Application of Quality 4.0 (Q4.0) and Industrial Internet of Things (IIoT) in Agricultural Manufacturing Industry

Abstract

1. Introduction

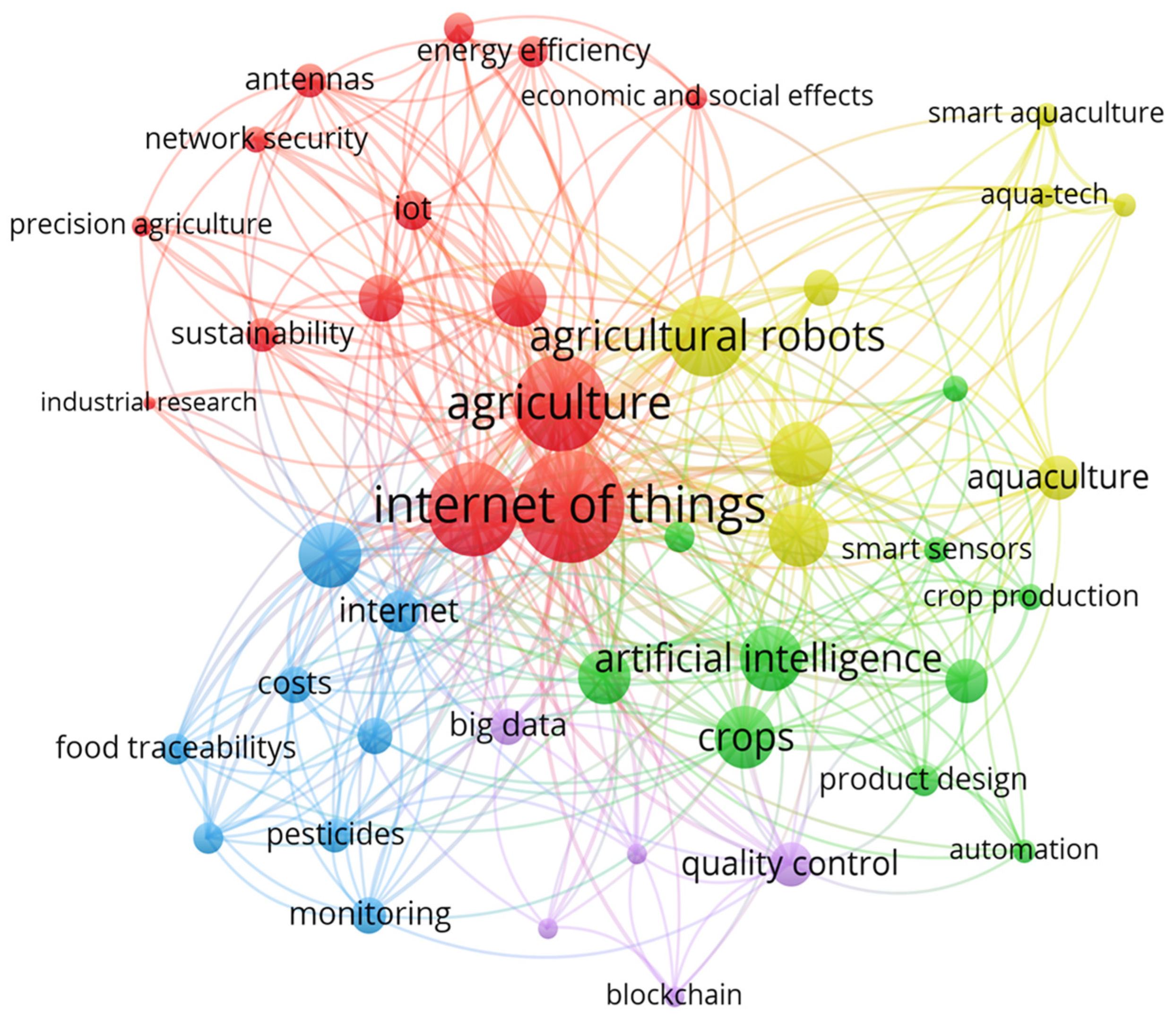

1.1. Research Concept and Background

1.2. Need for the Study

2. Research Methodology

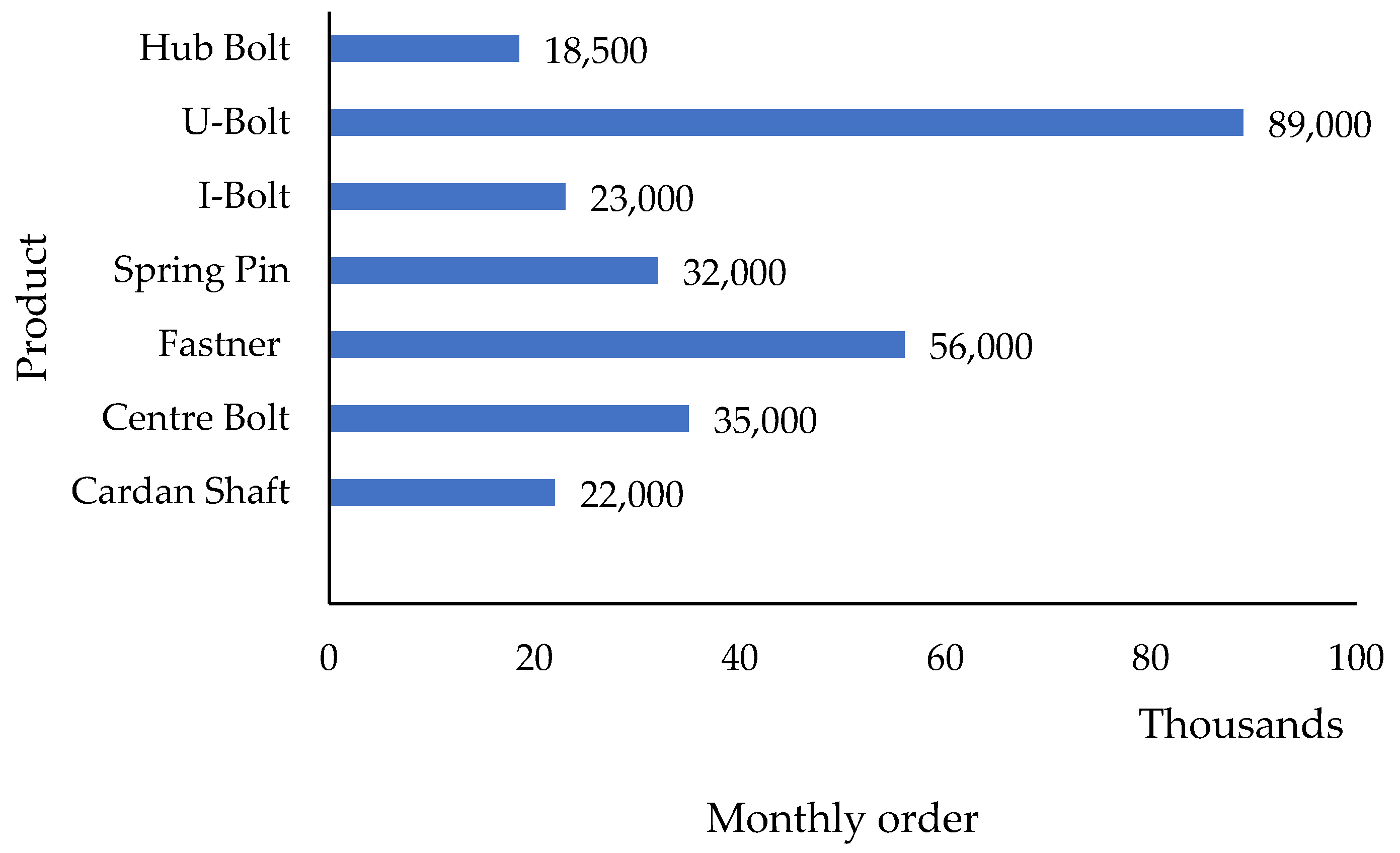

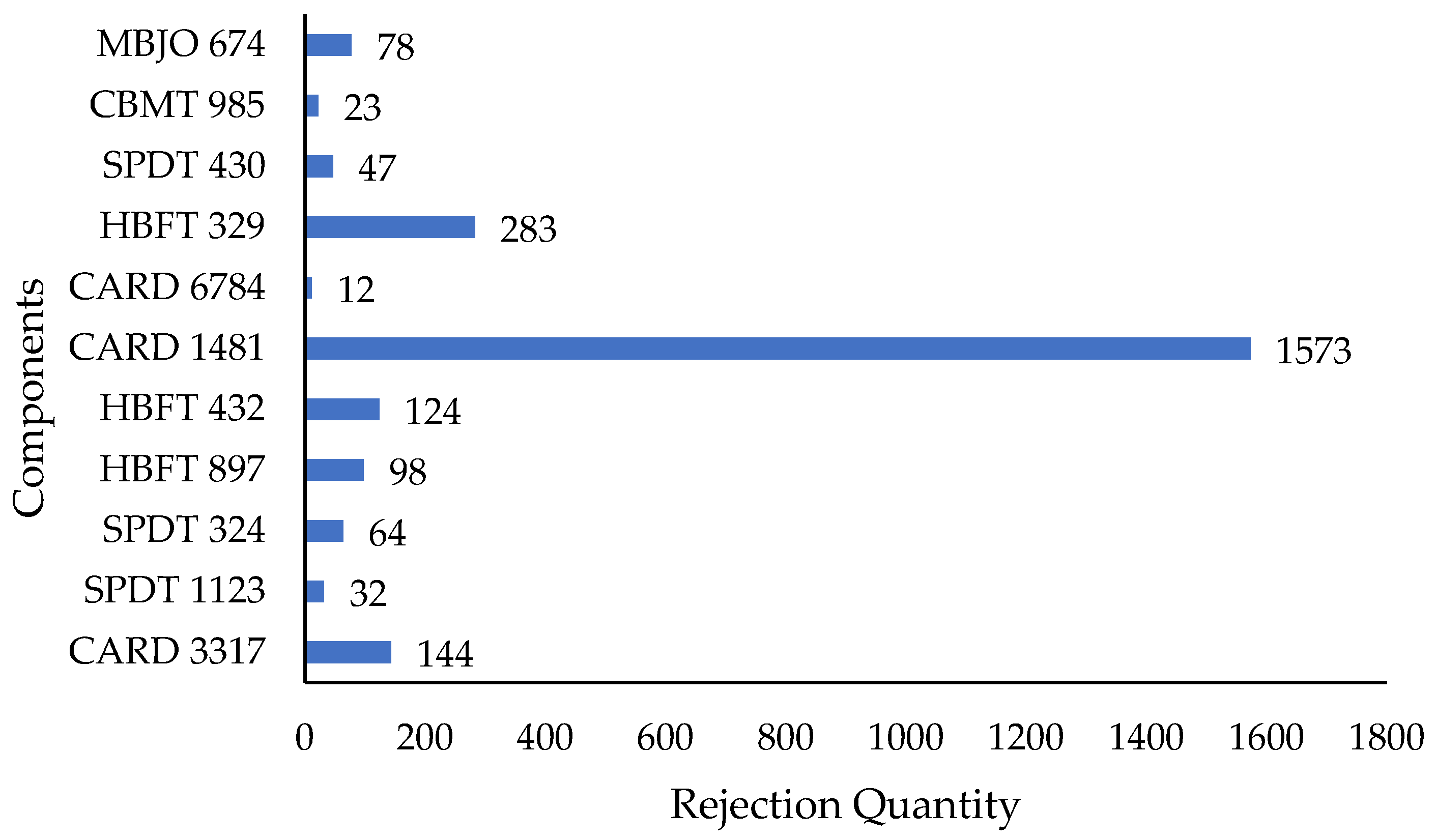

2.1. Selection of Manufacturing Section

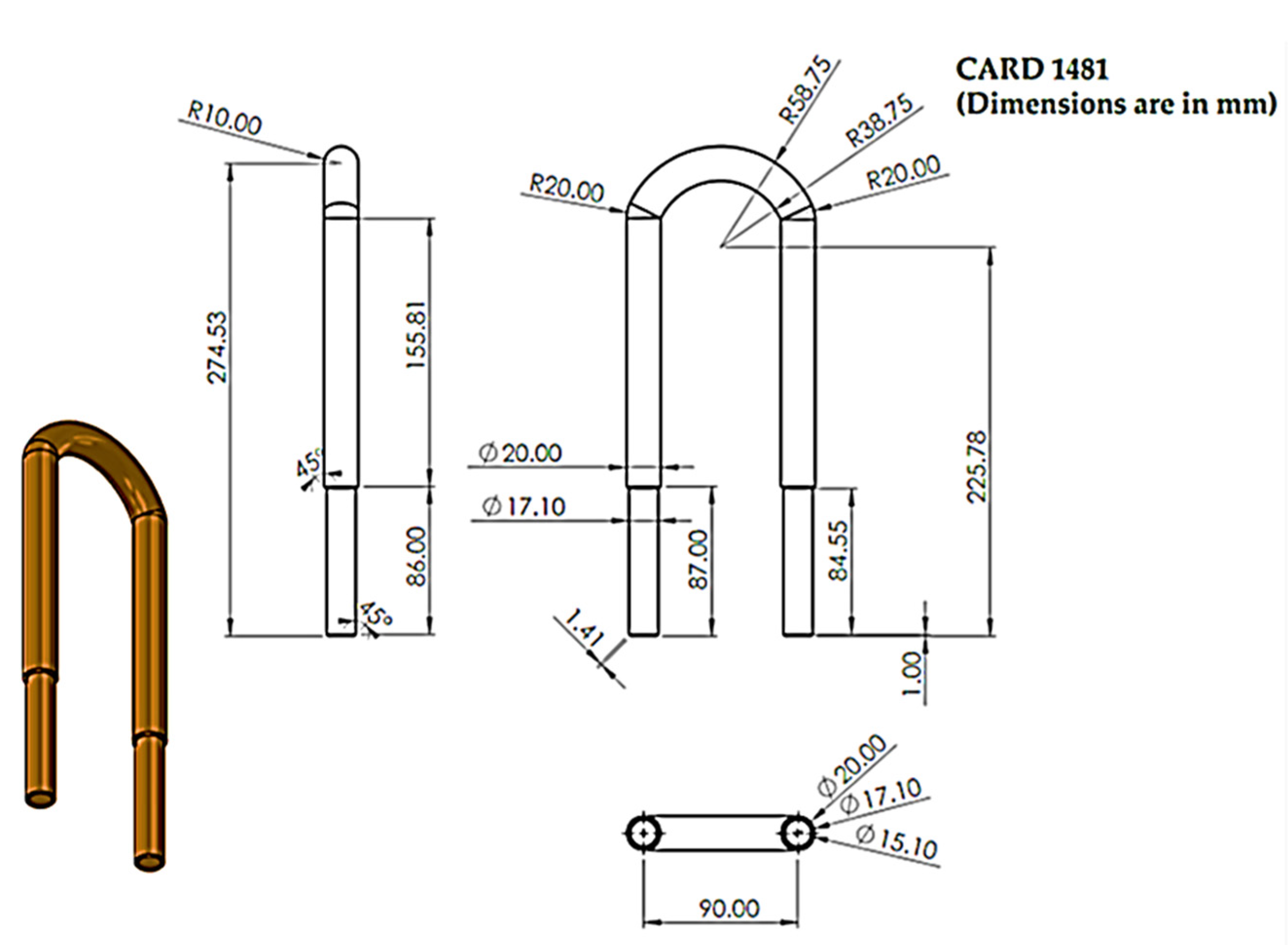

2.2. CARD 1481 Manufacturing Process Analysis

2.3. Process Flow Analysis with Rejection Quantity Response Data

2.4. System Design

2.4.1. Design

2.4.2. Monitoring Module Design

2.4.3. Validation

2.5. Development of ZDM

- Machining Quality Measuring Model-Quality Analysis: The machine product quality is measured with the ZDM LVDT setup installed in each individual machine tool. Six-sigma process capability analysis has been performed, including before and after implementation, for experimental trials of CARD1481 manufacturing. The data were collected in Excel files in a quantitative model to analyse the statistics between the machine tool wear rate values.

- ZDM Device–Autonomous Measuring System: In addition, the presented data would be utilised to design and develop an autonomous measuring system. The measured value of the machined product will be automatically used as input, while the results are generated by the ZDM system. This phase consists of designing and developing an autonomous system to measure, monitor, and control real-time machined data.

- Supervision Design: The ZDM system will be engaged to develop the correction system that triggers the autonomous measurement system. The result of the CARD1481 manufacturing is compared to the desired machined tolerances as per OEM drawings so that the machining error is evaluated. This input value is sent to the ZDM system, which is further used as an input value to a machine tool. This input value is used as a fine amendment to the ZDM system.

- ZDM Validation: The ZDM system was developed using the ESP32 module, and testing has been performed in the CARD1481 manufacturing section. Testing ZDM on a manufacturing shop floor will evaluate the effectiveness of the ZDM module and control the quality of the machined component. Moreover, the RT assessment is an important step before implementing the physical system. A comparison between the machined product quality in current practices and the ZDM module results will be carried out. The process then begins by feeding the desired parameters from the customer’s drawing into the ZDM module as an initial condition. Each machine product is measured automatically, and individually captured measurement readings are fed into the ZDM system. Consequently, the measurement values of the machined product will be analysed, demonstrating the capabilities of the machining process and automatically correcting the tool wear rate.

3. Results and Discussion

3.1. Assessment of Traditional Quality Control System of CARD 1481 Machining

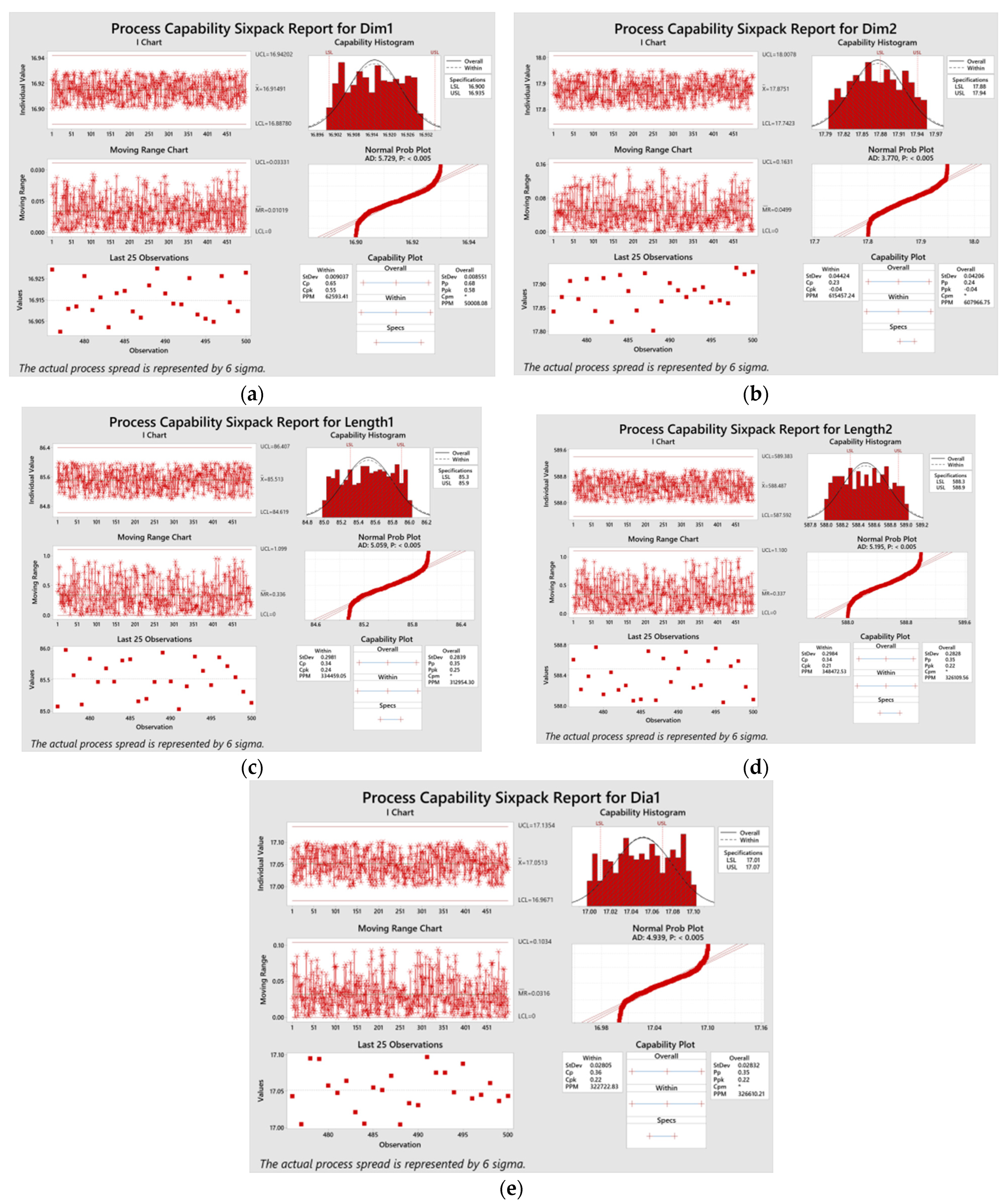

3.1.1. Machining Operation Capability Assessment of CARD 1481 Machining Process

3.1.2. Analysis of the Rejection Response of CARD 1481 Manufacturing Section

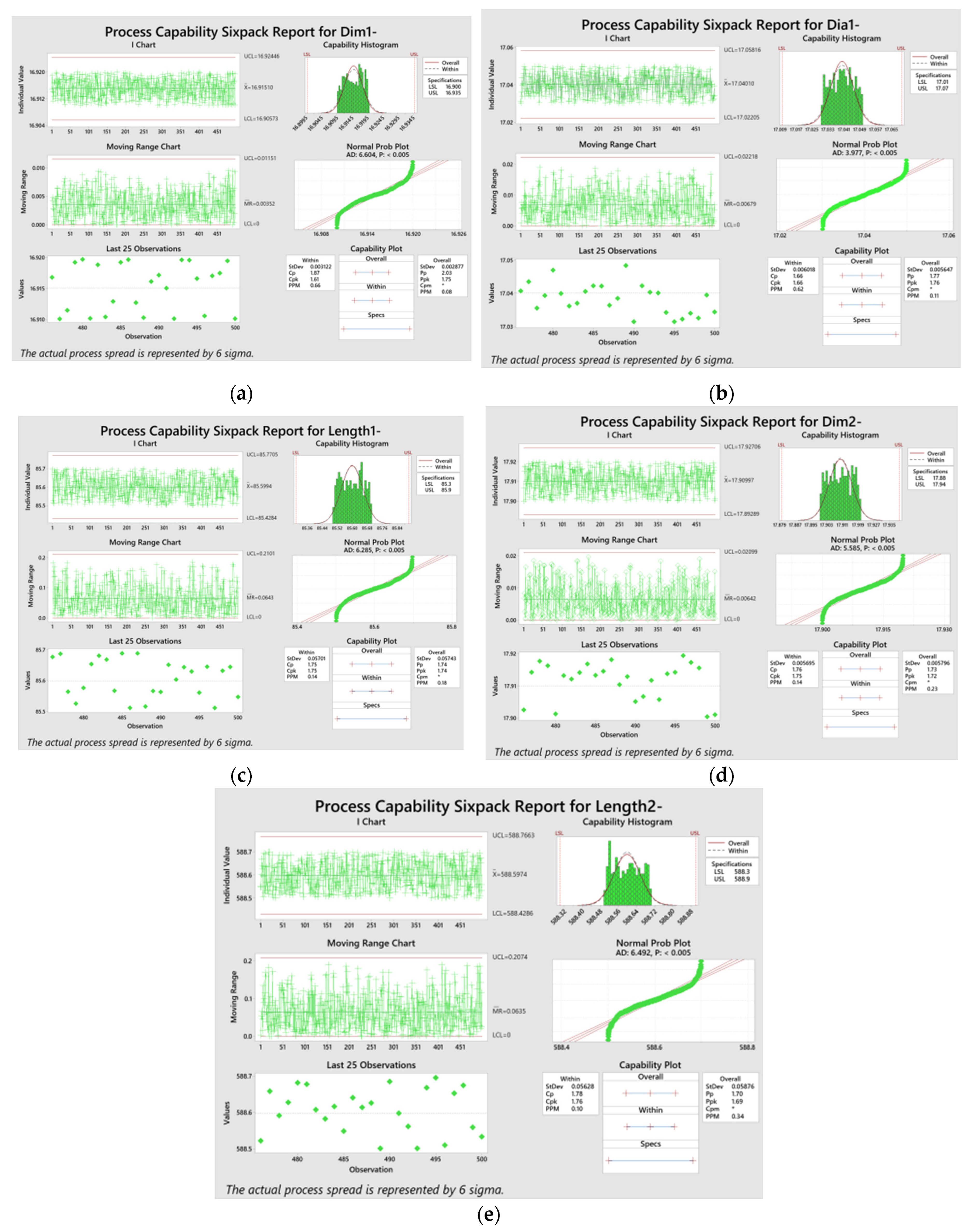

3.2. Machining Process Capability Assessment with ZDM System for CARD1481 Machining Process

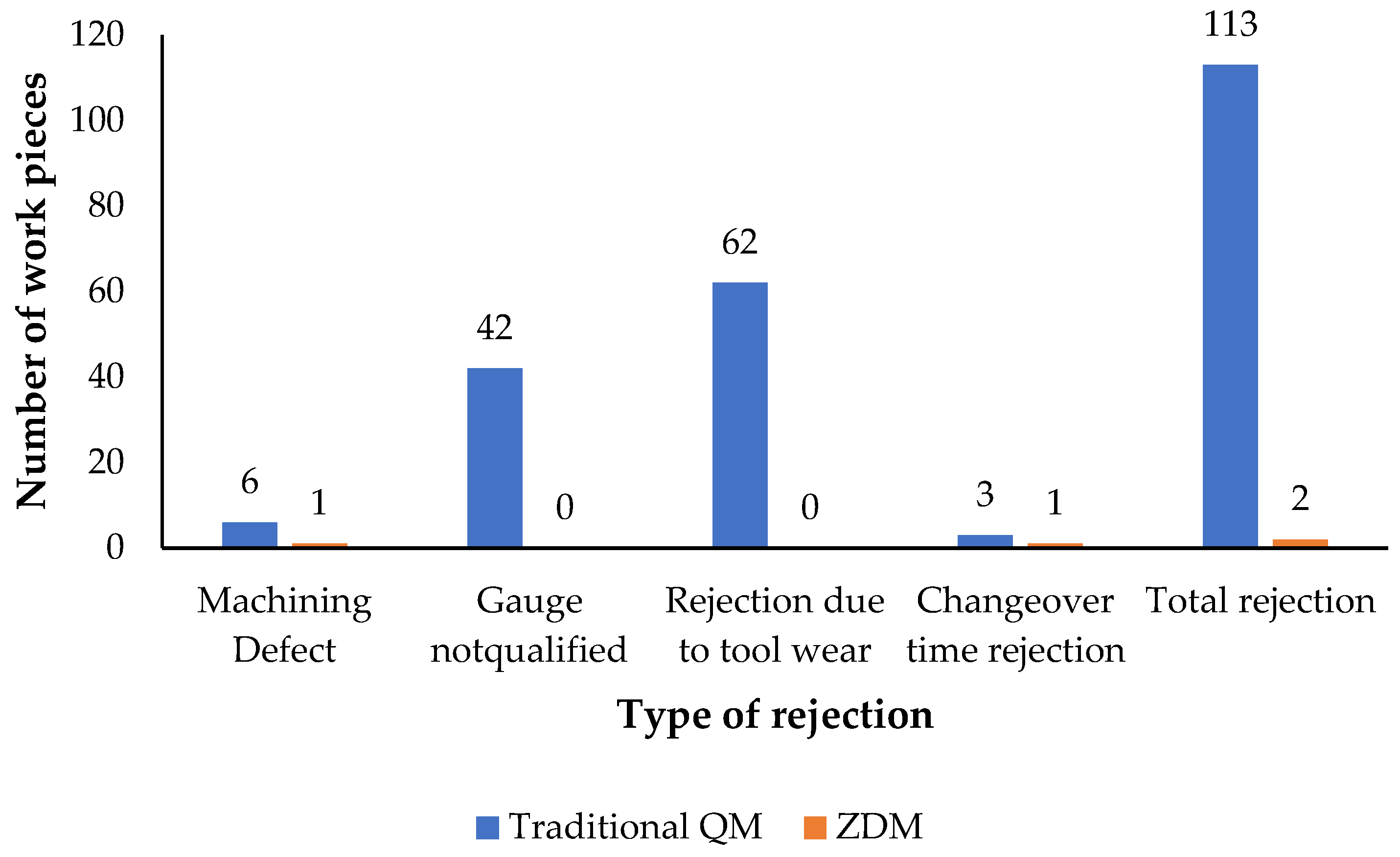

3.3. Traditional QM and ZDM Comparison

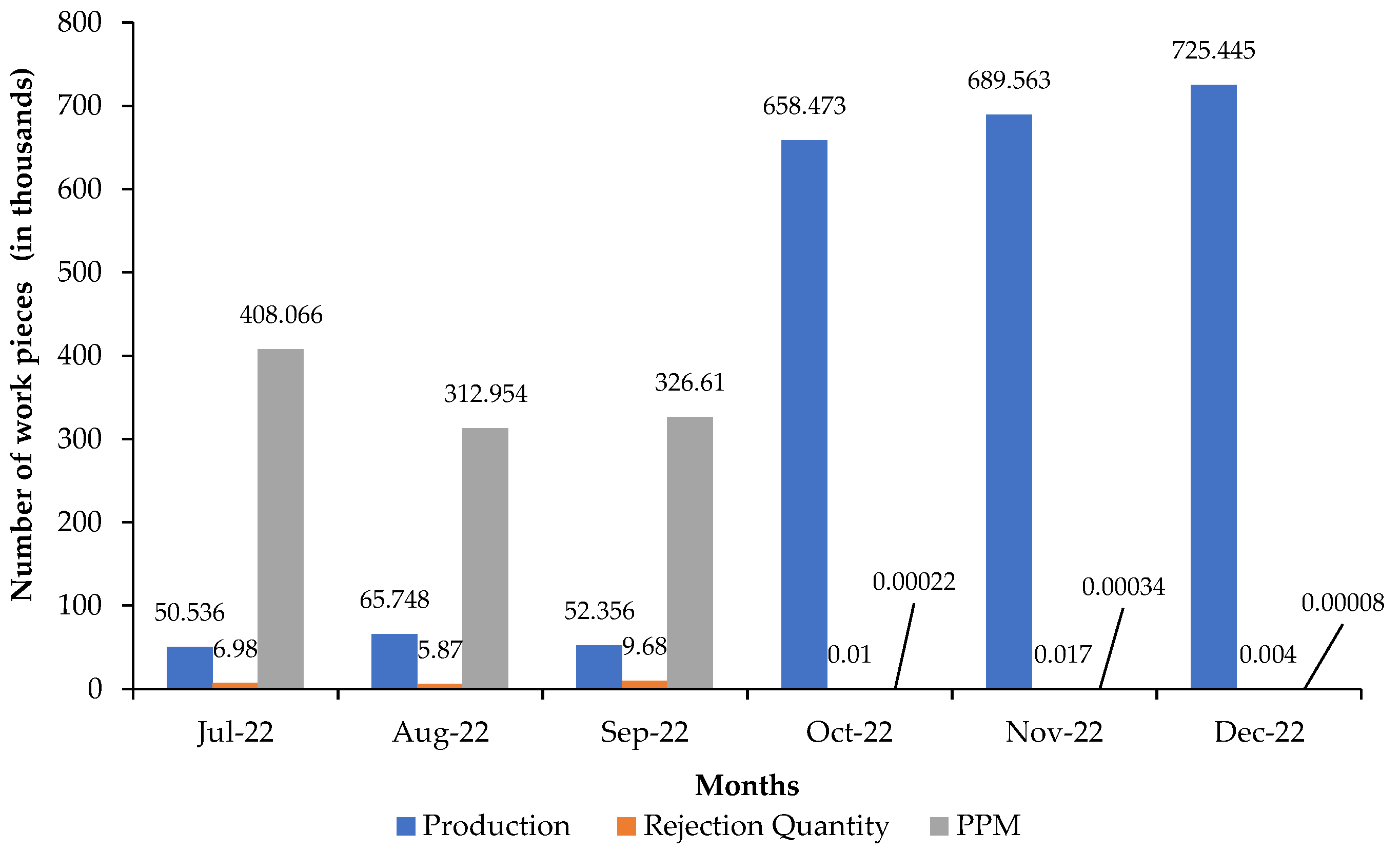

3.4. General PPM Comparison of Traditional QM and ZDM

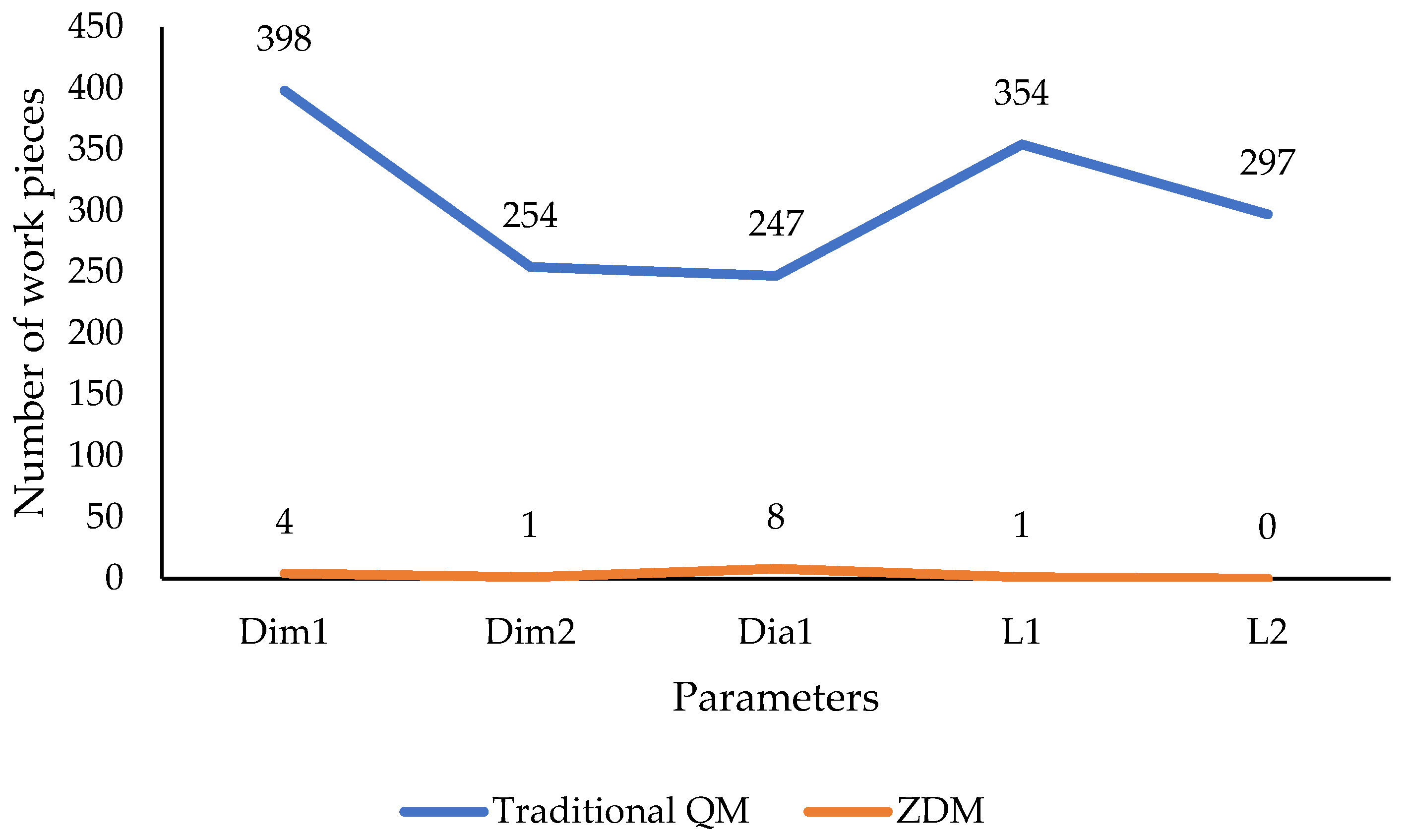

3.5. Response to the Comparison of the Rejection Rate

3.6. Quality Improvement in Machining

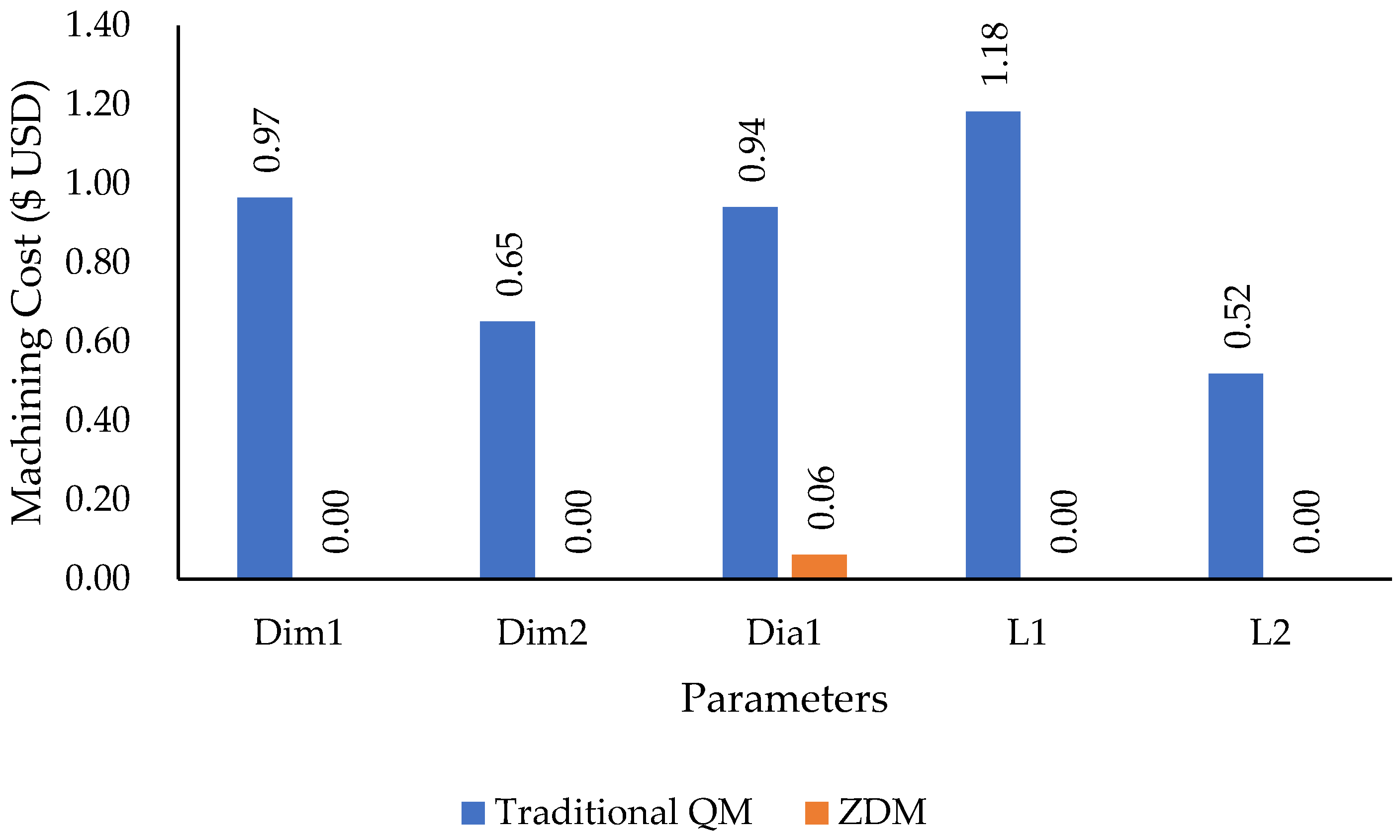

3.7. Machining Cost Analysis

3.8. Machining Process Analysis

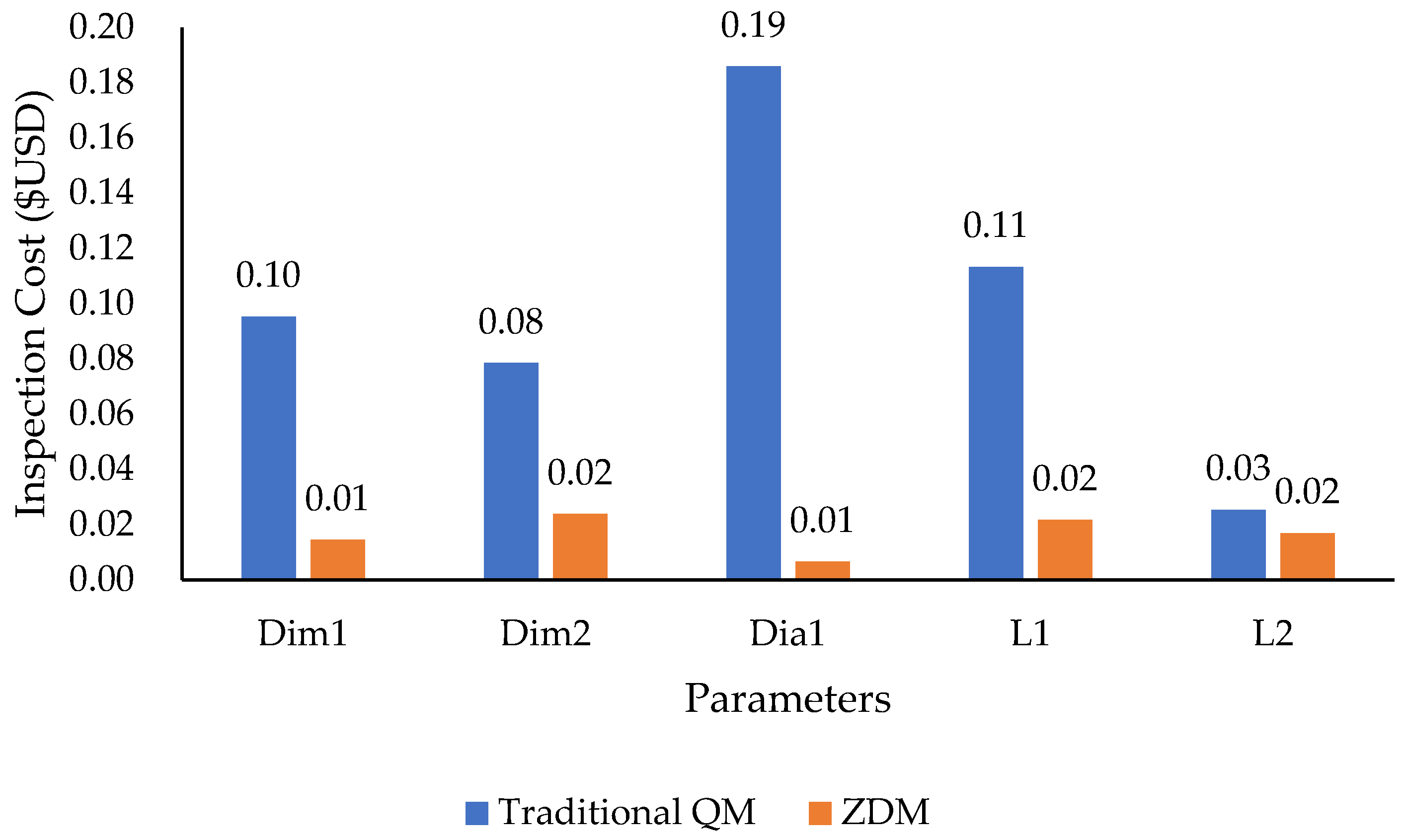

3.9. Cost of Inspection

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| CONTROL PLAN NO: CP-B/120 (CARD1481) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PART FAMILY GROUP: ‘B’ VECV IC 305970-C | CUSTOMER ENGG. APPROVAL (IF REQD) | |||||||||||

| PART NAME/DESCRIPTION: BOLT–11.14 | SUPPLIER PLANT APPROVAL: | CUSTOMER QUALITY APPROVAL/DATE (IF REQD) | ||||||||||

| SUPPLIER: GS Engitech (SUPPLIER CODE: 110249) | OTHER APPROVAL (IF REQD) | OTHER APPROVAL/DATE (IF REQD) | ||||||||||

| CHARACTERISTICS | SPECIAL CHARACT. CLASS | METHOD | CONTROL METHOD/ ERROR PROOFING | RESPONSIBILITY | REACTION PLAN/CORRECTIVE ACTION | |||||||

| PART/ PROCESS NO. | PROCESS NAME/ OPERATION DESCRIPTION | MACHINE DEVICE/ JIGS/ TOOLS FOR MANUFACTURING | NO. | PRODUCT | PROCESS | PRODUCT/ PROCESS SPECIFICATION TOLERANCE | EVALUATION MEASUREMENT TECHNIQUE | SIZE | FREQUENCY | |||

| 120 | MARKING | SPM | 1 | GS LOGO, BATCH NO. | STAMP IMPRESS SHOULD BE CLEARLY VISIBLE | VISUAL | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | |

| 5 PCS | 3 h | PATROL INSPECTION FM/QA/008 | INSPECTOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 100% | EVERY PC | OPERATOR INSPECTION | OPERATOR | RE-SET/NOTIFY THE SEC. I/C. | ||||||||

| 2 | STAMP CONDITION | WORN OUT STAMP NOT TO BE USED | PRODUCT INSPECTION | OPERATOR | REPLACE STAMP | |||||||

| 130 | THREADING | THREAD ROLLING MACHINE | 1 | THREAD SIZE | M18 × 1.5P | THREAD RING GAUGE ‘GO & NO T GO’ | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | |

| 2PCS | 3 h | PATROL INSPECTION FM/QA/008 | INSPECTOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 2 PCS | 2/200 PCS | OPERATOR INSPECTION | OPERATOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 2 | MAJOR DIA | 17.95/17.80 | MICROMETER/SNAP GAUGE | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | ||||

| 2PCS | 3 h | PATROL INSPECTION FM/QA/008 | INSPECTOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 2 PCS | 2/200 PCS | OPERATOR INSPECTION | OPERATOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 3 | THREAD LENGTH | 75.00 + 3 | V.C./LENGTH GAUGE | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | ||||

| 2PCS | 3 h | PATROL INSPECTION FM/QA/008 | INSPECTOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 2 PCS | 2/200 PCS | OPERATOR INSPECTION | OPERATOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 4 | RADIUS | RI | PROFILE PROJECTOR | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | ||||

| 5 | ROLLER PRESSURE | 80 BARS | PRESSURE GAUGE | SEC I/C | ADJUST THE TIME & PRESSURE | |||||||

| 6 | ROLLER CONIDITION | WORN OUT ROLLER NOT TO BE USED | PRODUCT INSPECTION | OPERATOR | REPLACE THE ROLLER | |||||||

| 7 | RPM | 35 | TECHOMETER | AT RANDOM | SHOP I/C | - | ||||||

| 140 | HEATING & BENDING (HOT) | ELECTRICAL HEATER & SPM | 1 | HOT ZONE | RED HOT (SPECIFIED ZONE) | VISUAL | EVERY PC | OPERATOR | ADJUST THE HEATING TIME | |||

| 2 | STEM LENGTH | 252.00 ± 1.50 | V.C./SCALE/ TRY SEQUARE | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | ||||

| 5 PCS | 3 h | PATROL INSPECTION FM/QA/008 | INSPECTOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 1 PC | 1/50TH PC | OPERATOR INSPECTION | OPERATOR | - | ||||||||

| 3 | DIM. | (270) | V.C./SCALE/ TRY SEQUARE | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | ||||

| 4 | C.D. | 90.00± 0.50 | SPG/V.C. | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | ||||

| 5 PCS | 3 h | PATROL INSPECTION FM/QA/008 | INSPECTOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 1 PC | 1/50TH PC | OPERATOR INSPECTION | OPERATOR | - | ||||||||

| 5 | RADIUS | R10 | TEMPLATE/ RADIUS GAUGE | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | ||||

| 5 PCS | 3 h | PATROL INSPECTION FM/QA/008 | INSPECTOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 1 PC | 1/50TH PC | OPERATOR INSPECTION | OPERATOR | - | ||||||||

| 6 | RADIUS | R97.5 | TEMPLATE | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | ||||

| 5 PCS | 3 h | PATROL INSPECTION FM/QA/008 | INSPECTOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 1 PC | 1/50TH PC | OPERATOR INSPECTION | OPERATOR | - | ||||||||

| 7 | HEATING TIME | 15–25SEC | TIMER | EVERY PC | TIMER | OPERATOR | RE SET | |||||

| 8 | CURRENT SUPPLY | 60–100 AMP | AM-METER | EVERY PC | AM-METER | OPERATOR | RE-CALIBRATE AM-METER | |||||

| 150 | MARKING | SPM | 1 | PART NO., HEAT CODE | IC 305970 -C, RUNNING HEAT CODE | STAMP IMPRESS SHOULD BE CLEARLY VISIBLE | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | |

| 5 PCS | 3 h | PATROL INSPECTION FM/QA/008 | INSPECTOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||||||

| 100% | EVERY PC | OPERATOR INSPECTION | OPERATOR | RE-SET/NOTIFY THE SEC. I/C. | ||||||||

| 2 | STAMP CONDITION | WORN OUT STAMP NOT TO BE USED | PRODUCT INSPECTION | OPERATOR | REPLACE STAMP | |||||||

| 160 | HARDENING | GCF | 1 | SOAKING TIME | 1.5 H | TIMER/CLOCK | EACH LOT | TIMER/ BUZZER | OPERATOR | RE-SET | ||

| 2 | SOAKING TEMP. | 860 °C ± 10° | TEMPERATURE CONTROLLER | EACH LOT | TEMPERATURE CONTROLLER | “ | RE-CALIBERATE THE EQUIPMENTS | |||||

| 3 | QUENCHING OIL TEMP. | 30°–80 °C | TEMPERATURE INDICATOR | EACH LOT | HAET EXCHANGER | HTM I/C/ OPERATOR | RE-ADJUST | |||||

| 4 | HARDNESS | 45 HRC. MIN | HARDNESS TESTER | 4 PCS | EVERY LOT | WORK INSTRUCTION/ PROCESS QUALIFICATION, FM/QA/078 | INSPECTOR | - | ||||

| 170 | TEMPERING | ELECTRIC TEMPERING FURNACE | 1 | SOAKING TEMP. | 530 °C ± 10° | TEMPERATURE CONTROLLER | EVERY LOT | OPERATOR | RE-ADJUST TEMP. CONTROLLER | |||

| 2 | SOAKING TIME | 2.50 H | BUZZER/ TMER | “ | BUZZER/ TIMER | OPERATOR | RE-SET | |||||

| 3 | HARDNESS | 304–361 BHN | HARDNESS TESTER | 4 PCS | EVERY LOT | STAGE INSPECTION, PROCESS QUALIFICATION, FM/QA/078 | INSPECTOR | NOTIFY THE SEC. I/C./SEGREGATE | ||||

| 4 | MICRO- STRUCTURE | TEMPERED MARTENSITE | MICROSCOPE | 1 PC | AS PER WI/QA/506 | FM/QA/004 | SEC. I/C. LAB. I/C. | - | ||||

| 5 | THREAD DE CARB | 0.10 PARTIAL | MICROSCOPE | 1PC/ LOT | FM/QA/004 | SEC. I/C. LAB. I/C. | - | |||||

| 170A | WASHING | PICKLING TANK | 1 | HCL CONCENTRATION | 50% | BY WEIGHT | EVERY LOT | OPERATOR | ADJUST THE RATIO/NOTIFY THE SEC.I/C. | |||

| 2 | PICKLING TIME | 15–20 MIN. | CLOCK | - | ||||||||

| 180 | GAP SETTING | MANUAL | 1 | 1. C.D | 90.00 ± 0.50 | C.D. GAUGE/V.C | 2 PCS | SET-UP | SET-UP APPROVAL FM/QA/010 | INSPECTOR | RE-SET | |

Appendix B

| Potential Failure Mode and Effects Analysis: PROCESS FMEA | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ITEM: BOLT (VECV)CARD-1481 | ||||||||||

| MODEL (S)/VEHICLE (S): (ECO-14–0601,04.04.14) | ||||||||||

| OPERATION NUMBER | OPERATION | POTENTIAL | POTENTIAL | SEV | POTENTIAL CAUSE(S)/ MECHANISM(S) OF FAILURE | OCCUR | PREVENTION | DETECTION | DET | RPN |

| 80 | BLANK CUTTING AT BANDSAW | LENGTH O/S/ TAPERED FACE | WASTAGE DUE TO EXCESSIVE-TO-EXCESSIVE CUT AT FACING EARLY TOOL WEAR | 5 | WRONG SET-UP BLADE WEAR | 2 | AUTOMATIC STOCK ADJUSTMENT PROVISION IN MACHINE SET-UP APPROVAL BLADE CHANGE OVER | PATROL INSPEC OPERATOR INSPECTION | 6 | 60 |

| LENGTH U/S/ TAPERED FACE | REJECTION WILL OCCUR | 6 | WRONG SET-UP- BLADE WEAR | 2 | AUTOMATIC STOCK ADJUSTMENT PROVISION IN MACHINE SET-UP APPROVAL BLADE CHANGE OVER | PATROL INSPEC OPERATOR INSPECTION | 6 | 72 | ||

| 90 | FACING AND ROUGH CHAMFERING BOTH SIDE | LENGTH VARIATION | RE-WORK MAY BE REQUIRED/WILL AFFECT FINAL LENGTH | 5 | WRONG SET-UP | 2 | STOPPER SET-UP TOOL SET-UP SET-UP APPROVAL WI/PP021 | PATROL INSPEC OPERATOR INSPECTION | 6 | 60 |

| 100 | STEP TURNING CHAMFERING BOTH SIDE | STEP DIA U/S | LOOSE FITMENT OF NUT/REDUCE LIFE/PRODUCT HAS TO BE SCRAPED OFF | 7 | WRONG SET-UP | 2 | SET-UP APPROVAL | PATROL INSPEC OPERATOR INSPECTION | 5 | 70 |

| STEP DIA O/S | PRODUCT HAS TO BE SORTED OUT/RE-WORK HAS TO BE DONE | 5 | WRONG SET-UP | 2 | SET-UP APPROVAL | PATROL INSPEC OPERATOR INSPECTION | 5 | 50 | ||

| 110 | PRE-ROLL DIA GRINDING | STEP DIA U/S | LOOSE FITMENT OF NUT/REDUCE LIFE/PRODUCT HAS TO BE SCRAPED OFF | 7 | WRONG SET-UP | 2 | SET-UP APPROVAL | PATROL INSPEC OPERATOR INSPECTION | 5 | 70 |

| STEP DIA O/S | PRODUCT HAS TO BE SORTED OUT/RE-WORK HAS TO BE DONE | 5 | WRONG SET-UP | 2 | SET-UP APPROVAL | PATROL INSPEC OPERATOR INSPECTION | 5 | 50 | ||

| 120 | MARKING | STAMP IMPRESSION NOT CLEAR | SUPPLIER | 2 | WORN OUT STAMP USED | 2 | SET-UP APPROVAL STAMP CHANGE OVER AS PER SCHEDULE | PATROL INSPEC OPERATOR INSPECTION | 5 | 20 |

| IDENTIFICATION MAY NOT BE POSSIBLE AT CUSTOMER END | ||||||||||

| 130 | THREADING BOTH SIDE | THREAD SIZE VARIATION | REJECTION WILL OCCUR | 6 | PRE-ROLL DIA VARIATION THREAD ROLLER WEAR | 2 | ROLLER SET-UP APPROVAL | PATROL INSPECTION AT PRE-ROLL DIA TURN AND THREADING STAGES OPERATOR INSPECTION | 5 | 60 |

References

- Elena, G.; Popkova, A.A.; Polukhin, J.V.R. (Eds.) Towards an Increased Security: Green Innovations, Intellectual Property Protection and Information Security; Springer Nature: London, UK, 2022; ISBN 9783030931544. [Google Scholar]

- Wigboldus, S.; Klerkx, L.; Leeuwis, C.; Schut, M.; Muilerman, S.; Jochemsen, H. Systemic perspectives on scaling agricultural innovations. A review. Agron. Sustain. Dev. 2016, 36, 46. [Google Scholar] [CrossRef]

- Erohin, M.; Leonov, O.; Kataev, U.; Vergazova, U. Calculation of Fits for Cylindrical Connections with Key for Reducers in Agricultural Machinery. Eng. Rural Dev. 2019, 18, 469–474. [Google Scholar] [CrossRef]

- Repcic, N.; Saric, I.; Muminovic, A. Software for Calculation and Analysis of ISO System of Tolerances, Deviations and Fits. In Annals of DAAAM for 2012 & Proceedings of the 23rd International DAAAM Symposium; DAAAM International: Vienna, Austria, 2012; Volume 1, pp. 195–198. [Google Scholar] [CrossRef]

- Software for Calculation and Analysis of ISO System of Tolerances, Deviations and Fits|Isad Saric—Academia.Edu. Available online: https://www.academia.edu/2975066/Software_for_Calculation_and_Analysis_of_ISO_System_of_Tolerances_Deviations_and_Fits (accessed on 19 February 2023).

- Ashok Kumar, A.; Tewari, V.K.; Maiti, J.; Nare, B. Design and Selection of Agricultural Machinery Using a Quality Function Deployment Technique. Agric. Eng. Int. CIGR J. 2015, 17, 91–99. [Google Scholar]

- Chen, C.; Zhang, Q.; Keer, L.M.; Yao, Y.; Huang, Y. The Multi-Factor Effect of Tensile Strength of Concrete in Numerical Simulation Based on the Monte Carlo Random Aggregate Distribution. Constr. Build. Mater. 2018, 165, 585–595. [Google Scholar] [CrossRef]

- Moreira, L.C.; Li, W.D.; Lu, X.; Fitzpatrick, M.E. Supervision Controller for Real-Time Surface Quality Assurance in CNC Machining Using Artificial Intelligence. Comput. Ind. Eng. 2019, 127, 158–168. [Google Scholar] [CrossRef]

- Abbasi, R.; Martinez, P.; Ahmad, R. An Ontology Model to Represent Aquaponics 4.0 System’s Knowledge. Inf. Process. Agric. 2022, 9, 514–532. [Google Scholar] [CrossRef]

- Alsamhi, S.H.; Afghah, F.; Sahal, R.; Hawbani, A.; Al-qaness, M.A.A.; Lee, B.; Guizani, M. Green Internet of Things Using UAVs in B5G Networks: A Review of Applications and Strategies. Ad. Hoc. Networks 2021, 117, 102505. [Google Scholar] [CrossRef]

- Anindya, D.S.; Yuliana, M.; Hadi, M.Z.S. IoT Based Climate Prediction System Using Long Short-Term Memory (LSTM) Algorithm as Part of Smart Farming 4.0. In Proceedings of the IES 2022 International Electronics Symposium: Energy Development for Climate Change Solution and Clean Energy Transition, Proceeding, Surabaya, Indonesia, 9–11 August 2022; Yunanto, A.A., Prayogi, Y.R., Eds.; Institute of Electrical and Electronics Engineers Inc.: Piscataway Township, NJ, USA, 2022; pp. 255–260. [Google Scholar]

- Ayed, R.B.; Hanana, M.; Ercisli, S.; Karunakaran, R.; Rebai, A.; Moreau, F. Integration of Innovative Technologies in the Agri-Food Sector: The Fundamentals and Practical Case of DNA-Based Traceability of Olives from Fruit to Oil. Plants 2022, 11, 1230. [Google Scholar] [CrossRef]

- Boppana, T.K.; Bagade, P. Security Risks in MQTT-Based Industrial IoT Applications. In Proceedings of the 2022 IEEE International Conference on Omni-Layer Intelligent Systems, COINS 2022, Barcelona, Spain, 1–3 August 2022; Institute of Electrical and Electronics Engineers Inc.: Piscataway Township, NJ, USA, 2022. [Google Scholar]

- Chaveesuk, S.; Chaiyasoonthorn, W.; Khalid, B. Understanding the Model of User Adoption and Acceptance of Technology by Thai Farmers: A Conceptual Framework. In Proceedings of the ACM International Conference Proceeding Series; Association for Computing Machinery, Osaka, Japan, 7–9 April 2020; pp. 279–285. [Google Scholar]

- de Abreu, C.L.; van Deventer, J.P. The Application of Artificial Intelligence (AI) and Internet of Things (IoT) in Agriculture: A Systematic Literature Review. Commun. Comput. Inf. Sci. 2022, 1551, 32–46. [Google Scholar] [CrossRef]

- Dias, K.C.; Lourenço, A.M.; Silva, G.V.; Miranda Cruz, M.V.; Macêdo Barbalho, S.C. Internet of Things (IoT) in Agriculture: An Exploratory Study on the Production of Growth Tomato (Industrial) in the South of Goiás, Brazil. In Proceedings of the International Conference on Electrical, Computer, Communications and Mechatronics Engineering, ICECCME 2022, Maldives, Maldives, 16–18 November 2022; Institute of Electrical and Electronics Engineers Inc.: Piscataway Township, NJ, USA, 2022. [Google Scholar]

- Ee, K.Y.; Lam, M.Q.; Mah, J.K.; Merican, A. Black Soldier Fly (Hermetia Illucens L.) Larvae in Degrading Agricultural Waste as a Sustainable Protein Production: Feedstock Modification and Challenges. Int. J. Trop. Insect Sci. 2022, 42, 3847–3854. [Google Scholar] [CrossRef]

- Ferrag, M.A.; Shu, L.; Djallel, H.; Choo, K.-K.R. Deep Learning-Based Intrusion Detection for Distributed Denial of Service Attack in Agriculture 4.0. Electronics 2021, 10, 1257. [Google Scholar] [CrossRef]

- Gunawan, I.; Wasil, M. Implementation Internet of Things (IoTs) to Monitoring Temperature Oven Tobacco System Towards 4.0 Industry. In Proceedings of the Journal of Physics: Conference Series; Nahdi, K., Djamaluddin, M., Eds.; Institute of Physics Publishing: Bristol, UK, 2020; Volume 1539. [Google Scholar]

- Hassoun, A.; Boukid, F.; Pasqualone, A.; Bryant, C.J.; García, G.G.; Parra-López, C.; Jagtap, S.; Trollman, H.; Cropotova, J.; Barba, F.J. Emerging Trends in the Agri-Food Sector: Digitalisation and Shift to Plant-Based Diets. Curr. Res. Food Sci. 2022, 5, 2261–2269. [Google Scholar] [CrossRef] [PubMed]

- 1st International Conference on Engineering Software for Modern Challenges, ESMoC 2021. Commun. Comput. Inf. Sci. 2022, 1615 CCIS.

- 21st International Multi-Conference on Advanced Computer Systems, ACS 2018. Adv. Intell. Syst. Comput. 2019, 889.

- Latino, M.E.; Menegoli, M.; Lazoi, M.; Corallo, A. Voluntary Traceability in Food Supply Chain: A Framework Leading Its Implementation in Agriculture 4.0. Technol. Forecast. Soc. Change 2022, 178, 121564. [Google Scholar] [CrossRef]

- Mahajan, H.B.; Badarla, A. Cross-Layer Protocol for WSN-Assisted IoT Smart Farming Applications Using Nature Inspired Algorithm. Wirel. Pers. Commun. 2021, 121, 3125–3149. [Google Scholar] [CrossRef]

- Naqvi, S.A.H.; Kazmi, R.; Iftikhar, E. Quality Assessment Framework for IoT Based Systems for Agriculture Industry 4.0. Commun. Comput. Inf. Sci. 2022, 1615 CCIS, 134–142. [Google Scholar] [CrossRef]

- Ouafiq, E.M.; Saadane, R.; Chehri, A.; Jeon, S. AI-Based Modeling and Data-Driven Evaluation for Smart Farming-Oriented Big Data Architecture Using IoT with Energy Harvesting Capabilities. Sustain. Energy Technol. Assess. 2022, 52, 102093. [Google Scholar] [CrossRef]

- Parri, L.; Parrino, S.; Peruzzi, G.; Pozzebon, A. A LoRaWAN Network Infrastructure for the Remote Monitoring of Offshore Sea Farms. In Proceedings of the I2MTC 2020—International Instrumentation and Measurement Technology Conference, Proceedings, Dubrovnik, Croatia, 25–28 May 2020; Institute of Electrical and Electronics Engineers Inc.: Piscataway Township, NJ, USA, 2020. [Google Scholar]

- Patel, C.; Doshi, N. A Novel MQTT Security Framework in Generic IoT Model. In Proceedings of the Procedia Computer Science; Thampi, S.M., Madria, S., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2020; Volume 171, pp. 1399–1408. [Google Scholar]

- Prapti, D.R.; Mohamed Shariff, A.R.; Che Man, H.; Ramli, N.M.; Perumal, T.; Shariff, M. Internet of Things (IoT)-Based Aquaculture: An Overview of IoT Application on Water Quality Monitoring. Rev. Aquac. 2022, 14, 979–992. [Google Scholar] [CrossRef]

- Prapti, D.R.; Shariff, A.R.M.; Man, H.C.; Ramli, N.M.; Perumal, T.; Shariff, M. An Overview of Water Quality Monitoring in IoT Based Aquaculture. In Proceedings of the American Society of Agricultural and Biological Engineers Annual International Meeting, ASABE 2021, Virtual, 12–16 July 2021; American Society of Agricultural and Biological Engineers: Saint Joseph, MI, USA, 2021; Volume 1, pp. 602–610. [Google Scholar]

- Radogna, A.V.; Latino, M.E.; Menegoli, M.; Prontera, C.T.; Morgante, G.; Mongelli, D.; Giampetruzzi, L.; Corallo, A.; Bondavalli, A.; Francioso, L. A Monitoring Framework with Integrated Sensing Technologies for Enhanced Food Safety and Traceability. Sensors 2022, 22, 6509. [Google Scholar] [CrossRef]

- Sabnis, V.; Kulkarni, S.S.; Gurav, S. NETra Model at Rajarambapu Institute of Technology (RIT): Transform Engineering Campus into Product Innovation Centre—Journey so Far. In Proceedings of the Procedia Computer Science; Jagadeesh Kannan, R., Jeganathan, L., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2020; Volume 172, pp. 98–105. [Google Scholar]

- Sott, M.K.; Nascimento, L.S.; Foguesatto, C.R.; Furstenau, L.B.; Faccin, K.; Zawislak, P.A.; Mellado, B.; Kong, J.D.; Bragazzi, N.L. A Bibliometric Network Analysis of Recent Publications on Digital Agriculture to Depict Strategic Themes and Evolution Structure. Sensors 2021, 21, 7889. [Google Scholar] [CrossRef]

- Tang, C.; Yang, N. A Monitoring and Control System of Agricultural Environmental Data Based on the Internet of Things. J. Comput. Theor. Nanosci. 2016, 13, 4694–4698. [Google Scholar] [CrossRef]

- Tóth, M.; Felföldi, J.; Várallyai, L.; Szilágyi, R. Application Possibilities of IoT-Based Management Systems in Agriculture. Springer Optim. Its Appl. 2022, 183, 77–102. [Google Scholar] [CrossRef]

- Voronova, V.I.; Bezumnov, D.N.; Voronov, V.I. Development of the Research Stand «Smart City Systems» INDUSTRY 4.0. In Proceedings of the 2019 International Conference “Quality Management, Transport and Information Security, Information Technologies” (IT&QM&IS), Sochi, Russia, 23–27 September 2019; pp. 577–582. [Google Scholar] [CrossRef]

- Winkler, R. MeteoMex: Open Infrastructure for Networked Environmental Monitoring and Agriculture 4.0. PeerJ Comput. Sci. 2021, 7, e343. [Google Scholar] [CrossRef] [PubMed]

- Wójcicki, K.; Biegańska, M.; Paliwoda, B.; Górna, J. Internet of Things in Industry: Research Profiling, Application, Challenges and Opportunities—A Review. Energies 2022, 15, 1806. [Google Scholar] [CrossRef]

- Yahya, N. Agricultural 4.0: Its Implementation Toward Future Sustainability. In Green Urea. Green Energy and Technology; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

| ITEM: BOLT (VECV) (CARD-1481) | PROCESS IDENTIFICATION: PF-B/120–01 | |||

|---|---|---|---|---|

| OPERATION NUMBER BRIEF DESCRIPTION | INCOMING SOURCE of VARIATION | PRODUCT CHARACTERISTICS | PROCESS CHARACTERISTICS | |

| 10 | MATERIAL RECEIVED AND STORAGE | - RUSTY | - STORAGE IN PROPER RACK | - |

| 20 | RAW MATERIAL INSPECTION | IMPROPER COMPOSITION | -COMPOSITION (ES)GRADE SAE 4140 | - STD. SAMPLE (NML & BCS) |

| DE-CARB | --DE-CARB (ES) AS PER IS-6396 | - SPECTRO | ||

| BANDED STRUCTURE | -MICROSTRUCTURE (ES) | - WORK INSTRUCTIONS | ||

| -SURFACE DEFECT | -SURFACE (FC) | |||

| -DIA UNDER SIZE | -DIA (IP) 20.00 | |||

| -LENGTH VARIATION | -LENGTH (IP) 5–6 m | |||

| 30 | MATERIAL COLOUR CODING | --------------- | - WI/QA/013 | - WI/QA/013 |

| 40 | ANNEALING | - DE-CARB MATERIAL | - HARDNESS (ES) 170 BHN MAX. | - ANNEALING TEMPERATURE |

| - BANDED STRUCTURE | --DE-CARB (ES) | - SOAKING TIME | ||

| - COOLING RATE | ||||

| - FURNACE OF TEMPERATURE | ||||

| 50 | STEP TURNING | --------- | - STEP DIA (IP) 17.20/16.70 | - TOOL CONDITION |

| - STEP LENGTH (IP) 100–115 | ||||

| 60 | PICKLING | - SCALE | - FREE FROM SCALE (FC) | - PICKLING TIME |

| - CONC. OF H2SO4 | ||||

| 70 | BAR DRAWING | - SCALES | - DIA (IP) 17.95/17.85 | - DIE CONDITION |

| - NO DIE MARKS (FC) | ||||

| 80 | BLANK CUTTING | --------------- | -LENGTH (IP) 591 + 1 | -BLADE CONDITION |

| -PUNCH/DIE CONDITION | ||||

| 90 | END FACING AND CHEMFER ROUGH | -LENGTH OVER SIZE | -LENGTH (IP) 589 + 1 | -TOOL CONDITION |

| -LENGTH UNDER SIZE | -CHEMFER (IP)1 × 45° | |||

| 100 | STEP TURNING (PRE-ROLLDIA TURNING) AND CHEMFERING | --------------- | -STEP DIA (IP) 17.10/17.00 | -TOOL CONDITION |

| -STEP LENGTH (BP) 85.00 ± 1 | ||||

| -CHEMFER (IP) 2.00 | ||||

| -CHEMFER ANGLE(BP) 45° | ||||

| - RADIUS (BP) | ||||

| 110 | PRE-ROLL DIA GRD. | - DIA U/S and DIA O/S | -DIA(IP) 16.93/16.90 | - GRD. WHEEL CONDITION |

| - RADIUS (BP) | ||||

| 120 | MARKING | --------------- | - GS LOGO, BATCH NO. | -STAMP CONDITION |

| 130 | THREADING | -DIA OVER SIZE | -THREAD SIZE (BP) M18 × 1.5P | -THREAD ROLLER WEAR |

| -DIA UNDER SIZE | -THREAD PROFILE (BP) | -WORK REST CONDITION | ||

| -TAPER | -THREAD LENGTH (BP) 75.00 + 3 | -PRESSURE | ||

| -HARDNESS | - MAJOR DIA (BP)17.95/17.80 | -RPM | ||

| - RADIUS (BP) | ||||

| 140 | HEATING AND BENDING (HOT) | -LENGTH VARIATION | -STEM LENGTH (BP) 252.00 ± 1.5 | -HEATING TIME |

| -STEM C.D (BP) 90.00 ± 0.50 | -ROLLER WEAR/DIE WEAR | |||

| -BEND RADIUS (BP) R97.5 × R10 | -CURENT SUPPLY | |||

| -NO SCALE/HEATER MARK (FC) | -COPPER BLOCK CONDITION | |||

| - LENGTH (BP)270 | ||||

| 150 | MARKING | --------------- | - PART NO IC 305970-C | -STAMP CONDITION |

| - HEAT CODE | ||||

| 160 | HARDENING | -DE-CARB | -HARDNESS (IP) 45 HRC MIN | -SOAKING TEMPERATURE |

| -SOAKING TIME | ||||

| -QUENCHING OIL TEMP. | ||||

| 170 | TEMPERING | -MATERIAL COMPOSITION | -HARDNESS (BP) 304–361 BHN | -SOAKING TEMPERATURE |

| -THREAD DE CARB | -SOAKING TIME | |||

| -MICROSTRUCTURE (BP) | (PROCESS QUALIFICATION) | |||

| 170A | WASHING | -SCALING | - FREE FROM FOREIGN MATERIAL/ | - SOAKING TIME |

| SCALING | -CONCENTRATION | |||

| 180 | GAP SETTING | -DISTORTION | -C.D. (BP) 90.00 ± 0.50 | -OPERATOR SKILL |

| -NO ROCKING (ES) | ||||

| Operation | Operations | Rejection | Rework |

|---|---|---|---|

| 40 | Bar Annealing & Inspection by Lab | 1 | Possible |

| 50 | Bar Step Turning to Facilitate Bar Drawing | 2 | Possible |

| 60 | Pickling | 1 | Possible |

| 70 | Bar Drawing | 1 | Possible |

| 80 | Blank Cutting at Bandsaw | 1 | Possible |

| 90 | Facing & Rough Chamfering Both Side | 134 | Not Possible |

| 100 | Step Turning Chamfering Both Side | 123 | Not Possible |

| 110 | Pre-Roll Dia Grinding | 120 | Not Possible |

| 120 | Marking | 1 | Possible |

| 130 | Threading Both Side | 123 | Not Possible |

| 140 | Bending | 1 | Possible |

| 150 | Marking | 5 | Possible |

| 160 | Hardening | 1 | Possible |

| 170 | Tempering | 3 | Possible |

| 180 | Gap Setting | 1 | Possible |

| 190 | Phosphating | 22 | Possible |

| 200 | Hydrogen De-Embrittlement | 1 | Possible |

| Parameter | Cp | Cpk | PPM | Pp | Ppk | PPM | |

|---|---|---|---|---|---|---|---|

| Traditional QM | Dim1 | 0.65 | 0.55 | 62,593.41 | 0.68 | 0.58 | 50,008.08 |

| ZDM | Dim1 | 1.87 | 1.61 | 0.66 | 2.03 | 1.75 | 0.08 |

| Traditional QM | Dim2 | 0.23 | −0.04 | 615,457.24 | 0.24 | −0.04 | 607,966.75 |

| ZDM | Dim2 | 1.76 | 1.75 | 0.14 | 1.73 | 1.72 | 0.23 |

| Traditional QM | Dia1 | 0.36 | 0.22 | 322,722.03 | 0.35 | 0.22 | 326,610.231 |

| ZDM | Dia1 | 1.66 | 1.66 | 0.62 | 1.77 | 1.76 | 0.11 |

| Traditional QM | L1 | 0.34 | 0.24 | 334,459.05 | 0.35 | 0.25 | 312,954.03 |

| ZDM | L1 | 1.75 | 1.75 | 0.14 | 7.74 | 1.74 | 0.18 |

| Traditional QM | L2 | 0.34 | 0.21 | 348,472.53 | 0.35 | 0.22 | 326,109.56 |

| ZDM | L2 | 1.78 | 1.76 | 0.10 | 1.70 | 1.69 | 0.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, J.; Ahuja, I.S.; Singh, H.; Singh, A. Application of Quality 4.0 (Q4.0) and Industrial Internet of Things (IIoT) in Agricultural Manufacturing Industry. AgriEngineering 2023, 5, 537-565. https://doi.org/10.3390/agriengineering5010035

Singh J, Ahuja IS, Singh H, Singh A. Application of Quality 4.0 (Q4.0) and Industrial Internet of Things (IIoT) in Agricultural Manufacturing Industry. AgriEngineering. 2023; 5(1):537-565. https://doi.org/10.3390/agriengineering5010035

Chicago/Turabian StyleSingh, Jagmeet, Inderpreet Singh Ahuja, Harwinder Singh, and Amandeep Singh. 2023. "Application of Quality 4.0 (Q4.0) and Industrial Internet of Things (IIoT) in Agricultural Manufacturing Industry" AgriEngineering 5, no. 1: 537-565. https://doi.org/10.3390/agriengineering5010035

APA StyleSingh, J., Ahuja, I. S., Singh, H., & Singh, A. (2023). Application of Quality 4.0 (Q4.0) and Industrial Internet of Things (IIoT) in Agricultural Manufacturing Industry. AgriEngineering, 5(1), 537-565. https://doi.org/10.3390/agriengineering5010035