An Effective and Affordable Internet of Things (IoT) Scale System to Measure Crop Water Use

Abstract

1. Introduction

2. Materials and Methods

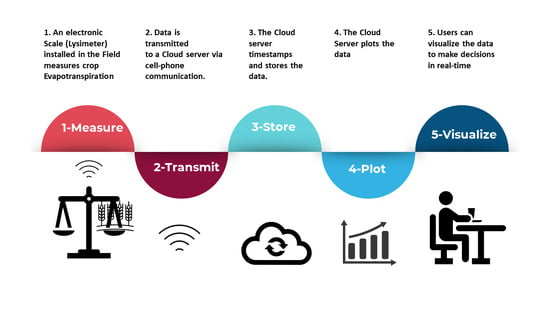

2.1. Design Requirements and General Functionality of the IoT Scale System

2.2. Electronic Components

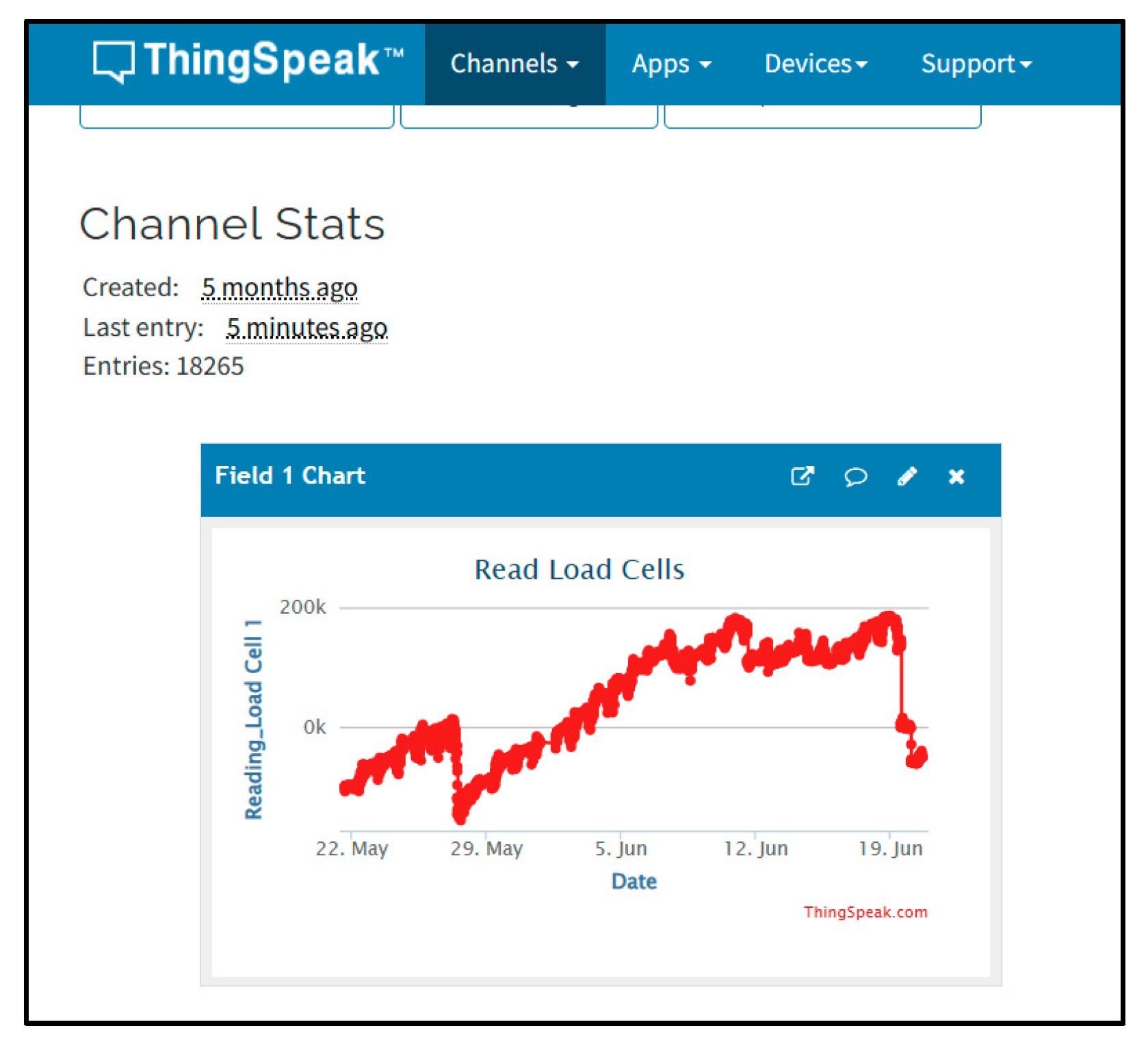

2.3. Internet of Things (IoT) System

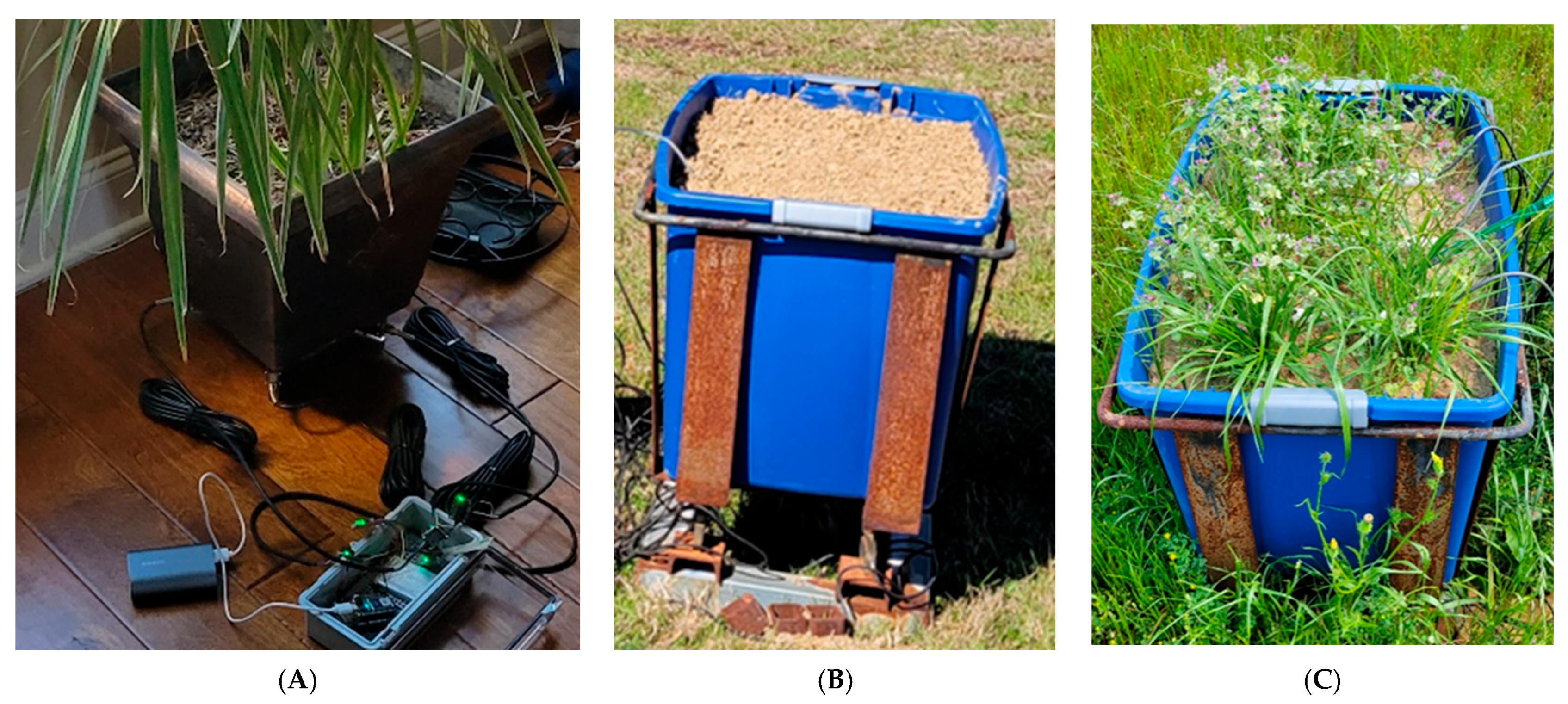

2.4. Indoor and Outdoor Experiments

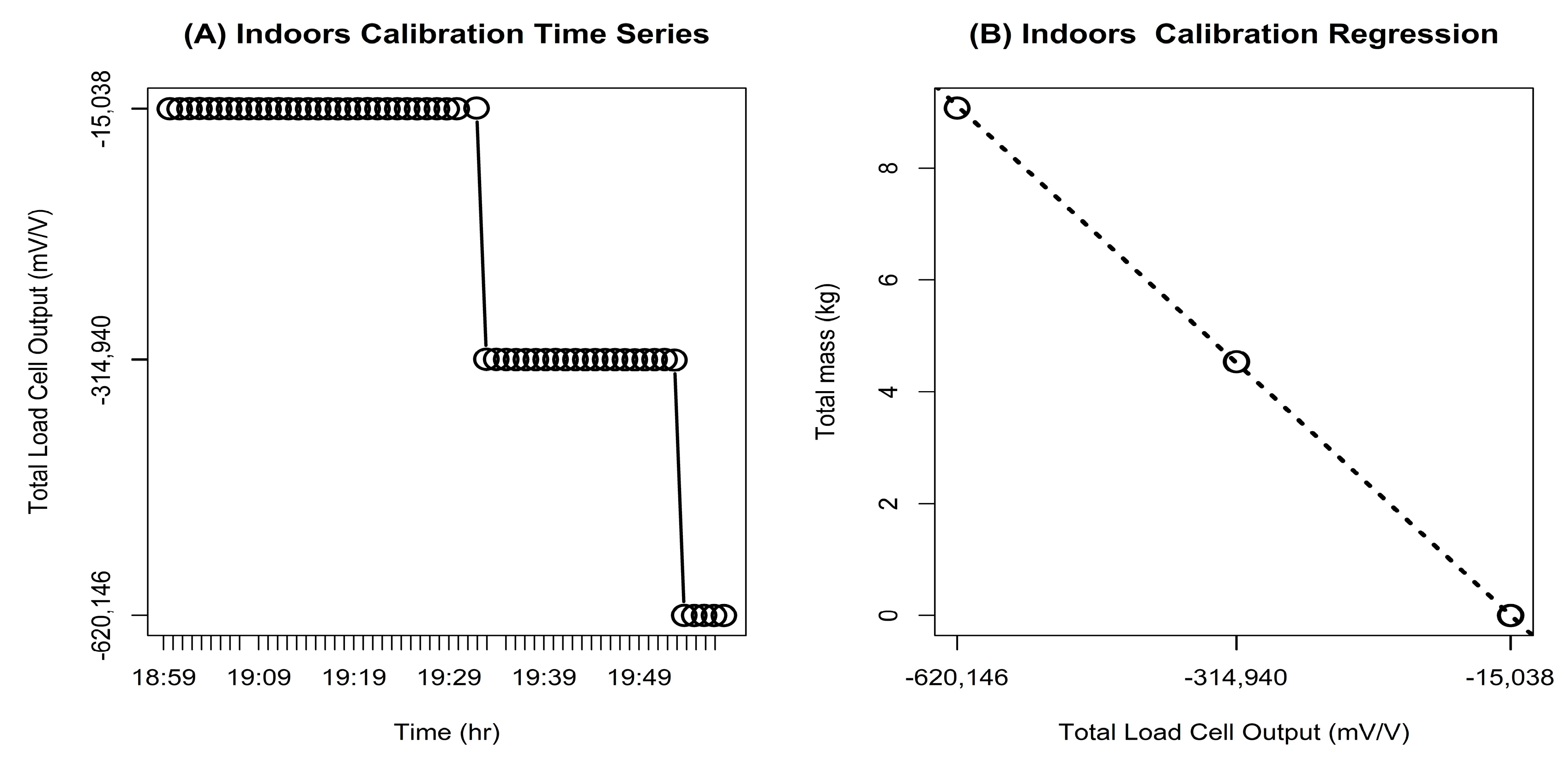

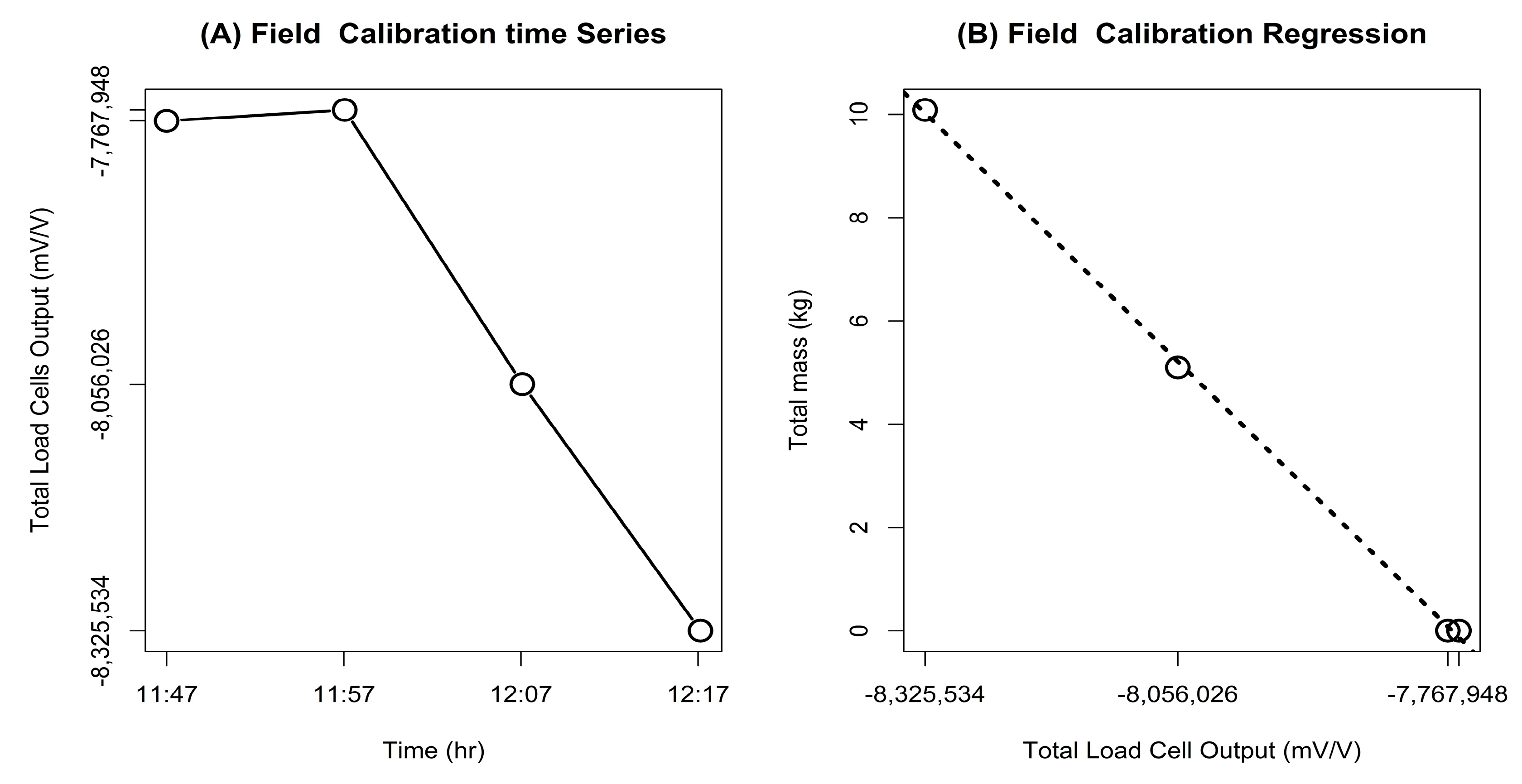

2.5. System Calibration

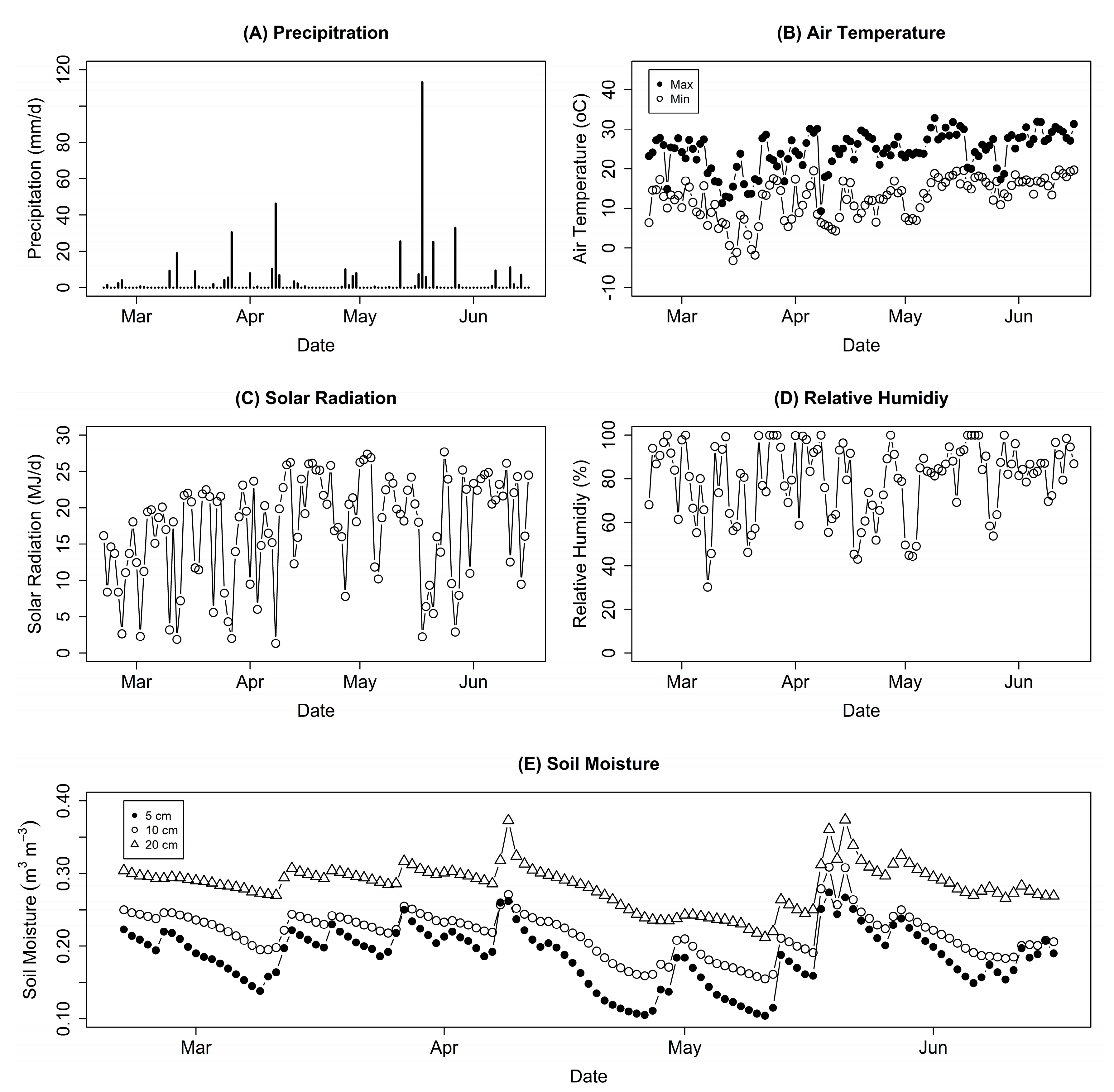

2.6. Weather and Soil Moisture Data

3. Results and Discussion

3.1. Calibration Results

3.2. Weather and Soil Moisture

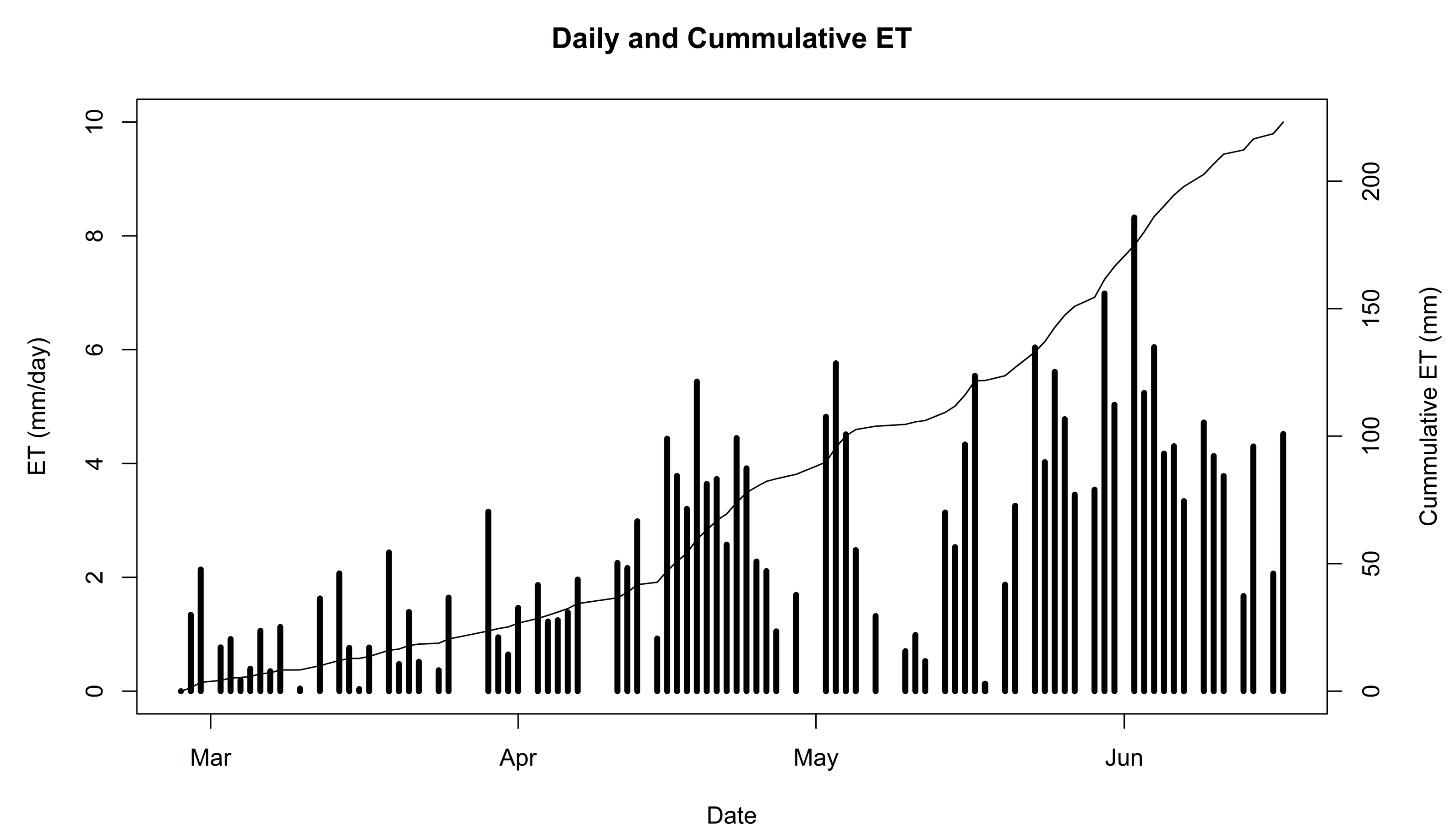

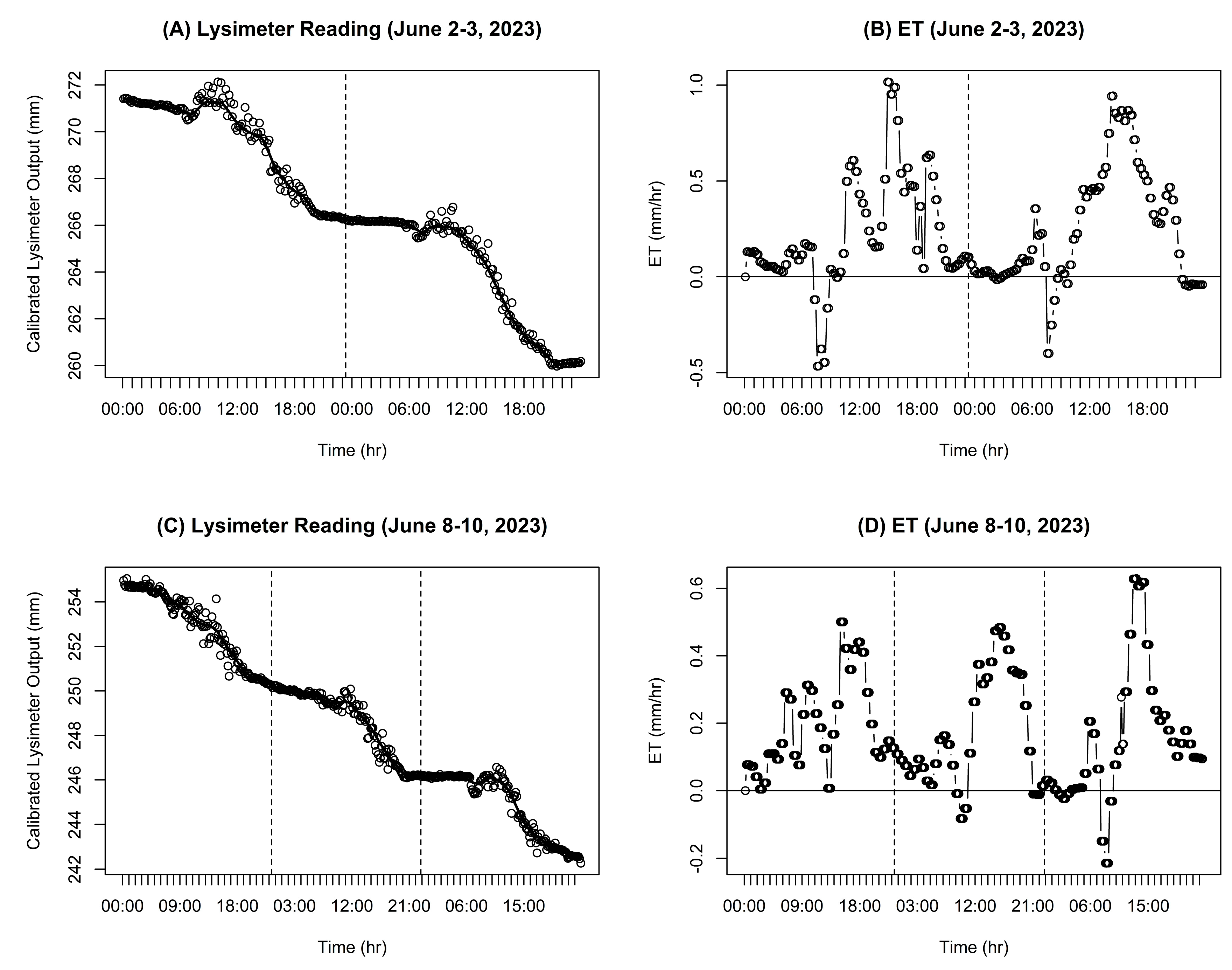

3.3. Results of the Outdoor Experiment

3.4. Cost of the IoT Scale System

3.5. Advantages and Disadvantages of the IoT Scale System

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Allen, R.G.; Jensen, M.E.; Wright, J.L.; Burman, R.D. Operational estimates of reference evapotranspiration. Agron. J. 1989, 81, 650–662. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration—Guidelines for Computing Crop Water Requirements—FAO Irrigation and Drainage Paper 56; FAO: Rome, Italy, 1998; Volume 300, p. D05109. [Google Scholar]

- Castellvi, F.; Snyder, R.L.; Baldocchi, D.D. Surface energy-balance closure over rangeland grass using the eddy covariance method and surface renewal analysis. Agric. For. Meteorol. 2008, 148, 1147–1160. [Google Scholar] [CrossRef]

- Holmes, J.W. Measuring evapotranspiration by hydrological methods. Agric. Water Manag. 1984, 8, 29–40. [Google Scholar] [CrossRef]

- Kizer, M.A.; Elliot, R.L. Eddy correlation systems for measuring evapotranspiration. Trans. ASAE 1991, 34, 387–392. [Google Scholar] [CrossRef]

- Payero, J.O.; Neale, C.M.U.; Wright, J.L.; Allen, R.G. Guidelines for validating Bowen ratio data. Trans. ASAE 2003, 46, 1051–1060. [Google Scholar] [CrossRef]

- Paw, U.K.T.; Qiu, J.; Su, H.; Watanabe, T.; Brunet, Y. Surface renewal analysis: A new method to obtain scalar fluxes. Agric. For. Meteorol. 1995, 74, 119–137. [Google Scholar]

- Todd, R.W.; Evett, S.R.; Howell, T.A. The Bowen ratio-energy balance method for estimating latent heat flux of irrigated alfalfa evaluated in a semi-arid, advective environment. Agric. For. Meteorol. 2000, 103, 335–348. [Google Scholar] [CrossRef]

- Niu, H.; Hollenbeck, D.; Zhao, T.; Wang, D.; Chen, Y. Evapotranspiration estimation with small UAVs in precision agriculture. Sensors 2020, 22, 6427. [Google Scholar] [CrossRef] [PubMed]

- Moorhead, J.; Marek, G.; Gowda, P.; Lin, X.; Colaizzi, P.; Evett, S.; Kutikoff, S. Evaluation of evapotranspiration from eddy covariance using large weighing lysimeters. Agronomy 2019, 2, 99. [Google Scholar] [CrossRef]

- Riedl, A.; Li, Y.; Eugster, J.; Buchmann, N.; Eugster, W. Technical note: High-accuracy weighing micro-lysimeter system for long-term measurements of non-rainfall water inputs to grasslands. Hydrol. Earth Syst. Sci. 2022, 26, 91–116. [Google Scholar] [CrossRef]

- Pruitt, W.O.; Angus, D.E. Large weighing lysimeter for measuring evapotranspiration. Trans. ASAE 1960, 3, 13–18. [Google Scholar]

- McFarland, M.J.; Worthington, J.W.; Newman, J.S. Design, installation, and operation of a twin weighing lysimeter for fruit trees. Trans. ASAE 1983, 26, 1717–1721. [Google Scholar] [CrossRef]

- Howell, T.A.; McCormick, R.L.; Phene, C.J. Design and installation of large weighing lysimeters. Trans. ASAE 1985, 28, 106–112. [Google Scholar] [CrossRef]

- Allen, R.G.; Fisher, D.K. Low-cost electronic weighing lysimeters. Trans. ASAE 1990, 33, 1823–1832. [Google Scholar] [CrossRef]

- Schneider, A.D.; Howell, T.A.; Moustafa, A.T.A.; Evett, S.R.; Abou-Zeid, W. A simplified weighing lysimeter for monolithic or reconstructed soils. Appl. Eng. Agric. 1998, 14, 267–274. [Google Scholar] [CrossRef]

- Payero, J.O.; Irmak, S. Construction, installation, and performance of two repacked weighing lysimeters. Irrig. Sci. 2008, 26, 191–202. [Google Scholar] [CrossRef]

- Evett, S.R.; Mazahrih, N.T.; Jitan, M.A.; Sawalha, M.H.; Colaizzi, P.D.; Ayars, J.E. A weighing lysimeter for crop water use determination in the Jordan Valley, Jordan. Trans. ASABE 2009, 52, 155–169. [Google Scholar] [CrossRef]

- Fisher, D.K. Simple weighing lysimeters for measuring evapotranspiration and developing crop coefficients. Int. J. Agric. Biol. Eng. 2012, 5, 35–43. [Google Scholar]

- Mariano, D.D.C.; Faria, R.T.D.; Freitas, P.S.L.D.; Lena, B.P.; Johann, A.L. Construction and calibration of a bar weighing lysimeter. Acta Sci. Agron. 2015, 37, 271–278. [Google Scholar] [CrossRef][Green Version]

- Fenner, W.; Dallacort, R.; Junior, C.; Freitas, P.; Queiroz, T.; Santi, A. Development, calibration and validation of weighing lysimeters for measurement of evapotranspiration of crops. Rev. Bras. Eng. Agrícola Ambient. 2019, 4, 297–302. [Google Scholar] [CrossRef]

- Nicolás-Cuevas, J.; Parras-Burgos, D.; Soler-Méndez, M.; Ruiz-Canales, A.; Martínez, J. Removable weighing lysimeter for use in horticultural crops. Appl. Sci. 2020, 14, 4865. [Google Scholar] [CrossRef]

- Clark, J.; Tape, K.; Young-Robertson, J. Quantifying evapotranspiration from dominant arctic vegetation types using lysimeters. Ecohydrology 2022, 16, e2484. [Google Scholar] [CrossRef]

- Karam, F.; Mounzer, O.; Sarkis, F.; Lahoud, R.; Amara, T.; Karam, F. Yield and nitrogen recovery of lettuce under different irrigation regimes. J. Appl. Hortic. 2002, 2, 70–76. [Google Scholar] [CrossRef]

- Wright, J.L. New evapotranspiration crop coefficients. J. Irrig. Drain. Div. ASCE 1982, 108, 57–74. [Google Scholar] [CrossRef]

- Oke, A.; Omotosho, O.; Ogedengbe, K. Determination of crop coefficient and water use of SUWAN-1-SR with a mini lysimeter in Ibadan, Nigeria. FUOYE J. Eng. Technol. 2019, 4, 116–121. [Google Scholar] [CrossRef]

- de Melo, D.A.; Silva, P.C.; da Costa, A.R.; Delmond, J.G.; Ferreira, A.F.A.; de Souza, J.A.; de Oliveira-Júnior, J.F.; da Silva, J.L.B.; da Rosa Ferraz Jardim, A.M.; Giongo, P.R.; et al. Development and Automation of a Photovoltaic-Powered Soil Moisture Sensor for Water Management. Hydrology 2023, 10, 166. [Google Scholar] [CrossRef]

- dos Santos Freitas, M.J.; Moraes, A.; Cardoso Marques, J.; Rodrigues, F. A contribution to real-time space weather monitoring based on scintillation observations and IoT. Adv. Space Res. 2022, 70, 456–469. [Google Scholar] [CrossRef]

- Oliveira, G.; Almeida, C.; Santos, J.; Martins, J.; Caeiro, J. IoT Lysimeter system with enhanced data security. In Proceedings of the APCA International Conference on Automatic Control and Soft Computing, CONTROLO 2022, Caparica, Portugal, 6–8 July 2022; pp. 119–129. [Google Scholar] [CrossRef]

- Goyal, P.; Sharda, R.; Siag, M.; Singh, K. Development of an IoT based weighing type micro-lysimeter for soilless cultivation. Indian J. Agric. Sci. 2020, 10, 1980–1987. [Google Scholar] [CrossRef]

- International Telecommunication Union. Overview of the Internet of Things. In Global Information Infrastructure, Internet Protocol Aspects and Next-Generation Networks; ITU-T Y-Series Recommendations (Y.2060); International Telecommunication Union: Geneva, Switzerland, 2013; 22p, Available online: https://www.itu.int/rec/T-REC-Y.2060-201206-I (accessed on 26 February 2024).

- Cariou, C.; Moiroux-Arvis, L.; Pinet, F.; Chanet, J. Internet of Underground Things in Agriculture 4.0: Challenges, Applications and Perspectives. Sensors 2023, 23, 84058. [Google Scholar] [CrossRef]

- Cariou, C.; Moiroux-Arvis, L.; Pinet, F.; Chanet, J. Data collection from buried sensor nodes by means of an unmanned aerial vehicle. Sensors 2022, 22, 5926. [Google Scholar] [CrossRef]

- Bertocco, M.; Parrino, S.; Peruzzi, G.; Pozzebon, A. Estimating volumetric water content in soil for IoUT contexts by exploiting RSSI-based augmented sensors via machine learning. Sensors 2023, 23, 2033. [Google Scholar] [CrossRef] [PubMed]

- Postolache, S.; Sebastião, P.; Viegas, V.; Postolache, O.; Cercas, F. IoT-Based systems for soil nutrients assessment in horticulture. Sensors 2023, 23, 403. [Google Scholar] [CrossRef] [PubMed]

- Jusoh, M.F.; Muttalib, M.F.A.; Krishnan, K.T.; Katimon, A. An overview of the internet of things (IoT) and irrigation approach through bibliometric analysis. IOP Conf. Ser. Earth Environ. Sci. 2021, 756, 012041. [Google Scholar] [CrossRef]

- Rodrigues, L.; Moura, P.; Terra, F.; Carvalho, A.M.; Sarmento, J.; dos Santos, F.N.; Cunha, M. Synergizing crop growth models and digital phenotyping: The design of a cost-effective Internet of Things-based sensing network. Biol. Life Sci. Forum 2023, 27, 41. [Google Scholar] [CrossRef]

- Junior, A.A.; Araújo da Silva, T.J.; Andrade, S.P. Smart IoT lysimetry system by weighing with automatic cloud data storage. Smart Agric. Technol. 2023, 4, 100177. [Google Scholar] [CrossRef]

- Bashir, R.N.; Saeed, M.; Al-Sarem, M.; Marie, R.; Faheem, M.; Karrar, A.E.; Elhussein, B. Smart reference evapotranspiration using Internet of Things and hybrid ensemble machine learning approach. Internet Things 2023, 24, 100962. [Google Scholar] [CrossRef]

- Alahi, E.E.; Mukhopathyay, S.C. An Internet-of-Things enabled smart sensing system for nitrate monitoring. IEEE Internet Things J. 2018, 5, 4409–4417. [Google Scholar] [CrossRef]

- Chandrappa, V.Y.; Ray, B.; Ashwath, N.; Shrestha, P. Application of Internet of Things (IoT) to develop a smart watering system for Cairns parklands—A case study. In Proceedings of the 2020 IEEE Region 10 Symposium (TENSYMP), Dhaka, Bangladesh, 5–7 June 2020. [Google Scholar]

- Payero, J.O.; Mirzakhani Nafchi, A.; Davis, R.; Khalilian, A. An Arduino-based wireless sensor network for soil moisture monitoring using Decagon EC-5 sensors. Open J. Soil Sci. 2017, 7, 288–300. [Google Scholar] [CrossRef]

- Payero, J.O.; Mirzakhani-Nafchi, A.; Khalilian, A.; Qiao, X.; Davis, R. Development of a low-cost Internet-of-Things (IoT) system for monitoring soil water potential using Watermark 200SS sensors. Adv. Internet Things 2017, 7, 71–86. [Google Scholar] [CrossRef]

- Payero, J.O.; Marshall, M.W.; Davis, R.; Nafchi, A.M. Development and application of cell-phone-based Internet of Things (IoT) systems for soil moisture monitoring. Agric. Sci. 2021, 12, 549–564. [Google Scholar] [CrossRef]

- Payero, J.O.; Marshall, M.W.; Nafchi, A.M.; Khalilian, A.; Farmaha, B.S.; Davis, R.; Porter, W.; Vellidis, G. Development of an Internet of Things (IoT) system for measuring agricultural runoff quantity and quality. Agric. Sci. 2021, 12, 584–601. [Google Scholar] [CrossRef]

- Nolz, R.; Kammerer, G.; Cepuder, P. Interpretation of lysimeter weighing data affected by wind. J. Plant Nutr. Soil Sci. 2013, 176, 200–208. [Google Scholar] [CrossRef]

- Kohfahl, C.; Molano-Leno, L.; Martínez, G.; Vanderlinden, K.; Guardiola-Albert, C.; Moreno, L. Determining groundwater recharge and vapor flow in dune sediments using a weighable precision meteo lysimeter. Sci. Total Environ. 2019, 656, 550–557. [Google Scholar] [CrossRef]

| Sensor Properties | Type/Value |

|---|---|

| Sensor Type | Compression/Tension Load Cell |

| Controlled By | Bridge Input |

| Weight Capacity Max | 100 kg |

| Maximum Overload | 120 kg |

| Electrical Properties | |

| Output Impedance | 350 Ω |

| Supply Voltage Min | 5 V DC |

| Supply Voltage Max | 18 V DC |

| Physical Properties | |

| Compensated Temperature Min | −10 °C |

| Compensated Temperature Max | 40 °C |

| Operating Temperature Min | −20 °C |

| Operating Temperature Max | 55 °C |

| Cable Length | 3 m |

| Cable Gauge | 20 AWG |

| Material | Alloy Steel |

| Screw Thread Size | M6 |

| Components | Web Link (accessed on 20 October 2023) |

|---|---|

| Microcontroller | https://docs.particle.io/reference/datasheets/b-series/brn404x-datasheet/ |

| Terminal block | https://www.adafruit.com/product/2926 |

| Multiplexer | https://www.adafruit.com/product/5626 |

| ADC | https://www.adafruit.com/product/4538 |

| Load cells | https://www.phidgets.com/?tier=3&catid=9&pcid=7&prodid=229 |

| Li-Po battery | https://www.adafruit.com/product/328 |

| Solar panel | https://www.amazon.com/gp/product/B099RSLNZ4/ |

| Instrument enclosure | https://www.amazon.com/gp/product/B07YBXSG1J/ |

| STEMMA cable | https://www.adafruit.com/product/4210 |

| STEMMA male header cable | https://www.adafruit.com/product/4209 |

| Components | Quantity | Unit Price (USD) | Total | % Total Cost |

|---|---|---|---|---|

| Microcontroller | 1 | USD 65.31 | USD 65.31 | 19.0% |

| Terminal block | 1 | USD 14.95 | USD 14.95 | 4.4% |

| Multiplexer | 1 | USD 6.95 | USD 6.95 | 2.0% |

| ADC | 4 | USD 5.95 | USD 23.80 | 6.9% |

| Load cells | 4 | USD 45.00 | USD 180.00 | 52.4% |

| Li-Po battery | 1 | USD 14.95 | USD 14.95 | 4.4% |

| Solar panel | 1 | USD 13.99 | USD 13.99 | 4.1% |

| Instrument enclosure | 1 | USD 18.62 | USD 18.62 | 5.4% |

| STEMMA cable | 4 | USD 0.95 | USD 3.80 | 1.1% |

| STEMMA male headers cable | 1 | USD 0.95 | USD 0.95 | 0.3% |

| Total | USD 343.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Payero, J.O. An Effective and Affordable Internet of Things (IoT) Scale System to Measure Crop Water Use. AgriEngineering 2024, 6, 823-840. https://doi.org/10.3390/agriengineering6010047

Payero JO. An Effective and Affordable Internet of Things (IoT) Scale System to Measure Crop Water Use. AgriEngineering. 2024; 6(1):823-840. https://doi.org/10.3390/agriengineering6010047

Chicago/Turabian StylePayero, José O. 2024. "An Effective and Affordable Internet of Things (IoT) Scale System to Measure Crop Water Use" AgriEngineering 6, no. 1: 823-840. https://doi.org/10.3390/agriengineering6010047

APA StylePayero, J. O. (2024). An Effective and Affordable Internet of Things (IoT) Scale System to Measure Crop Water Use. AgriEngineering, 6(1), 823-840. https://doi.org/10.3390/agriengineering6010047