Experimental Evaluation of Nano Coating on the Draft Force of Tillage Implements and Its Prediction Using an Adaptive Neuro-Fuzzy Inference System (ANFIS)

Abstract

1. Introduction

2. Materials and Methods

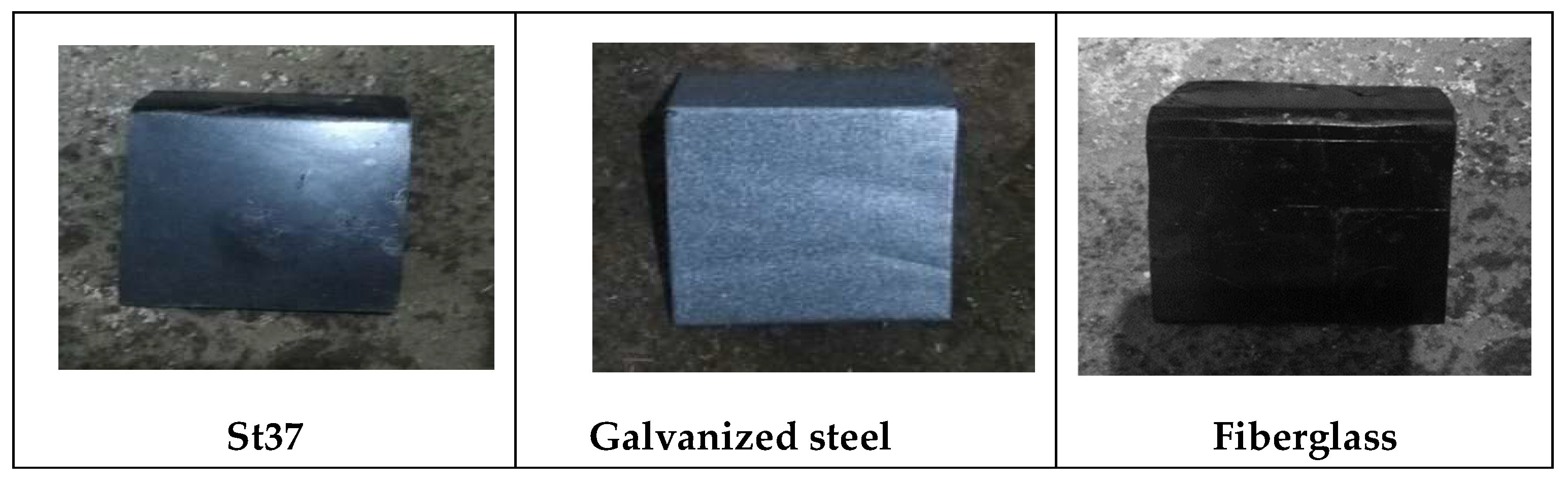

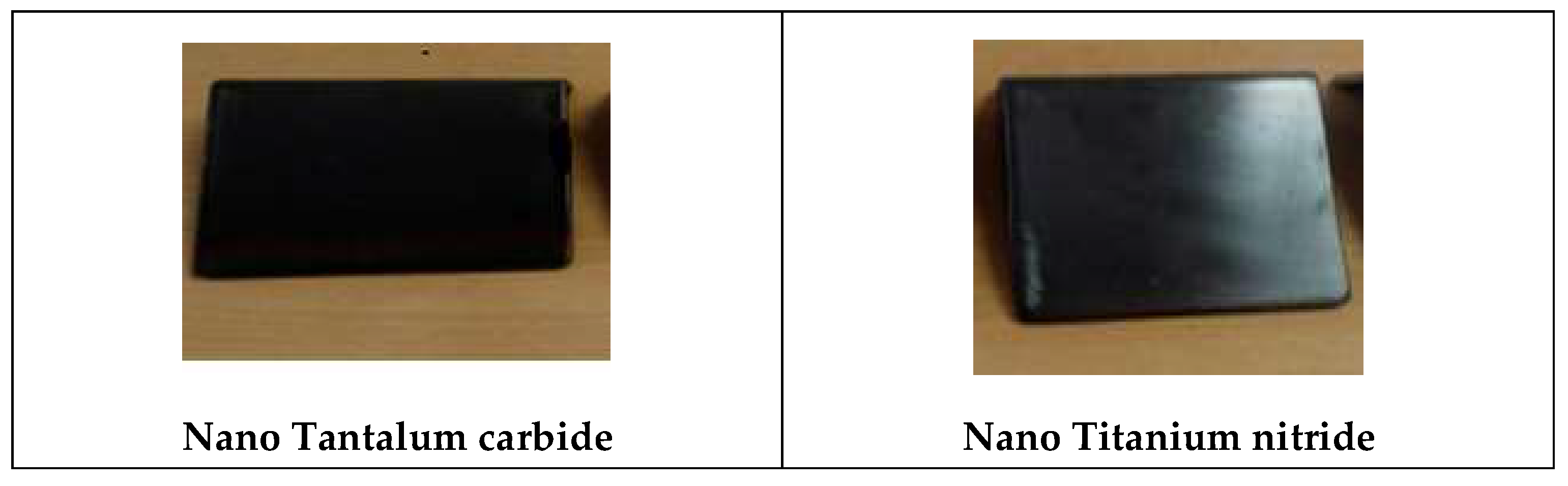

2.1. Material Characteristics

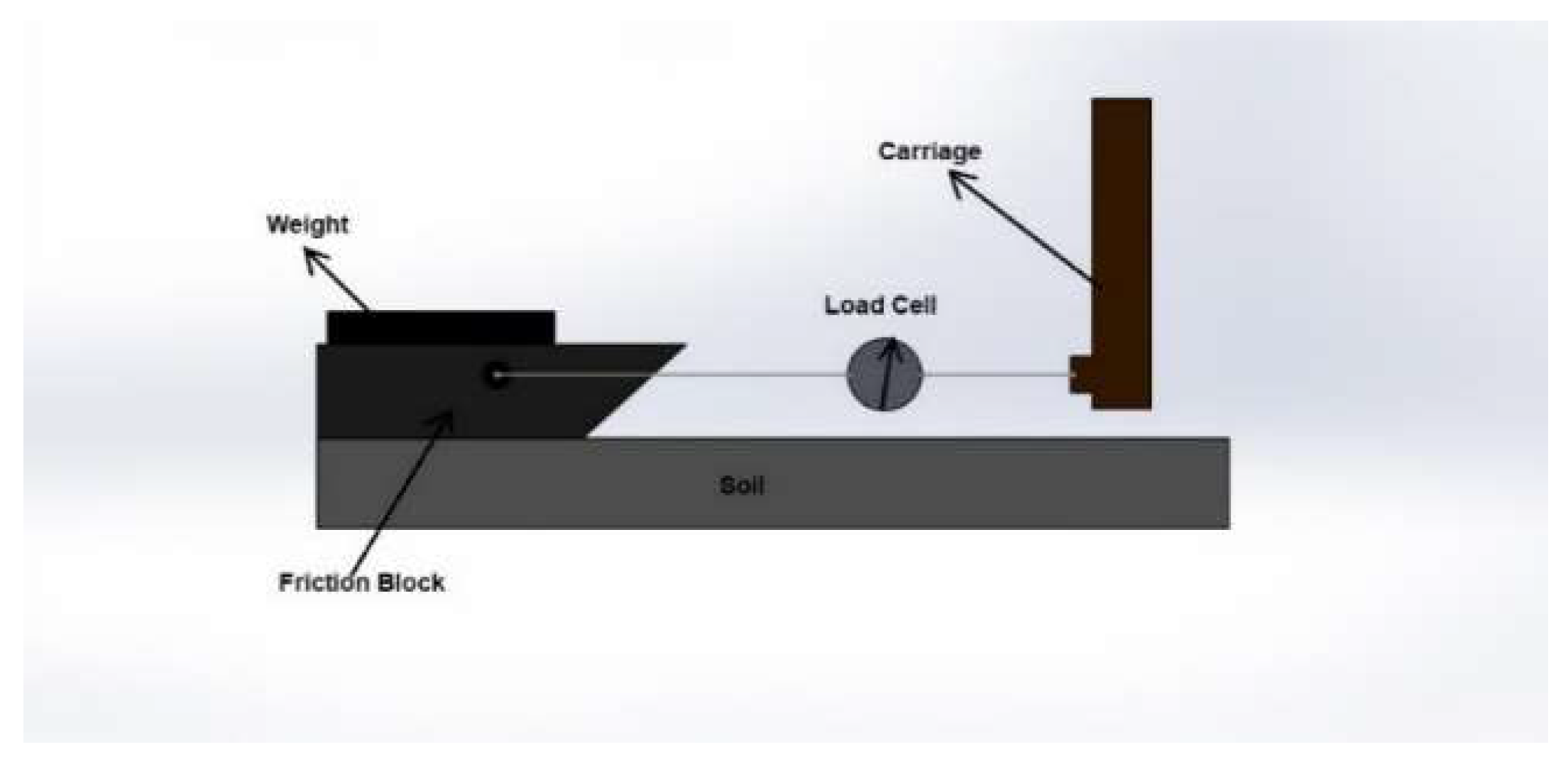

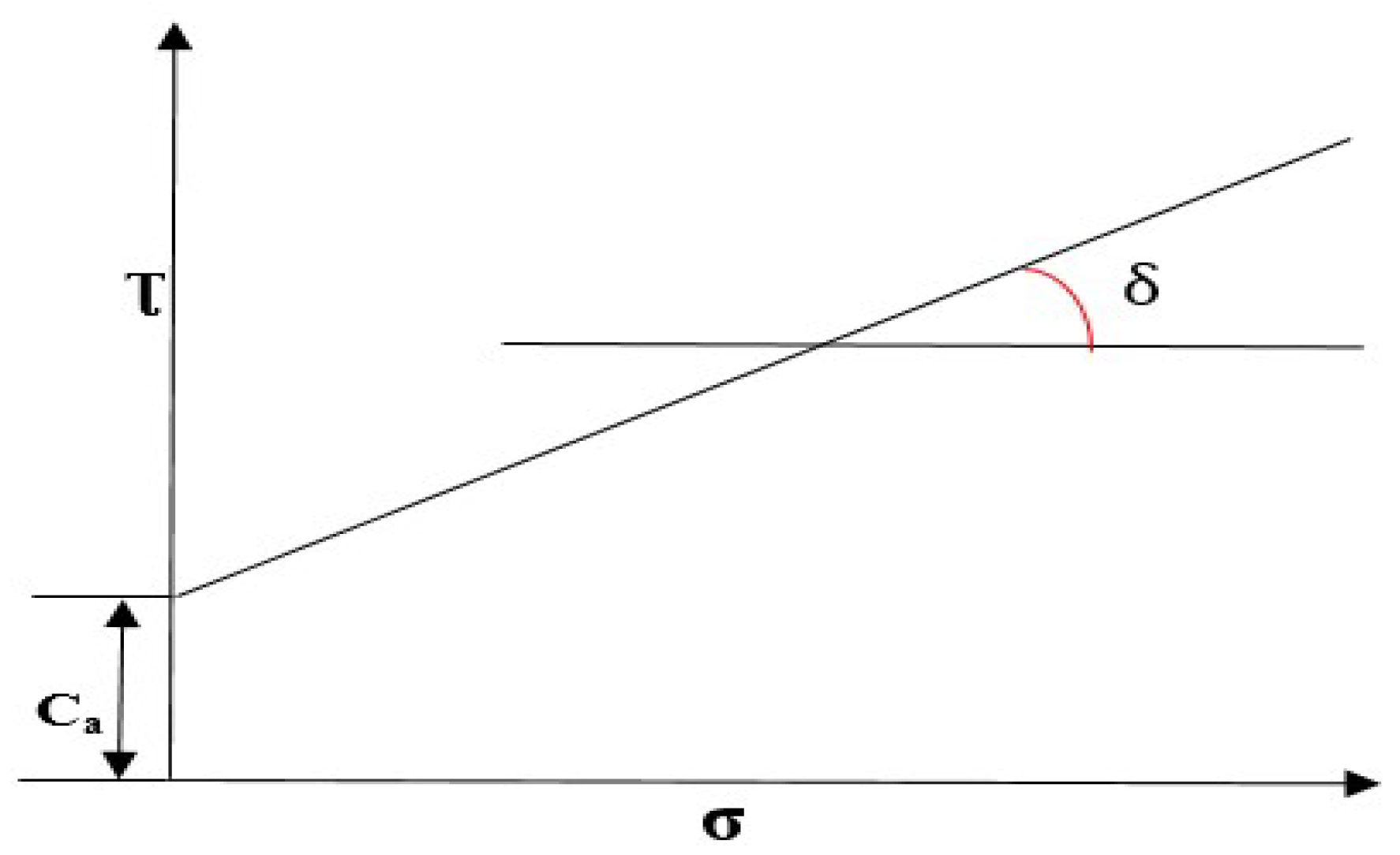

2.2. Test Stand

2.3. ANFIS Modelling

3. Results and Discussion

4. Conclusions

- The ANFIS model showed better performance in predicting the draft force than the stepwise regression models.

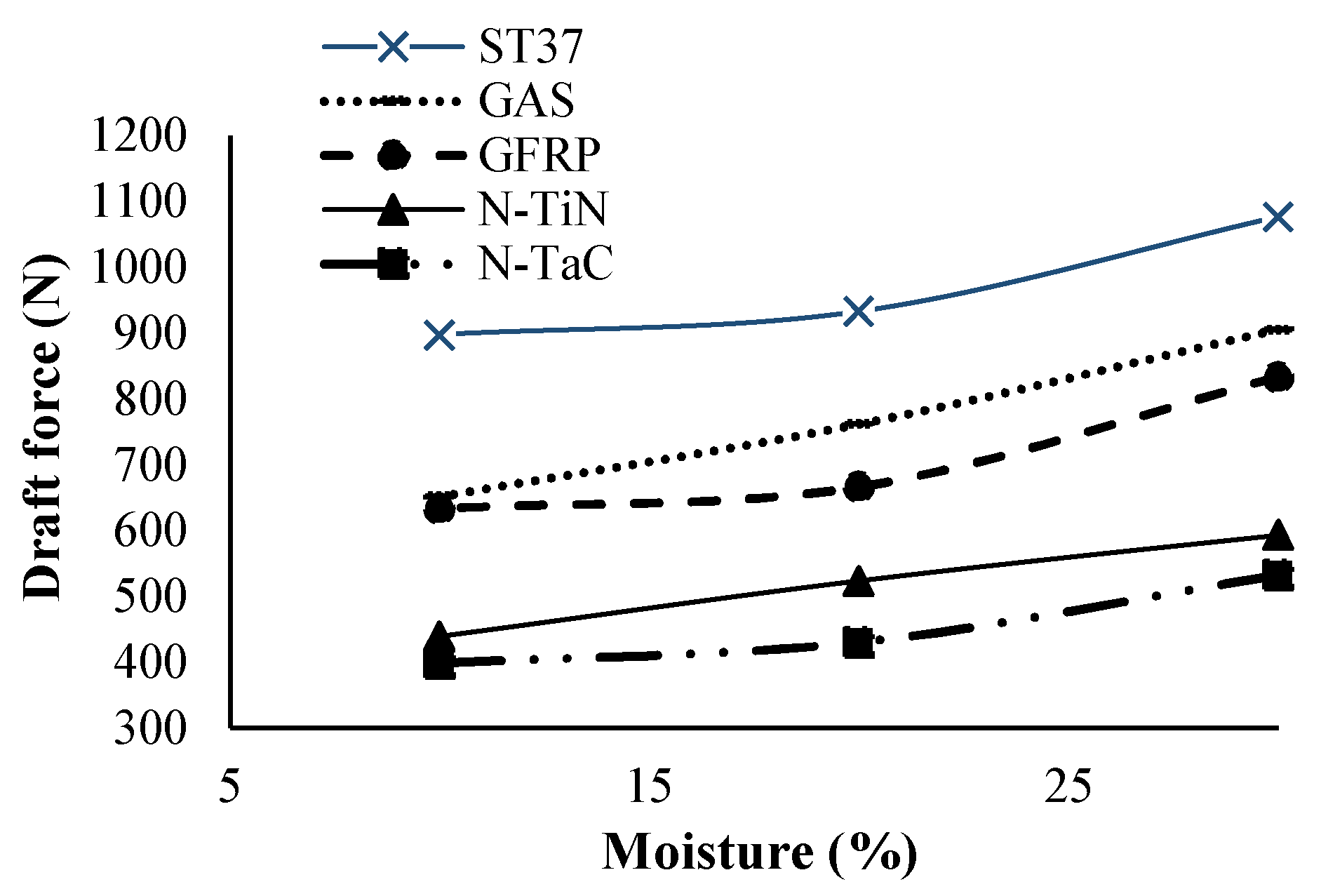

- It was found that soil–tool adhesion showed the greatest effect on draft force.

- The results showed that nano-coating of blades was significant in reducing draft force, especially in sticky soils, compared to normal St37 and galvanized steel. At a moisture content of 20%, the draft requirement of St37 and nano-coated blades was 936 and 477 N, respectively, indicating a 49% and 53% draft reduction in studying the blade speed effect on the draft requirement. These high percentages of draft reduction show the importance of Nano-coating in reducing the energy requirement of tillage operations. Also, the soil furrow created by nano blades was more symmetrical and monotonic.

- By understanding the conditions of the blades in the soil and the issues governing the tillage, the use of fiberglass through reinforced polymer fibers demonstrated acceptable performance compared to common galvanized steel against on draft reduction. However, nano-tantalum carbide was the best coating in terms of its resistance and draft force reduction.

- Improving the surface of the blades in the tools involved with the soil should be done in such a way as to reduce production costs and fuel consumption and increase tillage efficiency. These results can be achieved by knowing the working conditions of the blades in the soil and the tribological issues governing the tillage blades. Due to the challenges in conducting field trials as well as the high cost of coatings and coating application processes for large-scale tests, tests were conducted in the soil bin. It is hopeful that in the near future, by studying and applying the new methods of coating, problems regarding agricultural industry equipment, such as friction, wear, corrosion, erosion, etc., can be solved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kheiralla, F.A.; Yahia, A.; Zohadie, M.; Ishak, W. Modelling of power and energy requirements for tillage implements operating on Serdang sandy clay loam, Malaysia. Soil Tillage Res. 2004, 78, 21–34. [Google Scholar] [CrossRef]

- Ren, L.Q.; Wang, Y.P.; Li, J.Q.; Tong, J. The flexible unsmoothed cuticles of soil animals and their characteristics of reducing adhesion and resistance. Chin. Sci. Bull. 1998, 43, 166–169. [Google Scholar] [CrossRef]

- Manuwa, S.I. Performance evaluation of tillage tines operating under different depths in a sandy clay loam soil. Soil Tillage Res. 2009, 103, 399–405. [Google Scholar] [CrossRef]

- Nalbant, A.M.; Palali, T. Effects of different material coatings on the wearing of plow blades in soil tillage. Turk. J. Agric. For. 2001, 35, 215–223. [Google Scholar] [CrossRef]

- Hou, X.; Chou, K.-C. Oxidation kinetics of TiN-containing composites. Ceram. Int. 2014, 40, 961–966. [Google Scholar] [CrossRef]

- Sharifi Malvajerdi, S.; Sharifi Malvajerdi, A.; Ghanaatshoar, M. Protection of CK45 carbon steel tillage tools using TiN coating deposited by an arc-PVD method. Ceram. Int. 2019, 45, 3816–3822. [Google Scholar] [CrossRef]

- Badiger, P.V.; Desai, V.; Ramesh, M.R. Development and characterization of Ti/TiC/TiN coatings by cathodic arc evaporation technique. Trans. Indian Inst. Met. 2017, 70, 2459–2464. [Google Scholar] [CrossRef]

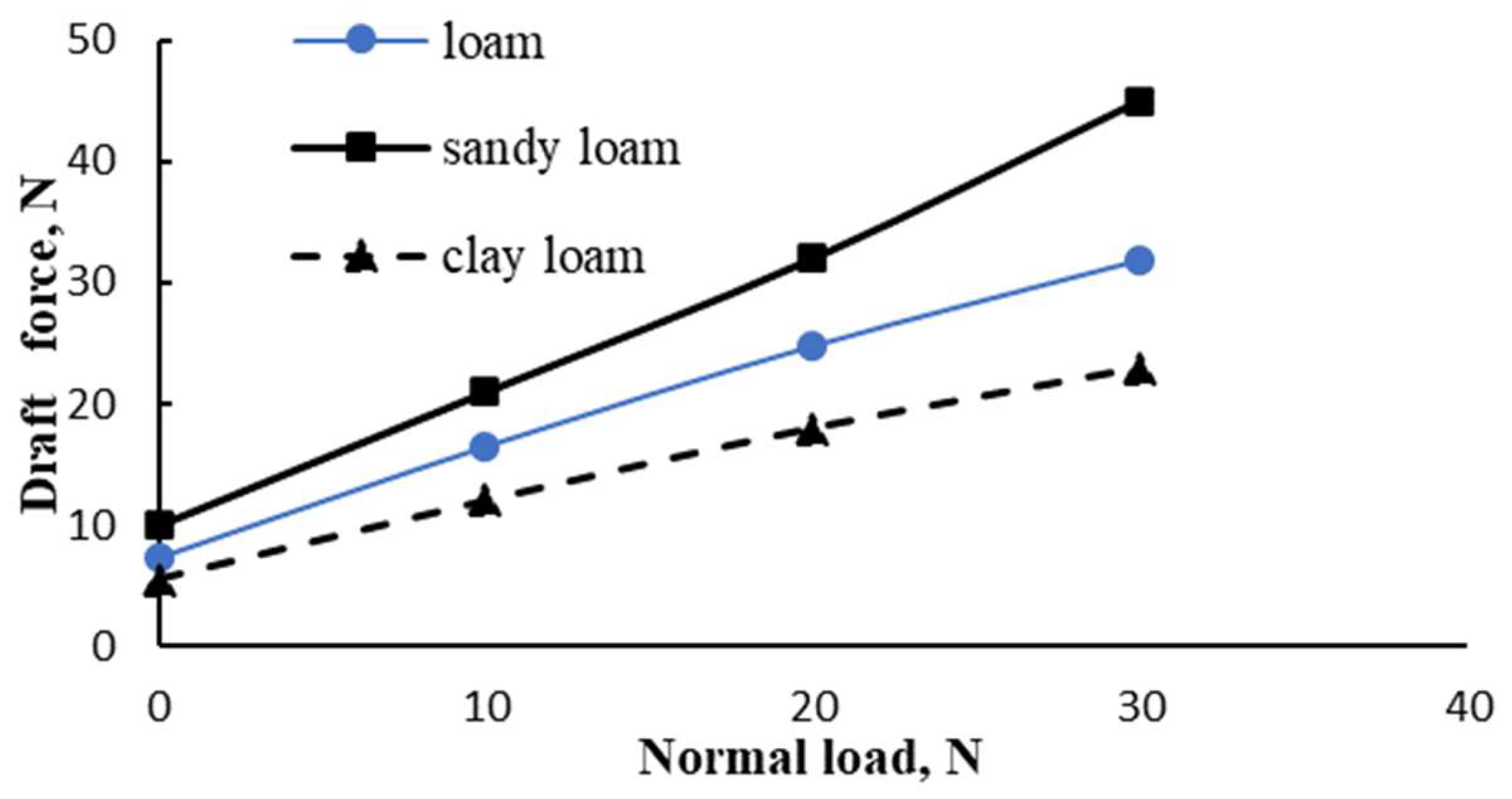

- Marani, S.M.; Shahgholi, G.; Moinfar, A. Effect of nano coating materials on reduction of soil adhesion and external friction. Soil Tillage Res. 2019, 193, 42–49. [Google Scholar] [CrossRef]

- Gill, W.R.; Vanden Berg, G.E. Soil Dynamics in tillage and traction. In USDAARS Agricultural Handbook No. 316.; Government Printing Office: Washington, DC, USA, 1968. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Goering, C.E.; Rohrbach, R.P.; Buckmastar, D.R. Soil tillage. In Chapter 8. Engineering Principles of Agricultural Machines, 2nd ed.; ASABE: St. Joseph, MI, USA, 2006; pp. 169–230. Available online: https://fsantos.utad.pt/bibliografia/06Ajit_Srivastava.pdf (accessed on 21 March 2023).

- Barzegar, M.; Hashemi, S.; Nazokdast, H.; Karimi, R. Evaluating the draft force and soil-tool adhesion of a UHMW-PE coated furrower. Soil Tillage Res. 2016, 163, 160–167. [Google Scholar] [CrossRef]

- Haines, W.B. Studies in the physical properties of soil. I. Mechanical properties concerned in cultivation. J. Agric. Sci. 1925, 15, 178–200. [Google Scholar] [CrossRef]

- Payne, P.C. The relationship between the mechanical properties of soil and the performance of simple cultivation implements. J. Agric. Eng. Res. 1956, 1, 23–50. [Google Scholar]

- Marakoglu, T.; Carman, K. Fuzzy knowledge-based model for prediction of soil loosening and draft force efficiency in tillage. J. Terramech. 2010, 47, 173–178. [Google Scholar] [CrossRef]

- Ghadernejad, K.; Shahgholi, G.; Mardani, A.; Ghafouri Chiyaneh, H. Prediction effect of farmyard manure, multiple passes and moisture content on clay soil compaction using adaptive neuro-fuzzy inference system. J. Terramech. 2018, 77, 49–57. [Google Scholar] [CrossRef]

- Badiger, P.V.; Desai, V.; Ramesh, M.R.; Joladarashi, S.; Gourka, H. Tribological behaviour of monolayer and multilayer Ti-based thin solid films deposited on alloy steel. Mater. Res. Express 2018, 6, 026419. [Google Scholar] [CrossRef]

- Badiger, P.V.; Desai, V.D.; Ramesh, M.R.; Prajwala, B.K.; Raveendra, K. Effect of cutting parameters on tool wear, cutting force and surface roughness in machining of MDN431 alloy using Al and Fe coated tools. Mater. Res. Express 2018, 6, 016401. [Google Scholar] [CrossRef]

- Jia, X.; Ling, X. Reduction of soil resistance through the use of a composite coating. J. Coat. Technol. Res. 2005, 2, 669–672. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, R.; Yuan, Z.; Shu, X.; Liu, E.; Han, Z. A comparative study of the corrosion performance of titanium (ti), titanium nitride (TiN), titanium dioxide (TiO2) and nitrogen-doped titanium oxides (N-TiO2), as coatings for biomedical applications. Ceram. Int. 2015, 41, 11844–11851. [Google Scholar] [CrossRef]

- Sahu, R.K.; Raheman, H. Draught prediction of agricultural implements using reference tillage tools in sandy clay loam soil. Biosyst. Eng. 2006, 94, 275–284. [Google Scholar] [CrossRef]

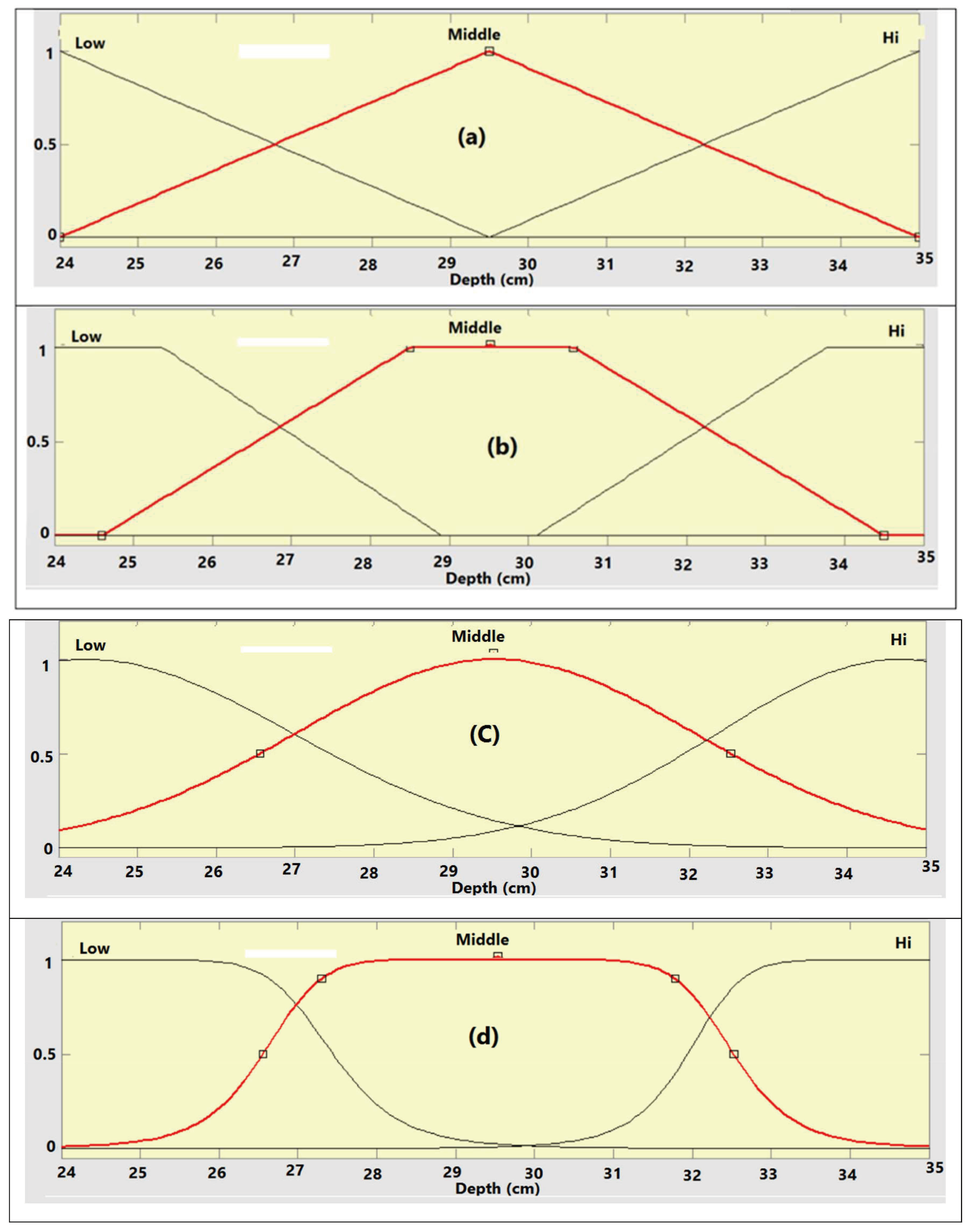

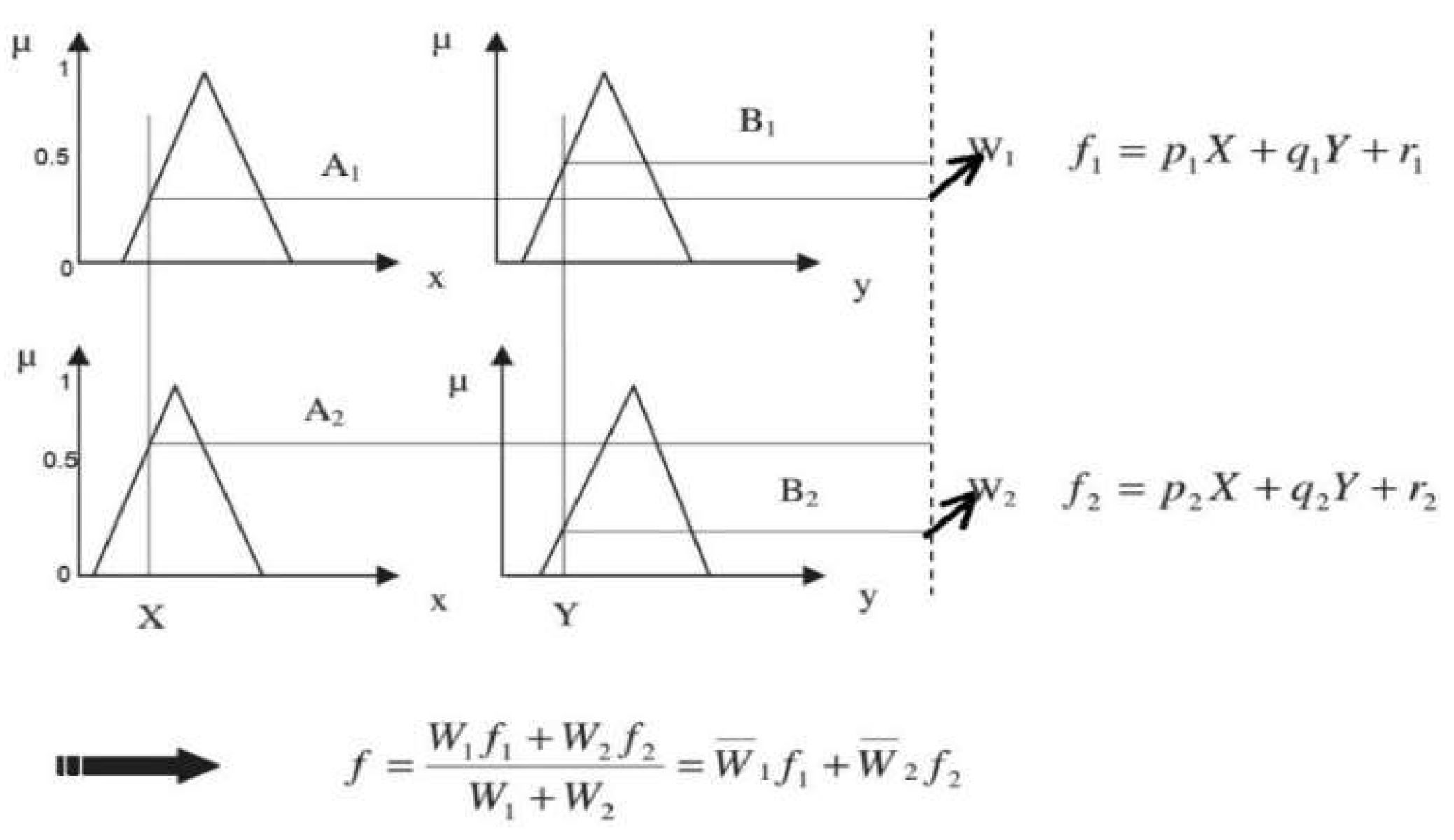

- Shafaei, S.M.; Loghavi, M.; Kamgar, S. Appraisal of Takagi-Sugeno-Kang type of adaptive neuro-fuzzy inference system for draft force prediction of chisel plow implement. Comput. Electron. Agric. 2017, 142, 406–515. [Google Scholar] [CrossRef]

- Al-Dosary, N.M.; Al-Hamed, S.A.; Aboukarima, A.M. Application of adaptive neuro-fuzzy inference system to predict draft and energy requirements of a disk plow. Int. J. Agric. Biol. Eng. 2020, 13, 198–207. [Google Scholar]

- Elsheikha, A.M.; Al-Rajhi, M.A.; El-Shabasy, T.M. Effect of Coating Chisel Plow Shares with Some Materials on Draft Force Requirement. J. Soil Sci. Agric. Eng. 2012, 12, 611–614. [Google Scholar]

- Kushwaha, R.L.; Chi, L.; Roy, C. Investigation of agricultural tools with plasma sprayed coatings. Tribol. Int. 1990, 23, 297–300. [Google Scholar] [CrossRef]

- Moinfar, A.; Shahgholi, G. The effect of Tractor driving system type on its slip and rolling resistance and its modelling using ANFIS. Acta Technol. Agric. 2019, 22, 116–122. [Google Scholar] [CrossRef]

- Harsono, S.S. Tillage implements effect on wet sticky soil. Res. J. Agric. Sci. 2011, 43, 86–94. [Google Scholar]

- Manuwa, S.I. Evaluation of soil/material interface friction and adhesion of akure sandy clay loam soils in Southwestern Nigeria. Adv. Nat. Sci. 2012, 5, 41–46. [Google Scholar] [CrossRef]

- Salokhe, V.M.; Cheunpakaranant, W.; Niyampa, T. Effects of enamel coating on the performance of tractor drawn rotavator. J. Terramech. 1999, 36, 127–138. [Google Scholar] [CrossRef]

- Chandon, K.; Kushwaha, R.L. Soil forces on deep tillage tools. In Proceedings of the AIC 2002 Meeting CSAE/SCGR Program, Saskatoon, SK, Canada, 14–17 July 2002; Available online: http://hdl.handle.net/10388/etd-07172012-083608 (accessed on 21 March 2023).

- Söhne, W. Some Basic Considerations of Soil Mechanics as Applied to Agricultural Engineering; National Institute of Agricultural Engineering: Silsoe, UK, 1958. [Google Scholar]

- Summers, J.O.; Khalilian, A.; Batchelder, D.G. Draft relationships for primary tillage in Oklahoma soils. Trans. ASAE 1986, 29, 37–39. [Google Scholar] [CrossRef]

- Dransfield, P.; Willat, S.T.; Willis, A.H. Soil-implement reaction experienced with simple tines at various angles of attack. J. Agric. Eng. Res. 1964, 9, 220–224. [Google Scholar]

- Soni, P.; Salokhe, V.M.; Nakashima, H. Modification of a mouldboard plough surface using arrays of polyethylene protuberances. J. Terramech. 2007, 44, 411–422. [Google Scholar] [CrossRef]

- Fielke, J.M. Interactions of the cutting edge of tillage implements with soil. J. Agric. Eng. Res. 1996, 63, 61–72. [Google Scholar] [CrossRef]

| Soil Texture | Sand Percentage (%) | Clay Percentage (%) | Silt Percentage (%) |

|---|---|---|---|

| Sandy-Loamy | 73 | 10 | 17 |

| Loamy | 46 | 24 | 30 |

| Clay-Loamy | 30 | 40 | 30 |

| Input Variables | Linear Output Function (Draft Force), N | ||||

|---|---|---|---|---|---|

| Rules | Speed, m·s−1 | Rake Angle, Degrees | Cohesion, Pa | Adhesion, Pa | |

| Rule1 | slow | small | low | poor | D = 2.8s + 83a − 16c + 3962ad + 2.8 |

| Rule8 | slow | small | high | mean | D = 45s + 1349a − 190c + 6741ad + 45 |

| Rule18 | slow | avg | high | rich | D = 94s + 4247a − 290c + 5302ad + 94 |

| Rule28 | normal | small | low | poor | D = −3.4s − 50.7a − 16.6c + 4136ad − 1.7 |

| Rule38 | normal | avg | low | mean | D = −91s − 2061a − 235c + 5069ad − 45 |

| Rule48 | normal | big | low | rich | D = −107s − 3220a − 566c + 6359ad − 53 |

| Rule58 | fast | small | medium | poor | D = −28s − 279a − 15c + 5152ad − 9.3 |

| Rule68 | fast | avg | medium | mean | D = −277s − 4161a − 131c + 3975ad − 92 |

| Rule78 | fast | big | medium | rich | D = −867s − 1735a − 470c + 7668ad − 289 |

| Rule81 | fast | big | high | rich | D = 1155s + 2310a − 469c + 7832ad + 385 |

| Source | DOF | Sum of Squares | Mean of Squares | F-Value | p-Value |

|---|---|---|---|---|---|

| Speed | 2 | 8,431,423 | 4,215,711 | 3488.02 ** | 0.000 |

| Rake angle | 2 | 6,209,571 | 3,104,785 | 2568.85 ** | 0.000 |

| Adhesion | 4 | 41,820,740 | 10,455,185 | 8650.46 ** | 0.000 |

| Cohesion | 8 | 15,521,397 | 1,940,175 | 1605.27 ** | 0.000 |

| Speed*Rake angle | 4 | 123,109 | 30,777 | 25.46 ** | 0.000 |

| Speed*Adhesion | 8 | 630,415 | 78,802 | 65.20 ** | 0.000 |

| Speed*Cohesion | 16 | 240,828 | 15,052 | 12.45 ** | 0.000 |

| Rake angle*Adhesion | 8 | 411,298 | 51,412 | 42.54 ** | 0.000 |

| Rake angle*Cohesion | 16 | 193,016 | 12,064 | 9.98 ** | 0.000 |

| Adhesion*Cohesion | 32 | 2,230,482 | 69,703 | 57.67 ** | 0.000 |

| Speed*Rake angle*Adhesion | 16 | 22,892 | 1431 | 1.18 * | 0.275 |

| Speed*Rake angle*Cohesion | 32 | 51,782 | 1618 | 1.34 * | 0.101 |

| Speed*Adhesion*Cohesion | 64 | 294,870 | 4607 | 3.81 ** | 0.000 |

| Rake angle*Adhesion*Cohesion | 64 | 177,193 | 2769 | 2.29 ** | 0.000 |

| Speed*Rake angle*Adhesion*Cohesion | 128 | 191,407 | 1495 | 1.24 * | 0.049 |

| Error | 810 | 978,988 | 1209 | ||

| Total | 1214 | 77,529,410 |

| Model | Type of MF | Number of MF | Optimization Method | Test | |||

|---|---|---|---|---|---|---|---|

| Input | Output | Input | Epoch | ε (%) | R2 | ||

| Grid Partition | Trimf | Linear | Hybrid | 30 | Hybrid | 6.77 | 0.9407 |

| Grid Partition | Gaussmf | Linear | Hybrid | 30 | Hybrid | 6.39 | 0.9491 |

| Grid Partition | Trapmf | Linear | Hybrid | 30 | Hybrid | 6.27 | 0.9511 |

| Grid Partition | Gbellmf | Linear | Hybrid | 30 | Hybrid | 6.1 | 0.9568 |

| Model | Unstandardized Coefficients | Standardized Coefficients | t | sig | |

|---|---|---|---|---|---|

| B | Std. Error | Beta | |||

| (Constant) | −576.275 | 40.645 | −14.178 | 0.000 | |

| Speed | 100.032 | 6.596 | 0.325 | 15.167 | 0.000 |

| Rake angle | 5.890 | 0.440 | 0.287 | 13.397 | 0.000 |

| Cohesion | 0.025 | 0.01 | 0.372 | 17.295 | 0.000 |

| Adhesion | 0.420 | 0.013 | 0.678 | 31.569 | 0.000 |

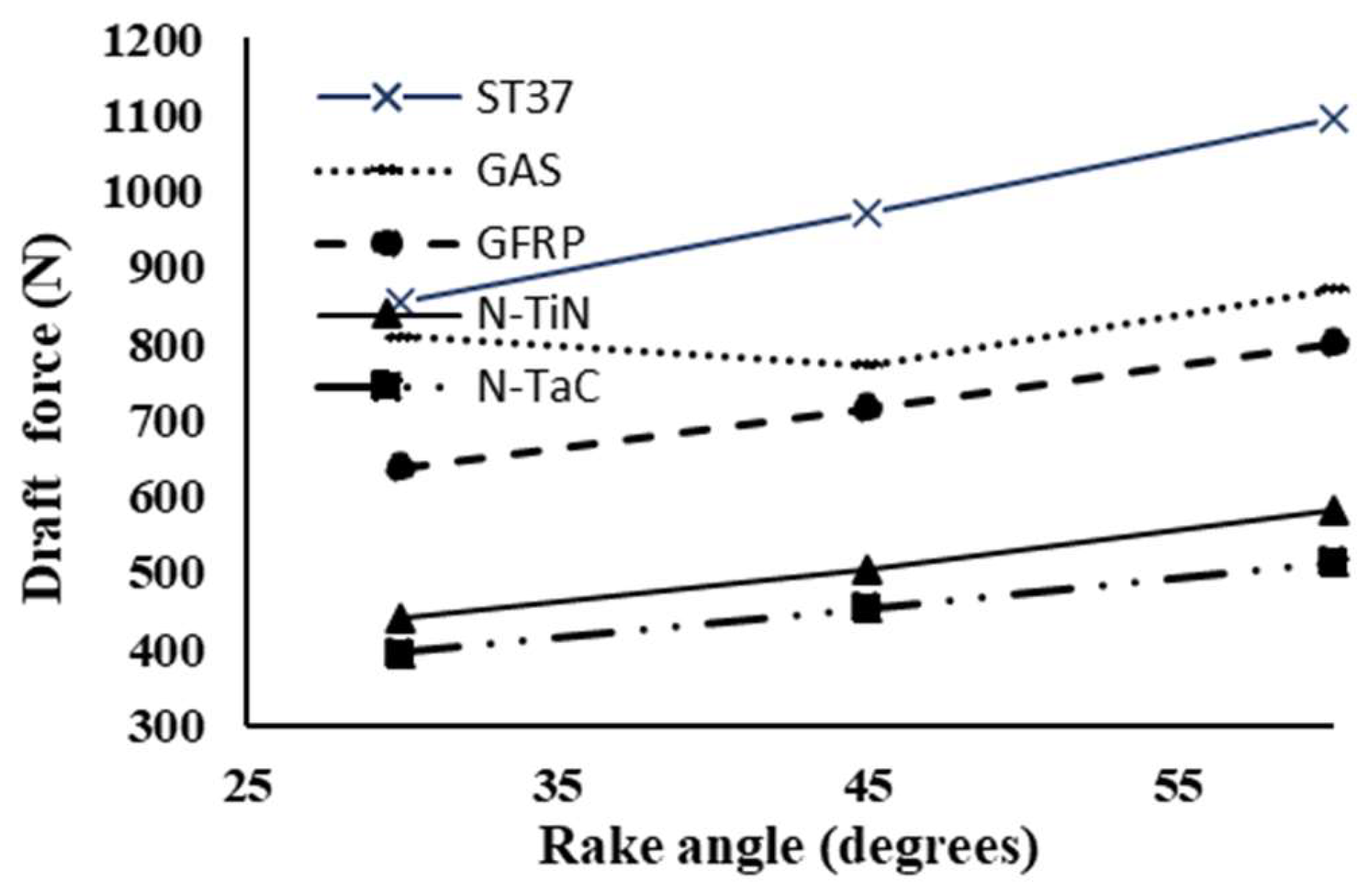

| Plate Material | Regression Equation | Coefficient of Determination |

|---|---|---|

| ST37 | y = 12.7x + 519.33 | 0.9941 |

| GAS | y = 8.95x + 790.67 | 0.8936 |

| GFRP | y = 10x + 511.67 | 0.8698 |

| N-TiN | y = 7.7x + 365.33 | 0.9973 |

| N_TaC | y = 6.7x + 320.33 | 0.9166 |

| Plate Material | Regression Equation | Coefficient of Determination |

|---|---|---|

| ST37 | y = 1425x + 684.67 | 0.9819 |

| GAS | y = 1195x + 522 | 0.9999 |

| GFRP | y = 980x + 521.67 | 0.9977 |

| N-TiN | y = 755x + 358.33 | 0.9958 |

| N_TaC | y = 645x + 325.33 | 0.9895 |

| Plate Material | Regression Equation | Coefficient of Determination |

|---|---|---|

| ST37 | y = 1425x + 684.67 | 0.9819 |

| GAS | y = 1195x + 522 | 0.9999 |

| GFRP | y = 980x + 521.67 | 0.9958 |

| N-TiN | y = 755x + 358.33 | 0.9958 |

| N_TaC | y = 645x + 325.33 | 0.9895 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marani, S.M.; Shahgholi, G.; Szymanek, M.; Tanaś, W. Experimental Evaluation of Nano Coating on the Draft Force of Tillage Implements and Its Prediction Using an Adaptive Neuro-Fuzzy Inference System (ANFIS). AgriEngineering 2024, 6, 1218-1234. https://doi.org/10.3390/agriengineering6020069

Marani SM, Shahgholi G, Szymanek M, Tanaś W. Experimental Evaluation of Nano Coating on the Draft Force of Tillage Implements and Its Prediction Using an Adaptive Neuro-Fuzzy Inference System (ANFIS). AgriEngineering. 2024; 6(2):1218-1234. https://doi.org/10.3390/agriengineering6020069

Chicago/Turabian StyleMarani, Saeed Mehrang, Gholamhossein Shahgholi, Mariusz Szymanek, and Wojciech Tanaś. 2024. "Experimental Evaluation of Nano Coating on the Draft Force of Tillage Implements and Its Prediction Using an Adaptive Neuro-Fuzzy Inference System (ANFIS)" AgriEngineering 6, no. 2: 1218-1234. https://doi.org/10.3390/agriengineering6020069

APA StyleMarani, S. M., Shahgholi, G., Szymanek, M., & Tanaś, W. (2024). Experimental Evaluation of Nano Coating on the Draft Force of Tillage Implements and Its Prediction Using an Adaptive Neuro-Fuzzy Inference System (ANFIS). AgriEngineering, 6(2), 1218-1234. https://doi.org/10.3390/agriengineering6020069