.

Repeat the above steps for three tests and calculate the average of the tests;

- e.

Remove the flat plate and replace it with the V-shaped plate, then repeat the above steps.

2.10.5. Performance Test

To evaluate the operational performance of the automatic fish bleeding machine, bleeding success rate and work efficiency were used as test indicators for the performance test.

The test method is as follows:

- a.

Prepare a batch of live fish and record the total number of fish; press the start button to activate the bleeding machine;

- b.

Start the stopwatch and feed the fish into the machine with their heads facing forward. Once a fish slides out of the exit, feed in the next one. Stop the timer after all fish have been processed;

- c.

Examine each fish after bleeding. If there is a cut on the gill area of the fish head and blood flows out, it is considered a successful bleeding; otherwise, it is a failure. Record the number of successfully bled fish;

- d.

Calculate the bleeding success rate and work efficiency for each test. The bleeding success rate is calculated according to Equation (8).

The formula for calculating work efficiency is

where

N—the total number of fish, in pieces;

K—the work efficiency, fish/hour;

t—the total processing time, s;

- e.

Repeat the above steps for at least 3 tests and calculate the average of the tests.