Abstract

Evaluating farm-scale energy used for broiler production can provide insight into how these facilities use energy and allow for seasonal and managerial influences to be evaluated. This study evaluated farm-scale energy consumption for South Carolina broiler production using energy records from 17 broiler and 4 pullet farms. Monthly electric use showed low to moderate correlation (r ranging from 0.476–0.630) with ambient temperature but had limited predictive usefulness. There was no clear pattern in monthly electrical energy use for broiler barns. However, pullet barns were more consistent and could be grouped into seasons. No significant differences (p < 0.05) in annual electric or gas use were observed between farms with generally better equipment and otherwise similar farms, but production type did influence annual electric use. The average annual electrical use was 23.6 kWh m−2 for farms producing larger birds, 8.7 kWh m−2 for those producing smaller birds, and 17.0 kWh m−2 for pullet farms. Electrical energy use accounted for 37% of total energy in broiler barns and 32% of energy in pullet barns. Combined electric and gas consumption averaged 214 MJ m−2 yr−1 across all farms. These findings help better quantify farm-scale energy used for broiler production and provide benchmark values for energy use.

1. Introduction

Poultry production is a major sector of the U.S. agricultural industry, with chicken leading the per capita meat availability [1]. In South Carolina alone, roughly 235 million broilers are produced each year [2]. Energy costs for operating broiler barns (electricity and gas) represent the largest variable production cost at about 57% of total cash expenses [3], and have also been estimated to be about 25% of gross farm income [4]. The majority of the energy used in broiler barns is dedicated to environmental modification, which includes ventilation, space heating, and lighting [5]. Better quantification of how and when energy is used in broiler barns is critical for evaluating energy-saving facility improvements. However, there has been little work to evaluate the farm-scale effects of these upgrades or to benchmark overall energy used in poultry housing.

Broiler chicken production occurs in three types of buildings (breeder barns, broiler barns, and pullet barns) that correspond to the three phases of production [6]. The first phase is the production of fertilized eggs in breeder barns that are designed to provide feeding, breeding, roosting, and nesting areas for hens and roosters. Here, the main uses of energy are mechanical ventilation, lighting, feed handling, and egg conveyance to the egg sorting area. A small amount of energy is also needed to control the temperature and humidity in the room where fertilized eggs are held before being transported to the hatchery. When chicks are about one day old, they are placed in a broiler barn that has been designed to provide the environmental modification needed for the brooding stage followed by the grow-out stage. During brooding, ventilation and heating systems are needed to provide air temperatures as high as 32 °C when the chicks are first placed [7]. As the birds grow and are better able to maintain body temperature, the temperature requirement decreases gradually to about 21 °C once the chicks are around 4–6 weeks old. The birds remain in the barn until they grow to market weight, which ranges from 1.8 to 4.5 kg per bird, depending on market requirements. The total time required to raise a flock of broiler chickens can range from 38 to 84 days depending on target market weight [3]. As the birds increase in body mass, the amount of energy needed for supplemental heating decreases to zero and the energy required for ventilation increases by a factor of 10 or more. Lighting requirements also change as the birds grow, with the highest light levels required during brooding. The number of flocks produced in a broiler barn each year can range from approximately four flocks for heavy birds (3.6 to 4.5 kg/bird) to six flocks for small birds (2.3 kg/bird).

The third type of broiler barn used in a commercial operation is the pullet barn, which is used to raise replacement hens and roosters for the brooder barns. These barns are designed to provide the same types of indoor environmental modifications as broiler barns and, as a result, are equipped with similar heating, ventilation, and lighting equipment. The main difference is that fewer birds are grown per unit of floor area and generally only two flocks are brooded per year with 4–6 weeks between flocks [6,8], resulting in less energy used for heating. The lighting programs (intensity and daylength) in pullet barns are more rigorously controlled compared with broiler barns. Light traps are used on fans and inlets to practically eliminate natural light from entering the barns. The use of light traps increases the static pressure drop that the ventilation fans must work against, resulting in an increase in electrical use for ventilation as compared to broiler or breeder barns.

The previously mentioned details of how production occurs in these barns is germane to energy use because the size of the bird grown impacts both environmental control and the energy consumption of broiler barns. Bird size determines the number of brooding periods per year and the number of months for which high ventilation rates are needed. For example, growing larger birds results in greater total metabolic heat production, which requires higher ventilation rates for more days a year, resulting in more electrical energy consumption. Conversely, producing larger birds results in fewer flocks per year, which translates to fewer weeks of brooding and reduced gas use for space heating.

The timing of flock placement also plays a crucial role in seasonal fluctuations in energy use. In much of the USA, and especially in the warm southern states, most of the electrical energy is used by the ventilation fans during the late spring, summer, and early fall. In general, hot weather ventilation rates are 10 times greater than the ventilation rates needed during cold winter weather, and periods when barns are left empty might coincide with the hottest part of summer, naturally reducing ventilation needs and associated energy consumption. Similarly, a flock placed during the coldest portion of the year would require extra energy for supplemental heat for the first few weeks. Therefore, something as simple as variations in the flock placement schedule can result in differences in energy consumption between broiler barns with similar types of equipment for ventilation, heating, and lighting.

The amount of energy used on a breeder, broiler, or pullet farm can also vary greatly between farms due to differences in the total airflow capacity of ventilation fans, fan efficiency, number of motors used for feed handling, the number and efficiency of the lamps used for lighting, insulation levels in the building envelop, the efficiency of the heating equipment, and the number of barns located on a single farm. Additional sources of variability in energy consumption between farms include weather, differences in control of the ventilation and heating systems, and variation in lighting programs. Most broiler producers grow under contract for companies that have ventilation and lighting requirements that often vary between companies, also increasing farm-to-farm variability.

Limited data are available to provide insight concerning the energy used to produce broiler chickens in general and specifically in the southeastern U.S. Some international works have reported energy consumption for poultry production in Turkey [9], Iran [10,11], and Nigeria [12]. The scope of what is included in these studies varies and often includes not only building energy but other energy inputs needed to grow the birds (human, machinery, feed, etc.), making it difficult to use them to assess building performance. Costantino et al. [13] reviewed several studies from Europe and reported a wide range of energy uses from 7 to 16 kWh m−2 yr−1 for electrical energy use and 86 to 137 kWh m−2 yr−1 for thermal energy use. The University of Georgia Cooperative Extension Service conducted a survey to gain information concerning energy use on broiler farms in the mid-2000s and found electrical costs ranged from USD 1.36 to USD 1.60 m−2 of broiler barn floor area per year, and gas use was approximately 165–225 MJ m−2 per year, depending on the insulation provided in the house sidewalls [14]. Baxevanou et al. [5] found the total energy used in broiler houses averaged 77.2 kWh m−2 in Greece, and a study in Poland concluded that 0.149 kWh were used per bird per year on the average [15].

Several equipment upgrades can be made to broiler barns to improve energy efficiency, including installation of energy efficient fans, changing from incandescent or fluorescent lamps to LED lamps, and adding additional building insulation [16,17]. Traditional incandescent bulbs have largely been phased out for more energy efficient LED bulbs, which can reduce lighting energy use by as much as 80% [17]. Replacing low-efficiency fans with high-efficiency fans can reduce ventilation energy requirements by 20% to 30% [18]. Fan accessories have a varying impact on efficiency, with discharge cones increasing efficiency by 15% on average and shutters and light traps potentially decreasing system efficiency by 2% to 25%, depending on design and maintenance [19]. Additionally, management practices influence energy (such as operating fans at higher static pressure), and fan maintenance has been shown to result in differences in performance of up to 24% [20].

Evaluating proposed changes and upgrades to a facility requires an assessment using the baseline energy consumption, system configuration, and comparison between the current system performance with the recommended standard of performance. It must also be recognized that the installation of new energy efficient equipment provides an opportunity to greatly improve the building environment for the animals. The realized improvement depends on the entire system where new equipment is installed, and some recommended improvements in building performance may not lower the seasonal or annual energy costs. For example, if old low-efficiency fans in a broiler barn are also shown to be deficient in the airflow needed for hot weather ventilation, the recommendation will be to increase the maximum ventilation rate as well as the energy efficiency of the fans. The new system may require more or larger high-efficiency fans to meet performance standards, and the additional airflow provided by the more energy efficient equipment can at least partially negate any energy savings compared with pre-retrofit conditions. In such cases, rather than focusing on energy savings, the value of the improvements could be better viewed through the lens of improved animal health and performance.

In recent years, several state and federal programs have been developed to provide cost sharing and incentive programs for producers to install energy efficient ventilation, lighting, and heating equipment. These programs often require an energy assessment to evaluate energy savings of potential upgrades. This study presents baseline assessment information for 17 broiler farms and 4 pullet farms that the authors were able to obtain from one of these programs. Because assessments were only provided by request, this population of farms was biased toward barns that needed efficiency and performance improvements in at least one of the three systems known to use the majority of energy on broiler farms, namely ventilation, lighting, and heating. Therefore, the information collected from these farms is best viewed as providing baseline energy use for broiler barns that could benefit from retrofitting one or more systems to improve energy efficiency. The objective of this study was to quantify annual electrical and gas consumption in broiler production. Differences in annual energy use between production types were evaluated, as was the influence of equipment characteristics on energy consumption. Additionally, the relationship between temperature and month on electrical energy use was explored.

2. Materials and Methods

The energy records and production characteristics utilized in this study were collected as part of a South Carolina program focused on providing cost share for energy-efficient upgrades for broiler production. An in-person assessment was completed to inventory lighting, heating, and ventilation equipment and to collect other pertinent production characteristics such as number, size, and age of the broiler barns, average bird size, and number of flocks produced in a year. The size, quantity, and location of each type of fan was recorded, as well as the primary use of the fan (tunnel or conventional ventilation). In the best-case scenario, specific make and model numbers were recorded, along with pictures of the equipment. However, in many cases, specific details were only recorded for systems that were of interest for upgrade, and, for older equipment, the specific model was often unintelligible, and general characteristics such as size, manufacturer, and style were collected. The location, rating, type, and quantity of lighting was similarly recorded. General observations concerning the adequacy and quality of building construction (e.g., insulation, ventilation inlets, and evaporative cooling pads) were also made, but improvements to the building envelope were ineligible for cost-share, so, in most cases, this information was limited and not used in this study.

2.1. Energy and Weather Data

The amount of electrical energy purchased per month and the amount of gas purchased per year were obtained from farm records. For electrical records, the exact format varied slightly by utility provider but generally included meter read dates, energy used (kWh), bill amount, bill dates, and days of service. In cases where multiple meters were present, they were aggregated to determine the total for the farm. Producers generally provided at least 2 years of records and annual totals were determined for each year (based on 12 consecutive months), along with an average for the operation. These values were normalized per unit floor area to compare different operations. A minority of operations only provided one year’s worth of energy data or only provided an annual total. These operations still met the minimum suggested in ANSI/ASABE S612 [21], and were noted in the results.

Most electrical bills were based on meter readings taken at specific intervals, not necessarily aligning with the calendar month. This created a discrepancy between billing and monthly energy use. In this study, monthly energy use was determined from read dates and adjusted for the number of days in the billing period. This was again normalized by floor area, and the percentage of annual electrical energy used in each month was determined. In instances where meter dates were not reported, energy use was assigned to the corresponding billing month. To examine the relationship between energy use and temperature, daily ambient air temperatures were obtained for each farm using the closest weather station available from the Midwestern Regional Climate Center database [22]. These daily temperatures were then aggregated into monthly averages that corresponded to the electrical billing period.

Annual gas use for heating was estimated utilizing producer-provided energy bills, similar to annual electrical use. For barns utilizing natural gas as a fuel source, the procedure for estimating annual use was the same as previously described, with annual usage based on 12 continuous months of data. For LP users, annual gas consumption was estimated by aggregating all billing records for a given calendar year, acknowledging that when the fuel was delivered did not precisely reflect actual usage. In both cases, energy use was converted to MJ equivalent and again normalized by floor area.

2.2. Analysis

This study quantified energy use for broiler production and evaluated how energy use varied between production systems and over the course of the year. The relationship between normalized monthly electrical use and mean monthly air temperature was investigated using Pearson’s correlation (Proc CORR in SAS (SAS 9.3, SAS Institute Inc., Cary, NC, USA)). Trends in monthly electrical use were further explored by using Tukey’s honest significant difference (HSD) test to evaluate whether normalized monthly energy use could be categorized into distinct seasons. This portion of the analysis was performed separately for each production group, and the number of observations was based on producer/month combinations. Differences in annual electric and gas use between production groups were evaluated using PROC GLM, and, in this portion of the analysis, the number of observations was based on producer/year combinations. Throughout this manuscript, all mentions of significance indicate statistical significance using p < 0.05.

Farms were grouped based on two characteristics: the size of the birds grown (small or large) for broilers, and, for large broilers, the relative efficiency of the equipment (high or low efficiency). Pullet barns have some differences in equipment (e.g., light traps) and how they are utilized relative to broiler barns, so they were analyzed as a separate category. A description of the groups evaluated and the number of farms included in each portion of the analysis is given in Table 1. Limited availability of exact performance specifications for older equipment (ex. VER of fans) and sparse details regarding the building envelope made quantitatively classifying the large broiler farms based on exact efficiency impractical; however, three farms were segregated into a “high-efficiency” group because their major electrical systems generally indicated higher efficiency relative to the other farms included in this study (e.g., cones on all tunnel and conventional ventilation fans, newer buildings, LED lighting). For LB-LE and SB, there was some variation in which farms were included in various portions of the analysis based on the data provided.

Table 1.

Description of production groups evaluated.

3. Results and Discussion

3.1. Farm Characteristics

Table 2 shows an overview of characteristics of the 21 farms included in this study, which represents producers who provided an equipment inventory and provided energy data. The farms consisted of two-to-eight barns, with a floor area ranging from 1047–2364 m2. The average age of the barns included ranged from the 1980s to the mid-2000s, and the energy records utilized were from between 2013 and 2018. Bird size plays a crucial role in energy use because it determines the length of time the birds stay in the house and the number of flocks that can be produced in a year. Eighteen total broiler farms were included, sixteen of which produced larger birds, which were treated as a separate group from the two farms that consistently produced smaller birds (2.0–2.2 kg) and the four pullet operations. The large broilers’ weight range was between 2.9 and 4.2 kg, which corresponded to the two largest weight classes from MacDonald [3]. Pullet producers typically produce two flocks per year and keep the birds for a longer duration.

Table 2.

Cooperating producer farm characteristics.

A summary of the equipment utilized by each operation is shown in Table 3. The electrical equipment inventory focused on tunnel ventilation and conventional ventilation fans, along with the quantity and types of light bulbs used. Large broiler farms were the largest group and were further categorized to evaluate how the relative efficiency of equipment impacted energy use. All of these producers provided data because they were interested in some form of upgrade, and some had already completed common upgrades (ex. LED lighting); however, 38% of the farms were still at least partially using incandescent light. The LB-HE farms were all using LED/CFL lighting and had discharge cones on all of their tunnel and conventional ventilation fans. They were also among the newest barns included and two of the three were at least partially using radiant heaters (note: older heating equipment is often not removed when upgrades are installed). This grouping had limitations but was similar to Baxevanou et al. [5], who used insulation levels and the presence of automatic ventilation and cooling systems to group farms.

Table 3.

Building and equipment characteristics.

Table 4 shows an overview of annual electrical and gas energy use for individual farms, along with the length of record used in the analysis. LB-LE3 only provided electrical energy use and LB-LE4 only provided annual fuel use and were only included in those respective analyses. Similarly, SB1 provided electric use records already aggregated on an annual basis, so they were not used in the seasonal analysis. The average electric usage was based on complete years; however, if additional months of data were provided, they were included in the seasonal analysis. As previously indicated, gas use records generally had lower temporal resolution, and, specifically for farms using LP, actual usage may be slightly shifted from the billing period. This shift occurred because billing was based on when tanks were filled not when the fuel was used, and producers commonly timed fuel purchases to take advantage of off-season prices. Total annual energy and percentage were calculated ignoring this limitation.

Table 4.

Annual electric and gas energy use for individual farms.

3.2. Electrical Energy Use

3.2.1. Correlation between Temperature and Energy Use

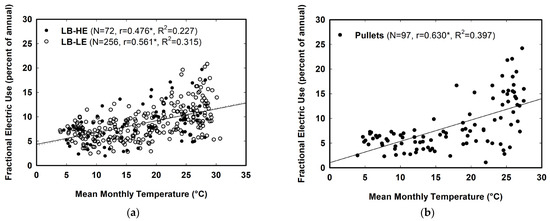

Because fan use is a large driver of electrical energy use, and there is an increased demand for tunnel ventilation at higher temperatures, the correlation between energy use and mean monthly temperature was evaluated. For all groups, there was a statistically significant positive correlation between temperature and both actual electrical energy use (kWh mo−1 per 1000 m2) and fractional electrical use (percentage of the annual total) (Table 5). This relationship was evaluated based on all producer/month combinations, which were separated by production type for consistency; however, similar results were obtained when all broiler farms were grouped together. Figure 1a shows the relationship between mean monthly temperature and fractional energy use for broiler farms, and Figure 1b shows the relationship for pullet farms. In both cases, there was increased variability in the energy use at higher mean monthly temperature. The increase was more pronounced for pullet farms, which had the highest correlation and were more consistent energy users at lower temperatures (averaging 5.5% of the annual total per month when temperatures were below 18 °C), at least in part because they produced fewer flocks per year. However, despite the significant correlation, the corresponding R2 values ranged from 0.23 to 0.39, indicating that the relationship explained less than 40% of the variation. This indicates that, although mean monthly temperature was related to energy use, it was not useful as a predictor of energy use, at least given the aggregated data from the multiple farms included here. Many factors, including intra-month temperature variation, bird development stage, and house management, contributed to the high variability observed and, combined with the low to moderate correlation between temperature and energy use, indicate that although energy use increased with temperature, temperature was not a suitable predictor of energy use.

Table 5.

Correlation between mean monthly temperature and electric by production group (see Table 1).

Figure 1.

Relationship between mean monthly air temperature and monthly electrical energy use for (a) broiler farms (b) pullet farms. * Indicates significance at p < 0.05.

3.2.2. Monthly Electrical Use

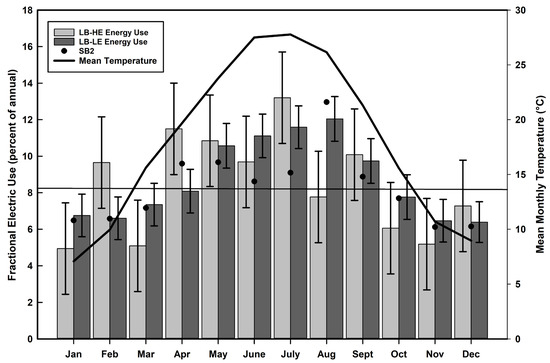

Further examination of electrical energy use by month illustrated why temperature did not effectively explain energy use and allowed for evaluation of seasonal fluctuations in electrical energy use. Figure 2 shows the fraction of electric use by month for broiler farms. Similar to the relationship between temperature energy use, there was a general trend of increased energy use in the warmer months when the demand for tunnel ventilation increased electrical energy use; however, in addition to the above-mentioned production influences, monthly energy use included additional variability due to fluctuations in temperature across months. This manifested as relatively large confidence intervals and, based on multiple comparisons from Tukey’s HSD, energy use could not be cleanly grouped into seasons for either LB-HE or LB-LE. Normalizing as a fraction of annual electrical use accounted for differences in baseline energy use levels between farms and allowed better evaluation of when energy was used, and there were no clear differences between broiler production groups.

Figure 2.

Percentage of total electricity used by month for broiler farms. Error bars represent the 95% CI. Number of observations was based on producer month combinations. SB2 was included for reference because this was the only producer in the category with monthly data. The horizontal line represents energy use distributed uniformly across all months. (Minimum significant difference = 2.6% for LB-LE and 6.02% for LB-HE.)

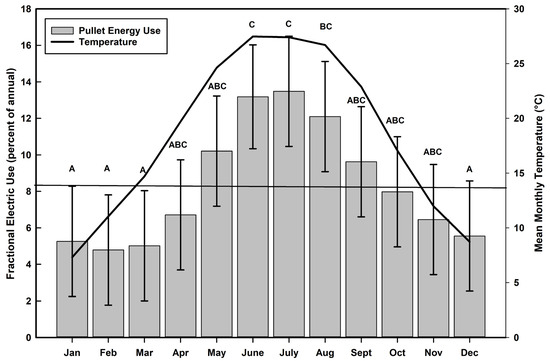

Figure 3 shows the percentage of electricity used by month by pullet farms. The seasonality of energy use was clearer in pullets because these operations produced fewer flocks in a year and the birds stayed in the house longer. Allowing overlap with the shoulder months, the results of Tukey’s HDS comparisons showed that pullet barns could be grouped into higher energy-using warm months (June, July, and August) and lower energy-using cool months (December, January, February, and March). The remaining months (April, May, September, and October) were transitional and overlapped with both the warm and cold months. The three warm months accounted for approximately 37% of the total electric use, which corresponded to increased electrical energy use for tunnel ventilation. During the cooler months, monthly energy use was on average between 4.8 and 5.6% of the annual total. Similarly, if the same seasonal delineation was applied to broiler barns, the warm months represented approximately 34% of the total.

Figure 3.

Percentage of total electricity used by month for pullets. Error bars represent the 95% CI. Number of observations was based on producer month combinations. The horizontal line represents energy use distributed uniformly across all months. Groups with the same letter were not significantly different (minimum significant difference = 7.18%).

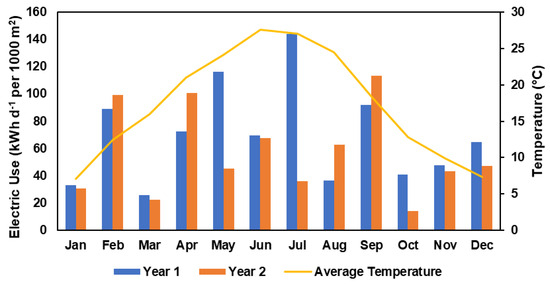

The large variation observed when electric energy was used was at least partially a result of interactions between flock placement and development stage and variation in seasonal needs for heating and ventilation. Heating and ventilation requirements varied over the course of the production cycle, and there were often gaps between flocks to allow for clean out. For a broiler farm, this is typically 2–4 weeks, but can vary greatly based on market demand [6,8]. Figure 4 shows two years of monthly energy use for a single operation and illustrates the potential for large variations in the electrical energy use pattern between years. Energy consumption in May year one was 45.3 kWh day−1 per 1000 m2 and in year two it was 116.1 kWh day−1 per 1000 m2, which represents a 156% difference in energy consumption between years for a single farm. Similar trends can be seen for July, August, and October. On an annual basis, these fluctuations represent a 22% difference in energy use between years.

Figure 4.

Example seasonal variation in energy use and average temperature for LB-HE2.

3.3. Annual Energy Use

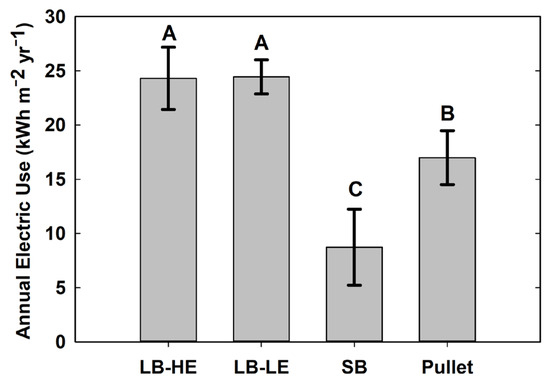

3.3.1. Annual Electric Use by Production Group

Electrical energy use was also evaluated on an annual basis, and Figure 5 shows the average electrical energy use separated by production group. There were no significant differences between the large broiler producer groups, who were the highest electrical energy users overall at 24.3 ± 2.9 kWh m−2 (mean ± 95% CI) and 24.4 ± 1.6 kWh m−2 for LB-HE and LB-LE, respectively. This indicates that, when compared on the aggregate, having generally better electrical equipment did not translate to reduced energy use relative to other farms that had similar production characteristics. As an example, one of the farms with general characteristics that indicated higher efficiency relative to the other farms (LB-HE3, Table 4) was the second highest total energy user. The lack of difference could be attributed to the same factors that influenced when the energy was used, including potential variations in flock timing, weather, and management practices (e.g., bedding moisture content, ventilation rates, static pressure, fan staging). It could also be partially attributed to the classification method. However, these results highlight the importance of considering the entire broiler production system when evaluating upgrades.

Figure 5.

Average annual electrical energy use separated by production type. Error bars represent the 95% CI. Number of observations based on producer year combinations (N = 20 for LB-LE, N = 6 for LB-HE, N = 4 for SB, N = 8 for pullets). Groups with the same letter are not significantly different (minimum significant difference = 5.08 kWh m−2 yr−1). See Table 1 for production type definitions.

Pullet farms used approximately 30% less electrical energy than both large broiler groups at 17.0 ± 2.5 kWh m−2, and small broiler farms used the least amount of electric energy at 8.7 ± 3.5 kWh m−2 per year. This is consistent with reduced fan energy used because of the increased instances of brooding and lower ventilation requirements associated with producing smaller birds [6]. There were, however, fewer farms in this group and the energy use was shown normalized by floor area, which did not account for differences in the total number/mass of birds produced in a given year. Electrical energy use by both large broiler groups was comparable to that reported for lowland farms with new technology in Greece [5]. Both larger broiler groups and pullets had a higher electrical energy use than the majority of studies from Europe reviewed by Costantino et al. [13], which was consistent with the increased need for tunnel ventilation in the southeastern United States.

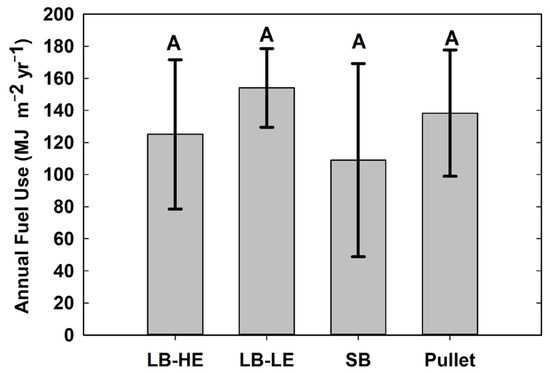

3.3.2. Annual Gas Use by Production Group

Gas used in broiler production primarily provided supplemental heat either during brooding or during cold periods and was impacted by the interaction between outdoor temperature and when brooding of chicks occurred. Figure 6 shows the average fuel energy use by production group. Because more frequent brooding is associated with increased heating gas use [6] and because large broilers, smaller broilers, and pullet farms have different brooding frequencies, differences in gas use were anticipated. However, no significant differences were observed between the groups, and estimated values were highly variable. Annual gas use was 125.1 ± 46.6 MJ m−2 and 154.0 ± 24.6 MJ m−2 for the high-efficiency large broiler and low-efficiency large broiler groups, respectively. No differences in gas use were anticipated between these groups because the initial groupings were based on electrical equipment. Small broilers used 109.0 ± 60.2 MJ m−2 on average, while pullets on average used the second most fuel per year at 138.3 ± 39.4 MJ m−2. All of these means were slightly less than the values reported by Cunningham [14], which is the closest geographic reference. Gas use here was also consistently less than half of the thermal energy range from Costantino et al. [13], again consistent with climatic differences.

Figure 6.

Average annual gas use separated by production type. Error bars represent the 95% CI. Number of observations based on producer year combinations (N = 18 for LB-LE, N = 5 for LB-HE, N = 3 for SB, N = 7 for pullets). Groups with the same letter are not significantly different (minimum significant difference = 83.9 MJ m−2 yr−1). See Table 1 for production type definitions.

3.3.3. Total Energy Use

No significant differences in total energy use were observed between production groups, consistent with the limited differences in annual electric use and the lack of differences in annual gas use. Given these limited differences, a practical way to summarize overall energy use was to combine all broiler farms and keep pullets separate due to their distinct practices (Table 6). Across all broiler farms, mean electrical energy use was 22.3 kWh yr−1 m−2, which had a large degree of variability, ranging from 6.5 to 30.1 kWh yr−1 m−2 (Table 4). Electrical energy used by pullet farms averaged 17.0 kWh yr−1 m−2 and was slightly less variable, ranging from 15.2 to 16.8 kWh yr−1 m−2. Gas use across broiler farms averaged 135.1 MJ yr−1 m−2, which was comparable to pullets; however, gas used by broilers varied considerably, with the top users consuming four times the amount of energy as the lowest (Table 4). Total energy use averaged 219 MJ yr−1 m−2 and 195 MJ yr−1 m−2 for broiler and pullet farms, respectively. On average, approximately 37% and 32% of total energy use was from electricity for broiler and pullet farms, respectively.

Table 6.

Overall energy use by group.

3.4. Implications and Limtations

The initial assumption behind this study was that monthly temperature and the quality/efficiency of the equipment installed in a building would be the dominant factors in describing how much energy was used by these farms. The results of this work did not bear out these assumptions. Many of the issues highlighted in this work are common amongst energy assessment programs. Decisions related to flock placement are based on integrator requirements, market demand for processed chickens, and are beyond the producer’s control. Management factors such as minimum ventilation rates during cold weather and high-volume summer ventilation rates are specified by the poultry production companies and impact energy use. These details are often difficult to ascertain from an assessment, which must balance a robust analysis against availability of data and the ability to accurately characterize the system. Justifying upgrades based on an equipment inventory utilizes an estimate of specific efficiency improvements from published performance standards (i.e., Bess Lab for ventilation fans [23]) combined with a best guess of usage. This work highlights the complexity associated with estimating usage, and care should be taken to account for difference in usage due to the new equipment. Monitoring energy use in the house by system would improve the ability to define the benefit of an efficiency upgrade, but the added accuracy would likely be outweighed by the additional time and expense.

This work represents an observational study of farm-level energy use for broiler and pullet farms. The electric and gas use data were collected as part of an energy efficiency cost-share program and represent buildings where the owners believed at least one of the major systems could benefit from efficiency improvement. As such, these values should be taken as representing the average to high end of energy use for the given climate. The classification method used to identify potentially higher efficiency farms here was a rough proxy which did not use specific equipment performance ratings or factors related to heating and insulation. More detailed classification could help discern aggregate reductions in energy use, but the difference could very well still be overshadowed by other factors that impact actual energy use discussed above. Further research based on a controlled experiment using instrumented houses could help better define the influence of equipment and management practices on overall energy use.

4. Conclusions

This study evaluated on-farm energy used in broiler and pullet production for 21 farms in South Carolina. Electrical energy use showed a significant correlation with mean monthly temperature; however, mean monthly temperature accounted for less than 40% of the observed variation in monthly electric use. No distinct pattern in monthly energy use was observed for broiler farms, but electrical energy use for pullet farms could be delineated into warm (June, July, and August) and cool (December, January, February, and March) seasons, with an overlapping shoulder. On an annual basis, farms with generally better equipment showed no significant differences in energy use compared with otherwise similar operations; however, pullet barns used on average 24% less electricity than broiler barns. Across all farms evaluated, annual electric use ranged from 6.5 kWh m−2 to 30.1 kWh m−2 and averaged 21.2 kWh m−2. No differences in gas use were observed and, when combined with electrical, total energy use ranged from 121 MJ m−2 to 319 MJ m−2, with an average of 214 MJ m−2. Overall, this study addressed the lack of data regarding energy used in broiler production and demonstrated the need to consider the whole system, including timing and management practices when evaluating facility upgrades.

Author Contributions

A.P.T., conceptualization, formal analysis, writing—review and editing; J.P.C., investigation, methodology, writing—review and editing; H.F.M., conceptualization, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by USDA-NRCS, grant number 68-4639-15-002.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to thank the anonymous growers who contributed data, and the personnel who conducted the site assessments. We would also like to thank Patrick Anderson and Delaney McGrady for their contributions to the project.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- USDA-ERS. Food Availability and Consumption. Available online: https://www.ers.usda.gov/data-products/ag-and-food-statistics-charting-the-essentials/food-availability-and-consumption/ (accessed on 25 May 2024).

- SC Poultry Federation. Economic Impact. Available online: https://scpoultry.org/ecoimpact/ (accessed on 24 May 2024).

- MacDonald, J.M. Technology, Organization, and Financial Performance in U.S. Broiler Production, EIB-126; USDA-ERS: Washington DC, USA, 2014.

- Tabler, G.; Berry, I.; Mendenhall, A. Energy costs associated with commercial broiler production. Avian Advice 2003, 5, 1–4. [Google Scholar]

- Baxevanou, C.; Fidaros, D.; Bartzanas, T.; Kittas, C. Energy consumption and energy saving measures in poultry. Energy Environ. Eng. 2017, 5, 29–36. [Google Scholar] [CrossRef]

- Brothers, D. New Farmer’s Guide to the Commercial Broiler Industry: Farm Types & Estimated Business Returns. Available online: https://www.aces.edu/blog/topics/farm-management/new-farmers-guide-to-the-commercial-broiler-industry-farm-types-estimated-business-returns/ (accessed on 15 July 2024).

- Fairchild, B.D. Environmental Factors to Control When Brooding Chicks. Available online: https://extension.uga.edu/publications/detail.html?number=B1287&title=environmental-factors-to-control-when-brooding-chicks (accessed on 15 July 2024).

- Stringham, M.; Waston, W.; Carver, D.; Toth, S. AG-598-16: Crop Profiles for North Carolina Agriculture: Poultry (Broilers, Layers, and Turkeys); North Carolina State University: Raleigh, NC, USA, 2018. [Google Scholar]

- Kilic, I. Analysis of the energy efficiency of poultry houses in the Bursa region of Turkey. J. Appl. Anim. Res. 2016, 44, 165–172. [Google Scholar] [CrossRef][Green Version]

- Amini, S.; Kazemi, N.; Marzban, A. Evaluation of energy consumption and economic analysis for traditional and modern farms of broiler production. Biol. Forum Int. J. 2015, 7, 905–911. [Google Scholar]

- Heidari, M.; Omid, M.; Akram, A. Energy efficiency and econometric analysis of broiler production farms. Energy 2011, 36, 6536–6541. [Google Scholar] [CrossRef]

- Babalola, A.A.; Sanusi, A.O.; Adetifa, B.O.; Adeyemi, H.O.; Olatunde, O.B. Energy use pattern of selected commercial poultry farms in ogun state, Nigeria. J. Eng. Sci. 2020, 27, 65–75. [Google Scholar]

- Costantino, A.; Fabrizio, E.; Biglia, A.; Cornale, P.; Battaglini, L. Energy use for climate control of animal houses: The state of the art in Europe. Energy Procedia 2016, 101, 184–191. [Google Scholar] [CrossRef]

- Cunningham, D.L. Broiler Tip: Comparing Utility Costs for Georgia Broiler Growers. Available online: https://poultry.caes.uga.edu/content/dam/caes-subsite/poultry/documents/archived-poultry-tips/comparing-utility-costs-for-broilers-mar-11.pdf (accessed on 9 May 2024).

- Sierocka, H.; Zajkowski, M.; Hołdyński, G.; Sołjan, Z. Characteristics of Electricity Consumption on the Example of Poultry Farming in Poland. Energies 2023, 16, 547. [Google Scholar] [CrossRef]

- Caslin, B. Energy Efficiency on Poultry Farms. Available online: https://www.teagasc.ie/media/website/publications/2016/06.-Energy-Efficiency-on-Poultry-Farms.pdf (accessed on 1 March 2023).

- Li, Y.; Arulnathan, V.; Heidari, M.; Pelletier, N. Design considerations for net zero energy buildings for intensive, confined poultry production: A review of current insights, knowledge gaps, and future directions. Renew. Sustain. Energy Rev. 2022, 154, 111874. [Google Scholar] [CrossRef]

- Chastain, J.P.; Anderson, P.T.; Vassalos, M. Analysis of Available Efficiency and Performance Data for Axial Flow Agricultural Ventilation Fans. In Proceedings of the 2017 ASABE Annual International Meeting, Spokane, WA, USA, 16–19 July 2017; pp. 1–11. [Google Scholar]

- ASABE Standards EP566.2; Guidelines for Selection of Energy Efficient Agricultural Ventilation Fans. ASABE: St. Joseph, MI, USA, 2012.

- Casey, K.; Gates, R.; Wheeler, E.; Xin, H.; Liang, Y.; Pescatore, A.; Ford, M. On-farm ventilation fan performance evaluations and implications. J. Appl. Poult. Res. 2008, 17, 283–295. [Google Scholar] [CrossRef]

- ASABE Standards S612; Performing On-Farm Energy Audits. ASABE: St. Joseph, MI, USA, 2021.

- Midwestern Regional Climate Center. cli-MATE Application Tools Environment Sub_Daily Data (DATABASE); Midwestern Regional Climate Center: West Lafayette, IN, USA, 2023. [Google Scholar]

- BESS Lab. Agricultural Ventilation Fans, Performance and Efficiencies. Available online: http://bess.illinois.edu/index2.htm (accessed on 10 July 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).