Influence of Ballast and Tyre Inflation Pressure on Traction Performance of Agricultural Tractors Evaluated in Trials on Concrete Track

Abstract

1. Introduction

2. Materials and Methods

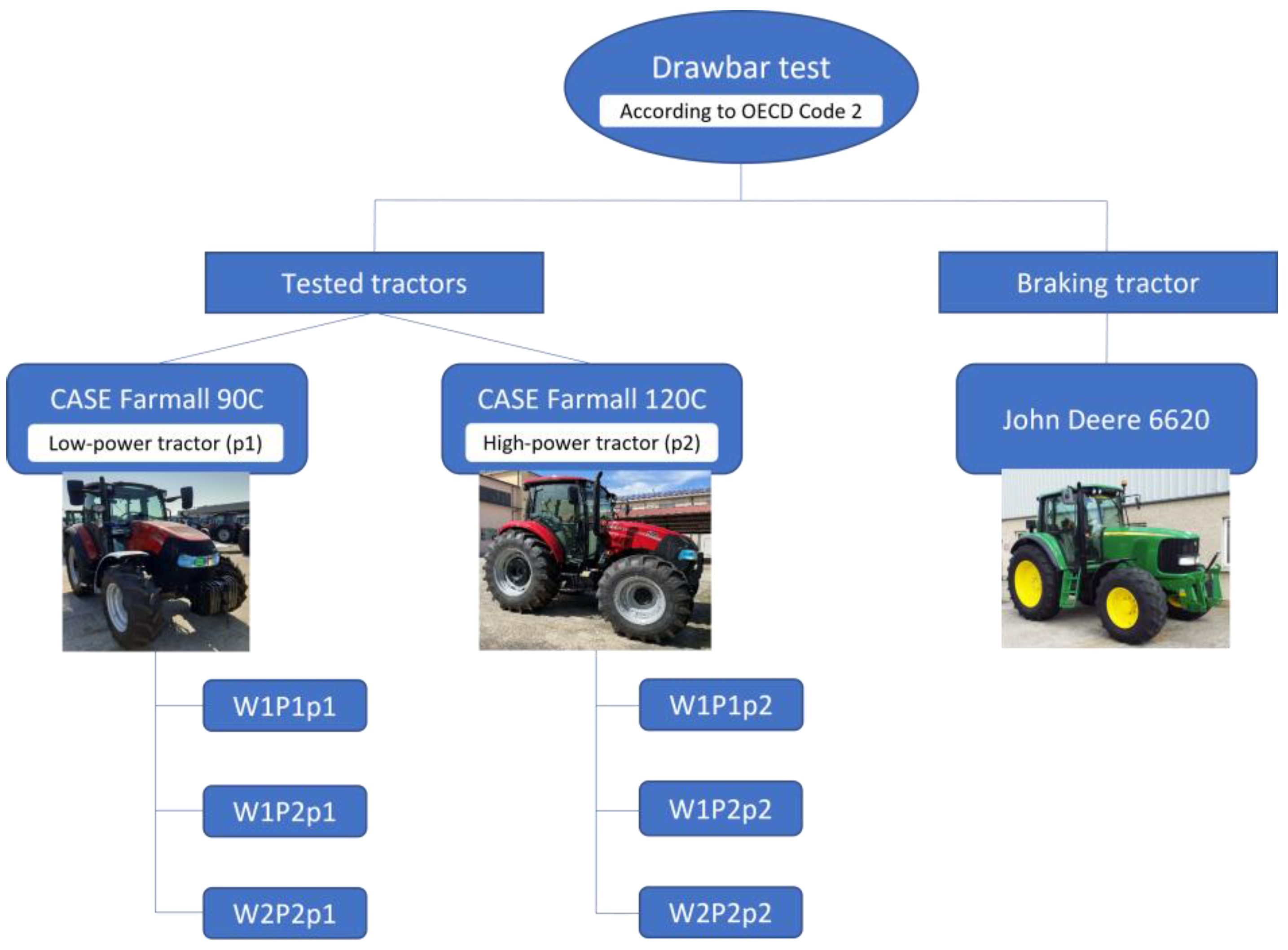

2.1. Characteristics of the Tractors

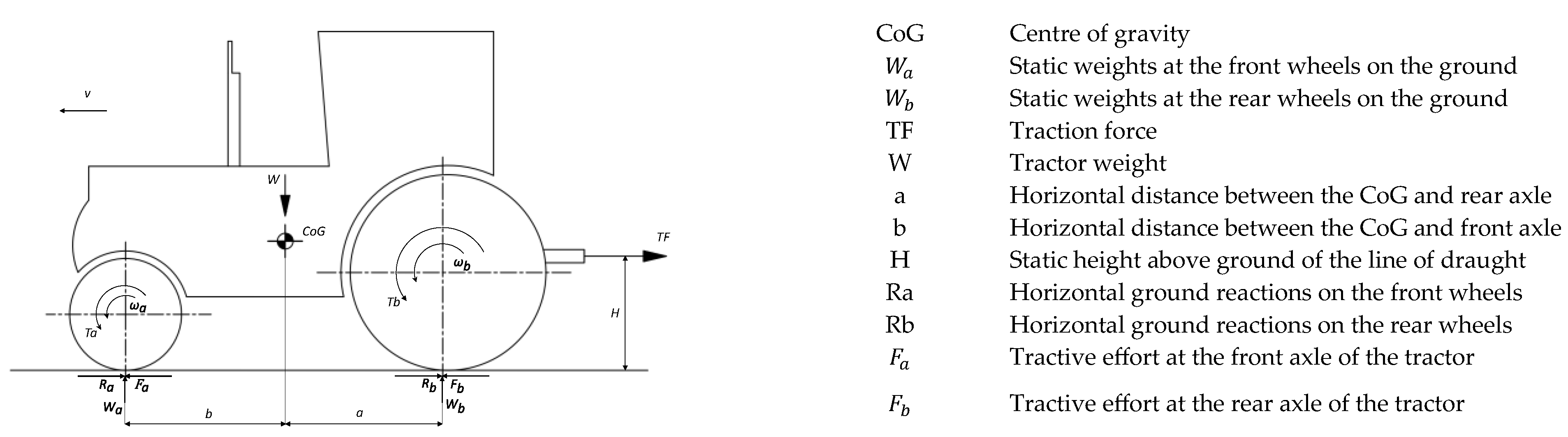

2.2. Traction Performance

2.3. Drawbar Tests Performed

3. Results

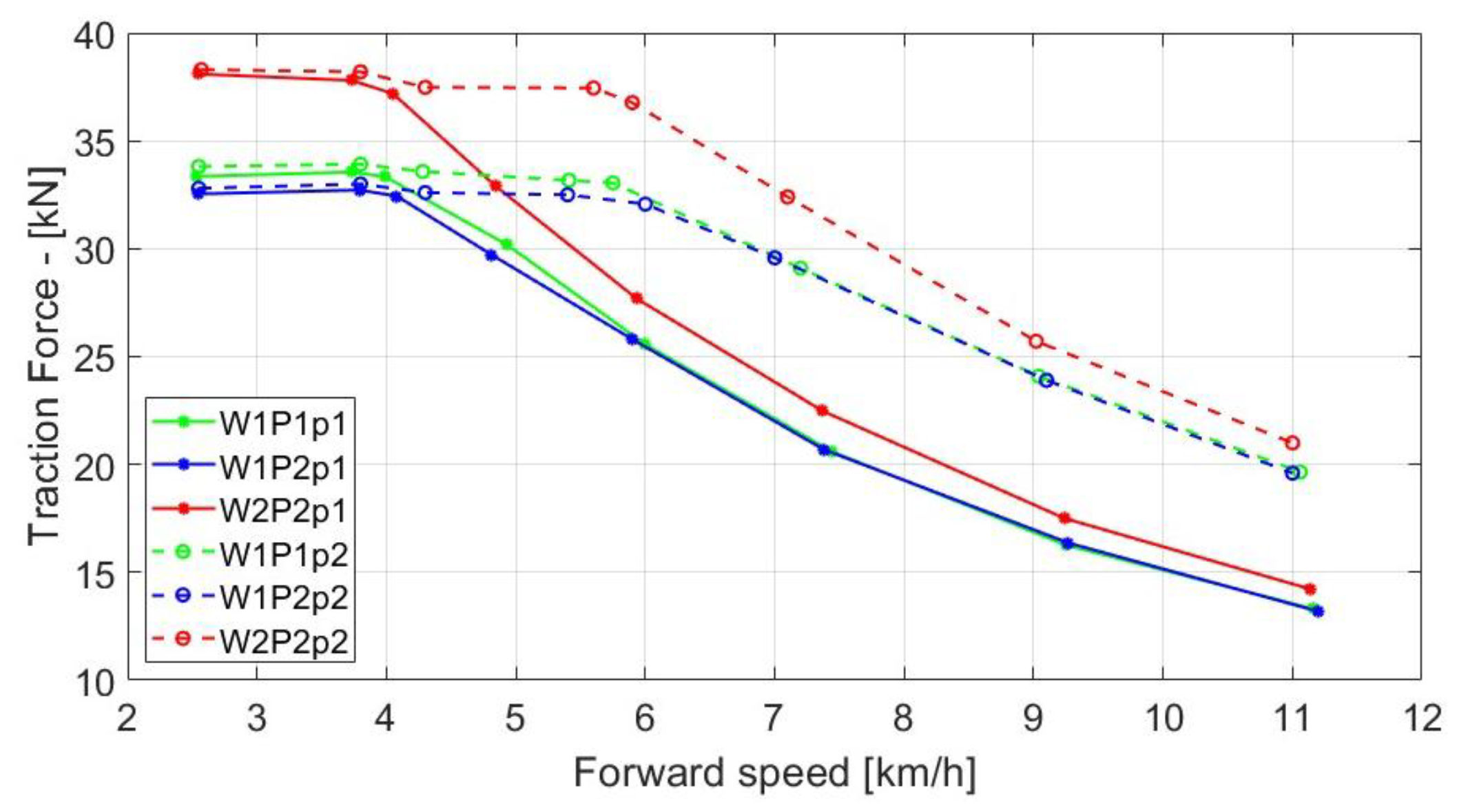

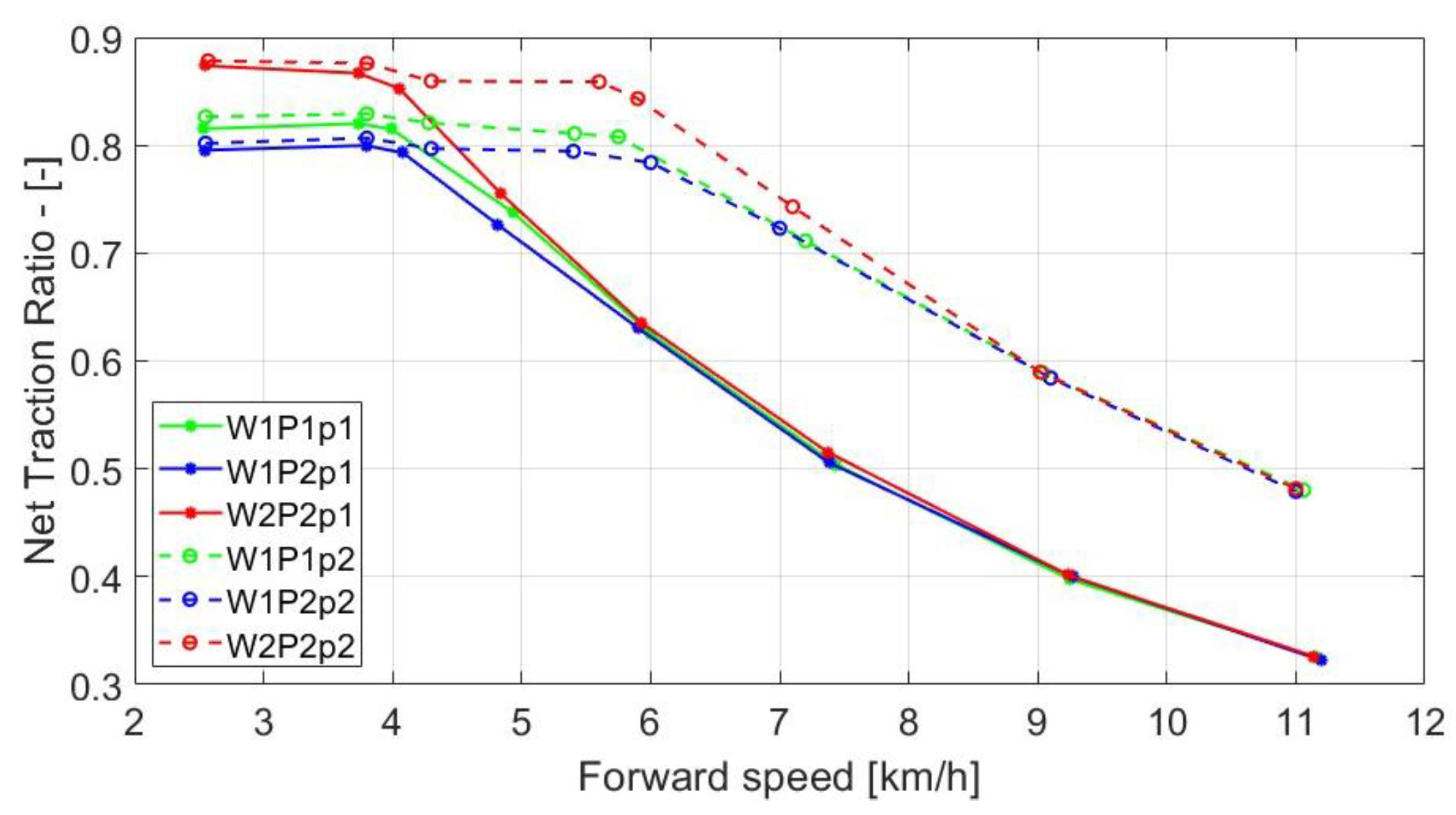

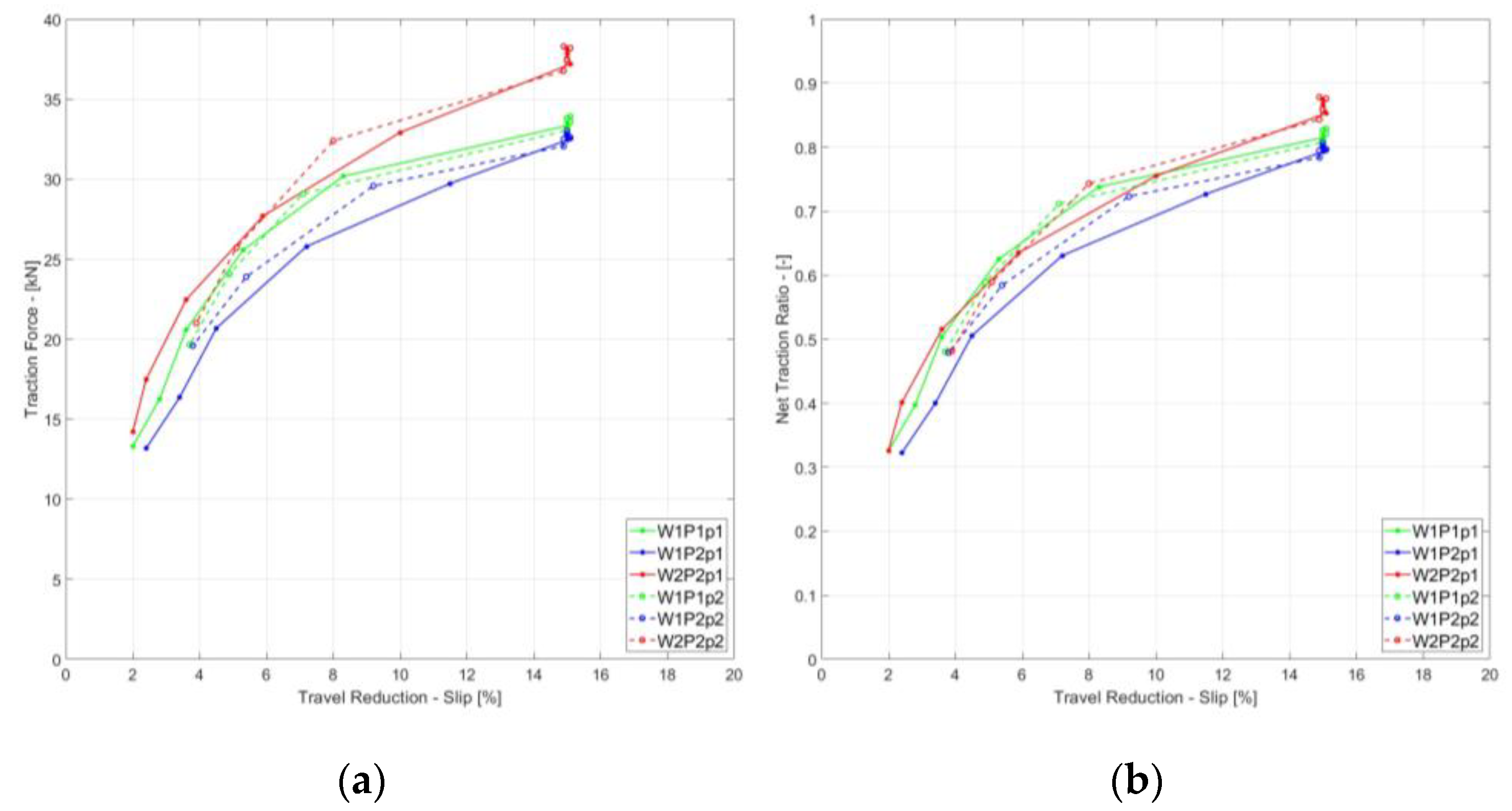

3.1. Drawbar Pull

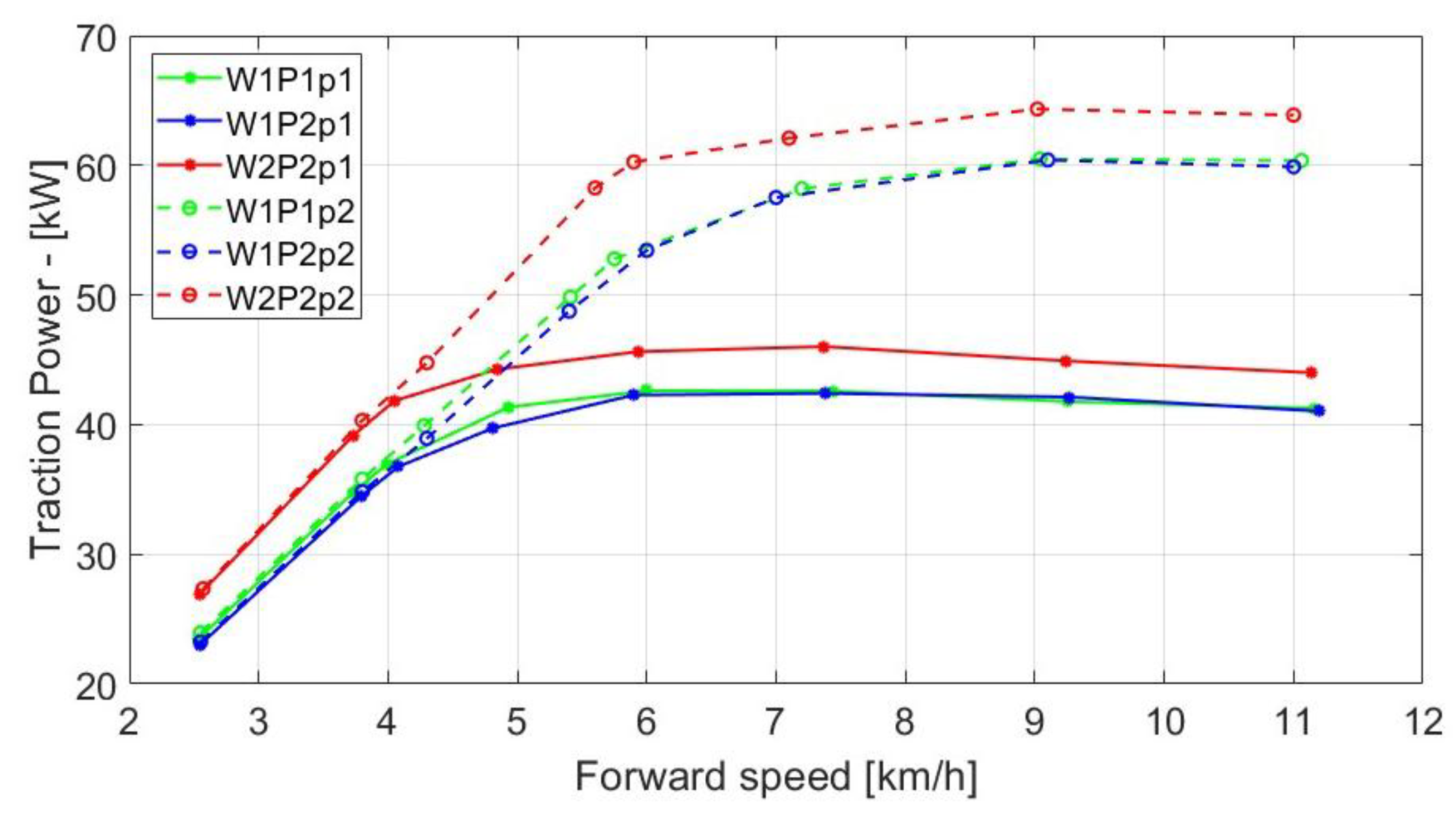

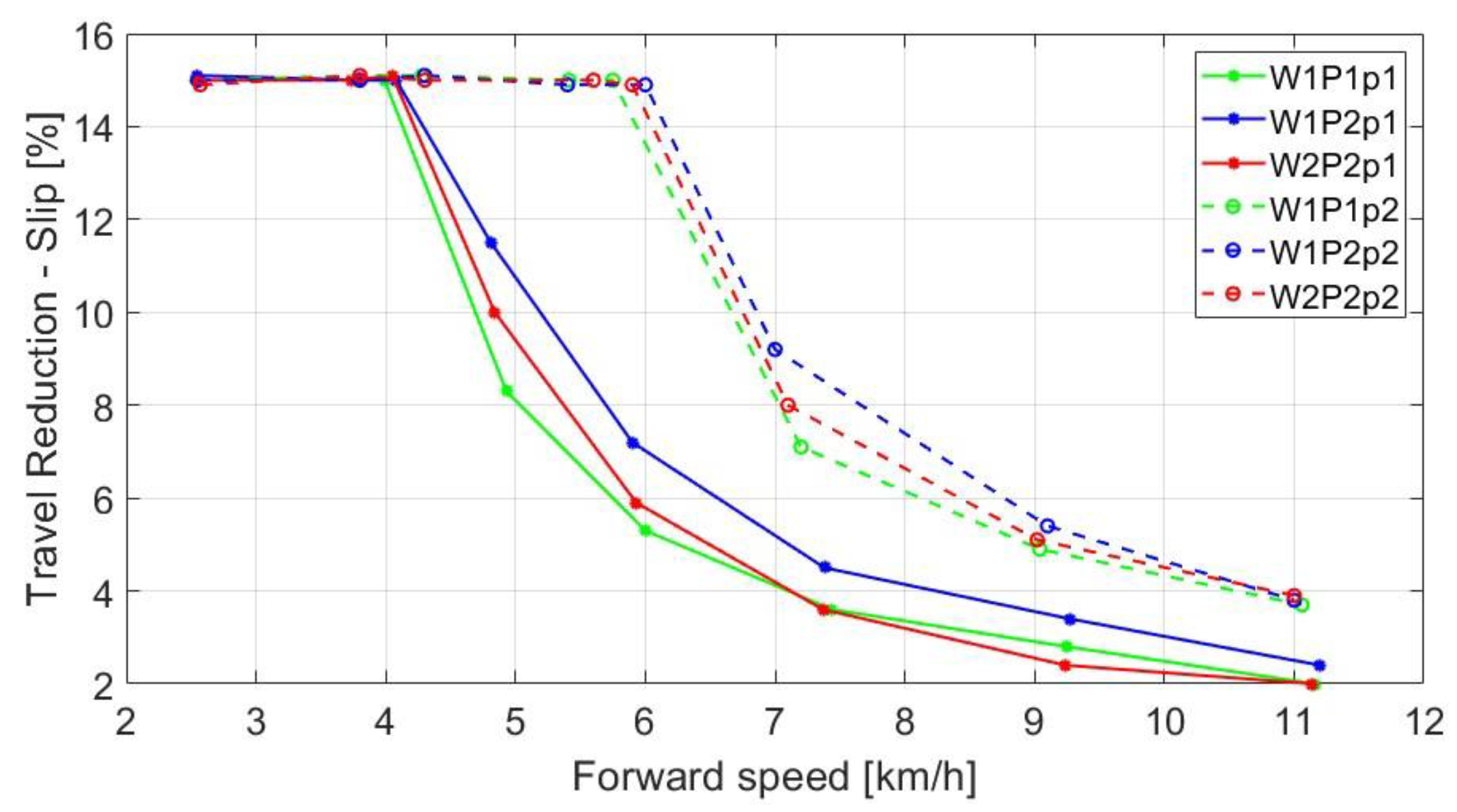

3.2. Travel Reduction and Traction Power

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| OECD | Organization for Economic Co-operation and Development |

| 4WD | Four-wheel drive |

| CoG | Centre of gravity |

| NTR | Net traction ratio |

| Static weights at the front wheels on the ground | |

| Static weights at the rear wheels on the ground | |

| TF | Traction force |

| W | Tractor weight |

| a | Horizontal distance between the CoG and rear axle |

| b | Horizontal distance between the CoG and front axle |

| H | Static height above ground of the line of draught |

| Ra | Horizontal ground reactions on the front wheels |

| Rb | Horizontal ground reactions on the rear wheels |

| Z | Wheelbase |

| Tractive effort at the front axle of the tractor | |

| Tractive effort at the rear axle of the tractor | |

| Total tractive effort of the tractor | |

| Dynamic axle load limit | |

| Engine speed | |

| Transmission ratio | |

| Theoretical forward speed | |

| Actual forward speed | |

| RI | Dynamic index radius |

| Travel reduction |

References

- Moinfar, A.M.; Shahgholi, G.; Gilandeh, Y.A.; Gundoshmian, T.M. The Effect of the Tractor Driving System on Its Performance and Fuel Consumption. Energy 2020, 202, 117803. [Google Scholar] [CrossRef]

- Taghavifar, H.; Mardani, A. Evaluating the Effect of Tire Parameters on Required Drawbar Pull Energy Model Using Adaptive Neuro-Fuzzy Inference System. Energy 2015, 85, 586–593. [Google Scholar] [CrossRef]

- Šmerda, T.; Čupera, J. Tire Inflation and Its Influence on Drawbar Characteristics and Performance—Energetic Indicators of a Tractor Set. J. Terramechanics 2010, 47, 395–400. [Google Scholar] [CrossRef]

- Kabir, M.S.N.; Chung, S.-O.; Kim, Y.-J.; Shin, S.-H. Comparison of Test Standards for the Performance and Safety of Agricultural Tractors: A Review. J. Biosyst. Eng. 2014, 39, 158–165. [Google Scholar] [CrossRef][Green Version]

- OECD Standard Codes. OECD Standard Code for the Official Testing of Agricultural and Forestry Tractors, Organisation for the Economic Co-Operation and Development. Available online: www.oecd.org/agriculture/tractor/codes (accessed on 1 April 2025).

- OECD Code 2. OECD Standard Code for the Official Testing of Agricultural and Forestry Tractor Performance, Organisation for the Economic Co-Operation and Development. Available online: www.oecd.org/agriculture/tractor/codes (accessed on 1 April 2025).

- Battiato, A.; Diserens, E. Influence of Tyre Inflation Pressure and Wheel Load on the Traction Performance of a 65 KW MFWD Tractor on a Cohesive Soil. J. Agric. Sci. 2013, 5, 197. [Google Scholar] [CrossRef]

- Raper, R.L.; Bailey, A.C.; Burt, E.C.; Way, T.R.; Liberatit, P. The effects of reduced inflation pressure on soil-tire interface stresses and soil strength. J. Terramechanics 1995, 32, 43–51. [Google Scholar] [CrossRef]

- Burt, E.C.; Bailey, A.C.; Patterson, R.M.; Taylor, J.H.; Asae, A. Combined Effects of Dynamic Load and Travel Reduction on Tire Performance. Trans. ASAE 1979, 22, 40–45. [Google Scholar]

- Kim, W.-S.; Kim, Y.-J.; Lee, N.-G.; Baek, S.-M.; Baek, S.-Y.; Kim, Y.-S. Influence of tire contact area on the traction performance of a 67-kw agricultural tractor in a paddy field. J. ASABE 2022, 65, 1421–1432. [Google Scholar] [CrossRef]

- Botta, G.F.; Jorajuria, D.; Draghi, L.M. Influence of the Axle Load, Tyre Size and Configuration on the Compaction of a Freshly Tilled Clayey Soil. J. Terramechanics 2002, 39, 47–54. [Google Scholar]

- Khalid, M.; Smith, J.L. Axle Torque Distribution in 4WD Tractors. J. Terramechanics 1981, 18, 157–167. [Google Scholar] [CrossRef]

- Spagnolo, R.T.; Volpato, C.E.S.; Barbosa, J.A.; Palma, M.A.Z.; De Barros, M.M. Fuel Consumption of a Tractor in Function of Wear, of Ballasting and Tire Inflation Pressure. Eng. Agrícola 2012, 32, 131–139. [Google Scholar] [CrossRef]

- Kumar, S.; Noori, M.T.; Pandey, K.P. Performance Characteristics of Mode of Ballast on Energy Efficiency Indices of Agricultural Tyre in Different Terrain Condition in Controlled Soil Bin Environment. Energy 2019, 182, 48–56. [Google Scholar] [CrossRef]

- Regazzi, N.; Mattetti, M.; Molari, G. Nuovi Sistemi Di Zavorramento per Trattori. Available online: https://terraevita.edagricole.it/macchine-agricole-trattori/nuovi-sistemi-zavorramento-per-trattori/ (accessed on 23 February 2024).

- Varani, M.; Mattetti, M.; Maraldi, M.; Molari, G. Mechanical Devices for Mass Distribution Adjustment: Are They Really Convenient? Agronomy 2020, 10, 1820. [Google Scholar] [CrossRef]

- Gazzetta Ufficiale. Available online: https://www.gazzettaufficiale.it/eli/id/1994/03/22/093A6158/sg (accessed on 23 February 2024).

- Alkhalifa, N.; Tekeste, M.Z.; Jjagwe, P.; Way, T.R. Effects of Vertical Load and Inflation Pressure on Tire-Soil Interaction on Artificial Soil. J. Terramechanics 2024, 112, 19–34. [Google Scholar] [CrossRef]

- European Tyre and Rim Technical Organisation (ETRTO). Standards Manual: ETRTO—The European Tyre and Rim Technical Organisation. 2025. Available online: https://www.etrto.org/Publications/Available/Standards-Manual (accessed on 1 April 2025).

- Swamy, V.S.; Pandit, R.; Yerro, A.; Sandu, C.; Rizzo, D.M.; Sebeck, K.; Gorsich, D. Review of Modeling and Validation Techniques for Tire-Deformable Soil Interactions. J. Terramechanics 2023, 109, 73–92. [Google Scholar]

- Gee-Clouch, D.; Pearson, G.; Mcallister, M. Ballasting Wheeled Tractors to Achieve Maximum Power Output in Frictional-Cohesive Soils. J. Agric. Eng. Res. 1982, 27, 1–19. [Google Scholar]

- Zhang, S.; Ren, W.; Xie, B.; Luo, Z.; Wen, C.; Chen, Z.; Zhu, Z.; Li, T. A Combined Control Method of Traction and Ballast for an Electric Tractor in Ploughing Based on Load Transfer. Comput. Electron. Agric. 2023, 207, 107750. [Google Scholar] [CrossRef]

| Description | Unit |

|---|---|

| Braking tractor | John Deere 6620 (97 kW) |

| Weight (kN) | 55.72 |

| Pulling tractors | CASE IH Farmall 90 (66 kW) CASE IH Farmall 120 (86 kW) |

| Weight W (kN) | 40.17 |

| Wheelbase Z (m) | 2.285 |

| Tyre (front–rear) (m) | 14.9 R24–18.4 R34 |

| Tyre width (front–rear) (m) | 0.378–0.467 |

| Speed Radius Index RI (front–rear) (m) | 0.60–0.775 |

| Rim diameter D (front–rear) (m) | 0.61–0.86 |

| Tyre inflation pressure (front–rear) (kPa) | 160–160 |

| Configuration | Power (kW) | Tyre Inflation Pressure (kPa) | Height of the Drawbar (m) | Total Weight (kN) | Front Weight (kN) | Rear Weight (kN) | Distance from CoG to Front Wheels (m) | Distance from CoG to Rear Wheels (m) |

|---|---|---|---|---|---|---|---|---|

| W1P1p1 | 66 | 80 | 0.495 | 40.17 | 16.23 | 23.94 | 1.362 | 0.923 |

| W1P2p1 | 66 | 160 | 0.495 | 40.17 | 16.23 | 23.94 | 1.362 | 0.923 |

| W2P2p1 | 66 | 160 | 0.490 | 42.87 | 18.88 | 23.99 | 1.279 | 1.006 |

| W1P1p2 | 86 | 80 | 0.495 | 40.17 | 16.23 | 23.94 | 1.362 | 0.923 |

| W1P2p2 | 86 | 160 | 0.495 | 40.17 | 16.23 | 23.94 | 1.362 | 0.923 |

| W2P2p2 | 86 | 160 | 0.490 | 42.87 | 18.88 | 23.99 | 1.279 | 1.006 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bruno, F.; Luigi, F.; Giulia, P.; Valda, R. Influence of Ballast and Tyre Inflation Pressure on Traction Performance of Agricultural Tractors Evaluated in Trials on Concrete Track. AgriEngineering 2025, 7, 109. https://doi.org/10.3390/agriengineering7040109

Bruno F, Luigi F, Giulia P, Valda R. Influence of Ballast and Tyre Inflation Pressure on Traction Performance of Agricultural Tractors Evaluated in Trials on Concrete Track. AgriEngineering. 2025; 7(4):109. https://doi.org/10.3390/agriengineering7040109

Chicago/Turabian StyleBruno, Franceschetti, Filannino Luigi, Piovaccari Giulia, and Rondelli Valda. 2025. "Influence of Ballast and Tyre Inflation Pressure on Traction Performance of Agricultural Tractors Evaluated in Trials on Concrete Track" AgriEngineering 7, no. 4: 109. https://doi.org/10.3390/agriengineering7040109

APA StyleBruno, F., Luigi, F., Giulia, P., & Valda, R. (2025). Influence of Ballast and Tyre Inflation Pressure on Traction Performance of Agricultural Tractors Evaluated in Trials on Concrete Track. AgriEngineering, 7(4), 109. https://doi.org/10.3390/agriengineering7040109