Abstract

This study presents the development and evaluation of a microwave-assisted prototype for scalable red palm oil production. The prototype, equipped with industrial magnetrons delivering a combined power of 2 kW, is designed to process up to 6 kg of oil palm fruit per batch. The design, optimized using COMSOL Multiphysics simulations, focused on waveguide configurations and cavity dimensions to ensure uniform energy distribution and minimize hotspots. Performance testing validated the system’s capability to deliver consistent heating across six trays and produce high-quality red palm oil. Results demonstrated a significant reduction in free fatty acid (FFA) content from 20.4% to 2.1% while retaining carotene content within the industrial standard range (558.2 ppm). The Deterioration of Bleachability Index (DOBI) showed a slight reduction but remained within acceptable limits, underscoring the prototype’s ability to maintain oil clarity and processability. Microwave heating effectively inactivated lipase enzymes, reducing FFA and enhancing oil stability, as confirmed by previous studies. The chemical-free process preserved essential nutrients, aligning with sustainability goals. This innovative system provides a scalable, energy-efficient solution for community and industrial applications, offering improved product quality with minimal environmental impact. Future work will focus on optimizing the system further and exploring its applications in broader agricultural processing contexts.

Keywords:

red palm oil; microwave heating; scale up; magnetron; waveguide; carotene; free fatty acid; extraction 1. Introduction

Red palm oil, extracted from the fruit of the oil palm (Elaeis guineensis), is a valuable agricultural product recognized for its nutritional benefits and diverse industrial applications [1,2,3]. Renowned for its high content of carotenoids and vitamin A, red palm oil provides significant health advantages. Carotenoids, which are potent antioxidants, mitigate oxidative stress, enhance eye health, and strengthen the immune system [4]. Vitamin A plays a crucial role in supporting vision, maintaining skin health, and strengthening immune function. Beyond its health benefits, red palm oil is a key ingredient in functional foods, nutraceuticals, and cosmetics. Its vibrant red-orange color and nutrient density make it highly desirable in global markets.

However, producing high-quality red palm oil presents notable challenges, particularly in preserving its sensitive nutritional components during processing. Conventional techniques such as steam sterilization, widely used in the palm oil industry, involve heating fresh fruit bunches (FFBs) with steam at 2.5–3.5 bars and 130–140 °C for 45–90 min. This process facilitates fruit detachment, softens the mesocarp, and inactivates lipase enzymes, preventing the formation of free fatty acids (FFAs). Following sterilization, the softened fruits are mechanically separated and pressed using a screw press to extract crude palm oil (CPO). Despite its effectiveness, steam sterilization is highly energy-intensive, requires large amounts of water (~0.256 kg of water per kg of FFB), and can lead to partial nutrient degradation due to prolonged exposure to high temperatures [5,6,7].

Microwave heating presents a viable alternative to steam sterilization by providing rapid, energy-efficient heating that preserves the oil’s nutritional integrity. Unlike steam sterilization, microwave-assisted processing selectively heats the fruit’s water molecules, generating internal heat that softens the mesocarp while maintaining lower overall temperatures. This controlled heating process inactivates lipase enzymes, reduces FFA formation, and minimizes nutrient loss, making it particularly advantageous for small-scale and community-based producers. Additionally, microwave heating eliminates the need for excessive water usage, aligning with sustainable processing goals and reducing the environmental impact of palm oil production. This study explores the development and evaluation of a microwave prototype to replace steam sterilization while ensuring high oil quality and efficiency. Chavalparit et al. [8] emphasized the importance of adopting clean technologies to improve the environmental performance of crude palm oil production. Their study specifically highlighted that sustainable and energy-efficient alternatives are crucial for enhancing production practices in SMEs, facilitating the development of more accessible and eco-friendly solutions

To address these challenges, recent research on red palm oil extraction has explored alternative methods, such as the use of modified household microwave ovens. These approaches aim to improve processing efficiency, reduce energy consumption, and preserve the nutritional integrity of red palm oil. They offer promising solutions for sustainable and scalable production. Microwave technology provides a transformative solution to red palm oil processing, effectively addressing many challenges associated with traditional methods. Unlike steam systems, microwaves penetrate directly into the material, ensuring uniform and efficient heating. This capability not only reduces processing time but also minimizes nutrient loss, preserving the high levels of carotenoids and vitamin A which are essential to red palm oil’s nutritional and market value [9,10,11,12]. Furthermore, microwave heating has been shown to effectively inhibit lipase enzymes, preventing the formation of free fatty acids (FFAs) which compromise oil quality. The ability to maintain low FFA levels while preserving essential nutrients positions microwave technology as a superior alternative to conventional methods [10]. However, studies utilizing household microwave systems have revealed critical limitations. Uneven energy distribution is a significant issue because household microwaves often produce inconsistent heating patterns, leading to localized overheating or underheating, that can degrade oil quality. Limited processing capacity is another drawback. The small size and low power output of household systems restrict their ability to handle large volumes, making them unsuitable for industrial or community-scale production [11]. Additionally, lack of specialized design presents a challenge, as household microwave ovens are not optimized for the specific requirements of red palm oil production, including enzyme inactivation and oil extraction efficiency [13]. These limitations underscore the need for industrial-scale microwave systems specifically tailored to meet the demands of red palm oil processing, offering a pathway to more efficient, scalable, and sustainable production methods.

To fully harness the potential of microwave technology and address the limitations of existing methods, it is essential to develop community-scale industrial prototypes specifically tailored to red palm oil production. These prototypes must feature scalable designs capable of processing larger volumes while maintaining high efficiency and consistent product quality, thus making them suitable for both small-scale and large-scale industrial applications. Additionally, the systems should optimize critical processing parameters, such as power distribution, heating uniformity, and nutrient preservation, to enhance oil yield and the retention of red palm oil’s nutritional integrity. Accessibility is another key consideration. By reducing production costs and simplifying operation, these systems can enable local producers to adopt advanced microwave technologies. This approach not only enhances economic sustainability but also reduces reliance on expensive imported systems, thereby empowering small and medium-sized enterprises (SMEs) and community-based producers. The integration of these features provides a transformative solution for sustainable and efficient red palm oil production, meeting the needs of local producers while addressing global demand for high-quality, environmentally friendly products.

This study introduces an innovative approach to sustainable and efficient red palm oil production through the development of a scalable and community-focused microwave prototype. The 2 kW system, equipped with industrial magnetrons and designed with six trays, is capable of processing up to 6 kg of oil palm fruits per batch. Using COMSOL Multiphysics, the prototype was modeled to ensure uniform energy distribution and minimize uneven heating. Key design features, including precise waveguide alignment and strategically placed reflectors, were integrated to optimize energy absorption. The use of industrial magnetrons provided stable and reliable microwave power, ensuring consistent heating across all trays. Performance testing validated the system’s ability to produce high-quality red palm oil with high carotene content, low free fatty acid (FFA) levels, and a Deterioration of Bleachability Index (DOBI) value that meets industrial standards. Furthermore, the oil retained its vibrant color and nutritional value, while nutrient loss was minimized. This modular design is practical for small-scale rural producers and adaptable for industrial applications, creating economic opportunities in developing regions. By enhancing product quality, reducing waste, and lowering energy consumption, this study addresses the growing global demand for sustainable palm oil production. It also supports broader sustainability goals, representing a significant advancement in microwave-assisted red palm oil processing.

2. Material and Methods

2.1. Simulation of an Industrial Microwave Prototype

The application of microwave heating technology for industrial-scale red palm oil extraction requires the design of a rectangular microwave cavity significantly larger than a household microwave oven. This design must incorporate multiple waveguides and magnetrons to deliver higher microwave power and ensure uniform energy distribution within the cavity. Achieving uniform energy distribution is critical for effective microwave heating, promoting consistent thermal activation throughout the palm fruit load. This ensures optimal energy efficiency and maximizes oil yield during the extraction process. The design of the microwave cavity and the strategic placement of magnetrons are pivotal steps in developing an efficient industrial microwave prototype. The use of COMSOL Multiphysics software version 6.2 provides a robust and cost-effective approach for accurately simulating microwave propagation and energy distribution within the waveguides and cavity. These simulations can be conducted on a standard personal computer, making the process both accessible and economical [14,15,16,17,18,19,20]. Compared to a household microwave oven, a larger industrial microwave cavity allows for the installation of multiple magnetrons. This enhancement increases the system’s heating capacity from a few hundred grams to several kilograms of palm fruit per batch, meeting the demands of industrial-scale processing. The simulation results guide the engineering design of the industrial microwave prototype, ensuring an optimal balance among cavity size, waveguide placement, and magnetron configuration for efficient energy absorption and heating uniformity. Once the prototype is constructed, its performance will be evaluated through rigorous testing. The testing phase includes analyzing the uniformity of heat distribution within the palm fruit load and assessing the quality of the extracted red palm oil. Key quality parameters, such as carotene content, free fatty acid (FFA) levels, and oil yield, will be measured to validate the system’s effectiveness and industrial applicability.

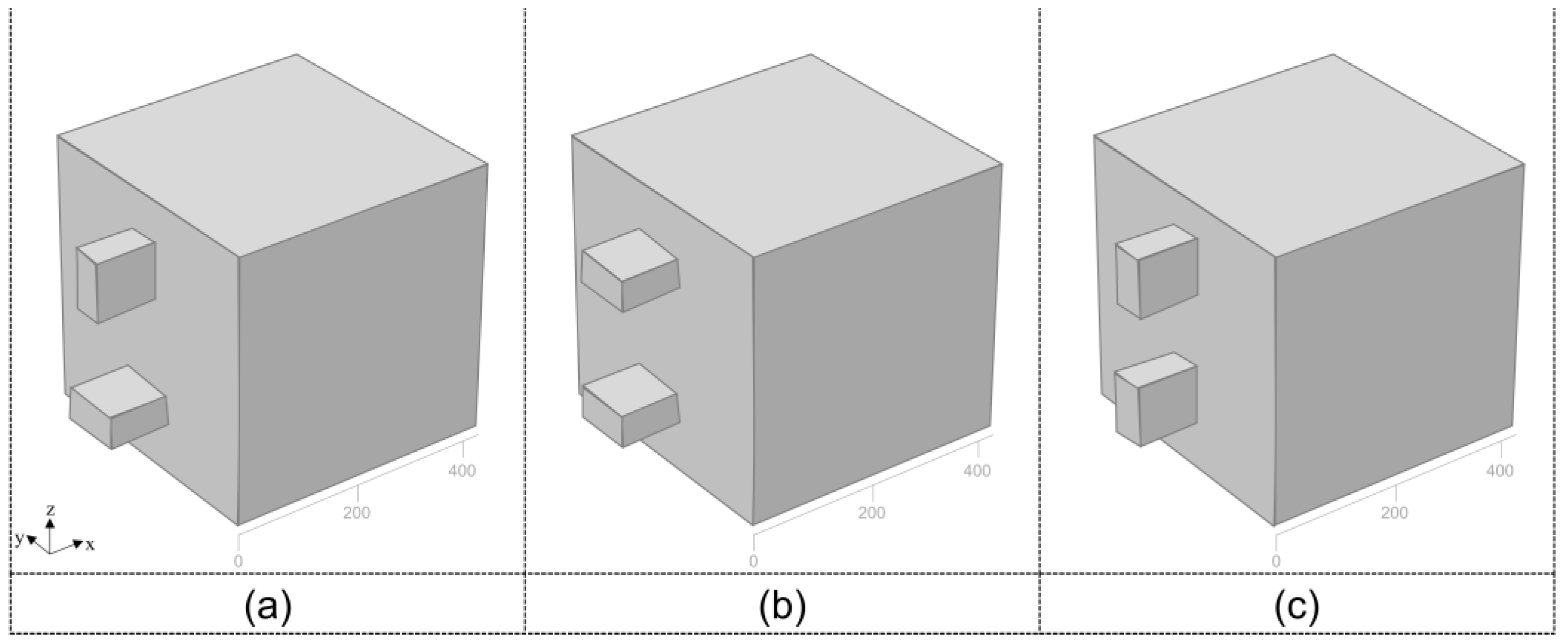

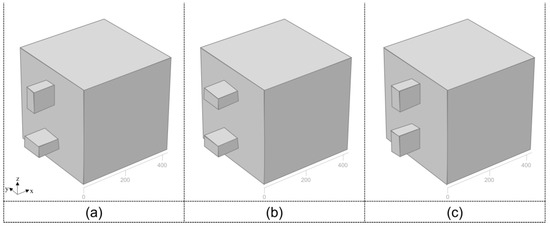

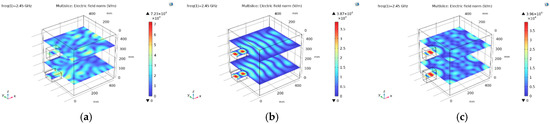

Figure 1 shows a schematic representation of the modeled microwave cavity with two magnetrons installed on the same external wall, illustrating different configurations of waveguide placements. The cavity, measuring , is a multi-mode cavity equipped with two WR340 standard waveguides (), designed to deliver microwaves at a frequency of 2.45 GHz in the mode. The WR340 waveguide was selected for its compatibility with industrial magnetrons operating at 2.45 GHz, a frequency commonly used in microwave heating systems. This waveguide supports the mode, which efficiently transfers microwave energy with minimal power loss. Its standardized dimensions make it suitable for a range of industrial and experimental microwave applications [20]. Three configurations were modeled to investigate the impact of waveguide placement configurations on microwave energy distribution within the cavity. Figure 1a shows magnetrons positioned perpendicular to each other, Figure 1b illustrates a horizontal alignment, and Figure 1c depicts a vertical alignment. These configurations were simulated to determine their effect on energy uniformity and to identify an optimal placement strategy for the magnetrons and waveguides. Proper waveguide alignment ensures effective coupling of microwave energy in the cavity and minimizes the formation of hot spots or cold spots caused by destructive interference patterns [13]. This modeling approach provided the necessary data to guide the design and construction of the microwave cavity and its components for optimal heating efficiency.

Figure 1.

Schematic representation of the microwave cavity with two magnetrons installed on the same side. (a) Magnetrons are positioned perpendicular to each other, (b) Magnetrons are aligned horizontally, and (c) Magnetrons are aligned vertically.

Microwaves are emitted from exciters and transmitted through the waveguides into the cavity, propagating at the speed of light in vacuum , which is approximately m/s. The temporal and spatial variations of the electric field are governed by Maxwell’s wave equation:

where is the relative permeability, is the wave number in free space, is the relative permittivity, and is the electrical conductivity. The electric field within the waveguides and cavity is a function of the spatial coordinates , , and , representing the position-dependent variation of the field inside these structures. This formulation is widely used in microwave cavity design and electromagnetic simulations [21,22]. When the waveguides and cavity are filled with vacuum, the relative permeability is equal to 1, indicating that the vacuum has no magnetic properties that would affect the microwaves. Similarly, the relative permittivity is also equal to 1, as the vacuum does not have any dielectric properties. Furthermore, the electrical conductivity is zero in a vacuum. With these assumptions, the wave equation simplifies to:

where is the wave number in free space, is the angular frequency, and is the speed of light. This simplification highlights the propagation of microwaves in a lossless medium, where energy is conserved, and no absorption or dissipation occurs [23]. The electric field of interest represents the propagating microwave field in both the waveguides and the cavity. In the waveguides, the field is typically modeled in the transverse electric () mode, where the electric field varies sinusoidally in the transverse direction. This mode is optimal for the transfer of microwave energy through the waveguide with minimal losses [22]. In the cavity, the microwaves interact with the walls and reflect, creating interference patterns that result in standing waves. These standing waves are influenced by the cavity dimensions, the magnetron positions, and the boundary conditions applied to the cavity walls. The boundary conditions for the waveguides and cavity walls are modeled as perfect electric conductors (PECs), which ensure total reflection of the electric field at the walls. The PEC boundary condition is mathematically expressed as:

where is the normal vector to the surface of the walls. This condition implies that the tangential component of the electric field at the conductor surface is zero, preventing any penetration of the field into the walls. This ensures that the microwaves are fully confined within the waveguides and cavity, maximizing energy efficiency and minimizing losses [24]. The electric field norm, denoted as , represents the magnitude of the electric field at a given point in the cavity or waveguide. It is defined as:

where , and are the components of the electric field vector in the , and directions, respectively. The electric energy intensity in vacuum , quantifying the energy stored in the electric field, is calculated as:

where is the permittivity of free space. The simulation was conducted in the frequency domain under steady-state conditions, enabling a detailed analysis of the electromagnetic field distribution within the cavity and waveguides. The frequency domain approach assumes that the electromagnetic field oscillates sinusoidally with a fixed frequency, allowing for the steady-state solution of Maxwell’s equations. This methodology is widely applied in the study of microwave heating systems and resonant cavities to achieve precise field distribution predictions [25,26]. The steady-state condition ensures that the simulated fields represent the system’s behavior after transient effects have dissipated, providing reliable insights into the electromagnetic energy distribution. By integrating over the -planes within the cavity, the distribution of electric energy intensity along the -axis, corresponding to the vertical axis of the microwave cavity, was analyzed. This approach enables a detailed evaluation of the uniformity of electric energy intensity at various heights along the -axis. Such analysis is critical because the cavity is designed to accommodate six trays arranged vertically along this axis. Integration over the -planes at different -positions provides a comprehensive understanding of how energy is distributed across each plane where the trays are positioned. Uniform electric energy intensity on the -planes ensures that all six trays receive consistent microwave energy, resulting in uniform heating of the materials placed on them.

This method not only identifies regions of high and low energy intensity but also facilitates the optimization of waveguide and magnetron placement to minimize energy discrepancies and maximize heating efficiency. Ensuring uniform energy delivery along the -axis is essential for achieving consistent heating across all trays, which is particularly important for applications requiring precise and efficient energy absorption, such as in the scale-up of red palm oil extraction. This detailed analysis provides valuable insights for the design and optimization of the microwave cavity, demonstrating its effectiveness and suitability for multi-tray configurations and scalable industrial applications.

2.2. Engineering Design

The engineering design of the microwave prototype for scaling up red palm oil production was guided by the simulation results presented in Section 2.1. These simulations identified the perpendicular waveguide configuration (Figure 1a) as the most effective in maximizing electric energy intensity within the cavity. This configuration was selected to ensure efficient energy transfer and uniform microwave energy distribution throughout the cavity. The cavity was designed as a multi-mode cavity with dimensions , constructed using stainless steel 304. This material was chosen for its excellent conductivity, corrosion resistance, durability, and classification as a food-grade material, making it ideal for food processing applications. The reflective properties of stainless steel 304 enhanced microwave efficiency by minimizing energy loss and optimizing wave distribution within the cavity. Two WR340 standard waveguides, each operating at 2.45 GHz in the mode, were installed perpendicularly on the same external wall of the cavity. Each waveguide was coupled with a magnetron mounted directly on its input flange. Cooling fans were installed on the heat sinks of each magnetron to dissipate heat during operation, ensuring stable performance and extending component lifespan. To ensure compliance with international safety standards, a door choke was designed to minimize microwave leakage. The door choke was modeled and constructed based on findings from the research by Boonthum and Nisoa, which focused on high-temperature multi-magnetron microwave furnaces (14). A series of quarter-wavelength choke structures were incorporated around the door frame to suppress microwave leakage by generating destructive interference patterns that canceled the escaping waves. This design ensured that microwave leakage remained below the international limit of 5 mW/cm2. The design was rigorously tested and validated to confirm compliance with safety standards [14,21]. To maintain optimal operating conditions, two exhaust fans were installed to regulate moisture levels within the cavity during operation. These fans efficiently removed moisture, preventing excessive humidity buildup and improving oil extraction efficiency. The removal of moisture also reduced the water content in the extracted red palm oil, contributing to higher product quality. The cavity was equipped with six rotating trays aligned vertically along the -axis, mounted on a central axis driven by a gear motor. This mechanism ensured uniform exposure of oil palm fruits to microwave energy, reducing temperature gradients and achieving consistent heating across all trays. The simulation-informed placement of the waveguides and magnetrons allowed for uniform energy intensity along the -axis, ensuring effective heating for all levels. The electrical control system enabled precise regulation of microwave power, allowing operators to adjust processing parameters to optimize energy efficiency and maintain consistent product quality. This flexibility ensured reliable operation across a variety of production scales.

By integrating the perpendicular waveguide configuration, stainless steel 304 for the cavity material, door choke for leakage prevention, magnetron cooling fans, and exhaust fans for moisture control, this engineering design successfully balanced energy efficiency, safety, uniform heating, and scalability. The prototype was tailored to support industrial-scale red palm oil production while ensuring compliance with safety standards and suitability for community-level applications.

2.3. Assembly and Testing

The assembly of the microwave prototype was conducted by engineers and technicians from the Center of Excellence of Plasmas and Electromagnetic Waves (PEwave) at Walailak University. The construction process strictly followed the engineering design outlined in Section 2.2, which served as the blueprint for component placement, material selection, and system integration. The fabrication and assembly took place in the PEwave workshop, equipped to handle the precision work required for building advanced microwave systems. The prototype utilized industrial magnetrons, chosen for their robustness and capability to operate at high power levels required for industrial applications. Each magnetron was paired with a WR340 waveguide, designed to deliver microwaves efficiently at a frequency of 2.45 GHz in the mode. The magnetrons were powered by switching power supplies capable of adjusting the microwave power continuously between 300 W and 1000 W for each magnetron. This configuration allowed for precise and independent control of the microwave power output from each magnetron. Together, the two magnetrons could deliver a combined maximum power of 2 kW, ensuring sufficient energy for uniform heating across all trays in the cavity. The cavity was constructed from stainless steel 304, a food-grade material that offers excellent reflective properties, durability, and resistance to corrosion. Two exhaust fans were installed in the cavity to regulate moisture levels during operation, preventing excessive humidity buildup and enhancing the efficiency of oil extraction. Each magnetron was equipped with a dedicated cooling fan mounted directly on its heat sink to ensure stable operation and effective thermal management during prolonged use. Performance testing was conducted to evaluate the prototype’s operational efficiency and safety. Six trays, arranged vertically in the cavity, were loaded with one kilogram of ripe oil palm fruits each. A microwave power of 2 kW was applied, with 1 kW supplied by each magnetron. The temperature of the fruits on each tray was measured every 10 min using an infrared thermometer (Fluke 64 MAX). Measurements were taken at both central and peripheral positions on each tray to assess the uniformity of microwave energy distribution. The temperature variations provided insights into the consistency of energy delivery, as the temperature rise is directly proportional to the square of the electric field intensity . Microwave leakage was evaluated using a microwave leakage meter, focusing on the door edges, the most likely points of leakage. The door choke, designed in accordance with the engineering design specifications, effectively suppressed leakage, ensuring levels remained below the standard limit of 5 mW/cm2 [27].

The successful assembly and testing of the prototype confirmed its ability to deliver uniform heating and safe operation. The use of industrial magnetrons with adjustable power supplies, capable of delivering a combined output of up to 2 kW, along with food-grade materials, demonstrated the system’s scalability and reliability for red palm oil production. These findings provide a strong foundation for further optimization to enhance performance and efficiency.

2.4. Red Palm Oil Production

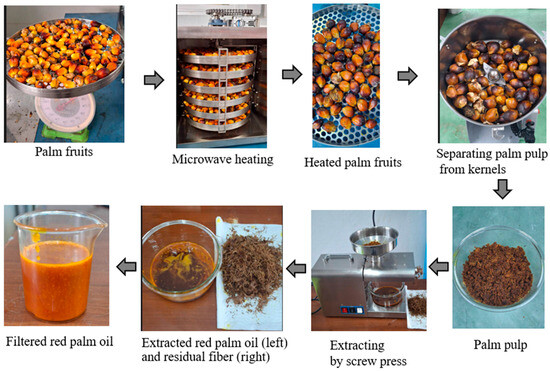

The production of red palm oil using the developed microwave prototype followed a carefully structured process designed to ensure efficiency and quality. Fresh oil palm bunches were purchased from a collection center near Walailak University, located in Tha Sala District, Nakhon Si Thammarat Province, Thailand. The bunches were left under a plastic sheet for two nights to facilitate the natural loosening of the fruits, making them easier to detach for processing. The oil palm fruits were then manually separated from the bunches after the resting period. The detached oil palm fruits were loaded onto six trays, each holding one kilogram, and arranged vertically within the microwave cavity. The microwave prototype, equipped with industrial magnetrons operating at 2 kW, was used to uniformly heat the fruits. This controlled heating process softened the mesocarp, optimizing conditions for efficient oil extraction. The fruits were microwaved at 2 kW for 55 min, with periodic temperature measurements. After microwave heating, the softened fruits were processed to separate the palm pulp from the kernels using a fine powder grinding machine.

The grinding process produced oil-rich palm fibers measuring approximately 2–4 cm in length. These fibers exhibited a curled structure, forming compacted clusters with diameters ranging from 1–2 mm, as illustrated in Figure 2. The grinding was performed using a multi-purpose grinding machine (Xiaojia, China) with a power rating of 1400 W, which effectively reduced the fruit mesocarp into fine fibers while maintaining the integrity of the oil-bearing structures. The fibrous palm pulp was then subjected to mechanical extraction using a screw press to obtain high-quality red palm oil. The extraction was carried out using a Small Business Home Mini Oil Press Machine (Lewin, China), designed for small-scale oil production. This screw press operates under cold-press conditions, ensuring the preservation of carotenoids and other essential nutrients in the extracted oil.

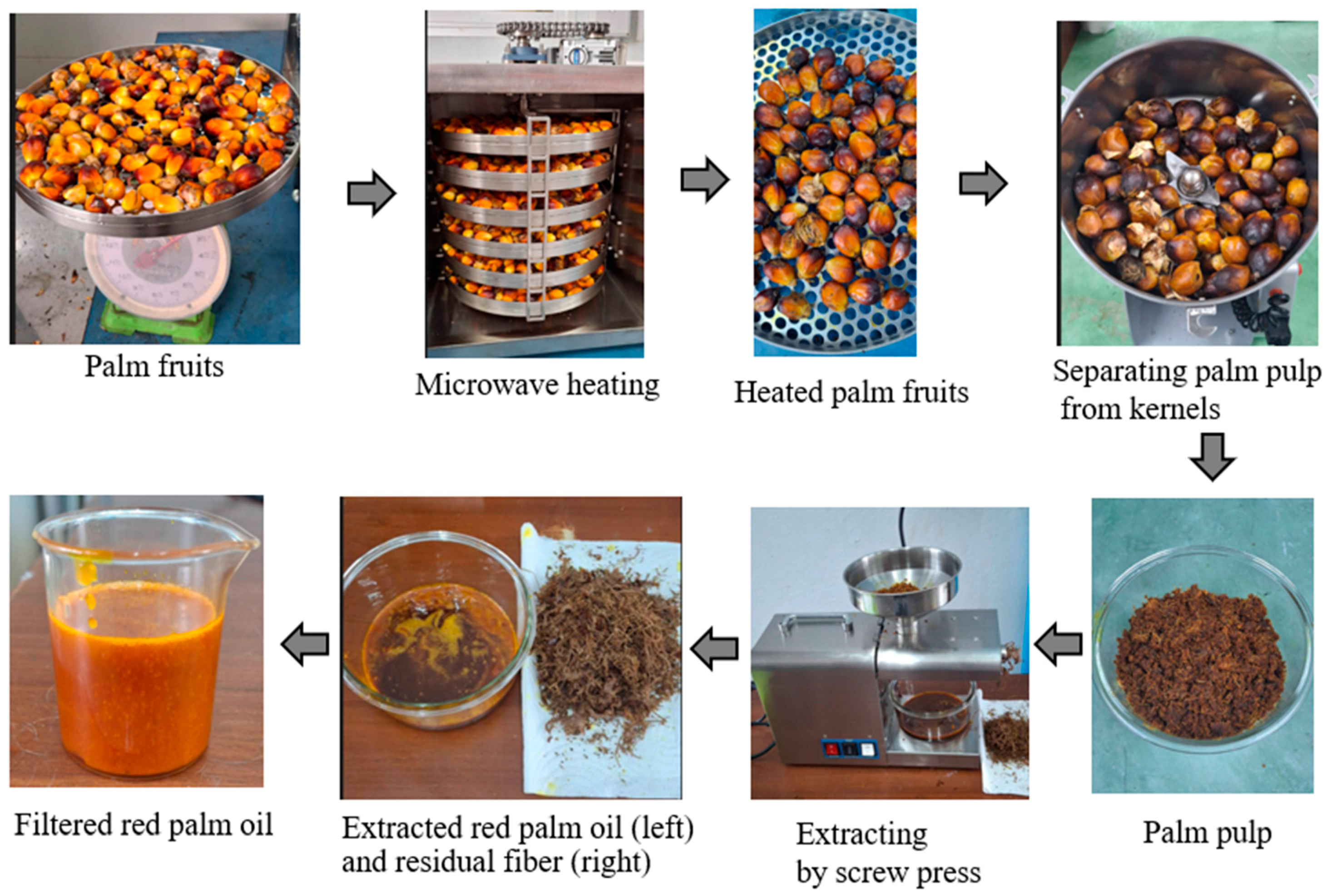

Figure 2.

Process flow for red palm oil production: ripe palm fruits are microwave-heated, separated into pulp and kernels, and pressed using a screw press to extract red palm oil.

Finally, the extracted oil was filtered using a cloth filter with a pore size of approximately 100 μm, manually pressed to remove impurities and suspended solids. This filtration process ensures the clarity and purity of the red palm oil, preserving its nutritional quality and enhancing its suitability for consumption and industrial applications. This distinctive coloration is attributed to its high carotene content, which provides antioxidant properties and significant health benefits [9,28,29,30]. Carotenoids are recognized for their role in reducing oxidative stress and supporting immune health, making this oil highly valuable for nutritional and functional applications. Figure 2 illustrates the entire production process, beginning with the preparation of ripe palm fruits, microwave heating, separation of palm pulp from kernels using a fine powder grinding machine, mechanical pressing, and filtration to produce red palm oil. This method underscores the efficiency and practicality of the prototype while preserving the oil’s nutritional integrity and ensuring environmentally friendly processing without chemical solvents. Additionally, the chemical-free extraction process aligns with sustainable practices, avoiding environmental harm caused by conventional solvent-based extraction methods.

2.5. Red Palm Oil Quality Assessment

The quality of red palm oil extracted using the microwave prototype was evaluated based on three key parameters: carotene content, Deterioration of Bleachability Index (DOBI), and free fatty acid (FFA) content. These parameters provide critical insights into the oil’s nutritional value, industrial applicability, and overall quality. The carotene content, responsible for the oil’s distinct orange-red color, was analyzed using a UV-Vis spectrophotometer (Shimadzu UV-1700 PharmaSpec). Oil samples were diluted with hexane, and absorbance was measured at 446 nm, the peak wavelength for carotenoids. The total carotene content was calculated using the following equation:

where represents the absorbance at 446 nm, is the total volume of the oil sample (mL), is the absorptivity constant (2592 for palm oil in hexane), and is the weight of the oil sample (g) [31,32]. A higher carotene content indicates better nutritional quality, as carotenoids serve as precursors for vitamin A and function as antioxidants essential for human health. The DOBI value, which reflects the clarity and bleachability of crude palm oil, was determined using UV-Vis spectrophotometry. It was calculated using the following formula:

where represents the absorbance at 446 nm (carotenoids) and represents the absorbance at 269 nm (secondary oxidation products). A higher DOBI value indicates better bleachability, making the oil more suitable for refining and industrial processing [13]. The FFA content, which determines the acidity of the oil, was analyzed using acid–base titration. The percentage of FFA (as oleic acid) was calculated using the following equation:

where is the volume of NaOH solution used (mL), is the normality of the NaOH solution (N), is the molecular weight of oleic acid (282.47 g/mol), and is the weight of the oil sample (g). A higher FFA content indicates hydrolytic degradation, which negatively affects shelf life and refining efficiency. Controlling FFA levels ensures better oil stability and extended storage life [33,34,35]. The sample data were statistically analyzed using mean and standard deviation (SD) calculations. Each measurement of carotene content, DOBI, and FFA content was performed in triplicate to ensure accuracy and reproducibility. The results were expressed as mean ± SD to account for measurement variations and improve reliability. The quality assessment results confirmed that the microwave prototype consistently produced red palm oil that met industrial quality benchmarks, demonstrating uniform heating, minimal FFA content, and high retention of carotenoids. These findings validate the effectiveness of the microwave-assisted extraction process as a reliable and scalable method for red palm oil production.

2.6. Statistical Analysis

To assess the significance of changes in red palm oil quality parameters due to microwave heating, an independent sample t-test was conducted. Each quality parameter, including FFA, DOBI, and carotene content, was measured in triplicate, and the results were expressed as mean ± standard deviation (SD) to account for variations in measurement. The t-test was performed at a 95% confidence level (p-value = 0.05) to determine whether there were significant differences between oil extracted from untreated palm fruits and those subjected to microwave heating. The analysis focused on FFA to verify a significant reduction after microwave heating, DOBI to determine if the clarity and bleachability of the oil remained stable, and carotene content to assess the retention of nutritional quality. A p-value < 0.05 was considered statistically significant, indicating a meaningful change in the parameter due to microwave heating, whereas a p-value > 0.05 suggested that differences were not statistically significant. All statistical analyses were performed using the online GraphPad T test calculator to ensure accuracy and reliability in data interpretation.

3. Results and Discussion

The section discusses outcomes of the simulation, engineering design process, assembly and testing of the microwave prototype, and evaluation of oil quality and system performance. Each subsection provides insights into the scalability, efficiency, and practical implications of the system for red palm oil production.

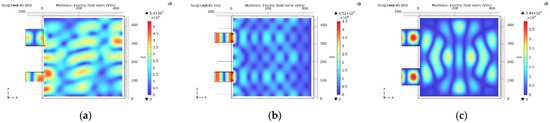

3.1. Simulation Results from COMSOL Multiphysics

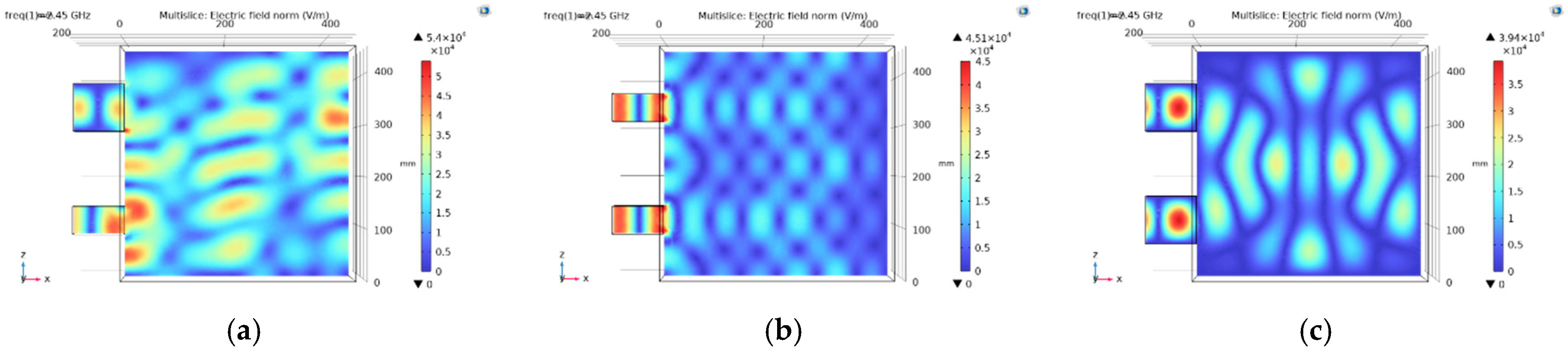

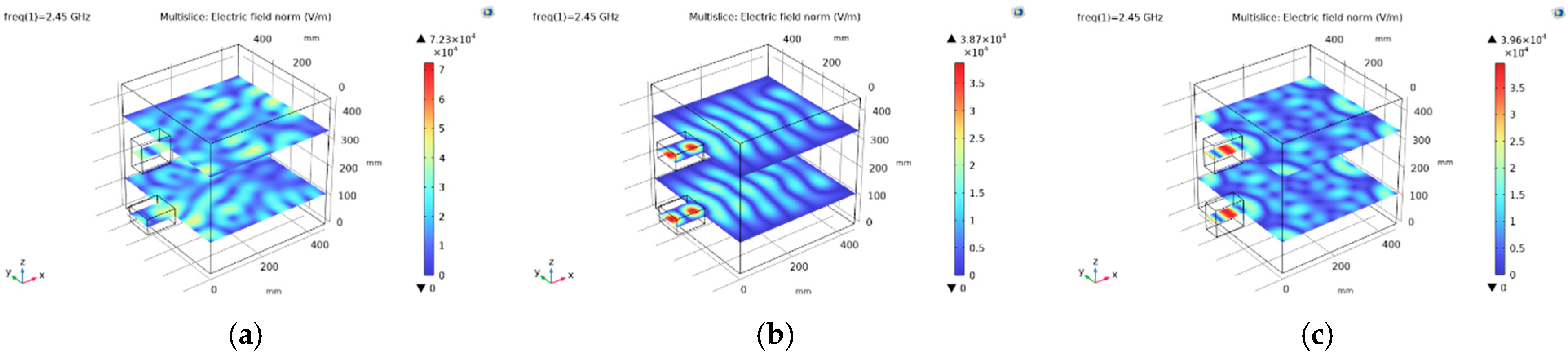

Figure 3, Figure 4 and Figure 5 illustrate the electric field norm and electric field intensity distributions for three magnetron configurations: (a) perpendicular magnetrons, (b) horizontally aligned magnetrons, and (c) vertically aligned magnetrons. These results highlight the importance of electric field uniformity and intensity along the z-axis for achieving efficient multi-level tray heating in scaled-up systems for red palm oil extraction. Figure 3 depicts the electric field norm distribution on the xz-plane within the waveguides and cavity. Among the three configurations, configuration (a), with magnetrons positioned perpendicularly, achieves the highest intensity and the most uniform distribution along the z-axis, corresponding to the cavity’s vertical axis. The intense color gradient in the cavity for configuration (a) indicates higher values than in configurations (b) and (c). This uniform and elevated electric field distribution is essential for accommodating multi-level trays along the z-axis, a critical feature for scaling up red palm oil extraction systems. Higher values ensure effective energy delivery to all six trays, promoting uniform heating and minimizing temperature variations across tray levels. Such consistency is vital for maintaining process efficiency and preserving product quality during large-scale operations. Additionally, the values within the waveguides for configuration (a) are lower than those in configurations (b) and (c), indicating reduced energy reflection back into the waveguides. This improved energy transfer efficiency ensures that more microwave energy is delivered into the cavity, minimizing energy losses and reducing the risk of magnetron overheating or damage. As noted by Boonthum et al. [14], lower electric field intensity within the waveguides is correlated with higher energy transmission efficiency, enhancing the system’s overall reliability and scalability.

Figure 3.

Electric field norm distribution on the xz-plane within the waveguides and cavity for three configurations: (a) perpendicular magnetrons, (b) horizontally aligned magnetrons, and (c) vertically aligned magnetrons. The color scale indicates the electric field intensity (W/m), highlighting variations in energy distribution based on magnetron positioning.

Figure 4.

Electric field norm distribution on the xy-plane within the waveguides and cavity for three configurations: (a) perpendicular magnetrons, (b) horizontally aligned magnetrons, and (c) vertically aligned magnetrons. The color scale indicates the electric field intensity (W/m), highlighting variations in energy distribution based on magnetron positioning.

Figure 5.

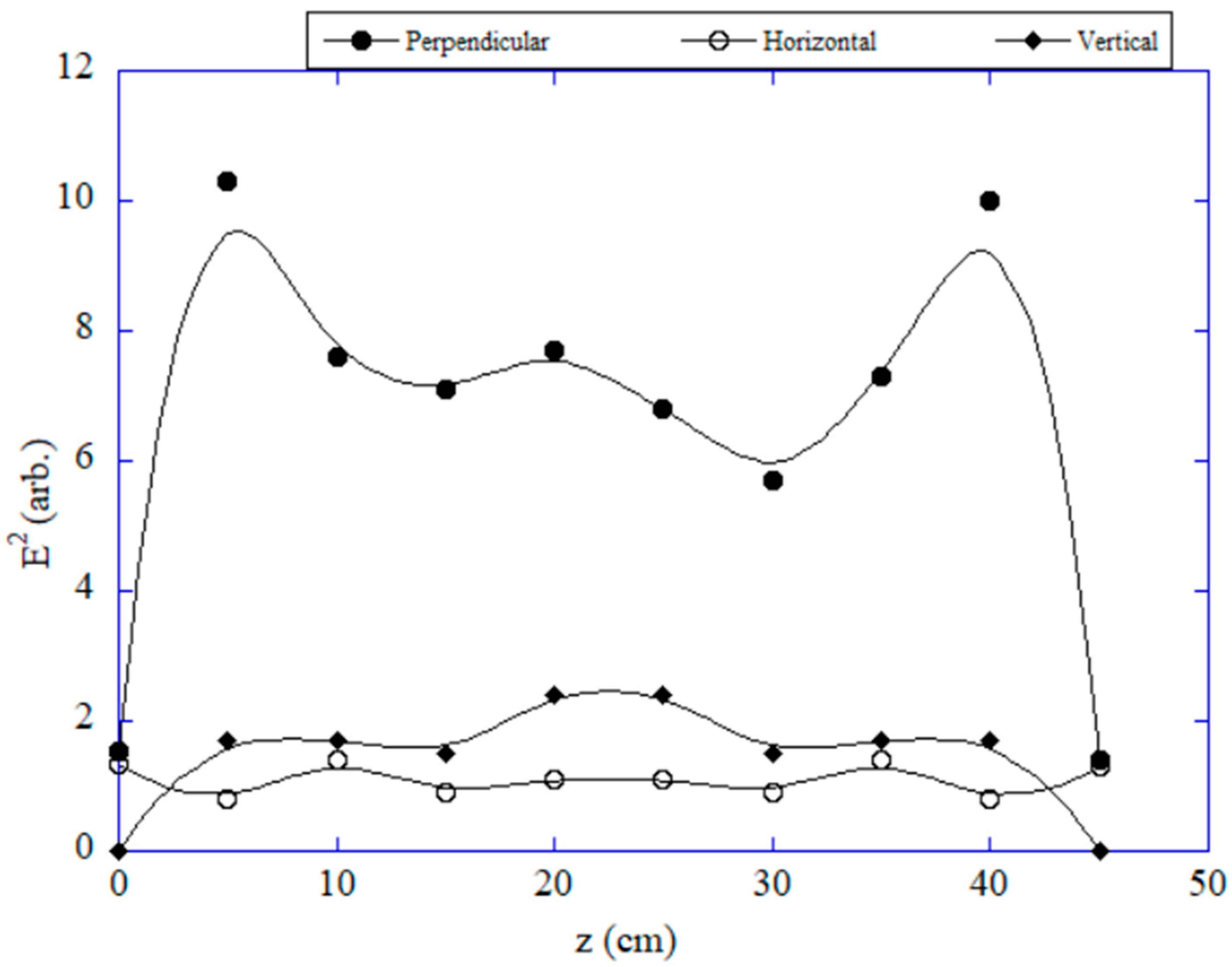

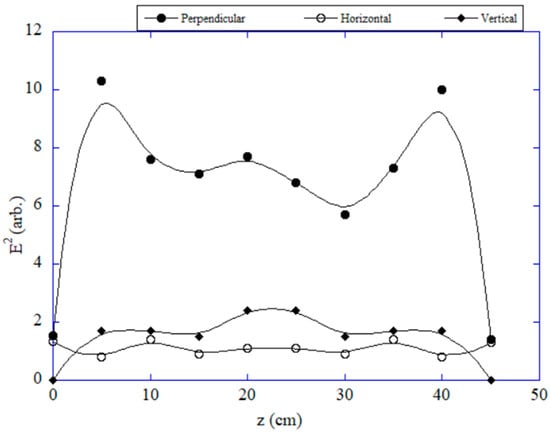

Electric field intensity along the z-axis within the cavity for three configurations: perpendicular, horizontal, and vertical waveguides.

Figure 4 illustrates the electric field norm distribution on the xy-plane within the waveguides and cavity. This view reinforces the findings from Figure 3, demonstrating that configuration (a) provides a more uniform and higher-intensity electric field distribution along the z-axis. The uniform distribution ensures consistent energy delivery across all the tray levels, minimizing discrepancies in energy absorption along the vertical axis. The perpendicular waveguide arrangement (a) optimizes energy utilization within the cavity, reducing energy losses and maximizing heating uniformity. These attributes further emphasize its suitability for large-scale industrial applications, particularly in red palm oil extraction systems.

Figure 5 presents the electric field intensity along the z-axis for the three configurations. Configuration (a) exhibits significantly higher and more uniform values than configurations (b) and (c). The consistent values along the z-axis in configuration (a) ensure uniform energy delivery to all six trays, resulting in even heating throughout the cavity. This uniformity is critical for maintaining process efficiency and achieving high-quality red palm oil extraction. Moreover, the elevated values in configuration (a) confirm its effectiveness in delivering sufficient energy for efficient processing while maintaining consistent heating across all tray levels. The lower values in the waveguides for configuration (a) further validate its efficiency in transferring microwave energy into the cavity. Reduced energy reflection minimizes energy losses and ensures optimal utilization within the cavity. This efficient energy transfer not only improves heating performance but also reduces the risk of magnetron overheating or damage, as highlighted by Boonthum et al. [14]. These advantages establish configuration (a) as the most effective magnetron arrangement for ensuring uniform, efficient heating and scalability in industrial microwave systems.

In summary, the simulation results confirm that configuration (a) provides the optimal electric field distribution for scaling up red palm oil extraction systems. Its superior uniformity and intensity of and along the z-axis, coupled with efficient energy transfer, make it the optimal configuration for industrial applications, ensuring consistent heating, process efficiency, and system reliability. These findings provide a robust foundation for the engineering design and practical implementation of the microwave system.

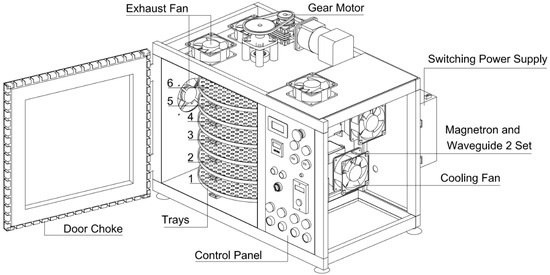

3.2. Engineering Design and Prototype Fabrication

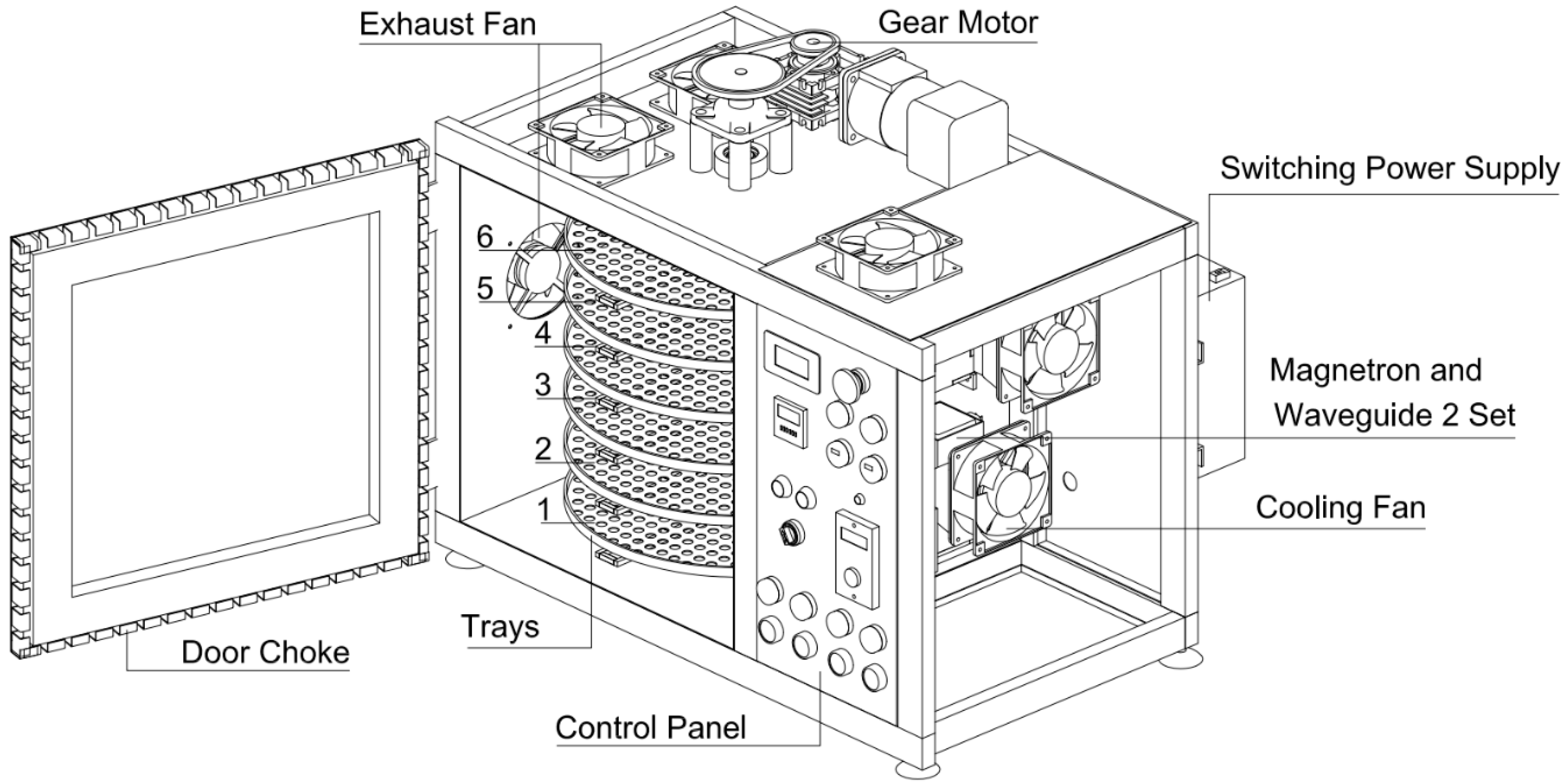

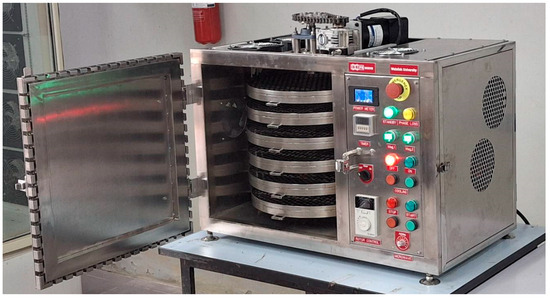

The engineering design, as shown in Figure 6, was developed using simulation results to ensure optimal energy distribution and system functionality. The multi-mode cavity, constructed from food-grade stainless steel (SUS304), was meticulously designed to minimize microwave leakage, adhering to the international safety standard of 5 mW/cm2 [14]. A door choke was incorporated into the cavity design to prevent microwave leakage, ensuring operator safety and system reliability. The cavity features six rotating trays (trays 1–6), driven by a gear motor, to provide uniform microwave exposure to the materials placed on each tray. Two industrial magnetrons, each connected to WR340 waveguides, were mounted in a perpendicular arrangement on the same wall of the cavity. This configuration was selected to maximize transfer efficiency within the cavity while reducing energy reflections back into the waveguides. Cooling fans were installed directly above the magnetrons to dissipate heat from their fins, ensuring stable operation and preventing overheating during prolonged use. Two exhaust fans were strategically positioned at the top of the cavity to control moisture levels, thereby maintaining optimal conditions for the red palm oil extraction process. The system included adjustable switching power supplies (300–1000 W), which allowed precise control of microwave power for each magnetron, enabling a total combined output of up to 2 kW. The control panel, located on the front of the prototype, provided intuitive access for operators to adjust system parameters and monitor performance. Figure 7 illustrates the fully assembled microwave prototype constructed in accordance with the engineering design in Figure 6. The assembly was performed at the PEwave Center workshop at Walailak University by skilled engineers and technicians. Components such as magnetrons, switching power supplies, waveguides, and cooling fans were sourced from reputable suppliers to ensure high performance, durability, and reliability. The stainless steel cavity and precision assembly ensure compliance with both functional and safety standards, making the system robust and suitable for large-scale red palm oil extraction.

Figure 6.

Engineering design of the microwave prototype, showing the cavity with door choke, six trays (trays 1–6), magnetron and waveguide sets, exhaust fans, cooling fans, gear motor, switching power supplies, and control panel.

Figure 7.

Microwave prototype constructed based on the engineering design in Figure 6. The system includes a stainless steel cavity with a door choke, six vertically arranged trays, dual magnetron and waveguide sets, exhaust fans, cooling fans, a gear motor, switching power supplies, and a control panel for precise operation.

This design seamlessly integrates efficient microwave energy transfer, uniform heating, and robust safety measures, highlighting its scalability and applicability for industrial operations aimed at producing high-quality red palm oil efficiently.

3.3. Prototype Testing and Performance Evaluation

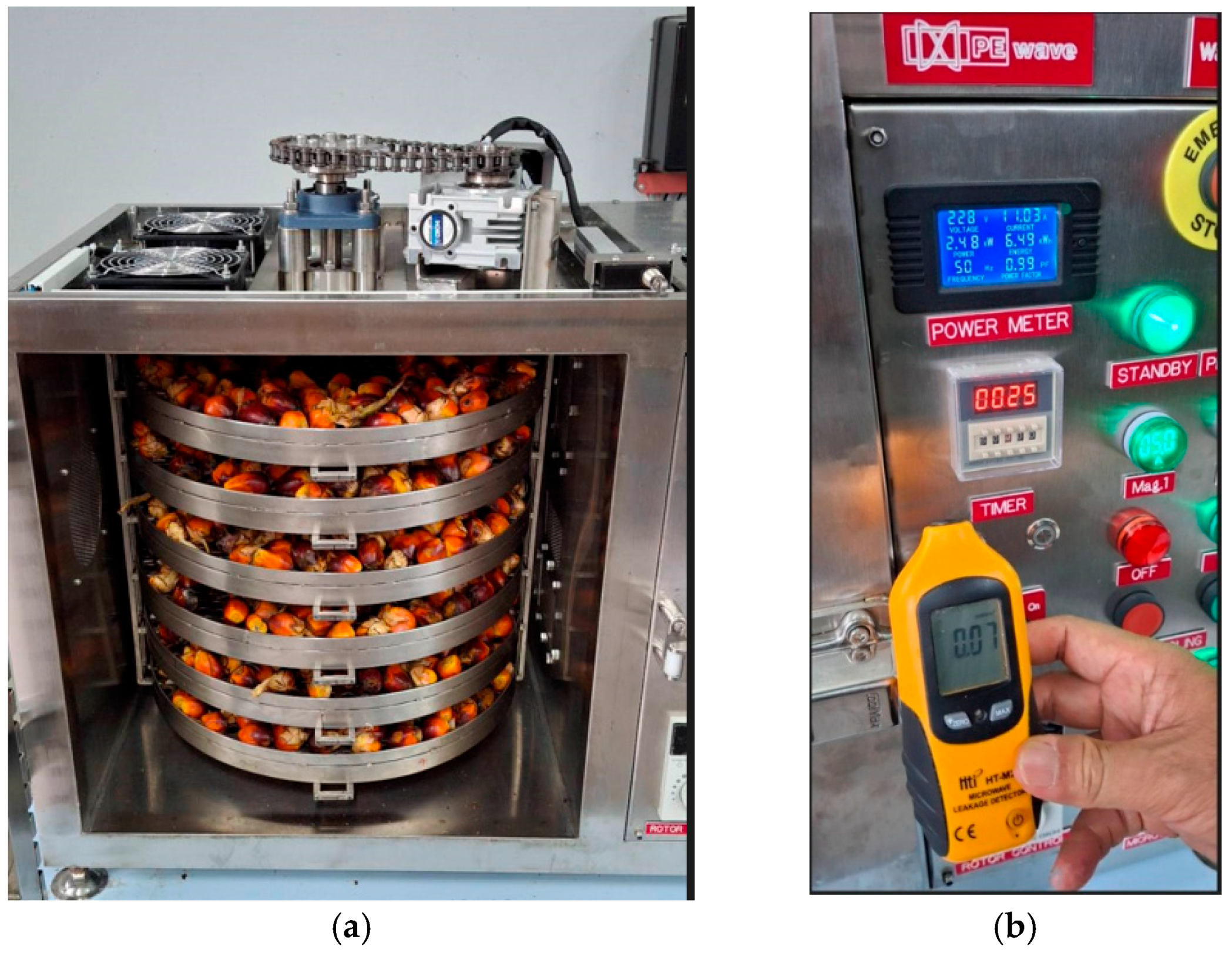

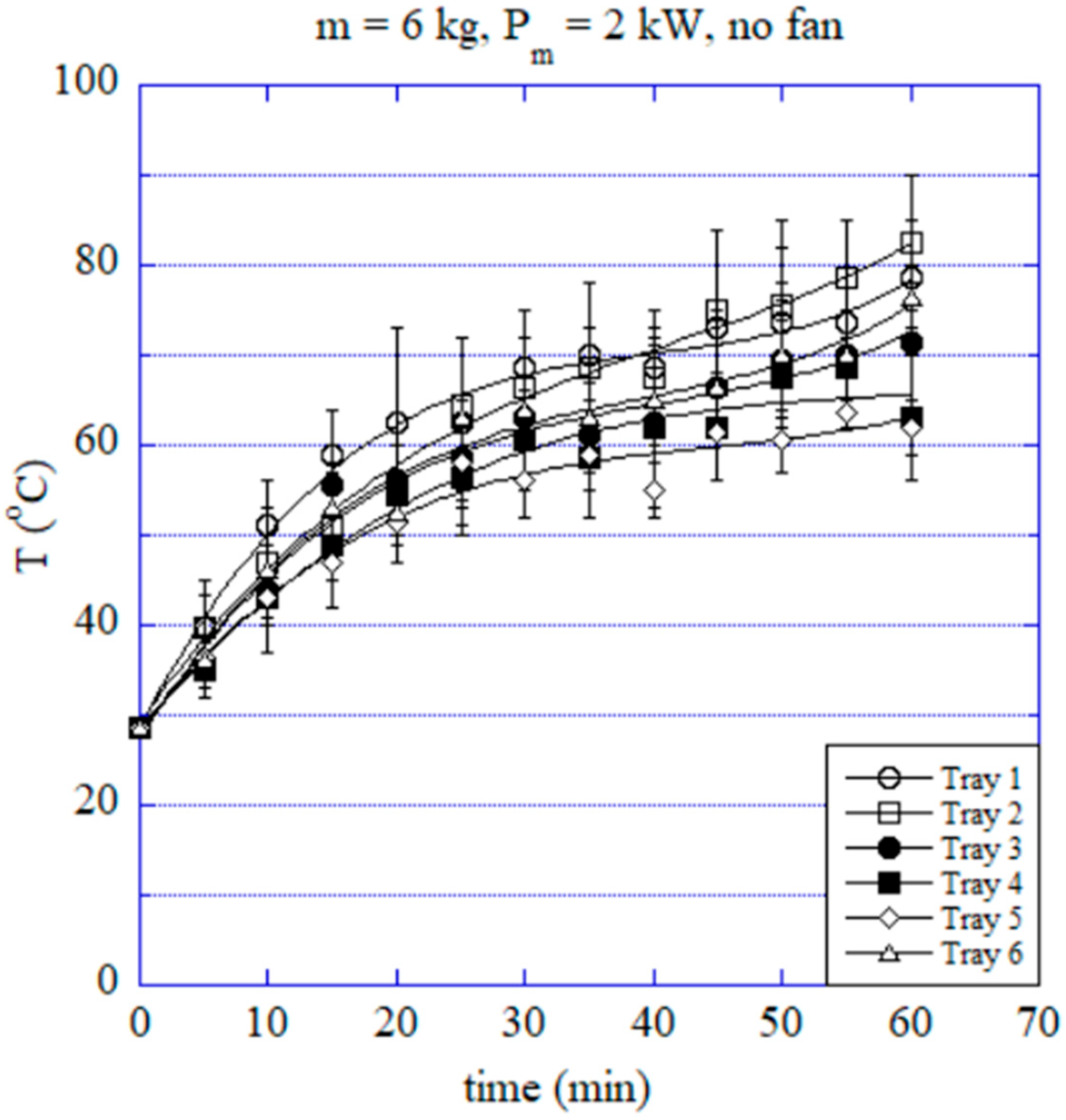

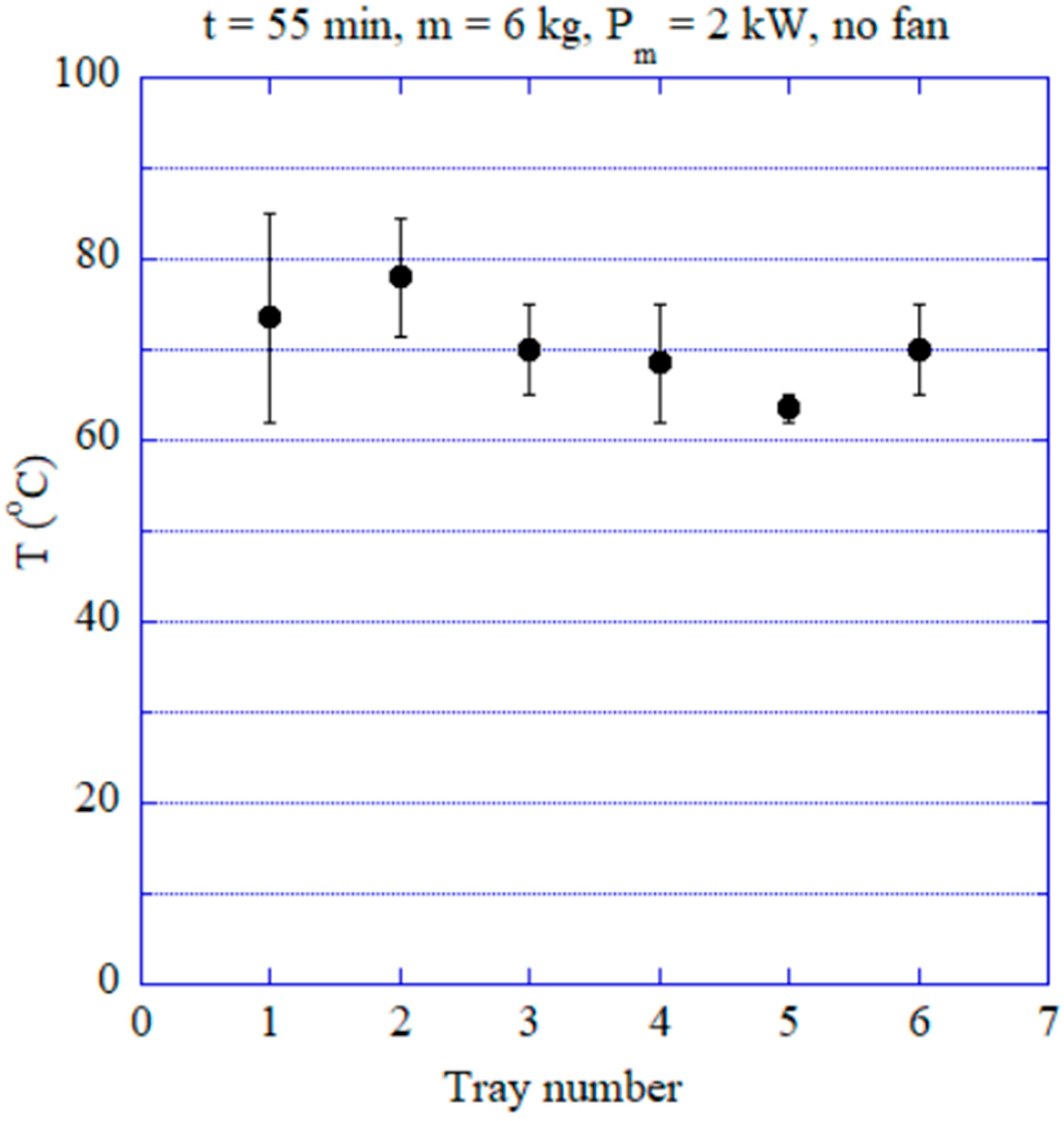

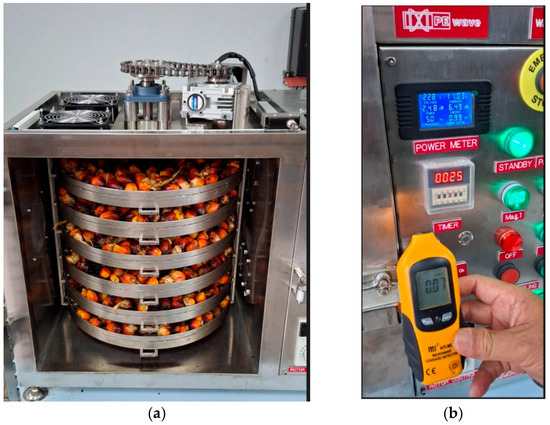

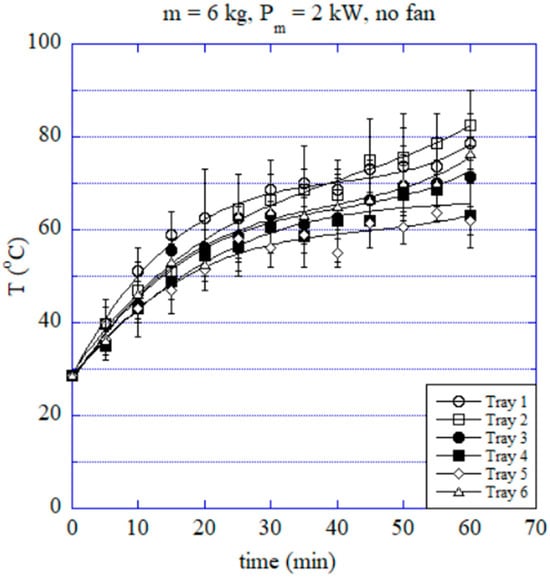

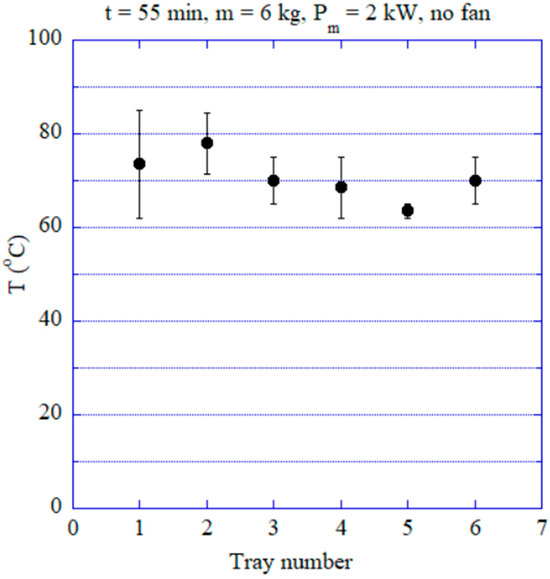

The operational testing of the microwave prototype was conducted to evaluate its heating performance and safety under industrial-like conditions. The tests focused on assessing the temperature increase of oil palm fruits over time and the uniformity of heating across multiple trays within the cavity, as shown in Figure 8, Figure 9 and Figure 10. Figure 8a illustrates the microwave cavity loaded with six trays, each containing 1 kg of ripe oil palm fruits, arranged vertically. The system was operated at a total microwave power of 2 kW, with each magnetron operating at 1 kW. Temperature measurements were recorded every 10 min using an infrared thermometer, both at the center and edges of each tray. This setup allowed for a detailed evaluation of heating uniformity along the z-axis, providing insights into the system’s ability to distribute microwave energy evenly across all trays. Figure 8b presents the results of microwave leakage testing conducted at the door edges. The leakage levels were confirmed to be below the international safety threshold of 5 mW/cm2 [27], demonstrating the effectiveness of the door choke design in suppressing leakage. Figure 9 depicts the temperature profiles of oil palm fruits on trays 1 through 6 during 60 min of microwave heating. Each tray held 1 kg of fruits. No moisture extraction fans were used during the experiment to maintain controlled conditions. The temperature profiles show a consistent increase over time due to the absorption of microwave energy. This phenomenon, known as dielectric heating, occurs when polar molecules, such as water, interact with microwaves, generating heat through molecular oscillations and friction. The steady temperature rise observed in Figure 9 is consistent with findings from prior studies [36,37,38,39], which report that microwave heating induces localized heat accumulation due to energy absorption and conversion to thermal energy. The error bars in Figure 9 represent temperature variations between the center and edges of each tray, indicating the prototype’s ability to deliver relatively uniform heating across all trays. Figure 10 illustrates the temperature distribution of oil palm fruits across the six trays after 55 min of microwave heating. The results indicate slight temperature variations, with the upper trays showing marginally higher temperatures. Overall, the temperature distribution was relatively uniform, reflecting the system’s ability to achieve consistent heating across all trays. These findings align closely with the simulation results of shown in Figure 5 (Section 3.1), where the perpendicular waveguide configuration demonstrated the most uniform electric field distribution along the z-axis. Since temperature is directly proportional to , the observed uniformity in heating further validates the engineering design and the effectiveness of the waveguide configuration.

Figure 8.

Operational testing of the microwave prototype. (a) Evaluation of electric field uniformity within the cavity, conducted by using oil palm fruits as the load, placed on six trays, each containing 1 kg of fruits. The system was operated at a microwave power of 2 kW, and the temperature of the fruits was measured at 10 min intervals to assess heating consistency. (b) Measurement of microwave leakage at the door edges during operation at 2 kW microwave power, ensuring compliance with international safety standards.

Figure 9.

Temperature profiles of oil palm fruits on trays 1 to 6 during 60 min of microwave heating at a power of 2 kW. Each tray was loaded with 1 kg of oil palm fruits, and no moisture extraction fans were used during the experiment. Error bars represent the temperature differences between the center and the periphery of each tray.

Figure 10.

Temperature of oil palm fruits on trays 1 to 6 after 55 min of microwave heating at a power level of 2 kW. Each tray contained 1 kg of oil palm fruits. The experiment was conducted without using moisture extraction fans, ensuring consistent test conditions. Error bars represent the temperature differences between the center and the edges of each tray.

The agreement between the simulation results of in Figure 5 and the experimental temperature profiles in Figure 10 reinforces the reliability of the engineering design and the effectiveness of the perpendicular waveguide configuration in achieving uniform heating. Figure 5 illustrates the electric field intensity distribution along the z-axis within the microwave cavity for different waveguide configurations. The perpendicular waveguide configuration (black circles) exhibits a more pronounced variation in along the z-axis, with peak values observed at multiple positions, suggesting stronger microwave energy absorption at these locations. Figure 10 presents the measured temperatures of oil palm fruits at different tray positions along the z-axis after 55 min of microwave heating. The temperature distribution follows a similar trend to the distribution in Figure 5, where trays corresponding to the higher regions exhibit higher temperatures, while trays in lower regions (such as tray 5) have relatively lower temperatures. This correlation indicates that the heating pattern observed in the experiments aligns with the simulated electric field distribution.

This consistency between simulation and experimental results confirms that the perpendicular waveguide configuration effectively distributes microwave energy, leading to localized heating variations that match the predicted intensities. These findings validate the accuracy of the simulation model in predicting real heating behavior and demonstrate that optimizing the waveguide configuration plays a crucial role in achieving effective and uniform heating for red palm oil extraction.

3.4. Red Palm Oil Quality Analysis

The quality of red palm oil extracted using the microwave prototype was assessed by analyzing the free fatty acid (FFA) content, Deterioration of Bleachability Index (DOBI), and carotene content. Table 1 summarizes the results, comparing oil extracted from untreated fruits (t = 0 min) with oil extracted from fruits microwaved for 50 min at 2 kW. The FFA content showed a significant reduction, decreasing from 20.4% in untreated fruits to 2.1% after 50 min of microwave heating. This reduction indicates a marked improvement in oil quality, as lower FFA content enhances stability and suitability for consumption. The decrease in FFA is attributed to the inactivation of lipase enzymes during microwave irradiation. Lipase enzymes catalyze the hydrolysis of triglycerides into free fatty acids, and their activity is suppressed by the rapid localized heating generated by microwave energy. Similar findings by Sarah et al. [12,40] and Tapanwong et al. [41] have demonstrated the effectiveness of microwave heating in reducing FFA through enzymatic deactivation. The DOBI, a key parameter reflecting oil clarity and bleachability, showed a slight decrease from 2.5 ± 0.2 to 2.4 ± 0.2 after 50 min of microwave treatment. Despite this minor reduction, the values remained within acceptable industrial standards for crude palm oil, confirming that microwave heating does not compromise the oil’s processability. This observation aligns with prior research by Zamanhuri et al. [11], which emphasized the thermal stability of oil properties under controlled microwave processing conditions.

Table 1.

Quality parameters of red palm oil extracted from untreated fruits (t = 0 min) and fruits microwaved for 50 min.

The statistical analysis of red palm oil quality parameters using an independent sample t-test confirmed the effects of microwave heating on FFA, DOBI, and carotene content at a 95% confidence level (α = 0.05). The t-test for FFA showed a highly significant reduction from 20.4 ± 0.1% at 0 min to 2.1 ± 0.1% at 50 min (p < 0.001), confirming that microwave heating effectively inactivates lipase enzymes, reducing hydrolytic degradation and improving oil stability. In contrast, the t-test for DOBI found no significant difference (p = 0.749), indicating that microwave heating does not alter the oil’s bleachability properties, ensuring suitability for refining. For carotene content, a statistical analysis using an independent sample t-test yielded a p-value of 0.012, which is lower than the significance threshold of 0.05. This indicates that the change is statistically significant. However, the actual reduction—from 616 ± 14 ppm to 558 ± 10 ppm—represents less than a 10% decrease. This small variation suggests that, although the difference is statistically detectable, the carotenoid degradation during microwave heating is minimal. Thus, the process preserves the nutritional integrity of the oil, keeping the carotene content well within the industrially accepted range of 500–700 ppm for high-quality red palm oil. Carotenoids, responsible for the oil’s bright orange hue, are known for their antioxidant properties and health benefits. The retention of carotene content observed in this study aligns with findings from Sarah et al. [12,40], Tapanwong et al. [41], and Zamanhuri et al. [11], which reported that controlled microwave-assisted processing effectively preserved carotenoids. These results underscore the capability of the prototype to maintain the nutritional integrity of red palm oil during processing.

Overall, these findings demonstrate that microwave-assisted processing significantly reduces FFA, maintains DOBI stability, and retains carotene content, making it a promising alternative to conventional extraction methods. The results validate the microwave prototype as an effective and scalable method for producing high-quality red palm oil with extended shelf life while minimizing nutrient loss.

The results of this study demonstrate the effectiveness of the microwave prototype in producing high-quality red palm oil. The significant reduction in FFA, coupled with the retention of carotene content within the industrially accepted range and the maintenance of acceptable DOBI values, highlights the potential of microwave-assisted processing for industrial applications. Furthermore, the chemical-free nature of this extraction method aligns with sustainable practices, providing both environmental and economic advantages.

3.5. Scalability and Practical Implications

The development and performance evaluation of the microwave prototype demonstrated its capability for scalable red palm oil production, emphasizing its practicality for both community-based and industrial applications. The system, designed to process up to 6 kg of oil palm fruits per batch, incorporates features that ensure energy efficiency, uniform heating, and consistent oil quality. These attributes make the prototype adaptable for various scales of operation. The scalability of the prototype is facilitated by its modular design, which allows for adjustments in capacity and power output to meet different production needs. The use of industrial magnetrons, combined with precise waveguide configuration and strategic placement of trays, ensures uniform microwave energy distribution. This design minimizes hotspots and energy losses, enabling efficient processing at larger scales. The six-tray vertical configuration supports batch processing, making it suitable for community-level production while maintaining industrial-level efficiency. The integration of food-grade stainless steel (SUS304) for the cavity and the inclusion of safety measures, such as the door choke to suppress microwave leakage, ensure compliance with international safety and hygiene standards. These features enhance the prototype’s reliability and applicability in various settings, from smallholder farms to industrial facilities. The testing results confirmed that the microwave prototype maintains the quality of red palm oil by achieving significant reductions in free fatty acid (FFA) content, retaining carotene levels within industrial standards, and preserving acceptable Deterioration of Bleachability Index (DOBI) values. These outcomes highlight the system’s ability to produce high-quality red palm oil with minimal environmental impact, as the chemical-free extraction process avoids the use of harmful solvents. The practical implications of this prototype extend beyond oil palm production. The demonstrated ability to uniformly heat and process agricultural products suggests potential applications in drying, sterilization, and nutrient preservation for other crops. This adaptability aligns with the increasing demand for sustainable agricultural processing technologies that address global food security challenges while minimizing environmental footprints.

By integrating simulation-driven design, robust engineering, and rigorous testing, the microwave prototype represents a significant advancement in microwave-assisted processing technologies. Its scalability, efficiency, and practicality position it as a transformative tool for sustainable red palm oil production, supporting community livelihoods and industrial demands. Further studies and optimizations could expand its applications and enhance its performance, paving the way for broader adoption in the agricultural processing sector.

4. Discussion Summary

The development and evaluation of a microwave prototype for red palm oil production have demonstrated its potential as a scalable and efficient alternative to conventional methods. By integrating simulation-based design, robust engineering, and rigorous testing, the system addresses key challenges in oil production, including uneven heating, nutrient loss, and high energy consumption. Simulation results confirmed that the perpendicular waveguide configuration achieved the most uniform electric field distribution, ensuring consistent heating across all trays. The engineering design, utilizing food-grade stainless steel and precise waveguide alignment, facilitated efficient energy transfer, reduced hotspots, and ensured compliance with international safety standards.

Operational testing validated the system’s ability to maintain uniform heating and produce high-quality red palm oil. The significant reduction in FFA, the retention of carotene content within the industrially accepted range of 500–700 ppm, and the maintenance of acceptable DOBI values underscore the prototype’s effectiveness. The results indicate the capability of the microwave-assisted system to inactivate lipase enzymes, reduce oil acidity, and preserve essential nutrients. The scalability of the prototype, processing up to 6 kg of fruits per batch, highlights its practicality for community and industrial applications. Its modular design, energy efficiency, and chemical-free processing align with sustainability goals, providing an environmentally friendly solution to red palm oil production.

A comparative analysis of the red palm oil quality parameters obtained in this study against other microwave-based and conventional extraction methods further highlights the advantages of the prototype system. Studies utilizing household microwave ovens for fruit sterilization have reported FFA reductions ranging from 0.3% to 3.4% [11,41,42]. Similarly, DOBI values in these methods varied from 2.36 to 4.1, with carotene content between 580 and 883 ppm. In contrast, conventional steam-based sterilization at 132 °C and 1.5 bar for 75 min resulted in FFA values of 2.1% and DOBI values of 3.4 [7].

Compared to these methods, the microwave prototype in this study achieved an FFA reduction to 2.1%, a DOBI value of 2.36, and a carotene content of 558.2 ppm. These results suggest that the prototype performs comparably to home microwave-based extraction systems while maintaining industrial-grade oil quality. Moreover, the ability of the microwave prototype to process larger batches (6 kg per cycle) makes it a more practical alternative for industrial applications. While household microwave ovens have demonstrated superior FFA reduction in some cases, their limited batch capacity and lack of process control restrict scalability. Conversely, steam-based methods require substantial energy input, longer processing times, and extensive infrastructure, making them less suitable for small-scale and community-based producers.

These findings establish the microwave prototype as a transformative tool for red palm oil production, paving the way for broader adoption in both local and industrial contexts. Future research could explore enhancements in throughput capacity and energy efficiency, reinforcing the system’s value as a sustainable processing technology for the agricultural sector.

Author Contributions

Conceptualization and methodology, M.N.; simulation, K.P.; fabrication of prototype, S.K., D.S. and W.K.; validation, K.W., writing—original draft preparation, K.W. and M.N.; writing—review and editing, V.R. and M.N.; visualization, M.N.; supervision, M.N.; funding acquisition, M.N. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Walailak University, Research Assistant Grant Number WU 02.

Data Availability Statement

All data supporting this study are included in the article. For further inquiries, contact the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tan, C.H.; Lee, C.J.; Tan, S.N.; Poon, D.T.S.; Chong, C.Y.E.; Pui, L.P. Red palm oil: A review on processing, health benefits and its application in food. J. Oleo Sci. 2021, 70, 1201–1210. [Google Scholar] [CrossRef] [PubMed]

- Akinyeye, R.O.; Adeyeye, E.I.; Fasakin, O.; Agboola, A. Physico-chemical properties and anti-nutritional factors of palm fruit products (Elaeis guineensis Jacq.) from Ekiti State Nigeria. Electron. J. Environ. Agric. Food Chem. 2011, 10, 2190–2198. [Google Scholar]

- Purnama, K.O.; Setyaningsih, D.; Hambali, E.; Taniwiryono, D. Processing, characteristics, and potential application of red palm oil-A review. Int. J. Oil Palm. 2020, 3, 40–55. [Google Scholar] [CrossRef]

- Olivares-Tenorio, M.-L.; Cortes-Prieto, C.-M.; Londoño-Univio, N.-C.; Rojas-Díaz, D.-A.; Quintanilla-Carvajal, M.-X.; Tibaquira-Perez, L.-N.; Ricaurte-Puentes, L.-Y.; Rada-Bula, A.-I.; Romero, H.-M.; Garcia-Nuñez, J.-A. Bioactive Compounds in Palm Oil: A Comprehensive Review of Recent Advances in Physicochemical Characteristics, Health-Promoting Properties and Technologies for Extraction, Concentration, Fractionation, Encapsulation and Functional Food Applications. J. Food Compos. Anal. 2024, 132, 106306. [Google Scholar] [CrossRef]

- Mayamol, P.; Balachandran, C.; Samuel, T.; Sundaresan, A.; Arumughan, C. Process technology for the production of micronutrient rich red palm olein. J. Am. Oil Chem. Soc. 2007, 84, 587–596. [Google Scholar] [CrossRef]

- Umudee, I.; Chongcheawchamnan, M.; Kiatweerasakul, M.; Tongurai, C. Sterilization of oil palm fresh fruit using microwave technique. Int. J. Chem. Eng. Appl. 2013, 4, 111. [Google Scholar] [CrossRef]

- Wae-hayee, M.; Pakdeechot, S.; Hanifarianty, S.; Suksuwan, W. Minimizing water consumption in oil palm sterilization using direct steaming: Effects of sterilization pressure and time. J. Food Eng. 2022, 315, 110804. [Google Scholar] [CrossRef]

- Chavalparit, O. Clean Technology for the Crude Palm Oil Industry in Thailand; Wageningen University and Research: Wageningen, The Netherlands, 2006. [Google Scholar]

- Rani, H.; Sharma, S.; Bala, M. Technologies for extraction of oil from oilseeds and other plant sources in retrospect and prospects: A review. J. Food Process Eng. 2021, 44, e13851. [Google Scholar] [CrossRef]

- Zamanhuri, N.A.; Abd Rahman, N.; Bakar, N.F.A. Extraction of palm fatty acids from sterilized oil palm mesocarp by microwave technique: Optimization and kinetics. Mater. Today Proc. 2022, 63, S166–S173. [Google Scholar] [CrossRef]

- Zamanhuri, N.A.; Abd Rahman, N.; Bakar, N.F.A. Effect of microwave power and extraction time on crude palm oil quality using microwave-assisted extraction process. Int. J. Renew. Energy Dev. 2021, 10, 495–505. [Google Scholar] [CrossRef]

- Sarah, M.; Widyastuti, S.; Ningsih, D. (Eds.) Red palm oil production by microwave irradiation. In IOP Conference Series: Materials Science and Engineering, Volume 309, Proceedings of the TALENTA—Conference on Engineering, Science and Technology 2017 (TALENTA-CEST 2017), Sumatera Utara, Indonesia, 7–8 September 2017; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Chin Chow, M.; Ngan Ma, A. Processing of fresh palm fruits using microwaves. J. Microw. Power Electromagn. Energy. 2005, 40, 165–173. [Google Scholar] [CrossRef] [PubMed]

- Boonthum, D.; Chanprateep, S.; Ruttanapun, C.; Nisoa, M. Development of high-temperature multi-magnetron microwave furnace for material processing. Songklanakarin J. Sci. Technol. 2019, 41, 494–500. [Google Scholar]

- Nisoa, M.; Plodkaew, A.; Wattanasit, K.; Polprasarn, K.; Sirisathitkul, Y. Multiphysics Modeling for Microwavable Packaging of Ready-to-Eat Baked Spinach with Cheese. Int. J. Eng. Appl. 2023, 11, 384. [Google Scholar] [CrossRef]

- Nisoa, M.; Plodkaew, A.; Sirisathitkul, Y.; Sirisathitkul, C. Multiphysics Modeling of Size and Shielding Effects on Power Absorbed by Loads in a Stationary Microwave Oven. Int. Rev. Model. Simul. 2023, 16, 216–226. [Google Scholar] [CrossRef]

- Nisoa, M.; Plodkaew, A.; Sirisathitkul, C.; Wattanasit, K.; Somjit, B.; Pacdeepin, P.; Sirisathitkul, Y. Simulation and experimentation on parameters influencing microwave-assisted extraction of bioactive compounds from Kaempferia parviflora rhizomes. Alex. Eng. J. 2023, 65, 357–366. [Google Scholar] [CrossRef]

- Frisa-Rubio, A.; Campo-Valera, M.; Mallah, M.; Murillo-Ciordia, G.; Rodríguez-Rodríguez, I. A novel combined design of vessel and resonant cavity for microwave multi-frequency heating chemical reactor using antennas as applicators. IEEE Access 2023, 11, 39448–39456. [Google Scholar] [CrossRef]

- Yang, B.; Peng, F.; Zhang, Z.; Wu, Z.; Huang, H.; Shi, Y.; Han, Z. Multi-source microwave heating temperature uniformity study based on adaptive dynamic programming. High. Temp. Mater. Process. 2023, 42, 20220303. [Google Scholar] [CrossRef]

- Patel, D.; Mohanty, A.; Panigrahi, S. A sustainable waveguide-based design strategy for improving the energy efficiency of microwave hybrid heating systems: A combined theoretical and multi-physics simulation approach. Therm. Sci. Eng. Prog. 2024, 56, 103054. [Google Scholar] [CrossRef]

- Pozar, D.M. Microwave Engineering; John Wiley & Sons I.: Hoboken, NJ, USA, 2012; pp. 26–30. [Google Scholar]

- Collin, R.E. Foundations for Microwave Engineering, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Jackson, J.D. Classical Electrodynamics, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Balanis, C.A. Advanced Engineering Electromagnetics, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Harrington, R. Time Harmonic Electromagnetic Fields; McGraw-Hill: New York, NY, USA, 2001. [Google Scholar]

- Haus, H.A.; Melcher, J.R. Electromagnetic Fields and Energy; Prentice Hall Englewood Cliffs: Hoboken, NJ, USA, 1989. [Google Scholar]

- Zin, N.M.; Jenu, M.Z.M.; Po’ad, F.A. (Eds.) Measurements and reduction of microwave oven electromagnetic leakage. In Proceedings of the 2011 IEEE International RF & Microwave Conference, Seremban, Malaysia, 12–14 December 2011. [Google Scholar]

- Sarip, M.S.M.; Morad, N.A.; Nawi, M.A.H.M.; Aziz, M.K.T.A.; Jaapar, S.Z.I.S. β-carotene enrichment in crude palm oil using subcritical water extraction and its relationship with the solubility. Food Chem. Adv. 2023, 2, 100245. [Google Scholar] [CrossRef]

- Kresnowati, M.; Lestari, D.; Anshori, M.; Jafar, R. (Eds.) Production of carotenoids from oil palm empty fruit bunches. In IOP Conference Series: Earth and Environmental Science, Volume 460, Proceedings of the International Conference of Biomass and Bioenergy, West Java, Indonesia, 19–20 August 2019; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Choo, Y.-M.; Yap, S.-C.; Ooi, C.-K.; Ma, A.-N.; Goh, S.-H.; Ong, A.S.-H. Recovered oil from palm-pressed fiber: A good source of natural carotenoids, vitamin E, and sterols. J. Am. Oil Chem Soc. 1996, 73, 599–602. [Google Scholar] [CrossRef]

- Kamaruddin, A.H.; Zamanhuri, N.A.; Raslan, R. Extraction Yield of Palm Oil and Carotenoids Value from Microwave-Sterilized Oil Palm Mesocarp. Adv. Sci. Technol. 2023, 127, 23–34. [Google Scholar]

- Kanjanapongkul, K. Single and combined effects of ohmic and microwave heating on crude palm oil quality and stability. Agric Nat. Resour. 2021, 55, 177–186. [Google Scholar]

- Azeman, N.H.; Yusof, N.A.; Othman, A.I. Detection of free fatty acid in crude palm oil. Asian J. Chem. 2015, 27, 1569. [Google Scholar] [CrossRef]

- Japir, A.A.-W.; Salimon, J.; Derawi, D.; Bahadi, M.; Al-Shuja’a, S.; Yusop, M.R. Physicochemical characteristics of high free fatty acid crude palm oil. OCL 2017, 24, D506. [Google Scholar] [CrossRef]

- Rusdi, H.O.; Kusumaningrum, I.K.; Nareswari, T.J.; Fauziah, P.N.; Maharani, R.N.; Natasya, S. Separation and Determination of Free Fatty Acids in Corn Oil and Palm Oil by Liquid-Liquid Extraction and Acidi-Alkalimetric Titration. Walisongo J. Chem. 2024, 7, 98–106. [Google Scholar] [CrossRef]

- Prakotmak, P. Finite element modeling of heat and mass transfer in food materials during microwave heating. J. Appl. Sci. Res. 2013, 9, 6115–6121. [Google Scholar]

- Liu, S.; Ogiwara, Y.; Fukuoka, M.; Sakai, N. Investigation and modeling of temperature changes in food heated in a flatbed microwave oven. J. Food Eng. 2014, 131, 142–153. [Google Scholar] [CrossRef]

- Zhang, Z.; Su, T.; Zhang, S. Shape effect on the temperature field during microwave heating process. J. Food Qual. 2018, 2018, 9169875. [Google Scholar] [CrossRef]

- Campañone, L.A.; Paola, C.A.; Mascheroni, R.H. Modeling and Simulation of Microwave Heating of Foods Under Different Process Schedules. Food Bioprocess Technol. 2012, 5, 738–749. [Google Scholar] [CrossRef]

- Sarah, M.; Ramadhan, M.R.; Zahra, A.; Madinah, I.; Maulina, S.; Misran, E. Sterilization of oil palm fruit utilizing continuous microwave sterilizer. Case Stud. Therm. Eng. 2023, 52, 103698. [Google Scholar] [CrossRef]

- Tapanwong, M.; Nokkaew, R.; Punsuvon, V. Effect of combination microwave and oven drying on the chemical properties of different ripeness crude palm oil. Int. J. GEOMATE 2020, 18, 27–32. [Google Scholar] [CrossRef]

- Cheng, S.; Chuah, C. Microwave pretreatment: A clean and dry method for palm oil production. Ind. Crop. Prod. 2011, 34, 967–971. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).