1. Introduction

Leafy vegetables are recognised for their nutritional importance, medicinal properties, and cultural significance, making them integral to the traditional diets and cultural practices of many societies [

1,

2,

3]. They are an important element of meals, providing critical vitamins A, B, and C, as well as minerals such as iron and calcium, and key bioactive compounds [

4]. Increased understanding of the health benefits of leafy green vegetables in developing nations is currently driving up demand and consumption [

4]. Coriander, like other green vegetables, is rich in vitamins C, A (β-carotene), B1, B2, protein, fat, minerals, fiber, carbohydrates, water, calcium, phosphorus, iron, carotene, thiamine, riboflavin, sodium, potassium, and oxalic acid [

5]. In addition to fatty and essential oils, coriander seeds contain 21.5% carbs, 32.5% fiber, 14% protein, 11.1% moisture, and 4.3% minerals [

6]. Coriander has a long history as a traditional medicine [

7] and aromatic plant in the Apiaceae family [

8]. The leaves have historically been used for their herbal properties when added to meals [

9], as a flavouring element [

10], and have been demonstrated to stimulate urine output and discharge while decreasing fever [

11]. In the Indian subcontinent, they are often used in boiling products and soups and are added at the end of cooking [

12,

13].

Climate change has a significant impact on agricultural yields [

14]. It is primarily caused by pollutants produced by internal combustion engines, which are widely used in agricultural machinery [

15] and account for approximately 95% of the energy consumed for propulsion [

16]. Agriculture and land-use change account for approximately one-quarter of total global greenhouse gas emissions [

17]. The Paris Agreement established global warming objectives of 2 °C and 1.5 °C by 2100, which have been supported academically by recently published IPCC assessments [

14]. Environmental issues arising from agricultural activities are becoming increasingly important worldwide as ecological sustainability is prioritised [

18,

19]. The global emphasis on reducing greenhouse gas (GHG) emissions has led to increased interest in climate-smart agricultural approaches, such as regenerative, digital, and regulated atmosphere farming systems [

20]. Electrification can help make automobiles more efficient and create new opportunities for work optimisation [

21]. Electric vehicle adoption is mainly driven by environmental concerns and government initiatives [

22]. As agricultural machinery is critical to achieving an adequate supply of food for a growing population, changes in common agricultural engineering thinking are required for the development of new farm equipment that can outperform conventional ones in terms of environmental harm, performance, productivity and safety [

23].

Agriculture is one of the major occupations in India and a significant contributor to the country’s economy [

24]. The rising cost and declining availability of manual labour [

25] have accelerated automation in nearly all processes of modern agriculture, except for the harvesting of leafy vegetables. Traditional harvesting is a labor-intensive and expensive procedure; farmers often spend 25 to 30 percent of crop production costs on harvesting [

26]. At present, in India, this crop is harvested manually with a sickle in the majority of smallholding farms [

27]. During harvesting, 77% of participants experienced discomfort in the lower back, shoulders, neck, hands, wrists, and fingers, with age being the primary cause of pain in all body locations except the neck and shoulders [

28]. Mechanisation in agriculture now encompasses the majority of farming activities, aiming to eliminate physically demanding work, enhance job scheduling, and increase production [

29]. Agriculture has evolved from a labour-intensive operation to one that is heavily mechanised over the last decade. Numerous technological developments, including harvesting equipment, sensors, and drones, have been combined to improve information collection and transmission, enhancing harvest efficiency and allowing for more precise and rapid decision-making [

30]. Automation in agriculture is necessary for producing food, fiber, and fuel to a rapidly rising population, especially since harvesting is an essential component in farming [

31]. Taking the above debate into account, a self-propelled battery-powered coriander harvester was developed that has been ergonomically built to benefit growers. This harvester aims to reduce human labour, eliminate post-harvest losses, increase production, mitigate risks associated with adverse weather conditions, lower total harvesting expenses, and facilitate early crop sales. In this study, the performance of the designed coriander harvester is analysed with an emphasis on harvesting efficiency, crop loss, and possible economic effects on coriander farming. The design of the coriander harvester is based on the study of various existing types of electrified harvesters. Okafor (2013) [

32] designed and built a self-propelled lawn mower powered by a battery-powered DC motor, using pulleys for blade operation and speed management, a 12 V alternator in the charging unit, and a lift mechanism for adjusting cut height, achieving an 89.55% cutting efficiency with 0.24 kN of human effort during evaluation. Amrutesh et al. (2014) [

33] developed a solar-powered lawn cutter featuring a scotch yoke mechanism, which included a 50 W solar panel (12 V), a 12 V battery (7.2 Ah), a solar charger, a circuit breaker, and blades. Kiran et al. (2017) [

34] shaped a battery-powered reaper for harvesting rice and wheat in Bangladesh, with a 1100 W, 48 V BLDC motor with 450 rpm to drive the cutting mechanism and traction wheels, powered by four 12 V batteries, a cutting width of 0.6 m, an average field capacity of 0.13 ha/h at 2.17 km/h, and a cutting efficiency of 98.24%. Mathan et al. (2019) [

35] developed a power weeder into an electrically driven system by replacing the 5.5 hp gasoline engine with a 2 hp, 1500 W DC motor powered by batteries, therefore reducing pollution.

2. Materials and Methods

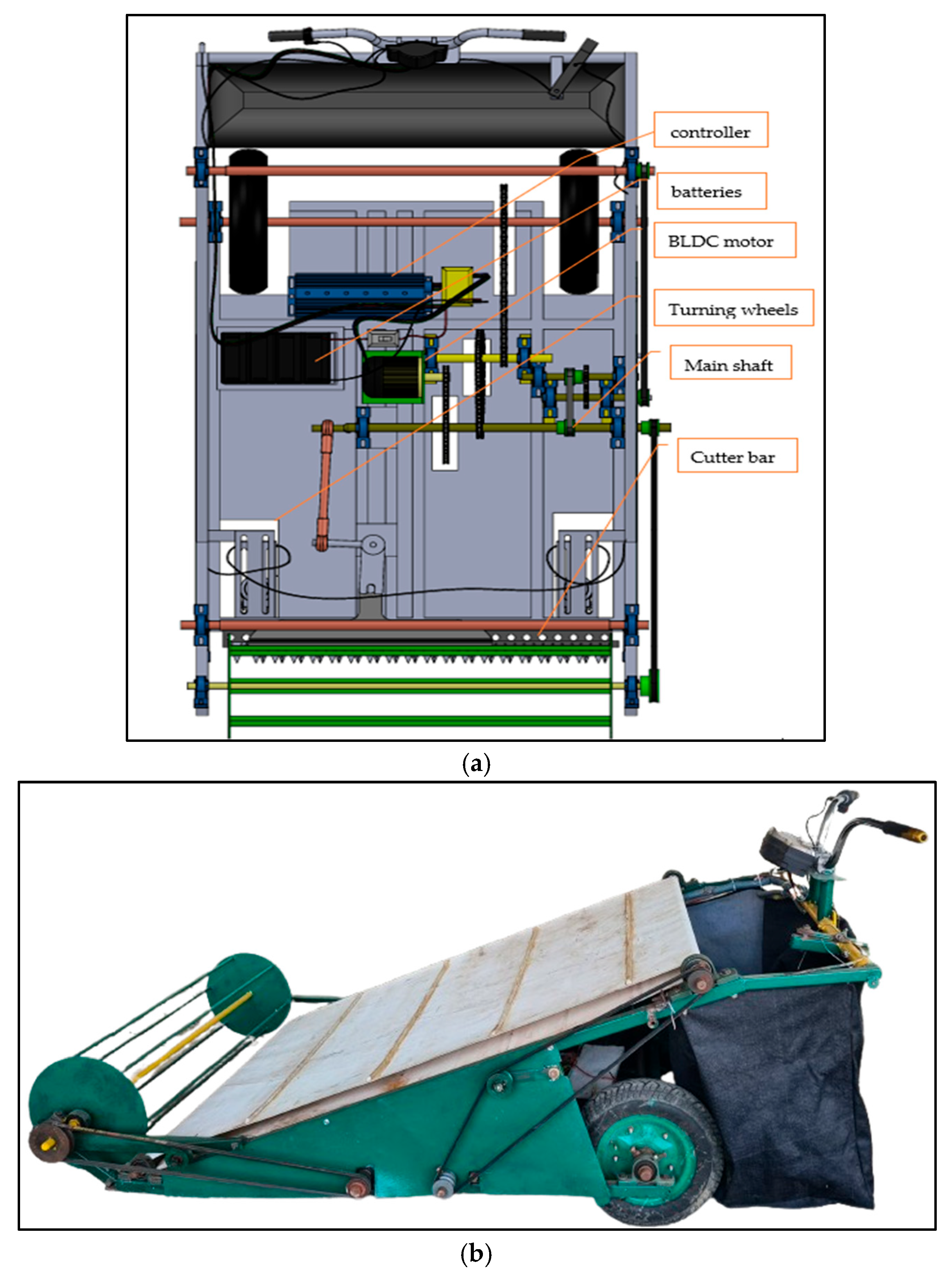

While offering a description of the necessary stages, it is essential to note that building such a coriander harvester takes engineering abilities as well as mechanical and electrical knowledge. We designed the harvester’s mechanical construction, which includes the cutting mechanism (Diamond, India brand), BLDC motor (CY, Qingdao, China), batteries (Exide, Kolkata, India), MCB (Legrand, Limoges, France), controller (CY, Qingdao, China), conveyor system (Kyungin, Incheon, Republic of Korea), and wheels. We used lightweight and sturdy materials to keep the weight under control and ensure optimal harvesting. Two pneumatic wheels were mounted on the back edges of the frame’s two corners. Two caster wheels with sliding adjustment were installed on the front side of the frame to adjust the cutting height and provide support. The BLDC motor was positioned three-quarters of its length from the front end of the frame and one-quarter of the length from the right side of the body. The controller, connection box, and battery stand were positioned between the rear wheels. The MCB was linked to the frame by a 50.8 mm bright bar, 150 mm in length, which was adjusted using a nut and bolt on the right side of the motor. The battery stands measured 560 mm in length, 76.2 mm in height, and 190 mm in breadth, and it was mounted on the back side of the frame, between the rear wheels. The controller was attached to a 300 mm long, one-inch light bar using a nut and bolt adjustment on the motor’s backside. The junction box was also fixed, along with the controller. A voltage display was inserted between the handles. The shaft linked to the motor was insufficiently sized; thus, a 13-tooth sprocket was welded to the BLDC motor shaft using a 24 mm inner diameter tubing. The primary shaft was mounted on pedestal bearings 500 mm from the front end of the frame. This primary shaft receives power from the BLDC motor via a 50-tooth sprocket connected by a 69-link chain; thus, the sprocket rotates four times less than the BLDC motor shaft. The main shaft was equipped with two pulleys, a connecting rod, and a small sprocket secured by grab screws to convey power to all harvester elements. An angle bar measuring 1050 mm was welded to the front portion of the structure to connect to the cutter unit, which receives power from the connecting rod. The reel was linked to the frame at the front end at a 135° angle. For conveyor belt support, two square pipes, each 1500 mm in length, were welded at the frame’s two front corners at an angle of 18°. Two square pipes, up to 457 mm in diameter, were welded to the conveyor belt to hold the pipes in place and secure the collecting bag. A 38 mm circular pipe was utilised to connect the collecting bag’s support pipes. According to the operator, the handle was fastened to the circular pipe using a flexible connection that allowed for height modification. We considered ergonomics while designing the harvester to make it more user-friendly and easier to operate. We assembled all of the components according to the design, ensuring that all connections and interfaces function properly. It works by automating the cutting and collection of crops, reducing the requirement for manual labour and expediting the harvesting procedure. The harvester was powered by a portable battery pack, eliminating the need for additional power or fuel. The battery gives electricity to the harvester’s motor and other electrical components. First, switch the ignition starting to the right before activating the MCB. After turning on the ignition starter, the display screen displays the voltage level. Once the ignition starter is turned on, all of the harvester’s components, including the cutting unit, backside wheels, conveyor unit, reel unit, and other elements, are activated by the action of the throttle.

Figure 1a shows the internal view of the harvester, while

Figure 1b presents the designed prototype view.

2.1. Theoretical Power Calculation for the Working of Self-Propelled Battery-Operated Leafy Vegetable Harvester

The power requirement of the developed harvester plays the most crucial role in its viability. The most important consideration was the human average walking speed, which is approximately 0.7–0.8 m/s, as specified in the design of the harvester [

36]. The self-propelled, battery-operated leafy vegetable harvester comprises four key functional units: the cutting blade unit, reel unit, conveyor system, and power train, including the back wheels. The power source for these components is batteries. Therefore, there is a need for individual power calculations for each functional unit, which are clearly explained in

Table 1 and following sections for the total power requirement of the harvester.

The power required for cutting a crop with a cutter bar can be estimated at 0.513 hp per meter of cutter length [

37].

So, the required power for the cutter bar was 0.513 hp = 383 W.

The velocity of the reel should be higher than the machine’s forward speed [

38].

where

N = Rotational speed, rpm;

V = Velocity, m/s;

F = Force, N;

The velocity of the conveyor should be higher than the harvester speed to avoid clogging of cut leaves. The calculation was based on the total mass to be lifted by the conveyor and the self-mass of the system involved in the conveyor’s transmission system.

In the case of the conveyor, the material was lifted at a 20-degree angle horizontally. It was considered that the leaves’ mass might reach the conveyor.

Now, the peripheral speed of the conveyor was taken as 1.25 times the harvester’s average running speed.

where

P = Power required, hp;

M = Power required, kg;

S = Peripheral speed, m/s.

Let the requirement of the number of revolutions of the wheel per minute for an average walking speed = 35 rpm.

where

P = Power, W;

N = Number of revolutions, rpm;

T = Torque, N-m.

From

Table 1, the total theoretical power requirement to run the harvester is 864 W. Thus, a 900-watt BLDC motor was easily available in the market. So, it was selected as the power source of the harvester.

2.2. Description of the Experimental Area

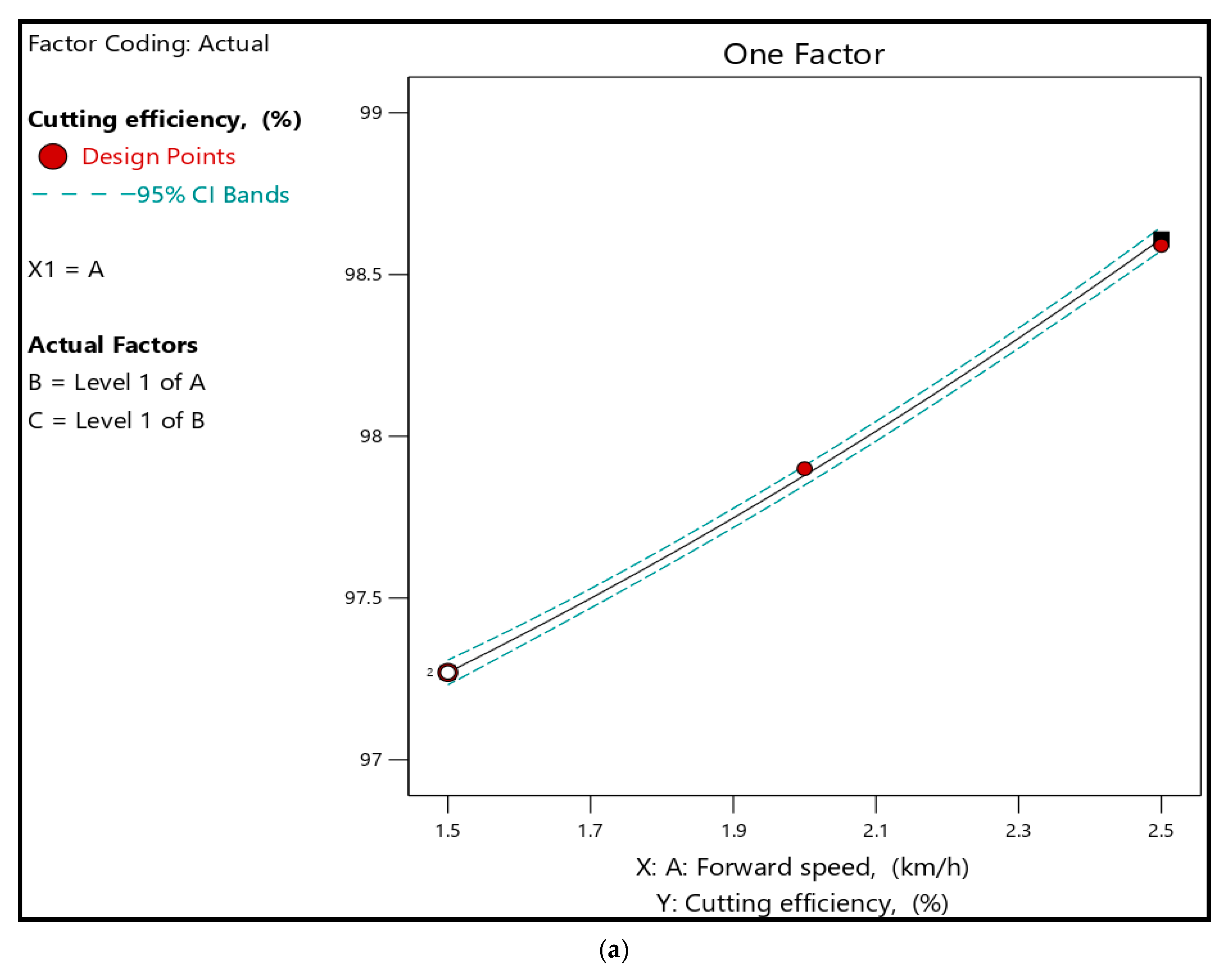

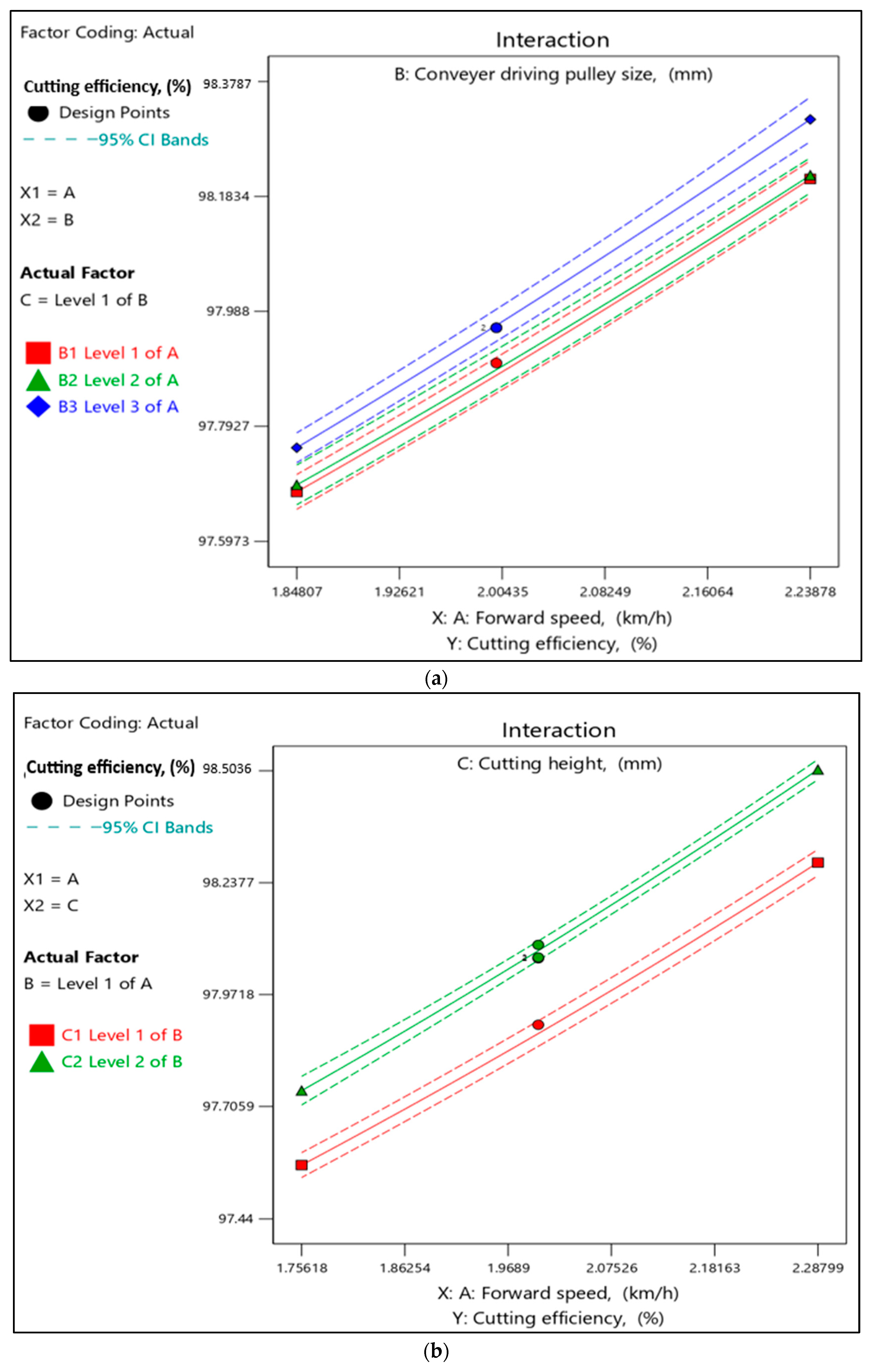

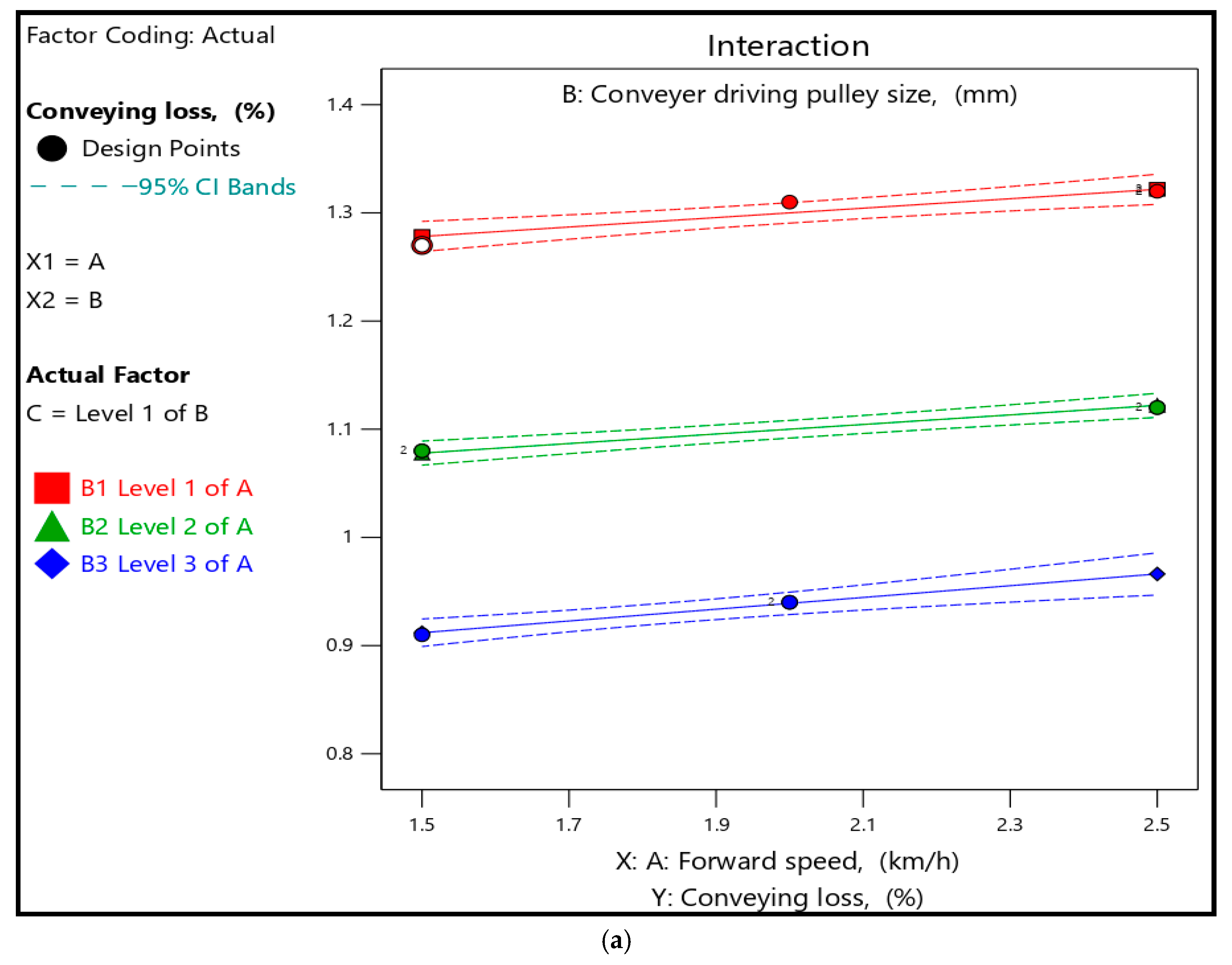

The study used a preset experimental setup. Each experiment was run for each possible combination of factors (

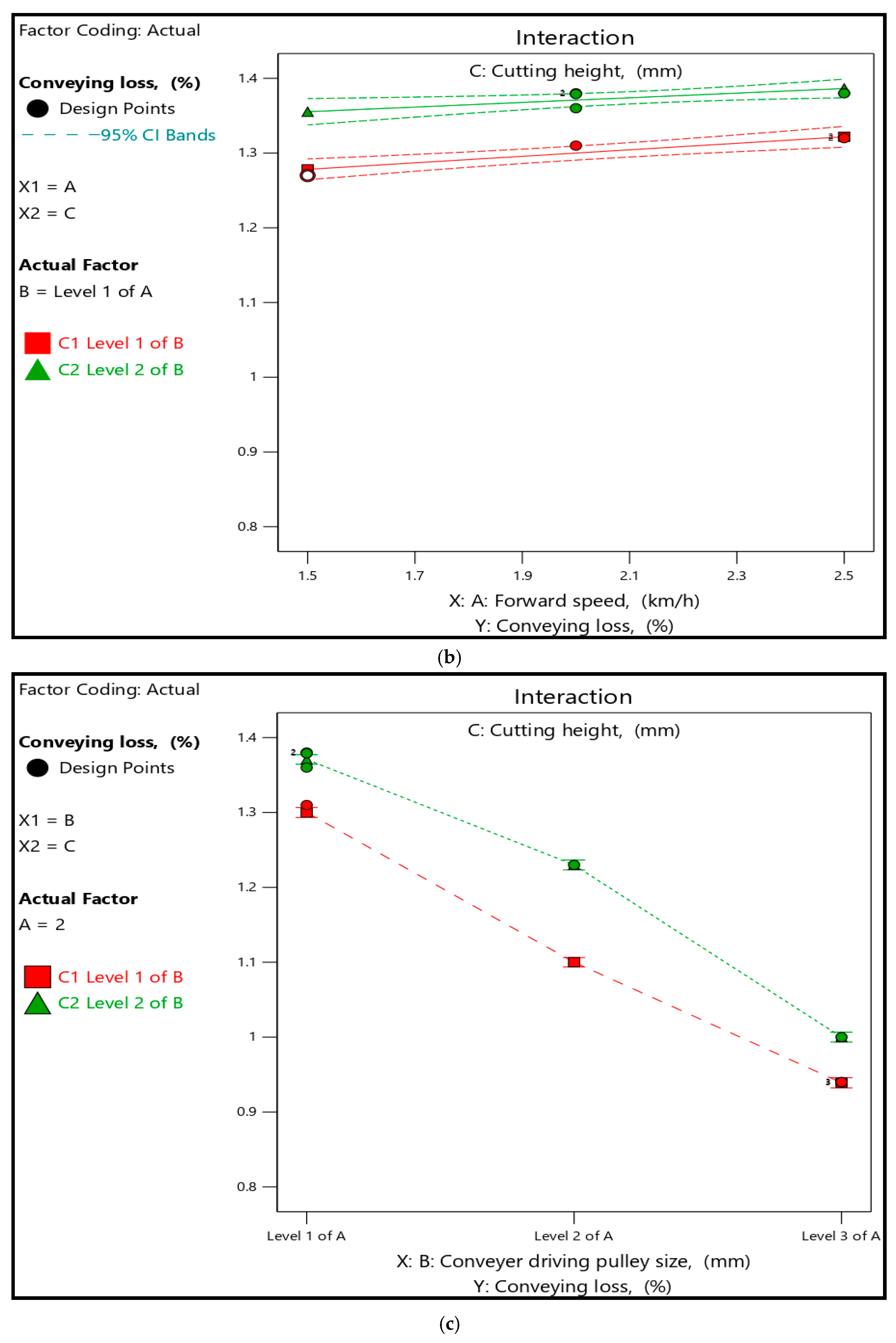

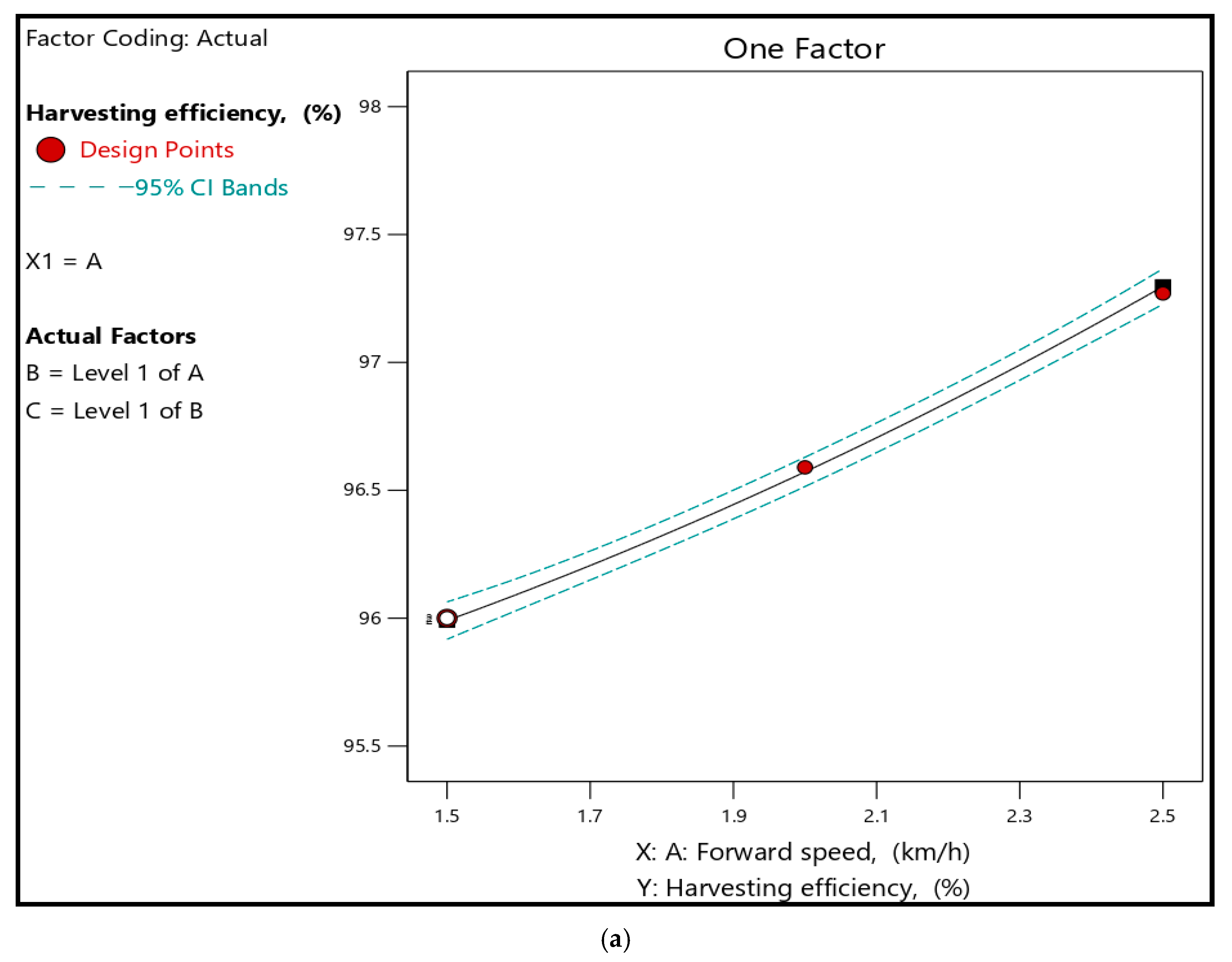

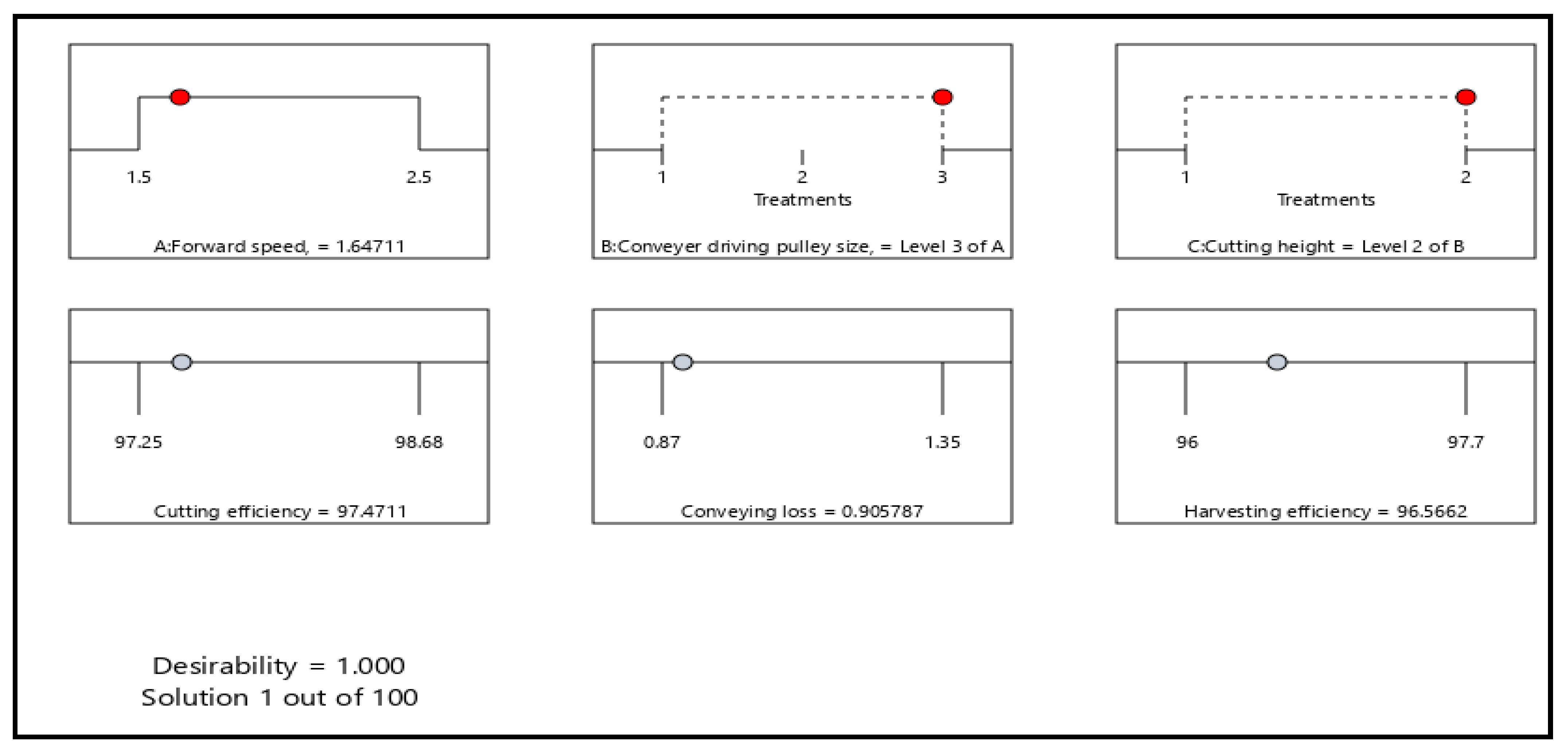

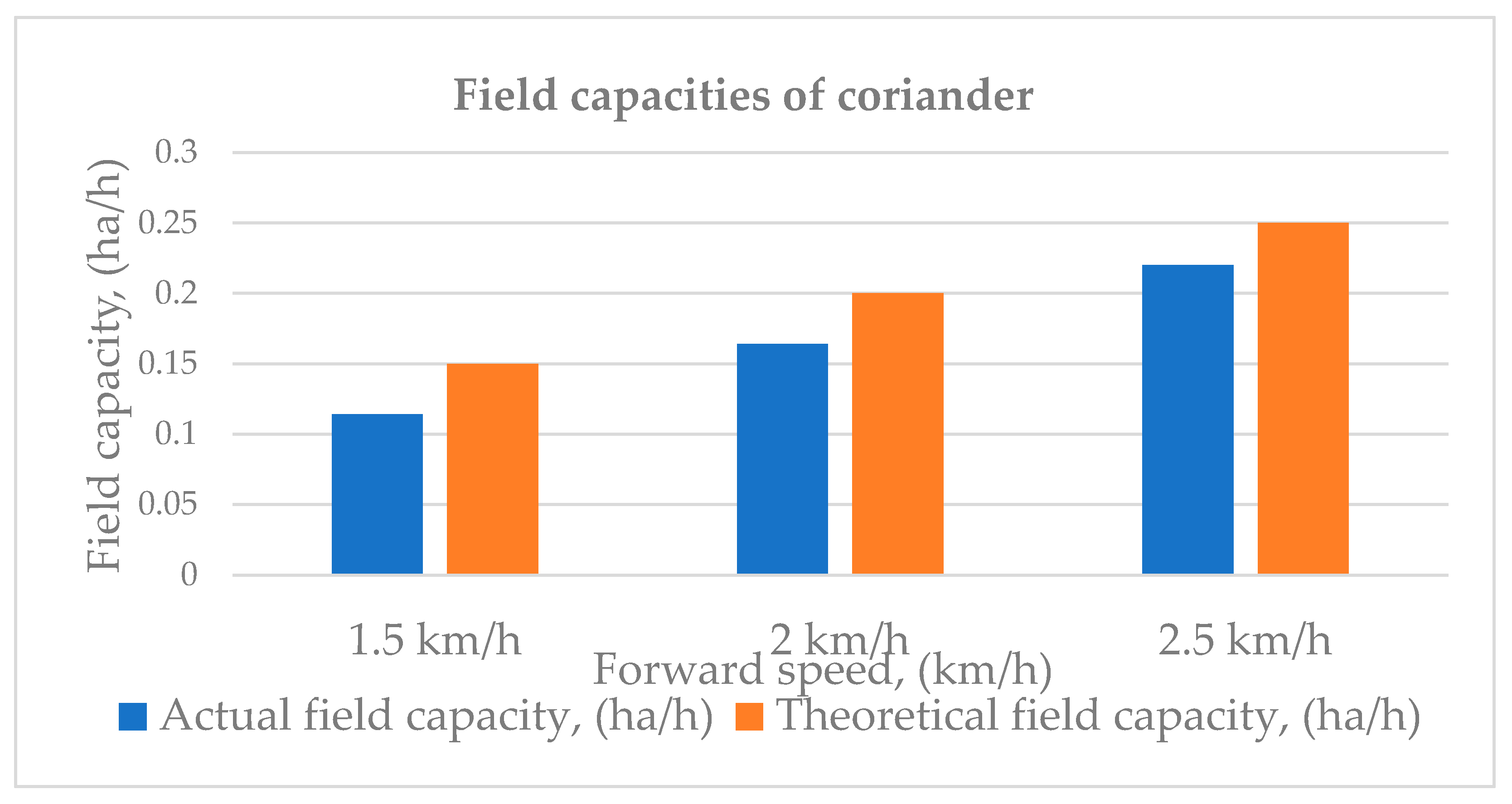

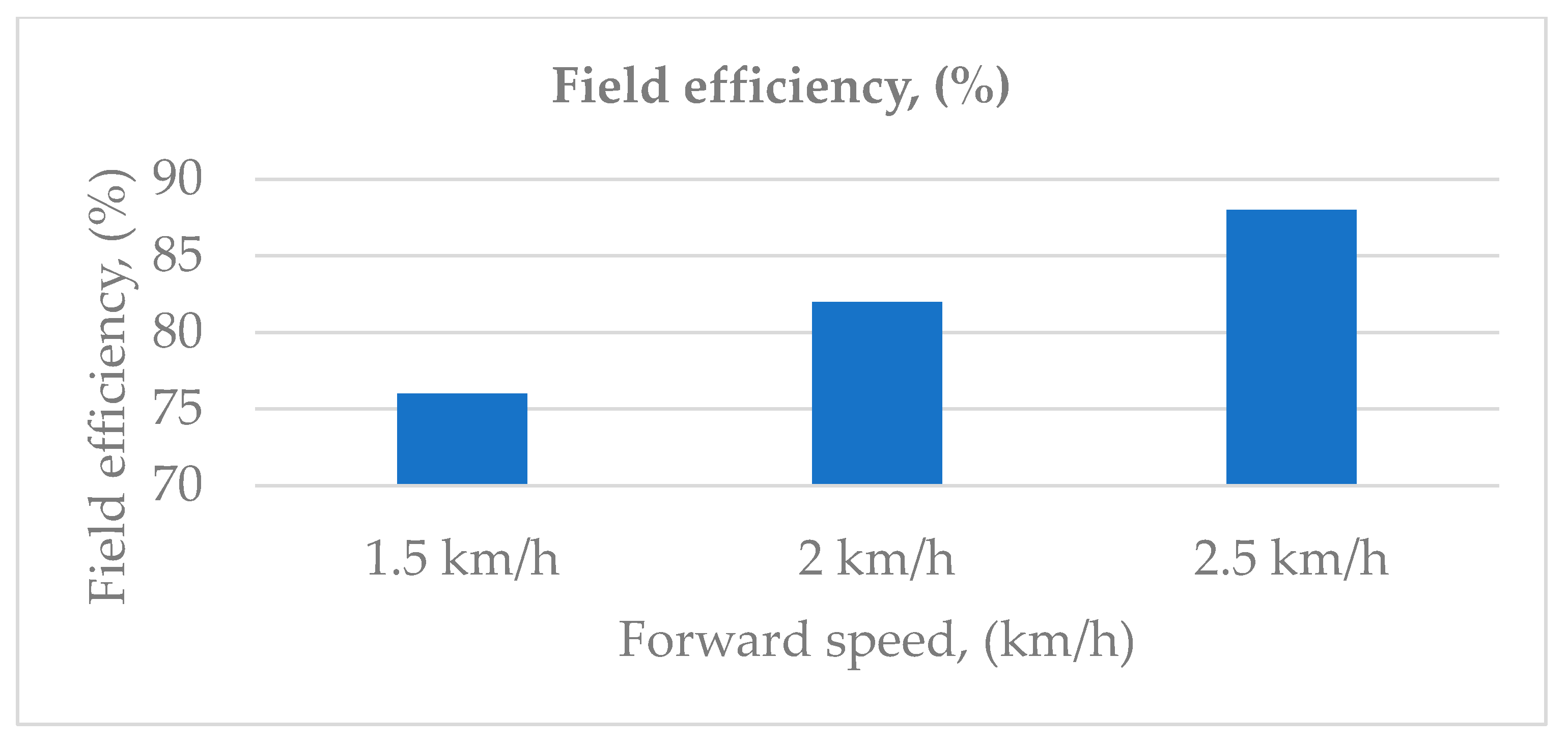

Table 2). The experiment included selected combinations of independent variables, each of which had three replications. Three levels of forward speed—1.5 km/h, 2 km/h and 2.5 km/h—were chosen based on statistical design. These speeds were achieved by varying the conveyor drive pulley sizes to 50.8 mm, 76.2 mm, and 101.6 mm, as well as the cutting heights to 50 mm and 75 mm for the selected crops. After each experiment, characteristics such as cutting efficiency, conveyance loss and harvesting efficiency, were measured.

2.3. Experimental Design

The experimental setup shown in

Figure 2 used a factorial randomised block design of trials. The experimental data for all dependent factors were statistically analysed using the Design-Expert software v23.1.

Based on the selected parameters, subsequent treatment combinations were taken.

The total quantity of possible treatment combinations in the field is 3 × 3 × 2 = 18.

Number of repetitions = 3.

So, the total quantity of events is 18 × 3 = 54.

Net plot dimensions: 54 × 3 = 162 m2.

Overall dimensions of all the plots = 162 m2.

The crop was cultivated on the farm using specified agronomical procedures. The sum of all areas of the coriander crop seeded was 180 m2, including all boundaries.

2.4. Physical Properties of Soil

To investigate the soil’s physical characteristics, soil samples were collected consistently from various locations across the field. Prior to harvesting, the soil parameters, including bulk density [

39] (Kushwaha et al., 2015), moisture content [

40], and cone index, were assessed in the field at various soil depths.

2.5. Field Evaluation of Self-Propelled Battery-Operated Coriander Harvester

The performance of the self-propelled battery-powered coriander harvester was tested in the field using essential measures such as adequate field capacity, theoretical field capacity [

41], field efficiency [

41] and cutting efficiency (2017) [

34]. Furthermore, conveyance loss (%) and harvesting efficiency (%) were used to evaluate overall performance. All trials were conducted according to the experimental plan to ensure uniform data collection and analysis.