Comparative Performance of a Sprayer Rate Controller and Pulse Width Modulation (PWM) Systems for Site-Specific Pesticide Applications

Abstract

1. Introduction

2. Materials and Methods

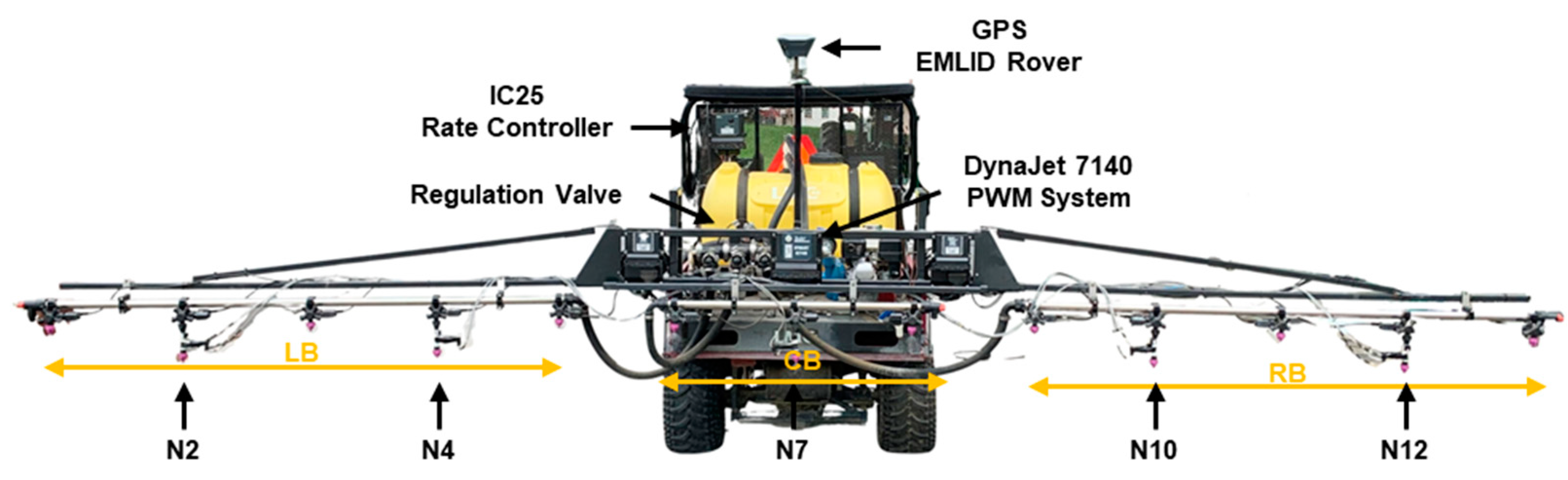

2.1. Application Equipment

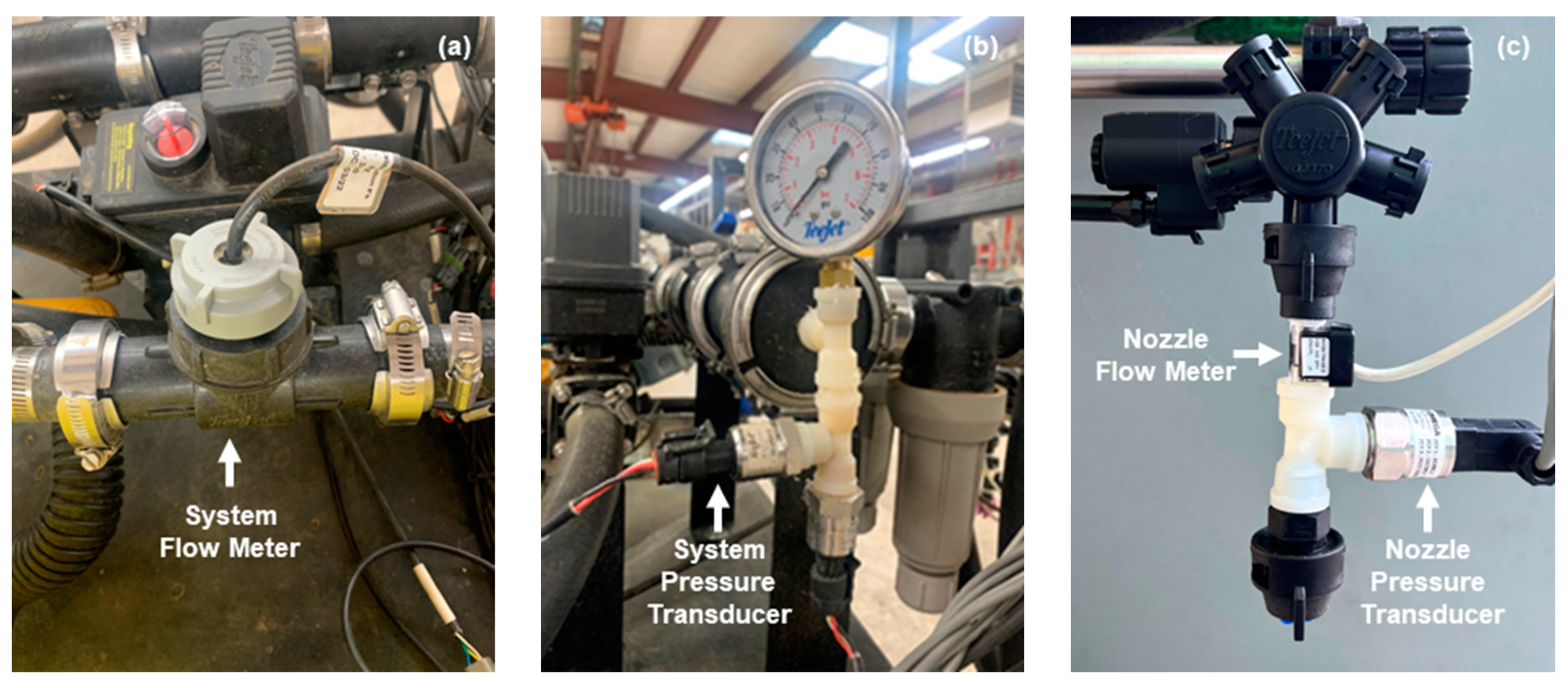

2.2. Instrumentation and Data Acquisition

2.3. Study Design and Data Collection

2.4. Data Analysis

3. Results and Discussion

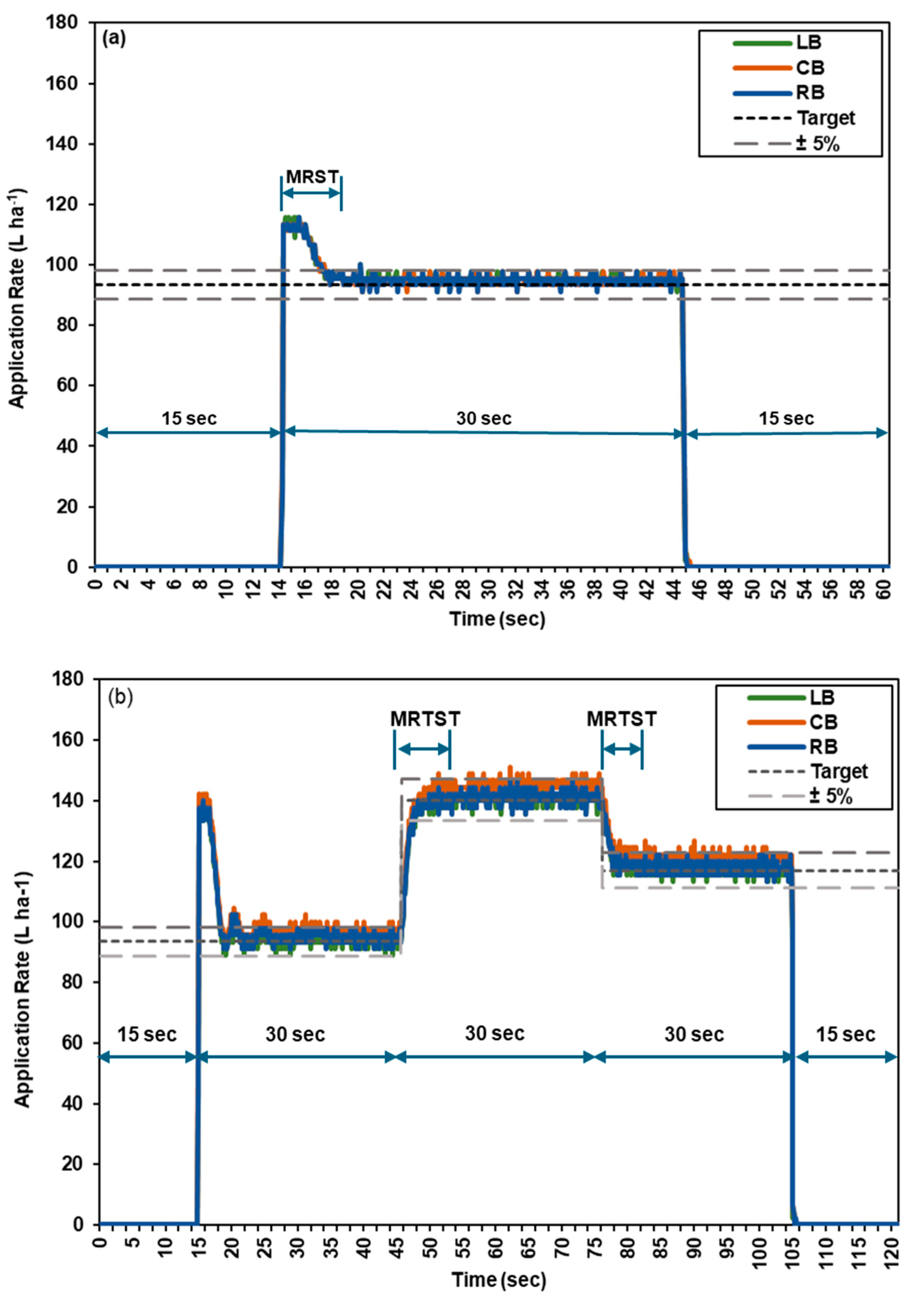

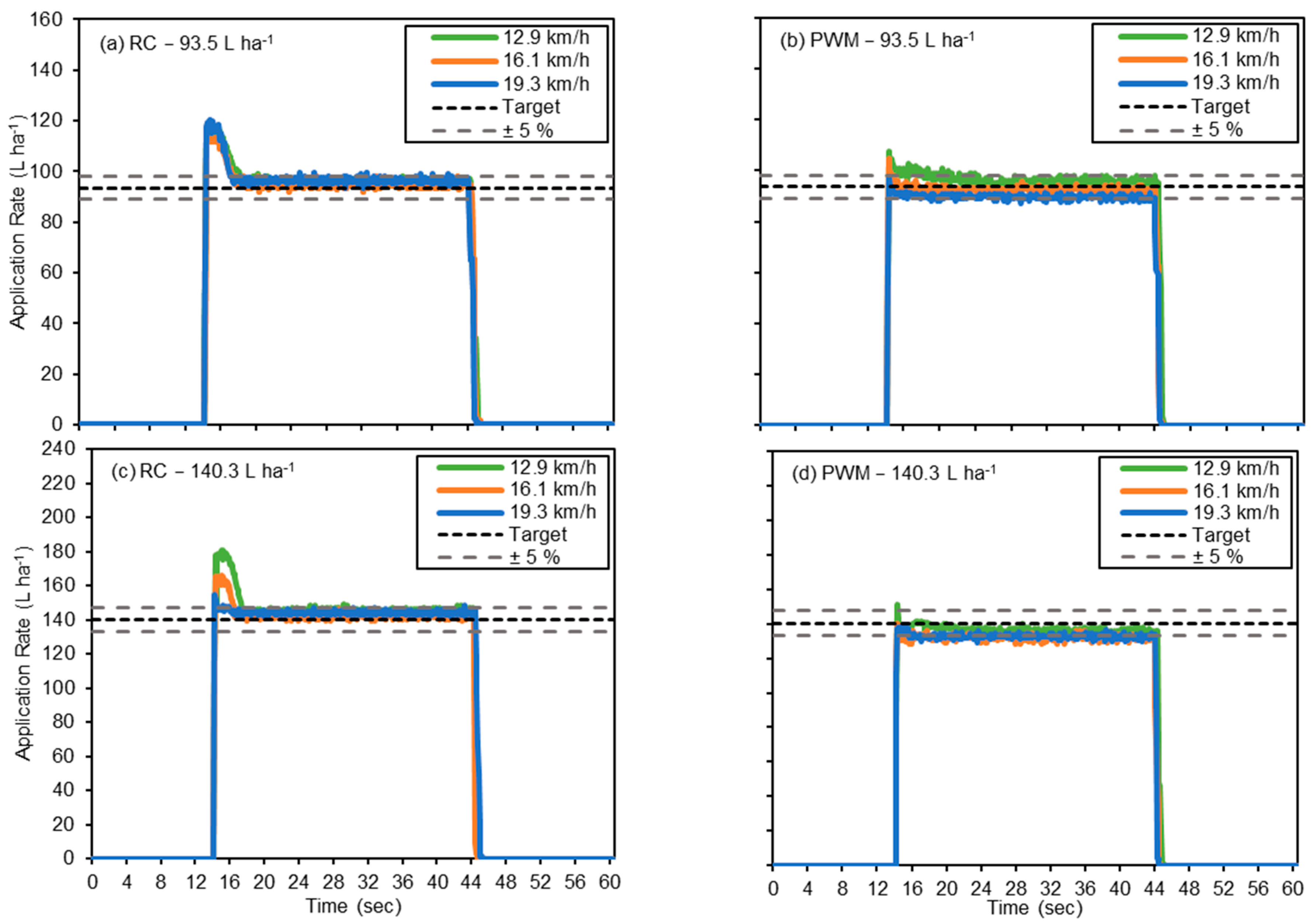

3.1. Single-Rate Site-Specific (SRSS) Tests

3.2. Variable-Rate Site-Specific (VRSS) Application Tests

4. Research Implications

5. Conclusions and Future Work

- Single-Rate Site-Specific Applications:

- The PWM system demonstrated a consistently lower mean rate stabilization time in achieving the target rates across all simulated speeds compared to the RC system.

- The RC system exhibited an increased mean rate stabilization time at lower simulated ground speeds.

- Both systems showed improved performance (reduced rate stabilization time) at higher target rates or increased simulated ground speeds.

- Variable-Rate Site-Specific Applications:

- The PWM system demonstrated a lower mean rate transition time across both rate increments and decrements across all simulated speeds.

- The RC system exhibited a higher rate transition time for rate decrements and a lower transition time for rate increments.

- Both systems demonstrated improved performance (reduced rate transition and stabilization times) at increased simulated ground speeds.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Pesticides Use and Trade—1990–2022; FAOSTAT Analytical Briefs, No. 89; FAO: Rome, Italy, 2024. [Google Scholar] [CrossRef]

- Swanton, C.J.; Shrestha, A.; Chandler, K.; Deen, W. An Economic Assessment of Weed Control Strategies in No-Till Glyphosate-Resistant Soybean (Glycine Max). Weed Technol. 2000, 14, 755–763. [Google Scholar] [CrossRef]

- Luck, J.D.; Zandonadi, R.S.; Luck, B.D.; Shearer, S.A. Reducing Pesticide Over-Application with Map-Based Automatic Boom Section Control on Agricultural Sprayers. Trans. ASABE 2010, 53, 685–690. [Google Scholar] [CrossRef]

- Sharda, A.; Fulton, J.P.; McDonald, T.P.; Zech, W.C.; Darr, M.J.; Brodbeck, C.J. Real-Time Pressure and Flow Dynamics Due to Boom Section and Individual Nozzle Control on Agricultural Sprayers. Trans. ASABE 2010, 53, 1363–1371. [Google Scholar] [CrossRef]

- Fabula, J.; Sharda, A.; Kang, Q.; Flippo, D. Nozzle Flow Rate, Pressure Drop, and Response Time of Pulse Width Modulation (PWM) Nozzle Control Systems. Trans. ASABE 2021, 64, 1519–1532. [Google Scholar] [CrossRef]

- Reyes, J.F.; Esquivel, W.; Cifuentes, D.; Ortega, R. Field Testing of an Automatic Control System for Variable Rate Fertilizer Application. Comput. Electron. Agric. 2015, 113, 260–265. [Google Scholar] [CrossRef]

- Yang, C.; Everitt, J.H.; Bradford, J.M. Comparisons of Uniform and Variable Rate Nitrogen and Phosphorus Fertilizer Applications for Grain Sorghum. Trans. ASAE 2001, 44, 201–209. [Google Scholar] [CrossRef]

- Langley, R.L.; Mort, S.A. Human Exposures to Pesticides in the United States. J. Agromed. 2012, 17, 300–315. [Google Scholar] [CrossRef]

- Bora, G.C.; Schrock, M.D.; Oard, D.L.; Grimm, J. Performance of a Pulse Width Modulated (PWM) Single to Multifold Outlet System for Variable-rate Anhydrous Ammonia Application. Trans. ASABE 2011, 54, 397–402. [Google Scholar] [CrossRef]

- Huang, H.; Deng, J.; Lan, Y.; Yang, A.; Deng, X.; Wen, S.; Zhang, H.; Zhang, Y. Accurate Weed Mapping and Prescription Map Generation Based on Fully Convolutional Networks Using UAV Imagery. Sensors 2018, 18, 3299. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, L.; Shi, W. Effects of Operating Parameters for Dynamic PWM Variable Spray System on Spray Distribution Uniformity. IFAC-PapersOnLine 2016, 49, 216–220. [Google Scholar] [CrossRef]

- Fabula, J.V.; Sharda, A. Field Evaluation of Turn Compensation Feature of Pulse Width Modulation (PWM) Equipped Agricultural Sprayer. In Proceedings of the 2021 ASABE Annual International Virtual Meeting, Online, 12–16 July 2021; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2021. [Google Scholar]

- Luck, J.D.; Zandonadi, R.S.; Luck, B.D.; Shearer, S.A. Effects of Field Shape and Size on Application Errors Using Manual and Automatic Boom Section Control on a Self-Propelled Agricultural Sprayer. In Proceedings of the 2010 ASABE Annual International Meeting, Pittsburgh, PA, USA, 20–23 June 2010; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2010. [Google Scholar]

- Sharda, A.; Fulton, J.P.; McDonald, T.P.; Brodbeck, C.J. Real-Time Nozzle Flow Uniformity When Using Automatic Section Control on Agricultural Sprayers. Comput. Electron. Agric. 2011, 79, 169–179. [Google Scholar] [CrossRef]

- Villette, S.; Maillot, T.; Guillemin, J.P.; Douzals, J.P. Simulation-Aided Study of Herbicide Patch Spraying: Influence of Spraying Features and Weed Spatial Distributions. Comput. Electron. Agric. 2021, 182, 105981. [Google Scholar] [CrossRef]

- Grella, M.; Gioelli, F.; Marucco, P.; Zwertvaegher, I.; Mozzanini, E.; Mylonas, N.; Nuyttens, D.; Balsari, P. Field Assessment of a Pulse Width Modulation (PWM) Spray System Applying Different Spray Volumes: Duty Cycle and Forward Speed Effects on Vines Spray Coverage. Precis. Agric. 2021, 23, 219–252. [Google Scholar] [CrossRef]

- Sharda, A.; Luck, J.D.; Fulton, J.P.; McDonald, T.P.; Shearer, S.A. Field Application Uniformity and Accuracy of Two Rate Control Systems with Automatic Section Capabilities on Agricultural Sprayers. Precis. Agric. 2013, 14, 307–322. [Google Scholar] [CrossRef]

- Ayers, P.D.; Rogowski, S.M.; Kimble, B.L. An Investigation of Factors Affecting Sprayer Control System Performance. Appl. Eng. Agric. 1990, 6, 701–706. [Google Scholar] [CrossRef]

- Luck, J.D.; Sharda, A.; Pitla, S.K.; Fulton, J.P.; Shearer, S.A. A Case Study Concerning the Effects of Controller Response and Turning Movements on Application Rate Uniformity with a Self-Propelled Sprayer. Trans. ASABE 2011, 54, 423–431. [Google Scholar] [CrossRef]

- Butts, T.R.; Butts, L.E.; Luck, J.D.; Fritz, B.K.; Hoffmann, W.C.; Kruger, G.R. Droplet Size and Nozzle Tip Pressure from a Pulse-Width Modulation Sprayer. Biosyst. Eng. 2019, 178, 52–69. [Google Scholar] [CrossRef]

- Mangus, D.L.; Sharda, A.; Engelhardt, A.; Flippo, D.; Strasser, R.; Luck, J.D.; Griffin, T. Analyzing the Nozzle Spray Fan Pattern of an Agricultural Sprayer Using Pulse Width Modulation Technology to Generate an On-Ground Coverage Map. Trans. ASABE 2017, 60, 315–325. [Google Scholar] [CrossRef]

- Fulton, J.P.; Shearer, S.A.; Chabra, G.; Higgins, S.F. Performance Assessment and Model Development of a Variable–Rate, Spinner–Disc Fertilizer Applicator. Trans. ASAE 2001, 44, 1071–1081. [Google Scholar] [CrossRef]

- Bandyopadhyay, D.; Bhavsar, D.; Pandey, K.; Gupta, S.; Roy, A. Red Edge Index as an Indicator of Vegetation Growth and Vigor Using Hyperspectral Remote Sensing Data. Proc. Natl. Acad. Sci. India Sect. A Phys. Sci. 2017, 87, 879–888. [Google Scholar] [CrossRef]

- Castaldi, F.; Pelosi, F.; Pascucci, S.; Casa, R. Assessing the Potential of Images from Unmanned Aerial Vehicles (UAV) to Support Herbicide Patch Spraying in Maize. Precis. Agric. 2017, 18, 76–94. [Google Scholar] [CrossRef]

- See and Spray. In John Deere’s See & Spray Ultimate Cuts Chemical Use by Targeting Weeds with Precision Spraying; John Deere: Moline, IL, USA, 2024; Available online: https://www.deere.com/en/sprayers/see-spray-ultimate/ (accessed on 14 September 2023).

- Virk, S.; Meena, R. Pulse Width Modulation Technology for Agricultural Sprayers; Circular 1277; University of Georgia Cooperative Extension: Tifton, GA, USA, 2022; Available online: https://extension.uga.edu/publications/detail.html?number=C1277&title=pulse-width-modulation-technology-for-agricultural-sprayers (accessed on 14 September 2023).

- Butts, T.R.; Luck, J.D.; Fritz, B.K.; Hoffmann, W.C.; Kruger, G.R. Evaluation of Spray Pattern Uniformity Using Three Unique Analyses as Impacted by Nozzle, Pressure, and Pulse-width Modulation Duty Cycle. Pest Manag. Sci. 2019, 75, 1875–1886. [Google Scholar] [CrossRef] [PubMed]

- GopalaPillai, S.; Tian, L.; Zheng, J. Evaluation of a Flow Control System for Site-Specific Herbicide Applications. Trans. ASAE 1999, 42, 863–870. [Google Scholar] [CrossRef]

| Control System | Speed (km h−1) | Target Rate (L ha−1) | Nozzle | Pressure (kPa) | Duty Cycle (%) |

|---|---|---|---|---|---|

| RC | 12.9 | 93.5 | XRC110025 | 255.1 | - |

| 116.1 | XRC11003 | 262.1 | - | ||

| 140.3 | XRC11004 | 234.4 | - | ||

| 16.1 | 93.5 | XRC11003 | 262.1 | - | |

| 116.1 | XRC11004 | 248.2 | - | ||

| 140.3 | XRC11005 | 234.4 | - | ||

| 19.3 | 93.5 | XRC11004 | 227.5 | - | |

| 116.1 | XRC11005 | 227.5 | - | ||

| 140.3 | XRC11006 | 262.1 | - | ||

| PWM | 12.9 | 93.5 | XRC11004 | 268.8 | 55 |

| 116.1 | XRC11004 | 268.8 | 70 | ||

| 140.3 | XRC11004 | 268.8 | 84 | ||

| 16.1 | 93.5 | XRC11005 | 282.7 | 56 | |

| 116.1 | XRC11005 | 282.7 | 72 | ||

| 140.3 | XRC11005 | 282.7 | 86 | ||

| 19.3 | 93.5 | APTJ11008 | 365.4 | 58 | |

| 116.1 | APTJ11008 | 365.4 | 75 | ||

| 140.3 | APTJ11008 | 365.4 | 85 |

| Control System | Speed (km h−1) | Target Rate (L ha−1) | Nozzle | Pressure (kPa) | Duty Cycle (%) |

|---|---|---|---|---|---|

| RC | 12.9 | 93.5 | XRC11003 | 172.4 | - |

| 116.1 | XRC11003 | 262.1 | - | ||

| 140.3 | XRC11003 | 365.4 | - | ||

| 16.1 | 93.5 | XRC11004 | 158.6 | - | |

| 116.1 | XRC11004 | 248.2 | - | ||

| 140.3 | XRC11004 | 351.6 | - | ||

| 19.3 | 93.5 | XRC11005 | 151.6 | - | |

| 116.1 | XRC11005 | 234.4 | - | ||

| 140.3 | XRC11005 | 337.8 | - | ||

| PWM | 12.9 | 93.5 | XRC11004 | 268.9 | 55 |

| 116.1 | XRC11004 | 268.9 | 70 | ||

| 140.3 | XRC11004 | 268.9 | 84 | ||

| 16.1 | 93.5 | XRC11005 | 282.7 | 56 | |

| 116.1 | XRC11005 | 282.7 | 72 | ||

| 140.3 | XRC11005 | 282.7 | 86 | ||

| 19.3 | 93.5 | APTJ11008 | 365.4 | 58 | |

| 116.1 | APTJ11008 | 365.4 | 75 | ||

| 140.3 | APTJ11008 | 365.4 | 85 |

| Control System | Speed (km h−1) | Target Rate (L ha−1) | Time (ms) | |||

|---|---|---|---|---|---|---|

| Mean[a] | Min. | Max. | Std. Dev. | |||

| RC | 12.9 | 93.5 | 4033 a | 4000 | 4100 | 58 |

| 116.1 | 3567 ab | 3500 | 3600 | 58 | ||

| 140.3 | 3400 b | 3100 | 3800 | 361 | ||

| 16.1 | 93.5 | 3300 b | 3100 | 3400 | 173 | |

| 116.1 | 3333 b | 2800 | 4400 | 924 | ||

| 140.3 | 2233 c | 2200 | 2300 | 58 | ||

| 19.3 | 93.5 | 2967 b | 2900 | 3100 | 115 | |

| 116.1 | 2967 b | 2800 | 3200 | 208 | ||

| 140.3 | 1133 de | 300 | 2400 | 1115 | ||

| PWM | 12.9 | 93.5 | 1350 d | 1300 | 1400 | 50 |

| 116.1 | 667 ef | 500 | 1000 | 289 | ||

| 140.3 | 300 f | 200 | 400 | 100 | ||

| 16.1 | 93.5 | 467 f | 400 | 500 | 58 | |

| 116.1 | 333 f | 300 | 400 | 58 | ||

| 140.3 | 200 f | 200 | 200 | 0 | ||

| 19.3 | 93.5 | 200 f | 200 | 200 | 0 | |

| 116.1 | 167 f | 100 | 200 | 58 | ||

| 140.3 | 100 f | 100 | 100 | 0 | ||

| Control System | Speed (km h−1) | Rate Transition (L ha−1) | Time (ms) | |||

|---|---|---|---|---|---|---|

| Mean[a] | Min | Max | Std. Dev. | |||

| RC | 12.9 | −46.8 | 3211 a | 2600 | 4800 | 694 |

| −23.4 | 1117 fgk | 600 | 1900 | 405 | ||

| 23.4 | 650 jk | 300 | 1000 | 192 | ||

| 46.8 | 2600 b | 2200 | 3000 | 352 | ||

| 16.1 | −46.8 | 1678 c | 1400 | 1800 | 130 | |

| −23.4 | 967 hi | 500 | 2500 | 535 | ||

| 23.4 | 661 jk | 500 | 1000 | 124 | ||

| 46.8 | 1433 cde | 1300 | 1600 | 151 | ||

| 19.3 | −46.8 | 1500 cde | 600 | 1800 | 354 | |

| −23.4 | 600 k | 400 | 800 | 133 | ||

| 23.4 | 593 k | 400 | 900 | 142 | ||

| 46.8 | 1417 cde | 1200 | 1800 | 264 | ||

| PWM | 12.9 | −46.8 | 833 ij | 200 | 1300 | 387 |

| −23.4 | 278 l | 100 | 700 | 173 | ||

| 23.4 | 478 k | 100 | 1400 | 366 | ||

| 46.8 | 1367 def | 1200 | 1500 | 121 | ||

| 16.1 | −46.8 | 244 l | 100 | 600 | 181 | |

| −23.4 | 247 l | 100 | 700 | 187 | ||

| 23.4 | 1227 efg | 800 | 1700 | 322 | ||

| 46.8 | 1600 cd | 1500 | 1700 | 100 | ||

| 19.3 | −46.8 | 150 l | 100 | 200 | 58 | |

| −23.4 | 222 l | 100 | 600 | 126 | ||

| 23.4 | 189 l | 100 | 400 | 96 | ||

| 46.8 | 1022 ghi | 600 | 1700 | 421 | ||

| Test | System | Target (L ha−1) | Speed (km h−1) | Mean Time (ms) | Distance (m) |

|---|---|---|---|---|---|

| SRSS | RC | 93.5 | 12.9 | 4033 | 14.4 |

| 116.1 | 12.9 | 3567 | 12.8 | ||

| 140.3 | 12.9 | 3400 | 12.2 | ||

| PWM | 93.5 | 12.9 | 1350 | 4.8 | |

| 116.1 | 12.9 | 667 | 2.4 | ||

| 140.3 | 12.9 | 300 | 1.1 | ||

| VRSS | RC | 23.4 | 12.9 | 1456 | 5.2 |

| 46.8 | 12.9 | 3211 | 11.5 | ||

| PWM | 23.4 | 12.9 | 222 | 0.8 | |

| 46.8 | 12.9 | 833 | 3.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meena, R.; Virk, S.; Rains, G.; Porter, W. Comparative Performance of a Sprayer Rate Controller and Pulse Width Modulation (PWM) Systems for Site-Specific Pesticide Applications. AgriEngineering 2024, 6, 3312-3326. https://doi.org/10.3390/agriengineering6030189

Meena R, Virk S, Rains G, Porter W. Comparative Performance of a Sprayer Rate Controller and Pulse Width Modulation (PWM) Systems for Site-Specific Pesticide Applications. AgriEngineering. 2024; 6(3):3312-3326. https://doi.org/10.3390/agriengineering6030189

Chicago/Turabian StyleMeena, Ravi, Simerjeet Virk, Glen Rains, and Wesley Porter. 2024. "Comparative Performance of a Sprayer Rate Controller and Pulse Width Modulation (PWM) Systems for Site-Specific Pesticide Applications" AgriEngineering 6, no. 3: 3312-3326. https://doi.org/10.3390/agriengineering6030189

APA StyleMeena, R., Virk, S., Rains, G., & Porter, W. (2024). Comparative Performance of a Sprayer Rate Controller and Pulse Width Modulation (PWM) Systems for Site-Specific Pesticide Applications. AgriEngineering, 6(3), 3312-3326. https://doi.org/10.3390/agriengineering6030189