Abstract

The canned fruits industry utilizes high amounts of water and energy, which results in the generation of vast quantities of wastewater and solid waste. The main scope of this study was to compare the environmental footprint of a canned fruits industry (alternative scenario) equipped with appropriate processes (pulsed electric fields, anaerobic digestion, composting, membrane bioreactors, and ultraviolet treatment) that sufficiently save energy and valorize production wastes to a typical setup that uses conventional waste methods (conventional scenario) via conducting a life cycle assessment study. Based on the results, the life cycle assessment confirmed the fact that the incorporation of the proposed methods, as described in the alternative scenario, dramatically reduced the environmental footprint of the industry, with certain environmental impact categories reaching a decrease of up to 90.00%. More specifically, according to the obtained results, a decrease of 11.81, 64.56, and 89.79% in regards to climate change, freshwater ecotoxicity, and freshwater consumption, respectively, was achieved in the alternative scenario compared to the conventional method. The study verified the environmental advantages of integrating such energy saving and waste treatment/valorization technologies across the canned fruits industry’s processing chain, contributing to environmental sustainability and safety.

1. Introduction

Fruits are among the most consumed foods worldwide and represent an integral part of a healthy and balanced diet due to the nutrients they contain, such as vitamins and minerals [1,2]. However, the production of fresh fruits is seasonal, thus they are commonly consumed after processing, mainly in the form of canned fruits. Moreover, the growing demand for healthy and ready-to-eat food products further strengthens the position of the canned fruit industry in the global market [3]. Although the canned fruit industry offers a sustainable solution for the consumption of nutritious food throughout the year and for their transportation all over the world, as an industrial branch, it is associated with high energy demands, high water consumption, and the production of a large volume of solid wastes, leading to a large environmental footprint [4,5,6]. Therefore, efforts have been focused on energy savings, wastewater treatment, and solid waste utilization, with the ultimate goal of promoting environmentally sustainable solutions for the canned food industry. Moreover, the continuous impact of global events further hinders sustainable development; thus, the significance of research regarding the conversion of solid wastes into value added products and energy carriers is further solidified [7].

Several methods have been studied for energy savings and for the treatment of wastewater and solid waste generated by the canned fruit industries. Among them, the most appealing ones, due to their high efficiency and the fact that they are environmentally friendly, are pulsed electric fields (PEF) processing, membrane bioreactors, ultraviolet (UV) treatment, anaerobic digestion, and digestate thickening. A necessary step in the canned fruit industry is the peeling of fruits, which is often achieved with steam or lye peeling and is characterized as a high energy-intensive process [8]. PEF is a non-thermal and low-energy process that utilizes short high voltage electric pulses, resulting in the electroporation (tissue softening) of fruits without altering their nutritional compounds, thus facilitating the peeling process [9]. Membrane bioreactors constitute a new wastewater treatment method that combines physical separation with biological treatment, producing effluents of higher quality than those obtained from the conventional aeration process [10]. UV treatment, which exposes water to ultraviolet light to deactivate hazardous microorganisms such as bacteria and viruses represents an efficient method for the disinfection of treated water [11].

Valorization of solid wastes, such as fruit peels, from the canned fruit industry can be achieved via an anaerobic fermentation process (anerobic digestion), in which microorganisms effectively break down organic material to produce biogas [12]. The biogas is then introduced into a biogas cogeneration (combined heat and transfer—CHP) unit where it produces heat and electricity, both of which are forms of renewable energy [13]. The solid by-product of anaerobic digestion (digestate), which can be used in composting to further increase the circularity of solid wastes, is another benefit of the process [14]. The adoption and implementation of the methods listed above not only reduce the overall amount of the wastes produced, but also provide an opportunity to recover water of high quality, generate renewable energy, increase (to some extent) the self-sufficiency of the industry, lower the operating costs, and significantly enhance the environmental footprint of the canned fruit industry [15].

Nevertheless, in order to compare the aforementioned techniques to the current conventional methods, it is required to confirm their environmental advantages and behavior. The International Organization for Standardization (ISO 14040:2006) has defined life cycle assessment (LCA) as a validated tool for evaluating the environmental behavior of processes, products, and services [16]. LCA analyzes a product system’s inputs, outputs, and potential environmental consequences over the course of its life cycle. It can identify problem areas and suggest changes to the manufacturing process that would improve environmental sustainability [17]. LCA can be carried out using either of two basic methodologies, attributional or consequential. The latter, used in this work, concentrates on forecasting the impact of changes in established procedures, whereas the former reports the environmental properties of a current system state [18,19]. The life cycle impact indicators can also be measured using a variety of techniques, such as ReCiPE, EDIP, and CML, which commonly show different impact categories, inventory classifications, and model characterizations [17].

The main purpose of this study was to document the environmental benefits of adopting appropriate methods in the industrial sector, to raise public awareness regarding the need for environmental protection, and to direct the research and industrial community towards the adoption of environmentally safe practices by assessing the environmental effect of various technologies in the field of wastewater treatment and solid waste utilization in canned fruit industries. To achieve that goal, a conventional scenario of a canned fruits industry was studied first to demonstrate the environmental effects of the respective industry and the requirements to efficiently treat and utilize the wastewater and solid wastes, respectively. Thereafter, a different scenario was investigated in which appropriate methods were used, both in the production process (PEF) and for waste utilization (MBR, UV treatment, anaerobic digestion and CHP), with the aim of highlighting the environmental advantages of the proposed processes. The novelty of the present study lies in the fact that it makes a direct comparison between the conventional production process of canned fruits and a production equipped with proper methods that are not yet applied on a large scale, enhancing sustainability, the circular economy, and environmental safety. Furthermore, the various methods that are studied for energy saving, wastewater treatment, and waste valorization have not been previously incorporated into one investigstion, thus providing a further novel aspect in our study.

2. Materials and Methods

LCA analysis was carried out in accordance with the ISO 14040 series of guidelines (14040:2006 and 14044:2006). The impact assessment technique ReCiPe 2016 (H, hierarchist) was adopted, and its primary goal was to convert the data of the life cycle inventory into a finite number of environmental effect scores using characterization elements. The impact categories were calculated using GABI ts software (Version 10.6.2.9, Sphera Solutions GmbH, Echterdingen, Stuttgard, Germany).

2.1. Goal and Scope

The objective of the LCA research was to ascertain the outcome on several environmental impact categories for implementing various wastewater and solid waste treatment techniques in a typical canned fruits industry. To begin with, the environmental effect of a typical canned fruit industry was evaluated based on data acquired from published studies. Afterwards, a different scenario was studied, according to the literature, in which various methods for wastewater treatment and waste valorization were incorporated into the system.

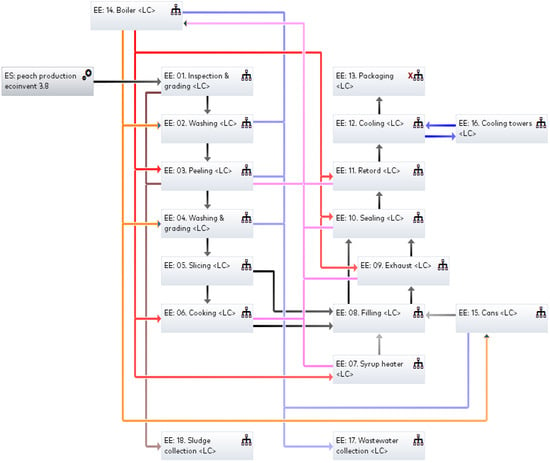

A conventional canned peach industry was used as the base case of the present study, with canned peaches being the final product. The production processes, along with all the relative flows, are presented in Figure 1. The main processes involved in the canning of peaches include:

Figure 1.

Canned peaches production flowchart.

- Inspection and grading;

- Washing;

- Peeling;

- Washing and grading;

- Slicing;

- Filling;

- Sealing;

- Cooling;

- Packaging.

The flows that are involved in the overall production are highlighted in different colors to provide a better classification. The flows depicted with black and dark blue correspond to the flows related to the used fruits and cold water, respectively, while the pink flows are related to the condensate. Finally, brown and red flows correspond to heated water and steam, respectively.

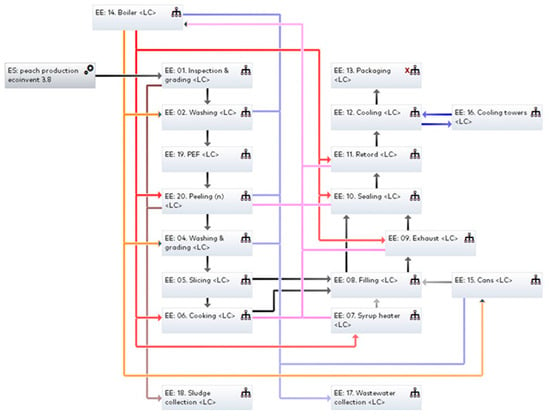

In the conventional scenario (Figure 2), for the treatment of the produced wastewater and solid wastes, wastewater was transferred and treated in a municipal wastewater treatment plant, while solid wastes were landfilled. According to this scenario, the canned fruits industry does not play an active role in the treatment and utilization of its waste, a practice that in previous years, was common within the industrial sector.

Figure 2.

Wastewater and solid wastes treatment in the conventional scenario.

According to the alternative scenario, PEF is incorporated in the production of canned peaches (Figure 3), and the produced wastewater and solid wastes are treated and valorized within the boundaries of the industry. Wastewater is specifically passed through screens to remove large solids, then processed in a membrane bioreactor, and subsequently treated with UV light. The resulting water will be of sufficient quality that it may either be recycled in industry to reduce the consumption of fresh water, or safely discharged into the aquatic environment. Solid wastes are processed in an anaerobic digester, and the resultant biogas is utilized to generate power and heat through cogeneration. A necessary treatment for the removal of CO2 and to increase the content of biogas in methane is required prior to cogeneration [20]. For economic viability, the produced electric power is sold to the grid as green energy, since it is highly subsidized, while the generated heat is returned to the anaerobic digester. Ultimately, the digestate is dewatered and transported in a composting unit. For the determination of the environmental footprint of the conventional scenario, literature data were used based on simple mass and energy balances, while for the alternative scenario, the determination was based on equations found in the cited literature and in the table entitled “Life cycle inventory (LCI) of alternative scenario”. A detailed flowchart of the wastewater and solid waste treatment is depicted in Figure 4.

Figure 3.

Canned peaches production (equipped with PEF) flowchart.

Figure 4.

Wastewater and solid wastes treatment of alternative scenario.

2.2. Functional Unit

The selected functional unit for the present study was 1 kg of produced canned peaches.

2.3. System Boundaries

A gate-to-gate approach was selected for the evaluation of the environmental footprint of a typical canned fruits industry. More specifically, the boundaries of the system encompass all the production processes from peach production to packaging, with the final products being excluded from the system boundaries. Moreover, a similar approach was selected for the two studied scenarios (conventional and alternative), consisting of the production processes and the wastewater and solid wastes treatment methods.

2.4. Data Requirements

In order to perform the LCA analysis, appropriate data were collected from published studies accessible in scientific journals, while verified databases (GABI professional and Ecoinvent), referring to the geographical area of European Union 28 (EU-28), were also used for data collection. In order for the results of the specific study to be representative and replicable, the selected studies and data refer to the last five years.

2.5. Assumptions and Limitations

The selected data in the production of canned fruits and in both studied scenarios are based on literature reviews; therefore, they may not accurately reflect the current state. As a result, there may be some ambiguity when estimating environmental footprints [21]. However, since the primary goal of this study was to confirm that the suggested methods were more environmentally friendly than the conventional approaches to handling solid and liquid wastes, it is not anticipated that this uncertainty will have an impact on the findings because it applies to both scenarios under consideration. Data were obtained from literature reviews and consist of both experimentally measured and simulation based values; however, the statistical error should not be higher than 15.0% and does not influence the final results, since it applies to both studied scenarios.

2.6. Life Cycle Inventory (LCI)

LCI links the processes with the corresponding quantitative data based on the adopted functional unit (1 kg of produced canned peaches). The input and output data of each involved production process, as depicted in Figure 1, are presented in Table 1. As mentioned previously, literature data were utilized for the establishment of the LCI; however, following communication with a canned peach producer located in Greece, proper modifications were made to verify the accuracy of the data. Data modification and verification was based on the collection of 1 year data corresponding to 280 working days and a total production of 800,000 kg of canned peaches.

Table 1.

Life cycle inventory (LCI) of a conventional canned peaches industry (according to [22] and modified to current data via communication with an producer located in Greece).

The input and output data for every process involved in conventional wastewater and solid wastes treatment (Figure 2) are presented in Table 2, while Table 3 exhibits the data of the processes included in the alternative scenario (PEF, screening, membrane bioreactor, UV treatment, anaerobic digestion, and CHP).

Table 2.

Life cycle inventory (LCI) of conventional scenario.

Table 3.

Life cycle inventory (LCI) of alternative scenario.

2.7. Uncertainty Analysis

The main processes that may influence the obtained results from the two studied scenarios include pulsed electric fields, membrnae bioreactors, and anaerobic digestion. However, from the life cycle inventory, it is evident that the energy consumption associated with PEF and MBR is relatively low; thus, any variations in these values will not affect the obtained results. However, the capacity of the anaerobic digester in biogas production may significantly affect the environmental footprint of the alternative scenario; therefore, a sensitivity analysis was carried out regarding its efficiency. More specifically, two additional values for biogas production were studied (0.061 and 0.217 cm3 CH4/kg VS) based on the literature, while the median of these values was selected for the initial study of the alternative scenario [27].

3. Results and Discussion

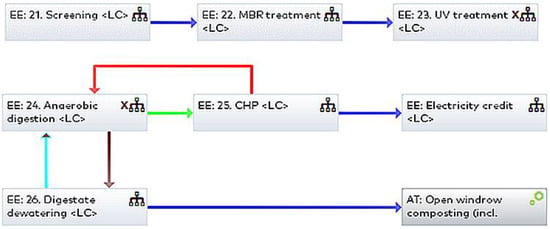

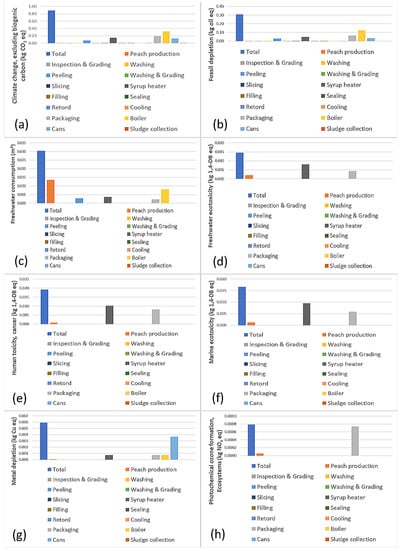

The total environmental effect of a conventional canned peach industry, along with the environmental impact of each separate process, are depicted in Figure 5.

Figure 5.

Environmental impact of the canned peach industry on (a) climate change (kg CO2 eq), (b) fossil depletion (kg oil eq), (c) freshwater consumption (m3), (d) freshwater ecotoxicity (kg 1,4-DB eq), (e) human toxicity—cancer (kg 1,4-DB eq), (f) marine ecotoxicity (kg 1,4-DB eq), (g) metal depletion (kg Cu eq), and (h) photochemical ozone formation—ecosystems (kg NOx eq).

Based on the results of the LCA analysis, the canned peach industry can be characterized as an energy intensive industrial sector resulting in the production of considerable amounts of wastewater and solid wastes. Moreover, a severe environmental effect on various studied categories is observed. In general, the most harmful of the environment processes include peach production, the peeling of fruits, the boiler, syrup heating, and can washing. It must be noted that the environmental effect of the cooking and exhaust processes are included in the environmental footprint of the boiler, since they utilize hot water and steam, thereby further burdening its footprint. More specifically, approximately 0.95 kg CO2 and 0.03 kg 1,4 DB eq, related to human toxicity (cancer), are generated per 1 kg of canned peaches, with the freshwater consumption reaching up to 0.02 m3/kg canned peaches.

The results of the LCA analysis are directly related to previous published studies. According to studies in the production of peach products conducted in the Mediterranean region (Spain and Italy), the carbon footprint of the overall process ranges between 0.90 and 1.24 kg CO2 eq/kg of peach products [29,30]. Additionally, noteworthy environmental impacts were detected for all the other studied indices, including freshwater ecotoxicity, marine ecotoxicity, and fossil depletion (0.04 kg 1,4-DB eq/kg canned peaches, 0.03 kg 1,4-DB eq/kg canned peaches, and 0.34 kg oil eq/kg canned peaches, respectively). Therefore, it is vital to implement appropriate techniques for waste utilization, water purification, and energy savings within the canned peaches industry to reduce its environmental impact in the context of environmental protection, sustainability, and circular economy. Based on the aforementioned, two distinct scenarios were chosen for this study; the first postulates that the industry is not directly involved in the treatment and valorization of its waste, whereas the latter hypothesizes that appropriate methods are implemented for energy savings, the disposal of solid wastes, and wastewater treatment.

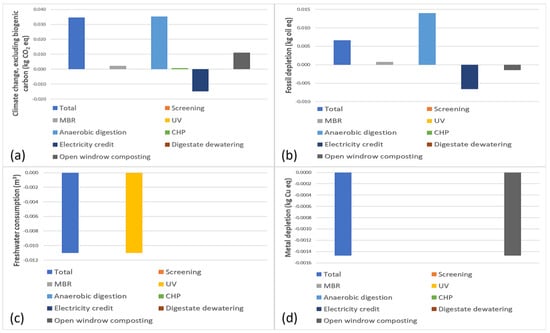

3.1. Effect of PEF Treatment

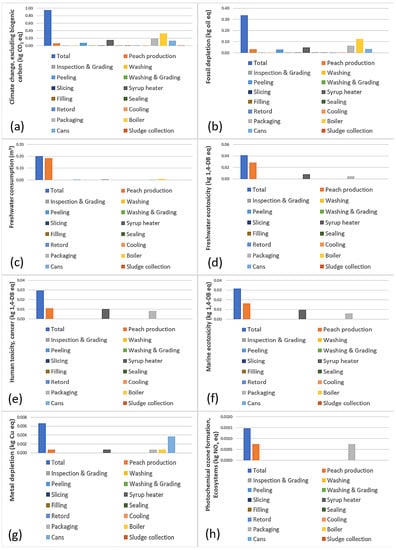

PEF is an innovative technique that can be utilized prior to peeling in order to reduce the energy and water consumption of this specific process. The environmental effect of utilizing PEF in the peeling of peaches is shown in Figure 6, while a direct comparison of the conventional production and the production equipped with PEF is presented in Table 4.

Figure 6.

Environmental impact of the canned peach industry equipped with PEF on (a) climate change (kg CO2 eq), (b) fossil depletion (kg oil eq), (c) freshwater consumption (m3), (d) freshwater ecotoxicity (kg 1,4-DB eq), (e) human toxicity—cancer (kg 1,4-DB eq), (f) marine ecotoxicity (kg 1,4-DB eq), (g) metal depletion (kg Cu eq), and (h) photochemical ozone formation—ecosystems (kg NOx eq).

Table 4.

Comparison of the environmental effect of a conventional canned peach industry and a canned peach industry equipped with PEF.

According to the results, the integration of PEF in the production results in a decrease in all studied indicators, thus improving the environmental footprint of the industry. The most notable reduction in the environmental footprint from the incorporation of PEF is reflected in the indicators related to water consumption and the quality of aquatic ecosystems. More specifically, the reduction in freshwater consumption, freshwater ecotoxicity, and marine ecotoxicity amounts to 84.88, 64.56, and 47.46%, respectively. This specific result captures all the advantages of using PEF, since its use significantly reduces the water demand during the peeling of fruits, while simultaneously conserving energy [31,32].

3.2. Comparison of Conventional and Alternative Treatment of Wastewater and Solid Wastes

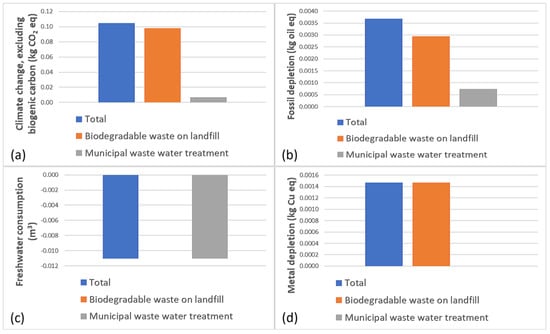

The overall environmental effect of the two studied scenarios regarding the treatment of wastewater and solid wastes (conventional and alternative) is presented in Figure 7 and Figure 8, with a direct comparison of the conventional and the alternative treatment presented in Table 5.

Figure 7.

Environmental impact of the conventional wastewater and solid wastes treatment on (a) climate change (kg CO2 eq), (b) fossil depletion (kg oil eq), (c) freshwater consumption (m3), and (d) metal depletion (kg Cu eq).

Figure 8.

Environmental impact of the alternative wastewater and solid waste treatment on (a) climate change (kg CO2 eq), (b) fossil depletion (kg oil eq), (c) freshwater consumption (m3), and (d) metal depletion (kg Cu eq).

Table 5.

Comparison of the environmental effects of conventional and alternative wastewater and solid waste treatment.

From the obtained findings of the LCA analysis of the conventional and the alternative wastewater and solid waste treatment, it can be concluded that the alternative treatment results in a significant decrease in greenhouse gas emissions (66.73%), which can be attributed to the valorization of solid wastes rather than disposing them as waste on land for landfilling purposes. On the other hand, the demand of anaerobic digestion for fuel consumption leads to an increase in fossil depletion in the alternative scenario, compared to the conventional method. Finally, the utilization of the digestate for composting leads to the valorization of waste metal, resulting in a positive environmental impact in this specific category [33].

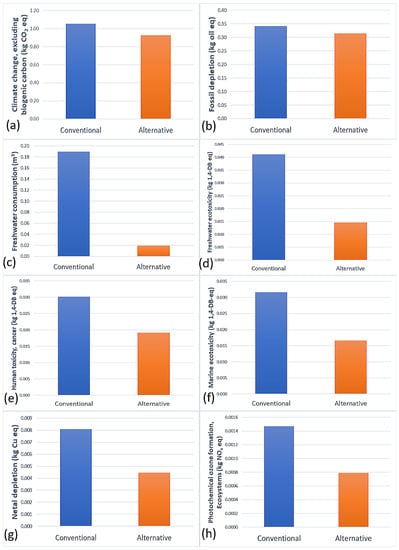

3.3. Comparison of Conventional and Alternative Studied Scenarios

The overall environmental effect of the two studied scenarios regarding the production of canned peaches and the treatment of wastewater and solid wastes is shown in Figure 9, with the overall reduction in the environmental footprint presented in Table 6.

Figure 9.

Environmental impact of the conventional and the alternative scenario on (a) climate change (kg CO2 eq), (b) fossil depletion (kg oil eq), (c) freshwater consumption (m3), (d) freshwater ecotoxicity (kg 1,4-DB eq), (e) human toxicity—cancer (kg 1,4-DB eq), (f) marine ecotoxicity (kg 1,4-DB eq), (g) metal depletion (kg Cu eq), and (h) photochemical ozone formation—ecosystems (kg NOx eq).

Table 6.

Comparison of the environmental effect of a conventional canned peach industry and a canned peach industry equipped with appropriate methods for energy saving and wastes valorization.

The use of innovative techniques aimed at energy conservation, wastewater purification, and solid waste valorization has significantly improved the environmental footprint of the canned peach industry across all studied categories, as shown by a direct comparison of the two researched scenarios. Utilizing the four cutting-edge technologies (PEF, membrane bioreactors, anaerobic digestion, and UV treatment) reduced freshwater consumption, metal and fossil depletion, and the quantity of generated greenhouse gases. Particularly, the significant decrease in freshwater consumption and freshwater ecotoxicity (89.79 and 64.56%, respectively) achieved in the alternative is a clear indication that environmental sustainability and ecosystem preservation are achievable through energy-saving, the valorization of wastes, and the adoption of cutting-edge, environmentally friendly treatment techniques. In order to better depict the improvement of the environmental footprint achieved in the alternative scenario, the obtained results are compared with results from similar studies (Table 7).

Table 7.

Comparison of the environmental effect of the studied alternative canned peach industry and those of similar studies (kg CO2 eq/kg of product).

The observed significant improvement in the environmental footprint in the alternative scenario demonstrates the benefits of implementing novel methods in the production process, the treatment of the wastewater, and the valorization of solid wastes, thus confirming and contributing to the existing literature regarding environmental safety and sustainability. Finally, it must be noted that apart from the LCA analysis, other advanced sustainability assessment tools (i.e., exergy analysis including exergoeconomic and exergoenvironmental analyses) could also be employed for study, offering some interesting insights into the sustainability of the proposed alternative scenario [38,39,40]

3.4. Uncertainty Analysis

The results of the uncertainty analysis are presented in Table 8.

Table 8.

Results of the uncertainty analysis regarding the efficiency of anaerobic digestion.

According to the results of the uncertainty analysis, it is evident that the environmental footprint of the alternative scenario does not change significantly as a function of the anaerobic digester’s biogas production capacity. In particular, the indicators related to freshwater consumption and quality do not alter at all, while a small change (approximately 1.5%) is observed for greenhouse gas emissions, with the high efficiency exhibiting a slightly better environmental footprint.

4. Conclusions and Future Directions

In order to assess their environmental impact using LCA analysis, two distinct scenarios of wastewater and solid waste treatment generated by the production of canned peaches were investigated. In the first scenario (conventional), wastewater was transported to a municipal wastewater treatment facility, while solid wastes were disposed of as non-hazardous wastes in landfills. In the alternative scenario, energy saving and waste treatment technologies were applied within the boundaries of the industry. Generally, the use of PEF and appropriate waste treatment technologies significantly reduced the environmental impact. Due to the energy and heat produced during cogeneration, anaerobic digestion exhibited the greatest environmental performance among the wastewater and solid waste treatment technologies examined in the alternative scenario. Even though thermal energy is required to heat the biomass during anaerobic digestion, this energy is significantly reduced by using the thermal energy generated in the cogeneration process. Furthermore, the water obtained in the alternative scenario is of a high standard; thus, it can be considered as safe for the environment; as a result, it may either be reused to lessen the industry’s environmental impact, or utilized for other means, such as agricultural purposes or aquatic discharge.

The current research findings imply that the proposed technology may be applied to advance towards the sustainable industrial production of canned fruits. The method described in this paper may also be generally applied to a variety of other food production systems to examine their environmental impacts and identify the key areas that require major improvement. In summary, according to the findings of the present study, it is imperative for the industrial sector to focus on and adopt environmentally friendly methods, replacing conventional ones, incorporating efficient methods for wastewater treatment and waste valorization that will further strengthen the context of sustainability and circular economy. For this purpose, it is necessary to focus on the investigation of novel methods, documenting their environmental and energy benefits through life cycle assessment studies.

Author Contributions

Conceptualization, F.D., T.K., and C.B.; methodology, C.B.; software, C.B.; validation, F.D., T.K., and C.B.; formal analysis, F.D. and T.K.; investigation, F.D. and T.K.; resources, C.B.; data curation, C.B.; writing—original draft preparation, F.D.; writing—review and editing, T.K.; visualization, C.B.; supervision, C.B.; project administration, C.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the data curation.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cui, J.; Lian, Y.; Zhao, C.; Du, H.; Han, Y.; Gao, W.; Xiao, H.; Zheng, J. Dietary Fibers from Fruits and Vegetables and Their Health Benefits via Modulation of Gut Microbiota. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1514–1532. [Google Scholar] [CrossRef]

- Dreher, M.L. Whole Fruits and Fruit Fiber Emerging Health Effects. Nutrients 2018, 10, 1833. [Google Scholar] [CrossRef] [PubMed]

- Vergara-Balderas, F.T. Canning: Process of Canning. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 628–632. ISBN 978-0-12-384953-3. [Google Scholar]

- Campos, D.A.; Gómez-García, R.; Vilas-Boas, A.A.; Madureira, A.R.; Pintado, M.M. Management of Fruit Industrial By-Products—A Case Study on Circular Economy Approach. Molecules 2020, 25, 320. [Google Scholar] [CrossRef] [PubMed]

- Parajuli, R.; Thoma, G.; Matlock, M.D. Environmental Sustainability of Fruit and Vegetable Production Supply Chains in the Face of Climate Change: A Review. Sci. Total Environ. 2019, 650, 2863–2879. [Google Scholar] [CrossRef] [PubMed]

- Swain, M.; Zimon, D.; Singh, R.; Hashmi, M.F.; Rashid, M.; Hakak, S. LoRa-LBO: An Experimental Analysis of LoRa Link Budget Optimization in Custom Build IoT Test Bed for Agriculture 4.0. Agronomy 2021, 11, 820. [Google Scholar] [CrossRef]

- Shams Esfandabadi, Z.; Ranjbari, M.; Scagnelli, S.D. The Imbalance of Food and Biofuel Markets amid Ukraine-Russia Crisis: A Systems Thinking Perspective. Biofuel Res. J. 2022, 9, 1640–1647. [Google Scholar] [CrossRef]

- Dadhe, P.S.; Mandavgane, S.A.; Kumar, A. Polyphenols in Fruit and Vegetable Peel Extract: Procedure of Selective Extraction and Method of Analysis. Biomass Convers. Biorefin. 2021. [Google Scholar] [CrossRef]

- Koch, Y.; Witt, J.; Lammerskitten, A.; Siemer, C.; Toepfl, S. The Influence of Pulsed Electric Fields (PEF) on the Peeling Ability of Different Fruits and Vegetables. J. Food Eng. 2022, 322, 110938. [Google Scholar] [CrossRef]

- Du, X.; Shi, Y.; Jegatheesan, V.; Haq, I.U. A Review on the Mechanism, Impacts and Control Methods of Membrane Fouling in MBR System. Membranes 2020, 10, 24. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Abbà, A.; Miino, M.C.; Caccamo, F.M.; Torretta, V.; Rada, E.C.; Sorlini, S. Disinfection of Wastewater by UV-Based Treatment for Reuse in a Circular Economy Perspective. Where Are We At? Int. J. Environ. Res. Public Health 2021, 18, 77. [Google Scholar] [CrossRef]

- dos Santos, L.A.; Valença, R.B.; da Silva, L.C.S.; de Barros Holanda, S.H.; da Silva, A.F.V.; Jucá, J.F.T.; Santos, A.F.M.S. Methane Generation Potential through Anaerobic Digestion of Fruit Waste. J. Clean Prod. 2020, 256, 120389. [Google Scholar] [CrossRef]

- Brémond, U.; Bertrandias, A.; Steyer, J.-P.; Bernet, N.; Carrere, H. A Vision of European Biogas Sector Development towards 2030: Trends and Challenges. J. Clean Prod. 2021, 287, 125065. [Google Scholar] [CrossRef]

- Song, B.; Manu, M.K.; Li, D.; Wang, C.; Varjani, S.; Ladumor, N.; Michael, L.; Xu, Y.; Wong, J.W.C. Food Waste Digestate Composting: Feedstock Optimization with Sawdust and Mature Compost. Bioresour. Technol. 2021, 341, 125759. [Google Scholar] [CrossRef]

- Fonseca, L.M.; Domingues, J.P.; Pereira, M.T.; Martins, F.F.; Zimon, D. Assessment of Circular Economy within Portuguese Organizations. Sustainability 2018, 10, 2521. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization [ISO]: Geneva, Switzerland, 2006.

- Askham, C. REACH and LCA—Methodological Approaches and Challenges. Int. J. Life Cycle Assess 2012, 17, 43–57. [Google Scholar] [CrossRef]

- Salemdeeb, R.; bin Daina, M.; Reynolds, C.; Al-Tabbaa, A. An Environmental Evaluation of Food Waste Downstream Management Options: A Hybrid LCA Approach. Int. J. Recycl. Org. Waste Agric. 2018, 7, 217–229. [Google Scholar] [CrossRef]

- Woodhouse, A.; Davis, J.; Pénicaud, C.; Östergren, K. Sustainability Checklist in Support of the Design of Food Processing. Sustain Prod. Consum. 2018, 16, 110–120. [Google Scholar] [CrossRef]

- Salman, C.A.; Schwede, S.; Naqvi, M.; Thorin, E.; Yan, J. Synergistic Combination of Pyrolysis, Anaerobic Digestion, and CHP Plants. Energy Procedia 2019, 158, 1323–1329. [Google Scholar] [CrossRef]

- Brandao, M.; Heijungs, R.; Cowie, A. On Quantifying Sources of Uncertainty in the Carbon Footprint of Biofuels: Crop/Feedstock, LCA Modelling Approach, Land-Use Change, and GHG Metrics. Biofuel Res. J. 2022, 9, 1608–1616. [Google Scholar] [CrossRef]

- Harry, L.B.; Bernard, B.; Hamel, B.A. Hedman Energy Analysis of 108 Industrial Processes; Fairmont Press: Philadelphia, PA, USA, 1987. [Google Scholar]

- Pataro, G.; Carullo, D.; Bakar Siddique, M.A.; Falcone, M.; Donsì, F.; Ferrari, G. Improved Extractability of Carotenoids from Tomato Peels as Side Benefits of PEF Treatment of Tomato Fruit for More Energy-Efficient Steam-Assisted Peeling. J. Food Eng. 2018, 233, 65–73. [Google Scholar] [CrossRef]

- Huber Technology Energy-Efficient Mechanical Pre-Treatment; Huber Publishing: Denver, CO, USA.

- Krzeminski, P.; van der Graaf, J.H.J.M.; van Lier, J.B. Specific Energy Consumption of Membrane Bioreactor (MBR) for Sewage Treatment. Water Sci. Technol. 2012, 65, 380–392. [Google Scholar] [CrossRef]

- Longo, S.; d’Antoni, B.M.; Bongards, M.; Chaparro, A.; Cronrath, A.; Fatone, F.; Lema, J.M.; Mauricio-Iglesias, M.; Soares, A.; Hospido, A. Monitoring and Diagnosis of Energy Consumption in Wastewater Treatment Plants. A State of the Art and Proposals for Improvement. Appl. Energy 2016, 179, 1251–1268. [Google Scholar] [CrossRef]

- Jiménez-Castro, M.P.; Buller, L.S.; Zoffreo, A.; Timko, M.T.; Forster-Carneiro, T. Two-Stage Anaerobic Digestion of Orange Peel without Pre-Treatment: Experimental Evaluation and Application to São Paulo State. J. Environ. Chem. Eng. 2020, 8, 104035. [Google Scholar] [CrossRef]

- Vondra, M.; Máša, V.; Bobák, P. The Energy Performance of Vacuum Evaporators for Liquid Digestate Treatment in Biogas Plants. Energy 2018, 146, 141–155. [Google Scholar] [CrossRef]

- Nanaki, E.A.; Koroneos, C.J. Sustainable Peach Compote Production: A Life Cycle Thinking Approach. Sustainability 2018, 10, 4229. [Google Scholar] [CrossRef]

- Núñez-Cárdenas, P.; San Miguel, G.; Báñales, B.; Álvarez, S.; Diezma, B.; Correa, E.C. The Carbon Footprint of Stone Fruit Production: Comparing Life Cycle Assessment Process-Based and Environmentally Extended Input-Output Analysis. J. Clean Prod. 2022, 381, 135130. [Google Scholar] [CrossRef]

- Hossain, M.B.; Aguiló-Aguayo, I.; Lyng, J.G.; Brunton, N.P.; Rai, D.K. Effect of Pulsed Electric Field and Pulsed Light Pre-Treatment on the Extraction of Steroidal Alkaloids from Potato Peels. Innov. Food Sci. Emerg. Technol. 2015, 29, 9–14. [Google Scholar] [CrossRef]

- Gómez, B.; Munekata, P.E.S.; Gavahian, M.; Barba, F.J.; Martí-Quijal, F.J.; Bolumar, T.; Campagnol, P.C.B.; Tomasevic, I.; Lorenzo, J.M. Application of Pulsed Electric Fields in Meat and Fish Processing Industries: An Overview. Food Res. Int. 2019, 123, 95–105. [Google Scholar] [CrossRef]

- Basu, P. Chapter 2—Biomass Characteristics. In Biomass Gasification and Pyrolysis; Basu, P., Ed.; Academic Press: Boston, MA, USA, 2010; pp. 27–63. ISBN 978-0-12-374988-8. [Google Scholar]

- Sachakamol, P.; Ngarmsa-Ard, P. Life Cycle Sssessment of Canned Sweet Corn in Chiang Mai. In Proceedings of the Managing Intellectual Capital and Innovatio for Sustainable and Inclusive Society; ToKnowPress: Bangkok, Thailand, 2015; pp. 1093–1101. [Google Scholar]

- Karakaya, A.; Özilgen, M. Energy Utilization and Carbon Dioxide Emission in the Fresh, Paste, Whole-Peeled, Diced, and Juiced Tomato Production Processes. Energy 2011, 36, 5101–5110. [Google Scholar] [CrossRef]

- Saikeaw, N.; Pridasawas, W.; Tia, S.; Sudaprasert, K. Improving a Canned Lychee Production by a Life Cycle Assessment I-SEEC 2012 Improving a Canned Lychee Production by a Life Cycle Assessment; I-SEEC: Japan, Tokyo, 2013. [Google Scholar]

- CarbonCloud Canned Pineapple w. Juice. Available online: https://apps.carboncloud.com/climatehub/product-reports/id/84223195698#:~:text=%E2%80%9DCanned%20pineapple%20w.,kg%20CO2e%2Fkg (accessed on 23 January 2023).

- Aghbashlo, M.; Hosseinzadeh-Bandbafha, H.; Shahbeik, H.; Tabatabaei, M. The Role of Sustainability Assessment Tools in Realizing Bioenergy and Bioproduct Systems. Biofuel Res. J. 2022, 9, 1697–1706. [Google Scholar] [CrossRef]

- Soltanian, S.; Kalogirou, S.A.; Ranjbari, M.; Amiri, H.; Mahian, O.; Khoshnevisan, B.; Jafary, T.; Nizami, A.-S.; Gupta, V.K.; Aghaei, S.; et al. Exergetic Sustainability Analysis of Municipal Solid Waste Treatment Systems: A Systematic Critical Review. Renew. Sustain. Energy Rev. 2022, 156, 111975. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Khounani, Z.; Hosseinzadeh-Bandbafha, H.; Gupta, V.K.; Amiri, H.; Lam, S.S.; Morosuk, T.; Tabatabaei, M. Exergoenvironmental Analysis of Bioenergy Systems: A Comprehensive Review. Renew. Sustain. Energy Rev. 2021, 149, 111399. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).