1. Introduction

Biomass is a distributed resource, thus the collection and delivery of feedstock to a biorefinery is a key cost issue, irrespective of the product produced. In this analysis, biomass is referred to as “feedstock”, and round baling of herbaceous material (switchgrass) is the harvest method. The bale is a 1.5 m long × 1.2 m diameter round bale, hereafter referred to as a “5 × 4 bale”. One argument against round baling has historically been the lack of an efficient system for highway hauling. The round bale was developed for hay harvest, where the hay is typically fed on the farm where it is produced. Its main advantage in a feedstock logistics system is that the bale self-protects from rainfall penetration in the field after harvest and in single layer ambient storage in a satellite storage location (SSL). The round baling of biomass feedstocks is preferable in regions such as the Piedmont to leverage existing hay-harvesting equipment where topography, precipitation levels, and farm size make large rectangular balers impractical [

1].

Lamers et al. [

2] presented a study that compared a conventional feedstock supply system (one-year contracts with farmers to deliver low-density, raw biomass) to an advanced feedstock supply system based on a network of depots. The processing of the raw biomass into a higher density, more uniform intermediate at the depot would “enable wider system benefits including supply risk reduction, industry scale-up conversion, yield improvements, and reduced receiving facility costs”. This study endorses their concept. The systems for the delivery of raw biomass (round bales) described here are applicable for delivery to a depot, where an intermediate is produced, or a biorefinery, where some final product (or products) is produced. Hereafter, we will use the term “depot”.

Labor productivity, defined as Mg-handled-per-hour, is a key issue in feedstock logistics. Consider the simple example of a worker using a telehandler to spear bales and load them individually onto a truck. A skilled operator, in a production setting, can average a bale loaded every 1.5 min. Assuming this is achieved, productivity will average 70% of ideal over an entire season, the per-Mg labor cost, just to load round bales for highway hauling, is 2.24 USD/Mg. The high labor cost of single-bale handling is a key consideration for logistics system design.

Another key issue is the impact of load and unload time on truck productivity. The time a truck is stopped to load, or unload, reduces the number of loads hauled per day and the labor cost for the truck operator, USD-per-Mg hauled, is increased.

The traditional method of hauling round bales is loading the bales individually onto a flatbed trailer. The bales are loaded two layers high and strapped down, creating a total load of 40 bales.

2. Objective

The objective of this study is to compare the cost for the delivery of round bales using three emerging hauling technologies. The study presumes that switchgrass, a dedicated energy crop, is harvested and stored in SSLs across a feedstock production region. The beginning point for the comparison is bales in single layer ambient storage in a network of SSLs, and the end point is a line of bales on a conveyor into a depot for 24/7 annual operation.

3. Description of Potential Round-Bale Hauling Technologies

3.1. Load-Securing Systems for Bales

An improved method for securing a load of bales was developed by Stinger [

3] as part of a DOE project [

4]. This technology, identified as the Stinger Advanced Load Securing System (ALSS) (

Figure 1) has been used to secure a load of 1 m × 1.2 m × 2.4 m large rectangular bales on a 16.2 m flatbed trailer modified for the installation of the ALSS. This system was analyzed in 2013 by Webb et al. [

5], and it is specified for the cost analysis reported by Roni et al. [

6]. No test data were found in the literature where 40 5 × 4 round bales were secured with the ALSS.

A technology to facilitate the securing of a load of round bales was developed by industry, but it is not commercially available at this time. The bales are individually loaded on a 16.2 m flatbed, and, when the load is complete, cables are folded into up into position along the sides. These cables are tightened to secure the load. The operator folds up the arms holding the cables and tightens the cables without leaving the truck cab. This system will hereafter be referred to as the “Cable” system.

3.2. Large Handling Units

The shipping industry was revolutionized in the mid-1950s by the introduction of the shipping container, and there are a number of examples of large handling units developed for agriculture that emulate this technology. The cotton module system and the bin system used for sugarcane in South Florida are two examples in the Southeastern USA.

A multi-bale handling unit for large rectangular bales was developed as part of the previously mentioned DOE project [

4]. Kellerman Mfg., Pelham, Iowa, developed a prototype self-propelled bale picking truck to build a 36-bale unit of large rectangular bales. The concept called for this unit to be self-loaded at the edge of the field using a live-bottom truck trailer, thus eliminating single-bale loading and significantly reducing truck load time. The truck self-unloads the 36-bale unit onto the ground for at-depot storage, or can deliver it directly onto a conveyor for bale singulation and immediate processing. Thus, single-bale handling is eliminated for unloading.

A subsequent DOE project [

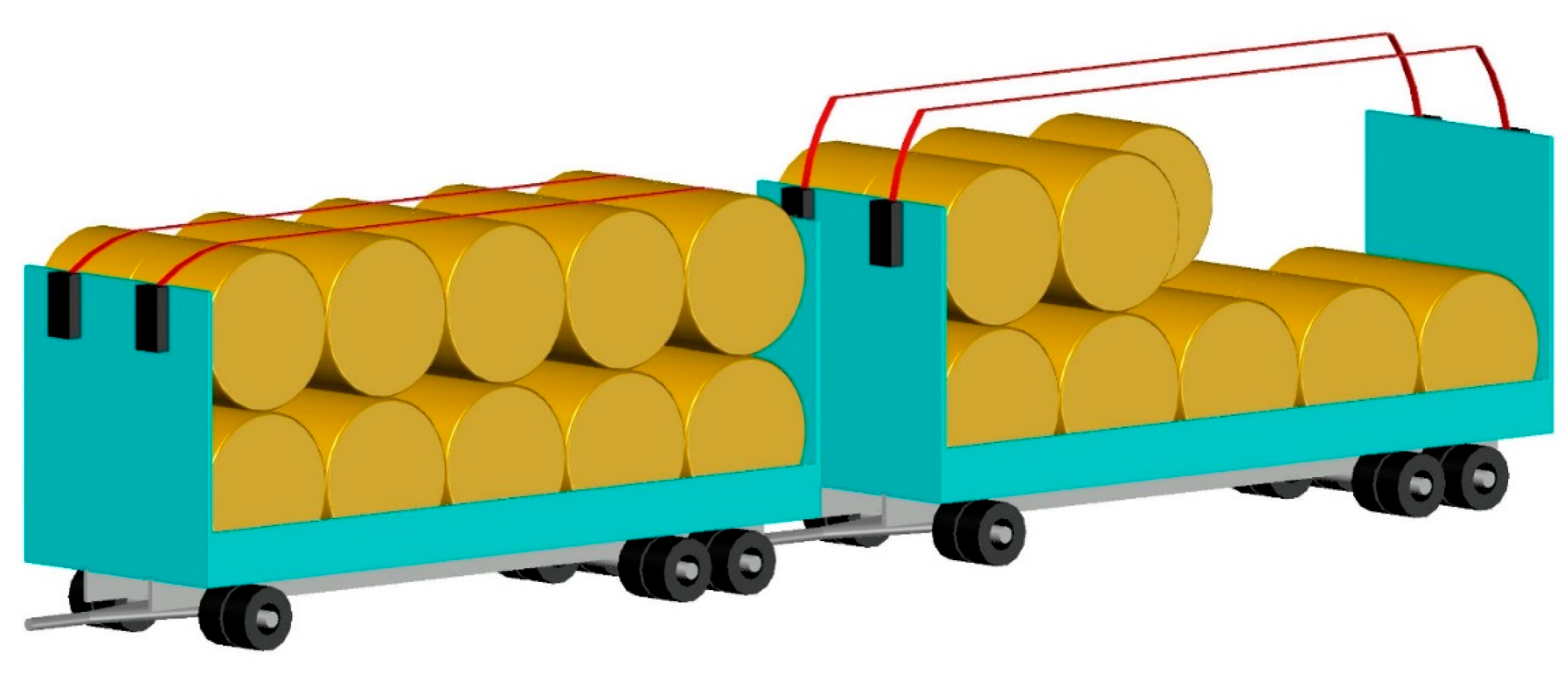

7] developed prototypes for a multi-bale handling system for round bales, identified as the “Rack” system. The rack holds twenty 5x4 bales and has dimensions that emulate a commercial dry freight container, thus the same logistics technology used for these containers is applicable for the racks. The rack is hauled on a trailer towed by a truck tractor with a pintle-hook hitch. Two trailers in tandem form a load, thus a truckload is 40 bales. The Rack system has been reported on several times since the initial work was done [

8,

9,

10] and data from these studies are used in this study. No reference for another multi-bale handling unit for round bales was found in the literature.

This study analyzes three technologies for the highway hauling of 5x4 round bales. (A truckload is defined as 40 bales.) The technologies are as follows: (1) the “Cable” system, (2) a modification to the Stinger ALSS, identified as the “ALSS-2” system, and (3) the “Rack” system. None of these technologies is available commercially, but could be developed if there is a market. The Cable system is installed on a standard 16.2 m flatbed trailer towed with a conventional (fifth-wheel) truck tractor. The ALSS-2 system is hypothesized for this study by installing the ALSS on a 20-bale flatbed trailer with features like the rack trailer. Two of these trailers towed in tandem form a 40-bale load (

Figure 2). Hereafter, the two-trailer unit for both the ALSS-2 and Rack systems is referred to as a “tandem”. Some prototyping of the Cable and Rack systems has been completed; however, the ALSS-2 is only a concept at this point.

4. Proposed Structure of Industry for the Comparison

Resop et al. [

11] did a study to document the benefit that can be achieved with a central control of highway hauling by a depot. Their study envisioned a business plan where the depot has a contract with producers to buy feedstock stored in SSLs. The producer grows, harvests, and stores feedstock in an SSL, which they build and maintain as part of their farmgate contract. Load-out and hauling is done by the depot.

The Resop et al. [

11] central control concept uses the assumptions shown in

Table 1 to structure the industry in a way that achieves the central control benefit. These same assumptions are used here for operation of the two systems (ALSS-2 and Rack) which use the two-trailer tandem.

The Resop et al. [

11] study used a database of potential production fields within a 48 km radius of a presumed depot in Gretna, Virginia, and this database, identified as the “Gretna database”, was used for the load-out simulations performed for this study. The depot annual capacity was 152,526 Mg, which equates to 47.3 bales/h (0.8 bale/min) for 24/7 operation, 48 week/y.

4.1. Load-Out Simulations

The loading of the truck is a key part of any feedstock logistics analysis. Here, these operations are referred to as “load-out” operations. There were three simulations developed to analyze the loading of trucks at the SSLs.

The load-out productivity for the first load-out simulation uses an “ideal” productivity of 5 loads per 10 h workday (2.0 h/load). The ideal productivity is then 5 × 16 Mg/load = 80 Mg/d, or 200 bales/d. Using an achieved productivity equal to 70% of ideal, the achieved productivity for this simulation is 0.7 × 80 = 56 Mg/d, or about 4.3 min/bale over a 10 h haul day.

For the second load-out simulation, the ideal load-out productivity is defined to be 6 loads/d, or about 1.7 h/load in a 10 h workday. Using the 70% factor, each load-out operation will average 6 × 0.7 = 4.2 loads/d over a 48-week season. The achieved productivity is 4.2 loads/d × 16 Mg/load = 67.2 Mg/d, or about 3.6 min/bale over a 10 h haul day.

For the third load-out simulation, an ideal productivity is defined as 7 loads per 10 h workday (about 1.4 h/load). Optimistically, the ideal productivity is then 7 × 16 Mg/load = 112 Mg/d, or 280 bales/d. The achieved ideal productivity in this simulation is 0.7 × 112 = 78.4 Mg/d.

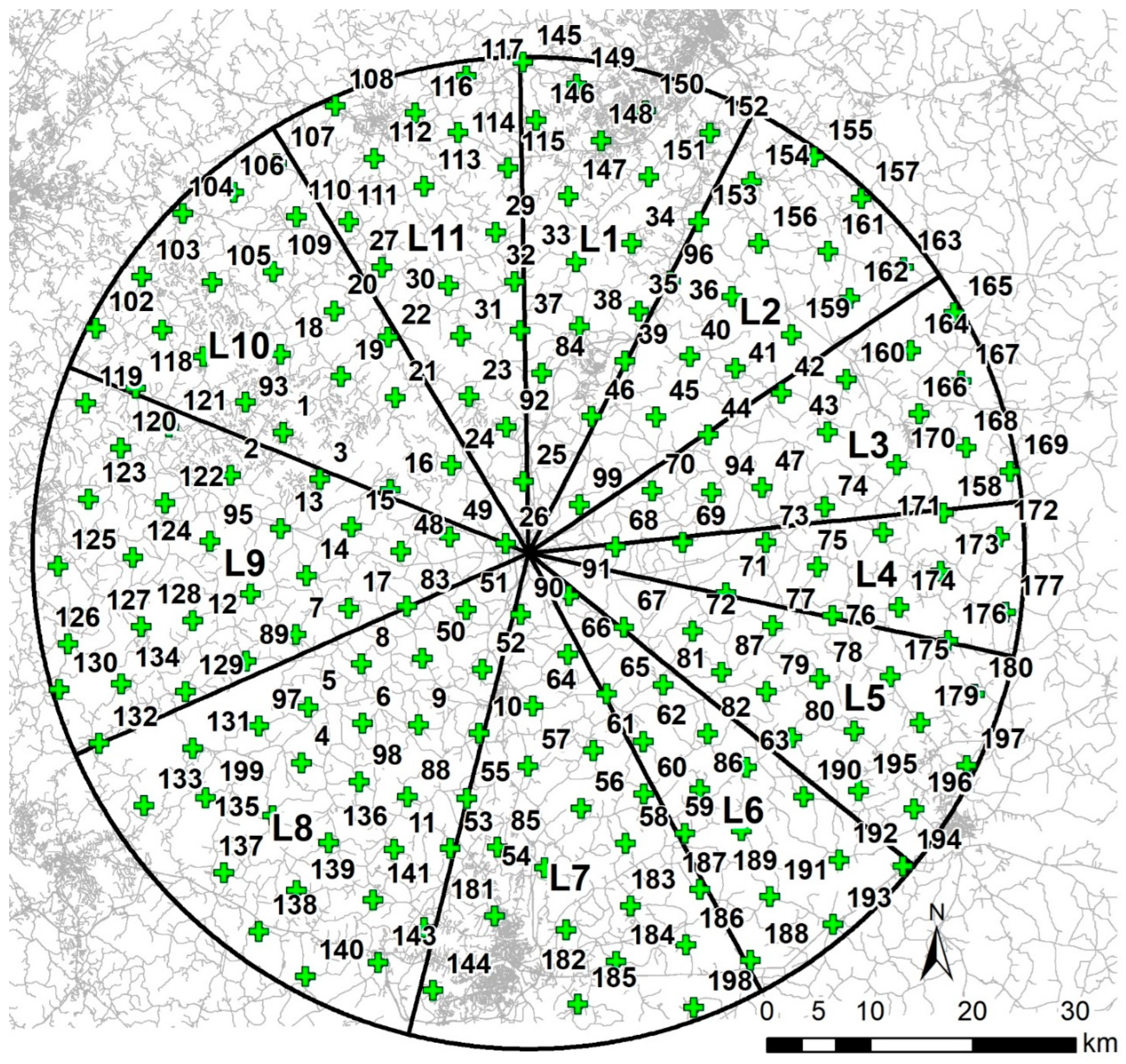

The Gretna database was divided into 11 subareas (

Figure 3) for the first load-out simulation, hereafter identified as the “11-load-out” simulation. The second load-out simulation divided the Gretna database into 9 subareas, the same as the division used by Resop et al. [

11]. The third load-out simulation presumes the highest productivity that the authors believe might be achieved. For this simulation, the Gretna database was divided into 8 subareas. For all three simulations, the “pie-shaped” subareas were defined such that each subarea had approximately the same total mass of feedstock storage. Assumptions used for the three load-out simulations are summarized in

Table 2.

Each simulation database had the same mass distribution across the 199 SSLs, and the same highway distance from the SSL to a theoretical depot located at the center of the feedstock supply area. There was an attempt to schedule the load-out sequence such that approximately the same total truck operating hours were required each week for the 48-week annual operation. For example, load-out operations in the 9-load-out simulation started at the center (i.e., depot) in subareas 1, 3, 5, 7, and 9 and proceeded outward, and load-outs in subareas 2, 4, 6, and 8 began at the outer edge of the subarea and proceeded inward. At the completion of the shipping from one SSL, the load-out moved to the next. Continuing with the 9-load-out simulation as an example, productivity for a 6 d week was 6 × 67.2 = 403.2 Mg/wk. Time required for a move between SSLs was assigned as 0.5 days, thus, if a move between SSLs occurred during the week, the productivity for that week was 403.2 (5.5/6) = 396.6 Mg/wk. A similar procedure was used to schedule the load-out sequence for the 8 and 11-load-out simulations.

Key constraint: no move to the next SSLs occurs until all full loads stored at a given SSL are shipped. An additional explanation of the load-out scheduling for the individual load-out operations is given by Resop et al. [

11].

4.2. Truck Load and Unload Times Used for Hauling Simulations

Average hauling speed on public roads, and the travel distance from the SSL to the depot, are set variables. Thus, given the constraint of a 40-bale load, the key variables in truck productivity (Mg/d) are the load and unload times.

Simulations were done for the three trucking technologies, identified as Cable, ALSS-2, and Rack. All three technologies use the same telehandler operation for load-out at the SSL. Single bales are lifted from single-layer ambient storage and loaded on the truck. For the Rack system, an extra piece of equipment is needed. The telehandler picks up individual bales from storage and loads them into a bale loader, which pushes bales into the lower tier of the rack as described by Grisso et al. [

9].

The truck load time for the Cable simulation is the time the truck is parked at the SSL to be loaded (Ltt = 65 min). The unload time estimate for the Cable system is based on multiple telehandlers operating to unload the parked truck at the biorefinery. The estimate used for the Cable truck cycle time is 80 min (Utt = 80), which is the time to weigh the truck in, sample for quality, unload the 40-bale load (which includes placing individual bales in “at-depot” storage), and then weighing the truck out.

The load time estimate for the ALSS-2 truck cycle time (time to hook and unhook a tandem at the SSL) is 15 min (Ltt = 15). The unload time for the truck cycle, time to weigh in the truck, sample for quality, unhook and hook a tandem, and weigh out is 35 min (Utt = 35 min).

The Rack system simulation used an average load time of 15 min (Ltt = 15). Unloading is done with a forklift that lifts off the two loaded racks and replaces them with two empty racks. The unload time for the truck cycle, time to weigh in the truck, sample for quality, lift off two full racks and load two empty racks, and weigh out, is 20 min (Utt = 20).

The assumed ideal truck load and unload times used in the hauling simulations are summarized in

Table 3. It is important to note that the Cable and ALSS-2 systems both presume that bales are stored at the depot by placing them

individually, as compared to the Rack system where the bales remain in the rack and are placed in storage as a 20-bale handling unit. The influence of this key operating difference is revealed in the cost analysis.

4.3. Description of Simulations

There were three hauling technology simulations for each of the load-out simulations, thus there were a total of 3 × 3 = 9 simulations. It was straightforward to simply change the truck load and unload times and rerun the Octave program to obtain results for the three hauling technologies.

For all simulations, the number of loads hauled from each SSL was rounded down to eliminate partial loads. Remaining feedstock at an SSL, which has to be purchased in accordance with the feedstock contract, was assumed to be hauled by a “clean-up” crew. The percentage of the total stored feedstock hauled by the clean-up crew was calculated; however, no clean-up cost estimate is reported.

Each hauling technology simulation calculated the total truck operating hours each week required to haul all loads from the SSLs loaded out that week. The road distances in the Gretna database were used, and the average haul speed was assumed to average 70 km/h for delivery and return. An ideal truck cycle time was computed using the haul speed and the ideal load and unload times (

Table 3). The achieved average cycle time used in the hauling simulations was 1.4 times the ideal to account for the unavoidable delays encountered in a commercial operation (e.g., traffic, waiting in a queue for loading or unloading, etc.).

5. Simulation Results

Results obtained for the three load-out simulations are summarized in

Table 4. The same feedstock distribution (152,526 Mg) was used across the 199 SSLs, so the results are similar, as expected. The small difference in number of loads, and thus the clean-up percentage, is a consequence of the scheduling of moves between SSLs; sometimes a move leaves behind a larger partial load.

In the load-out simulations, load-out was done continuously, thus there was no allowance for weather events (e.g., heavy rain or ice or snow on roads), major equipment issues (beyond routine maintenance), or holidays. These delays are accounted for with “contingency days”. For example, if continuous operation completes the hauling for a given subarea in 258 days, and the 48-week season has 48 × 6 = 288 days, then the contingency days for this schedule are calculated as 288 − 258 = 30 days.

The variability in contingency days between load-outs within a given simulation is not a significant issue. In a commercial operation, the various load-out operations will be rescheduled at the end of the season to have all finished their assigned SSLs at approximately the same time. It is interesting to calculate the average contingency days per work week for each load-out. The 329 contingency days for the 11 load-outs equates to about 0.62 days per load-out per week, which compares to the 0.66 days for the 8-load-out simulation. The 214 contingency days for the 9 load-outs equates to about 0.50 days per load-out per week.

The achieved average load-out productivity, calculated with the 11-load-out simulation, averaged across all 11 load-outs over a 48-week season, was 48.1 Mg/d, which is about 85.9% of the 56 Mg/d ideal. Thus, moves between SSLs, plus the contingency days, reduced the average achieved productivity by 14.1%.

The achieved average load-out productivity for the 9-load-out simulation, averaged over a 48-week season, ranged from 56.6 to 61.9 Mg/d, and the overall was 58.8 Mg/d, which is 87.5% of the 67.2 Mg/d ideal. Thus, moves between SSLs plus the contingency days decreased productivity by about 12.5%.

The achieved average load-out productivity for the 8-load-out simulation, averaged over a 48-week season, ranged from 64.0 to 67.3 Mg/d, and the overall was 66.2 Mg/d, which is about 84.4% of the 78.4 Mg/d ideal. Thus, moves between SSLs plus the contingency days reduced the average achieved productivity by 15.6%.

5.1. Required Truck Fleet

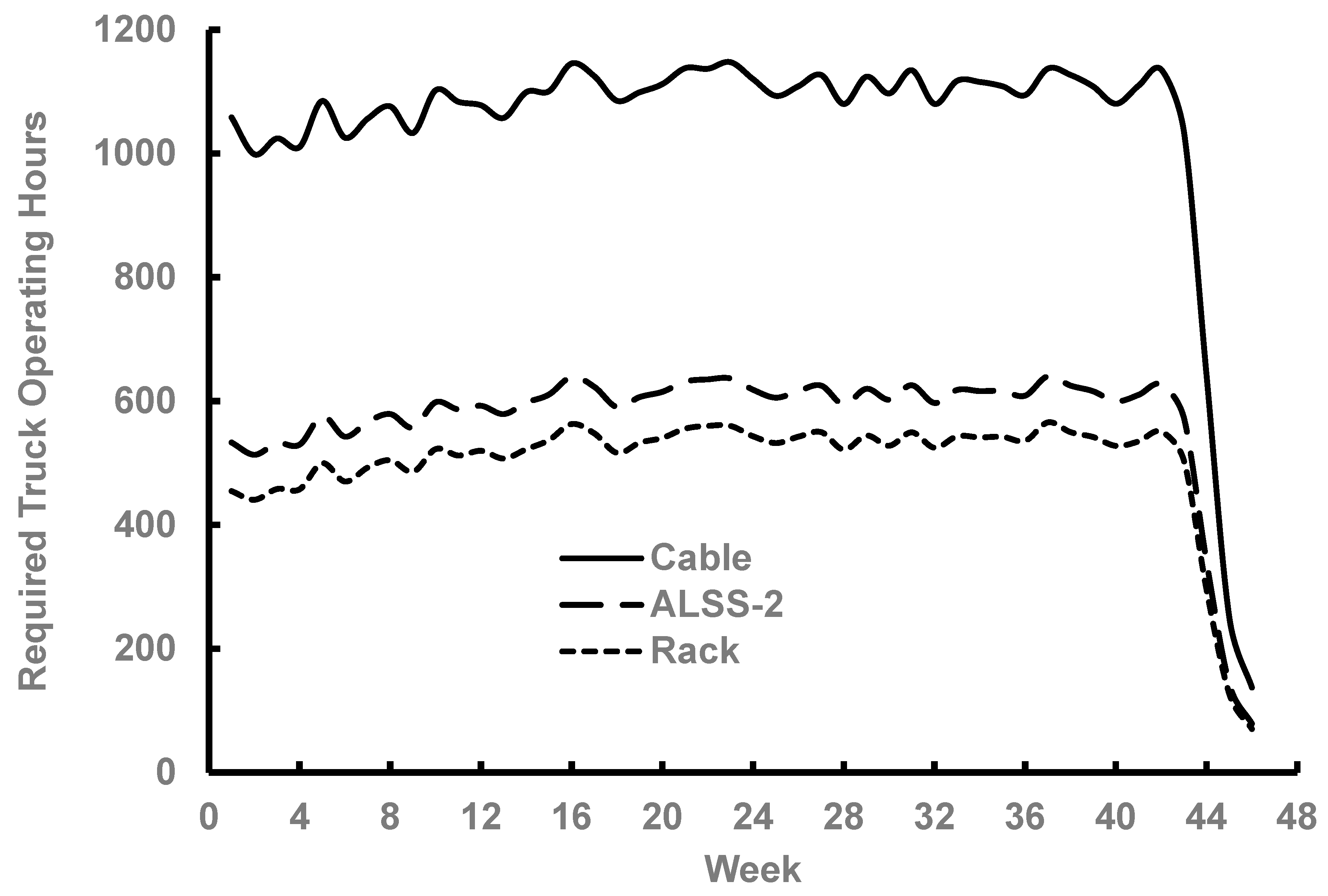

The required total truck operating hours for each load-out and hauling combination are given in

Table 5. These results highlight the impact of load and unload time on truck productivity. The fact that the number of load-out operations (11, 9, or 8) has a modest impact on total truck operating hours requires explanation. The number of loads hauled from each SSL is approximately the same for all three load-out simulations. (There is a small change in number of loads due to varying amounts of feedstock left at the SSL because of the full-load restriction.) For this study, a crew is always ready to load the truck when it arrives at an SSL, and unload it when it arrives at the biorefinery. No delays were programed in the simulations.

It requires more than twice the truck operating hours to haul with the Cable system as the Rack system. Truck operating hours required each week over a 48-week season are given in

Figure 4 for the three hauling simulations using the 9-load-out database. These results show that the sequencing procedure chosen for the various unload operations in the subareas gave a reasonably uniform total truck operating hours for each week of the 48-week season.

The number of trucks required by the Cable system was calculated as follows. The potential operating hours for a single truck operating 48 weeks, 12 h per day, 6 days per week are 3456 h/y. Using the 9-load-out simulation data (

Table 5), 48,043 total operating hours are required, and these hours could be supplied by 13.9~14 trucks. (The maximum of 1249 h required in Week 12 would require 17.3~18 trucks.) A system design decision must be made, and the following rule is proposed.

Suppose a given truck can average productive hours equal to 70% of the total hours, identified here as the “truck productivity factor”. This factor is used because there will always be unscripted delays in loading and unloading, a constraint not fully accounted for with the simple calculation of total required hours. This means the average productive hours are 3456 × 0.7 = 2419.2~2420 h. The required truck fleet is 48,043/2420 = 19.9~20 trucks, and the productive hours must average 2402 h per truck, which is a truck productivity factor of 0.695; thus, a 20-truck fleet is chosen. Results for the other two hauling systems are summarized in

Table 6. The ALSS-2 reduced the truck fleet size by 45% from 20 to 11, primarily because of the reduction in truck load and unload times. However, the Rack system, because of an additional reduction in truck unload time, reduced the fleet size by 50% from 20 to 10 trucks.

5.2. Required Trailers (or Trailer Tandems) for Cable and ALSS-2 Systems

Each truck in the Cable fleet has one trailer equipped with the cable system, a total of 20 trailers. In the ALSS-2 fleet, each truck has one tandem attached and one extra tandem, either parked at the SSL for loading, or parked at the depot for unloading. The system design calls for two extra tandems, thus the total required is 11 × 2 + 2 = 24 tandems.

The computation of the number of racks (and rack trailers) required is given in

Appendix A. Assuming an 8 h contingency remaining in at-depot storage when the haul weeks begins, the total is 109 racks, which includes 5 racks in reserve, in case a rack is damaged. On average, each rack is used to haul 3.8 loads/wk, which means each rack hauls over 180 loads per year, a fairly heavy duty cycle.

6. Receiving Facility Design

The design of the receiving facility at the depot, because it defines the unload time for the trucks, is critical for the logistics system analysis. The receiving facility includes all operations required to receive deliveries of round bales and process these bales into a continuous stream of size-reduced material for 24/7 operation, year-round. This comparison considers only the operations required to unload trucks and flow round bales into, and out of, at-depot storage. The operations to weigh the truck and sample for quality are basically the same for all three systems, thus these costs are expected to be approximately the same. Additionally, the operations are the same for all three systems once a line of bales has been established on a conveyor feeding the initial size reduction operation.

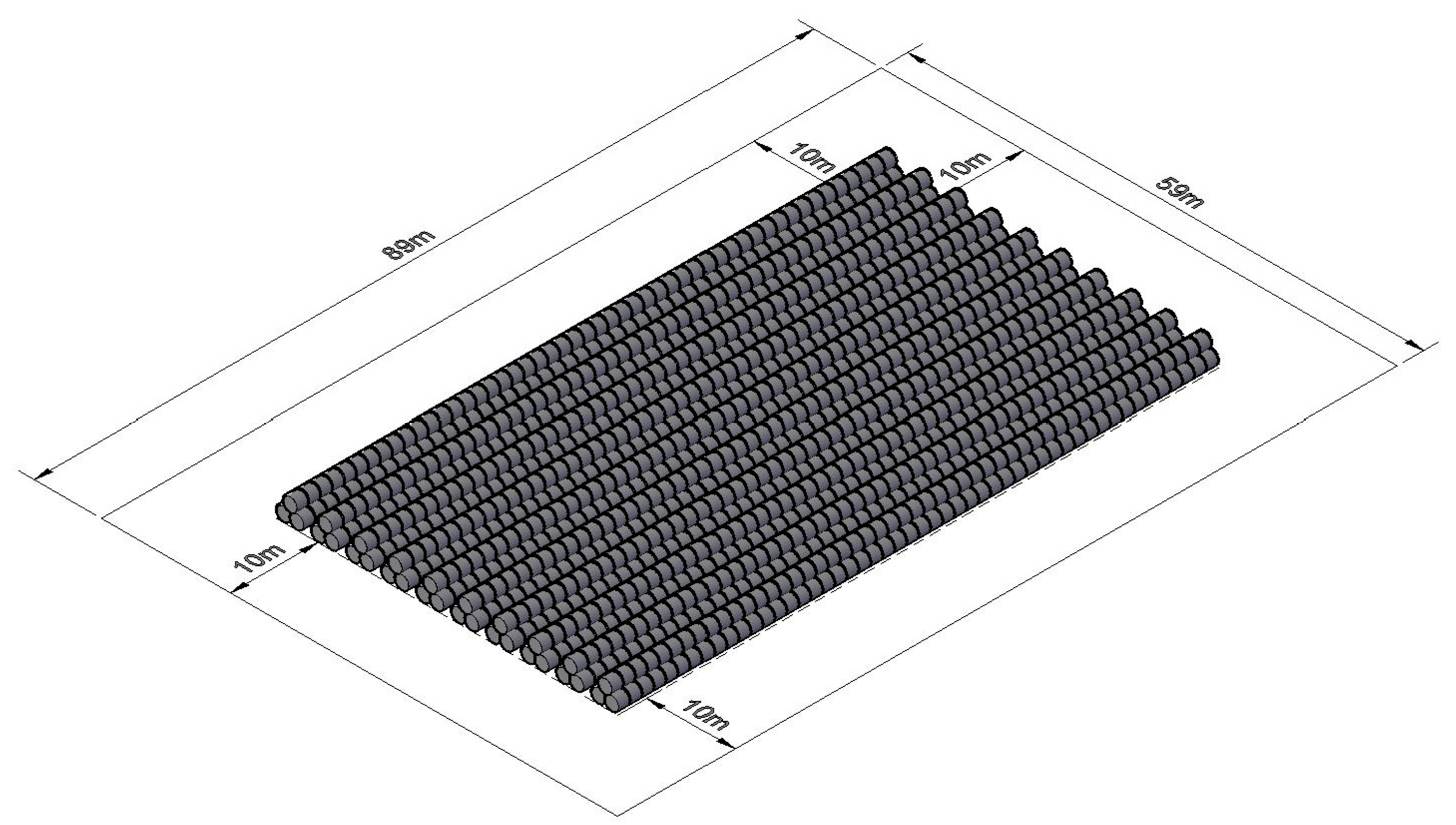

The design of the receiving facility is given in

Appendix B. The total operation-storage area for the Cable and ALSS-2 systems was 11,250 m

2, and for the Rack system it was 8000 m

2.

For the biorefinery to process all feedstock, the processing rate must average 3178 Mg/week (48-week season). An average truckload is 16 Mg; thus, the biorefinery must receive, on average, 199 truckloads/week or an average of 33.2 truckloads/d for a 6-day haul week. For a 12 h hauling workday, the receiving rate must average about 3 loads/h, which is a truckload every 20 min, the specified average unload time of the Rack system.

7. Cost Comparison

For the analysis in this study, the cost for the load-out operation is calculated separately from the cost to operate the truck fleet. For example, the cost for an 8-load-out operation was paired with the cost for the truck fleet operated using the Cable, ALSS-2, or Rack technologies. The same pairing was done for both the 9 and 11 load-outs giving a total of nine operating conditions for the average delivered cost comparison.

It is important to re-emphasize that none of the three hauling technologies are commercially available. Thus, certain of the cost parameters are based on “reasonable estimates”. We denote these parameters with an (lc), indicating a low confidence in the value.

7.1. Cost for Trailers—Cable System

The purchase price for a 16.2 m steel flatbed trailer is 43,000 (purchase) + 5160 FET + 3000 (delivery) = USD 51,160. The cost for the Cable system installed on the trailer is estimated to be USD 30,000 (lc), thus the total cost per trailer is USD 81,160. Since the mass per load (40 bales) is the same for all three systems, the same number of loads is hauled from each SSL, and the total travel distance is approximately the same for all three systems. For the Cable system, each of the 20 trailers travels, on average, 773,953/20 = 38,700 km/y. Using accepted cost procedures [(PP = USD 81,160), (n = 10 y), and (R/M = 0.22 USD/km)], the annual cost per trailer is USD 19,235. Thus,

7.2. Cost for Tandems—ALSS-2 System

The purchase price for a steel flatbed trailer with a pintle hook hitch, and with the ALSS system installed, is estimated to cost 25,000 (trailer) + 30,000 (ALSS) = USD 55,000 (lc). Thus, a tandem costs USD 110,000. There is one tandem for each of the 11 trucks plus two extra for a total of 13 tandems. On average, each of the 13 tandems travels 773,953/13 = 59,535 km/y. Using accepted cost procedures [(PP = USD 110,000), (n = 10 y), and (R/M = 0.22 USD/km)], the annual cost per trailer is USD 28,718. Thus,

7.3. Cost of Racks for Rack System

Sea Box, Cinnaminson, New Jersey, was the manufacturer of the rack prototype built by the DOE “BALES” project [

8]. This company estimates the manufactured rack cost at USD 15,175 (lc). The procedure for calculating the cost to own and maintain racks is based on the following parameters [purchase price (PP = USD 15,175), design life (n = 5 y), interest rate (r = 6.25%), insurance rate (Ins = 0.8%), tax rate (Tx = 1%), cost recovery factor (CRF = 0.239), and repair and maintenance factor (R/M = 10% of PP over design life)]. The rack cost for 109 racks was found to be 3.00 USD/Mg of annual depot capacity.

7.4. Cost for Rack Trailers

The purchase price for the rack trailer prototype built for the DOE BALES project [

7] was USD 25,000 (lc). A tandem is two trailers. For the 11-load-out simulation, the number of tandems required was 10 (trucks with loaded racks at plant) + 11 (loaded tandems at SSLs) = 21. Using the same cost procedures used for the ALSS-2 tandems, the annual cost per tandem is USD 16,020, thus the cost for the 11-load-out simulation is

In like manner, the cost for 19 tandems for the 9-load-out simulation is 2.00 USD/Mg, and the cost for 18 tandems for the 8-load-out simulation is 1.89 USD/Mg.

7.5. Cost for Load-Out Operation at the SSL—Cable and ALSS-2 Systems

A telehandler cycles back and forth to pick up individual bales from single-layer ambient storage and load them onto the trailer. The average achieved productivity of the load-out operation (i.e., telehandler) was 48.1 Mg/d for the 11-load-out simulation. The telehandler is estimated to operate 75% of the total load-out hours (1772 h/y). This equals 1329 h/y; thus, the equipment factor is 0.46. Telehandler cost per operating hour was calculated for 1329 annual operating hours and found to be 22.00 USD/h [(PP = USD 83,055), (n = 10,000 h), (Sv = 20%), (R/M = 2.67 USD/h), and fuel use (7 L/h)]. The load-out cost per operating day for an individual load-out operation is then

The cost per Mg loaded, using the achieved average productivity (11 load-outs operating 48 weeks), is

The cost per Mg loaded, using the achieved average productivity (9 load-outs operating 48 weeks), is 7.04 USD/Mg, and the cost per Mg loaded, using the achieved average productivity (8 load-outs operating 48 weeks), is 6.25 USD/Mg.

The worker at each SSL is expected to report to work at the SSL being unloaded that day. A travel payment (0.364 USD/km) is made for the distance from the depot to the SSL for each workday during the 48-week season. The same procedures used by Resop et al. [

11], were used to compute travel payment, service truck cost, and equipment hauler cost (

Table 7).

7.6. Cost for Load-Out Operation at the SSL—Rack System

The cost for loading racks at the SSLs was calculated using procedures given by Resop et al. [

11]. This cost was computed for one operator operating a telehandler and a bale loader (by remote control) at each of the load-outs in simultaneous operation. The labor cost was based on 10 h/d × 6 d/week × 48 week/y = 2880 h/y, and the equipment operating time, allowing for estimated delays, was 1772 h/y. Thus, the equipment factor was 1772/2880 = 0.615. The load-out cost per operating day for an individual load-out operation is then

The cost per Mg loaded, using the achieved average productivity of 48.1 Mg/d (11 load-outs operating 48 weeks) is

The cost per Mg loaded, using the achieved average productivity of 58.8 Mg/d (9 load-outs operating 48 weeks) is 8.61 USD/Mg, and the cost per Mg loaded, using the achieved average productivity of 66.2 Mg/d (8 load-outs operating 48 weeks) is 7.65 USD/Mg.

Total load-out cost, using the load-out equipment required for the Cable and ALSS-2 hauling technology, was calculated as follows.

Total load-out cost using the Rack hauling technology, which includes the cost of the bale loader, was calculated as follows.

7.7. Cost to Unload Trucks and Supply the Depot—Cable and ALSS-2 Systems

The total telehandler cost (including labor) computed for a telehandler operating 12 h/d × 6 d/week × 48 week/y = 3456 h/y is 51.15 USD/h. The annual operating hours for a 24 h/d operation are 8064 h/y, and the operating cost is 50.38 USD/h. Per Mg annual capacity cost for two telehandlers operating 24 h/d (7 d/week) (two for continuous daytime and nighttime operation) and two operating 12 h/d (6 d/week) (daytime operation during haul week) (

Appendix B) is

7.8. Cost to Unload Trucks and Supply the Depot—Rack System

The cost to operate a 30,000 lb capacity forklift (30 k forklift) to move racks was calculated using the parameters [(PP = USD 154,400), (n = 15,000 h), (R/M = 3.00 USD/h), and fuel use (12 L/h)]. The cost to operate the 24 h forklift is 54.15 USD/h and the cost to operate the 12 h forklift is 55.19 USD/h. The total cost for 48 weeks of operation is

On a per-Mg annual capacity basis, the cost is 4.32 USD/Mg.

The cost to operate one rack unloader is calculated using the following estimated parameters [(PP = USD 230,000 lc), (n = 10 y), (Sv = 10%), (R/M = 25% of PP over design life), and energy cost = 0.08 USD/kW-h)]. The question of two rack unloaders to ensure operations can continue if one is down for maintenance is left unanswered. On a per-Mg annual capacity, the cost is 0.78 USD/Mg.

The total cost for rack system operations at the receiving facility is

7.9. Cost for Receiving Facility Infrastructure

The total area needed for the Cable and ALSS-2 systems, considering the larger bale storage area (

Figure A1), and the larger area to park trucks, is 11,250 m

2 = 1.125 ha, and the annual cost to own and maintain is USD 75,525 {RSMeans} [

12]. On a per-Mg annual capacity basis, the cost is 0.50 USD/Mg.

There are three subspaces needed for the Rack system.

One needed subspace is an operation area where the trucks are unloaded and the forklifts place racks in the rack unloader. This area includes needed access and egress for the trucks making deliveries.

Another subspace is needed as central storage for racks (

Figure A2).

Another subspace is needed where 10 trucks with loaded racks are parked at the end of the haul week.

The total area needed is estimated to be 8000 m

2 = 0.8 ha, and the annual cost to own and maintain this facility is USD 54,754 based on construction cost estimates given by RSMeans [

12]. On a per-Mg annual capacity basis, the cost is 0.36 USD/Mg.

7.10. Total Receiving Facility Cost

As stated in the objective, the cost comparison begins with bales in single-layer ambient storage in the SSLs and ends with bales in single file on a conveyor into the plant for 24/7 operation. The receiving facility cost (USD/Mg annual capacity) for the Cable and ALSS-2 systems is

The receiving facility cost (USD/Mg annual capacity) for the Rack system is

7.11. Truck Cost

Restating the business plan, the truck fleet is operated by the depot, and its scheduling is the responsibility of the Feedstock Manager. All maintenance for the truck tractors is covered by a rental contract. No cost is included for truck insurance by the depot.

The current rental cost for the truck tractor required for all three systems is 1100 USD/week, plus 0.11 USD/km. Average travel for the 20-truck fleet required for the Cable system is 38,550 km/y. The annual cost per truck tractor is

Average travel for the 11-truck fleet required for the ALSS system is 70,090 km/y. The annual cost per truck tractor is 60,510 USD/y.

Average travel for the 10-truck fleet required for the rack system is 77,098 km/y. The annual cost per truck tractor is 61,281 USD/y.

The labor cost for an operator, including benefits, is 31.25 USD/h, thus the annual labor cost (48 week/y) is USD 108,000 per truck per year. In the three hauling simulations, the total truck travel to haul all loads (199 SSLs) was approximately 771,000 km. Total fuel cost for the truck fleet (based on 1.7 km/L consumption, at 1.31 USD/L) was USD 594,125.

On a per-Mg basis, the truck cost for the 20 trucks required for the Cable system was

Total truck cost (rental, fuel, and operator) for the 11-truck fleet for the ALSS-2 system was calculated as 16.05 USD/Mg.

Total truck cost (rental, fuel, and operator) for the 10-truck fleet for the Rack system was calculated as 15.15 USD/Mg.

8. Results and Discussion

There are over 200,000 trucking companies in the U.S., thus the cost to operate a truck tractor is well defined in all locales. The critical issue for all short-haul operations is wait time to load and unload, which defines the number of loads hauled per day. It is unlikely that conventional technology, where the truck driver straps the load by throwing over individual straps and tightening them, will be utilized in the emerging biorefinery industry. There is a shortage of truck drivers, and a driver that can get a job that does not require the strapping of loads for a short haul, will not work in the biorefinery industry.

The three hauling technologies in this study were selected as a hierarchy of load–unload options. The Cable system envisions single-bale handling with the truck stopped for loading and unloading. (Time for strapping and unstrapping is basically eliminated.) The ALSS-2 system also uses single-bale handling for loading and unloading, but it uncouples the loading and unloading from the hauling by having extra tandems which are left at the SSL for loading and at the receiving facility for unloading. This significantly reduces the truck cycle time and increases truck productivity (Mg/d). The Rack system has the same single-bale handling for loading and the same uncoupling of loading and hauling. The key difference between it and the ALSS-2 option occurs at the receiving facility. All handling to unload, place in at-depot storage, and retrieve from storage for 24/7 operations is done with a 20-bale handling unit; single-bale handling is eliminated.

A key question, then, is the cost of the extra equipment for the Rack system offset by a reduction in total delivered cost?

The cost comparison for all three load-out simulations and all three hauling technologies is given in

Table 8. The maximum cost was 48.56 USD/Mg (eleven-load-outs, Cable), and the minimum was 34.90 USD/Mg (eight-load-outs, ALSS-2). For all three load-outs simulations, the ALSS-2 hauling system gave the lowest cost. Comparing the ALSS-2 and Rack systems, the Rack system cost was 0.90, 0.53, and 1.64 USD/Mg higher for the eleven, nine, and eight-load-out simulations, respectively. This comparison between the two systems assigns no credit for the reduced damage to bales achieved with the multi-bale handling unit. The resulting damage reduction can be significant, particularly for bales that have been in ambient storage 6+ months.

This study projects that the required truck fleet can be reduced from 20 trucks to 10 trucks by progressing from the Cable to the Rack system. Subsequent truck cost is reduced from 25.54 USD/Mg to 15.15 USD/Mg, or 38%, an encouraging result. The key question now is, what about the cost of the extra equipment required, racks, rack trailers, bale loader, and rack unloader? This question is addressed by the total cost comparison. For the 11-load-out simulation, with a productivity closest to what might be achieved with a phase-1 rollout of the described technologies, the total cost was 48.56 and 40.10 USD/Mg for the Cable and Rack systems, respectively. The reduction in truck cost more than pays for the additional cost to own and operate the Rack system.

The reason that the load-out and hauling operations must be studied together is readily explained. Suppose investments have been made to achieve the 15–20 min load time, and a truck gets to the SSL and has to wait 30 min for the load-out crew to finish loading the load. Now the “load” time is 45–50 min, and the advantage of the rapid load technology is lost. This explains why the authors recommend for the biorefinery industry to be structured with a central control for feedstock hauling. The technology to optimize short-haul operations is used by other industries, and it should be adapted for the biorefinery industry.

The cost for the Rack system, using nine load-outs operating simultaneously at SSLs and a 10-truck fleet, was calculated to be 37.76 USD/Mg (annual capacity) which compares to 45.63 USD/Mg for the Cable system (nine load-outs operating simultaneously, 20-truck fleet), and 35.84 USD/Mg for the ALSS-2 system (nine load-outs operating simultaneously, 11-truck fleet). The most significant cost issue was the reduction in truck cost; 25.54 USD/Mg for the 20 trucks required for the Cable system vs. 15.15 USD/Mg for the 10 trucks required for the Rack system. The additional cost for the equipment needed for the Rack system was offset by increased truck productivity achieved with a reduction in load time at the SSL and unload time at the biorefinery.

A valid question is, can a system of eight load-outs and 10 trucks be operated with the efficiency required to haul 152,526 Mg of feedstock from 199 SSLs over a 48-week season? A mature central-control system will certainly be required, and even with central control, it may not be achievable in a “real world” setting. The eight load-outs will need to average seven loads per 10 h day, about 1.4 h per load, for a six-day haul week over the 48-week season. This means the average wait time between loads will need to be less than 45 min. The authors recognize that this is quite optimistic. It does, however, set a goal for the implementation of the most efficient hauling technology currently available.

The last ALSS trailer for hauling large rectangular bales was manufactured by Stinger in 2016 [

3]. No data were found on the use of the ALSS system for hauling 5 × 4 round bales. As stated in the beginning of this study, we hypothesize that the current ALSS design, with modest modification, can be used for hauling round bales. We believe the cost estimates used for the ALSS-2 system are close to the costs that might be attained in a commercial application.

Some prototyping of the Rack system has been done, but we clearly state that several development steps are needed before commercialization could proceed. We provide some opinions for this discussion. The rack and rack trailer designs are close, maybe 90%. The rack unloader design is not close, maybe only 50% of the design information needed for a commercial design has been learned. The bale loader prototype, used to load bales into the rack at the SSL, has not been built. (The cost estimates used for the bale loader in this study are based on modification of the three-wheel forklift that is hauled on the back of a building supply delivery truck.) The cost estimate for the rack and rack trailers has a relatively high certainty, but the estimate to load bales into the rack at the SSL, and the estimate to unload bales with the rack unloader at the receiving facility, have a lower certainty. We did try to “err on the high side” for the cost estimates with the lowest certainty.