Abstract

Ground speed variations are common and unavoidable during pesticide applications with agricultural sprayers. Field tests were conducted to evaluate the effect of varying ground speeds on spray deposition and quality with a commercial agricultural boom sprayer without a rate controller (CNS) in 2021 and equipped with a rate controller (SRC) in 2022. During each year, the sprayer boom was split evenly among three different nozzle types (XRC, AIXR, and TTI) to attain different droplet sizes (medium, very coarse, and ultra-coarse, respectively). Prior to testing, the sprayer was calibrated to deliver an application rate of 187 L ha−1 at a spray pressure of 207 kPa and ground speed of 9.7 km h−1. For spray deposition and quality assessment, pesticide applications were made at five different ground speeds of 9.7, 12.9, 16.1, 19.3, and 22.5 km h−1, and data were collected by placing water-sensitive paper at different locations across the sprayer boom and in the field. Results for CNS indicated that spray deposition reduced significantly (p < 0.05) with an increase in ground speed across all three nozzle types, primarily due to a decrease in the quantity of spray droplets applied per unit area. The quantity of spray droplets and spray deposition was more consistent among the ground speeds for SRC. Ground speed affected spray quality for both CNS and SRC; however, the spray quality variations were greater for SRC due to an increase in spray pressure with ground speed. Among nozzle types, the trends in spray deposition and quality were similar for the XRC and TTI nozzles as observed for CNS and SRC. However, the AIXR nozzle showed inconsistent spray deposition and quality as ground speed varied. The results of this study indicated agricultural sprayers equipped with a rate controller provide adequate and consistent spray deposition compared to conventional sprayers (no rate controller) when ground speed changes occur during pesticide applications. While spray quality is also affected when using a rate controller, best management practices including proper nozzle selection and application at nominal ground speeds should be followed to minimize these effects and ensure effective technology utilization.

1. Introduction

Pesticide application has been an indispensable part of row crop production in the United States. The use of pesticides to manage weeds, insects, and diseases has increased steadily over the years [1]. A comprehensive survey conducted by the USDA Economic Research Service on the pesticide use of 21 selected crops from 1960 to 2008 indicated that the use of pesticides dramatically increased by more than three folds in the first two decades, from 88.9 million kg of pesticide active ingredient in 1960 to 286.7 million kg in 1981, and then declined slightly to 234.1 million kg in 2008 [2]. This trend of increasing pesticide use has continued until today and shows that pesticide application has been a major component of input costs for row crops production in the United States [3]. Effective and judicious use of pesticides is important to extend the usefulness and longevity of pesticides in agriculture. Maintaining application accuracy while minimizing off-rate errors and off-target movement of pesticides is critical to ensure safe and efficient pesticide applications. Along with following the best management practices, one of the ways to achieve this is through effective utilization of available spray technologies such as rate controller [4,5], automatic boom section, individual nozzle control [6,7], and PWM system [8,9].

The spray coverage and efficacy of pesticide application can be influenced by many equipment and application-related factors. Among them, ground speed and nozzle type/droplet size are important parameters as they can influence spray coverage, quality, efficacy, and drift [10,11,12,13,14]. Currently, there is an increasing trend of using agricultural sprayers with wider booms (application swaths ≥ 27.4 m) along with applications at greater than nominal ground speeds (≥19.3 km h−1) to cover more acres and save time. However, a common concern with an increase in ground speed is the reduced application rate due to the overall decreased amount of total spray droplets reaching the target [15]. Ground speed variations during pesticide application also affect nozzle performance and droplet size distribution. An increase in ground speed results in increased production of finer droplets, thereby increasing the potential for spray drift. Several studies have reported greater pesticide drift and reduced coverage associated with the increase in application speed [10,11,13].

The Spray quality is an important spray characteristic that is used to classify nozzle type based on the droplet size (VMD). Spray quality also affects coverage and particle drift [16]. Generally, conventional flat-fan nozzles (such as Teejet® XR or XRC) that produce fine spray droplets are used for applying contact pesticides because of the greater coverage required on soil or leaf surfaces. However, increased pesticide drift associated with finer droplets led to the introduction of venturi/AI nozzles (such as Teejet® AIXR or TTI). These AI nozzles produce coarser spray droplets which are more suited for applying systemic pesticides while minimizing the risk of spray particle drift [17]. The improved drift control performance of AI nozzles [18,19] and comparable coverage (or improved coverage in some cases) and efficacy to the conventional flat nozzles [14,20] have been reported by several researchers. Therefore, the appropriate selection of nozzle type—to attain desired spray quality—is highly recommended to maintain a balance between spray coverage and drift during pesticide applications [21,22,23,24].

Ground speed variations coupled with other operational errors make maintaining a target rate during pesticide applications, a challenging task. However, maintaining a target application rate (L ha−1) is critical to apply the desired pesticide amount (kg ha−1), and achieving adequate coverage and efficacy. Therefore, different precision spray technologies have been developed over the years and are available to be utilized on agricultural sprayers to maintain application accuracy. Amongst them, a rate controller is one of the common spray technologies, that helps in addressing the issues of off-rate application errors associated with traditional sprayers, by controlling the flow rate and maintaining the desired rate despite changes in ground speed [4,5,15]. However, these flow rate adjustments are accomplished by changes to the system spray pressure and any changes in spray pressure also affects spray quality. Therefore, for a nozzle with a fixed orifice, an increase in spray pressure results in the production of a large number of finer droplets [25]. Thus, while the changes in spray pressure help in maintaining the target application rate and may improve coverage by increased production of finer droplets, it also greatly increases the drift potential [26]. To overcome this issue, PWM systems are becoming more common recently on agricultural sprayers where the flow rate is controlled across a range of ground speeds by varying duty cycle (proportion of time that nozzle is open) while still maintaining a constant spray pressure and droplet size [8,9].

A review of the literature suggested that most of the previous studies that investigated the influence of nozzle type and/or ground speed have been focused primarily on assessing spray coverage [10,11,12,13,14,20,27] or particle drift [17,21,22,23,24,26,28,29,30,31]. Spray quality has received minimal to no attention in these studies. Further, most of these studies have not investigated how some of the commonly available spray technologies such as a rate controller can influence spray quality during pesticide applications. Currently, a large number of traditional agricultural boom sprayers—both within and outside the United States—especially by small acreage or specialty crop growers, are used without a rate controller while most modern agricultural sprayers (especially self-propelled) come equipped with a rate controller today. To ensure efficient pesticide applications with both conventional and newer technology-equipped sprayers, it is important to assess and understand their spray performance at a varying range of ground speeds. Therefore, the objective of this study was to evaluate spray deposition and quality at varying ground speeds for an agricultural sprayer equipped with and without a rate controller.

2. Materials and Methods

2.1. Site and Application Equipment

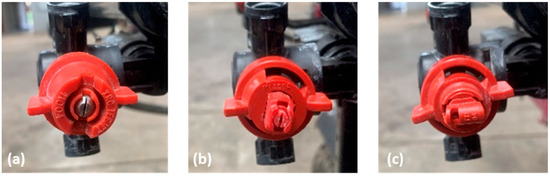

Field experiments in this study were conducted in 2021 and 2022 at the Southeast Georgia Research and Education Center in Midville, Georgia, USA (32°49′ N, 82°14′ W). A tractor-mounted commercial agricultural boom sprayer (Demco X-fold, Demco Manufacturing Co., Boyden, IA, USA) was used for herbicide applications (Figure 1a) during both years. The sprayer had a boom length of 18.3 m with nozzles spaced equidistant (0.46 m) across the length of the boom. In 2021, the sprayer was used without a rate controller whereas a Micro-Trak MT-2405F II rate controller (Micro-Trak, Mankato, MN, USA) in conjunction with a TeeJet® 346BPR-2F-03 (TeeJet Technologies, Springfield, IL, USA) regulating valve was used on the same sprayer in 2022 (Figure 1b and Figure 1c, respectively). During both years, all other application settings including boom height and nozzles on the sprayer were kept similar. The only difference was the applications without and with a rate controller between the study years. Thus, these sprayer setups utilized in 2021 and 2022 will be referred to as CNS and SRC, respectively, from here forward.

Figure 1.

(a) The commercial Demco X-fold boom sprayer used for spray performance testing in 2021 and 2022. (b) The Micro-Trak MT-2405F II rate controller and (c) the TeeJet® 346BPR-2F-03 regulating valve used in 2022.

To evaluate and compare spray performance between CNS and SRC, herbicide applications were made using five different ground speeds of 9.7, 12.9, 16.1, 19.3, and 22.5 km h−1 in the selected field. These ground speeds were attained by selecting the appropriate gear ratio of the tractor. Further, three different nozzle types, XRC, AIXR, and TTI (Teejet® Technologies, Springfield, IL, USA) (Figure 2a, Figure 2b and Figure 2c, respectively) were used to produce medium, very coarse, and ultra-coarse droplets, respectively, as per the ASABE standard S572.1 [16]. All nozzles used in this study had a 110° spray angle and a 04 orifice size. The nozzles were split evenly across the sprayer boom (18.3 mL) in the following arrangement from left to right (Figure 1a): XRC, AIXR, and TTI. During testing, each nozzle sprayed six rows (row spacing 0.91 m) which constituted a sub-plot that measured 5.5 m wide and approximately 182 to 200 m in length, which was equivalent to the length of the field. Before testing each year, the sprayer was calibrated to deliver 187 L ha−1 of spray volume at 207 kPa and 9.7 km h−1 for a 04 nozzle size. During testing, the study treatments were attained by varying the ground speed while keeping the nozzle type and size constant throughout the whole testing period each year.

Figure 2.

Three different nozzle types: TeeJet® (a) XRC 11004; (b) AIXR 11004; and (c) TTI 11,004. These nozzle types were used to attain medium, very coarse, and ultra-coarse spray droplets, respectively, [16] in this study.

2.2. Spray Applications and Data Collection

During both years, two herbicide applications—a pre-emergence and a post-emergence—were made in the field planted with peanuts. Pre-emergence applications were made at or right after planting and before the emergence of peanut seedlings while the post-emergence spray applications were made approximately three to four weeks after the pre-emergence application. Details on the herbicide program used for pre-emergence and post-emergence applications in these research trials conducted in 2021 and 2022 are shown in Table 1. In 2021, the pre-emergence and the post-emergence herbicide applications were made on May 11 and June 16, respectively, whereas these applications were made on May 3 and June 1, respectively, in 2022.

Table 1.

Information on different herbicides and their corresponding active ingredient rates applied during the spray testing conducted in 2021 and 2022.

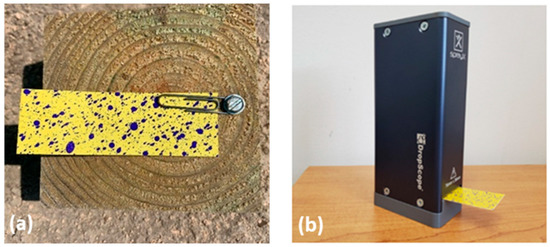

For data collection, nine wooden blocks—with a paper clip attached on the top of each block to hold a WSP (Figure 3a)—were placed on the ground in a grid pattern (5.5 × 15.2 m) prior to any herbicide applications in the field. Within each grid, the blocks were placed 15.2 m apart along the length of the spray pass (each row serving as a replication) and 1.8 m apart along the sprayer boom. Each 3 × 3 grid of blocks during application covered six rows and represented data collection for one nozzle type. WSP (26 × 76 mm) were placed on all the blocks prior to each sprayer pass. Herbicides were mixed with water as a carrier in their labeled concentration (Table 1) and spray applications were made implementing different ground speed treatments. After each sprayer pass, WSP were allowed to dry for few minutes and then collected in standard labeled envelopes to prevent further contamination due to moisture or humidity. At the end of the field testing, samples were carefully transported to the laboratory located in the Engineering building at the University of Georgia Tifton campus in Tifton, GA for further analysis.

Figure 3.

(a) Illustration of data collection setup (wooden block and water-sensitive paper) used in the field, and (b) the DropScope instrument used for analyzing water-sensitive paper.

During spray testing each year, meteorological conditions including wind speed (m/s), wind direction, temperature (°C), relative humidity (%), and dew point (°C) were monitored and recorded at 1-min intervals by installing an on-site weather station (Model 6357 Vantage VueTM, Davis Instruments, Hayward, CA, USA). The averaged meteorological data for the entire application period for 2021 and 2022 are presented in Table 2. The meteorological conditions during both years remained consistent throughout the entire testing period including the wind speed, which was low (mean wind speed ≤ 1 ms−1) during both years and did not have any significant effect on spray deposition during applications.

Table 2.

Meteorological conditions recorded during spray testing in 2021 and 2022. Values are averaged across the applications for each year and represent mean ± standard deviation.

2.3. Data Analysis

In the laboratory, WSP were scanned using a DropScope (SprayX, São Paulo, Brazil) instrument (Figure 3b) and a compatible SprayX software (SprayX, São Paulo, Brazil). The analysis provided spray coverage, droplet density, D0.1, D0.5/VMD, D0.9, and spray quality. Spray coverage refers to the percentage of area covered by the spray droplets while droplet density refers to the quantity of spray droplets per unit area. D0.5 (VMD) is the droplet diameter (µm) where 50% of the spray volume is in droplets smaller than this value. Similarly, D0.1 and D0.9 are the droplet diameters where 10% and 90%, respectively, of the spray volume is in droplets smaller than this value. Spray quality refers to the droplet size classification based on the VMD as per the ASABE S572.3 [16]. For each treatment, the WSP analysis also classified the overall spray quality in different droplet sizes based on their VMD as VF (61–105 µm), F (106–235 µm), M (236–340 µm), C (341–403 µm), VC (404–502 µm), EC (503–665 µm) and UC (>665 µm) [16]. The SprayX software utilized the spread factor and other related information as listed in the ASABE S572.1 to provide D0.1, D0.5, D0.9, and spray quality (droplet size distribution) information for each treatment.

All data were analyzed using JMP® Pro 16.0.0 (SAS, Cary, NC, USA). Statistical analysis indicated no significant interaction between the pre- and post-emergence applications for all the measured responses (p-values > 0.05); therefore, data were pooled across both applications for each year. Since the main goal of this study was to understand the influence of varying ground speed on spray deposition and quality for CNS and SRC, the spray performance data were analyzed separately for each nozzle to avoid any unnecessary interactions among the ground speed and nozzle types. Data were subjected to ANOVA with ground speed as the main effect for each nozzle type. For effects that were significant, treatment means were separated with a Student’s t-test procedure using α = 0.05.

3. Results and Discussion

3.1. Spray Deposition

Table 3 presents the p-values from ANOVA analysis for spray deposition (spray coverage and quantity of spray droplets) for CNS and SRC for three different nozzle types used in this study. For CNS, ground speed affected spray coverage where a decrease in spray coverage was observed with an increase in ground speed (Table 4). This trend of reduced spray coverage was noticed across all three nozzle types (XRC, AIXR, and TTI) with an increase in ground speed from 9.7 km h−1 to 22.5 km h−1. Among all nozzle types, the spray coverage was highest (40.1, 35.9, and 26.3% for XRC, AIXR, and TTI, respectively) at the slowest speed of 9.7 km h−1 (which was also the speed used for sprayer calibration prior to testing) whereas it was lowest (11.3, 18.0, and 9.4% for XRC, AIXR, and TTI, respectively) at the highest ground speed of 22.5 km h−1. This reduction in spray coverage for CNS was somewhat expected as when ground speed increases, the number of spray droplets per unit area decreases due to the system pressure, and consequently the flow rate still being the same as selected during sprayer calibration. This is also evident from the reduction in the quantity of drops with an increase in ground speed, presented in Table 4. However, these results were only noticed across XRC and TTI nozzles. These findings differed for the AIXR nozzle where a reduction in spray coverage from 35.9% at 16.1 km h−1 to 18.0% at 22.5 km h−1 was observed; however, the quantity of spray droplets was comparable between the ground speeds. As mentioned earlier, a decrease in spray coverage is generally accompanied by a reduction in the number of spray droplets in the absence of a rate controller, so these findings for AIXR nozzles were unexpected.

Table 3.

ANOVA results (p-values) for spray coverage and quantity of spray droplets by nozzle type for CNS and SRC. CNS represents the sprayer without a rate controller and SRC represents the sprayer equipped with a rate controller used in this study.

Table 4.

Influence of ground speed on spray coverage (%) and quantity of spray droplets by nozzle type for CNS. CNS represents the sprayer without a rate controller used in this study.

Ozkan and Womac [15] reported that ground speed is one of the most influential factors affecting application rate, and suggested determining an appropriate ground speed before any pesticide application. The results for CNS sprayers emphasize the importance of selecting and maintaining the appropriate ground speed during pesticide applications for agricultural sprayers without a rate controller. As observed for CNS, the reduction in spray coverage for the XRC and TTI nozzles was also expected due to the overall reduced applied rate at ground speeds higher than the speed (9.7 km h−1) used for sprayer calibration. Ayers et al. [5] also observed greater rate errors during applications at different ground speeds with a sprayer without a rate controller.

For SRC, the spray coverage for XRC and TTI nozzles was more consistent as ground speed increased from 9.7 km h−1 to 22.5 km h−1 (Table 5) as compared to CNS. While the quantity of spray droplets exhibited some variability among the ground speeds; however, the mean quantity of spray droplets was statistically similar (p > 0.05) for both nozzle types. As for the AIXR nozzle, the increase in ground speed again provided inconsistent results for both spray coverage and quantity of spray droplets, where the spray coverage reduced at increased ground speeds and the quantity of spray droplets varied among the ground speeds.

Table 5.

Influence of ground speed on spray coverage (%) and quantity of spray droplets by nozzle type for SRC. SRC represents the sprayer equipped with a rate controller used in this study.

With ground speed variations in the field during pesticide applications, a rate controller maintains the target application rate by adjusting spray pressure and consequently the nozzle flow rate [32]. The results for XRC and TTI nozzles verified this where SRC showed consistent spray coverage over the range of ground speeds used in this study. Similar spray performance results with the use of a rate controller were shared by Al-Gaadi and Ayers [4] and Ayers et al. [5]. These studies concluded that the use of a sprayer controller resulted in a significant reduction of application errors, thus maintaining the desired application rate over a wide range of ground speeds. Fewer rate errors during application also mean more uniform spray coverage as noticed in the present study. Although it can be observed that the quantity of spray droplets increased with an increase in ground speed from 9.7 km h−1 to 22.5 km h−1 for both XRC and TTI nozzles (Table 5); however, this trend was not statistically significant (p > 0.05). For a sprayer equipped with a rate controller, an increase in ground speed results in increased spray pressure at the nozzle orifice, thus producing finer spray droplets [10,13]. Generally, finer spray droplets provide better coverage as compared to coarser droplets; however, they are also more prone to off-target movement, especially at higher ground speeds. The results for the AIXR nozzle for both CNS and SRC imply an inconsistent spray performance at varying ground speeds of this nozzle compared to XRC and TTI nozzles.

3.2. Spray Quality

Table 6 presents the p-values from ANOVA analysis for spray quality (D0.1, D0.5, and D0.9) for CNS and SRC for three different nozzle types used in this study. D0.1, D0.5, and D0.9 are the droplet diameters (µm) where 10%, 50%, and 90%, respectively, of the spray volume is contained in the spray droplets smaller than this value. For CNS, ground speed affected D0.1 across all nozzle types whereas no effect of ground speed on D0.5 and D0.9 was observed with the exception of D0.5 for the AIXR nozzle (Table 7). The observed trend was that D0.1 decreased with an increase in ground speed regardless of the nozzle type. For the AIXR nozzle, D0.5 decreased with an increase in the ground speed.

Table 6.

ANOVA results (p-values) for D0.1, D0.5, and D0.9 by nozzle type for CNS and SRC. D0.1, D0.5, and D0.9 are the droplet diameters (µm) where 10%, 50%, and 90%, respectively, of the spray volume is contained in the spray droplets smaller than this value. CNS represents the sprayer without a rate controller and SRC represents the sprayer equipped with a rate controller.

Table 7.

Influence of ground speed on D0.1, D0.5, and D0.9 by nozzle type for CNS. D0.1, D0.5, and D0.9 are the droplet diameters (µm) where 10%, 50%, and 90%, respectively, of the spray volume is contained in the spray droplets smaller than this value. CNS represents the sprayer without a rate controller.

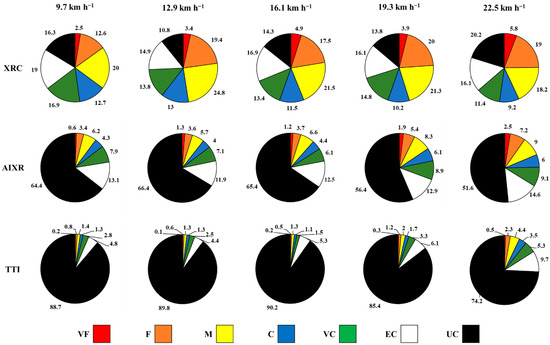

A graphical illustration of spray quality, i.e., droplet size classification based on VMD for XRC, AIXR, and TTI nozzles at different ground speeds used in this study is presented in Figure 4 for CNS. Observing the graphs, a change in spray quality with an increase in ground speed can be noticed across all nozzle types. For the XRC nozzle, the largest variations with ground speed increase were observed in the VF and F spray droplets where the percentage of F and VF droplets increased from 2.5% to 5.8% and 12.6% to 19.0%, respectively, as ground speed increased from 9.7 km h−1 to 22.5 km h−1. Similarly, the AIXR and TTI nozzles exhibited the greatest variation in UC droplets followed by F, VF, and M. As ground speed increased from 9.7 to 22.5 km h−1, the UC droplets decreased by 12.8% for the AIXR nozzle and by 14.5% for the TTI nozzle. Since the spray pressure remained constant for CNS during herbicide applications as ground speed varied, the observed changes in the spray quality (different droplet sizes) can be attributed to the overall lower number of spray droplets applied per unit area with an increase in ground speed, which is also evident from the data presented in Table 4. A review of the literature shows limited information on the influence of varying ground speed on the overall spray quality, especially on different droplet sizes ranging from VF to UC. Thus, these findings cannot be compared to any of the previous work conducted on ground speed influence on spray deposition. Though, it will be useful to provide data for comparison and verification of results with similar spray performance studies conducted in the future.

Figure 4.

Spray quality (droplet size classification based on volume median diameter) for XRC, AIXR, and TTI nozzles at varying ground speeds for CNS. CNS represents the sprayer without a rate controller while XRC, AIXR, and TTI represent TeeJet® extended range, air induction extended range, and turbo-teejet induction nozzle types, respectively, used in this study. VF, F, M, C, VC, EC, and UC represents the very fine, fine, medium, coarse, very coarse, extremely coarse, and ultra-coarse spray droplets, respectively, as defined by the ASABE S572.3 [16].

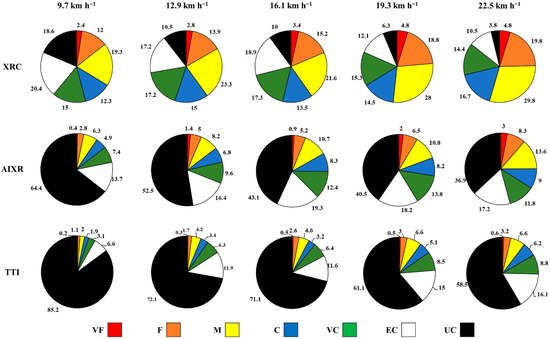

For SRC, no effect of ground speed on D0.1, D0.5, and D0.9 was observed for XRC and TTI nozzles (Table 6); however, it had a significant effect on D0.1 and D0.5 for the AIXR nozzle. The D0.1 and D0.5 for the AIXR nozzle decreased with an increase in the ground speed from 9.7 to 22.5 km h−1 (Table 8). A similar trend was also observed in the D0.1, D0.5, and D0.9 values for the XRC and TTI nozzles but it was not statistically valid (p > 0.05). Figure 5 illustrates spray quality in terms of droplet size classification based on VMD by nozzle type at different ground speeds for SRC. The XRC nozzle exhibited a considerable increase in the quantity of F and VF spray droplets from 12.0% to 19.8% and 19.3% to 29.8%, respectively, with an increase in ground speed from 9.7 to 22.5 km h−1. Conversely, the quantity of UC and EC spray droplets decreased by 14.8% and 9.9%, respectively, with an increase in ground speed. A similar trend for VF, F, EC, and UC spray droplets was noticed for the AIXR and TTI nozzles, where the amount of finer (VF and F) spray droplets increased and the coarser spray droplets (EC and UC) decreased as ground speed increased.

Table 8.

Influence of ground speed on D0.1, D0.5, and D0.9 by nozzle type for SRC. D0.1, D0.5, and D0.9 are the droplet diameters (µm) where 10%, 50%, and 90%, respectively, of the spray volume is contained in the spray droplets smaller than this value. SRC represents the sprayer equipped with a rate controller used in this study.

Figure 5.

Spray quality (droplet size classification based on volume median diameter) for XRC, AIXR, and TTI nozzles at varying ground speeds for SRC. SRC represents the sprayer equipped with a rate controller while XRC, AIXR, and TTI represent TeeJet® extended range, air induction extended range, and turbo-teejet induction nozzle type, respectively, used in this study. VF, F, M, C, VC, EC, and UC represents the very fine, fine, medium, coarse, very coarse, extremely coarse, and ultra-coarse spray droplets, respectively, as defined by the ASABE S572.3 [16].

Since a rate controller was used on SRC during applications, these results were expected as the target application rate with increasing ground speed is maintained by an increase in spray pressure, which also affects spray quality. A higher spray pressure at the same nozzle orifice results in the production of more finer spray droplets [10,13], which was noticed here across all three nozzle types. These data also suggest a degradation in spray quality at higher ground speeds compared to the ground speed of 9.7 km h−1 at which the sprayer was calibrated to deliver a target rate (GPA) and the desired spray quality.

Though the effect of ground speed on spray quality was observed for both CNS and SRC, the variations in spray quality were greater for SRC due to the change in spray pressure with an increase in ground speed. Besides an overall degradation in spray quality, the increase in ground speed for SRC is also increasing the potential for off-target movement of spray particles, as finer spray droplets are highly susceptible to pesticide drift [10,13]. As evident from the data provided in Figure 5, this is more concerning for the XRC nozzles due to the greatest quantity of finer spray droplets (VF and F) produced at higher ground speeds among all the nozzles used in this study.

4. Conclusions

The spray performance of two different sprayer setups (CNS and SRC) was evaluated at varying ground speeds by assessing spray deposition and quality across three nozzle types (XRC, AIXR, and TTI). The following conclusions can be drawn from the results obtained in the study:

- For CNS, an increase in the ground speed decreased the quantity of spray droplets applied per unit area and consequently reduced the spray deposition;

- For SRC, the quality of spray droplets and the spray deposition was more consistent among the ground speeds due to the flow rate adjustments (and accordingly spray pressure changes) by the rate controller as ground speed increased;

- Spray quality variations (difference in droplet size distributions) with an increase in the ground speed were observed for both CNS and SRC. However, these variations were greater for SRC because of the changes in spray pressure with ground speed;

- Among nozzle types, the trends in spray deposition and quality were similar for the XRC and TTI nozzles as observed within each sprayer setup (CNS and SRC). The AIXR nozzle exhibited inconsistent spray deposition and quality as ground speed varied.

5. Implications and Future Research

Ground speed variations during pesticide applications are common and can considerably affect both spray deposition and quality as shown by the results of this study. Inadequate coverage can further result in reduced pesticide efficacy, thereby leading to poor pest control. The findings from this study suggest that agricultural sprayers equipped with a rate controller can provide adequate and consistent spray deposition when ground speed variations occur during pesticide applications. The study also highlights one of the limitations associated with a rate controller, which is the degradation of spray quality and production of greater drift-susceptible finer sprayer droplets, due to an increase in spray pressure with ground speed. This is more concerning for pesticide applications that require using a certain droplet size(s) to attain adequate coverage, such as fine-to-medium spray droplets for fungicide applications, or to mitigate spray drift such as ultra-coarse droplets for auxin herbicide applications. Minimizing spray drift while maintaining adequate spray coverage is challenging, yet an important consideration for effective pesticide applications. Therefore, best management practices including proper nozzle selection and application within the nominal ground speed range should always be followed for effective technology utilization. Additionally, since advanced spray technologies such as PWM systems (that maintains a constant spray pressure while also regulating flow to achieve target application rate) are available today to utilize on agricultural sprayers, future research efforts need to investigate the effect of PWM system on spray deposition and quality during pesticide applications. These studies should also consider spray performance assessment for conventional and PWM-compatible nozzles at varying duty cycles.

Author Contributions

Conceptualization, M.S. and S.V.; methodology, M.S. and S.V.; investigation, S.V. and M.S.; writing—original draft preparation, M.S. and S.V.; writing—review and editing, M.S., S.V. and G.R.; visualization, S.V. and M.S.; supervision, S.V.; funding acquisition, S.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Georgia Peanut Commission and the National Peanut Board.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors would also like to thank the farm manager and the staff of the University of Georgia Southeast Research and Education Center for their assistance with planting, spray applications, maintaining research fields, data collection, and harvest.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| AI | Air Induction |

| AIXR | Air Induction Extended Range |

| CNS | Conventional Sprayer without a rate controller |

| PWM | pulse width modulation |

| SRC | Sprayer equipped with a rate controller |

| TTI | Turbo-Teejet Induction |

| VMD | Volume Median Diameter |

| WSP | Water Sensitive Paper |

| XRC | Extended Range |

| Spray Quality | |

| VF | Very Fine |

| F | Fine |

| M | Medium |

| C | Coarse |

| VC | Very Coarse |

| EC | Extremely Coarse |

| UC | Ultra-Coarse |

References

- [USDA-NASS]. United States Department of Agriculture-National Agricultural Statistics Service. 2021 Agricultural Chemical Use Highlights. 2022. Available online: https://www.nass.usda.gov/Surveys/Guide_to_NASS_Surveys/Chemical_Use/ (accessed on 13 November 2022).

- Fernandez-Cornejo, J.; Nehring, R.F.; Osteen, C.; Wechsler, S.; Martin, A.; Vialou, A. Pesticide Use in US Agriculture: 21 Selected Crops, 1960–2008; USDA-ERS Economic Information Bulletin 124; United States Department of Agriculture: Washington, DC, USA, 2014. [Google Scholar] [CrossRef]

- [USDA-NASS]. United States Department of Agriculture-National Agricultural Statistics Service. 2021 U.S. Farm Production Expenditures. 2022. Available online: https://www.nass.usda.gov/Publications/Highlights/2022/2021_FarmExpenditures.pdf (accessed on 11 November 2022).

- Al-Gaadi, K.; Ayers, P. Monitoring controller-based field sprayer performance. Appl. Eng. Agric. 1994, 10, 205–208. [Google Scholar] [CrossRef]

- Ayers, P.; Rogowski, S.; Kimble, B. An investigation of factors affecting sprayer control system performance. Appl. Eng. Agric. 1990, 6, 701–706. [Google Scholar] [CrossRef]

- Luck, J.; Zandonadi, R.; Luck, B.; Shearer, S. Reducing pesticide over-application with map-based automatic boom section control on agricultural sprayers. Trans. ASABE 2010, 53, 685–690. [Google Scholar] [CrossRef]

- Sharda, A.; Fulton, J.P.; McDonald, T.P.; Zech, W.C.; Darr, M.J.; Brodbeck, C.J. Real-time pressure and flow dynamics due to boom section and individual nozzle control on agricultural sprayers. Trans. ASABE 2010, 53, 1363–1371. [Google Scholar] [CrossRef]

- Butts, T.R.; Samples, C.A.; Franca, L.X.; Dodds, D.M.; Reynolds, D.B.; Adams, J.W.; Zollinger, R.K.; Howatt, K.A.; Fritz, B.K.; Clint Hoffmann, W. Spray droplet size and carrier volume effect on dicamba and glufosinate efficacy. Pest Manag. Sci. 2018, 74, 2020–2029. [Google Scholar] [CrossRef] [PubMed]

- Virk, S.; Meena, R. Pulse Width Modulation Technology for Agricultural Sprayers. University of Georgia Cooperative Extension, Athens, GA. Circular 1277; 2022; pp. 1–8. Available online: https://extension.uga.edu/publications/detail.html?number=C1277 (accessed on 14 February 2023).

- Miller, P.; Smith, R. The effects of forward speed on the drift from boom sprayers. In Proceedings of the Brighton Crop Protection Conference, Weeds, Brighton, UK, 17–20 November 1997. [Google Scholar]

- Taylor, W.; Anderson, P.; Cooper, S. The use of air assistance in a field crop sprayer to reduce drift and modify drop trajectories. In Proceedings of the Brighton Crop Protection Conference, Weeds, Brighton, UK, 20–23 November 1989. [Google Scholar]

- Hofman, V.; Solseng, E. Reducing Spray Drift. North Dakota State University Extension Service; Agricultural and Biosystems Engineering: Fargo, ND, USA, 2001; Available online: http://hdl.handle.net/10365/5111 (accessed on 11 November 2022).

- Nuyttens, D.; De Schampheleire, M.; Baetens, K.; Sonck, B. The influence of operator-controlled variables on spray drift from field crop sprayers. Trans. ASABE 2007, 50, 1129–1140. [Google Scholar] [CrossRef]

- Virk, S.; Prostko, E.; Kemerait, R.; Abney, M.; Rains, G.; Powell, C.; Carlson, D.; Jacobs, J.; Tyson, W. On-Farm Evaluation of Nozzle Types for Peanut Pest Management Using Commercial Sprayers. Peanut Sci. 2021, 48, 87–96. [Google Scholar] [CrossRef]

- Ozkan, H.; Womac, A. Best Management Practices for Boom Spraying. Ohio State University Extension Publication AEX-527-05. 2005. Available online: https://ohioline.osu.edu/factsheet/fabe-527 (accessed on 11 November 2022).

- ASABE S572.3; Spray Nozzle Classification by Droplet Spectra. American Society of Agricultural Biological Engineers: St. Joseph, MI, USA, 2020.

- Ramsdale, B.K.; Messersmith, C.G. Drift-reducing nozzle effects on herbicide performance. Weed Technol. 2001, 15, 453–460. [Google Scholar] [CrossRef]

- Etheridge, R.E.; Womac, A.R.; Mueller, T.C. Characterization of the spray droplet spectra and patterns of four venturi-type drift reduction nozzles. Weed Technol. 1999, 13, 765–770. [Google Scholar] [CrossRef]

- Lund, I. Nozzles for drift reduction. Asp. Appl. Biol. 2000, 57, 97–102. [Google Scholar]

- Carter, O.; Prostko, E.; Davis, J. The influence of nozzle type on peanut weed control programs. Peanut Sci. 2017, 44, 93. [Google Scholar] [CrossRef]

- Bouse, L.; Kirk, I.; Bode, L. Effect of spray mixture on droplet size. Trans. ASAE 1990, 33, 783–0788. [Google Scholar] [CrossRef]

- Hanna, M.; Kruckeberg, J.; Darr, M.; Steward, B. Nozzle and droplet size effects on pesticide performance and drift. In Proceedings of the 21st Annual Integrated Crop Management Conference, Ames, IA, USA, 1 December 2009; Iowa State University: Ames, IA, USA, 2009; pp. 49–52. [Google Scholar]

- Taylor, W.; Womac, A.; Miller, P.; Taylor, B. An Attempt to Relate Drop Size to Drift Risk. In Proceedings of the International Conference on Pesticide Application for Drift Management, Waikoloa, HI, USA, 27–29 October 2004; Washington State University: Pullman, WA, USA, 2004; pp. 210–213. [Google Scholar]

- Yates, W.E.; Cowden, R.E.; Akesson, N.B. Drop size spectra from nozzles in high-speed airstreams. Trans. ASAE 1985, 28, 405–0410. [Google Scholar] [CrossRef]

- TeeJet Technologies. A User Guide to Spray Nozzles. 2013. Available online: http://www.teejet.com/ (accessed on 11 November 2022).

- Ferguson, J.C.; Hewitt, A.J.; O’Donnell, C.C. Pressure, droplet size classification, and nozzle arrangement effects on coverage and droplet number density using air-inclusion dual fan nozzles for pesticide applications. Crop Prot. 2016, 89, 231–238. [Google Scholar] [CrossRef]

- Carroll, J. The Effects of Sprayer Speed and Droplet Size on Herbicide Burndown Efficacy. Master’s Thesis, University of Arkansas, Fayetteville, AK, USA, 2017. Available online: https://scholarworks.uark.edu/etd/2435 (accessed on 11 November 2022).

- Ozkan, H.E.; Zhu, H. Effects of Major Variables on Drift Distances of Spray Droplets; Ohio State Cooperative Extension: Columbus, OH, USA, 1998; pp. 525–598. [Google Scholar]

- Wolf, T.M.; Grover, R.; Wallace, K.; Shewchuk, S.R.; Maybank, J. Effect of protective shields on drift and deposition characteristics of field sprayers. Can. J. Plant Sci. 1993, 73, 1261–1273. [Google Scholar] [CrossRef]

- Van de Zande, J.; Stallinga, H.; Michielsen, J.; Van Velde, P. Effect of sprayer speed on spray drift. Annu. Rev. Agric. Eng. 2005, 4, 129–142. [Google Scholar]

- Al Heidary, M.; Douzals, J.P.; Sinfort, C.; Vallet, A. Influence of spray characteristics on potential spray drift of field crop sprayer: A literature review. Crop Prot. 2014, 63, 120–130. [Google Scholar] [CrossRef]

- ASABE S592.1; Best Management Practices for Boom Spraying. American Society of Agricultural Biological Engineers: St. Joseph, MI, USA, 2020.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).