Levels of Whole-Body Vibrations Transmitted to the Driver of a Tractor Equipped with Self-Levelling Cab during Soil Primary Tillage

Abstract

:1. Introduction

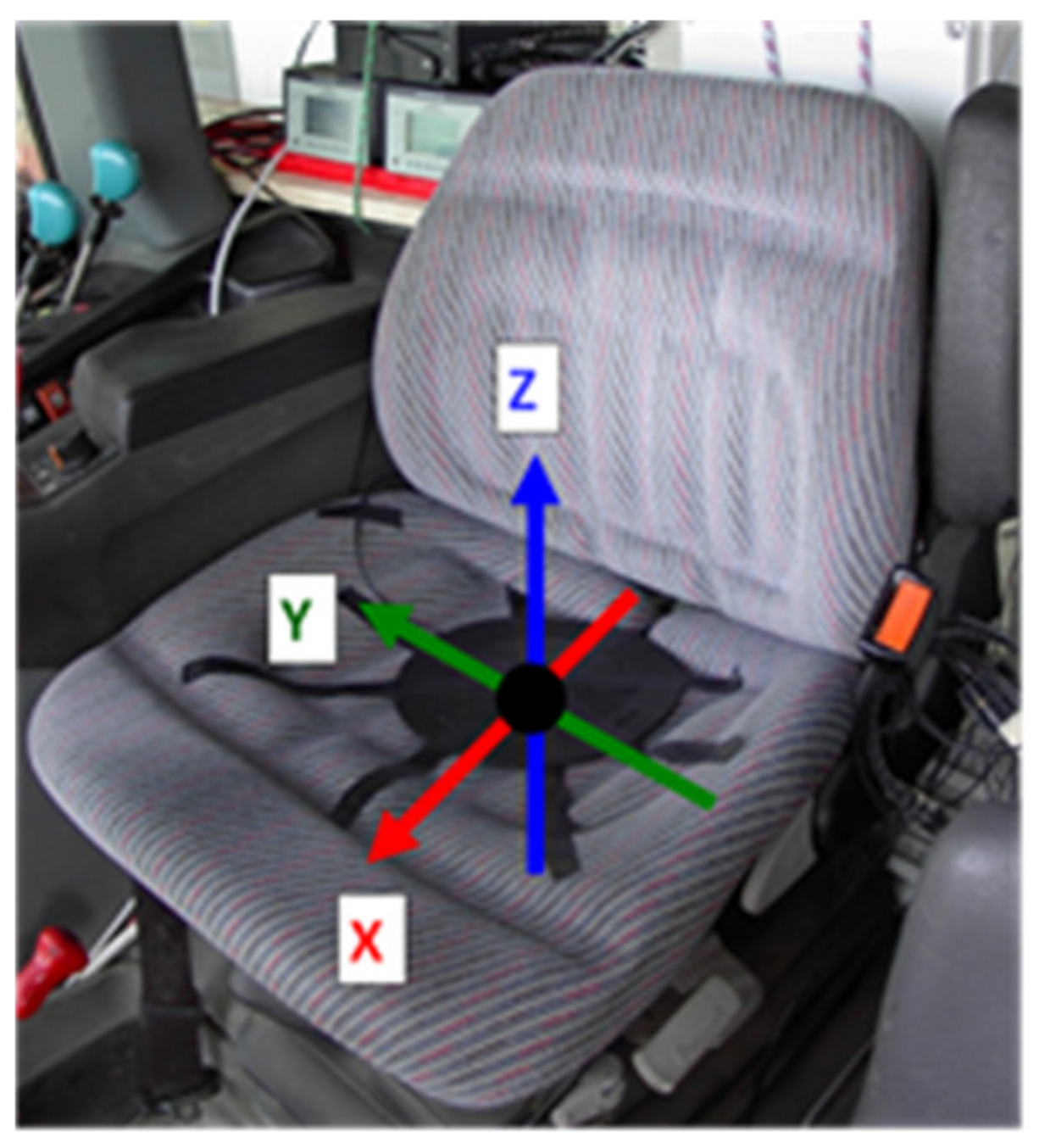

2. Materials and Methods

2.1. The Tractor Used in the Tests

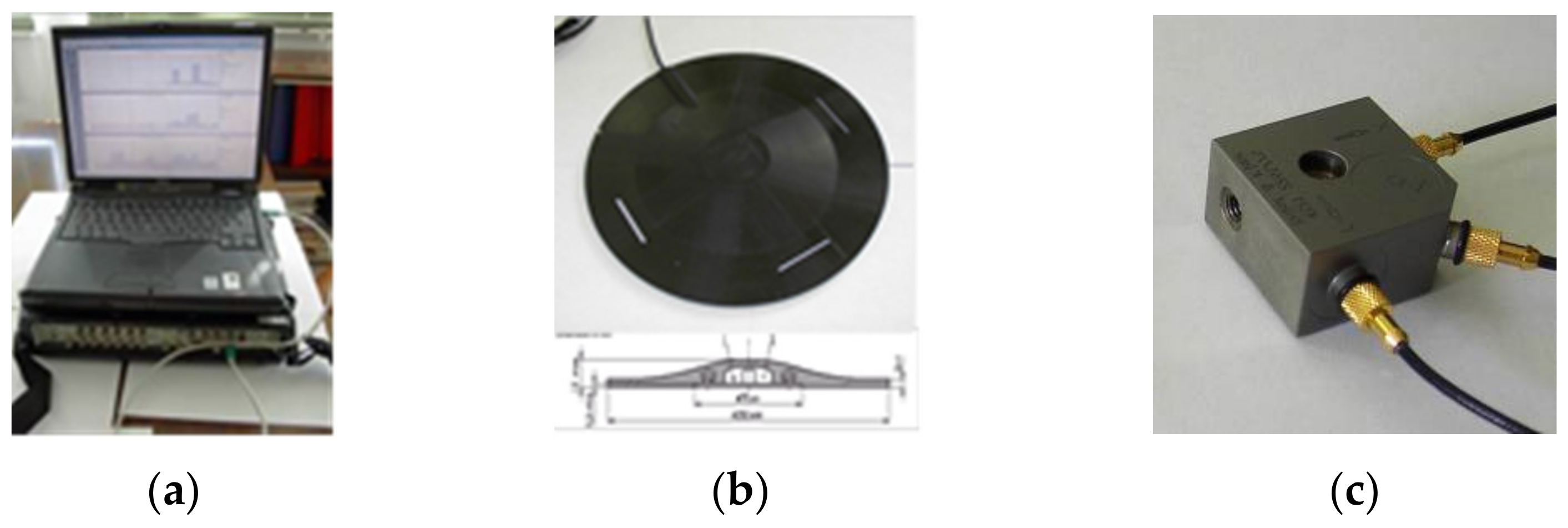

2.2. Instruments

- -

- Two six-channel signal conditioners Brüel & and Kjær;

- -

- Eight-channel digital recorder;

- -

- Signal acquisition and processing system Brüel & Kjær 5/1-ch. Input/Output Controller Module 0 Hz to 25.6 kHz frequency range (Figure 3a). The used sampling frequency was 160 Hz—suitable for analysing the level of vibration on tractors during field operations;

- -

- Tri-axial accelerometer adapted for driver seat Brüel & Kjær, type 4322 (Figure 3b) with relative calibrator, type 4294;

- -

- Two tri-axial accelerometers Brüel & Kjær, type 4321, positioned on the tractor chassis and on the cab floor (Figure 3c).

2.3. Measured Parameters, Data Processing and Reference Parameters

2.4. Soil Tillage Tests

3. Results and Discussion

- -

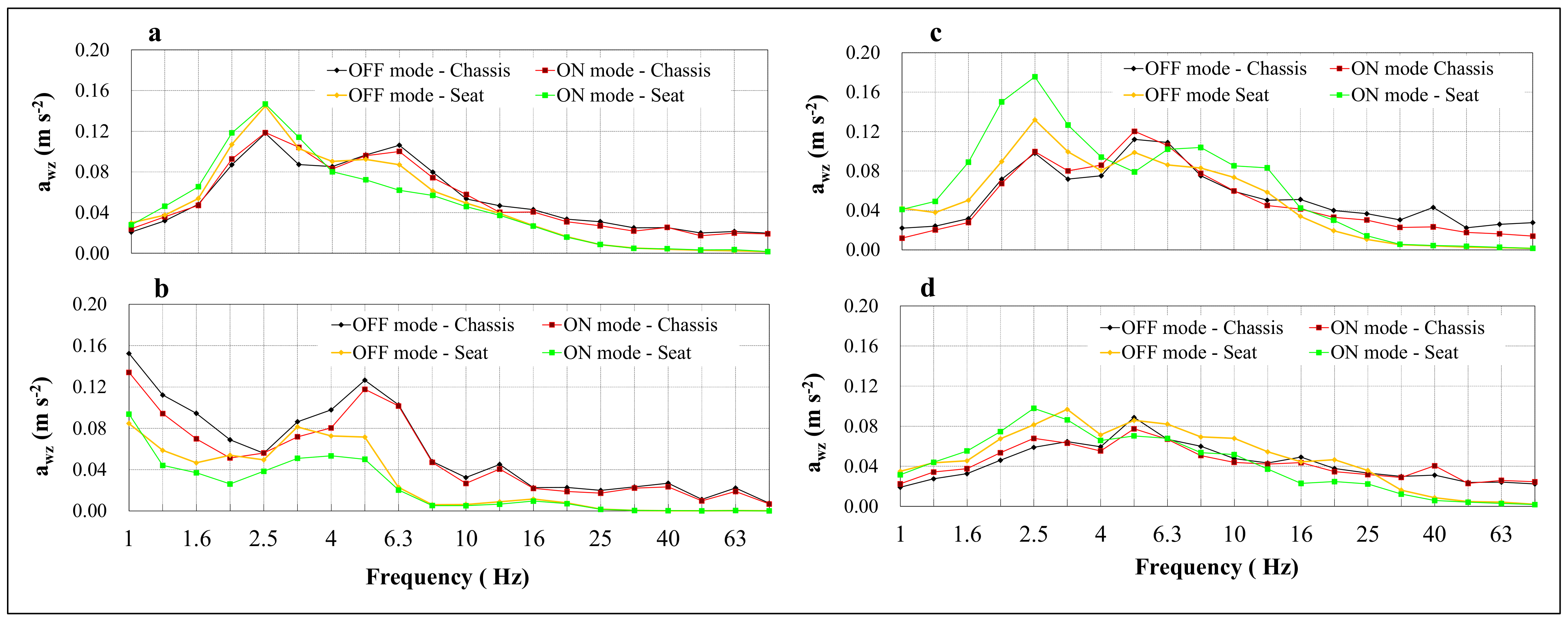

- Ploughing in-plain (Figure 7a): the curves at the driver seat in OFF and ON modes are very similar with their peak at 2.5 Hz, with values higher than those at the chassis. Small differences can be noticed for frequencies lower than 4.0 Hz, where the accelerations for “ON mode” are slightly greater, and in the interval 4.0–12.5 Hz, where the values of “ON mode” are lower;

- -

- Hillside ploughing (Figure 7c): the differences between OFF and ON have widened: “ON mode” clearly shows higher acceleration than OFF mode in the interval 1.0–4.0 Hz and 6.3–16.0 Hz. Additionally in this case, the peaks occurred at 2.5 Hz;

- -

- Subsoiling in-plain (Figure 7b): even if the curves of the Z-acceleration at the chassis have similar shapes (with peaks at 5.0 Hz), below 6.3 Hz they have lower values in ON mode than in OFF. This is probably due to differences in soil unevenness and is reflected by the curves at the seat where, in the interval 1.0–6.3 Hz, the ON mode acceleration is much less than in “OFF mode”. The shapes of the curves of the acceleration at the seat are different from those at the chassis, with peaks at 1.0 Hz in both theses;

- -

- Hillside subsoiling (Figure 7d): in this case, the curves of the acceleration at the chassis have similar shapes (with peaks at 5.0 Hz), with small differences in the interval 1.0–6.3 Hz where the values of the “ON mode” are slightly higher than in A. At seat level, in the interval 1.0–5.0 Hz, the accelerations are higher than at the chassis and the “ON mode” shows worse behaviour (with peak at 2.5 Hz) than the “OFF mode” (with peak at 3.15 Hz).

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fanigliulo, R.; Del Duca, L.; Fornaciari, L.; Grilli, R.; Tomasone, R.; Pochi, D. Efficiency of an ANC system in the tractor cabin under controlled engine workload. Noise Control Eng. J. 2020, 68, 339–357. [Google Scholar] [CrossRef]

- Park, M.-S.; Fukuda, T.; Kim, T.-G.; Maeda, S. Health Risk Evaluation of Whole-body Vibration by ISO 2631-5 and ISO 2631-1 for Operators of Agricultural Tractors and Recreational Vehicles. Ind. Health 2013, 51, 364–370. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, V.N.; Inaba, S. Effects of tire inflation pressure and tractor velocity on dynamic wheel load and rear axle vibrations. J. Terramech. 2011, 48, 3–16. [Google Scholar] [CrossRef]

- Stojić, B.; Poznanović, N.; Poznić, A. Research and modelling of the tractor tire enveloping behavior. J. Vib. Control 2017, 23, 290–304. [Google Scholar] [CrossRef]

- Pochi, D.; Fanigliulo, R.; Fornaciari, L.; Vassalini, G.; Fedrizzi, M.; Brannetti, G.; Cervellini, C. Levels of vibration transmitted to the operator of the tractor equipped with front axle suspension. J. Agric. Eng. 2013, 44, e151, 752–756. [Google Scholar] [CrossRef]

- Kim, J.; Dennerlein, J.; Johnson, P. The effect of a multi-axis suspension on whole body vibration exposures and physical stress in the neck and low back in agricultural tractor applications. Appl. Ergon. 2018, 68, 80–89. [Google Scholar] [CrossRef]

- Deboli, R.; Calvo, A.; Preti, C. Whole-body vibration: Measurement of horizontal and vertical transmissibility of an agricultural tractor seat. Int. J. Ind. Ergon. 2017, 58, 69–78. [Google Scholar] [CrossRef]

- Pochi, D.; Fornaciari, L.; Grilli, R.; Betto, M.; Benigni, S.; Fanigliulo, R. First tests on a prototype device for the active control of whole-body vibrations on agricultural tractors. In Innovative Biosystems Engineering for Sustainable Agriculture, Forestry and Food Production; Coppola, A., Di Renzo, G.C., Altieri, G., D’Antonio, P., Eds.; Lecture Notes in Civil Engineering Book, Series; Springer Nature: Cham, Switzerland, 2020; Volume 67, pp. 661–670. [Google Scholar] [CrossRef]

- Brunetti, J.; D’Ambrogio, W.; Fregolent, A. Analysis of the vibrations of operators’ seats in agricultural machinery using dynamic substructuring. Appl. Sci. 2021, 11, 4749. [Google Scholar] [CrossRef]

- Newell, G.S.; Mansfield, N.J. Evaluation of reaction time performance and subjective workload during whole-body vibration exposure while seated in upright and twisted postures with and without armrests. Int. J. Ind. Ergon. 2008, 38, 499–508. [Google Scholar] [CrossRef]

- Lines, J.; Stiles, M.; Whyte, R. Whole body vibration during tractor driving. J. Low Freq. Noise Vib. Act. Control 1995, 14, 87–104. [Google Scholar] [CrossRef]

- Okunribido, O.O.; Magnusson, M.; Pope, M.H. Low back pain in drivers: The relative role of whole body vibration, posture and manual materials handling. J. Sound Vib. 2006, 298, 540–555. [Google Scholar] [CrossRef]

- Zeng, X.; Kociolek, A.M.; Khan, M.I.; Milosavljevic, S.; Bath, B.; Trask, C. Whole body vibration exposure patterns in Canadian prairie farmers. Ergonomics 2017, 60, 1064–1073. [Google Scholar] [CrossRef] [PubMed]

- Essien, S.K.; Trask, C.; Khan, M.; Boden, C.; Bath, B. Association between whole-body vibration and low-back disorders in farmers: A scoping review. J. Agromed. 2018, 23, 105–120. [Google Scholar] [CrossRef]

- Muzammil, M.; Siddiqui, S.S.; Hasan, F. Physiological effect of vibrations on tractor drivers under variable ploughing conditions. J. Occup. Health 2004, 46, 403–409. [Google Scholar] [CrossRef] [Green Version]

- Cutini, M.; Costa, C.; Bisaglia, C. Development of a simplified method for evaluating agricultural tractor’s operator whole body vibration. J. Terramech. 2016, 63, 23–32. [Google Scholar] [CrossRef]

- Scarlett, A.J.; Price, J.S.; Stayner, R.M. Whole-body vibration: Evaluation of emission and exposure levels arising from agricultural tractors. J. Terramech. 2007, 44, 65–73. [Google Scholar] [CrossRef]

- European Community. Directive 2002/44/EC of the European Parliament and of the Council of 25 June 2002 on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (vibration) (sixteenth individual Directive within the meaning of Article 16 (1) of Directive 89/391/EEC). Off. J. Eur. Communities 2002, 117, 6–7. [Google Scholar]

- Ragni, L.; Vassalini, G.; Fang, X.; Zhang, L. Vibration and noise of small implements for soil tillage. J. Agric. Eng. Res. 1999, 74, 403–409. [Google Scholar] [CrossRef]

- Singh, A.; Samuel, S.; Singh, H.; Kumar, Y.; Prakash, C. Evaluation and analysis of whole-body vibration exposure during soil tillage operation. Safety 2021, 7, 61. [Google Scholar] [CrossRef]

- Pochi, D.; Biocca, M.; Fanigliulo, R.; Gallo, P.; Pulcini, P. Sowing of seed dressed with thiacloprid using a pneumatic drill modified for reducing abrasion dust emissions. Bull. Insectol. 2015, 68, 273–279. [Google Scholar]

- Fanigliulo, R.; Biocca, M.; Pochi, D. Effects of six primary tillage implements on energy inputs and residue cover in central Italy. J. Agric. Eng. 2016, 47, 177–180. [Google Scholar] [CrossRef] [Green Version]

- Fanigliulo, R.; Biocca, M.; Pochi, D. An analysis of eight tillage methods in a silty-clay soil: Proposal for flexible tillage cycles. INMATEH—Agric. Eng. 2018, 56, 49–58. [Google Scholar]

- Fanigliulo, R.; Antonucci, F.; Figorilli, S.; Pochi, D.; Pallottino, F.; Fornaciari, L.; Grilli, R.; Costa, C. Light Drone-Based Application to Assess Soil Tillage Quality Parameters. Sensors 2020, 20, 728. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ISO 2631-1:1997; Mechanical Vibration and Shock—Evaluation of Human Exposure to Whole-Body Vibration—Part 1: General Requirements. International Organisation for Standardisation: Geneva, Switzerland, 1997.

- Cutini, M.; Brambilla, M.; Bisaglia, C. Whole-Body Vibration in Farming: Background Document for Creating a Simplified Procedure to Determine Agricultural Tractor Vibration Comfort. Agriculture 2017, 7, 84. [Google Scholar] [CrossRef] [Green Version]

- Pochi, D.; Fanigliulo, R.; Pagano, M.; Grilli, R.; Fedrizzi, M.; Fornaciari, L. Dynamic-energetic balance of agricultural tractors: Active systems for the measurement of the power requirements in static tests and under field conditions. J. Agric. Eng. 2013, 44, e84, 415–420. [Google Scholar] [CrossRef]

- Nunes, M.R.; Denardin, J.E.; Pauletto, E.A.; Faganello, A.; Spinelli Pinto, L.F. Effect of soil subsoiling on soil structure and root growth for a clayey soil under no-tillage. Geoderma 2015, 259–260, 149–155. [Google Scholar] [CrossRef] [Green Version]

- Fanigliulo, R.; Pochi, D.; Servadio, P. Conventional and conservation seedbed preparation systems for wheat planting in silty-clay soil. Sustainability 2021, 13, 6506. [Google Scholar] [CrossRef]

- Cutini, M.; Deboli, R.; Calvo, A.; Preti, C.; Inserillo, M.; Bisaglia, C. Spectral analysis of a standard test track profile during passage of an agricultural tractor. J. Agric. Eng. 2013, 44, e145. [Google Scholar] [CrossRef]

- Cutini, M.; Bisaglia, C. Procedure and layout for the development of a fatigue test on an agricultural implement by a four-poster test bench. J. Agric. Eng. 2013, 44, e81. [Google Scholar] [CrossRef]

- Romano, E.; Cutini, M.; Bisaglia, C. Study of posture during plowing operation. Analysis of the pressures to the seat. In Proceedings of the International Conference Rural Health & Ragusa SHWA, Lodi, Italy, 8–11 September 2015. [Google Scholar]

- Killen, W.; Eger, T. Whole-Body Vibration: Overview of Standards used to Determine Health Risks. CRE-MDS 2016. pp. 4164–4165. Available online: https://uwaterloo.ca/centre-of-research-expertise-for-the-prevention-of-musculoskeletal-disorders/resources/position-papers/whole-body-vibration-overview-standards-used-determine (accessed on 20 May 2022).

- Cecchini, M.; Piccioni, F.; Ferri, S.; Coltrinari, G.; Bianchini, L.; Colantoni, A. Preliminary investigation on systems for the preventive diagnosis of faults on agricultural operating machines. Sensors 2021, 21, 1547. [Google Scholar] [CrossRef] [PubMed]

| Tillage Mode | Sensor’s Position | X Axis | Y Axis | Z Axis | Dom. | Te (Dom.) | Res. | Te (Res.) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| awx | apeak | Fpeak | awy | apeak | Fpeak | awz | apeak | Fpeak | 1.4·awmax | ST | LT | av | ST | LT | |||

| (m s−2) | (Hz) | (m s−2) | (Hz) | (m s−2) | (Hz) | (m s−2) | (h:min) | (h:min) | (m s−2) | (h:min) | (h:min) | ||||||

| Ploughing in plain | Off | Seat | 0.38 | 0.22 | 1.2 | 0.36 | 0.2 | 1.2 | 0.28 | 0.14 | 2.5 | 0.53 | 6:31 | 28:16 | 0.78 | 2:60 | 12:60 |

| Cab floor | 0.3 | 0.16 | 1.2 | 0.29 | 0.17 | 1.2 | 0.29 | 0.13 | 2.5 | 0.42 | - | - | 0.65 | - | - | ||

| Chassis | 0.28 | 0.15 | 1.2 | 0.23 | 0.14 | 1.2 | 0.28 | 0.12 | 2.5 | 0.39 | - | - | 0.58 | - | - | ||

| On | Seat | 0.37 | 0.2 | 1.4 | 0.33 | 0.17 | 1.0 | 0.27 | 0.15 | 2.5 | 0.52 | 6:52 | 29:49 | 0.74 | 3:19 | 14:25 | |

| Cab floor | 0.26 | 0.13 | 1.4 | 0.24 | 0.14 | 1.0 | 0.3 | 0.13 | 2.5 | 0.30 | - | - | 0.58 | - | - | ||

| Chassis | 0.4 | 0.26 | 1.1 | 0.17 | 0.1 | 1.0 | 0.28 | 0.12 | 2.5 | 0.56 | - | - | 0.67 | - | - | ||

| Diff. On-Off | Seat | −0.01 | - | - | −0.03 | - | - | −0.01 | - | - | −0.01 | 0:21 | 1:33 | −0.04 | 0:20 | 1:25 | |

| Cab floor | −0.04 | - | - | −0.05 | - | - | 0.01 | - | - | −0.12 | - | - | −0.07 | - | - | ||

| Chassis | 0.12 | - | - | −0.06 | - | - | 0 | - | - | 0.17 | - | - | 0.09 | - | - | ||

| Subsoiling in plain | Off | Seat | 0.37 | 0.22 | 1.2 | 0.35 | 0.28 | 1.7 | 0.19 | 0.1 | 1.0 | 0.52 | 6:52 | 29:49 | 0.74 | 3:23 | 14:42 |

| Cab floor | 0.5 | 0.28 | 1.2 | 0.62 | 0.41 | 1.0 | 0.49 | 0.2 | 2.2 | 0.87 | - | - | 1.22 | - | - | ||

| Chassis | 0.41 | 0.24 | 1.2 | 0.57 | 0.34 | 1.7 | 0.32 | 0.16 | 1.0 | 0.80 | - | - | 1.03 | - | - | ||

| On | Seat | 0.39 | 0.25 | 1.3 | 0.23 | 0.17 | 1.6 | 0.15 | 0.08 | 1.0 | 0.55 | 6:11 | 26:50 | 0.65 | 4:21 | 18:51 | |

| Cab floor | 0.46 | 0.26 | 1.0 | 0.56 | 0.39 | 1.0 | 0.43 | 0.17 | 2.6 | 0.78 | - | - | 1.10 | - | - | ||

| Chassis | 0.35 | 0.19 | 1.0 | 0.49 | 0.28 | 1.6 | 0.28 | 0.13 | 1.0 | 0.69 | - | - | 0.89 | - | - | ||

| Diff. On-Off | Seat | 0.02 | - | - | −0.12 | - | - | −0.04 | - | - | 0.03 | −0:41 | −2:59 | −0.09 | 0:58 | 4:10 | |

| Cab floor | −0.04 | - | - | −0.06 | - | - | −0.06 | - | - | −0.08 | - | - | −0.12 | - | - | ||

| Chassis | −0.06 | - | - | −0.08 | - | - | −0.04 | - | - | −0.11 | - | - | −0.15 | - | - | ||

| Hillside ploughing | Off | Seat | 0.34 | 0.19 | 1.0 | 0.30 | 0.14 | 1.1 | 0.28 | 0.12 | 2.5 | 0.48 | 8:08 | 35:18 | 0.69 | 3:50 | 16:37 |

| Cab floor | 0.24 | 0.13 | 1.0 | 0.24 | 0.14 | 1.1 | 0.27 | 0.11 | 5.0 | 0.27 | - | - | 0.55 | - | - | ||

| Chassis | 0.21 | 0.11 | 1.0 | 0.21 | 0.14 | 1.0 | 0.27 | 0.11 | 5.0 | 0.27 | - | - | 0.50 | - | - | ||

| On | Seat | 0.33 | 0.18 | 1.1 | 0.35 | 0.2 | 1.0 | 0.29 | 0.12 | 4.3 | 0.49 | 7:41 | 33:19 | 0.73 | 3:26 | 14:53 | |

| Cab floor | 0.25 | 0.13 | 1.2 | 0.31 | 0.2 | 1.0 | 0.34 | 0.14 | 6.3 | 0.34 | - | - | 0.65 | - | - | ||

| Chassis | 0.21 | 0.1 | 1.2 | 0.22 | 0.16 | 1.0 | 0.3 | 0.13 | 5.0 | 0.30 | - | - | 0.52 | - | - | ||

| Diff. On-Off | Seat | −0.01 | - | - | 0.05 | - | - | 0.01 | - | - | 0.01 | −0:27 | −1:59 | 0.04 | −0:24 | −1:44 | |

| Cab floor | 0.01 | - | - | 0.07 | - | - | 0.07 | - | - | 0.07 | - | - | 0.11 | - | - | ||

| Chassis | 0 | - | - | 0.01 | - | - | 0.03 | - | - | 0.03 | - | - | 0.03 | - | - | ||

| Hillside subsoiling | Off | Seat | 0.34 | 0.21 | 1.1 | 0.3 | 0.18 | 1.0 | 0.22 | 0.09 | 2.9 | 0.48 | 8:08 | 35:18 | 0.67 | 4:05 | 17:43 |

| Cab floor | 0.22 | 0.14 | 1.0 | 0.24 | 0.16 | 1.0 | 0.19 | 0.08 | 5.0 | 0.34 | - | - | 0.49 | - | - | ||

| Chassis | 0.18 | 0.11 | 1.0 | 0.18 | 0.13 | 1.0 | 0.2 | 0.08 | 5.0 | 0.20 | - | - | 0.41 | - | - | ||

| On | Seat | 0.36 | 0.23 | 1.1 | 0.33 | 0.22 | 1.0 | 0.23 | 0.1 | 2.3 | 0.50 | 7:15 | 31:30 | 0.72 | 3:33 | 15:22 | |

| Cab floor | 0.22 | 0.15 | 1.1 | 0.26 | 0.19 | 1.0 | 0.2 | 0.08 | 4.0 | 0.36 | - | - | 0.52 | - | - | ||

| Chassis | 0.18 | 0.12 | 1.1 | 0.18 | 0.13 | 1.0 | 0.2 | 0.08 | 5.0 | 0.20 | - | - | 0.41 | - | - | ||

| Diff. On-Off | Seat | 0.02 | - | - | 0.03 | - | - | 0.01 | - | - | 0.03 | −0:53 | −3:49 | 0.05 | −0:32 | −2:21 | |

| Cab floor | 0 | - | - | 0.02 | - | - | 0.01 | - | - | 0.03 | - | - | 0.02 | - | - | ||

| Chassis | 0 | - | - | 0 | - | - | 0 | - | - | 0.00 | - | - | 0.00 | - | - | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pochi, D.; Fornaciari, L.; Vassalini, G.; Grilli, R.; Fanigliulo, R. Levels of Whole-Body Vibrations Transmitted to the Driver of a Tractor Equipped with Self-Levelling Cab during Soil Primary Tillage. AgriEngineering 2022, 4, 695-706. https://doi.org/10.3390/agriengineering4030044

Pochi D, Fornaciari L, Vassalini G, Grilli R, Fanigliulo R. Levels of Whole-Body Vibrations Transmitted to the Driver of a Tractor Equipped with Self-Levelling Cab during Soil Primary Tillage. AgriEngineering. 2022; 4(3):695-706. https://doi.org/10.3390/agriengineering4030044

Chicago/Turabian StylePochi, Daniele, Laura Fornaciari, Gennaro Vassalini, Renato Grilli, and Roberto Fanigliulo. 2022. "Levels of Whole-Body Vibrations Transmitted to the Driver of a Tractor Equipped with Self-Levelling Cab during Soil Primary Tillage" AgriEngineering 4, no. 3: 695-706. https://doi.org/10.3390/agriengineering4030044

APA StylePochi, D., Fornaciari, L., Vassalini, G., Grilli, R., & Fanigliulo, R. (2022). Levels of Whole-Body Vibrations Transmitted to the Driver of a Tractor Equipped with Self-Levelling Cab during Soil Primary Tillage. AgriEngineering, 4(3), 695-706. https://doi.org/10.3390/agriengineering4030044