Abstract

The application of pesticides using unmanned aerial vehicles (UAVs) has grown, but there is a lack of information to support more efficient applications. Using a DJI AGRAS-MG-1P octocopter equipped with different spray tips, this study sought to explore spray deposition (leaves and fruit) and efficacy of chlorpyrifos on control of coffee berry borer at different spray volumes and flight heights. The study was conducted in an Arabica coffee plantation. The study consisted of eight treatments and four replications in a 2 × 2 × 2 factorial scheme: two flight heights (1.5 and 3.0 m), two spray tips (hollow cone and flat fan), and two spray volumes (10 and 15 L ha−1). Deposition was assessed by detecting a tracer in the coffee leaves and fruit using spectrophotometry. The coffee berry borer-control efficacy trial was conducted in two areas by evaluating the percentage of damaged fruit 60 days after two insecticide applications. The flight height of 1.5 m promoted higher spray deposition on leaves and fruit and a lower incidence of damaged fruit. Flat fan spray tips resulted in higher spray deposition on the leaves, not interfering with the deposition on fruit or the coffee berry borer control. Increasing the spray volume from 10 to 15 L ha−1 did not increase spray deposition on coffee leaves and fruit. Chlorpyrifos applied via UAVs reduced the incidence of coffee berry borer.

1. Introduction

Coffee (Coffea arabica L.) cultivation is an agricultural activity of high economic and social importance in several countries, which justifies the need for new research efforts to continuously improve productivity. Pests contribute to reducing crop productivity and coffee quality. Among them, the coffee berry borer, Hypothenemus hampei (Ferrari, 1867) (Coleoptera: Curculionidae, Scolytinae), is one of the most important pests due to the great economic losses it causes by reducing crop productivity and affecting coffee quality [1]. Morris and Perfecto [2] mentioned that the coffee berry borer is the pest that most damages coffee plantations worldwide.

Attack by the coffee berry borer causes quantitative loss, with a reduction in bean weight and fruit falling, and qualitative loss, with a reduction in coffee quality due to changes in the drink. The losses are caused by insect larvae that live inside the coffee fruit, attacking the seed for food, and the fruit destruction can be partial or total [3]. Berry borer is distinguished from all 850 other insect species that can feed on parts of the coffee plant in that it is the only one able to feed and complete its life cycle in the coffee seed, causing more than USD 500 million in damages annually [4].

The management of this pest often consists of frequent plot monitoring to treat the plants with insecticides at the onset of the infestation. In this context, application technology plays a fundamental role in ensuring the product reaches the target. Coffee plants pose a series of challenges to the application technology of pesticides [5], as they have high leaf density, a need for spray-solution penetration inside the canopy, and an irregular canopy arrangement. In this context, new technologies that allow higher deposition of active ingredients at the target are needed.

The use of unmanned aerial vehicles (UAVs), frequently referred to as drones, for the application of agricultural pesticides has increased significantly worldwide. It is a relatively new technology in many countries and little research data are available. Its use has grown significantly, but there is a lack of information to support more efficient application [6]. This technology uses a reduced spray volume, airflow, and higher heights relative to the plants, among other characteristics, which makes it more complex and requires better understanding, especially in perennial crops such as coffee.

Variables such as flight height, type of spray tip, and spray volume are recurring questions among technicians and farmers. Ozkan [7] discussed these factors in detail, showing that the correct choice depends on many factors. Increased launch altitudes extend the time during which droplets encounter wind-induced drag, potentially leading to drift and consequently reducing the amount of product reaching the intended target. Wang et al. [8] showed the essentiality of finding a balance between height and flight speed to obtain good results. Furthermore, different spray tips result in different droplet spectra, which, associated with the spray volume, directly interfere with the degree of coverage of the target, as well as the penetration of the spray solution inside the plant canopy. Appropriate droplet size is essential for safe and effective application considering good agricultural practices [6].

This study sought to examine spray deposition on coffee fruit and leaves and the effectiveness of chlorpyrifos on control of the coffee berry borer, using a UAV equipped with flat fan and hollow cone nozzles operating at two different flight heights and spray volumes.

2. Materials and Methods

The study was carried out in the Sector of Coffee Farming (Federal University of Uberlândia—UFU, Uberlândia, Brazil). The area has an altitude of 912 m, with geographic coordinates of 18°58′52″ S latitude and 48°12′24″ W longitude. The climate in the region is the megathermal humid tropical Aw, according to the Köppen classification, characterized by hot, humid summers and cold, dry winters. The mean monthly air temperature varies from 20.9 to 23.1 °C. The mean annual precipitation is 1500–1600 mm [9]. The soil has a slightly undulating topography.

The unmanned aerial vehicle used in this study was an AGRAS MG-1P octocopter (DJI, China), with a 10 L spray solution tank, four spray nozzles, and eight engines (Figure 1). It used an effective swath of 4.0 m, based on the work of Cunha and Silva [6] and the manufacturer recommendation (4.0 to 6.0 m). However, this swath was influenced by wind speed, nozzle position, release height, ground speed, and droplet size [10]. Deposition uniformity and the applied spray rate from finer spray treatments were less sensitive to changes in swath width than coarse spray applications [11]. The aircraft calibration was checked, determining the volume applied in 10,000 m2.

Figure 1.

Aircraft used in the tests.

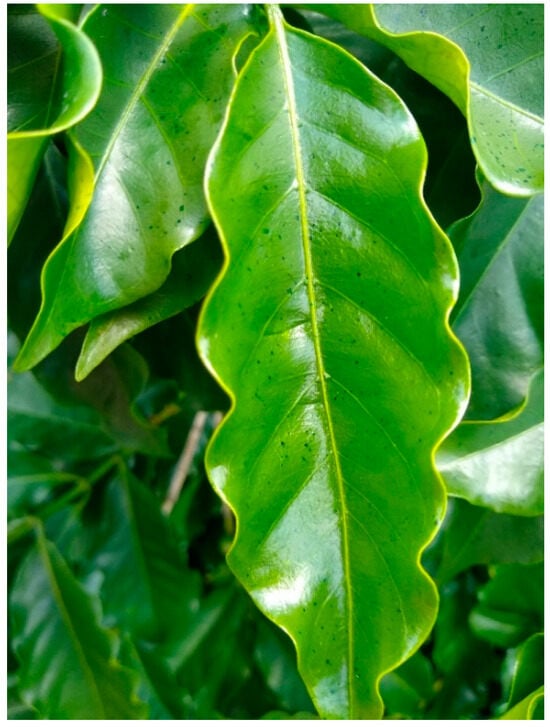

The studies on spray solution deposition and coffee berry borer control efficacy were conducted in an area of coffee cultivar Catuaí IAC 99 aged 11 years, with an inter-row spacing of 3.5 m, 0.6 m between plants, mean height of 2.1 m, and crown projection with a diameter of 1.7 m. The experimental plots were 50 m long and 24 m wide, with a useful portion of 40 m long and 16 m wide; the remaining portion was regarded as boundaries. The crop was at the reproductive stage (fruit filling) at the time the study was conducted in the area.

The spray solution deposition was evaluated by detecting a tracer in the leaves of the coffee canopy, considering the lower and upper parts of the plant separately. This trial consisted of eight treatments (Table 1) and four replications. A completely randomized design was used in a 2 × 2 × 2 factorial scheme: two flight heights (1.5 and 3.0 m), two spray tips (flat fan and hollow cone spray tips), and two spray volumes (10 and 15 L ha−1). The most used application parameters have been 10 L ha−1 and 3 to 4 m flight height. However, greater spray volumes and lower heights have the potential to improve the quality of the applications.

Table 1.

Treatments used in the spray solution deposition test.

Flat fan spray tips XR 11001 (Teejet, Glendale Heights, IL, USA) with a very fine to fine droplet spectrum depending on the working pressure (the spray tips come factory-installed with the equipment), and hollow cone spray tips COAP 9001 (KGF, Brazil) with a very fine droplet spectrum (Figure 2) were used, as they are the most commonly used types among practitioners. All droplet spectra were reported by the manufacturers.

Figure 2.

Spray tips used in the applications: flat fan XR 11001 (left) and hollow cone COAP 9001 (right).

Wind speed, temperature, and relative humidity were observed during applications using a digital thermo-hygro-anemometer (model 4000, Kestrel, Boothwyn, PA, USA). The temperature ranged from 25 to 28 °C, relative humidity from 68% to 74%, and wind speed from 4 to 6 km h−1. Environmental conditions are fundamental to the success of the aerial application technology, and, in most cases, applications with relative humidity below 55% and ambient temperature higher than 30 °C should be avoided. Ideally, applications should be performed with wind speed between 3 and 7 km h−1 [12]. In this way, it is possible to ensure that the applications are made under ideal conditions, and probably with little interference in the results.

Brilliant blue FCF (Food, Drug & Cosmetic as FD&C Blue No. 1) was added at 500 g ha−1 as a tracer to the spray solution to determine deposition using spectrophotometry. A spectrophotometer with 3.5 mL glass cuvettes and a 10 mm optical path with a tungsten–halogen lamp was used to take the readings. Detection occurred through absorbance measurement at 630 nm.

Spectrophotometry quantifies the light absorption of a chemical substance by assessing the intensity of light as it traverses a sample solution. Fundamentally, compounds absorb or transmit light within specific wavelength ranges. This technique enables the quantification of known chemical substances [13].

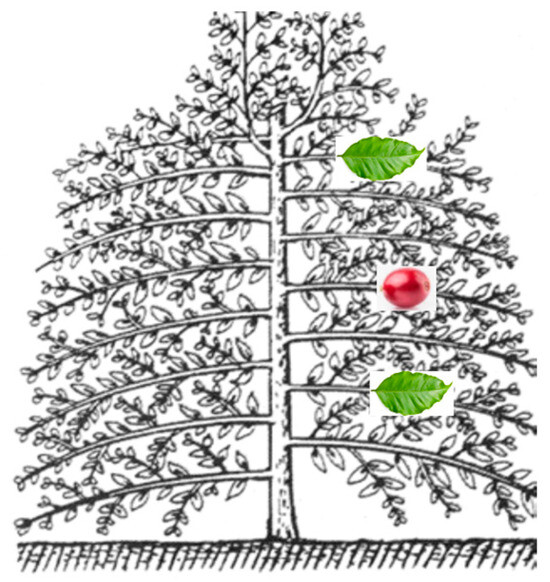

Ten plants were randomly labeled subsequent to spraying in each replication and one leaf at the top, one leaf at the bottom, and one fruit at the middle portion were collected from each plant (Figure 3). Subsequently, the leaves, separated by position, and the fruit were enclosed within plastic bags and placed in containers with thermal and light insulation for transport to the laboratory.

Figure 3.

Coffee leaf and fruit collection positions.

In the laboratory, 100 mL of distilled water was added to each plastic bag containing the leaves and 30 mL to each bag containing the fruit. They were closed and stirred for 10 min in a TE-240 pendulum stirrer (Tecnal, Piracicaba, SP, Brazil) at 250 rpm to extract the tracer. Then, the liquid was transferred to plastic cups, and stored in refrigerated equipment for 24 h for subsequent absorbance readings on the spectrophotometer. The leaf area was measured with a LI 3100C leaf area meter (Licor, Lincoln, NE, USA). The surface area of the fruit was estimated using the methodology by Miranda et al. [14].

The absorbance data were transformed into concentration (µg L−1) with a calibration curve, established from tracer standard solution. The initial solution concentration and sample dilution volumes allowed the determination of the mass of the colorant retained in the leaves collected in the plots. The total deposition was divided by the area of each sample to obtain the amount in µg of tracer per cm2 of leaf and fruit area. A variable composed of the ratio of depositions between the upper and lower parts was also analyzed, with the aim of also understanding the distribution uniformity of the spray solution throughout the canopy.

The coffee berry borer control efficacy test was conducted in duplicate in two areas 100 m apart, after completion of the deposition test. The results allowed the definition of the operating conditions for the applications: operating width of 4 m and spray solution volume of 10 L ha−1 (we decided not to use the spray volume of 15 L ha−1, considering the absence of differences in deposition and aiming to reduce the total area of the experiment). Thus, each trial consisted of five treatments and four replications. A completely randomized design was used in a 2 × 2 + 1 factorial scheme: two flight heights (1.5 and 3.0 m), two spray tips (flat fan and hollow cone spray tips), and a control without application. Two applications using the insecticide chlorpyrifos (concentration of 480 g L−1 in the emulsifiable concentrate formulation) at a dose of 1.5 L ha−1 were performed 30 days apart. The first application occurred when the incidence of fruit damaged by the coffee berry borer reached 3% [3]. The temperature during the first application ranged from 24 to 26 °C, relative humidity from 63% to 69%, and wind speed from 5 to 7 km h−1. Moreover, the temperature during the second application ranged from 26 to 29 °C, relative humidity from 61% to 68%, and wind speed from 6 to 8 km h−1.

The efficacy of treatment control was evaluated using the percentage of incidence of fruit damaged by the coffee berry borer, calculated 60 days after the 2nd application. The percentage of damaged fruit was evaluated using one liter of coffee, which contains around 500 fruit, 250 on each side of the inter-rows, distributed over the three thirds of the plants in the useful part of each plot. In the laboratory, the fruit were counted and those with holes were separated and then opened to check visually whether the borer larvae had developed [15].

For statistical analysis, the assumptions of the linear model were studied using the Shapiro–Wilk (W) test to test the normality of residuals and the Bartlett test for homogeneity of variances. Once the assumptions of the variables were satisfied, an analysis of variance was conducted for a completely randomized design, followed by Snedecor’s F-test at a 0.05 significance level. The Dunnet test at a 0.05 significance level was used to compare treatments with the control without application in the efficacy test. The analyses were performed using the software R version 4.2.2 [16].

3. Results and Discussion

The results of the tracer deposition on coffee fruit are presented in Table 2. The interaction between the factors of flight height, spray tips, and spray-solution volumes was not significant (p > 0.05) and, therefore, the interactions were not sliced, and each factor was analyzed in isolation. The effect of spray volume and tips was also not significant, demonstrating that there was no difference between them. Importantly, volumes of 10 and 15 L ha−1 were tested. Therefore, the use of higher spray solution volumes would result in higher deposition, but from a practical point of view, these larger volumes would make the operation very costly given the low operating capacity, resulting from the high volume of water used per hectare. Furthermore, the solutions were always prepared with the same tracer dose, which reduced the effect of the spray volume on the deposition assessment based on the mass per unit area.

Table 2.

Tracer deposition (µg cm−2) on coffee fruit promoted by aerial application with a UAV using different flight heights, spray tips, and spray solution volumes.

The analysis of tracer deposition on fruit also demonstrated that the UAV flying at 1.5 m promoted higher deposition on fruit compared with flying at a height of 3.0 m. Elevated launch altitudes prolonged the time during which the droplets were prone to wind-induced drag, resulting in a more prominent occurrence of the drift phenomenon and, consequently, less product reaching the target. Moreover, Wang et al. [17] mentioned that the launch height of the droplet also affects its evaporation, reducing the product arrival at the target.

Crause et al. [18] studied the application of leaf fertilizers to coffee using UAVs at different flight heights (2, 4, and 6 m). The authors concluded that the best deposition results were obtained at 2 m height, reinforcing that higher heights can result in a loss of application efficiency, mainly due to the drag caused by air currents.

Table 3 shows the tracer deposition on the leaves of the upper and lower parts of the plant. The interactions between the factors flight height, spray tip, and spray solution volume were also not significant. The different spray solution volumes were again not different between the two parts of the coffee canopy.

Table 3.

Tracer deposition (µg cm−2) in the upper and lower parts of the coffee canopy promoted by the aerial application with a UAV using different flight heights, spray tips, and spray solution volumes.

The lower flight height provided higher deposition in both the upper and lower parts of the canopy. Tang et al. [19] investigated the effect of flight height on the quality of UAV application in citrus and concluded that 1.2 m over the canopy provided better spray distribution throughout the canopy. The increase in flight height reduces the effect of the airflow that projects the droplets in the direction of the target, altering their deposition on the plant canopy [20].

Qin et al. [21] found that a UAV operating at 1.5 m height and 5 m s−1 also produced a uniform droplet distribution on rice plants, with an insect control superior to that found with ground application. The authors justified the results due to the effect of the airflow generated by the aircraft’s propellers.

The flat fan tips also resulted in higher deposition on coffee tree foliage. The lower spray solution deposition with the hollow cone spray tip may have occurred due to the working pressure. Although the UAV has no pressure gauge, the approximate flow per tip using two tips, 10 L ha−1, 10.2 km h−1, and 4 m width was 0.34 L min−1, which corresponds to an approximate pressure of 300 kPa (3 bar). According to the manufacturer of this tip, its operation starts at 200 kPa, but it is a relatively low pressure for this type of tip to fully open the jet.

Hollow cone spray tips generally work at pressures of 200 to 1000 kPa and produce fine droplets [22], and are commonly recommended for insecticide and fungicide applications in crops with heavy leaf cover, in which good penetration into the canopy is required. However, it is common to work with hollow cone spray tips at pressures higher than 400 kPa.

Importantly, the deposition on the leaves, in general, was higher than the deposition on the fruit, which demonstrates the difficulty of reaching this specific part of the coffee plant, as the fruit are found in the middle of the plant’s branches, often covered by leaves. This fact is very relevant in the study of coffee berry borer control, as it interferes with the efficacy of the insecticide that should preferably reach the coffee fruit. In addition, there was higher variability in the data, demonstrated by the higher coefficient of variation value. This variability is intrinsic to this type of assessment, given the different positions in which the fruit may have been collected even though they are at the same height on the plant and distance from the stem.

The uniformity of spray solution deposition throughout the coffee canopy was analyzed using the ratio between the tracer deposition values on the upper and lower parts of the plants (Table 4). No significant difference was observed, indicating similarity between treatments. Values close to 1 indicate a uniform deposition and positive values indicate a higher deposition on the upper part of the plants.

Table 4.

Ratio between tracer deposition on the upper and lower parts of coffee plants promoted by the aerial application with UAV using different flight heights, spray tips, and spray solution volumes.

Deposition on the lower part of the plants was slightly lower than on the upper part. This occurred due to the higher distance from the droplet launch point. The furthest point in ground applications was generally at the top of the trees, but the point of greatest deposition difficulty in aerial applications was generally at the bottom of the crop.

Table 5 shows the incidence of fruit damaged by coffee berry borer. The higher flight height resulted in a higher incidence of damaged fruit in the two evaluated areas. This was probably due to the lower spray solution deposition both on the fruit and on the leaves. Chlorpyrifos is a contact and ingestion insecticide and, therefore, deposition on the fruit is very important. According to Reis [3], one should aim to reach fruit in which the coffee berry borer has not reached the seed, where it will be killed by the action of contact with the applied insecticide before laying eggs.

Table 5.

Incidence (%) of fruit damaged by the coffee berry borer as a function of aerial application of insecticide with a UAV using different flight heights and spray tips in two areas.

The flat fan spray tip promoted higher spray solution deposition on the leaves, but this trend did not occur relative to the fruit. Therefore, the difference obtained for the leaves was not sufficient to differentiate the incidence of fruit damaged by the coffee berry borer. The droplet class was similar although the jet shape was different at both ends, ranging from fine to very fine, according to the manufacturer.

All treatments differed from the control with lower incidences of damaged fruit, demonstrating the effect of the insecticide in controlling the coffee berry borer. According to Metellus et al. [23], chlorpyrifos is effective in controlling the coffee berry borer, reducing the insect population and the attack on fruit. However, there is still room to improve the application efficiency, as there was an incidence of damaged fruit even in the plots that received insecticide. This may have been related to the insecticide efficacy or method of application.

Figure 4 shows an image of a leaf immediately after applying the tracer in a volume of 10 L ha−1. The use of fine droplets associated with the reduced spray solution volume meant that the coverage was not high, which could be a problem for pesticides that have contact action.

Figure 4.

Detail of tracer deposition on coffee tree foliage by UAV application.

Wang et al. [24] compared insecticide application to wheat using UAVs and ground sprayers. The study showed the feasibility of using UAVs for spraying. However, the authors found that the deposition uniformity and droplet penetration need to be improved. Actions such as optimizing the spraying system or adding adjuvant in the tank are essential, given the reduced coverage and uneven deposition.

4. Conclusions

The flight height of 1.5 m, relative to the coffee crown, promoted higher spray solution deposition on the leaves and fruit and a lower incidence of fruit damaged by the coffee berry borer, proving this height to be more suitable for application with a UAV than a height of 3.0 m.

The use of flat fan spray tips resulted in higher spray solution deposition on the coffee foliage compared with the hollow cone spray tip, and did not interfere with deposition on the fruit or the coffee berry borer control.

Increasing the spray solution volume from 10 to 15 L ha−1 did not increase spray solution deposition on coffee leaves and fruit. The studied parameters showed no influence on the uniformity of spray solution deposition throughout the coffee canopy.

The insecticide chlorpyrifos applied via UAV reduced the incidence of coffee berry borer.

Author Contributions

Conceptualization, J.P.A.R.d.C.; methodology, J.P.A.R.d.C., L.d.L.L. and C.B.d.A.; formal analysis, J.P.A.R.d.C. and L.d.L.L.; writing—original draft preparation, J.P.A.R.d.C.; writing—review and editing, L.d.L.L. and C.B.d.A.; supervision, J.P.A.R.d.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially funded by Fundação de Amparo a Pesquisa do Estado de Minas Gerais—Brazil (FAPEMIG)—APQ-00856-23, and Conselho Nacional de Desenvolvimento Científico e Tecnológico—Brazil (CNPq)—311371/2021-3.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Souza, J.C.; Reis, P.R.; Silva, R.A.; Carvalho, T.A.F.; Pereira, A.B. Chemical control of the coffee berry borer with cyantraniliprole. Coffee Sci. 2013, 8, 404–410. [Google Scholar]

- Morris, J.R.; Perfecto, I. Testing the potential for ant predation of immature coffee berry borer (Hypothenemus hampei) life stages. Agric. Ecosyst. Environ. 2016, 233, 224–228. [Google Scholar] [CrossRef]

- Reis, P.R. Manejo da broca do café. Rev. Cultiv. Gd. Cult. 2015, 198, 38–40. [Google Scholar]

- Johnson, M.A.; Ruiz-Diaz, C.P.; Manoukis, N.C.; Verle Rodrigues, J.C. Coffee berry borer (Hypothenemus hampei), a global pest of coffee: Perspectives from historical and recent invasions, and future priorities. Insects 2020, 11, 882. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, A.P.; Ferreira, M.C.; Oliveira, C.A.L. Eficiência de diferentes ramais de pulverização e volumes de calda no controle de Brevipalpus phoenicis na cultura do café. Rev. Bras. De Entomol. 2010, 54, 130–135. [Google Scholar] [CrossRef]

- Cunha, J.P.A.R.; da Silva, M.R.A. Spray deposition from a remotely piloted aircraft on the corn crop. Rev. Ciência Agronômica 2023, 54, e20217862. [Google Scholar] [CrossRef]

- Ozkan, E. Drones for Spraying Pesticides—Opportunities and Challenges; The Ohio State University: Columbus, OH, USA, 2024; pp. 1–16. [Google Scholar]

- Wang, J.; Lan, Y.; Wen, S.; Hewitt, A.J.; Yao, W.; Chen, P. Meteorological and flight altitude effects on deposition, penetration, and drift in pineapple aerial spraying. Asia-Pac. J. Chem. Eng. 2020, 15, e2382. [Google Scholar] [CrossRef]

- Rodrigues, E.A.S.; Lima, S.C. Associação entre a incidência do levantamento de índice rápido de Aedes aegypti (Liraa) e as condições climáticas em Uberlândia, Minas Gerais, Brasil, entre 2014 a 2016. Caminhos De Geogr. 2019, 20, 251–263. [Google Scholar] [CrossRef]

- Richardson, B.; Rolando, C.A.; Somchit, C.; Dunker, C.; Strand, T.M.; Kimberley, M.O. Swath pattern analysis from a multi-rotor unmanned aerial vehicle configured for pesticide application. Pest Manag. Sci. 2020, 76, 1282–1290. [Google Scholar] [CrossRef] [PubMed]

- Fritz, B.K.; Martin, D.E. Measurement and analysis methods for determination of effective swath width from unmanned aerial vehicles. In Pesticide Formulation and Delivery Systems: 40th Volume, Formulation, Application and Adjuvant Innovation; Elsik, C.M., Ed.; ASTM International: West Conshohocken, PA, USA, 2020; pp. 62–85. [Google Scholar]

- Baio, F.H.R.; Antuniassi, U.R.; Castilho, B.R.; Teodoro, P.E.; Silva, E.E. Factors affecting aerial spray drift in the Brazilian Cerrado. PLoS ONE 2019, 14, e0212289. [Google Scholar] [CrossRef] [PubMed]

- Absorbance. Available online: https://www.horiba.com/bra/medical/academy/technology/absorbance/ (accessed on 17 May 2024).

- Miranda, G.R.; Raetano, C.G.; Silva, V.C.; Cunha, M.D.Q.; Carvalho, R.H.; Pinheiro, J.M.; Gonçalves, M.P.; Reinato, C.H.R.; Paiva, L.C.; Araújo, D.A. Avaliação dos depósitos da pulverização em frutos de cafeeiro utilizando dois equipamentos associados a diferentes volumes de calda. Rev. Agrogeoambiental 2012, 4, 15–20. [Google Scholar] [CrossRef]

- Zampiroli, R.; Parenti, M.V.; Alvarenga, C.B.; Celoto, F.J.; Cunha, J.P.A.R.; Rinaldi, P.C.N. Use of different spray volumes and hydraulic nozzles in air-assisted electrostatic insecticide application technologies to control coffee berry borer (Hypothenemus hampei) populations. Acta Sci.-Agron. 2022, 44, e53751. [Google Scholar] [CrossRef]

- R CORE TEAM The R Foundation for Statistical Computing Platform 2020; R Foundation for Statistical Computing: Vienna, Austria, 2020; Available online: https://www.r-project.org (accessed on 3 February 2024).

- Wang, G.; Li, X.; Andaloro, J.; Chen, P.; Song, C.; Shan, C.; Lan, Y. Deposition and biological efficacy of UAV-based low-volume application in rice fields. Int. J. Precis. Agric. Aviat. 2020, 3, 65–72. [Google Scholar] [CrossRef]

- Crause, D.H.; Vitória, E.L.D.; Ribeiro, L.F.O.; Ferreira, F.D.A.; Lan, Y.; Chen, P. Droplet deposition of leaf fertilizers applied by an unmanned aerial vehicle in Coffea canephora plants. Agronomy 2023, 13, 1506. [Google Scholar] [CrossRef]

- Tang, Y.; Hou, C.J.; Luo, S.M.; Lin, J.T.; Yang, Z.; Huang, W.F. Effects of operation height and tree shape on droplet deposition in citrus trees using an unmanned aerial vehicle. Comput. Electron. Agric. 2018, 148, 1–7. [Google Scholar] [CrossRef]

- Ahmad, F.; Qiu, B.; Dong, X.; Ma, J.; Huang, X.; Ahmed, S.; Chandio, F.A. Effect of operational parameters of UAV sprayer on spray deposition pattern in target and off-target zones during outer field weed control application. Comput. Electron. Agric. 2020, 172, 105350. [Google Scholar] [CrossRef]

- Qin, W.C.; Qiu, B.J.; Xue, X.Y.; Chen, C.; Xu, Z.F.; Zhou, Q.Q. Droplet deposition and control effect of insecticides sprayed with an unmanned aerial vehicle against plant hoppers. Crop Prot. 2016, 85, 79–88. [Google Scholar] [CrossRef]

- Christofoletti, J.C. Bicos de Pulverização: Seleção e Uso; Spraying Systems: Diadema, Brazil, 1991; pp. 1–9. [Google Scholar]

- Metellus, D.; Sampaio, M.V.; Celoto, F.J. Activity of insecticides on coffee berry borer (Hypothenemus hampei) (coleoptera: Curculionidae, scolytinae). Biosci. J. 2020, 36, 1099–1115. [Google Scholar]

- Wang, G.; Lan, Y.; Yuan, H.; Qi, H.; Chen, P.; Ouyang, F.; Han, Y. Comparison of spray deposition, control efficacy on wheat aphids and working efficiency in the wheat field of the unmanned aerial vehicle with boom sprayer and two conventional knapsack sprayers. Appl. Sci. 2019, 9, 218. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).