Abstract

The loss of fresh fruits after harvesting is not new since it has constantly been a challenge for humankind. The growing population in developing countries, where food shortages exist, require serious food security measures to address hunger and malnutrition. Present research focused on the development, fabrication and testing of mango pulp extractor to assist small-scale fruit farmers in the countryside with a view to minimizing fruit spoilage. The unit, whose major material was food grade stainless steel (SS-304), consists of major components such as teflon brushes mounted shaft, motor, main frame, hopper, extraction compartment, pulp outlet, fruit residue outlet, perforated sieve and bearings. After construction, the machine was tested at three feed rate (2.0, 2.5, 3.0 kg/min) and extraction speed levels (500, 900 and 1400 rpm). Each of these factors was replicated three times, which resulted into 3 × 3 × 3 factorial experimental design. The optimum operating parameters for maximum pulp yield, maximum extraction efficiency and minimum extraction losses were determined. The physicochemical analysis of the extracted pulp was also carried out. Results revealed a maximum pulp yield of 77.9%, highest extraction efficiency of 96.03% and highest extraction loss of 9.3%. The mango pulp extraction machine was found to be affordable, easy to operate and maintain. The breakeven point of the machine was found to be 40 h if the machine is operated at its peak capacity. Therefore, it is recommended for small-scale farmers and for cottage industry.

1. Introduction

Mango (Mangifera indica L.) is the most popular and an economically imperative tropical fruit across the world, owing to the exceptional eating quality (bright color, sweetened taste and excellent flavor), as well as high nutritional composition, providing fiber, micronutrients as carbohydrates (10–32% in ripe pulp), proteins (0–5%), amino acids (alanine, arginine, glycine, serine, leucine and isoleucine), lipids (0.75% to 1.7%) and organic acids (citric is the major organic acid, 0.13% to 0.71% FW). Mango fruit also provides macronutrients such as vitamins (vitamin C, from 9.79 to 186 mg/100 g of mango pulp; vitamin A, from 1000 to 6000 IU; E and K vitamins are found in minor quantities; D vitamin has not been detected in any cultivars until now). [1]. Therefore, it is best known as ‘The King of Fruits’ [2]. A significant quantity of mangoes is wasted each year due to poor postharvest systems and shortage of adequate facilities in developing countries. The development and implementation of low-cost preventive measures to produce high quality and acceptable mango products are important, allowing for better fruit consumption [3].

Pakistan is primarily an agricultural country and its economy is heavily reliant on agricultural products, particularly fruits. Pakistan faces 35–40% postharvest losses annually, mainly of perishable crops [4]. Some of the major factors contributing to such high postharvest losses include postharvest diseases, poor postharvest handling practices and scarceness of proper facilities for processing [5]. Therefore, post-harvest losses remain a serious challenge facing the country’s economy and production. Mangoes are among these fruits that have substantial losses due to poor postharvest practices [6,7].

Processing the fruit into the form that can be easily preserved, packed, transported and or consumed is essential to make the product available throughout the year [8]. Pulp extraction has been found to be one of the most efficient methods of fruit preservation. Some fruit pulps have a very long shelf life, from months to years before they expire according to the preservation and packaging methodology [9,10]. In addition, mango pulp can be consumed freshly, blended with other juice to form fruit jams or it can be evaporated to form concentrates. These products have a great potential in beverage and other food industries for export and foreign exchange earnings. In this regard, mango pulp is highly sought after by food companies nationally as well as globally as it is the most promising ingredient for the production of mango juices [11]. Therefore, the growth of mango pulp industries brings huge benefits through employment and income [12]. In recent years, a rise is observed in the global market of mango pulp. Although Pakistan is among the leading exporters of mangoes in the global market, it has not yet been able to become a key exporter of mango pulp.

The processing of mangoes has been on the rise as represents an important step in the production of nutritious products [13]. Moreover, the high demand for the fruit means that it can provide small farmers with a significant income. Mango processing presents multiple challenges in terms of industrialization, as well as in terms of market expansion, due to its perishability, ample wastage during the production season and shortage during the off-season has been reported by farmers. The postharvest losses of mango were estimated at 6.94% of total production. The highest losses accounted 3.22% in harvesting followed by 1.67% in transportation, 0.60% in handling, 0.58% in loading, 0.47% in late auction, 0.28% in unloading and 0.11% in packing [14].

This research was very important since it will encourage the commercial production of fruits reducing the cost of fruit juice that can adequately substitute for bottled drinks and therefore, help boost the agricultural sector of the economy. As a result, the consumption of fruits will increase, thus improving the human health. In addition, pulp will no longer be a luxury, since the cost of importation of foreign extractors which tends to reduce the country’s GDP will be greatly reduced. Although successes have been recorded in the design and development of pulp extractors, emphasis is always placed on those fruits that contain a large amount of liquid, herein called soft fruits, such as orange, pineapple and mango. [15]. There is the need to work on the possibility of designing and developing a machine that can extract juice from both soft and hard fruits. This mango pulp extractor has been developed to assist small-scale fruit farmers in the countryside with a view to minimize fruit spoilage.

Considering postharvest losses, the study was designed to fulfil the following objectives: develop and manufacture a mango pulp extractor, determine the optimum operating parameters for the machine and determine its breakeven point.

2. Materials and Methods

2.1. Development of Mango Pulp Extractor

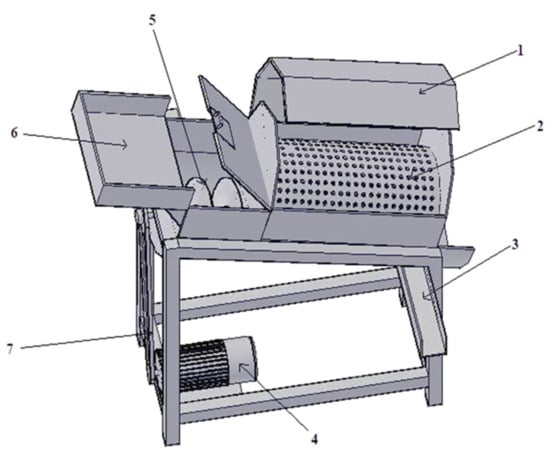

The research was carried out at the Department of Food Engineering, University of Agriculture Faisalabad (Pakistan). Suitable food grade material (SS-304) for the fabrication of the machine was purchased from local market of Faisalabad. Various units of mango pulp extractor were fabricated at the Engineering Workshop of the University of Agriculture Faisalabad as follows (Figure 1).

Figure 1.

Mango pulp extractor. 1. Pulp extraction compartment Cover, 2. Sieve, 3. Pulp outlet, 4. Electric motor, 5. Auger conveyor, 6. Feeding hop-per, 7. V-Belt.

2.1.1. Feed Hopper

The feed hopper is a part of the machine through which the mango is fed into the machine. The hopper acts as a container and at the same time helps to gradually introduce the mango into the pulp-extracting compartment. The hopper is rectangular with a volume of 0.00708 m3 to accommodate mangoes and their gradual introduction into the pulp extraction compartment. It was constructed from a 1.5 mm thickness stainless steel plate and welded to the barrel of the machine to introduce mangoes into the extraction compartment.

2.1.2. Pulp Extraction Compartment

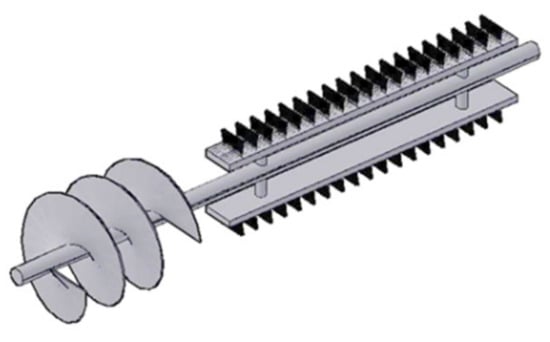

The pulp extraction compartment of the machine comprises the cylindrical sieve having 0.914 m (36 inches) length, which houses a teflon brushes mounted shaft conveyor and the pulley with bearing at both ends (Figure 2). The screw shaft is supported by the bearings at both ends. The auger (screw) conveyor and the sieve were both fabricated from stainless steel and the pulley was fabricated from mild-steel, which is mounted on the screw shaft (made of stainless steel) with the main function of transmitting the rotary power (torque) from the electric motor to the pulp extraction compartment through the V-belt connection. The V-belts provide a means of changing speed. The auger has a length of 0.2286 m (9 inches) with the diameter of 0.2032 m (8 inches). The brushes have the length of 0.4064 m (16 inches). The sieve cylinder is 0.4572 m (18 inches) long and has an outer diameter of 0.2032 m (8 inches).

Figure 2.

Teflon brushed mounted shaft.

2.1.3. Frame and Stand

The frame and the stand were fabricated from angle iron bar. These parts provide support for both the pulp extractor and the electric motor. The frame also provides rigidity when the machine is in operation.

2.1.4. Outlet Compartments

The outlet compartment comprises two major outlets: the pulp and the residue outlet. The pulp outlet was attached to the pulp collection compartment, available under the perforations drilled under the cylindrical sieve for pulp collection. The residual outlet was attached to the posterior end of the sieve.

2.1.5. Power Unit

The power unit consists of a 3 hp three-phase electric motor with belts and pulleys and a variable frequency drive (VFD) for speed variation. The motor powers the machine via V-belts, pulleys and VFD, which is present on a seating that is mounted on one side of pulping compartment. The pulley that is mounted on the shaft of available motor, pro-vides necessary power to the belt.

2.2. Performance Evaluation of the Mango Pulp Extractor

2.2.1. Extraction Parameters

After manufacturing, the performance of the mango pulp extractor was evaluated to determine the optimum pulp extraction parameters, i.e., feed rate (kg/min) and rotor speed (rpm). The extraction parameters considered were:

- -

- Operating factors: This includes three levels of feed rate (F) (F1 = 2.0, F2 = 2.5 and F3 = 3.0 kg/min) and extraction speed (S) (S1 = 500, S2 = 900 and S3 = 1400 rpm).

- -

- Performance parameters: This includes pulp yield (JY), pulp extraction efficiency (JE) and extraction losses (EL).

2.2.2. Test Procedure

Bulk quantities of fully ripened, freshly harvested mangoes (Sindhri variety) were purchased from a local fruit market of Faisalabad. After washing and cleaning the mangoes, the damaged fruits were discarded. After weighing, the undamaged fruits were divided into three portions of 2.0, 2.5 and 3.0 kg. After setting the pulper into operation through the power supply, the identified weights of fruits were fed into the hopper. Through the hopper, mangoes were introduced into the extraction compartment where the auger (screw conveyor) crushed and conveyed mangoes towards rotating sieve drum. After extraction, the mass of fruits fed into the hopper, the mass of pulp obtained, as well as the mass of residual waste (chaff) were documented. All the samples were individually stored in washed and sanitized plastic jars for further analysis. The mass of pulp in chaff was determined by oven drying the chaff at 130 °C until a constant weight was reached. Each experiment was replicated thrice. The test was run at different rotor speeds (S) and at different feed rates (F).

The evaluation of the performance of the mango pulp extractor was carried out using the following expressions (Equations (1)–(3)) given by Olaniyan and Oje [16].

where WJE, was the pulp extracted (kg); WRW, the residual waste/dry chaff (kg); WFS, the feed sample (kg); JY, the pulp yield (%); JE, the extraction efficiency (%); EL, the extraction loss (%); WJC, the juice in the residual waste.

2.3. Physicochemical Analysis of Mango Pulp

The extracted mango pulp was used for the evaluation of proximate composition (moisture, ash, fat, protein and total sugars (TS)), total soluble solids (TSS), pH, titratable acidity and ascorbic acid with the respective methods given by AOAC standards [17].

2.3.1. Chemical Composition

The moisture contents of the extracted pulp were determined by oven (BOHA-102 Canada) drying method at a temperature of 105 °C for a period 24 h using the method No. 925.098 described by AOAC [17]. The ash content of pulp was calculated according to AOAC method No. 923.03, incinerating the sample at 550 °C in a muffle furnace [17]. The fat content was determined following the procedure given by AOAC through a Soxhlet system with 2:1 (v/v) chloroform [17]. The protein contents of the mango pulp were calculated by Kjeldahl’s apparatus using the AOAC method 960.52 [17]. Finally, the measurement of total sugars was made calorimetrically in the dry weight of fruit with following the method described by Smith et al. [18].

2.3.2. Total Soluble Solids

A handheld digital refractometer was employed to determine the total soluble solids (TSS). A drop of mango pulp was poured on prism of the refractometer and TSS was read as °Brix on the scale at room temperature (25 °C).

2.3.3. pH

For the determination of pH, a small quantity of sample was taken in 50 mL beaker by means of pH meter following the method described by AOAC [17].

2.3.4. Titratable Acidity

For the determination of TA as citric acid, 10 mL fruit pulp was diluted (1:4) with distilled water. Then, it was poured in beaker and titrated with 0.1 sodium hydroxide (NaOH) solution, through the subsequent addition of 2–3 phenolphthalein (C20H14O4) drops as an indicator [19].

2.3.5. Vitamin C

The ascorbic acid (Vitamin C) of mango pulp was recorded following the AOAC method 967.21 using 2.6 dichloro-phenol indophenol [17].

2.4. Economic Analysis of Mango Pulp Extractor

The main requirement was to develop a machine to achieve the objectives in an economical way to make it affordable for the purchase of the end users. For assessing the economic feasibility, a machine cost analysis was carried out according to the method proposed by Khan et al. [20]. Two major elements of cost analysis were taken into account in this economic analysis [21]:

- -

- Fixed costs: Fixed costs, also recognized as ownership cost of machine, paid by the holder to acquire the machine.

- -

- Variable costs: Variable costs, also called operating costs, result of the machine operation. Variable costs vary with annual use and, thus, are recognized as operating costs.

2.4.1. Factors Affecting Fixed Costs

The elements included in the fixed cost are:

- -

- Depreciation: Depreciation of the machinery is an important element while approximating ownership cost of machinery [22]. The depreciation may be calculated through various methods, being the straight-line method the most common [23,24].

- -

- Straight-line depreciation method: The straight-line method for depreciation calculation is the most used, being convenient and easy to perform. In this method, a suitable salvage value is assigned to machine, usually 10–15% of first cost [21]. A difference of salvage value and first cost is then taken and divided by useful life of the machine in years [25,26].where Ds = annual depreciation by straight-line method, (PKR); P = first value (PKR), S = salvage/junk value (PKR); L = life of machine (yr).

- -

- Insurance: Although an insurance policy is not implemented on obsolete and inexpensive machines, even then 0.25–0.50% is charged and added to the outstanding value of machine [21].

2.4.2. Factors Affecting Variable Cost

- -

- Labor to operate the machine: Labor cost is not included in the operating cost if the possessor is operating it himself or herself. However, it is one of the key operating costs and must always be given a charge with respect to the local circumstances. Hours saved by using a large machine are an important factor in decision making. The hourly rate is used to calculate labor costs [27].

- -

- Repair and maintenance: Periodic repair and maintenance operations increase the machine life. Irregular maintenance plan decreases the machine life, damaging the parts of machine, which are expensive to replace. Therefore, familiarity with this cost is vital in making machinery replacement decisions [28].

- -

- Interest: Interest is believed to be an opportunity cost, that is, a loss of financial opportunity to earn an interest on an account or other investment [21]. Their relation is used to calculate interest in a machine as:where I = annual interest, (PKR); P = first value, (PKR), S = salvage value, (PKR); i = %interest rate.

- -

- Taxes: Machinery is private property, so tax is imposed in consistent with the local regulations of state. Generally, rate of tax fluctuates from 1–2% of the purchase cost of machine [29].

- -

- Housing: The requirement for machinery housing/shed is dependent on the size of the machine, as well as the climate conditions of the country. Normally, machines saved from rough weather conditions need less maintenances. The service centers for the repair and maintenance and repair may also be included in the housing cost. These reasons add 1–2% annual charge on the remaining value of machine for the housing purpose [23].

2.5. Statistical Analysis

Statistical analyses were performed using IBM SPSS statistics for Windows (version 19.0. IBM Corp., New York, NY, USA). Normal distribution and variance homogeneity had been previously tested (Shapiro–Wilk). The data were submitted to an analysis of variance (ANOVA), followed by Tukey’s test when the ANOVA was significant (p < 0.05).

3. Results and Discussion

The current experiments were conducted in the laboratory of Food Engineering Operations, Department of Food Engineering, University of Agriculture, Faisalabad (Pakistan) during the year 2018. The study was conducted to develop, fabricate and evaluate the performance of mango pulp extractor at three levels of rotor speed, S (rpm) and three levels of feed rate, F (kg/min) to ascertain the best operating parameters to maximize pulp yield (JY) and extraction efficiency (JE) with lowest extraction losses (EL).

3.1. ANOVA for Yield, Extraction Efficiency and Extraction Losses of Mango Pulp

The effects of rotor speed of electric motor and mango feed rate on JY, JE and EL from mango pulp extractor were statistically analyzed and presented in Table 1. The results revealed that both factors had a significant effect on the evaluated parameters. Change in speed, S (rpm) and feed rate, F (kg/min) had greatly influenced performance parameters. Similar results were found previously by other authors [30]. It was observed from the results that the interaction of speed, S (rpm) and feed rate, F (kg/min) was marginally significant at 5% probability level for mango pulp yield, but highly significant for percentages of extraction efficiency (JE) and extraction losses (EL).

Table 1.

ANOVA for yield, extraction efficiency and extraction losses of mango pulp.

3.2. Effect of Rotor Speed of Electric Motor on Mango Pulp Yield, Extraction Efficiency and Extraction Losses

The statistically analyzed data indicated that speed, S (rpm), had significantly affected the mango pulp yield (JY), extraction efficiency (JE) and extraction losses (EL). A similar trend was observed previously by other authors [31]. As the rotor speed of the electric motor was increased from S1 to S3, the mango JY increased to a speed level of S2 (900 rpm), beyond this speed JY started declining. It was observed from the tests that the pulper, when operated at speed level of S2 (900 rpm) had the optimum yield of 77.96% compared to the other speed levels S1 (500 rpm) and S3 (1400 rpm), where JY was found to be 62.87 and 72.33%, respectively (Table 2).

Table 2.

Effect of speed on mango pulp yield, extraction efficiency and extraction losses.

The lowest JY was recorded at a speed level S1 (500 rpm). This may be due to the slower speed at which the shaft rotated. This caused the fruits to take longer to move through the extraction compartment of machine. Moreover, the centrifugal force generated in the pulper, which advances the fruits to outer boundaries of the auger to be pressed against the hard surface of perforated sieve for pulp extraction, was insufficient. The magnitude centrifugal increased directly with speed till S2 (900 rpm) where the force was adequate to assist pulp extraction. At the S3 speed level (1400 rpm), the centrifugal force was too high. When this happens, the traces of the mango were appeared at the outlet. Similar observations were observed by other authors for other pulp extractors [15,32,33]. At high speeds, there was a reduction in the pulp extracted from the fruits. This may be due to the losses arising from the vibrations of the machine at high operating speeds, causing splashing of pulp to the walls of the machine and out of the cover of feeding compartment, thus reducing the mango pulp yield.

The statistically analyzed data indicated that speed significantly affected the extraction efficiency (JE) of mango pulp extractor. It can be seen from the results that the efficiency of extraction increased to a maximum value of 96.03% at optimum rotor speed of electric motor S2 (900 rpm) and then decreased at speed level beyond S2 (900 rpm). Extraction efficiencies of 91.52% and 88.51% were recorded at rotor speed levels of S1 (500 rpm) and S3 (1400 rpm), respectively, at probability level of 5%. At speed levels of S1 (500 rpm) and S3 (1400 rpm) fruits were not completely grinded and that may be responsible for the reduction of extraction efficiency compared when the machine was running at a rotor speed level of S2 (900 rpm). Thus, performance tests showed that the optimum extraction efficiency of the mango pulp extractor depends on the extraction speed of the machine. Similar observations were observed by Gbabo et al. [34] and Ndubisi et al. [35] for other juice extractors.

Speed also significantly affected the extraction losses (EL) of the pulp extraction machine. Referring to Table 2, it could be easily seen that an increase in machine operating speed increases the extraction losses and vice versa, which agrees with the results found by Adebayo et al. [32]. This happened due to the vibrations that occur at high speeds, which cause losses derived from the splashing of the pulp on the walls of the machine. The results revealed that EL was minimal at the slowest rotor speed of electric motor S1 (500 rpm) than those observed with S2 (900 rpm) and S3 (1400 rpm).

3.3. Effect of Feed Rate on Mango Pulp Yield, Extraction Efficiency and Extraction Losses

The statistically analyzed data indicated that feed rate, F (kg/min) significantly affected the mango pulp yield (JY), extraction efficiency (JE) and extraction losses (EL). The results showed that the optimum feed rate of the machine for the optimum extraction of mango pulp was F2 (2.5 kg/min) as shown in Table 3.

Table 3.

Effect of feed rate on mango pulp yield, extraction efficiency and extraction losses.

More pulp was yielded at feed rate F2 (2.5 kg/min) and F3 (3.0 kg/min) than that of feed rate F1 (2.0 kg/min). This may be because at lower feed rate F1 (2.0 kg/min) the fruits passed the extraction section rapidly. When this occurred, the traces of the mango were appeared at the outlet. A similar trend was previously observed in other studies [31,32]. At feed rate F1, the mango pulp yield (JY) was found to be 71.32%, which was significantly lower than that obtained at feed rate F2 (2.5 kg/min) and F3 (3.0 kg/min). Our results revealed that means at feed rates F2 and F3 were not significantly different from each other. Thus, more pulp had extracted at feed rate F2 and F3 than that of feed rate F1.

The statistically analyzed data indicated that mango feed rate significantly affected the extraction efficiency (JE) of mango pulp extraction machine. The results showed that the optimum mango feed rate of the machine for the optimum extraction efficiency of mango pulp was F1 (2.0 kg/min) as shown in Table 3. Low extraction efficiency of machine was observed at higher mango feed rates F2 = 2.5 kg/min and F3 = 3.0 kg/min than that of F1 = 2.0 kg/min. Our findings agree with those previously reported by Adebayo et al. [32].

The effect of feed rate on percentage extraction losses (EL) is showed in Table 3. The highest extraction losses were observed at feed rate F3 (3.0 kg/min) than that of other two levels of feed rate (7.55% vs. 4.94% and 6.67% for F3, F1 and F2, respectively). Similar results were stated by other authors [31,32]. Thus, more pulp had extracted at feed rate F2 and F3 than that of feed rate F1 with the help of the fabricated pulp extractor. This made clear that the feed rate must be controlled in order to minimize the extraction losses.

3.4. Combined Effect of Speed and Feed Rate on Mango Pulp Yield, Extraction Efficiency and Extraction Losses

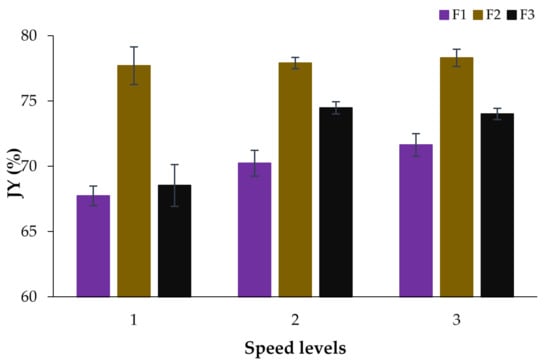

The combined effect of rotor speed of electric motor and mango feed rate on mango pulp yield (%JY) could be easily observed in Figure 3.

Figure 3.

Effect of speed (S) and feed rate (F) on mango pulp yield (JY) (F1 = 2.0 kg/min, F2 = 2.5 kg/min, F3 = 3.0 kg/min, S1 = 500 rpm, S2 = 900 rpm, S3 = 1400 rpm).

The mango pulp yield (JY) at three levels of speed (S1 = 500 rpm, S2 = 900 rpm and S3 = 1400 rpm) and feed rate (F1 = 2.0 kg/min, F2 = 2.5 kg/min and F3 = 3.0 kg/min) was analyzed statistically. The interaction S1F1 had significantly different effect on JY than those observed by interaction S2F1 and S3F1. However, the interaction S2F1 and S3F1 had insignificant effect on JY. The same effects were observed among S1F3, S2F3 and S3F3 treatments. The interaction S1F2, S2F2 and S3F3 showed insignificant effects on JY.

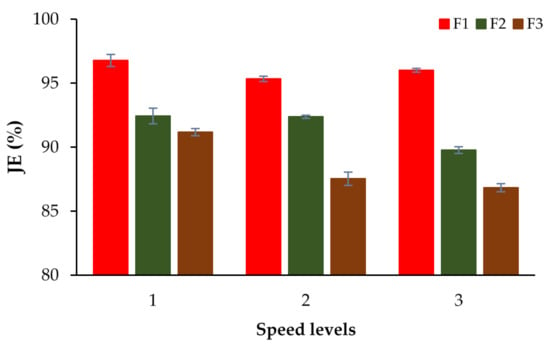

The combined effect of rotor speed of electric motor and mango feed rate on extraction efficiency (JE) is shown in Figure 4.

Figure 4.

Effect of speed (S) and feed rate (F) on extraction efficiency (JE) (F1 = 2.0 kg/min, F2 = 2.5 kg/min, F3 = 3.0 kg/min, S1 = 500 rpm, S2 = 900 rpm, S3 = 1400 rpm).

The extraction efficiency at three levels of speed (S1 = 500 rpm, S2 = 900 rpm and S3 = 1400 rpm) and at three levels of feed rate (F1 = 2.0 kg/min, F2 = 2.5 kg/min and F3 = 3.0 kg/min) was analyzed statistically. The interaction S1F1, S2F1 and S2F3 had significantly different effect on JE. However, the interaction S3F2 had statistically different effect on JE. However, S1F2 and S2F2 had significant effects on JE. The same effects were observed among S1F3, S2F3 and S3F3.

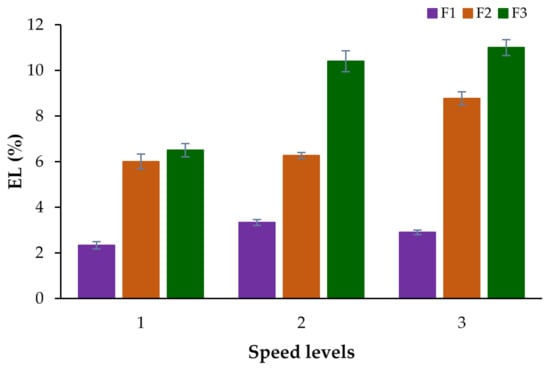

The combined effect of rotor speed of electric motor (rpm) and mango feed rate (kg/min) on extraction losses (EL) could be easily observed in the Figure 5.

Figure 5.

Effect of speed (S) and feed rate (F) on extraction losses (EL). (F1 = 2.0 kg/min, F2 = 2.5 kg/min, F3 = 3.0 kg/min, S1 = 500 rpm, S2 = 900 rpm, S3 = 1400 rpm).

The extraction losses (EL) at three levels of rotor speed of electric motor (S1 = 500 rpm, S2 = 900 rpm and S3 = 1400 rpm) and at three levels of mango feed rate (F1 = 2.0 kg/min, F2 = 2.5 kg/min and F3 = 3.0 kg/min) were analyzed statistically. The interaction S1F1, S2F1 and S3F1 had significantly different effect on EL. However, the interaction S3F2 had statistically different effect on %JE. However, S1F2 and S2F2 had significant effects on JE. Same effects were observed among S1F3, S2F3 and S3F3 on EL.

3.5. Physicochemical Profiling of Extracted Mango Pulp

The effects of rotor speed of electric motor and mango feed rate on physicochemical parameters are shown in Table 4. The results revealed that the rotor speed and mango feed rate had significant effect on the contents of ash, fat and MC at 5% probability level. Changes in S (rpm) and F (kg/min) had greatly influenced performance parameters. In addition, it was observed that the interaction of speed and feed rate (S × F) was also significant at 5% probability level.

Table 4.

ANOVA for chemical composition, pH, titratable acidity (TA), total sugars (TS), total soluble solids (TSS), vitamin C of mango pulp.

The mean values of chemical components extracted at optimum speed level (S2) and optimum feed rate level (F2) are shown in Table 5. Our values are comparable with the observations made by Naz et al. [36] with some variations, which are may be due to the shear forces and high temperature occurred due to friction in the extraction compartment.

Table 5.

Mean values of all the chemical components during combined effect of speed and feed.

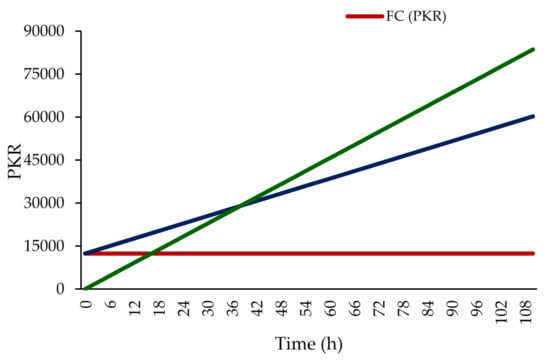

3.6. Breakeven Analysis

Breakeven analysis focuses on the viability of an organization. The specific concern in breakeven analysis is finding the stage of operation that results in zero profit. The breakeven is an important planning tool, especially if the organization is about to launch new products. The breakeven point is useful reference in that it represents the stage of operation when the total revenue becomes equal to total cost. The breakeven point of mango pulp extractor befallen at 40 h of use as shown in Figure 6.

Figure 6.

Breakeven point for mango pulp extractor.

4. Conclusions

The development and fabrication of the mango pulp extractor has been carried out and the machine was successfully constructed, assembled and tested. The optimum operating speed of the electric motor for pulp extraction was S2 (900 rpm) for mango fruits, while the optimum mango feed rate was F2 (2.5 kg/min), but it can also operate at F3 (3.0) kg/min. The breakeven point of the machine was 40 h if the machine is operated at its peak capacity. With a machine cost of about PKR. 60,000/-, it is affordable for small-scale farmers (cottage industry) in the rural communities.

Author Contributions

Conceptualization, M.U.K., M.H. and M.S.M.; data curation, M.E.A. and U.A.; writing—original draft preparation, M.E.A. and M.A.K.; writing—review and editing, M.U.K., M.H., M.S.M., A.Z., M.P. and J.M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this review are available on request from the corresponding author.

Acknowledgments

The authors are grateful to GAIN (Axencia Galega de Innovación) for supporting this work (grant number IN607A2019/01).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Maldonado-Celis, M.E.; Yahia, E.M.; Bedoya, R.; Landázuri, P.; Loango, N.; Aguillón, J.; Restrepo, B.; Guerrero Ospina, J.C. Chemical Composition of Mango (Mangifera indica L.) Fruit: Nutritional and Phytochemical Compounds. Front. Plant Sci. 2019, 10, 1073. [Google Scholar] [CrossRef]

- Gerbaud, P. Mango. Fruit Trop 2008, 153, 10–35. [Google Scholar]

- Ulloa, J.A.; Escalona, H.B.; de la Mora, E.E.V.; Díaz-Jiménez, L.; Hernández-Tinoco, A. Color and texture properties of minimally processed mango (Mangifera indica) segments by hurdle technology, auto stabi-lized in glass jars. In Proceedings of the Annual Meeting Book of Abstracts, Las Vegas, Nevada, 12–16 July 2004; Institute of Food Technologists: Chicago, IL, USA, 2004. Abstract 83D-6. p. 216. [Google Scholar]

- Ahmada, K.; Khanc, M.A.N.A.; Sarward, A. Quality Deterioration of Postharvest Fruits and Vegetables in Developing Country Pakistan: A Mini Overview. Asian J. Agric. Food Sci. 2021, 9, 83–90. [Google Scholar]

- Singh, Z.; Singh, R.K.; Sane, V.A.; Nath, P. Mango—Postharvest Biology and Biotechnology. CRC Crit. Rev. Plant Sci. 2013, 32, 217–236. [Google Scholar] [CrossRef]

- Baltazari, A.; Mtui, H.; Chove, L.; Msogoya, T.; Kudra, A.; Tryphone, G.; Samwel, J.; Paliyath, G.; Sullivan, A.; Subramanian, J.; et al. Evaluation of Post-harvest Losses and Shelf Life of Fresh Mango (Mangifera indica L.) in Eastern Zone of Tanzania. Int. J. Fruit Sci. 2020, 20, 855–870. [Google Scholar] [CrossRef]

- Ahmed, J.; Ramaswamy, H.S.; Hiremath, N. The effect of high pressure treatment on rheological characteristics and colour of mango pulp. Int. J. Food Sci. Technol. 2005, 40, 885–895. [Google Scholar] [CrossRef]

- Kasso, M.; Bekele, A. Post-harvest loss and quality deterioration of horticultural crops in Dire Dawa Region, Ethiopia. J. Saudi Soc. Agric. Sci. 2018, 17, 88–96. [Google Scholar] [CrossRef] [Green Version]

- Ramos, B.; Miller, F.A.; Brandão, T.R.S.; Teixeira, P.; Silva, C.L.M. Fresh fruits and vegetables—An overview on applied methodologies to improve its quality and safety. Innov. Food Sci. Emerg. Technol. 2013, 20, 1–15. [Google Scholar] [CrossRef]

- Abulude, F.; Elemide, A.; Ogunkoya, M.; Adesanya, W. Design and performance evaluation of a juice extractor constructed in Nigeria. Res. J. Appl. Sci. 2007, 2, 31–34. [Google Scholar]

- Akhtar, S.; Mahmood, S.; Naz, S.; Nasir, M.; Sultan, M.T. Sensory evaluation of mangoes (Mangifera indica L.) grown in different regions of Pakistan. Pak. J. Bot. 2009, 41, 2821–2829. [Google Scholar]

- Bates, R.P.; Morris, J.R.; Crandall, P.G. Principles and practices of small-and medium-scale fruit juice processing. FAO Agric. Serv. Bull. 2001, 146, 3–9. [Google Scholar]

- Siddiq, M.; Sogi, D.S.; Roidoung, S. Mango processing and processed products. In Handbook of Mango Fruit: Production, Postharvest Science, Processing Technology and Nutrition; Siddiq, M., Brecht, J.K., Sidhu, J.S., Eds.; Wiley-Blackwell: Hoboken, NJ, USA, 2017; pp. 195–216. ISBN 978-1-119-01435-5. [Google Scholar]

- Ghafoor, A.; Mustafa, K.; Zafar, I.; Mushtaq, K. Determinants of mango export from Pakistan. J. Agric. Res. 2010, 48, 105–119. [Google Scholar]

- Olaniyan, A.M. Development of a small scale orange juice extractor. J. Food Sci. Technol. 2010, 47, 105–108. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Olaniyan, A.M.; Oje, K. Development of model equations for selecting optimum parameters for dry process of shea butter extraction. J. Cereal. Oilseeds 2011, 5, 47–56. [Google Scholar]

- Helrich, K. Official Methods of Analysis of the Association of Official Analytical Chemists, 15th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 1990. [Google Scholar]

- Smith, F.M.A.; Hamilton, G.D.K.; Geeds, P.A.G. Calorimetric methods for determination of sugar and related substances. Anal. Chem. 1956, 28, 55–67. [Google Scholar]

- Akhtar, S.; Riaz, M.; Ahmad, A.; Nisar, A. Physico-chemical, microbiological and sensory stability of chemically preserved mango pulp. Pak. J. Bot. 2010, 42, 853–862. [Google Scholar]

- Khan, M.U.; Shariati, M.A.; Kadmi, Y.; Elmsellem, H.; Majeed, M.; Khan, M.R.; Fazel, M.; Rashidzadeh, S. Design, development and performance evaluation of distillery yeast sludge dryer. Process Saf. Environ. Prot. 2017, 111, 733–739. [Google Scholar] [CrossRef]

- Jacobs, C.O.; Williams, R.H. Agricultural Power and Machinery; National Book Foundation: Lahore, Pakistan, 1987; ISBN 9780070322103. [Google Scholar]

- Robb, J.G.; Smith, J.A.; Ellis, D.E. Whole Farm Machine Cost Estimator WFMACH: A Spreadsheet Program. J. Nat. Resour. Life Sci. Educ. 1998, 27, 25–29. [Google Scholar] [CrossRef]

- Kepner, R.A.; Bainer, R.; Bagner, E.L. Principles of Farm Machinery, 3rd ed.; CBS Publishers & Distributors Pvt. Ltd.: New Delhi, India, 2017; ISBN 978-93-887-2550-7. [Google Scholar]

- Cross, T.L.; Perry, G.M. Depreciation Patterns for Agricultural Machinery. Am. J. Agric. Econ. 1995, 77, 194–204. [Google Scholar] [CrossRef]

- Kieso, D.E.; Weygandt, J.J.; Warfield, T.D. Intermediate Accounting: IFRS Edition, 2nd ed.; Wiley: Danvers, MA, USA, 2014; ISBN 978-1-118-80069-0. [Google Scholar]

- Weygandt, J.J.; Kieso, D.E.; Kimmel, P.D. Accounting Principles, 10th ed.; Wiley: Danvers, MA, USA, 2011; ISBN 978-0-470-53479-3. [Google Scholar]

- Yasin, M. Test Comparative Study of Different Methods of Wheat Harvesting and Threshing in the Punjab Province; National Book Foundation: Lahore, Pakistan, 1986. [Google Scholar]

- Morris, J. Estimation of tractor repair and maintenance costs. J. Agric. Eng. Res. 1988, 41, 191–200. [Google Scholar] [CrossRef]

- Lazarus, W.F. Machinery cost estimates. Univ. Minn. Ext. 2009, 378, 1–8. [Google Scholar]

- Asoiro, F.; Udo, U. Development of Motorized Oil Palm Fruit Rotary Digester. Niger. J. Technol. 2013, 32, 455–462. [Google Scholar]

- Hmar, B.Z. Design and Development of a Pulper for Kendu Fruit; National Institute of Technology Rourkela: Odisha, India, 2018. [Google Scholar]

- Adebayo, A.; Unuigbe, O.; Atanda, E. Fabrication and performance evaluation of a portable motorized pineapple juice extractor. Innov. Syst. Des. Eng. 2014, 5, 22–29. [Google Scholar]

- Badmus, G.; Adeyemi, N. Design and fabrication of a small scale whole pineapple fruit juice extractor. In Proceedings of the 5th International Conference and 26th Annual General Meeting of the Nigerian Institution of Agricultural Engineers, Ilorin, Nigeria, 28 November–2 December 2004; Nigerian Institution of Agricultural Engineers: Ilorin, Nigeria, 2004; Volume 26, pp. 285–291. [Google Scholar]

- Gbabo, A.; Liberty, J.; Akingbala, A. Design, construction and performance evaluation of a bush mango juice and seed extractor. Int. J. Eng. Res. Technol. 2013, 2, 711–723. [Google Scholar]

- Aviara, N.A.; Lawa, A.A.; Nyam, D.S.; Bamisaye, J. Development and performance evaluation of a multi-fruit juice extractor. Glob. J. Eng. Des. Technol. 2013, 2, 16–21. [Google Scholar]

- Naz, S.; Anjum, M.A.; Chohan, S.; Akhtar, S.; Siddique, B. Physico chemical and sensory profiling of promising mango cultivars grown in peri-urban areas of Multan, Pakistan. Pak. J. Bot. 2014, 46, 191–198. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).