A CFD Methodology for the Modelling of Animal Thermal Welfare in Hybrid Ventilated Livestock Buildings

Abstract

1. Introduction

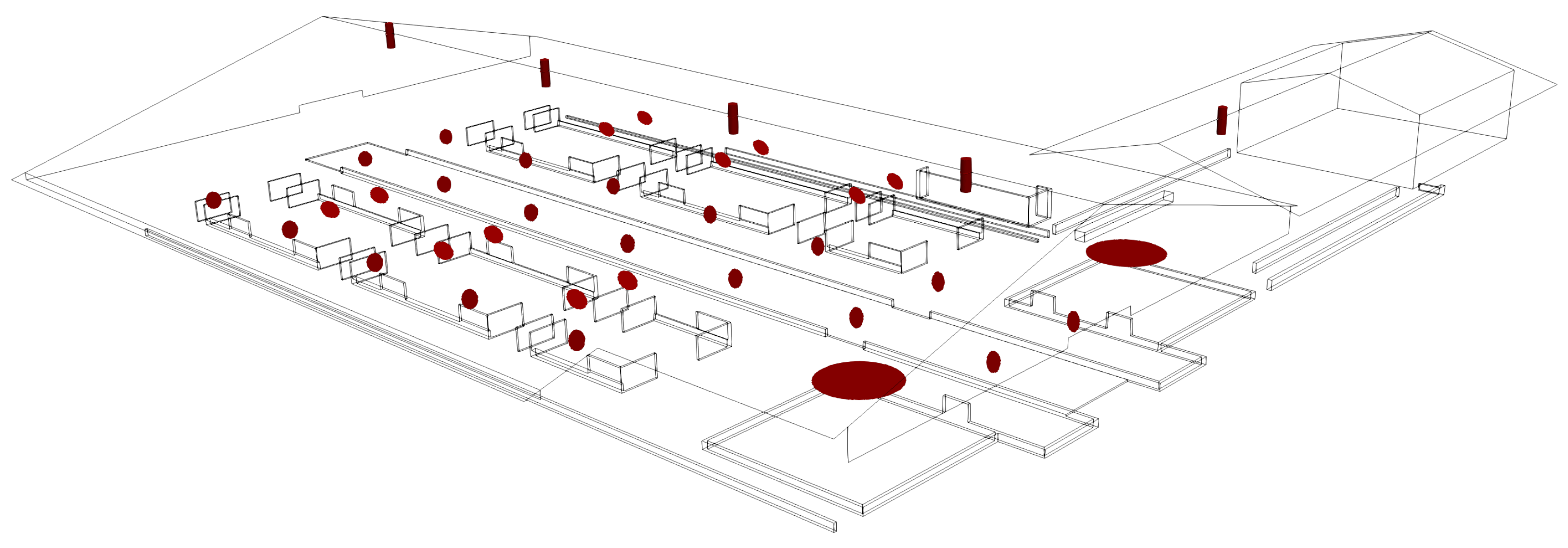

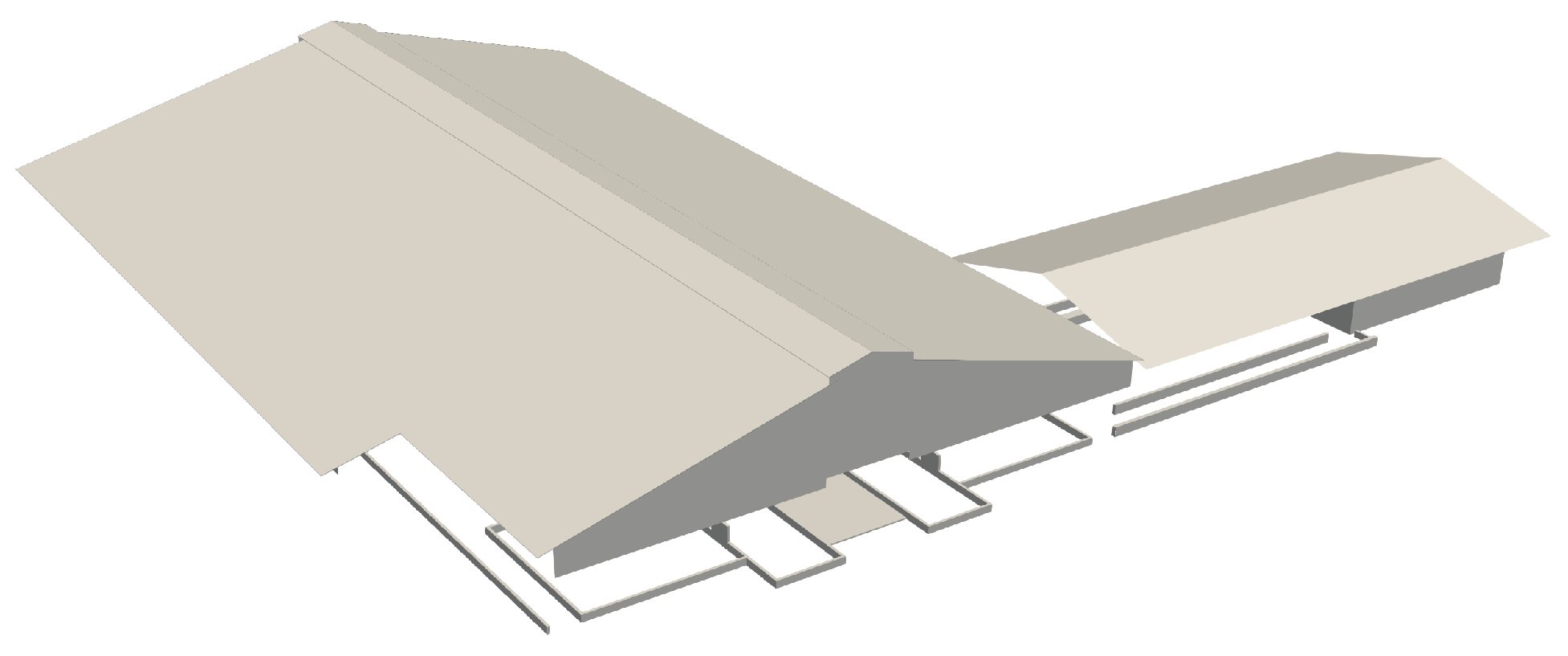

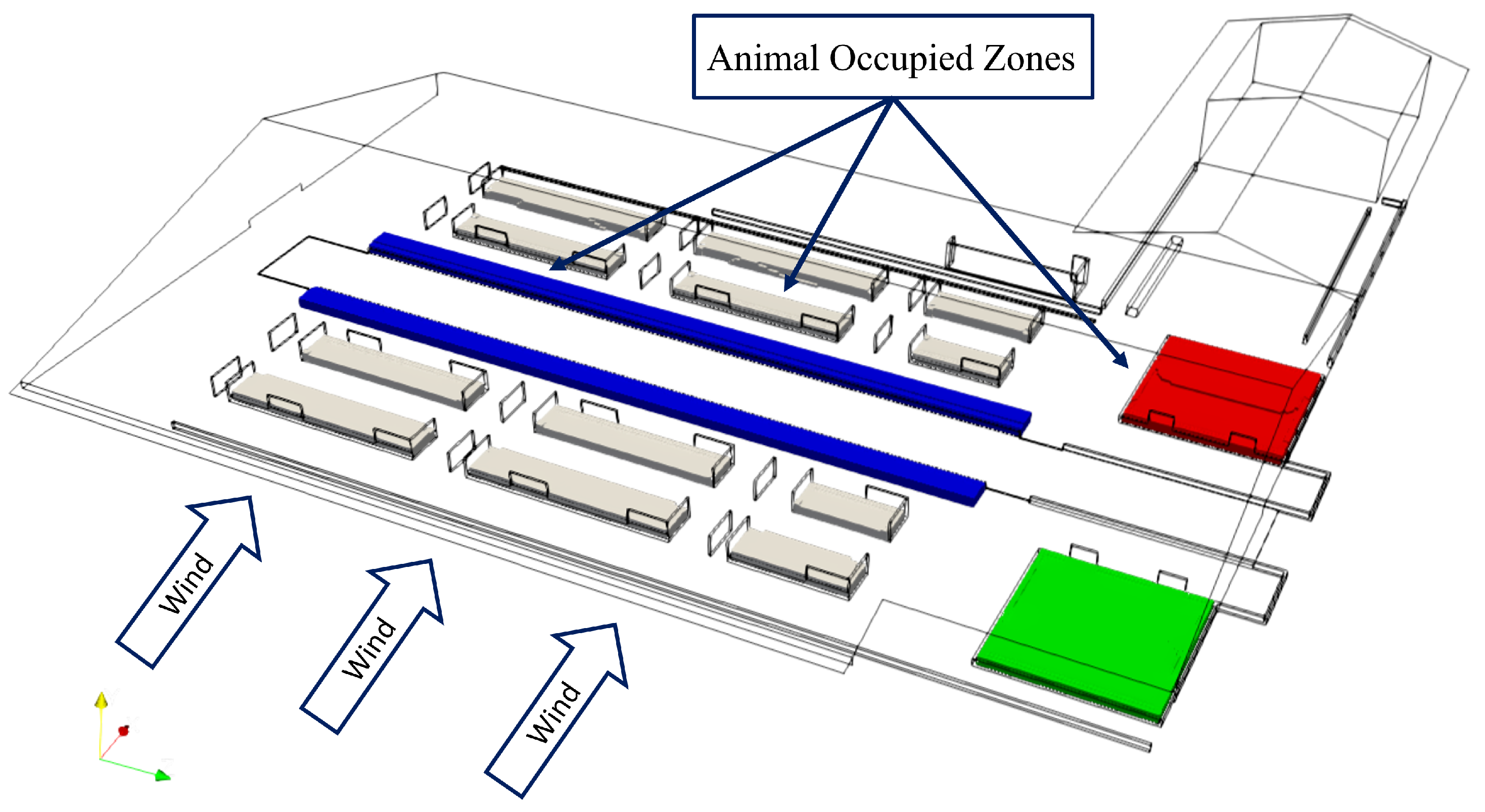

2. Motivation, Objective and Analysed Case Study

3. Materials and Methods

3.1. Animal Thermal Modelling

3.2. Wind-Induced Ventilation and Turbulence Modelling

3.3. Assessment of Animal Welfare

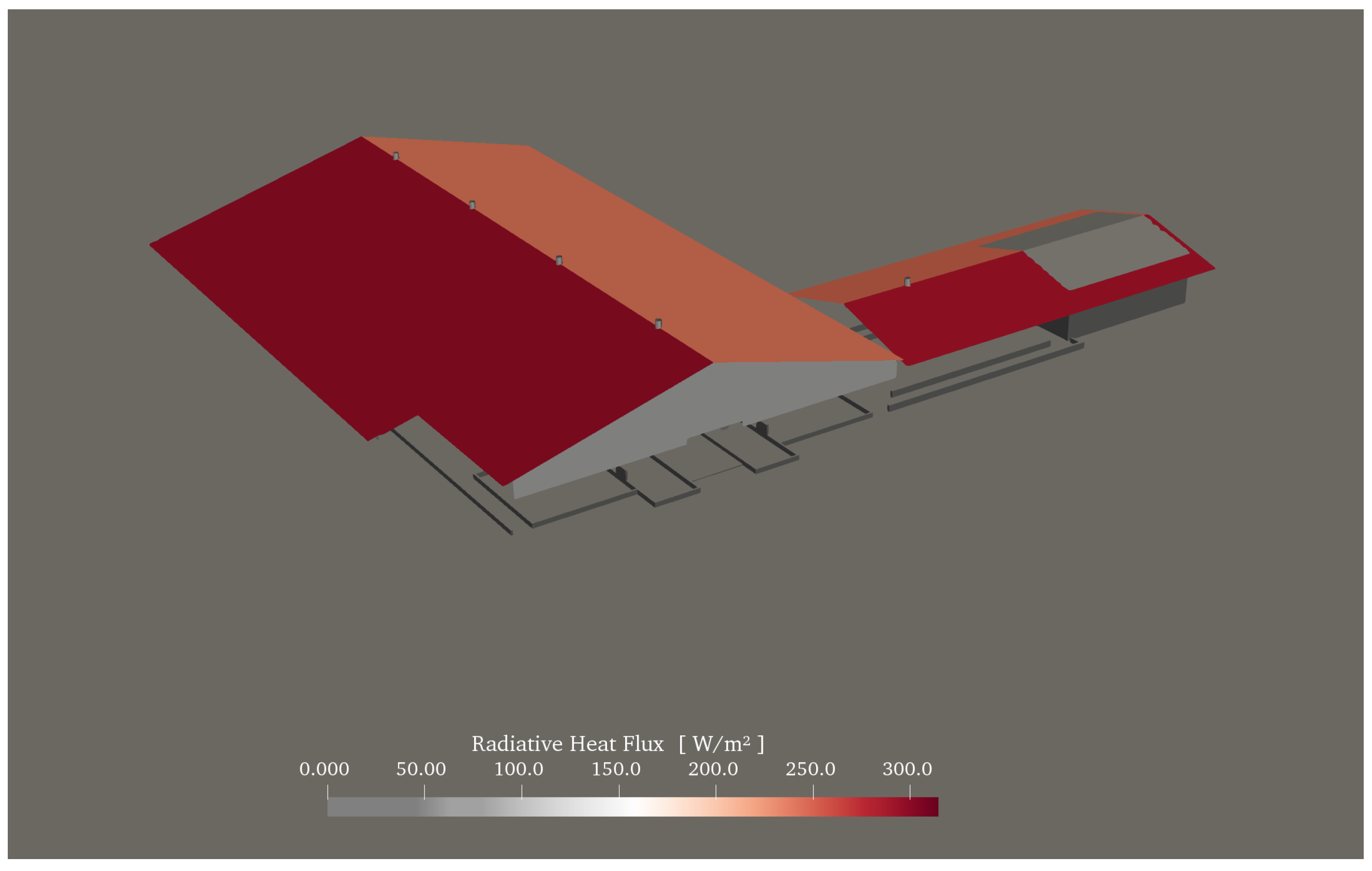

3.4. Solar Radiation

3.5. Air Change Rate and Wind-Induced Ventilation

3.6. Weather Conditions and Analysed Configurations

3.7. Heat-Stress Abatement Devices

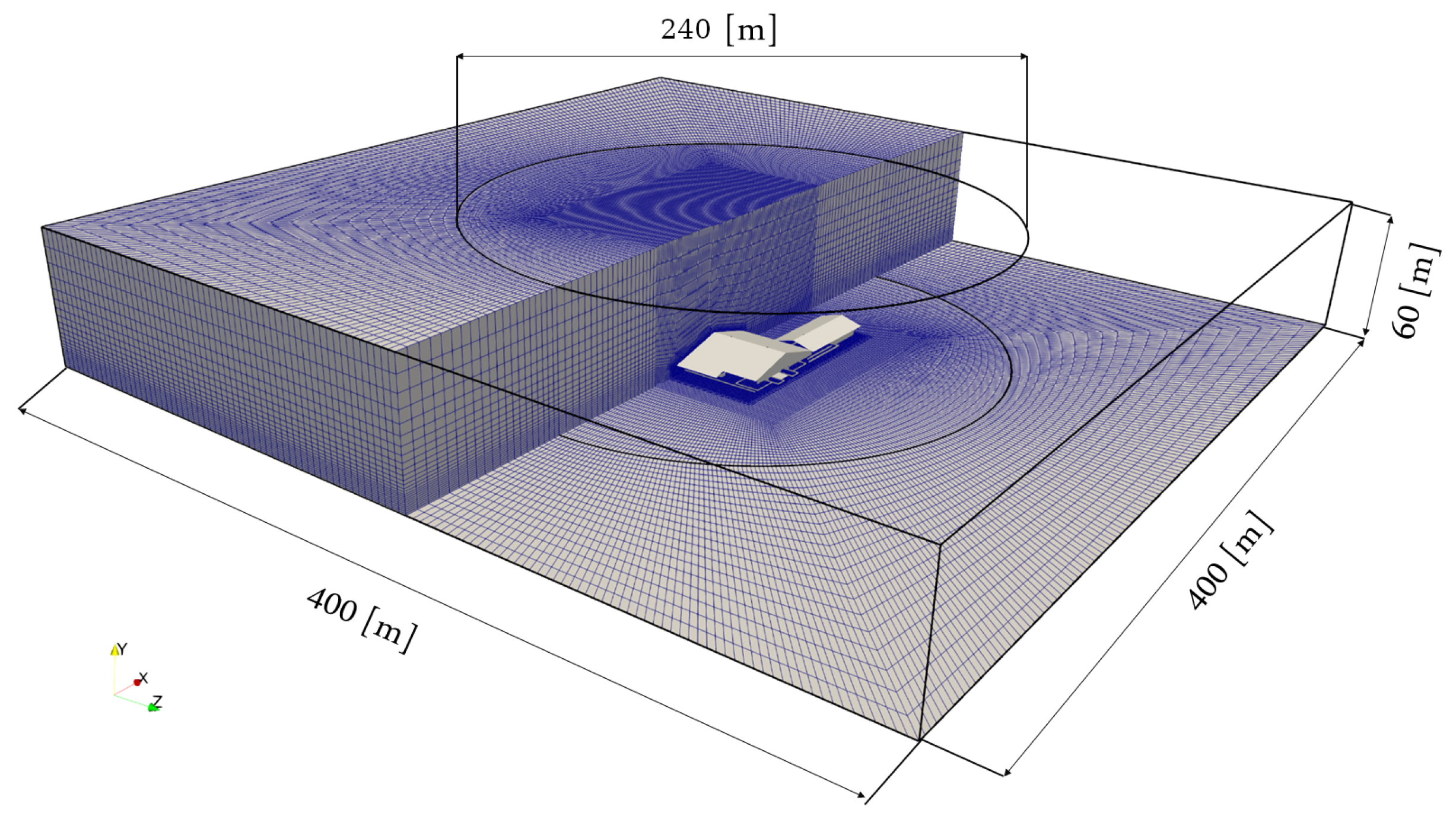

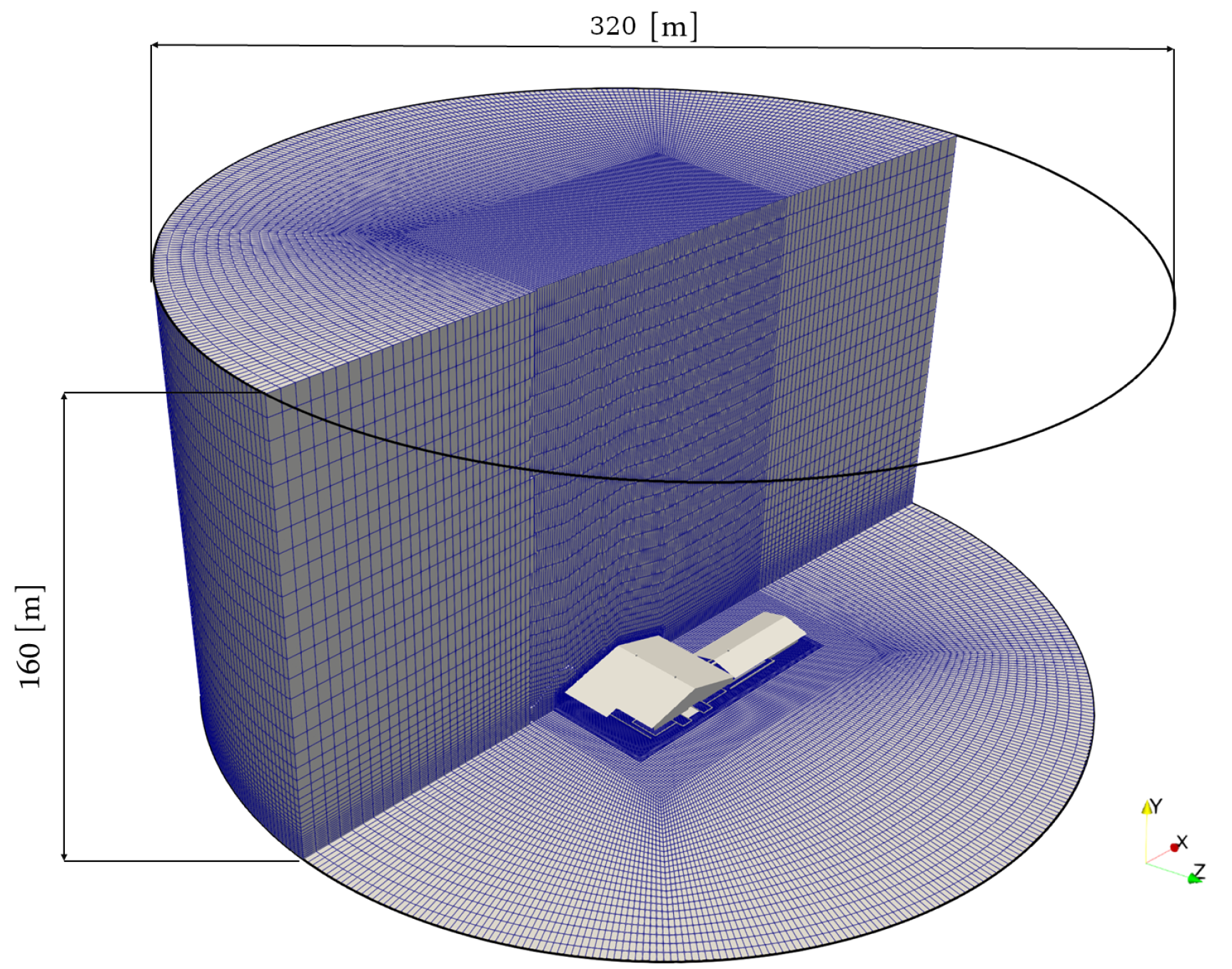

3.8. Meshing Strategy

3.9. Solution Strategy

3.10. Experimental and Simulated Heat-Stress Intensity

4. Results and Discussion

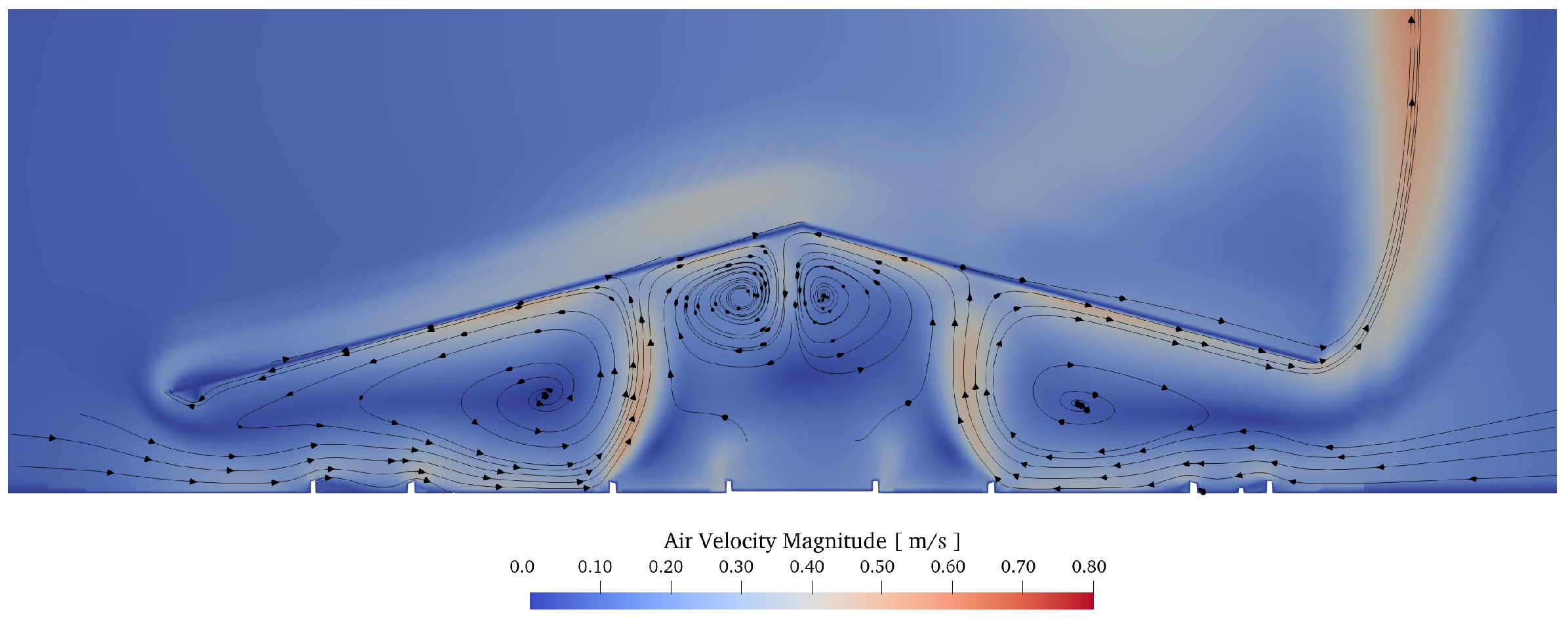

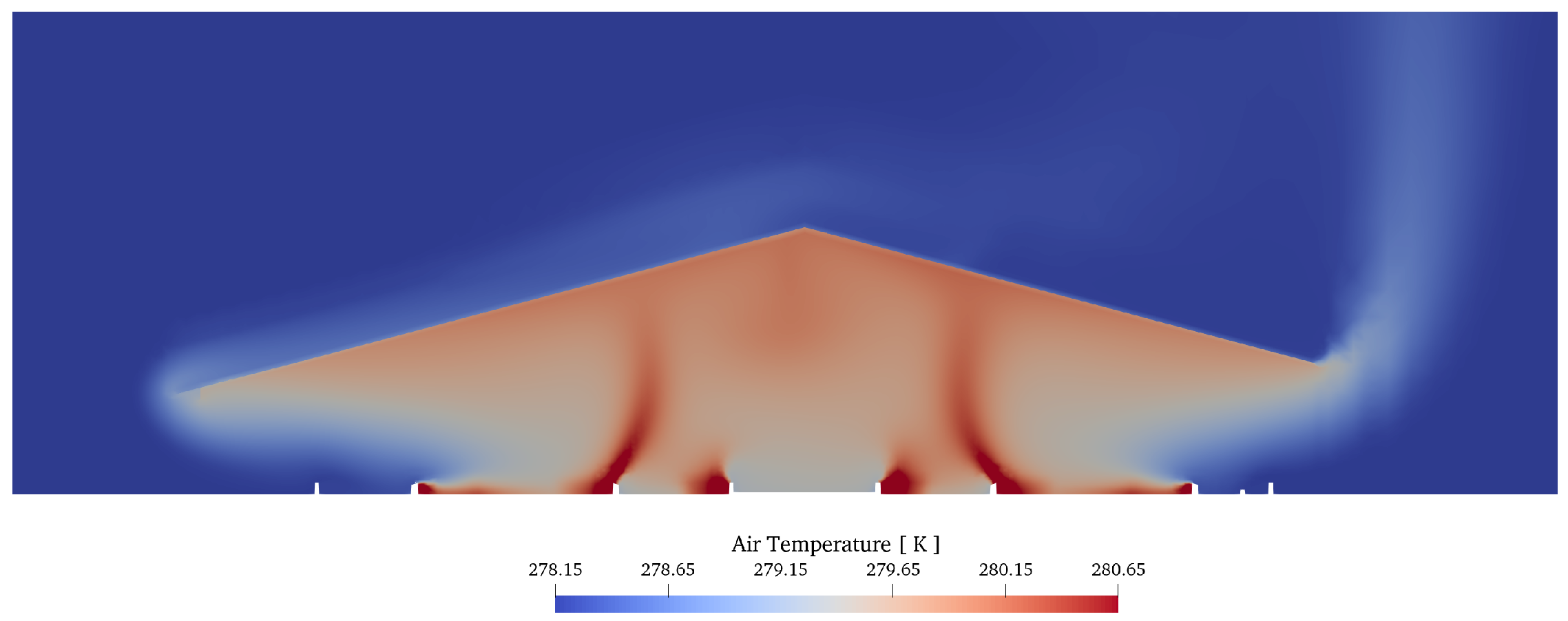

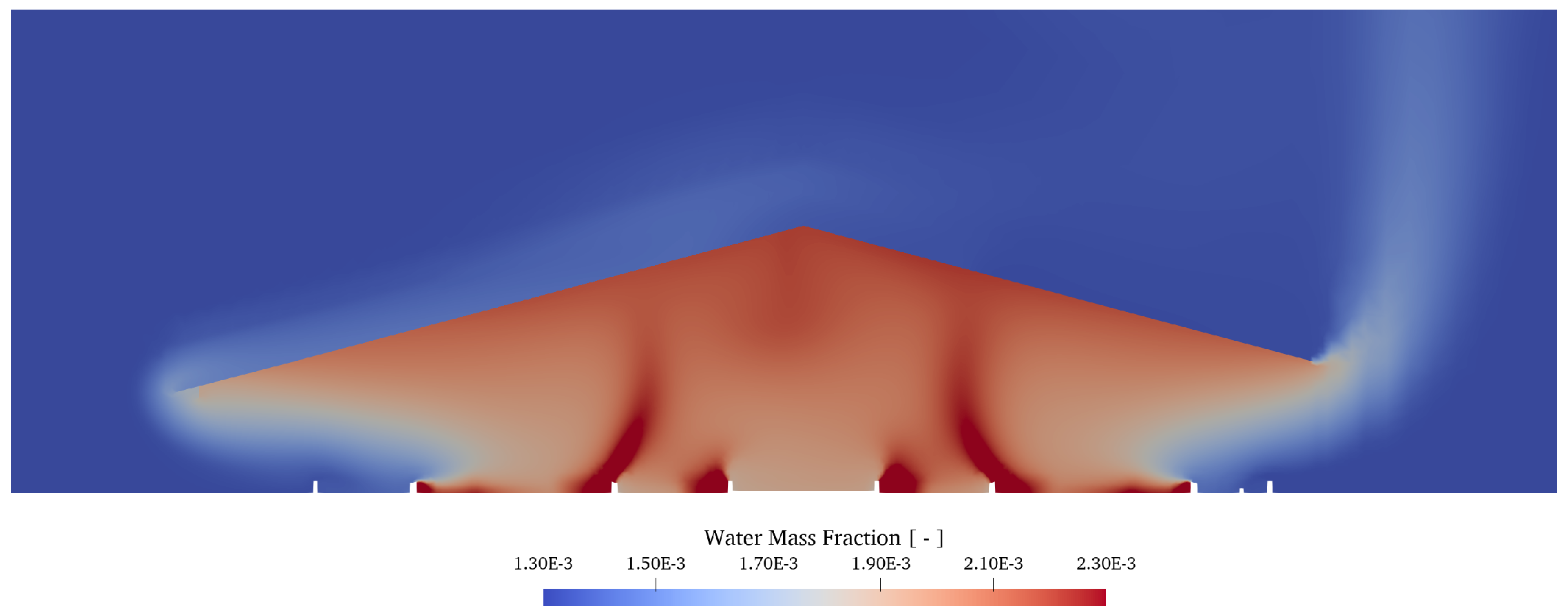

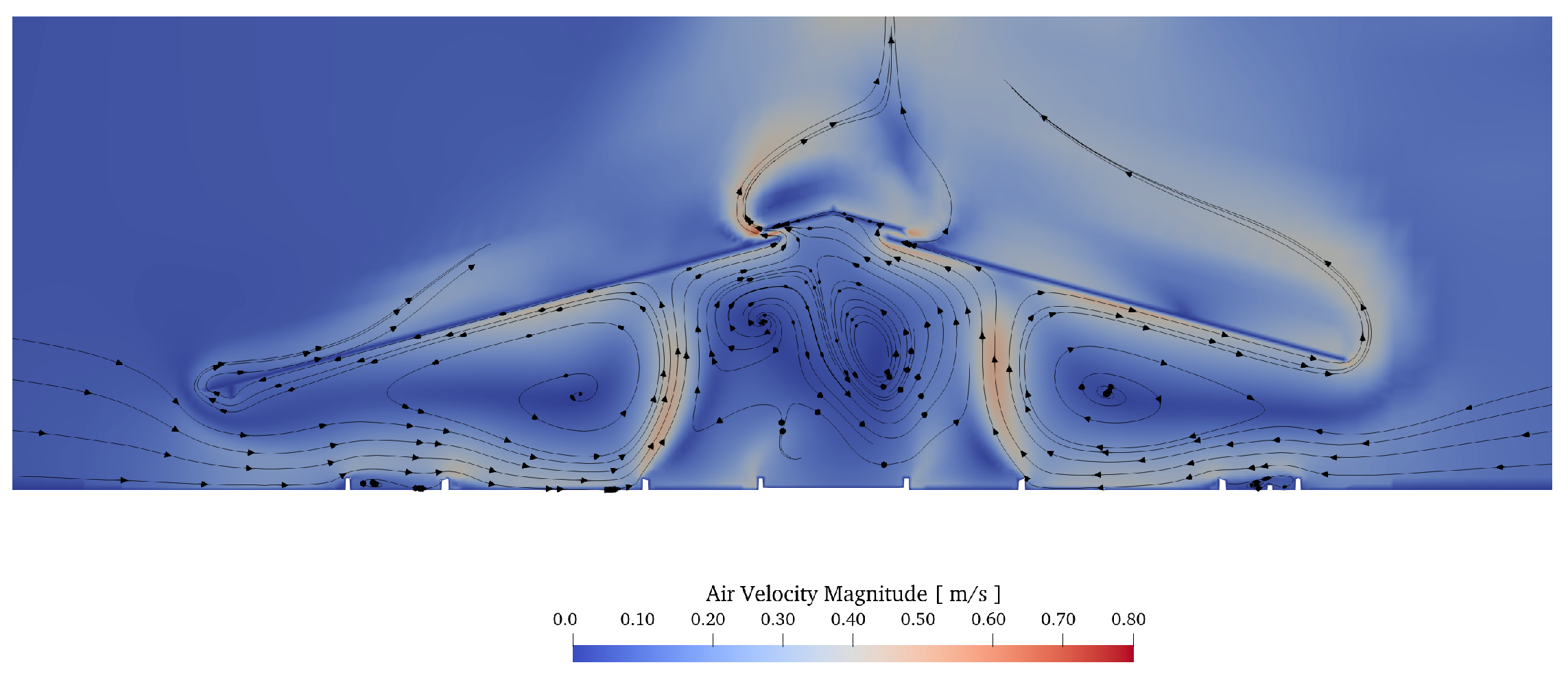

4.1. Simulations in Winter Weather

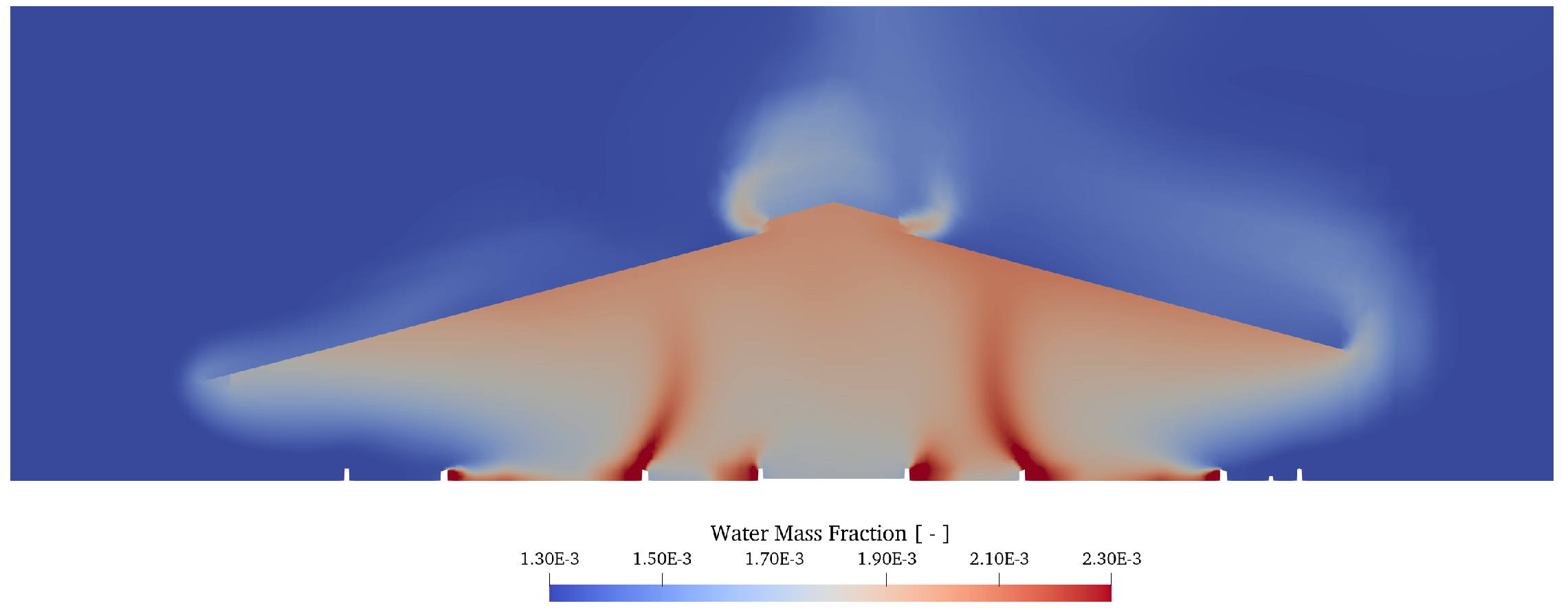

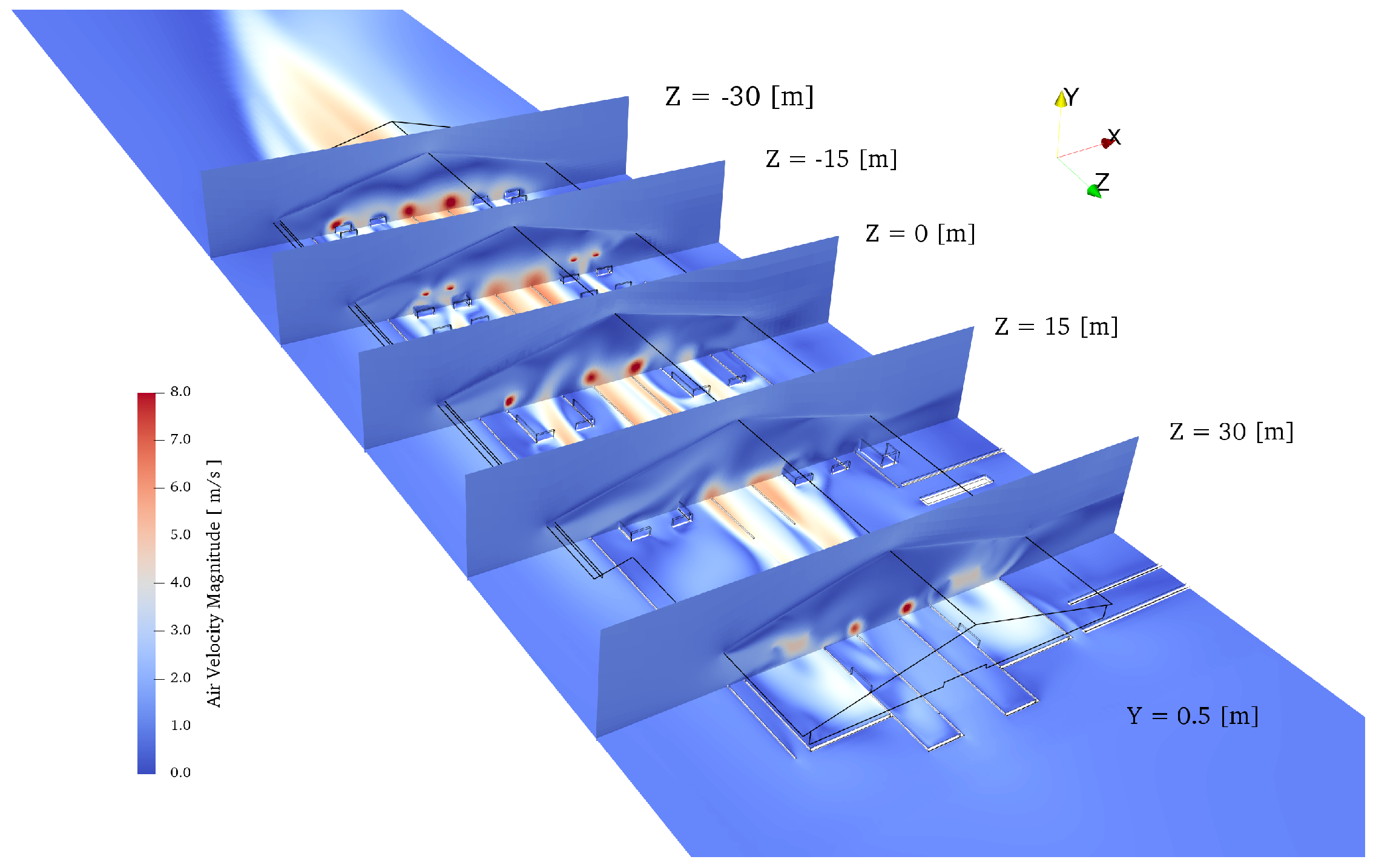

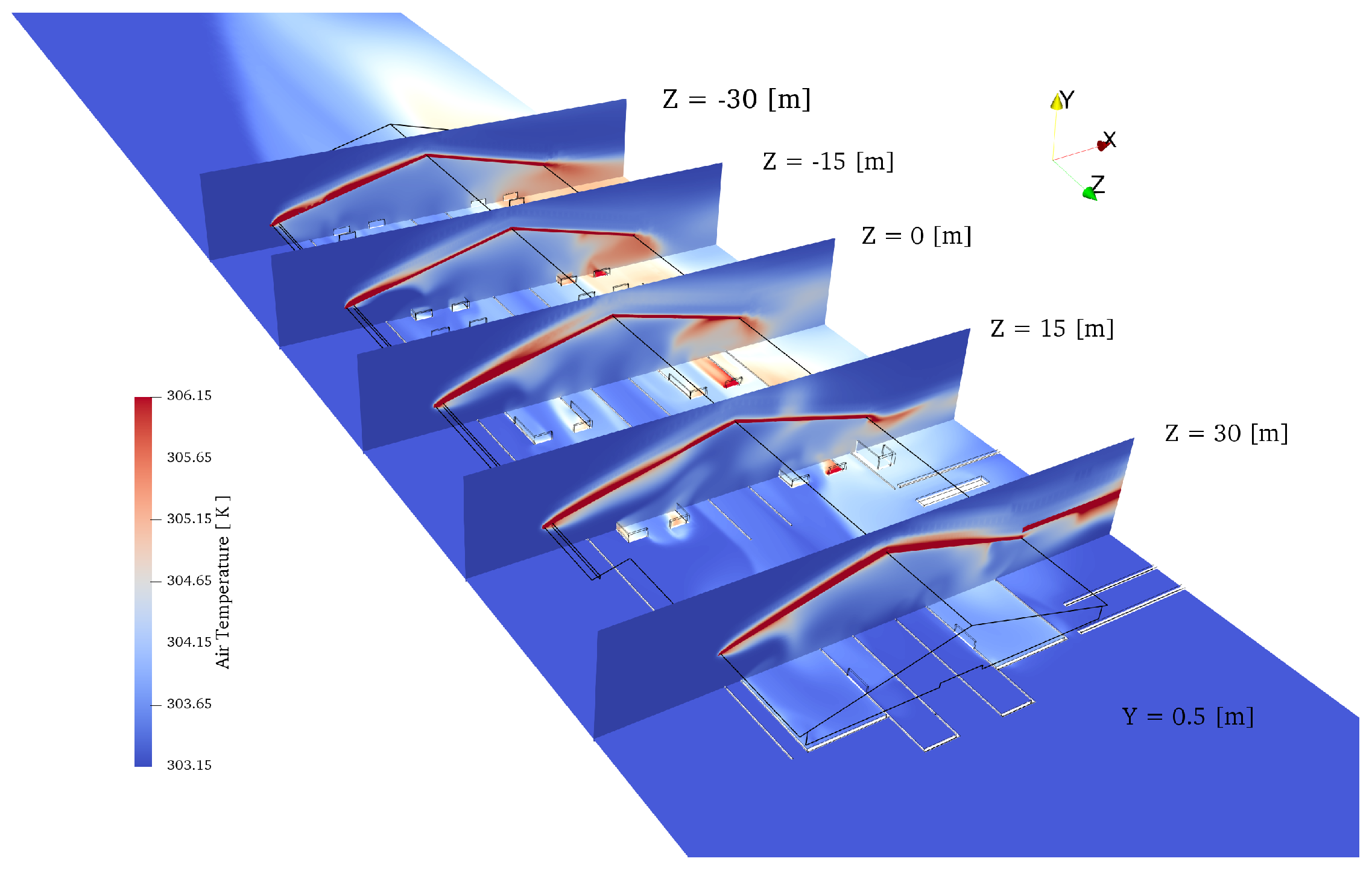

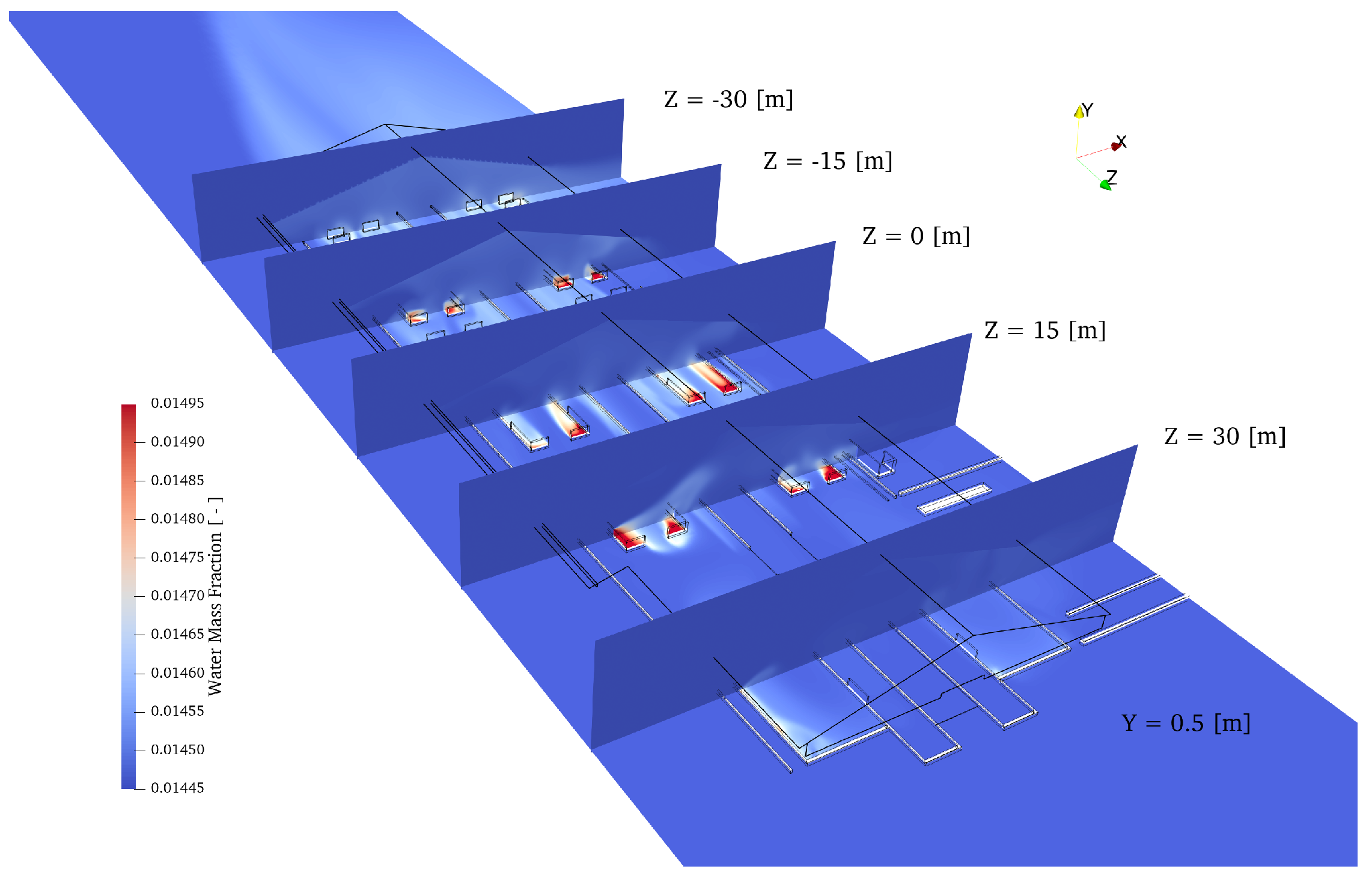

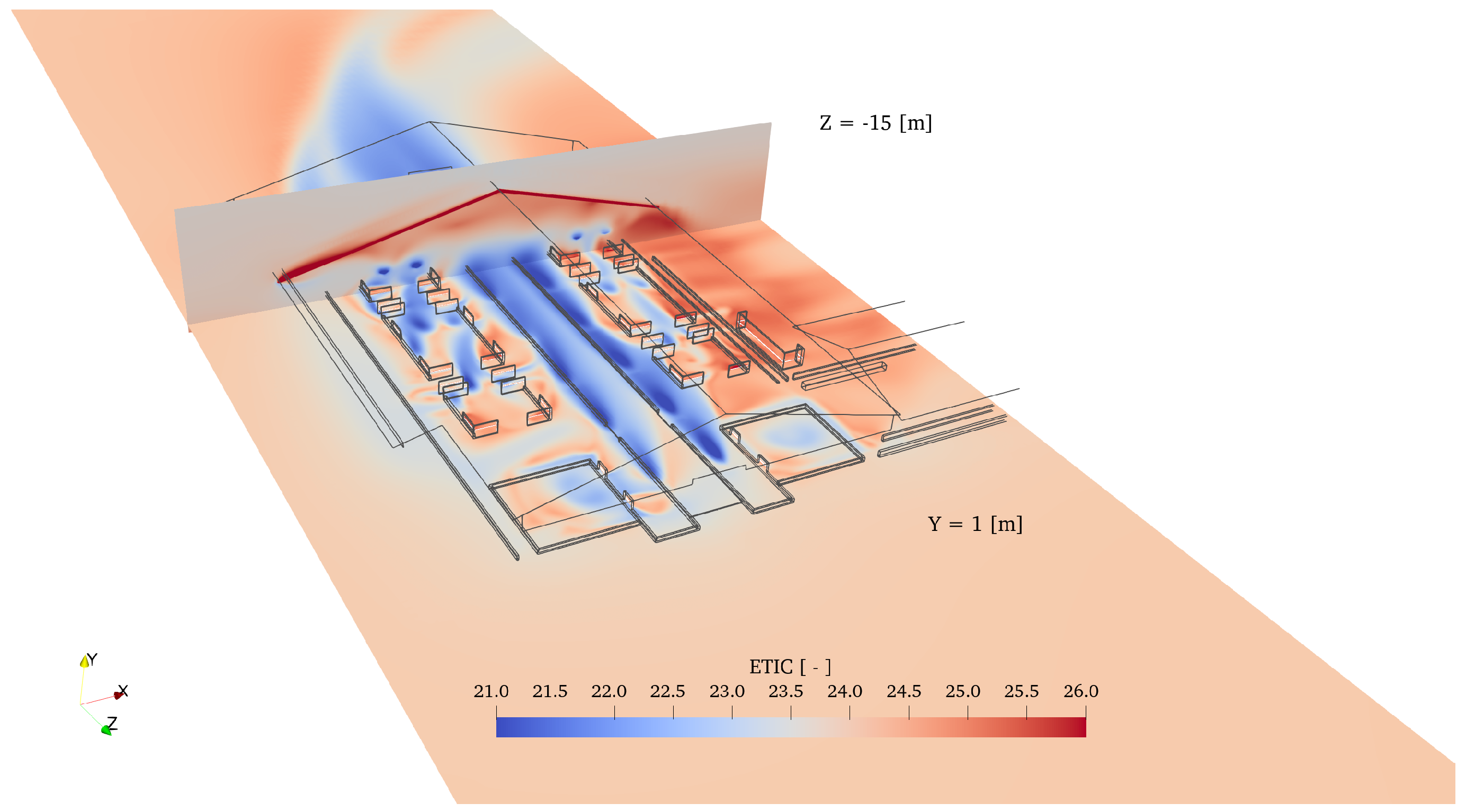

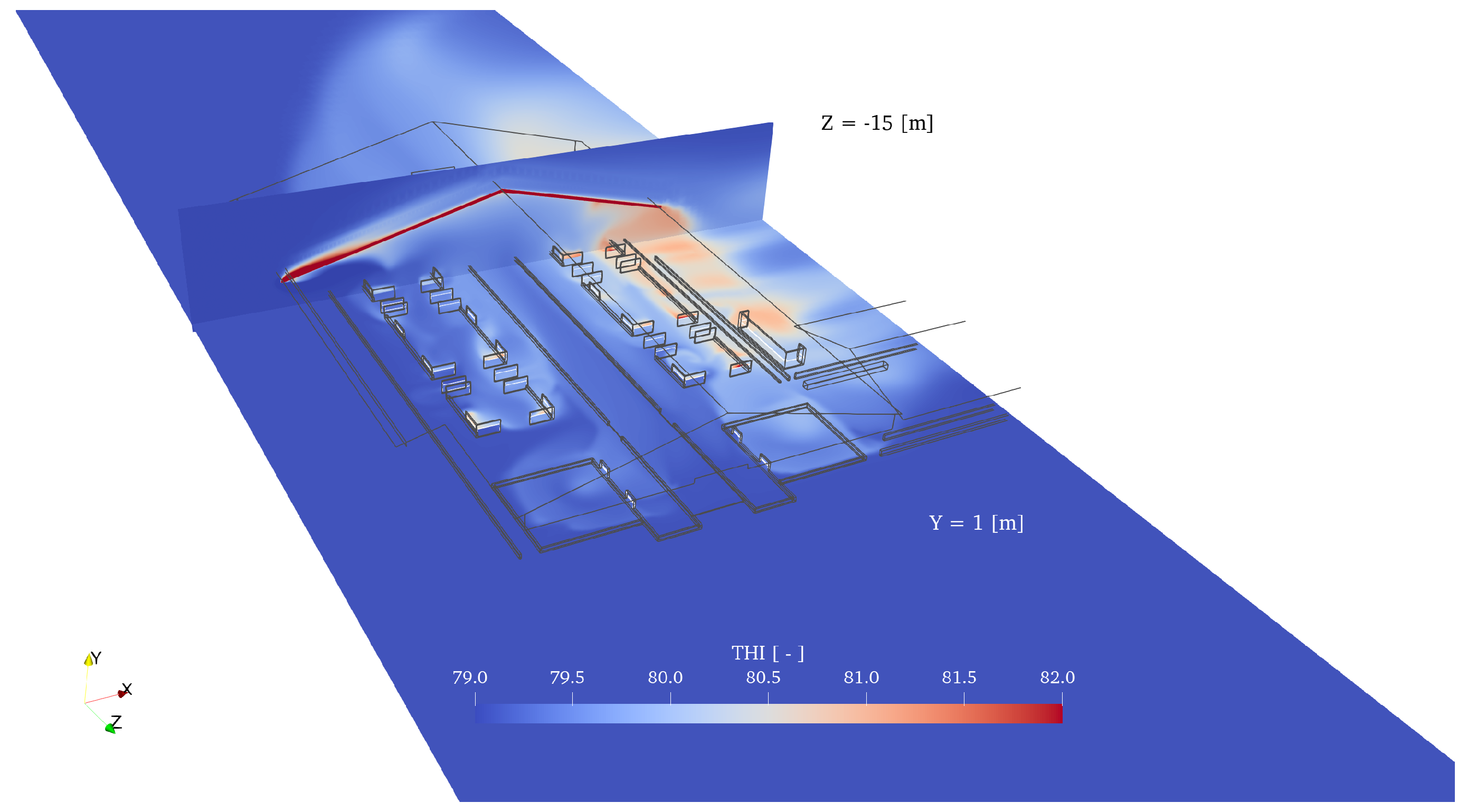

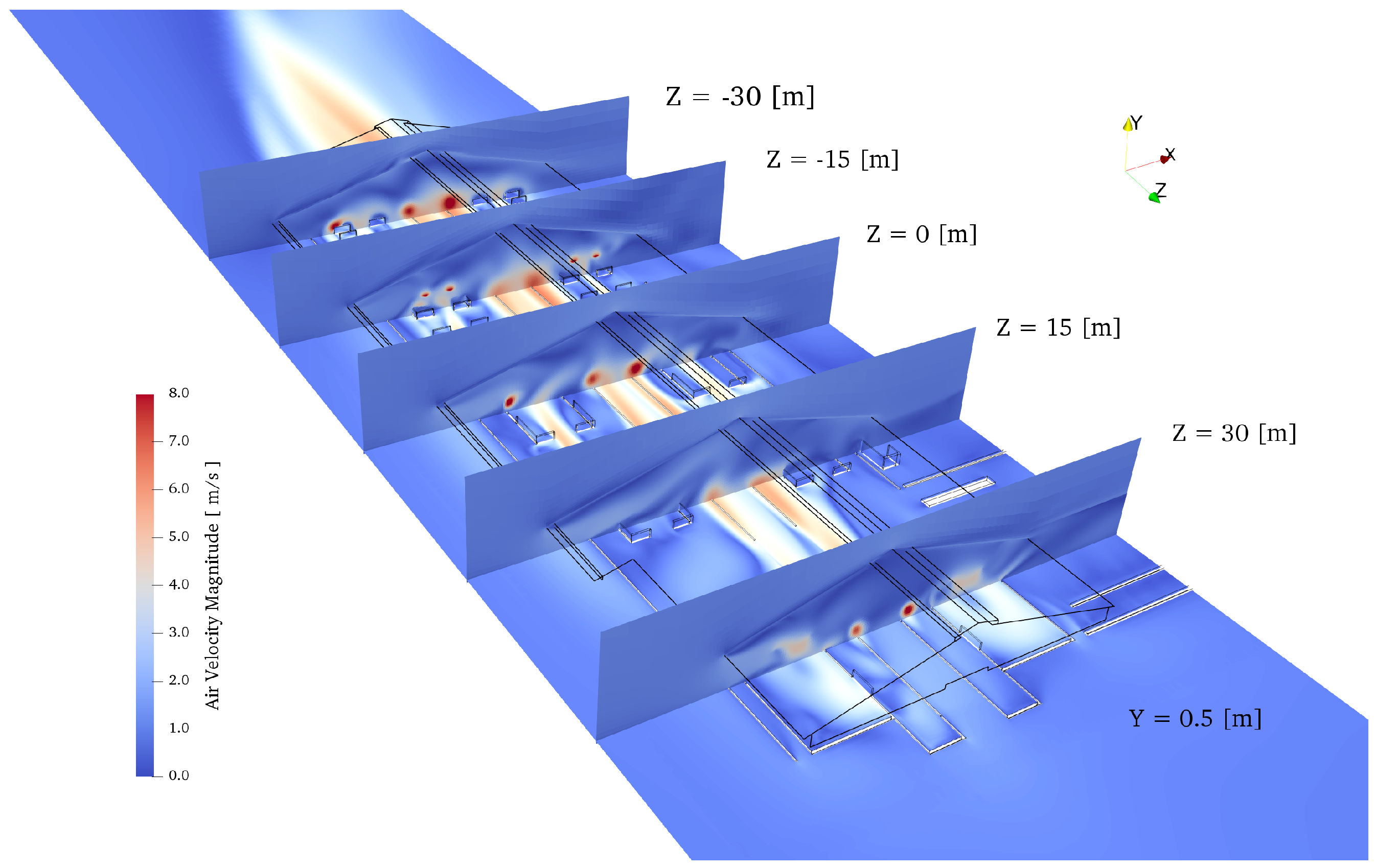

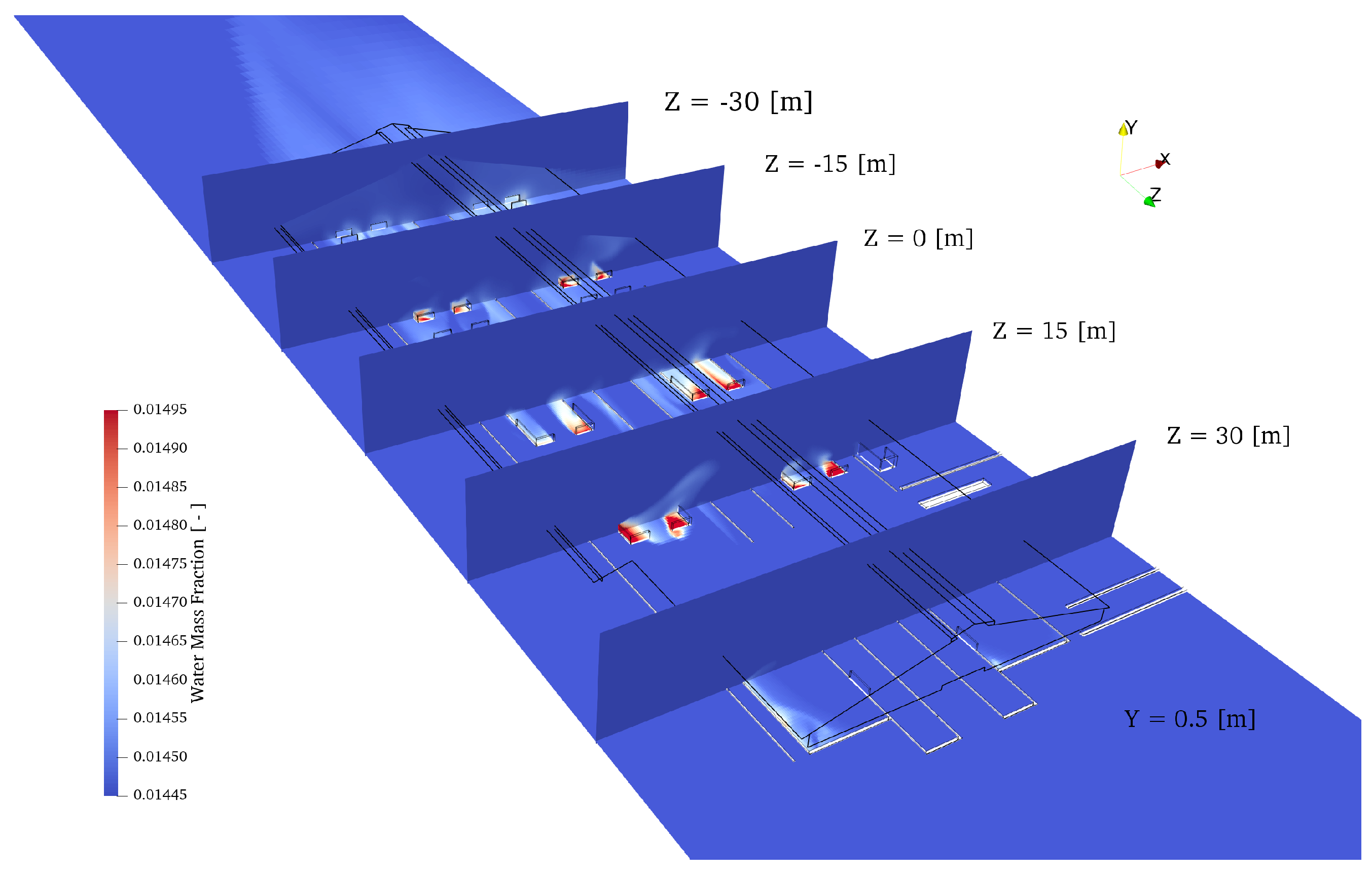

4.2. Simulations in Summer Weather

4.3. Comparison of Experimental and Simulated Heat-Stress Intensity

5. Conclusions and Future Works

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABL | Atmospheric boundary layer |

| ACR | Air change rate |

| AMI | Arbitrary mesh interface |

| CerZoo | Centro di Ricerche per la Zootecnia e l’Ambiente |

| CFD | Computational fluid dynamics |

| ETIC | Equivalent temperature index for cattle |

| GAMG | Geometric–algebraic multigrid solver |

| HBD | Heavy breathing duration |

| HVLS | High-volume low-speed fans |

| LRNS | Large Ruminant Nutrition System |

| PBiCGStab | Preconditioned biconjugate gradient solver |

| RR | Respiration rate |

| RH | Relative humidity |

| TDB | Dry-bulb temperature |

| THI | Temperature humidity index |

References

- Kadzere, C.T.; Murphy, M.; Silanikove, N.; Maltz, E. Heat stress in lactating dairy cows: A review. Livest. Prod. Sci. 2002, 77, 59–91. [Google Scholar] [CrossRef]

- Ealy, A.D.; M, D.; Hansen, P.J. Developmental Changes In Embryonic Resistance to Adverse Effects of Maternal Heat Stress In Cows. J. Dairy Sci. 1993, 76, 2899–2905. [Google Scholar] [CrossRef] [PubMed]

- Becker, C.; Collier, R.; Stone, A. Invited review: Physiological and behavioral effects of heat stress in dairy cows. J. Dairy Sci. 2020, 103, 6751–6770. [Google Scholar] [CrossRef] [PubMed]

- Polsky, L.; von Keyserlingk, M.A.G. Effects of Heat Stress on Dairy Cattle Welfare. J. Dairy Sci. 2017, 100, 8645–8657. [Google Scholar] [CrossRef]

- Tao, S.; Rivas, R.M.O.; Marins, T.N.; Chen, Y.C.; Gao, J.; Bernard, J.K. Impact of heat stress on lactational performance of dairy cows. Theriogenology 2020, 150, 437–444. [Google Scholar] [CrossRef] [PubMed]

- Bernabucci, U.; Biffani, S.; Buggiotti, L.; Vitali, A.; Lacetera, N.; Nardone, A. The Effects of Heat Stress in Italian Holstein Dairy Cattle. J. Dairy Sci. 2014, 97, 471–486. [Google Scholar] [CrossRef] [PubMed]

- Key, N.; Sneeringer, S.; Marquardt, D. Climate Change, Heat Stress, and U.S. Dairy Production; Technical Report; United States Department of Agriculture: Washington, DC, USA, 2014.

- Giannone, C.; Bovo, M.; Ceccarelli, M.; Torreggiani, D.; Tassinari, P. Review of the Heat Stress-Induced Responses in Dairy Cattle. Animals 2023, 13, 3451. [Google Scholar] [CrossRef] [PubMed]

- Ji, B.; Banhazi, T.; Perano, K.; Ghahramani, A.; Bowtell, L.; Wang, C.; Li, B. A Review of Measuring, Assessing and Mitigating Heat Stress in Dairy Cattle. Biosyst. Eng. 2020, 199, 4–26. [Google Scholar] [CrossRef]

- Das, B.; Dutta, P.P.; Bardalai, M.; Dutta, P.P. Comparative study on performance of high volume low speed (HVLS) fans with high-speed fans for the use in dairy barns. Mater. Today Proc. 2021, 47, 4606–4610. [Google Scholar] [CrossRef]

- Flamenbaum, I.; Wolfenson, D.; Mamen, M.; Berman, A. Cooling Dairy Cattle by a Combination of Sprinkling and Forced Ventilation and Its Implementation in the Shelter System. J. Dairy Sci. 1986, 69, 3140–3147. [Google Scholar] [CrossRef]

- West, J.W. Effects of Heat-Stress on Production in Dairy Cattle. J. Dairy Sci. 2003, 86-6, 723–731. [Google Scholar] [CrossRef]

- Masi, R.F.D.; Ruggiero, S.; Tariello, F.; Vanoli, G. Passive envelope solutions to aid design of sustainable livestock buildings in Mediterranean climate. J. Clean. Prod. 2021, 311, 127444. [Google Scholar] [CrossRef]

- Tong, X.; Hong, S.; Zhao, L. CFD Modelling of airflow pattern and thermal environment in a commercial manure-belt layer house with tunnel ventilation. Biosyst. Eng. 2019, 178, 275–293. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, X.; Mondaca, M.R.; Rong, L.; Choi, C.Y. Assessment of Optimal Airflow Baffle Locations and Angles in Mechanically-Ventilated Dairy Houses using Computational Fluid Dynamics. Biosyst. Eng. 2019, 165, 104930. [Google Scholar] [CrossRef]

- Pakari, A.; Ghani, S. Comparison of different mechanical ventilation systems for dairy cow barns: CFD simulations and field measurements. Comput. Electron. Agric. 2021, 186, 106207. [Google Scholar] [CrossRef]

- Cheng, Q.; Feng, H.; Meng, H.; Zhou, H. CFD study of the effect of inlet position and flap on the airflow and temperature in a laying hen house in summer. Biosyst. Eng. 2021, 203, 109–123. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, G.; Choi, C.Y. Evaluation of a precision air-supply system in naturally ventilated freestall dairy barns. Biosyst. Eng. 2018, 175, 1–15. [Google Scholar] [CrossRef]

- Yi, Q.; Zhang, G.; Li, H.; Wang, X.; Janke, D.; Amon, B.; Hempel, S.; Amon, T. Estimation of opening discharge coefficient of naturally ventilated dairy buildings by response surface methodology. Comput. Electron. Agric. 2020, 169, 105224. [Google Scholar] [CrossRef]

- Shen, X.; Zhang, G.; Wu, W.; Bjerg, B. Model-based control of natural ventilation in dairy buildings. Comput. Electron. Agric. 2013, 94, 47–57. [Google Scholar] [CrossRef]

- Wu, W.; Zhai, J.; Zhang, G.; Nielsen, P.V. Evaluation of methods for determining air exchange rate in a naturally ventilated dairy cattle building with large openings using computational fluid dynamics. Atmos. Environ. 2012, 63, 179–188. [Google Scholar] [CrossRef]

- Janke, D.; Caiazzo, A.; Ahmed, N.; Alia, N.; Knoth, O.; Moreau, B.; Wilbrandt, U.; Willink, D.; Amon, T.; John, V. On the Feasibility of Using Open-Source Solvers for the Simulation of a Turbulent Air Flow in a Dairy Barn. Comput. Electron. Agric. 2020, 175, 105546. [Google Scholar] [CrossRef]

- Hong, S.W.; Exadaktylos, V.; Lee, I.; Amon, T.; Youssef, A.; Norton, T.; Berckmans, D. Validation of an Open Source CFD Code to Simulate Natural Ventilation for Agricultural Buildings. Comput. Electron. Agric. 2017, 138, 80–91. [Google Scholar] [CrossRef]

- de Costa, C.C.; Maia, A.S.C.; Nascimento, S.T.; Nascimento, C.C.N.; Neto, M.C.; de França Carvalho Fonsêca, V. Thermal balance of Nellore cattle. Int. J. Biometeorol. 2018, 62, 723–731. [Google Scholar] [CrossRef] [PubMed]

- Maia, A.S.C.; da Silva, R.G.; de Souza Junior, J.B.F.; da Silva, R.B.; Domingos, H.G.T. Effective Thermal Conductivity of the Hair Coat of Holstein Cows in a Tropical Environment. Rev. Bras. Zootec. 2009, 39, 2218–2223. [Google Scholar] [CrossRef]

- Kapadnis, P.J.; Thakur, P.N. Study on skin thickness in crossbreed cattle. Asia J. Anim. Sci. 2018, 13, 72–74. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Rong, L.; Zhang, G. Study on convective heat transfer from pig models by CFD in a virtual wind tunnel. Comput. Electron. Agric. 2016, 123, 203–210. [Google Scholar] [CrossRef]

- Maia, A.S.C.; da Silva, R.G.; Loureiro, C.M.B. Sensible and latent heat loss from the body surface of Holstein cows in a tropical environment. Int. J. Biometeorol. 2005, 50, 17–22. [Google Scholar] [CrossRef]

- Maia, A.S.C.; Silva, R.D.; Loureiro, C.M.B. Respiratory heat loss of Holstein cows in a tropical environment. Int. J. Biometeorol. 2005, 49, 332–336. [Google Scholar] [CrossRef] [PubMed]

- McGovern, R.E.; Bruce, J.M. A Model of the Thermal Balance for Cattle in Hot Conditions. J. Agric. Eng. Res. 2000, 77, 81–92. [Google Scholar] [CrossRef]

- Neves, S.F.; Silva, M.C.F.; Miranda, J.M.; Stilwell, G.; Cortez, P.P. Predictive Models of Dairy Cow Thermal State: A Review from a Technological Perspective. Vet. Sci. 2022, 9, 416. [Google Scholar] [CrossRef]

- Bertipaglia, E.C.A.; Silva, R.G.; Maia, A.S.C. Fertility and hair coat characteristics of Holstein cows in a tropical environment. Anim. Reprod. 2005, 2, 187–194. [Google Scholar]

- Ostyakova, M.E.; Sayapina, I.Y.; Mandro, N.M.; Trush, N.V.; Gavrilov, Y.A.; Gavrilova, G.A.; Hibchenov, L.V.; Chubin, A.N. Morphological and Quantitative Characteristics of the Skin of Holstein Cattle in the Amur Region. Int. J. Eng. Technol. 2018, 7, 78–82. [Google Scholar] [CrossRef]

- Li, G.; Chen, S.; Chen, J.; Peng, D.; Gu, X. Predicting rectal temperature and respiration rate responses in lactating dairy cows exposed to heat stress. J. Dairy Sci. 2020, 103, 5466–5484. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, A.; Gautam, K.R.; Zhang, G.; Rong, L. Modelling of Animal Occupied Zones in CFD. Biosyst. Eng. 2017, 204, 181–197. [Google Scholar] [CrossRef]

- National Academies of Sciences Engineering and Medicine. In Nutrient Requirements of Dairy Cattle: Eighth Revised Edition; The National Academies Press: Washington, DC, USA, 2021.

- Arndt, C.; Powell, J.M.; Aguerre, M.J.; Crump, P.M.; Wattiaux, M.A. Feed conversion efficiency in dairy cows: Repeatability, variation in digestion and metabolism of energy and nitrogen, and ruminal methanogens. J. Dairy Sci. 2015, 96, 3938–3950. [Google Scholar] [CrossRef] [PubMed]

- Gebremedhin, K.G.; Wu, B.; Perano, K. Modeling conductive cooling for thermally stressed dairy cows. J. Therm. Biol. 2016, 56, 91–99. [Google Scholar] [CrossRef] [PubMed]

- Elting, E.C. A formula for estimating surface area of dairy cattle. J. Agric. Res. 1926, 33-3, 269–279. [Google Scholar]

- Khakimov, A.R.; Pavkin, D.Y.; Yurochka, S.S.; Astashev, M.E.; Dovlatov, I.M. Development of an Algorithm for Rapid Herd Evaluation and Predicting Milk Yield of Mastitis Cows Based on Infrared Thermography. Appl. Sci. 2022, 12, 6621. [Google Scholar] [CrossRef]

- Collier, R.J.; Gebremedhin, K.G. Thermal Biology of Domestic Animals. Annu. Rev. Anim. Biosci. 2015, 3, 513–532. [Google Scholar] [CrossRef]

- Li, J.; Narayanan, V.; Kebreab, E.; Dikmen, S.; Fadel, J.G. A Mechanistic Thermal Balance Model of Dairy Cattle. Biosyst. Eng. 2021, 209, 256–270. [Google Scholar] [CrossRef]

- Fregonesi, J.A.; Tucker, C.B.; Weary, D.M. Overstocking Reduces Lying Time in Dairy Cows. J. Dairy Sci. 2007, 90, 3349–3354. [Google Scholar] [CrossRef] [PubMed]

- Fregonesi, J.A.; Veira, D.M.; von Keyserlingk, M.A.G.; Weary, D.M. Effects of Bedding Quality on Lying Behavior of Dairy Cows. J. Dairy Sci. 2007, 90, 5468–5472. [Google Scholar] [CrossRef] [PubMed]

- Yi, Q.; Li, H.; Wang, X.; Zong, C.; Zhang, G. Numerical investigation on the effects of building configuration on discharge coefficient for a cross-ventilated dairy building model. Biosyst. Eng. 2019, 182, 107–122. [Google Scholar] [CrossRef]

- Hargreaves, D.; Wright, N. On the Use of the k-ε Model in Commercial CFD Software to Model the Neutral Atmospheric Boundary Layer. J. Wind. Eng. Ind. Aerodyn. 2007, 95, 355–369. [Google Scholar] [CrossRef]

- OpenCFD. OpenFOAM: Open Source CFD Toolbox. User Guide Version 1.9.5; OpenCFD: Reading, UK, 2023. [Google Scholar]

- Wang, X.; Bjerg, B.S.; Choi, C.Y.; Zong, C.; Zhang, G. A review and quantitative assessment of cattle-related thermal indices. J. Therm. Biol. 2018, 77, 24–37. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Gao, H.; Gebremedhin, K.G.; Bjerg, B.S.; Os, J.V.; Tucker, C.B.; Zhang, G. A predictive model of equivalent temperature index for dairy cattle (ETIC). J. Therm. Biol. 2018, 76, 165–170. [Google Scholar] [CrossRef] [PubMed]

- Bjerg, B.; Cascone, G.; Lee, I.B.; Bartzanas, T.; Norton, T.; Hong, S.W.; Seo, I.H.; Banhazi, T.; Liberati, P.; Marucci, A.; et al. Modelling of Ammonia Emissions from Naturally Ventilated Livestock Buildings. Part 3: CFD Modelling. Biosyst. Eng. 2013, 116, 259–275. [Google Scholar] [CrossRef]

- Snell, H.; Seipelt, F.; den Weghe, H.V. Ventilation Rates and Gaseous Emissions from Naturally Ventilated Dairy Houses. Biosyst. Eng. 2003, 86, 67–73. [Google Scholar] [CrossRef]

- Tominaga, Y.; Mochida, A.; Yoshie, R.; Kataoka, H.; Nozu, T.; Yoshikawa, M.; Shirasawa, T. AIJ guidelines for practical applications of CFD to pedestrian wind environment around buildings. J. Wind. Eng. Ind. Aerodyn. 2008, 96, 1749–1761. [Google Scholar] [CrossRef]

- Marrero, T.R.; Mason, E.A. Gaseous Diffusion Coefficients. J. Phys. Chem. Ref. Data 1972, 1, 3–119. [Google Scholar] [CrossRef]

- Leliveld, L.M.; Lovarelli, D.; Finzi, A.; Riva, E.; Provolo, G. Effects of cow reproductive status, parity and lactation stage on behaviour and heavy breathing indications of a commercial accelerometer during hot weather conditions. Int. J. Biometereology 2023, 67, 1263–1272. [Google Scholar] [CrossRef]

- Armstrong, J.; Janni, K. Heat Stress in Dairy Cattle; Technical Report; University of Minnesota: Minneapolis, MN, USA, 2023. [Google Scholar]

- Islam, M.A.; Lomax, S.; Doughty, A.K.; Islam, M.R.; Clark, C.E.F. Automated Monitoring of Panting for Feedlot Cattle: Sensor System Accuracy and Individual Variability. Animals 2020, 10, 1518. [Google Scholar]

- Agenzia Regionale per la Prevenzione, l’Ambiente e l’Energia dell´Emilia-Romagna. Hourly Weather Database for Emilia-Romagna; Open Database; ARPAE: Bologna, Italy, 2024. [Google Scholar]

- Chen, C.; Gorle, C. Full-scale validation of CFD simulations of buoyancy-driven ventilation in a three-story office building. Build. Environ. 2022, 221, 109240. [Google Scholar] [CrossRef]

- Teye, F.K.; Hautala, M.; Pastell, M.; Praks, J.; Veerma, I.; Poikalainen, V.; Pajuma, A.; Kivinen, T.; Ahokas, J. Microclimate and ventilation in Estonian and Finnish dairy buildings. Energy Build. 2008, 40, 1194–1201. [Google Scholar] [CrossRef]

- Maltz, E.; Kroll, O.; Barash, H.; Shamy, A.; Silanikove, N. Lactation and body weight of dairy cows: Interrelationships among heat stress, calving season and milk yield. J. Anim. Feed. Sci. 2000, 9, 33–45. [Google Scholar] [CrossRef]

- Santolini, E.; Bovo, M.; Barbaresi, A.; Al-Rikabi, S.H.F.; Torreggiani, D.; Tassinari, P. CFD modelling of gaseous emissions and dispersion from pig barn to surrounding areas. In Proceedings of the IEEE International Workshop on Metrology for Agriculture and Forestry, MetroAgriFor 2021, Trento, Italy, 3–5 November 2021; pp. 320–324. [Google Scholar]

- National Oceanic and Atmospheric Administration. Atmospheric Ammonia: Sources and Fate; Technical Report, CENR Air Quality Research Subcommittee; Aeronomy Laboratory: Boulder, CO, USA, 2000.

| Region | Number | State | Metabolic Heat | Total Energy Source | Total Water Source |

|---|---|---|---|---|---|

| [-] | [-] | [-] | [W] | [kW] | [g/s] |

| Stalls | 70 | Lactation | 1938 | 67.83 | 27.92 |

| Feeding line | 30 | Lactation | 1938 | 29.07 | 11.96 |

| Prepartum box | 6 | Dry | 1197 | 3.59 | 1.48 |

| Postpartum box | 6 | Early lactation | 1357 | 4.07 | 1.68 |

| Thermophysical Property | Unit of Measure | Winter Weather | Summer Weather |

|---|---|---|---|

| Density | kg/m3 | Not needed | 1.1641 |

| Specific heat capacity | J/kgK | Not needed | 1007 |

| Kinematic viscosity | m2/s | 1.382 × 10−5 | 1.608 × 10−5 |

| Expansion coefficient | 1/K | −4.562 × 10−3 | −3.841 × 10−3 |

| Reference temperature | K | 278.15 | 303.15 |

| Prandtl number | − | 0.735 | 0.728 |

| Lewis number | − | 0.809 | 0.814 |

| Date | Time Interval | Heavy Breathing Duration | |||||

|---|---|---|---|---|---|---|---|

| [–] | [h] | [°C] | [%] | [W/] | [min/day] | [%] | [%] |

| 23 June 2022 | 8 | 29.8 | 52.0 | 437 | 60 | 87.5 | 12.5 |

| 28 August 2022 | 8 | 29.1 | 50.3 | 370 | 23 | 95.2 | 4.8 |

| 2 July 2023 | 8 | 30.2 | 50.5 | 612 | 17 | 96.5 | 3.5 |

| 13 July 2023 | 8 | 29.2 | 51.2 | 475 | 57 | 88.1 | 11.9 |

| 29 July 2023 | 8 | 30.2 | 51.2 | 540 | 24 | 95.0 | 5.0 |

| 1 August 2023 | 8 | 29.4 | 53.5 | 576 | 36 | 92.5 | 7.5 |

| Average | 8 | 29.6 | 51.4 | 502 | 36 | 92.5 | 7.5 |

| Simulation | Steady State | 30.0 | 55.0 | 500 | See Table 4 | ||

| THI | ETIC | |||

|---|---|---|---|---|

| Heat Stress Intensity | Class Range | Class Range | ||

| [-] | [%] | [-] | [%] | |

| Thermoneutral | THI < 68 | 0.0 | ETIC < 23 | 25.3 |

| Mild | 0.0 | 70.5 | ||

| Moderate | 25.0 | 4.2 | ||

| Severe | 75.0 | 0.0 | ||

| Critical | 0.0 | 0.0 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colombari, D.; Masoero, F.; Della Torre, A. A CFD Methodology for the Modelling of Animal Thermal Welfare in Hybrid Ventilated Livestock Buildings. AgriEngineering 2024, 6, 1525-1548. https://doi.org/10.3390/agriengineering6020087

Colombari D, Masoero F, Della Torre A. A CFD Methodology for the Modelling of Animal Thermal Welfare in Hybrid Ventilated Livestock Buildings. AgriEngineering. 2024; 6(2):1525-1548. https://doi.org/10.3390/agriengineering6020087

Chicago/Turabian StyleColombari, Dario, Francesco Masoero, and Augusto Della Torre. 2024. "A CFD Methodology for the Modelling of Animal Thermal Welfare in Hybrid Ventilated Livestock Buildings" AgriEngineering 6, no. 2: 1525-1548. https://doi.org/10.3390/agriengineering6020087

APA StyleColombari, D., Masoero, F., & Della Torre, A. (2024). A CFD Methodology for the Modelling of Animal Thermal Welfare in Hybrid Ventilated Livestock Buildings. AgriEngineering, 6(2), 1525-1548. https://doi.org/10.3390/agriengineering6020087