Innovative Use of Ultra-Low-Frequency Dynamic Electronic Impulses for Sustainable Performance of Drippers Applying Produced Water

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Area and Types of Water Tested

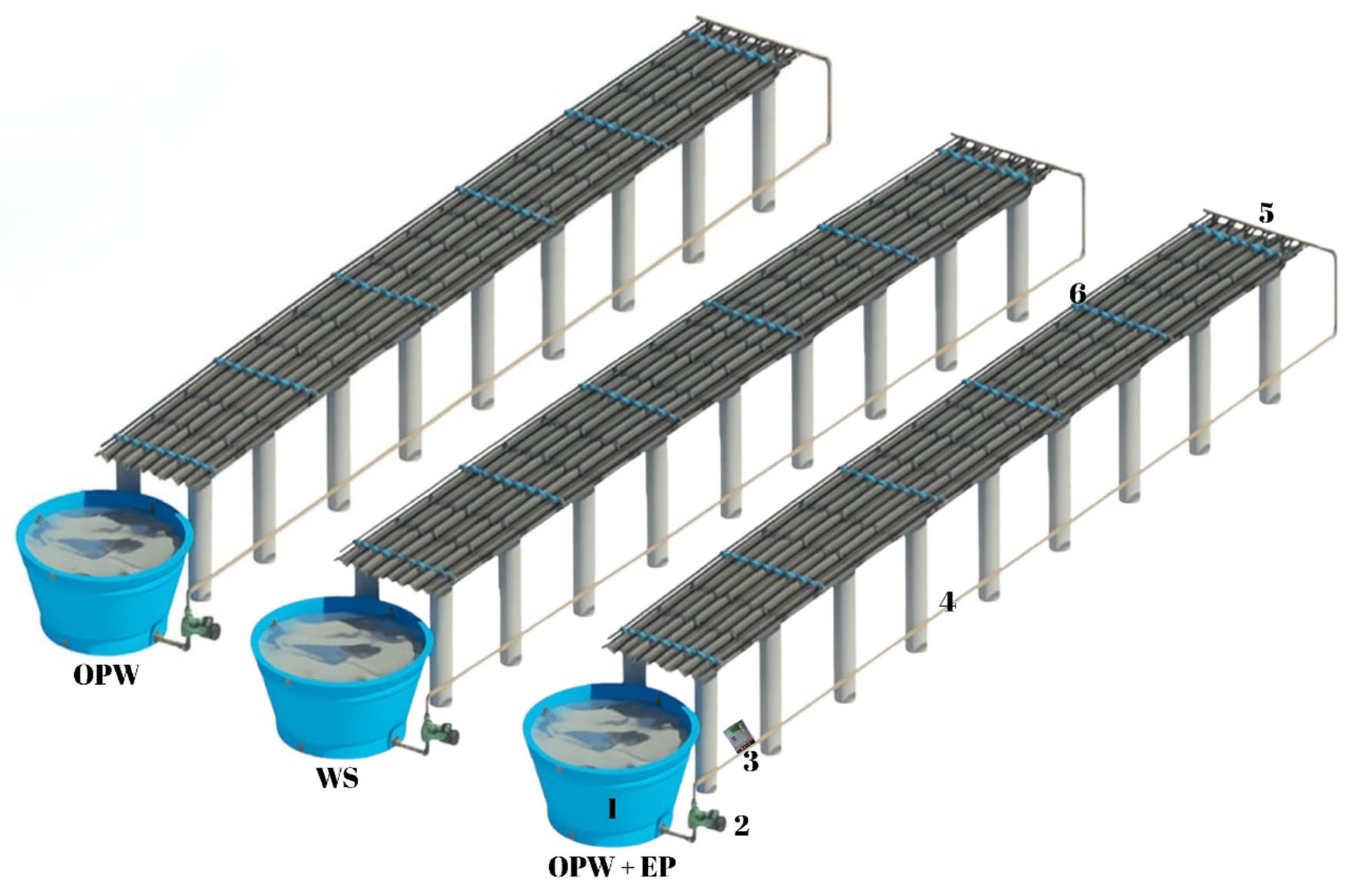

2.2. Experimental Design

2.3. Experiment Set up and Drip Unit Operation

2.4. Characterization of the Physical–Chemical Parameters of the Three Water Sources over Time During the Operation of the Experimental Benches

2.5. Monitoring of Hydraulic Performance and Clogging in Drippers

2.6. Micrographs by Electron Microscopy and Scanning (SEM)

2.7. Statistical Analysis

2.8. Economic Analysis

3. Results

3.1. Analysis of the Parameters of the Three Water Sources Used to Supply the Benches

3.2. RT-1 Analysis with Bonferroni Post Hoc Test for Ranking Treatments by Time

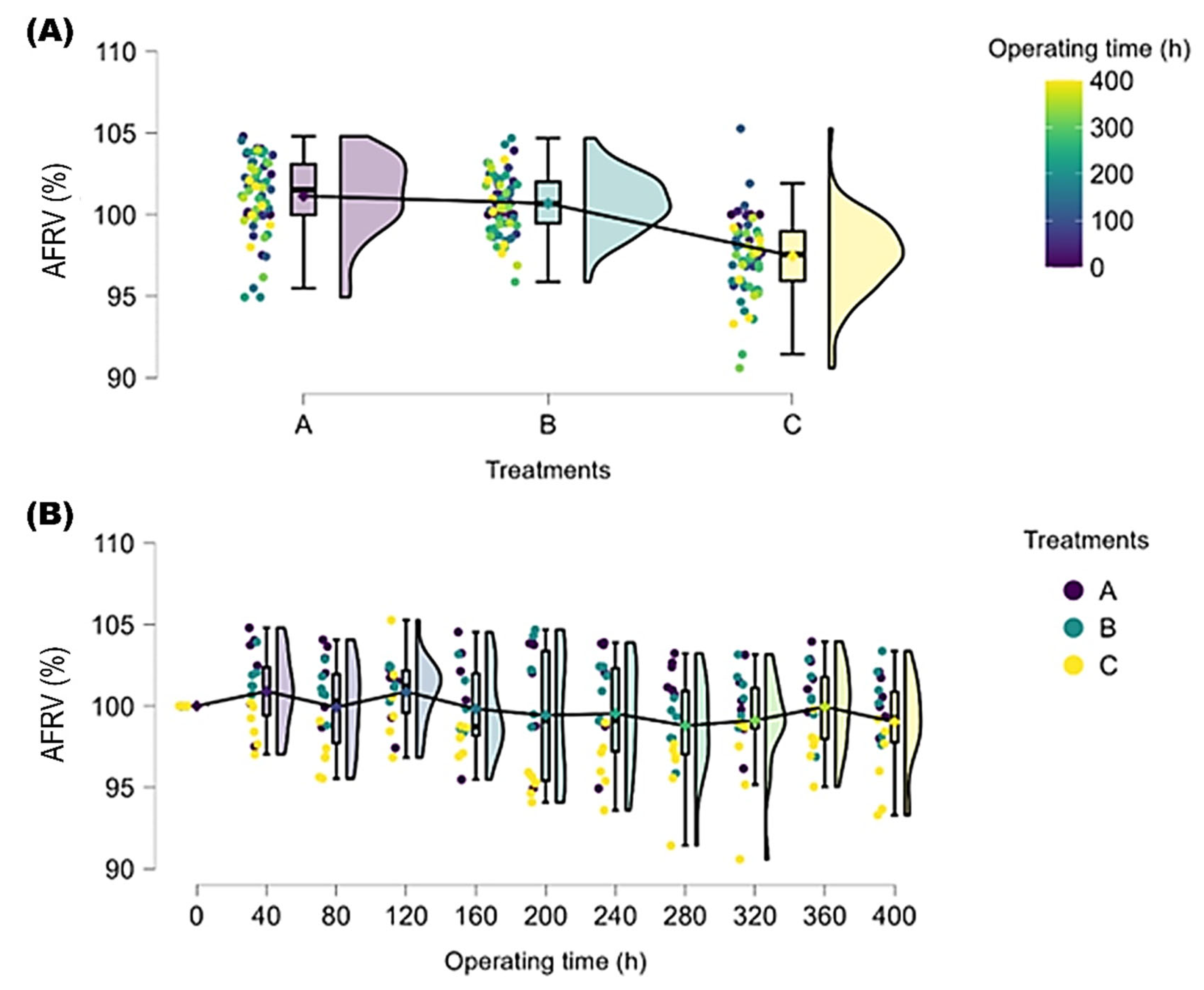

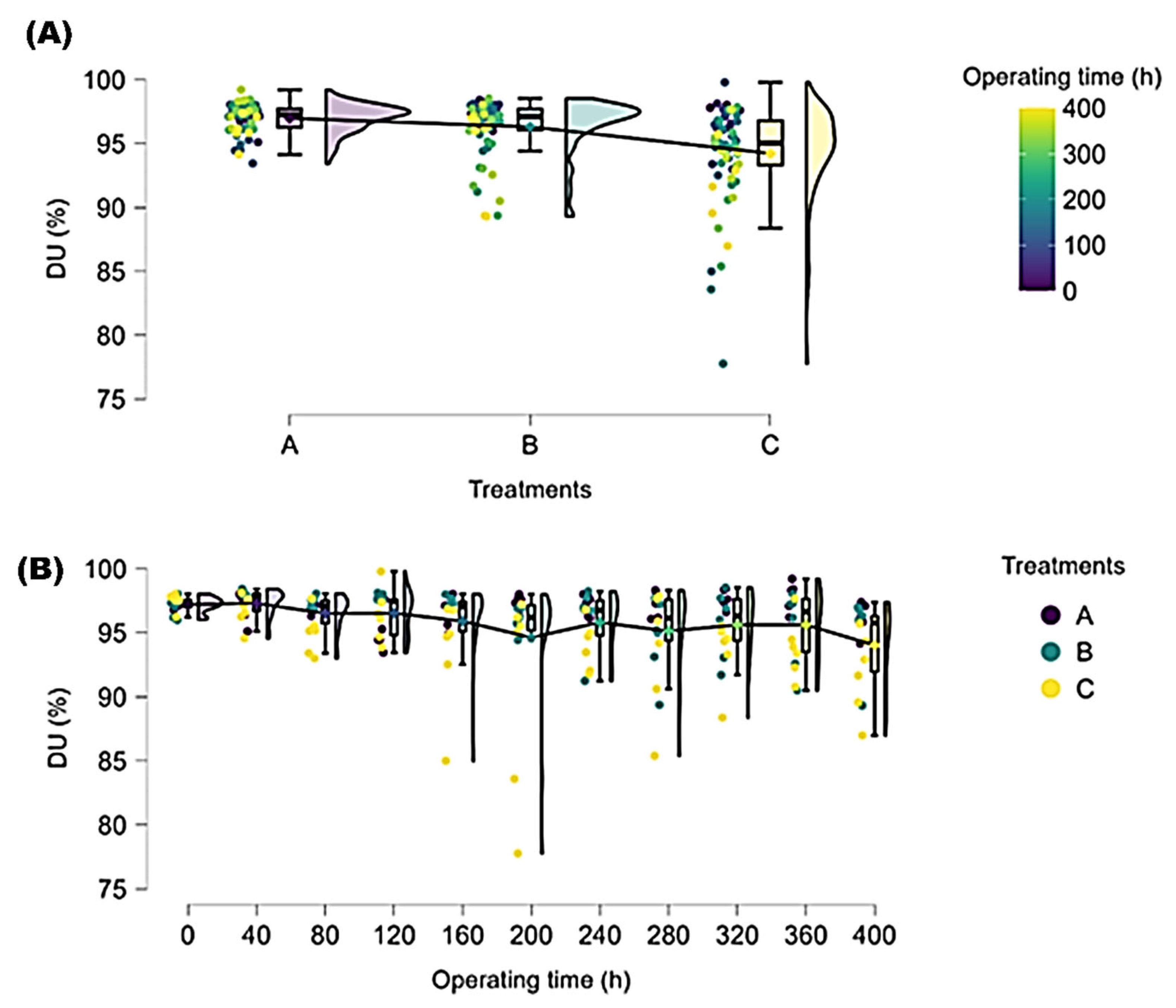

3.3. Dynamics of the Hydraulic Performance of Non-Self-Compensating Drippers: Analysis of Treatments and Operating Time

3.4. Micrographs of Biofouling Formed on Non-Self-Compensating Emitters That Applied the Three Water Sources

3.5. Annual Energy Cost

4. Discussion

4.1. Water Quality for Irrigation Purposes and Risk of Dripper Clogging by the Three Water Sources That Supplied the Experimental Benches

4.2. Analysis of Hydraulic Performance Index Rankings for Water Sources as a Function of Operating Times

4.3. Effect of Ultra-Low-Frequency Dynamic Electronic Pulses on Hydraulic Performance and Mitigation of Dripper Clogging

4.4. Morphology and Formation Pattern of Biofouling Observed by SEM

4.5. Economic Analysis and Environmental Impacts of Ultra-Low-Frequency Dynamic Electronic Impulses

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A | Water Supply |

| AFRV | Average Flow Rate Variation |

| APHA | American Public Health Association |

| ASAE | American Society of Agricultural Engineers |

| B | Oil-and-Gas-Produced Water with Ultra-Low-Frequency Dynamic Electronic impulses |

| BSh | Köppen Climate Classification (Hot Semi-Arid) |

| C | Oil-and-Gas-Produced Water |

| Ca | Calcium |

| CAERN | Water and Sewage Company of Rio Grande do Norte |

| Ca2+ | Calcium Ion |

| Cl− | Chloride Ion |

| CO2 | Carbon dioxide |

| CROSS | Cationic Structural Stability Ratio |

| CV | Coefficient of Variation |

| DU | Coefficient of Uniformity of Distribution |

| EC | Electrical Conductivity |

| EDTA | Ethylenediaminetetraacetic Acid |

| FAO | Food and Agriculture Organization of the United Nations. |

| Fe | Iron |

| Fe2+ | Reduced iron |

| Fe3+ | Insoluble iron |

| FVC | Flow Rate Variation Coefficient |

| H2CO3 | Carbonic Acid |

| ICP-OES | Inductively Coupled Plasma Optical Emission Spectrometry |

| K | Potassium |

| K+ | Potassium Ion |

| kHz | Kilohertz |

| kPa | Kilopascal |

| LASAP | Soil. Water and Plant Analysis Laboratory |

| Mg2+ | Magnesium Ion |

| Mn | Manganese |

| Na+ | Sodium Ion |

| NBR | Brazilian Standard |

| OPW | Oil-and-Gas-Produced Water |

| OPW + EP | Oil-and-Gas-Produced Water with Ultra-Low-Frequency Dynamic Electronic Impulses; |

| PVC | Polyvinyl chloride |

| SAR | Sodium Adsorption Ratio |

| SDG | Sustainable Development Goal |

| SEM | Scanning Electron Microscopy |

| TDS | Total dissolved solids |

| TSS | Total Suspended Solids |

| UFERSA | Federal Rural University of the Semi-Arid Region |

| UN | United Nations |

| US | United States of America |

| W | Watt |

| WS | Water Supply |

| WT | Water Temperature |

| X | Flow Exponent |

References

- Food and Agriculture Organization of the United Nations (FAO). The Future of Food and Agriculture: Alternative Pathways to 2050; FAO: Rome, Italy, 2018; 224p. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). The State of Food and Agriculture 2020: Overcoming Water Challenges in Agriculture; FAO: Rome, Italy, 2020; 210p. [Google Scholar]

- Karimi, M.; Tabiee, M.; Karami, S.; Karimi, V.; Karamidehkordi, E. Climate change and water scarcity impacts on sustainability in semi-arid areas: Lessons from the South of Iran. Groundw. Sustain. Dev. 2024, 24, 101075. [Google Scholar] [CrossRef]

- Organisation for Economic Co-Operation and Development (OECD). OECD Environmental Outlook to 2050; OECD Publishing: Paris, France, 2012; 353p. [Google Scholar]

- United Nations (UN WATER). Summary Progress Update 2021: SDG 6—Water and Sanitation for All—July 2021; UN-Water: Geneva, Switzerland, 2021; 58p. [Google Scholar]

- Ritchie, H.; Roser, M. Water Use and Stress. 2018. Available online: https://ourworldindata.org/water-use-stress (accessed on 24 August 2025).

- Food And Agriculture Organization of the United Nations (FAO). Trees, Forests and Land Use in Drylands: The First Global Assessment—Full Report; FAO: Rome, Italy, 2019; 207p, (FAO Forestry Paper no. 18). [Google Scholar]

- Gaur, M.K.; Squires, V.R. (Eds.) Climate Variability Impacts on Land Use and Livelihoods in Drylands; Springer International Publishing: New York, NY, USA, 2018; 360p. [Google Scholar]

- Tomasella, J.; Cunha, A.M.D.A.; Zeri, M.; Costa, L.C. Changes in the aridity index across Brazilian biomes. Sci. Total Environ. 2025, 989, 179869. [Google Scholar] [CrossRef]

- Instituto Nacional do Semiárido (INSA). Delimitação do Semiárido Brasileiro. 2024. Available online: https://www.gov.br/insa/pt-br/centrais-de-conteudo/mapas/mapas-em-pdf/delimitacao-do-semiarido-brasileiro-2024.pdf/view (accessed on 24 August 2025).

- Silva, L.A.P.d.; Silva, C.R.d.; Souza, C.M.P.d.; Bolfe, É.L.; Souza, J.P.S.; Leite, M.E. Mapping of aridity and its connections with climate classes and climate desertification in future scenarios-Brazilian semi-arid region. Soc. Natur. 2023, 35, e67666. [Google Scholar] [CrossRef]

- Superintendência do Desenvolvimento do Nordeste (SUDENE). Resolução CONDEL/SUDENE nº 176, de 3 de Janeiro de 2024. Aprova Relatório Conclusivo Elaborado pela Equipe Técnica do Comitê Provisório do Conselho Deliberativo da SUDENE (CONDEL/SUDENE), Instituído pela Resolução CONDEL/SUDENE nº 155, de 29 de Abril de 2022, Sobre as Irresignações Apresentadas por Entes Federativos Subnacionais Contra a Exclusão de Municípios do Semiárido Brasileiro e dá Outras Providências. Brasília, DOU, 23 January 2024. Available online: https://www.gov.br/sudene/pt-br/acesso-a-informacao/legislacao/hierarquia/resolucoes-conselho-deliberativo/resolucao-condel-sudene-no-176-de-3-de-janeiro-de-2024 (accessed on 24 August 2025).

- Tomaz, A.R.; da Silva, W.R.; Inagaki, T.M.; Santos, E.O.; Fracetto, G.G.M.; Fracetto, F.J.C.; Freitas, V.d.S.; Babos, D.V.; Milori, D.M.B.P.; Montenegro, A.A.d.A.; et al. Impacts of reclaimed water irrigation on mulch decomposition, microbial activity, and soil nutrient availability in the Brazilian semi-arid. Geoderma Reg. 2025, 42, e00978. [Google Scholar] [CrossRef]

- Angelakis, A.N.; Asano, T.; Bahri, A.; Jimenez, B.E.; Tchobanoglous, G. Water reuse: From ancient to modern times and the future. Front. Environ. Sci. 2018, 6, 26. [Google Scholar] [CrossRef]

- Kama, R.; Song, J.; Liu, Y.; Hamani, A.K.M.; Zhao, S.; Li, Z. Water availability and status of wastewater treatment and agriculture reuse in China: A review. Agronomy 2023, 13, 1187. [Google Scholar] [CrossRef]

- de Anda, J.; Shear, H. Sustainable wastewater management to reduce freshwater contamination and water depletion in Mexico. Water 2021, 13, 2307. [Google Scholar] [CrossRef]

- Beutel, M.; Mendoza-Espinosa, L.; Medina, C.; Morandé, J.A.; Harmon, T.C.; Medellín-Azuara, J. Achieving Responsible Reclaimed Water Reuse for Vineyard Irrigation: Lessons from Napa Valley, California and Valle de Guadalupe, Baja California. Water 2024, 16, 2817. [Google Scholar] [CrossRef]

- Jiménez, B.; Asano, T. Water reclamation and reuse around the world. In Water Reuse: An International Survey of Current Practice, Issues and Needs; Jimenez, B., Asano, T., Ellis, B., Bertrand-Krajewski, J., Eds.; IWA Publishing: London, UK, 2008; pp. 3–26. [Google Scholar]

- Leiva, E.; Vargas, I.T.; Labatut, R. Water Reuse in Chile: An alternative to face the drought. In Droughts in Chile: Impacts, Monitoring, and Adaptation (Management) Policies; Springer Nature Switzerland: Cham, Switzerland, 2025; pp. 365–385. [Google Scholar]

- Avidar, O. Israel: From Water Scarcity to Water Surplus. In The Palgrave International Handbook of Israel; Springer Nature Singapore: Singapore, 2023; pp. 1–13. [Google Scholar]

- Gude, V.G. Desalination and water reuse to address global water scarcity. Rev. Environ. Sci. Bio-Technol. 2017, 16, 591–609. [Google Scholar] [CrossRef]

- Echchelh, A.; Hess, T.; Sakrabani, R. Reusing oil and gas produced water for irrigation of food crops in drylands. Agric. Water. Manag. 2018, 206, 124–134. [Google Scholar] [CrossRef]

- Agência Nacional do Petróleo, Gás Natural e Biocombustíveis (ANP). Anuário Estatístico Brasileiro do Petróleo, Gás Natural e Biocombustíveis 2025. 2025. Available online: https://www.gov.br/anp/pt-br/centrais-de-conteudo/publicacoes/anuario-estatistico/anuario-estatistico-brasileiro-do-petroleo-gas-natural-e-biocombustiveis-2025#Outras (accessed on 24 August 2025).

- Salem, F.; Thiemann, T. Produced water from oil and gas exploration—Problems, solutions and opportunities. J. Water Resour. Prot. 2022, 14, 142–185. [Google Scholar] [CrossRef]

- Choi, Y.; Kim, Y.; Woo, Y.C.; Hwang, I. Water management and produced water treatment in oil sand plant: A review. Desalination 2023, 567, 116991. [Google Scholar] [CrossRef]

- Grafton, R.Q.; Williams, J.; Perry, C.J.; Molle, F.; Ringler, C.; Steduto, P.; Udall, B.; Wheeler, S.A.; Wang, Y.; Garrick, D.; et al. The paradox of irrigation efficiency. Science 2018, 361, 748–750. [Google Scholar] [CrossRef] [PubMed]

- TAL, A. Rethinking the sustainability of Israel’s irrigation practices in the Drylands. Water Res. 2016, 90, 387–394. [Google Scholar] [CrossRef]

- Yuan, T.; Li, S.; Zhai, S.; Luo, B.; Wu, J.; Tai, A.P. Impacts of drip irrigation and plastic-film mulching on regional climate in Northwest China: Implications for climate-resilient agriculture in dryland regions. Agric. Water. Manag. 2025, 317, 109661. [Google Scholar] [CrossRef]

- Shen, Y.; Puig-Bargués, J.; Li, M.; Xiao, Y.; Li, Q.; Li, Y. Physical, chemical and biological emitter clogging behaviors in drip irrigation systems using high-sediment loaded water. Agric. Water. Manag. 2022, 270, 107738. [Google Scholar] [CrossRef]

- Almeida, I.A.; Pereira, D.J.D.S.; Costa, J.D.O.; Quiloango-Chimarro, C.A.; Coelho, R.D. Dripper clogging: Emphasis on the problem and how to minimize impact. Rev. Bras. Eng. Biossistemas 2022, 16. [Google Scholar]

- Shi, K.; Lu, T.; Zheng, W.; Zhang, X.; Zhangzhong, L. A review of the category, mechanism, and controlling methods of chemical clogging in drip irrigation system. Agriculture 2022, 12, 202. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, B.; Zhang, J.; Xu, F.; Li, Y. Effects of fertilizer types on biofilm growth in the drip irrigation system using the reclaimed water. Irrig. Sci. 2021, 39, 725–734. [Google Scholar] [CrossRef]

- Bucks, D.A.; Nakayama, F.S.; Gilbert, R.G. Trickle irrigation water quality and preventive maintenance. Agr. Water Manag. 1979, 2, 149–162. [Google Scholar] [CrossRef]

- Capra, A.; Scicolone, B. Water quality and distribution uniformity in drip/trickle irrigation systems. J. Agric. Eng. Res. 1998, 70, 355–365. [Google Scholar] [CrossRef]

- Qian, J.; Horn, H.; Tarchitzky, J.; Chen, Y.; Katz, S.; Wagner, M. Water quality and daily temperature cycle affect biofilm formation in drip irrigation devices revealed by optical coherence tomography. Biofouling 2017, 33, 211–221. [Google Scholar] [CrossRef]

- Green, O.; Katz, S.; Tarchitzky, J.; Chen, Y. Formation and prevention of biofilm and mineral precipitate clogging in drip irrigation systems applying treated wastewater. Irrig. Sci. 2018, 36, 257–270. [Google Scholar] [CrossRef]

- Kanarek, P.; Breza-Boruta, B.; Rolbiecki, R. Microbial composition and formation of biofilms in agricultural irrigation systems-a review. Ecohydrol. Hydrobiol. 2024, 24, 583–590. [Google Scholar] [CrossRef]

- Ramachandrula, V.R.; Kasa, R.R. Prevention and treatment of drip emitter clogging: A review of various innovative methods. Water Pract. Technol. 2022, 17, 2059–2070. [Google Scholar] [CrossRef]

- Petit, J.; García, S.M.; Molle, B.; Bendoula, R.; Ait-Mouheb, N. Methods for drip irrigation clogging detection, analysis and understanding: State of the art and perspectives. Agric. Water. Manag. 2022, 272, 107873. [Google Scholar] [CrossRef]

- Reges, L.B.L.; Batista, R.O.; Rocha, L.L.; Muniz, G.L.; Paiva, L.A.L.D.; Oliveira, F.É.R.D.; Medeiros, J.F.d.; Souto, A.G.d.L.; Antunes, L.F.d.S.; Silva, E.F.d.; et al. L Hydraulic performance and mitigation of biofouling in drippers applying aquaculture effluent with anti-clogging fertilizer. AgriEngineering 2025, 7, 189. [Google Scholar] [CrossRef]

- Japhet, N.; Tarchitzky, J.; Chen, Y. Effectiveness of hydrogen peroxide treatments in preventing biofilm clogging in drip irrigation systems applying treated wastewater. Biofouling 2022, 38, 575–592. [Google Scholar] [CrossRef]

- CALMAT®. Available online: https://www.calmat.net/en/ (accessed on 24 August 2025).

- Zhangzhong, L.; Zhang, W.; Chen, W.; Zheng, W.; Xiao, Y.; Li, Y. Magnetic field treatment for mitigating inorganic and particulate fouling in reclaimed wastewater distribution systems. J. Clean. Prod. 2025, 526, 146667. [Google Scholar] [CrossRef]

- Liu, Z.; Xiao, Y.; Muhammad, T.; Zhou, Y.; Hou, P.; Zha, Y.; Ruihong, Y.; Shen, Q.; Changjian, M.; Li, Y. Combination of magnetic field and ultraviolet for fouling control in saline wastewater distribution systems. Water Res. 2024, 251, 121118. [Google Scholar] [CrossRef]

- Lin, L.; Jiang, W.; Xu, X.; Xu, P. A critical review of the application of electromagnetic fields for scaling control in water systems: Mechanisms, characterization, and operation. npj Clean Water 2020, 3, 25. [Google Scholar] [CrossRef]

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.C.; Gonçalves, J.D.M.; Sparovek, G. Köppen’s climate classification map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef]

- Lipps, W.C.; Braun-Howland, E.B.; Baxter, T.E. Standard Methods for the Examination of Water and Wastewater, 24th ed.; APHA Press: Washington, DC, USA, 2023; 1516p. [Google Scholar]

- Almeida, O.Á.d. Qualidade da Água de Irrigação; Embrapa Mandioca e Fruticultura: Cruz das Almas, Brasil, 2010; 232p. [Google Scholar]

- Drechsel, P.; Marjani Zadeh, S.; Pedrero, F. (Eds.) Water Quality in Agriculture: Risks and Risk Mitigation; FAO & IWMI: Rome, Italy, 2023; 192p. [Google Scholar]

- Richards, L.A. (Ed.) Diagnosis and Improvement of Saline and Alkali Soils; US Government Printing Office: Washington, DC, USA, 1954; 160p. [Google Scholar]

- Rengasamy, P.; Marchuk, A. Cation ratio of soil structural stability (CROSS). Soil Res. 2011, 49, 280–285. [Google Scholar] [CrossRef]

- Keller, J.; Karmeli, D. Trickle irrigation design parameters. Trans. ASAE 1974, 17, 678–684. [Google Scholar] [CrossRef]

- NBR ISO 9261; Equipamentos de Irrigação Agrícola. Emissores e Tubos Emissores. Especificação e Métodos de Ensaio. Associação Brasileira de Normas Técnicas (ABNT): São Paulo, Brasil, 2006; 17p.

- ASAE EP 405.1 FEB03; Design and Installation of Microirrigation Systems. ASAE Standards Engineering Practices: St. Joseph, MO, USA, 2003; pp. 901–905.

- Merriam, J.L.; Keller, J. Farm Irrigation System Evaluation: A Guide for Management; Utah State University: Logan, UT, USA, 1978; 271p. [Google Scholar]

- Pei, Y.; Li, Y.; Liu, Y.; Zhou, B.; Shi, Z.; Jiang, Y. Eight emitters clogging characteristics and its suitability under on-site reclaimed water drip irrigation. Irrig. Sci. 2014, 32, 141–157. [Google Scholar] [CrossRef]

- Borssoi, A.L.; Vilas Boas, M.A.; Reisdörfer, M.; Hernández, R.H.; Follador, F.A. Water application uniformity and fertigation in a dripping irrigation set. Eng. Agrícola 2012, 32, 718–726. [Google Scholar] [CrossRef]

- Fernandes, J.E.G.; Portela, J.C.; Silva, E.F.d.; Mota, P.J.; Vieira, W.M.; Cunha, W.A.; Gomes, D.V.d.O.; Fernandes, B.C.C.; Silva, M.L.d.N.; Dantas, M.d.S.; et al. Correction to: Soil functioning and interrelations with hydrophysical attributes and organic and microstructural fractions in soils under land uses in the Brazilian Semiarid. Environ. Monit. Assess. 2025, 197, 813. [Google Scholar] [CrossRef]

- Royston, P. Remark AS R94: A remark on Algorithm AS 181: The W-test for normality. Appl. Stat. 1995, 44, 547–551. [Google Scholar] [CrossRef]

- Ferreira, D.F. SISVAR: Um sistema computacional de análise estatística. Rev. Bras. De Biom. 2019, 37, 529–535. [Google Scholar] [CrossRef]

- JASP Team. JASP (Version 0.19.3). [Computer Software]. 2025. Available online: https://jasp-stats.org/ (accessed on 24 August 2025).

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017; 640p. [Google Scholar]

- Veil, J.A.; Puder, M.G.; Elcock, D. A White Paper Describing Produced Water from Production of Crude Oil, Natural Gas, and Coal Bed Methane; Argonne National Laboratory: Lemont, IL, USA, 2004; 87p. [Google Scholar]

- Emam, E.A.; Moawad, T.M.; Aboul-Gheit, N. Evaluating the characteristics of offshore oilfield produced water. Pet. Coal 2014, 56, 363–372. [Google Scholar]

- Zaman, M.; Shahid, S.A.; Heng, L. Irrigation water quality. In Guideline for Salinity Assessment, Mitigation and Adaptation Using Nuclear and Related Techniques; Springer International Publishing: Cham, Switzerland, 2018; pp. 113–131. [Google Scholar]

- Cordeiro, E.D.A.; Mantovani, E.C.; Vieira, G.H.S.; Silva, J.G.F.D.; Haddade, I.R.; Lo Monaco, P.A.V. Treatment of Ferruginous Water in the Performance of Drip Irrigation Systems. AgriEngineering 2025, 7, 26. [Google Scholar] [CrossRef]

- Cetin, B.; Li, D. Effect of Joule heating on electrokinetic transport. Electrophoresis 2008, 29, 994–1005. [Google Scholar] [CrossRef]

- Hollanda, L.R.; Santos, S.B.F.; Faustino, J.G.A.A.; Dotto, G.L.; Foletto, E.L.; Chiavone-Filho, O. Oil field–produced water treatment: Characterization, photochemical systems, and combined processes. Environ. Sci. Pollut. Res. 2021, 28, 52744–52763. [Google Scholar] [CrossRef]

- Adamczyk, K.; Prémont-Schwarz, M.; Pines, D.; Pines, E.; Nibbering, E.T. Real-time observation of carbonic acid formation in aqueous solution. Science 2009, 326, 1690–1694. [Google Scholar] [CrossRef]

- Al-Haleem, A.A.; Abdulah, H.H.; Saeed, E.A. Components and treatments of oilfield produced water. Al-Khwarizmi Eng. J. 2010, 6, 24–30. [Google Scholar]

- Ait-Mouheb, N.; Schillings, J.; Al-Muhammad, J.; Bendoula, R.; Tomas, S.; Amielh, M.; Anselmet, F. Impact of hydrodynamics on clay particle deposition and biofilm development in a labyrinth-channel dripper. Irrig. Sci. 2019, 37, 1–10. [Google Scholar] [CrossRef]

- Zhangzhong, L.; Peiling, Y.; Shumei, R.; Yunkai, L.; Yu, L.; Yuhong, X. Chemical clogging of emitters and evaluation of their suitability for saline water drip irrigation. IRD 2016, 65, 439–450. [Google Scholar]

- Haman, D.Z. Causes and Prevention of Emitter Plugging in Microirrigation Systems; University of Florida: Gainesville, FL, USA, 2022; 11p. [Google Scholar]

- Zhangzhong, L.; Yang, P.; Zhen, W.; Zhang, X.; Wang, C. A kinetic model for the chemical clogging of drip irrigation system using saline water. Agric. Water. Manag. 2019, 223, 105696. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, P.; Zhu, D.; Zhang, L.; Chen, J. Effect of water hardness on emitter clogging of drip irrigation. Trans. Chin. Soc. Agric. Eng. 2015, 31, 95–100. [Google Scholar]

- Smith, C.J.; Oster, J.D.; Sposito, G. Potassium and magnesium in irrigation water quality assessment. Agric. Water Manag. 2015, 157, 59–64. [Google Scholar] [CrossRef]

- Qadir, M.; Sposito, G.; Smith, C.J.; Oster, J.D. Reassessing irrigation water quality guidelines for sodicity hazard. Agric. Water Manag. 2021, 255, 107054. [Google Scholar] [CrossRef]

- Kanakiya, S.; Adam, L.; Esteban, L.; Rowe, M.C.; Shane, P. Dissolution and secondary mineral precipitation in basalts due to reactions with carbonic acid. J. Geophys. Res. Solid Earth 2017, 122, 4312–4327. [Google Scholar] [CrossRef]

- Fathi, A.; Mohamed, T.; Claude, G.; Maurin, G.; Mohamed, B.A. Effect of a magnetic water treatment on homogeneous and heterogeneous precipitation of calcium carbonate. Water Res. 2006, 40, 1941–1950. [Google Scholar] [CrossRef]

- Saghatoleslami, N.; Salooki, M.K.; Armin, M.A. Prediction of thickness and fouling rate in pulsating flow heat exchangers, using FLUENT simulator. Korean J. Chem. Eng. 2010, 27, 96–103. [Google Scholar] [CrossRef]

- Baydar, A.; Bozkurt-Çolak, Y.; Küçükyumuk, C.; Dalkılıç, B. Evaluation of hydraulic and irrigation performances of drip systems in nectarine orchards (Prunus persica var. nucipersica) in the Mediterr. Region. Water 2025, 17, 758. [Google Scholar]

- Li, Y.; Feng, J.; Xue, S.; Muhammad, T.; Chen, X.; Wu, N.; Li, W.; Zhou, B. Formation mechanism for emitter composite-clogging in drip irrigation system. Irrig. Sci. 2019, 37, 169–181. [Google Scholar] [CrossRef]

- Shi, K.; Zhangzhong, L.; Han, F.; Zhang, S.; Guo, R.; Yao, X. Reducing emitter clogging in drip fertigation systems by magnetization technology. Sustainability 2023, 15, 3712. [Google Scholar] [CrossRef]

- Liu, Z.; Di Luccio, M.; García, S.; Puig-Bargués, J.; Zhao, X.; Trueba, A.; Muhammad, T.; Xiao, Y.; Li, Y. Effect of magnetic field on calcium-silica fouling and interactions in brackish water distribution systems. Sci. Total Environ. 2021, 798, 148900. [Google Scholar] [CrossRef]

- Xiao, Y.; Seo, Y.; Lin, Y.; Li, L.; Muhammad, T.; Ma, C.; Li, Y. Electromagnetic fields for biofouling mitigation in reclaimed water distribution systems. Water Res. 2020, 173, 115562. [Google Scholar] [CrossRef]

- Turkey, Z.; Yeser, A.E.; Elbagoury, K.F.; Mahmoud, M. Hydraulic performance analysis of emitters under magnetied saline water conditions. Arab. Univ. J. Agric. Sci. 2020, 28, 1055–1064. [Google Scholar] [CrossRef]

- Abdelsalam, H.; Mostafa, H.; El-Ansary, M.; Awad, M.; Sultan, W. Evaluation of saline and magnetized water on emitter hydraulic performance and clogging in drip irrigation. Sci. Rep. 2024, 14, 7339. [Google Scholar] [CrossRef]

- Khoshravesh, M.; Mirzaei, S.M.J.; Shirazi, P.; Valashedi, R.N. Evaluation of dripper clogging using magnetic water in drip irrigation. Appl. Water Sci. 2018, 8, 81. [Google Scholar] [CrossRef]

- Sahin, U.; Tunca, T.; Eroglu, S. Evaluation of CaCO3 clogging in emitters with magnetized saline waters. Desalination Water Treat. 2012, 40, 168–173. [Google Scholar] [CrossRef]

- Du, X.; Perera, H.; Ahasan, T.; Wang, Y.; Shu, F.; Wang, H.; Yuan, K.; Anovitz, L.M.; Ishai, P.B.; Xu, P. Mechanisms of electromagnetic field control on mineral scaling in brackish water reverse osmosis: Combined homogenous and heterogeneous nucleation. Sep. Purif. Technol. 2025, 355, 129630. [Google Scholar] [CrossRef]

- Han, S.; Li, Y.; Xu, F.; Sun, D.; Feng, J.; Liu, Z.; Wu, R.; Wang, Z. Effect of lateral flushing on emitter clogging under drip irrigation with Yellow River water and a suitable method. Irrig. Drain. 2018, 67, 199–209. [Google Scholar] [CrossRef]

- Lavanholi, R.; Oliveira, F.C.; Camargo, A.P.; Frizzone, J.A.; Molle, B.; Ait-Mouheb, N.; Tomas, S. Methodology to evaluate dripper sensitivity to clogging due to solid particles: An assessment. Sci. World J. 2018, 2018, 7697458. [Google Scholar] [CrossRef]

- Hi, K.; Kong, J.; Yue, H.; Huang, Y.; Wei, X.; Zhangzhong, L. Magnetized water irrigation alleviates emitter clogging of a drip fertigation system. Agronomy 2023, 13, 108. [Google Scholar]

- Zhang, Y.; Sun, H.; Ge, M.; Zhao, H.; Hu, Y.; Cui, C.; Wu, Z. Difference in energy input and output in agricultural production under surface irrigation and water-saving irrigation: A case study of Kiwi Fruit in Shaanxi. Sustainability 2023, 15, 3114. [Google Scholar] [CrossRef]

| Parameters | Operating Time (h) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 200 | 400 | |||||||

| WS | OPW + EP | OPW | WS | OPW + EP | OPW | WS | OPW + EP | OPW | |

| WT (°C) | 31.1 | 31.7 | 31.1 | 31.1 | 30.7 | 30.7 | 31.5 | 32.5 | 31.2 |

| TSSs (mg L−1) | 8 | 18 | 14 | 6 | 32 | 26 | 0 | 14 | 26 |

| pH | 8.15 | 8.1 | 8.19 | 6.7 | 6.1 | 8.22 | 8.16 | 8.26 | 8.19 |

| CE (dS m−1) | 0.46 | 4.93 | 4.97 | 0.69 | 7.31 | 7.36 | 0.57 | 5.36 | 5.3 |

| Na+ (mmolc L−1) | 3.33 | 33.33 | 31.99 | 5.38 | 54.32 | 53.01 | 4.06 | 40.21 | 39.77 |

| K+ (mmolc L−1) | 0.18 | 1.24 | 1.24 | 0.26 | 1.91 | 1.83 | 0.22 | 1.36 | 1.31 |

| Ca2+ (mmolc L−1) | 0.44 | 7.40 | 7.65 | 0.56 | 8.70 | 9.40 | 0.48 | 5.50 | 6.00 |

| Mg2+ (mmolc L−1) | 0.64 | 4.35 | 3.65 | 0.52 | 3.50 | 2.69 | 0.16 | 3.00 | 2.55 |

| Fe (mg L−1) | 0.018 | 0.185 | 0.241 | 0.049 | 0.093 | 0.079 | 0.017 | 0.021 | 0.009 |

| Mn (mg L−1) | 0.004 | 0.005 | 0.006 | 0.005 | 0.001 | 0.001 | 0 | 0.002 | 0.003 |

| Parameters | Mean ± Standard Deviation (Coefficient of Variation in %) | ||

|---|---|---|---|

| WS | OPW + EP | OPW | |

| WT | 31.10 ± 0.23 (0.7) | 31.70 ± 0.90 (2.8) | 31.10 ± 0.26 (0.8) |

| TSS (mg L−1) | 6.00 ± 4.16 (69) | 18.00 ± 9.45 (52) | 26.00 ± 6.93 (27) |

| EC (dS m−1) | 0.57 ± 0.11 (19) | 5.36 ± 1.27 (24) | 5.30 ± 1.29 (24) |

| TDS (mg L−1) | 367 ± 74 (29) | 4430 ± 1352 (30) | 4436 ± 1364 (31) |

| pH | 8.15 ± 0.84 (10) | 8.10 ± 1.20 (15) | 8.19 ± 0.02 (0.2) |

| Na+ (mmolc L−1) | 4.26 ± 1.04 (24) | 42.62 ± 10.70 (25) | 41.59 ± 10.63 (25) |

| Ca2+ (mmolc L−1) | 0.48 ± 0.06 (12.5) | 7.40 ± 1.61 (22) | 7.65 ± 1.70 (22) |

| Mg2+ (mmolc L−1) | 0.52 ± 0.25 (48) | 3.50 ± 0.68 (19) | 2.69 ± 0.60 (22) |

| K+ (mmolc L−1) | 0.22 ± 0.04 (18) | 1.50 ± 0.36 (24) | 1.46 ± 0.32 (22) |

| SAR (mmolc L−1)0.5 | 6.34 ± 1.57 (25) | 18.42 ± 4.23 (23) | 18.08 ± 4.17 (23) |

| CROSS (mmolc L−1)0.5 | 7.17 ± 1.61 (22) | 20.16 ± 4.45 (22) | 19.55 ± 4.30 (22) |

| Mg2+/Ca2+ | 0.90 ± 0.56 (62) | 0.51 ± 0.09 (18) | 0.40 ± 0.10 (25) |

| Fe (mg L−1) | 0.018 ± 0.018 (100) | 0.093 ± 0.082 (88) | 0.079 ± 0.119 (150) |

| Mn (mg L−1) | 0.004 ± 0.003 (75) | 0.002 ± 0.002 (100) | 0.003 ± 0.003 (100) |

| Time (Hours) | AFRV (%) * | FVC (%) * | DU (%) * |

|---|---|---|---|

| Ranking | Ranking | Ranking | |

| 0 | OPW + EP^a = WS^a = OPW^a | OPW^a > WS^b = OPW + EP^b | OPW^a > WS^b > OPW + EP^c |

| 40 | WS^a = OPW + EP^a = OPW^b | OPW + EP^a = WS^a > OPW^b | OPW + EP^a > WS^b = OPW^b |

| 80 | WS^a = OPW + EP^a > OPW^b | OPW + EP^a = WS^a > OPW^b | OPW + EP^a = WS^a > OPW^b |

| 120 | OPW + EP^a = WS^a = OPW^a | OPW + EP^a > WS^b = OPW^b | OPW + EP^a > OPW^b = WS^b |

| 160 | WS^a = OPW + EP^a > OPW^b | OPW + EP^a = WS^a > OPW^b | OPW +EP^a = WS^a > OPW^b |

| 200 | OPW + EP^a = WS^a > OPW^b | WS^a = OPW + EP ^a > OPW^b | WS^a > OPW + EP^b > OPW^c |

| 240 | WS^a = OPW + EP^a > OPW^b | WS^a = OPW + EP ^a > OPW^b | WS^a = OPW + EP^a > OPW^b |

| 280 | WS^a > OPW + EP^b > OPW^c | WS^a > OPW + EP ^b = OPW^b | WS^a > OPW + EP^b = OPW^b |

| 320 | OPW + EP^a = WS^a > OPW^b | WS^a > OPW + EP ^b > OPW^c | WS^a > OPW + EP^b > OPW^c |

| 360 | WS^a > OPW + EP^b > OPW^c | WS^a > OPW + EP ^b = OPW^b | WS^a > OPW + EP ^b = OPW^b |

| 400 | OPW + EP^a = WS^a > OPW^b | WS^a > OPW + EP ^b > OPW^c | WS^a > OPW + EP ^b > OPW^c |

| Tariff (US$ kWh−1) | Hours Day−1 | Annual Consumption (kWh) | AEC (US$ Year−1) |

|---|---|---|---|

| 0.10 | 1 | 1.57 | 0.16 |

| 0.10 | 3 | 4.71 | 0.47 |

| 0.10 | 6 | 9.42 | 0.94 |

| 0.14 | 1 | 1.57 | 0.22 |

| 0.14 | 3 | 4.71 | 0.66 (Baseline scenario) |

| 0.14 | 6 | 9.42 | 1.32 |

| 0.20 | 1 | 1.57 | 0.31 |

| 0.20 | 3 | 4.71 | 0.94 |

| 0.20 | 6 | 9.42 | 1.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cruz, N.L.R.; Morais, L.P.L.; Silva, D.V.; Medeiros, J.F.d.; Carmo, F.R.d.; Souto, A.G.d.L.; Antunes, L.F.d.S.; Silva, E.F.d.; Carvalho, S.C.F.d.; Oliveira, P.V.C.d.; et al. Innovative Use of Ultra-Low-Frequency Dynamic Electronic Impulses for Sustainable Performance of Drippers Applying Produced Water. AgriEngineering 2025, 7, 371. https://doi.org/10.3390/agriengineering7110371

Cruz NLR, Morais LPL, Silva DV, Medeiros JFd, Carmo FRd, Souto AGdL, Antunes LFdS, Silva EFd, Carvalho SCFd, Oliveira PVCd, et al. Innovative Use of Ultra-Low-Frequency Dynamic Electronic Impulses for Sustainable Performance of Drippers Applying Produced Water. AgriEngineering. 2025; 7(11):371. https://doi.org/10.3390/agriengineering7110371

Chicago/Turabian StyleCruz, Norlan Leonel Ramos, Luara Patrícia Lopes Morais, Daniel Valadão Silva, José Francismar de Medeiros, Frederico Ribeiro do Carmo, Antônio Gustavo de Luna Souto, Luiz Fernando de Sousa Antunes, Eulene Francisco da Silva, Simone Cristina Freitas de Carvalho, Palloma Vitória Carlos de Oliveira, and et al. 2025. "Innovative Use of Ultra-Low-Frequency Dynamic Electronic Impulses for Sustainable Performance of Drippers Applying Produced Water" AgriEngineering 7, no. 11: 371. https://doi.org/10.3390/agriengineering7110371

APA StyleCruz, N. L. R., Morais, L. P. L., Silva, D. V., Medeiros, J. F. d., Carmo, F. R. d., Souto, A. G. d. L., Antunes, L. F. d. S., Silva, E. F. d., Carvalho, S. C. F. d., Oliveira, P. V. C. d., Melo, S. B. d., Muniz, G. L., Reges, L. B. L., & Batista, R. O. (2025). Innovative Use of Ultra-Low-Frequency Dynamic Electronic Impulses for Sustainable Performance of Drippers Applying Produced Water. AgriEngineering, 7(11), 371. https://doi.org/10.3390/agriengineering7110371