Effects of Biochar Type on the Growth and Harvest Index of Onion (Allium cepa L.)

Abstract

1. Introduction

2. Materials and Methods

2.1. Soil Characteristics

2.2. Biochar Production

2.3. Pot Experiment

2.4. Data Collection

2.5. Data Analysis

3. Results

3.1. Biochar Characteristics

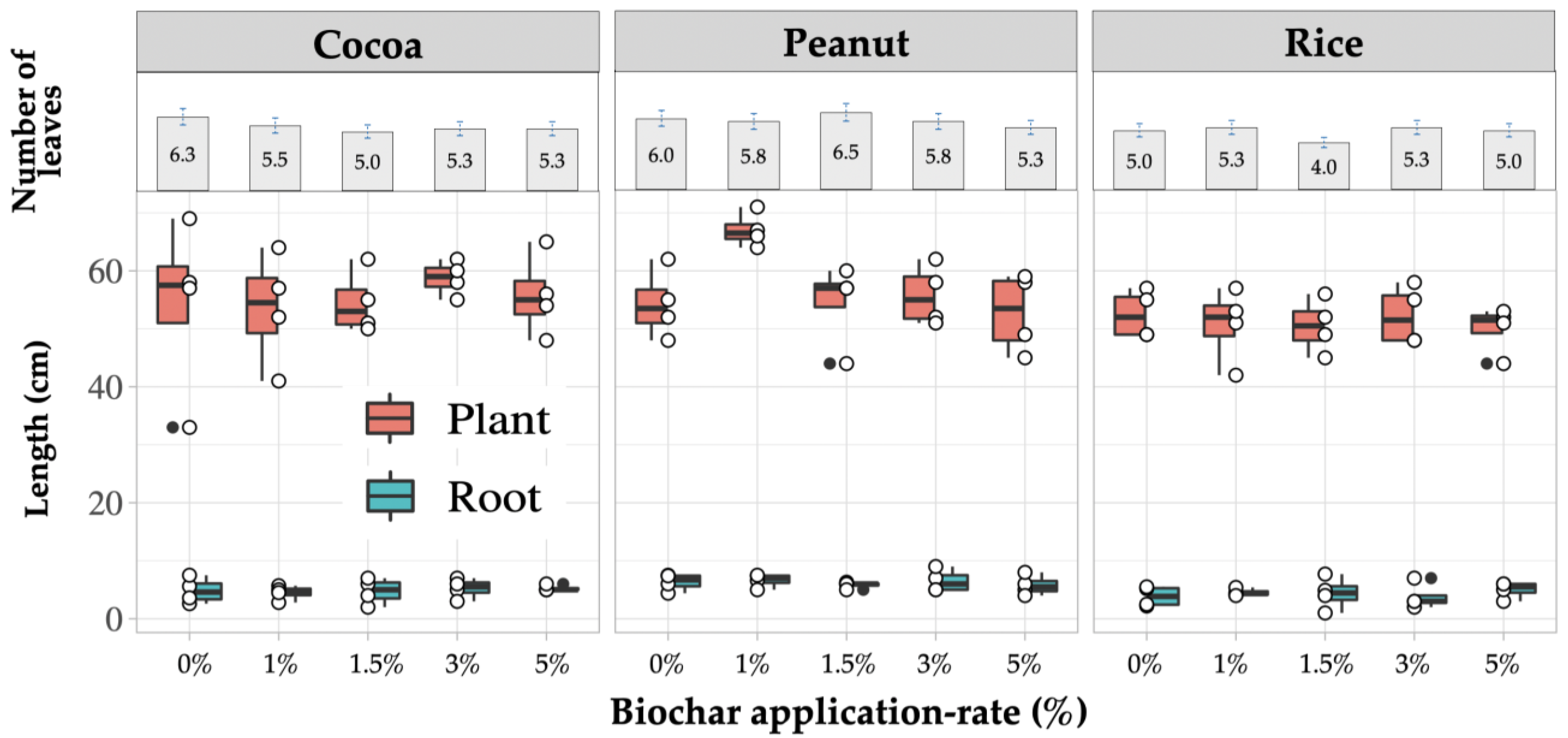

3.2. Biochar Effects on Plant and Root Length

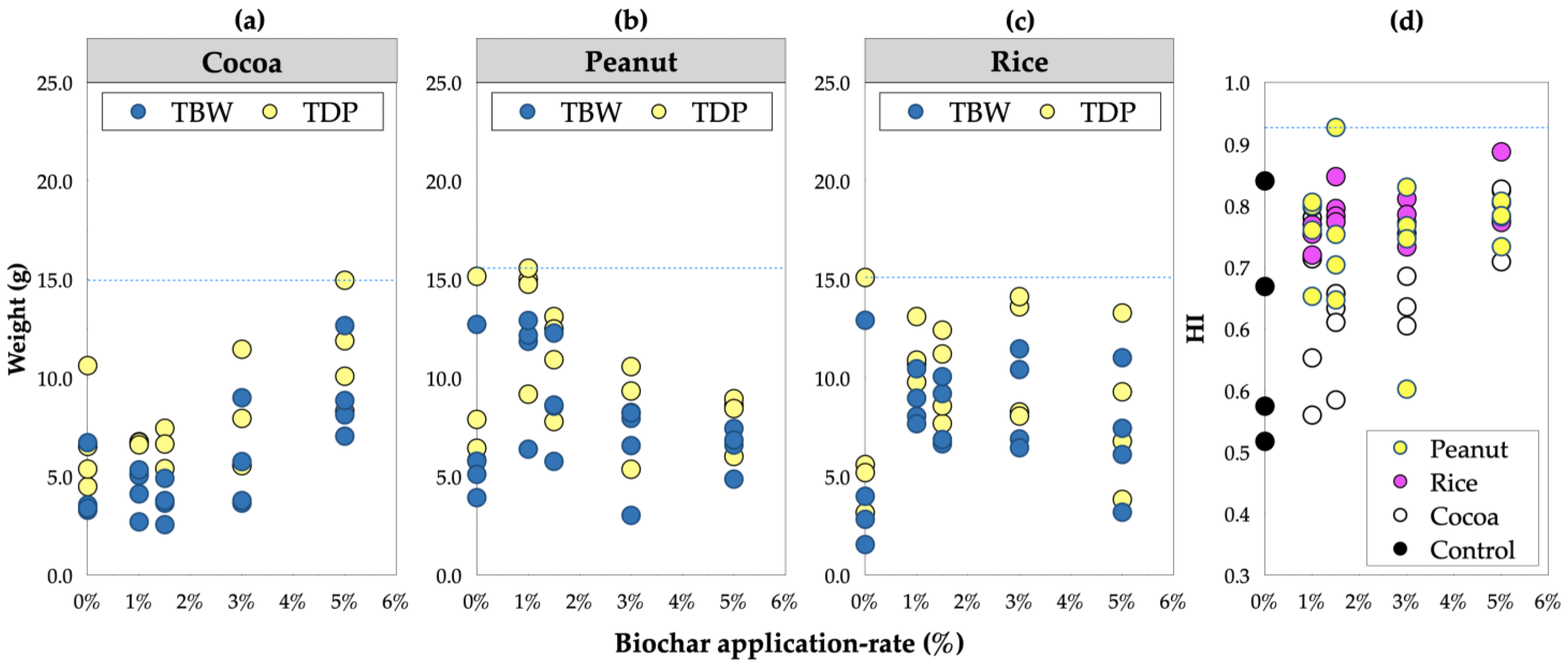

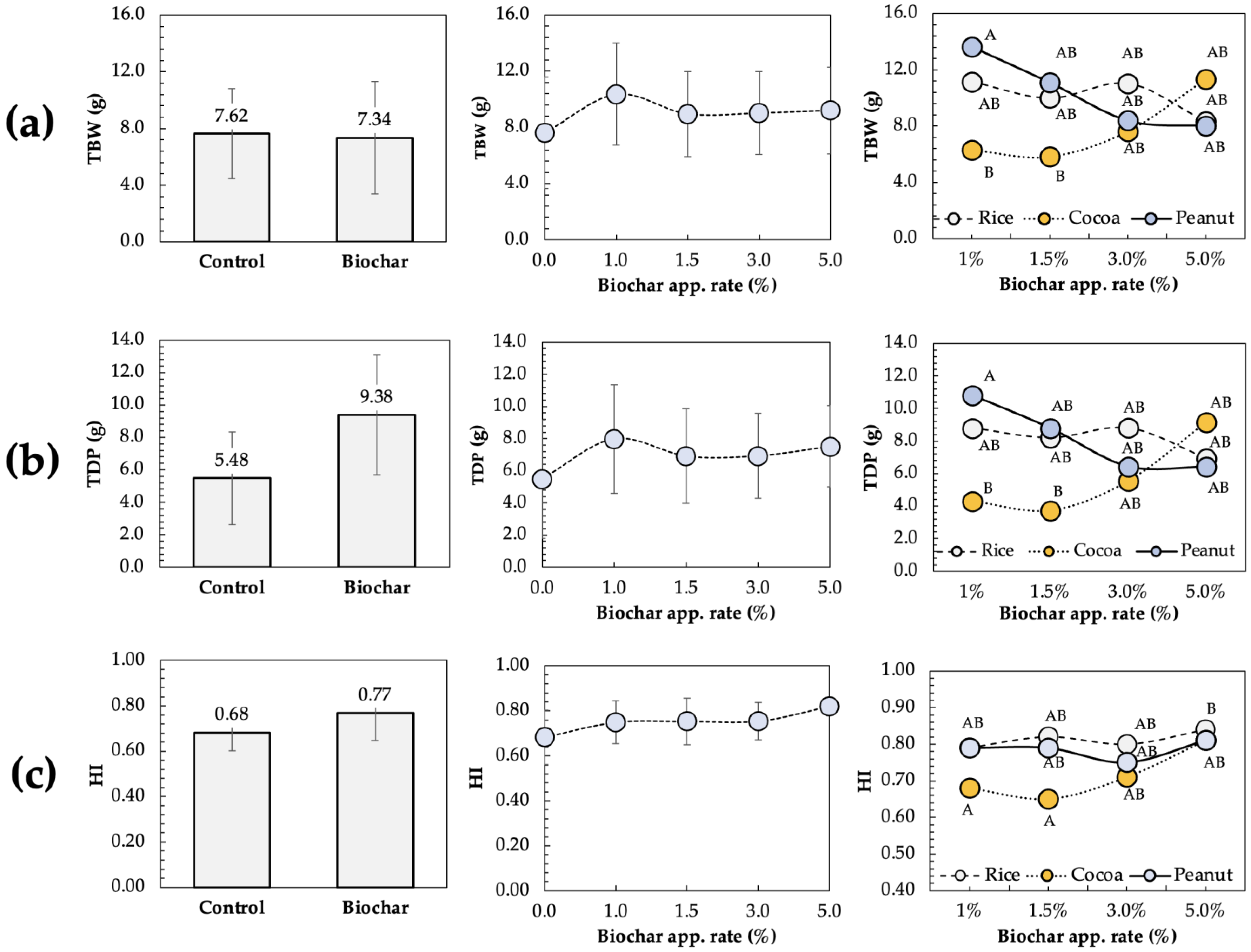

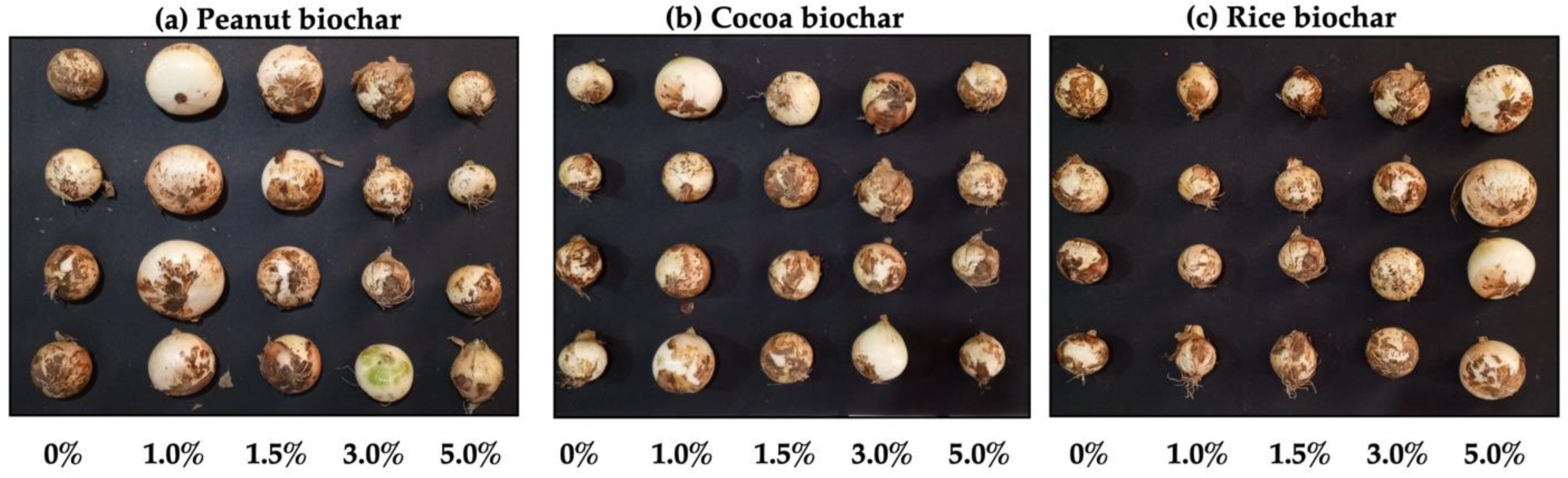

3.3. Biochar Effects on Dry Weight

4. Discussion

4.1. Biochar Characteristics

4.2. Functional Traits

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO Onion. Available online: https://www.fao.org/land-water/databases-and-software/crop-information/onion/en/ (accessed on 1 February 2024).

- Kumar, M.; Barbhai, M.; Hasan, M.; Punia, S.; Dhumal, S.; Radha; Rais, N.; Chandran, D.; Pandiselvam, R.; Kothakota, A.; et al. Onion (Allium cepa L.) Peels: A Review on Bioactive Compounds and Biomedical Activities. Biomed. Pharmacother. 2022, 146, 112498. [Google Scholar] [CrossRef] [PubMed]

- Sagar, N.A.; Pareek, S.; Benkeblia, N.; Xiao, J. Onion (Allium cepa L.) Bioactives: Chemistry, Pharmacotherapeutic Functions, and Industrial Applications. Food Front. 2022, 3, 380–412. [Google Scholar] [CrossRef]

- Abdelrasheed, K.G.; Mazrou, Y.; Omara, A.E.-D.; Osman, H.S.; Nehela, Y.; Hafez, E.M.; Rady, A.M.S.; El-Moneim, D.A.; Alowaiesh, B.F.; Gowayed, S.M. Soil Amendment Using Biochar and Application of K-Humate Enhance the Growth, Productivity, and Nutritional Value of Onion (Allium cepa L.) under Deficit Irrigation Conditions. Plants 2021, 10, 2598. [Google Scholar] [CrossRef] [PubMed]

- Geries, L.S.M.; El-Shahawy, T.A.; Moursi, E.A. Cut-off Irrigation as an Effective Tool to Increase Water-Use Efficiency, Enhance Productivity, Quality and Storability of Some Onion Cultivars. Agric. Water Manag. 2021, 244, 106589. [Google Scholar] [CrossRef]

- Malhi, G.S.; Kaur, M.; Kaushik, P. Impact of Climate Change on Agriculture and Its Mitigation Strategies: A Review. Sustainability 2021, 13, 1318. [Google Scholar] [CrossRef]

- Cui, H.; Zhang, L.; Zhang, Q.; Li, X.; Huang, Y.; Peng, Y. Advanced Nitrogen Removal from Low C/N Municipal Wastewater by Combining Partial Nitrification-Anammox and Endogenous Partial Denitrification-Anammox (PN/A-EPD/A) Process in a Single-Stage Reactor. Bioresour. Technol. 2021, 339, 125501. [Google Scholar] [CrossRef] [PubMed]

- Diatta, A.A.; Fike, J.H.; Battaglia, M.L.; Galbraith, J.M.; Baig, M.B. Effects of Biochar on Soil Fertility and Crop Productivity in Arid Regions: A Review. Arab. J. Geosci. 2020, 13, 595. [Google Scholar] [CrossRef]

- Kapoor, A.; Sharma, R.; Kumar, A.; Sepehya, S. Biochar as a Means to Improve Soil Fertility and Crop Productivity: A Review. J. Plant Nutr. 2022, 45, 2380–2388. [Google Scholar] [CrossRef]

- Jatav, H.S.; Rajput, V.D.; Minkina, T.; Singh, S.K.; Chejara, S.; Gorovtsov, A.; Barakhov, A.; Bauer, T.; Sushkova, S.; Mandzhieva, S.; et al. Sustainable Approach and Safe Use of Biochar and Its Possible Consequences. Sustainability 2021, 13, 10362. [Google Scholar] [CrossRef]

- Phillips, C.L.; Meyer, K.M.; Garcia-Jaramillo, M.; Weidman, C.S.; Stewart, C.E.; Wanzek, T.; Grusak, M.A.; Watts, D.W.; Novak, J.; Trippe, K.M. Towards Predicting Biochar Impacts on Plant-Available Soil Nitrogen Content. Biochar 2022, 4, 9. [Google Scholar] [CrossRef]

- Singh, E.; Mishra, R.; Kumar, A.; Shukla, S.K.; Lo, S.-L.; Kumar, S. Circular Economy-Based Environmental Management Using Biochar: Driving towards Sustainability. Process Saf. Environ. Prot. 2022, 163, 585–600. [Google Scholar] [CrossRef]

- Kumar, A.; Bhattacharya, T.; Shaikh, W.A.; Roy, A.; Chakraborty, S.; Vithanage, M.; Biswas, J.K. Multifaceted Applications of Biochar in Environmental Management: A Bibliometric Profile. Biochar 2023, 5, 11. [Google Scholar] [CrossRef]

- Guo, M.; Uchimiya, S.M.; He, Z. Agricultural and Environmental Applications of Biochar: Advances and Barriers. Agric. Environ. Appl. Biochar: Adv. Barriers 2016, 63, 495–504. [Google Scholar]

- Lehmann, J.; Joseph, S. Biochar for Environmental Management: Science and Technology; Earthscan: London, UK; Sterling, VA, USA, 2009; ISBN 978-1-84407-658-1. [Google Scholar]

- Ding, Y.; Liu, Y.; Liu, S.; Li, Z.; Tan, X.; Huang, X.; Zeng, G.; Zhou, L.; Zheng, B. Biochar to Improve Soil Fertility. A Review. Agron. Sustain. Dev. 2016, 36, 36. [Google Scholar] [CrossRef]

- Olmo, M.; Villar, R.; Salazar, P.; Alburquerque, J.A. Changes in Soil Nutrient Availability Explain Biochar’s Impact on Wheat Root Development. Plant Soil. 2016, 399, 333–343. [Google Scholar] [CrossRef]

- Alkharabsheh, H.M.; Seleiman, M.F.; Battaglia, M.L.; Shami, A.; Jalal, R.S.; Alhammad, B.A.; Almutairi, K.F.; Al-Saif, A.M. Biochar and Its Broad Impacts in Soil Quality and Fertility, Nutrient Leaching and Crop Productivity: A Review. Agronomy 2021, 11, 993. [Google Scholar] [CrossRef]

- Singh Karam, D.; Nagabovanalli, P.; Sundara Rajoo, K.; Fauziah Ishak, C.; Abdu, A.; Rosli, Z.; Melissa Muharam, F.; Zulperi, D. An Overview on the Preparation of Rice Husk Biochar, Factors Affecting Its Properties, and Its Agriculture Application. J. Saudi Soc. Agric. Sci. 2022, 21, 149–159. [Google Scholar] [CrossRef]

- Jeffery, S.; Verheijen, F.G.A.; Van Der Velde, M.; Bastos, A.C. A Quantitative Review of the Effects of Biochar Application to Soils on Crop Productivity Using Meta-Analysis. Agric. Ecosyst. Environ. 2011, 144, 175–187. [Google Scholar] [CrossRef]

- Ali, L.; Xiukang, W.; Naveed, M.; Ashraf, S.; Nadeem, S.M.; Haider, F.U.; Mustafa, A. Impact of Biochar Application on Germination Behavior and Early Growth of Maize Seedlings: Insights from a Growth Room Experiment. Appl. Sci. 2021, 11, 11666. [Google Scholar] [CrossRef]

- Cedeño, A.; Olmo, M.; Cedeño, G.; Lucas, M.; Saldarriaga, V.; Villar, R. Effects of Different Biochar Types on the Growth and Functional Traits of Rice (Oryza sativa L.). J. Ecol. Eng. 2024, 25, 282–290. [Google Scholar] [CrossRef]

- Sohi, S.P.; Krull, E.; Lopez-Capel, E.; Bol, R. A Review of Biochar and Its Use and Function in Soil. In Advances in Agronomy; Elsevier: Amsterdam, The Netherlands, 2010; Volume 105, pp. 47–82. ISBN 978-0-12-381023-6. [Google Scholar]

- Lehmann, J.; Cowie, A.; Masiello, C.A.; Kammann, C.; Woolf, D.; Amonette, J.E.; Cayuela, M.L.; Camps-Arbestain, M.; Whitman, T. Biochar in Climate Change Mitigation. Nat. Geosci. 2021, 14, 883–892. [Google Scholar] [CrossRef]

- Asai, H.; Samson, B.K.; Stephan, H.M.; Songyikhangsuthor, K.; Homma, K.; Kiyono, Y.; Inoue, Y.; Shiraiwa, T.; Horie, T. Biochar Amendment Techniques for Upland Rice Production in Northern Laos. Field Crops Res. 2009, 111, 81–84. [Google Scholar] [CrossRef]

- Xu, H.; Cai, A.; Wu, D.; Liang, G.; Xiao, J.; Xu, M.; Colinet, G.; Zhang, W. Effects of Biochar Application on Crop Productivity, Soil Carbon Sequestration, and Global Warming Potential Controlled by Biochar C:N Ratio and Soil pH: A Global Meta-Analysis. Soil. Tillage Res. 2021, 213, 105125. [Google Scholar] [CrossRef]

- Ye, L.; Camps-Arbestain, M.; Shen, Q.; Lehmann, J.; Singh, B.; Sabir, M. Biochar Effects on Crop Yields with and without Fertilizer: A Meta-analysis of Field Studies Using Separate Controls. Soil. Use Manag. 2020, 36, 2–18. [Google Scholar] [CrossRef]

- Hussain, R.; Ravi, K. Investigating Soil Properties and Vegetation Parameters in Different Biochar-Amended Vegetated Soil at Large Suction for Application in Bioengineered Structures. Sci. Rep. 2022, 12, 21261. [Google Scholar] [CrossRef]

- Wu, M.; Feng, Q.; Sun, X.; Wang, H.; Gielen, G.; Wu, W. Rice (Oryza sativa L.) Plantation Affects the Stability of Biochar in Paddy Soil. Sci. Rep. 2015, 5, 10001. [Google Scholar] [CrossRef] [PubMed]

- Niu, Z.; Ma, J.; Fang, X.; Xue, Z.; Ye, Z. Effects of Application of Rice Husk Biochar and Limestone on Cadmium Accumulation in Wheat under Glasshouse and Field Conditions. Sci. Rep. 2022, 12, 21929. [Google Scholar] [CrossRef] [PubMed]

- Wijaya, P.; Syam’un, E.; Syaiful, S.A. Interaction between Rice Husk Biochar and Three Species of Fungus on Growth and Yield of Shallot (Allium ascalonicum L.). Int. J. Life Sci. Agric. Res. 2023, 2, 71–79. [Google Scholar] [CrossRef]

- Gamage, D.N.V.; Mapa, R.B.; Dharmakeerthi, R.S.; Biswas, A. Effect of Rice-Husk Biochar on Selected Soil Properties in Tropical Alfisols. Soil. Res. 2016, 54, 302. [Google Scholar] [CrossRef]

- Kleyer, M.; Trinogga, J.; Cebrián-Piqueras, M.A.; Trenkamp, A.; Fløjgaard, C.; Ejrnaes, R.; Bouma, T.J.; Minden, V.; Maier, M.; Mantilla-Contreras, J.; et al. Trait Correlation Network Analysis Identifies Biomass Allocation Traits and Stem Specific Length as Hub Traits in Herbaceous Perennial Plants. J. Ecol. 2019, 107, 829–842. [Google Scholar] [CrossRef]

- Xiang, Y.; Deng, Q.; Duan, H.; Guo, Y. Effects of Biochar Application on Root Traits: A Meta-Analysis. GCB Bioenergy 2017, 9, 1563–1572. [Google Scholar] [CrossRef]

- Pérez-Harguindeguy, N.; Díaz, S.; Garnier, E.; Lavorel, S.; Poorter, H.; Jaureguiberry, P.; Bret-Harte, M.S.; Cornwell, W.K.; Craine, J.M.; Gurvich, D.E.; et al. New Handbook for Standardised Measurement of Plant Functional Traits Worldwide. Aust. J. Bot. 2013, 61, 167. [Google Scholar] [CrossRef]

- Higashikawa, F.S.; Silva, C.A.; Carducci, C.E.; Jindo, K.; Kurtz, C.; De Araújo, E.R.; Sousa Resende, R.; Alves, D.P. Effects of the Application of Biochar on Soil Fertility Status, and Nutrition and Yield of Onion Grown in a No-Tillage System. Arch. Agron. Soil. Sci. 2023, 69, 212–227. [Google Scholar] [CrossRef]

- Xiong, D.; Wang, D.; Liu, X.; Peng, S.; Huang, J.; Li, Y. Leaf Density Explains Variation in Leaf Mass per Area in Rice between Cultivars and Nitrogen Treatments. Ann. Bot. 2016, 117, 963–971. [Google Scholar] [CrossRef] [PubMed]

- Arif, M.; Fawaz, M.S.; Zuan, A.T.K.; Shah, R.U.; Ullah, R.; Elshehawi, A.M.; Al-Sadi, A.M.; Ihsan Ullah, M.; Güldür, M.E.; Alotaibi, S.S.; et al. The Impact of Different Biochars on Stemphylium Leaf Blight (SLB) Suppression and Productivity of Onion (Allium cepa L.). J. King Saud. Univ.-Sci. 2021, 33, 101575. [Google Scholar] [CrossRef]

- Lehmann, J.; Rillig, M.C.; Thies, J.; Masiello, C.A.; Hockaday, W.C.; Crowley, D. Biochar Effects on Soil Biota–A Review. Soil. Biol. Biochem. 2011, 43, 1812–1836. [Google Scholar] [CrossRef]

- Latimer, G.W., Jr. Official Methods of Analysis of AOAC International, 22nd ed.; Oxford University Press: Oxford, UK, 2023; ISBN 978-0-19-761013-8. [Google Scholar]

- Abrishamkesh, S.; Gorji, M.; Asadi, H.; Bagheri-Marandi, G.H.; Pourbabaee, A.A. Effects of Rice Husk Biochar Application on the Properties of Alkaline Soil and Lentil Growth. Plant Soil. Environ. 2015, 61, 475–482. [Google Scholar] [CrossRef]

- Aneseyee, A.B.; Wolde, T. Effect of Biochar and Inorganic Fertilizer on the Soil Properties and Growth and Yield of Onion (Allium cepa) in Tropical Ethiopia. Sci. World J. 2021, 2021, 5582697. [Google Scholar] [CrossRef] [PubMed]

- Shura, G.; Beshir, H.M.; Haile, A. Improving Onion Productivity through Optimum and Economical Use of Soil Macronutrients in Central Rift Valley of Ethiopia. J. Agric. Food Res. 2022, 9, 100321. [Google Scholar] [CrossRef]

- Sarkar, M.d.D.; Solaiman, A.H.M.; Jahan, M.S.; Rojoni, R.N.; Kabir, K.; Hasanuzzaman, M. Soil Parameters, Onion Growth, Physiology, Biochemical and Mineral Nutrient Composition in Response to Colored Polythene Film Mulches. Ann. Agric. Sci. 2019, 64, 63–70. [Google Scholar] [CrossRef]

- Hemowng, S.; Sangrit, C.; Phunthupan, P.; Butnan, S.; Vityakon, P. Rice-Derived Biochar Enhance the Yield of Spring Onion (Allium cepa L. Var. Aggregatum), While Reducing Pesticide Contamination in Soil and Plant. Appl. Ecol. Env. Res. 2021, 19, 349–358. [Google Scholar] [CrossRef]

- Steduto, P.; Hsiao, T.C.; Raes, D.; Fereres, E. AquaCrop—The FAO Crop Model to Simulate Yield Response to Water: I. Concepts and Underlying Principles. Agron. J. 2009, 101, 426–437. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, H.; Yang, S.; Wang, Y. Impacts of Biochar Addition on Rice Yield and Soil Properties in a Cold Waterlogged Paddy for Two Crop Seasons. Field Crops Res. 2016, 191, 161–167. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; Calero, J.M.; Barrón, V.; Torrent, J.; del Campillo, M.C.; Gallardo, A.; Villar, R. Effects of Biochars Produced from Different Feedstocks on Soil Properties and Sunflower Growth. Z. Pflanzenernähr. Bodenk. 2014, 177, 16–25. [Google Scholar] [CrossRef]

- Burachevskaya, M.; Minkina, T.; Bauer, T.; Lobzenko, I.; Fedorenko, A.; Mazarji, M.; Sushkova, S.; Mandzhieva, S.; Nazarenko, A.; Butova, V.; et al. Fabrication of Biochar Derived from Different Types of Feedstocks as an Efficient Adsorbent for Soil Heavy Metal Removal. Sci. Rep. 2023, 13, 2020. [Google Scholar] [CrossRef]

- Alsultan, R.M.H.; Al-Shamary, W.F.A.; Ibrahim, M.A.; Kahlel, A.S. Effect of Bio Char and Amino Acid (Steam) on Growth and Green Yield of Onion (Allium cepa L.) Variety (Karbala). IOP Conf. Ser. Earth Environ. Sci. 2023, 1259, 012047. [Google Scholar] [CrossRef]

- Khan, M.; Fatima, K.; Ahmad, R.; Younas, R.; Rizwan, M.; Azam, M.; Abadin, Z.U.; Ali, S. Comparative Effect of Mesquite Biochar, Farmyard Manure, and Chemical Fertilizers on Soil Fertility and Growth of Onion (Allium cepa L.). Arab. J. Geosci. 2019, 12, 563. [Google Scholar] [CrossRef]

- Permana, E.; Aulia, K.; Aziz, H.; Murti, S.D.S. Synthesis of Slow-Release Fertilizer with Coconut Shell Biochar and Activated Natural Zeolite for Red Onion (Allium ascalonium). J. Degrade. Min. Land. Manag. 2023, 11, 5037. [Google Scholar] [CrossRef]

- Rafique, M.; Ortas, I.; Ahmed, I.A.M.; Rizwan, M.; Afridi, M.S.; Sultan, T.; Chaudhary, H.J. Potential Impact of Biochar Types and Microbial Inoculants on Growth of Onion Plant in Differently Textured and Phosphorus Limited Soils. J. Environ. Manag. 2019, 247, 672–680. [Google Scholar] [CrossRef]

| Parameters | Rice | Cocoa | Peanut |

|---|---|---|---|

| pH | 7.5 | 10.2 | 8.7 |

| Electrical conductivity (mS/cm) | 2.4 | 30.1 | 2.59 |

| Organic matter (%) | 51.8 | 66.8 | 74.2 |

| Dry matter (%) | 93.4 | 84.8 | 91.3 |

| Moisture (%) | 6.6 | 15.2 | 8.7 |

| Density (g/cm3) | 0.233 | 0.377 | 0.204 |

| Apparent density (g/L) | 218 | 320 | 186 |

| C (%) | 30.1 | 38.8 | 43.1 |

| N (%) | 0.78 | 1.31 | 1.28 |

| C/N | 39 | 30 | 34 |

| P (%) | 0.16 | 0.61 | 0.1 |

| K (%) | 0.44 | 12.1 | 1.47 |

| Mg (%) | 0.07 | 0.84 | 0.37 |

| Ca (%) | 0.12 | 1.27 | 1.01 |

| Na (%) | 0.01 | 0.06 | 0.09 |

| Fe (ppm) | 121 | 1034 | 4589 |

| Mn (ppm) | 69.6 | 65 | 77 |

| Cu (ppm) | 1.7 | 15.2 | 20.2 |

| Zn (ppm) | 141 | 248 | 182 |

| B (ppm) | 22.2 | 87.6 | 52 |

| Variables | % VC | Biochar Type | App. Rate | Biochar App. Rate | Control vs. Treat. |

|---|---|---|---|---|---|

| Plant height (cm) | 10.82 | 0.0093 ** | 0.2567 ns | 0.0871 ns | 0.1613 ns |

| Number of leaves per plant | 22.02 | 0.0879 ns | 0.8545 ns | 0.5492 ns | 0.4188 ns |

| Root length (cm) | 31.92 | 0.0145 * | 0.9659 ns | 0.8725 ns | 0.3385 ns |

| Variables | % VC | Biochar Type | Application Rate | Biochar Application Rate | Control vs. Treatments |

|---|---|---|---|---|---|

| DPW (g) | 33.66 | 0.7369 ns | 0.1207 ns | 0.3662 ns | 0.4236 ns |

| DRW (g) | 48.49 | 0.044 * | 0.1095 ns | 0.6705 ns | 0.2424 ns |

| TBW (g) | 30.18 | 0.0034 ** | 0.5947 ns | 0.0024 ** | 0.0089 ** |

| TDP (g) | 26.49 | 0.0113 * | 0.4837 ns | 0.0021 ** | 0.0163 * |

| HI | 9.45 | 0.0012 ** | 0.0642 ns | 0.3565 ns | 0.0042 ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cedeño, Á.; Saldarriaga, V.; Cedeño, G.; López, G.; Mendoza, J. Effects of Biochar Type on the Growth and Harvest Index of Onion (Allium cepa L.). AgriEngineering 2024, 6, 1568-1580. https://doi.org/10.3390/agriengineering6020089

Cedeño Á, Saldarriaga V, Cedeño G, López G, Mendoza J. Effects of Biochar Type on the Growth and Harvest Index of Onion (Allium cepa L.). AgriEngineering. 2024; 6(2):1568-1580. https://doi.org/10.3390/agriengineering6020089

Chicago/Turabian StyleCedeño, Ángel, Veris Saldarriaga, Galo Cedeño, Geoconda López, and José Mendoza. 2024. "Effects of Biochar Type on the Growth and Harvest Index of Onion (Allium cepa L.)" AgriEngineering 6, no. 2: 1568-1580. https://doi.org/10.3390/agriengineering6020089

APA StyleCedeño, Á., Saldarriaga, V., Cedeño, G., López, G., & Mendoza, J. (2024). Effects of Biochar Type on the Growth and Harvest Index of Onion (Allium cepa L.). AgriEngineering, 6(2), 1568-1580. https://doi.org/10.3390/agriengineering6020089