Theoretical Study of a Pneumatic Device for Precise Application of Mineral Fertilizers by an Agro-Robot

Abstract

1. Introduction

2. Materials and Methods

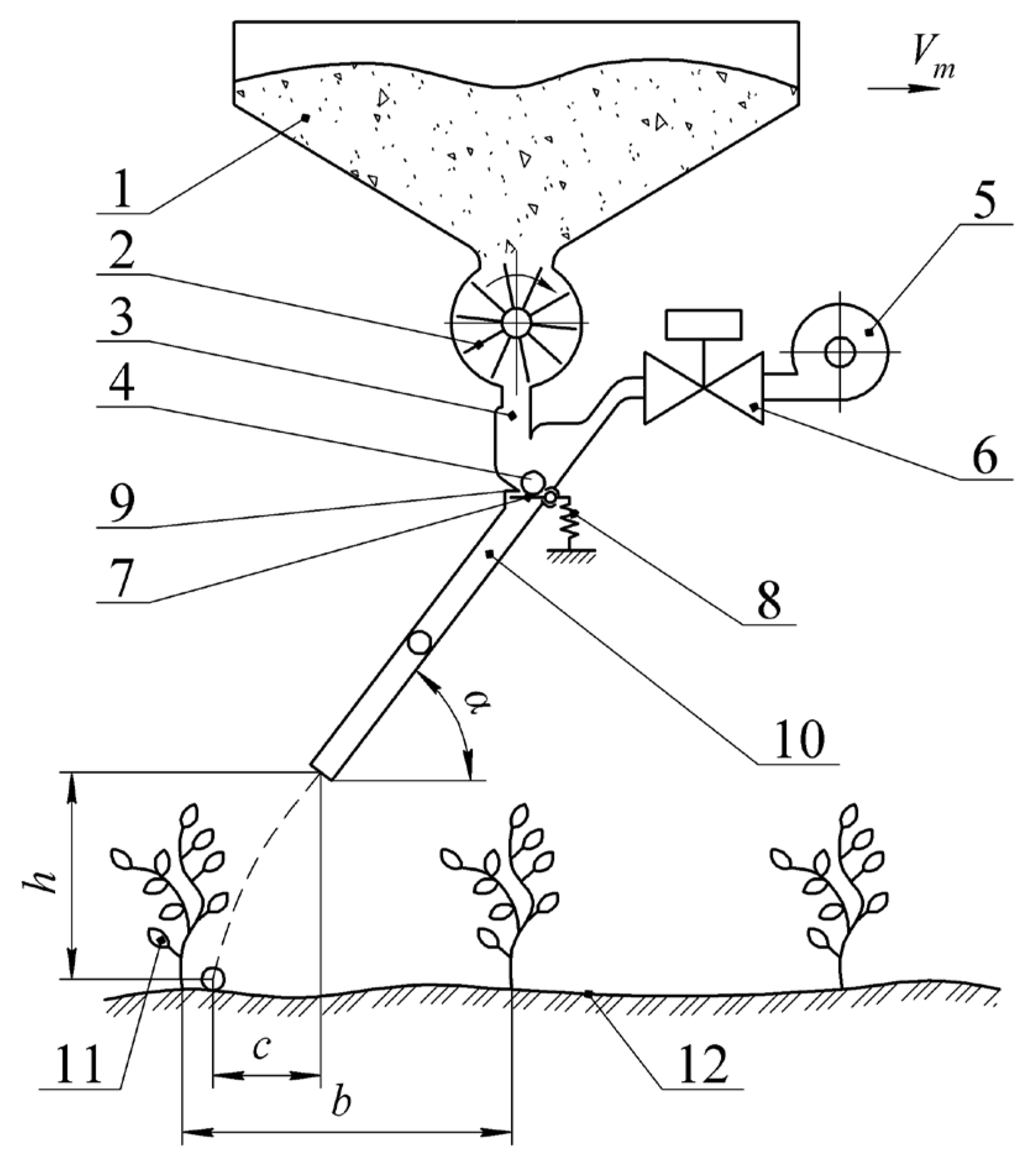

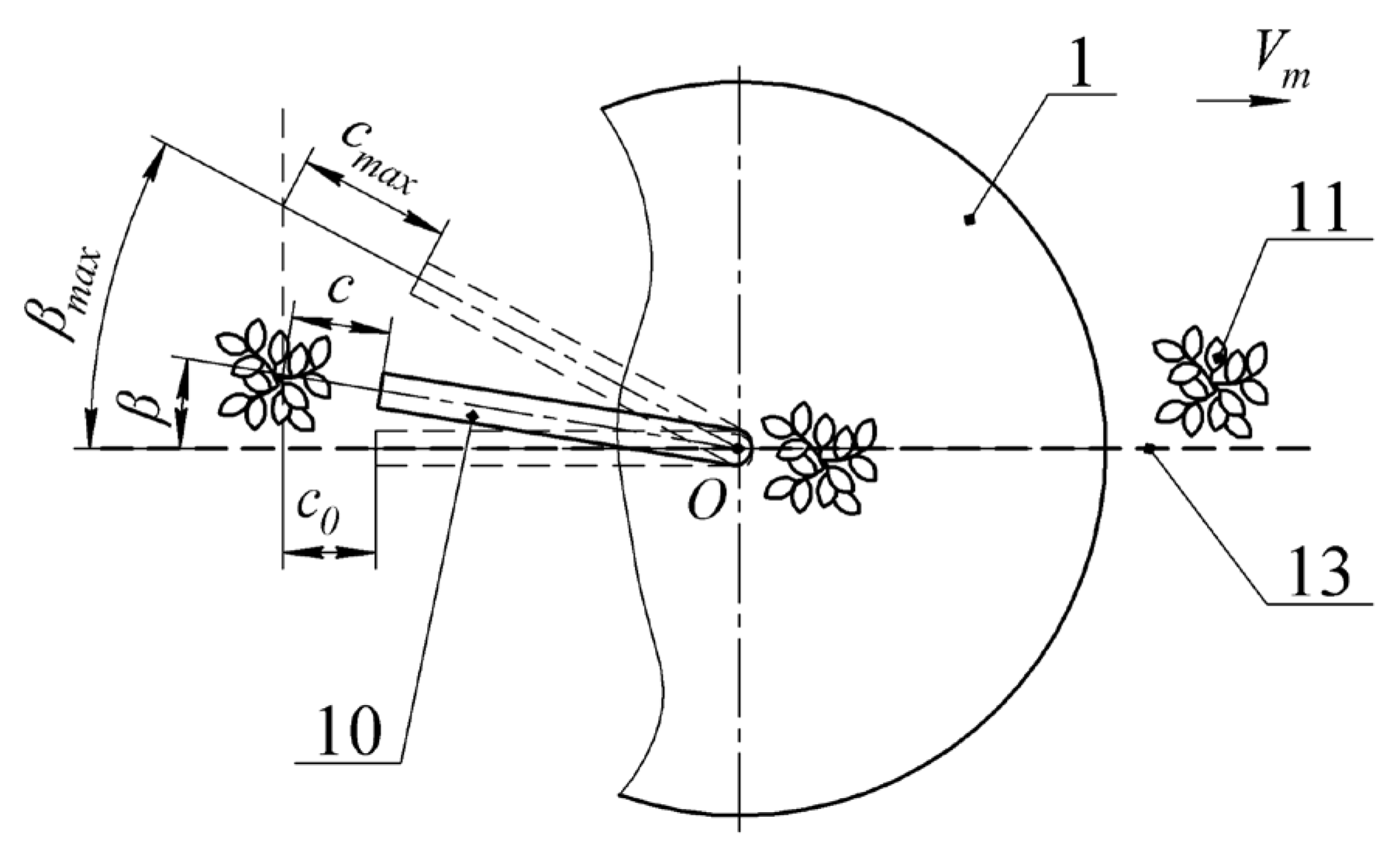

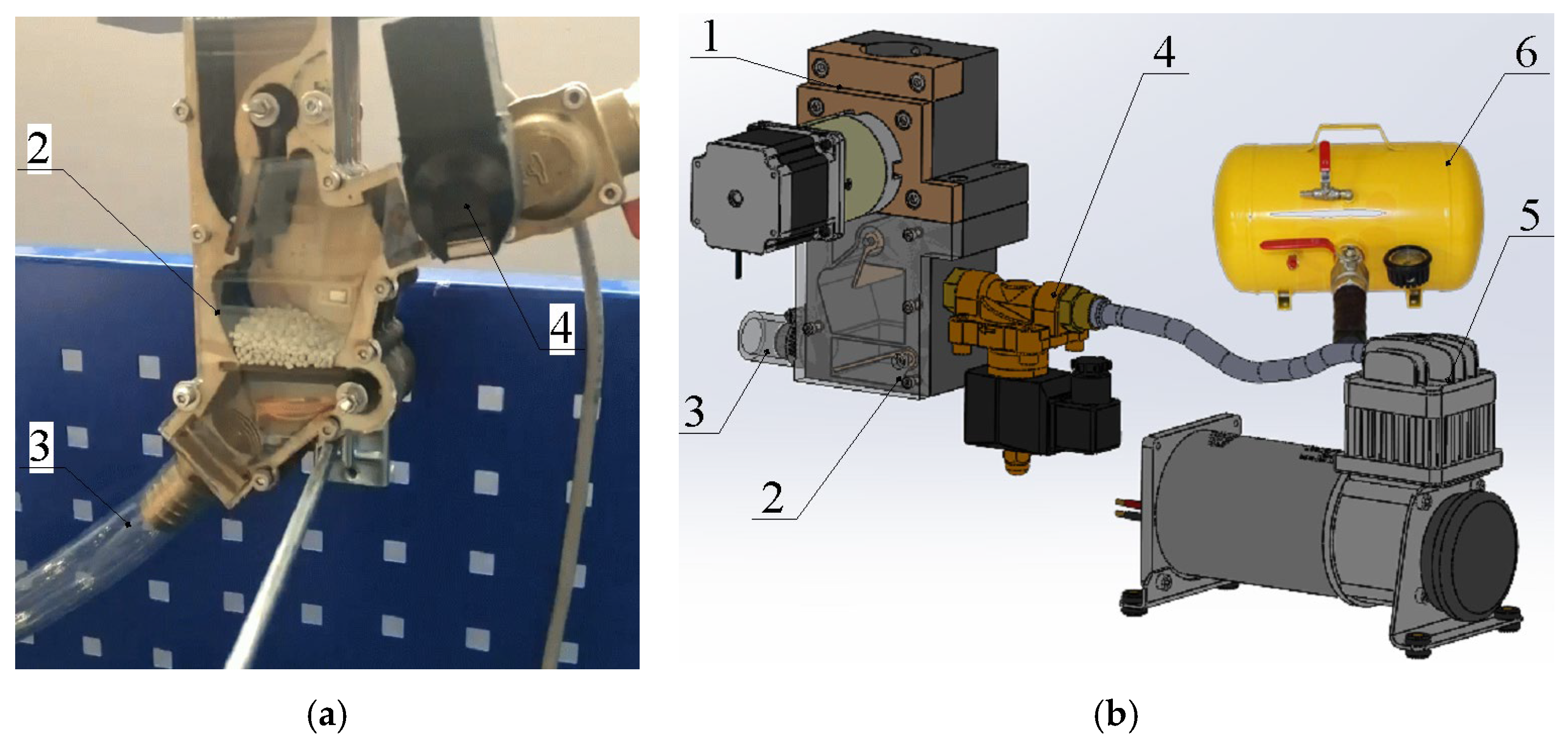

2.1. Device Description

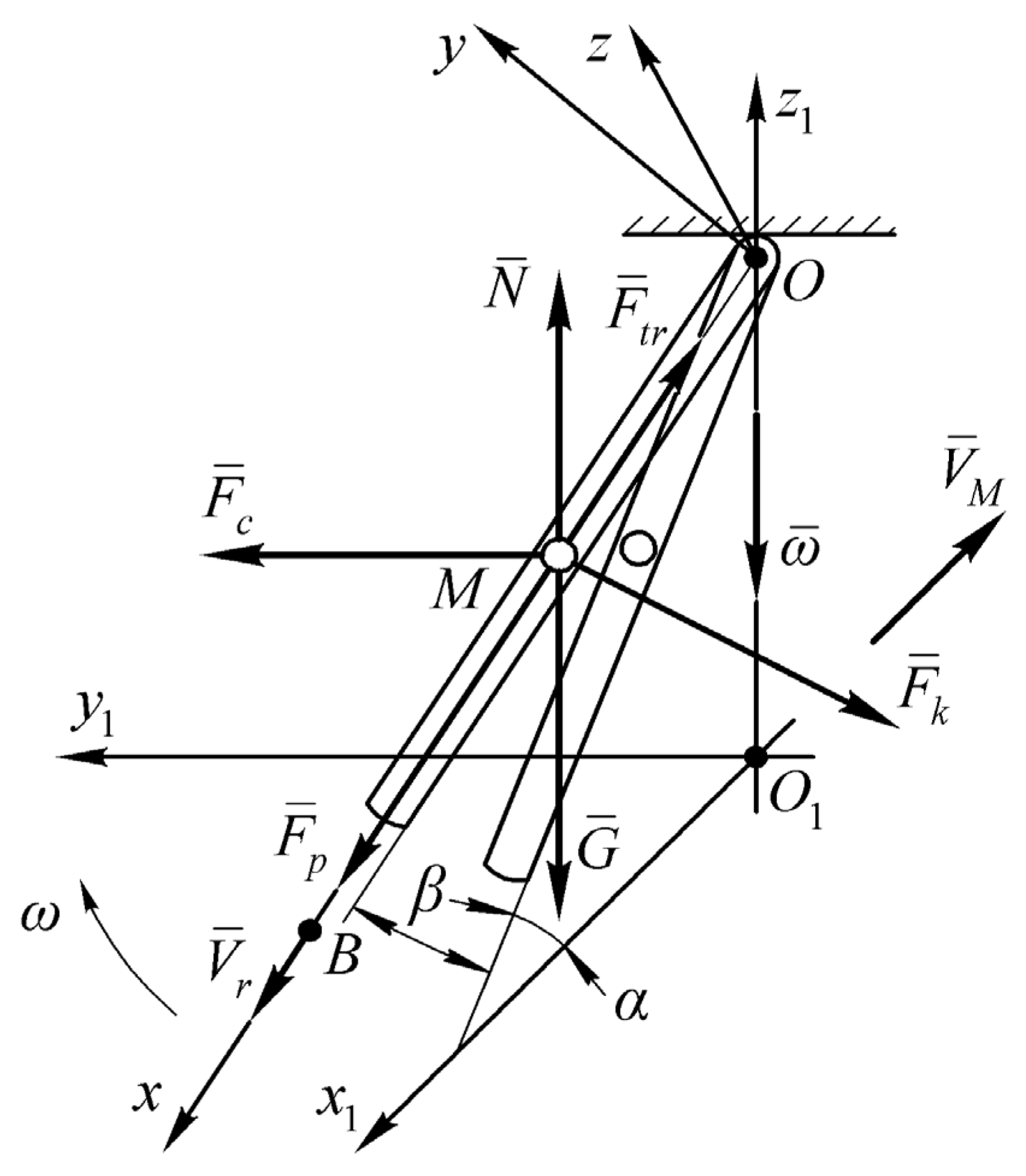

2.2. Mathematical Model

2.3. Mathematical Model Analyzes

2.4. Methodology for Verifying the Adequacy of Theoretical Studies

3. Results and Discussion

4. Limitations and Future Work

5. Conclusions

- As a result of the conducted research, a new design solution for a device for precise mineral fertilizer application to the root zone of plants using a farming robot has been proposed. This contributes to the implementation of precision farming technology and enables the efficient and accurate application of fertilizers to specific points in the field.

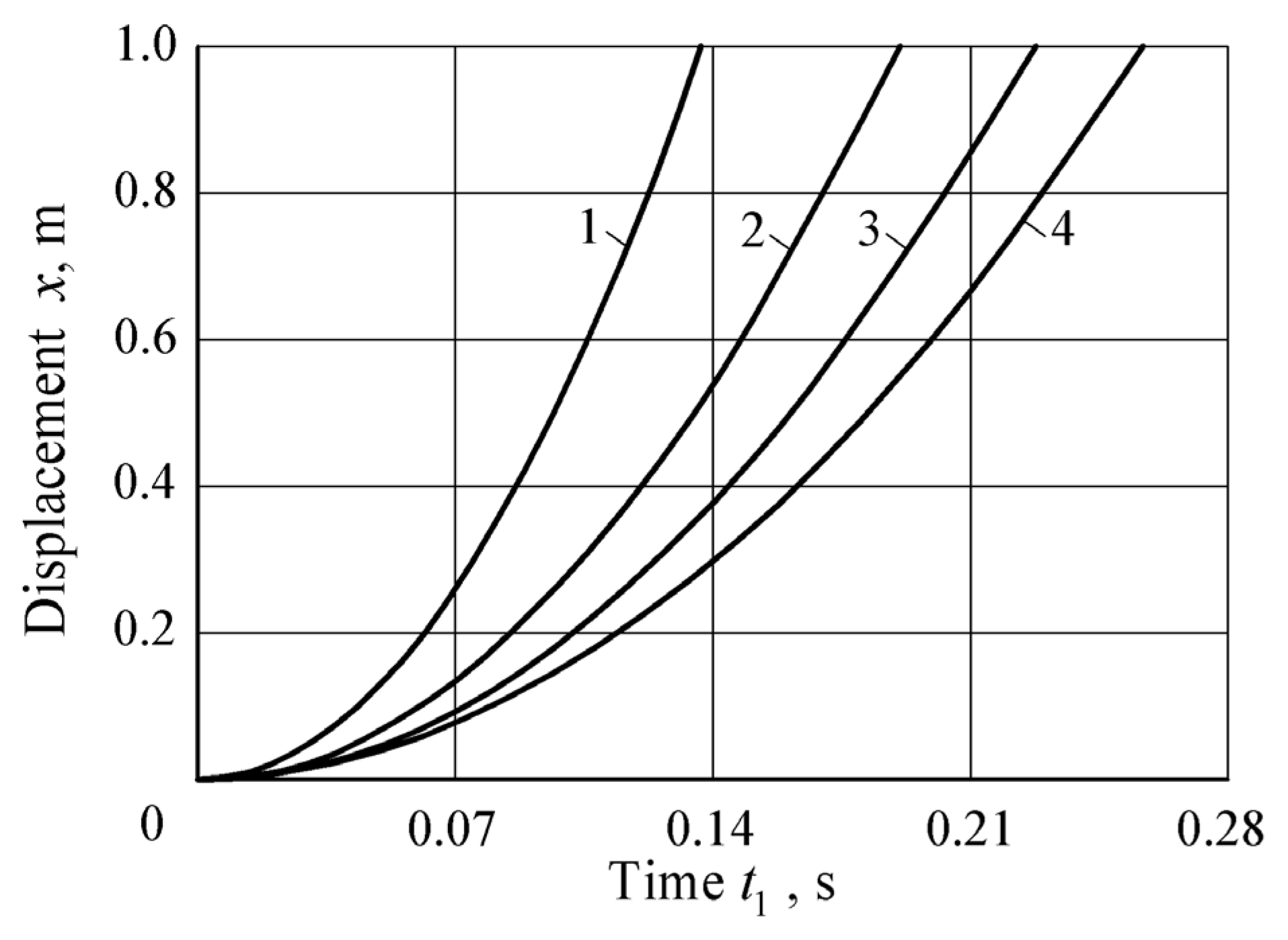

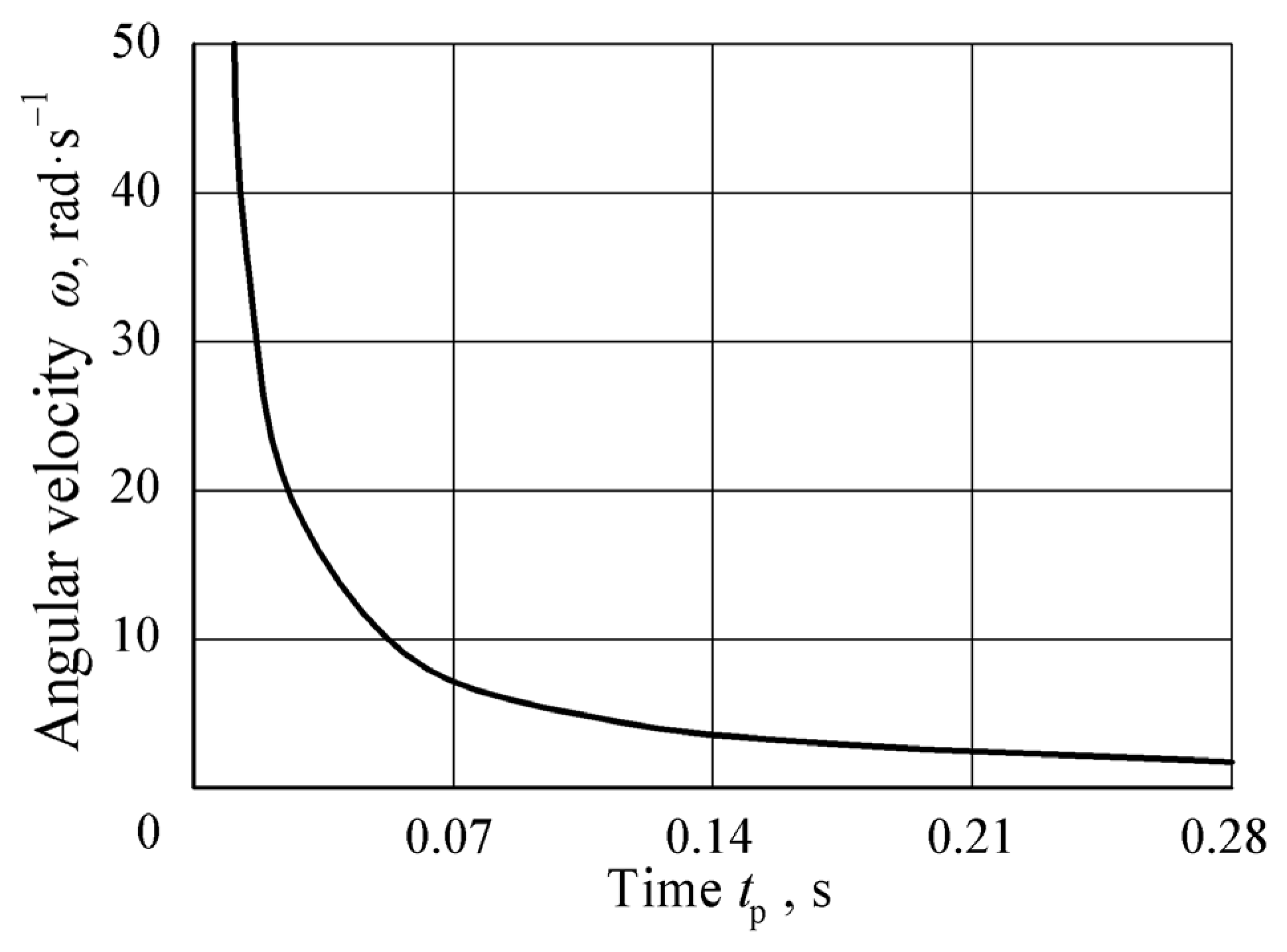

- It was established that the synchronization of the fertilizer particle ejection time from the applicator tube and the angle of its rotation towards the plant is a key factor in ensuring the accuracy of fertilizer application during the continuous movement of the farming robot. To improve the accuracy of this process, graphical dependencies of the fertilizer dose movement over time were constructed and analyzed for different masses ( = 0.01–0.04 kg) and airflow pressure forces ( = 1–3 N).

- Experimental comparison confirmed the adequacy of the developed model for predicting the transit time of fertilizer portions through the tube. For a mass of 0.01 kg, the relative error was approximately 3%, and for 0.04 kg, about 9.5%, which is explained by the increased number of particles and the fixation of the exit moment of the last granule. The obtained results confirm the reliability of the model and provide a basis for its further refinement using DEM modeling. Future DEM simulations will evaluate particle–wall collisions, granule breakage, and airflow interactions to further optimize application precision and efficiency.

- The conducted research creates prerequisites for minimizing energy costs through the efficient use of compressed air, as well as for reducing fertilizer losses and improving their effectiveness.

- The research results have practical significance for agricultural engineering, as the proposed design contributes to the integration of robotic systems into the agricultural sector.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hofstee, J.W.; Huisman, W. Handling and spreading of fertilizers part 1: Physical properties of fertilizer in relation to particle motion. J. Agric. Eng. Res. 1990, 47, 213–234. [Google Scholar] [CrossRef]

- Cerović, V.; Petrovic, D.; Radojevic, R.; Barac, S.; Vukovic, A. On the fertilizer particle motion along the vane of a centrifugal spreader disc assuming pure sliding of the particle. J. Agric. Sci. 2018, 63, 83–97. [Google Scholar] [CrossRef]

- Cointault, F.; Sarrazin, P.; Paindavoine, M. Measurement of the Motion of Fertilizer Particles Leaving a Centrifugal Spreader Using a Fast Imaging System. Precis. Agric. 2003, 4, 279–295. [Google Scholar] [CrossRef]

- Cool, S.; Pieters, J.; Mertens, C.K.; Hijazi, B.; Vangeyte, J. A simulation of the influence of spinning on the ballistic flight of spherical fertilizer grains. Comput. Electron. Agric. 2014, 105, 121–131. [Google Scholar]

- Cool, R.S.; Pieters, G.J.; Acker, V.J.; Van Den Bulcke, J.; Mertens, C.K.; Nuyttens, R.E.D.; Van De Gucht, C.T.; Vangeyte, J. Determining the effect of wind on the ballistic flight of fertilizer particles. Biosyst. Eng. 2016, 151, 425–434. [Google Scholar]

- Adamchuk, V.; Bulgakov, V.; Beloev, H.; Korenko, M. Mineral Fertilization Theory and Working Tools of Fertilizer Spreading Machines; Professor Marin Drinov Publishing House of Bulgarian Academy of Sciences: Sofia, Bulgaria, 2017; p. 165. [Google Scholar]

- Aphale, A.; Bolander, N.; Park, J.; Shaw, L.; Svec, J.; Wassgren, C. Granular fertiliser particle dynamics on and off a spinner spreader. Biosyst. Eng. 2003, 85, 319–329. [Google Scholar] [CrossRef]

- Villette, S.; Cointault, F.; Piron, E.; Chopinet, B.; Paindavoine, M. Simple imaging system to measure velocity and improve the quality of fertilizer spreading in agriculture. J. Electron. Imaging 2008, 17, 31–109. [Google Scholar] [CrossRef]

- Adamchuk, V.; Ratushnyi, V. Pneumatic Seeder for Subsoil Application of Mineral Fertilizers. Patent of Ukraine UA117844, 10 October 2018. (In Ukrainian). [Google Scholar]

- Lillerand, T.; Virro, I.; Maksarov, V.; Olt, J. Granulometric Parameters of Solid Blueberry Fertilizers and Their Suitability for Precision Fertilization. Agronomy 2021, 11, 1576. [Google Scholar] [CrossRef]

- Virro, I.; Arak, M.; Maksarov, V.; Olt, J. Precision fertilisation technologies for berry plantation. Agron. Res. 2020, 18, 2797–2810. [Google Scholar]

- Dawson, C.J.; Hilton, J. Fertilizer availability in a resource-limited world: Production and recycling of nitrogen and phosphorus. Food Policy 2011, 36, 14–22. [Google Scholar]

- Adamchuk, V.; Vozjik, Y. Method of Pneumatic Transportation for Application of Granular Mineral Fertilizers. Patent of Ukraine UA146033, 20 January 2021. (In Ukrainian). [Google Scholar]

- Hatem, A.E.M. Simulation of Rotary Spreader. Ph.D. Thesis, Agricultural Engineering Department, Mansoura University, Mansoura, Egypt, 2013. [Google Scholar]

- Bulgakov, V.; Adamchuk, V.; Arak, M.; Petrychenko, I.; Olt, J. Theoretical research into the motion of combined fertilizing and sowing tractor-implement unit. Agron. Res. 2020, 5, 1498–1516. [Google Scholar]

- Bulgakov, V.; Adamchuk, V.; Kuvachov, V.; Shymko, L.; Olt, J. A theoretical and experimental study of combined agricultural gantry unit with a mineral fertilizer spreader. Agraarteadus J. Agric. Sci. 2020, 31, 139–146. [Google Scholar]

- Bulgakov, V.; Adamchuk, O.; Pascuzzi, S.; Santoro, F.; Olt, J. Research into engineering and operating parameters of mineral fertilizer application machine with new fertilizer spreading tools. Agron. Res. 2021, 19, 676–686. [Google Scholar]

- Tijskens, E.; Van Liederkerke, P.; Ramon, H. Modelling to aid assessment of fertiliser handling and spreading characteristics. In Proceedings of the International Fertiliser Society, London, UK, 14 April 2005. No. 553. [Google Scholar]

- Krklješ, D.; Kitić, G.; Panić, M.; Petes, C.; Filipović, V.; Stefanović, D.; Obrenović, N.; Lalić, M.; Marko, O. Agrobot Gari, a multimodal robotic solution for blueberry production automation. Comput. Electron. Agric. 2025, 237 Pt B, 110626. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, W.; Jin, C.; Feng, Y.; Liu, G.; Hu, Y. Research Progress on Key Mechanical Components of the Pneumatic Centralized Fertilizer Discharge System. Appl. Sci. 2024, 14, 3884. [Google Scholar] [CrossRef]

- Wang, L.; Gao, J.; Qureshi, W.A. Evolution and Application of Precision Fertilizer: A Review. Agronomy 2025, 15, 1939. [Google Scholar] [CrossRef]

- Zaman, A.G.M.; Roy, K.; Olt, J. Normalized Difference Vegetation Index Prediction for Blueberry Plant Health from RGB Images: A Clustering and Deep Learning Approach. AgriEngineering 2024, 6, 4831–4850. [Google Scholar] [CrossRef]

- Beer, P.F.; Johnston, E.R., Jr.; Mazurek, F.D.; Cornwell, J.P.; Elliot, E.R. Vectormechanics for Engineers—Statics and Dynamics, 9th ed.; The McGraw-Hill Companies, Inc.: New York, NY, USA, 2010. [Google Scholar]

- Hibbeler, C.R. Engineering Mechanics–Dynamics, 12th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Backhaus, K. Multivariate Analysemethoden, 12th ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1–575. [Google Scholar]

- Van Liedekerke, P.; Tijskens, E.; Ramon, H. Discrete element simulations of the influence of fertilizer physical properties on the spread pattern from spinning disc spreaders. Biosyst. Eng. 2009, 102, 392–405. [Google Scholar] [CrossRef]

- Lv, H.; Yu, J.; Fu, H. Simulation of the operation of a fertilizer spreader based on an outer groove wheel using a discrete element method. Math. Comput. Model. 2013, 58, 842–851. [Google Scholar] [CrossRef]

- Xiong, D.; Wu, M.; Xie, W.; Liu, R.; Luo, H. Design and Experimental Study of the General Mechanical Pneumatic Combined Seed Metering Device. Appl. Sci. 2021, 11, 7223. [Google Scholar] [CrossRef]

- Bangura, K.; Gong, H.; Deng, R.; Tao, M.; Chuang, L.; Cai, Y.; Liao, K.; Liu, J.; Qi, L. Simulation analysis of fertilizer discharge process using the Discrete Element Method (DEM). PLoS ONE 2020, 15, e0235872. [Google Scholar] [CrossRef]

- Zhong, W.; Zhao, X.; Liu, F.; Bai, H.; Dong, W.; Hu, H.; Kong, X. Design and Experiment of Precision Seed Metering Device for Flow Adsorption of Quinoa Seeds. Agriculture 2024, 14, 434. [Google Scholar] [CrossRef]

- Valero, C.; Krus, A.; Cruz Ulloa, C.; Barrientos, A.; Ramírez-Montoro, J.J.; del Cerro, J.; Guillén, P. Single Plant Fertilization Using a Robotic Platform in an Organic Cropping Environment. Agronomy 2022, 12, 1339. [Google Scholar] [CrossRef]

- Cheng, B.; He, R.; Xu, Y.; Zhang, X. Simulation Analysis and Test of Pneumatic Distribution Fertilizer Discharge System. Agronomy 2022, 12, 2282. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lillerand, T.; Liivapuu, O.; Ihnatiev, Y.; Olt, J. Theoretical Study of a Pneumatic Device for Precise Application of Mineral Fertilizers by an Agro-Robot. AgriEngineering 2025, 7, 320. https://doi.org/10.3390/agriengineering7100320

Lillerand T, Liivapuu O, Ihnatiev Y, Olt J. Theoretical Study of a Pneumatic Device for Precise Application of Mineral Fertilizers by an Agro-Robot. AgriEngineering. 2025; 7(10):320. https://doi.org/10.3390/agriengineering7100320

Chicago/Turabian StyleLillerand, Tormi, Olga Liivapuu, Yevhen Ihnatiev, and Jüri Olt. 2025. "Theoretical Study of a Pneumatic Device for Precise Application of Mineral Fertilizers by an Agro-Robot" AgriEngineering 7, no. 10: 320. https://doi.org/10.3390/agriengineering7100320

APA StyleLillerand, T., Liivapuu, O., Ihnatiev, Y., & Olt, J. (2025). Theoretical Study of a Pneumatic Device for Precise Application of Mineral Fertilizers by an Agro-Robot. AgriEngineering, 7(10), 320. https://doi.org/10.3390/agriengineering7100320