Energy Efficiency of Variable Rate Fertilizer Application in Coffee Production in Brazil

Abstract

:1. Introduction

2. Materials and Methods

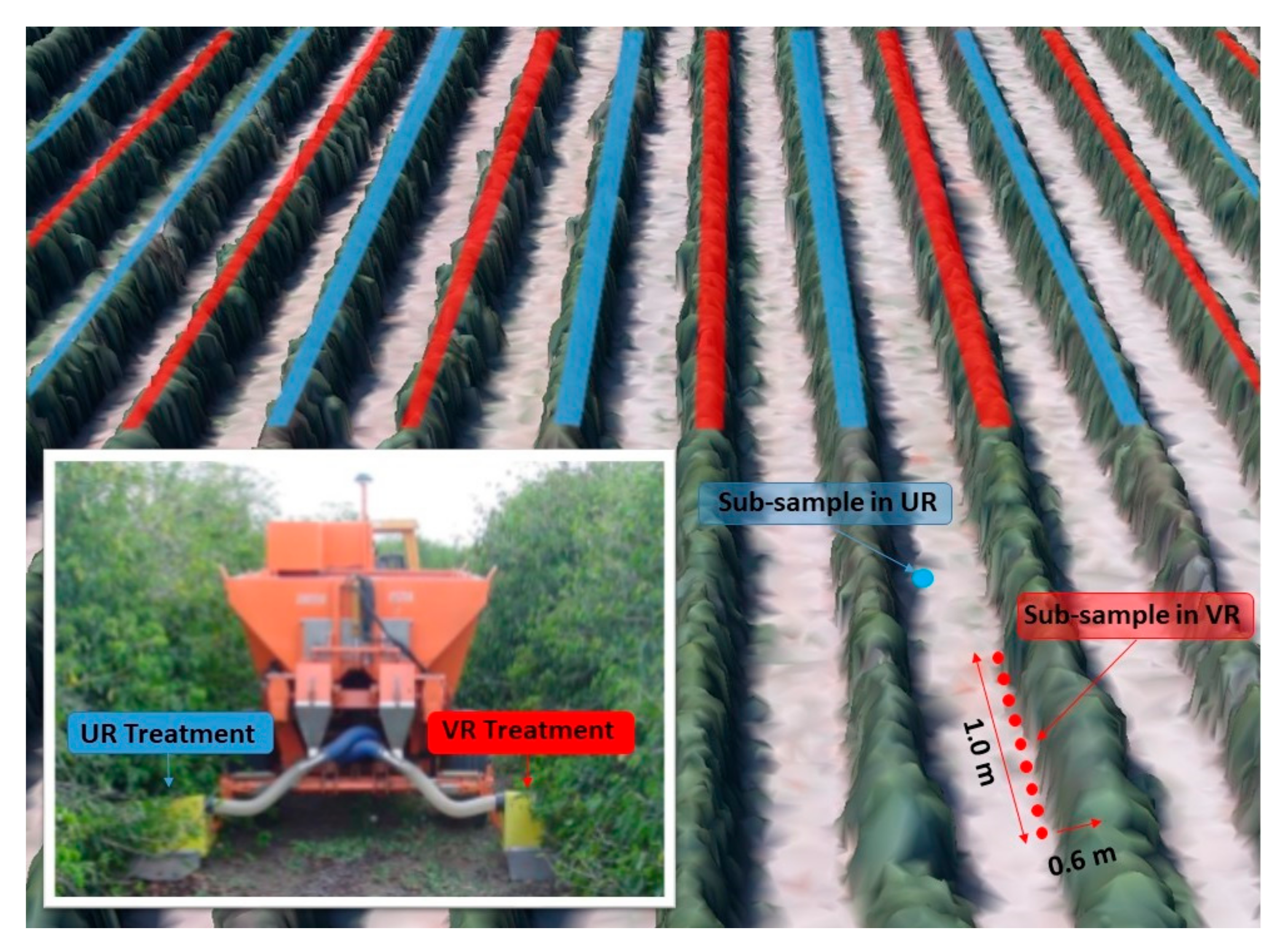

2.1. Coffee Areas and Treatments

2.2. Material Flow and Energy Analysis

2.3. Spatial Variability Analysis

3. Results

3.1. Material Flow

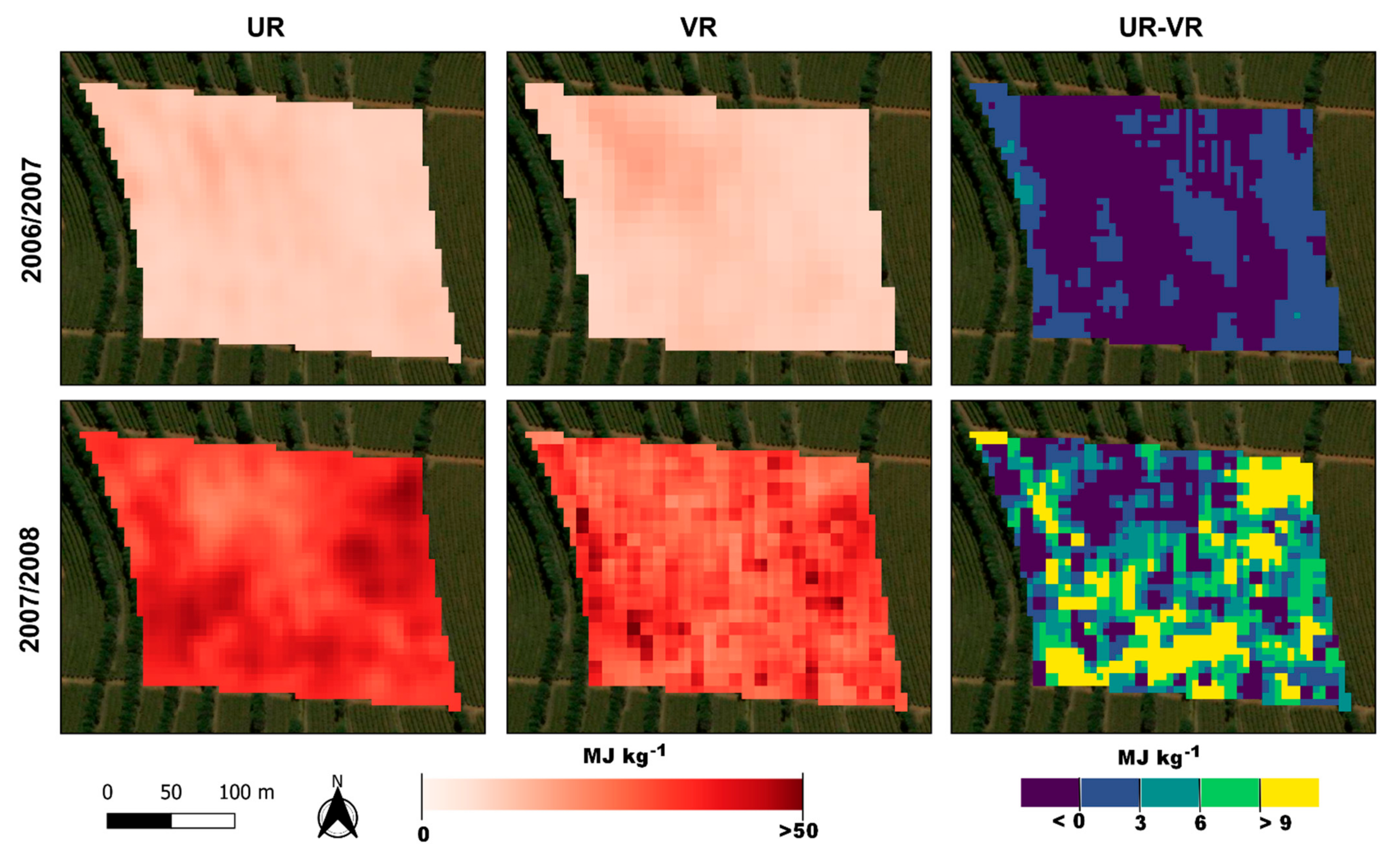

3.2. Energy Flows

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Embrapa. Faturamento Bruto Estimado dos Cafés do Brasil da Espécie Arábica Corresponde a 78% e de Conilon a 22% do Total das Lavouras Cafeeiras. 2021. Available online: https://www.embrapa.br/busca-de-noticias/-/noticia/63076571/faturamento-bruto-estimado-dos-cafes-do-brasil-da-especie-arabica-corresponde-a-78-e-de-conilon-a-22-do-total-das-lavouras-cafeeiras (accessed on 11 June 2021).

- Molin, J.P.; Motomiya, A.V.A.; Frasson, F.R.; Faulin, G.D.C.; Tosta, W. Test procedure for variable rate fertilizer on coffee. Acta Sci. Agron. 2010, 32, 569–575. [Google Scholar] [CrossRef] [Green Version]

- Mulla, D.J.; Bhatti, A.V.; Kunkel, R. Methods for removing spatial variability from field research trials. Adv. Soil Sci. 1990, 13, 201–213. [Google Scholar]

- Lowenberg-DeBoer, J.; Erickson, B. Setting the record straight on precision agriculture adoption. Agron. J. 2019, 111, 1552–1569. [Google Scholar] [CrossRef] [Green Version]

- Molin, J.P.; Faulin, G.D.C. Spatial and temporal variability of soil electrical conductivity related to soil moisture. Sci. Agric. 2013, 70, 01–05. [Google Scholar] [CrossRef]

- Colaço, A.F.; Pagliuca, L.G.; Romanelli, T.L.; Molin, J.P. Economic viability, energy and nutrient balances of site-specific fertilization for citrus. Biosyst. Eng. 2020, 200, 138–156. [Google Scholar] [CrossRef]

- Yang, C.; Everitt, J.H.; Bradford, J.M. Comparisons of uniform and variable rate nitrogen and phosphorus fertilizer applications for grain sorghum. Trans. ASAE 2001, 44, 201–209. [Google Scholar] [CrossRef]

- Wang, D.; Prato, T.; Qiu, Z.; Kitchen, N.R.; Sudduth, K.A. Economic and environmental evaluation of variable rate nitrogen and lime application for claypan soil fields. Precis. Agric. 2003, 4, 35–52. [Google Scholar] [CrossRef]

- Johnson, R.M.; Richard, E.P. Variable-rate lime application in Louisiana sugarcane production systems. Precis. Agric. 2010, 11, 464–474. [Google Scholar] [CrossRef]

- Thomason, W.E.; Phillips, S.B.; Davis, P.H.; Warren, J.G.; Alley, M.M.; Reiter, M.S. Variable nitrogen rate determination from plant spectral reflectance in soft red winter wheat. Precis. Agric. 2011, 12, 666–681. [Google Scholar] [CrossRef]

- Swinton, S.M.; Lowenberg-DeBoer, J. Evaluating the profitability of site-specific farming. J. Prod. Agric. 1988, 11, 439–446. [Google Scholar]

- Diacono, M.; Rubino, P.; Montemurro, F. Precision nitrogen management of wheat: A review. Agron. Sustain. Dev. 2013, 33, 219–241. [Google Scholar] [CrossRef]

- Balafoutis, A.T.; Koundouras, S.; Anastasiou, E.; Fountas, S.; Arvanitis, K. Life cycle assessment of two vineyards after the application of precision viticulture techniques: A case study. Sustainability 2017, 9, 16. [Google Scholar] [CrossRef] [Green Version]

- Spekken, M.; Molin, J.P.; Romanelli, T.L. Cost of boundary manoeuvres in sugarcane production. Biosyst. Eng. 2015, 129, 112–126. [Google Scholar] [CrossRef]

- Colaço, A.F.; Povh, F.P.; Molin, J.P.; Romanelli, T.L. Energy assessment for variable rate nitrogen application. CIGR J. 2012, 14, 85–90. [Google Scholar]

- Romanelli, T.L.; Milan, M. Energy performance of a production system of eucalyptus. Rev. Bras. Eng. Agrícola Ambient. 2010, 14, 896–903. [Google Scholar] [CrossRef]

- Kuosmanen, N. Estimating stocks and flows of nitrogen: Application of dynamic nutrient. Ecol. Econ. 2014, 108, 68–78. [Google Scholar] [CrossRef]

- Parris, K. Agricultural nutrient balances as agrienvironmental indicators: An OECD perspective. Environ. Pollut. 1998, 102, 219–225. [Google Scholar] [CrossRef]

- Ferreira, C.O. Análise energética de sistemas de produção agrícola. Rev. Econ. Energ. 1999, 3. [Google Scholar]

- Odum, H.T.; Odum, B. Concepts and methods of ecological engineering. Ecol. Eng. 2003, 20, 339–361. [Google Scholar] [CrossRef]

- Veiga, J.P.S.; Romanelli, T.L.; Gimenez, L.M.; Brusato, P.; Milan, M. Energy embodiment in Brazilian agriculture: An overview of 23 crops. Sci. Agric. 2015, 72, 471–477. [Google Scholar] [CrossRef]

- Roberts, D.F.; Kitchen, N.R.; Scharf, P.C.; Sudduth, K.A. Will variable-rate nitrogen fertilization using corn canopy reflectance sensing deliver environmental benefits? Agron. J. 2010, 102, 85. [Google Scholar] [CrossRef] [Green Version]

- Colaço, A.F.; Molin, J.P.; Romanelli, T.L. Mapping nutrient energy embodiment in variable and fixed rate fertilization in orange. In Proceedings of the EFITA-WCCA-CIGR Conference, Turin, Italy, 24–27 June 2013. [Google Scholar]

- Lacerda Filho, A.F.; Palacin, J.J.F.; Rigueira, J.A.R.; Ribeiro, A.; Melo, E.C. Energy balance in the production of mountain coffee. Renew. Sustain. Energy Rev. 2014, 39, 1208–1213. [Google Scholar] [CrossRef]

- Muner, L.H.; Masera, O.; Fornazier, M.J.; Souza, C.V.; Loreto, M.D.S. Energetic sustainability of three arabica coffee growing systems used by family farming units in Espírito Santo state. Engenharia Agrícola 2015, 35, 3. [Google Scholar] [CrossRef] [Green Version]

- Turco, P.H.N.; Esperancini, M.S.T.; de Carvalho Bueno, O.; Oliveira, M.D.M. Balanço energético dos sistemas de produção de café convencional e irrigado. Energ. Agric. 2018, 33, 73–80. [Google Scholar] [CrossRef]

- Molin, J.P.; Faulin, G.D.C.; Stanislavski, W.M. Yield mapping and variable rate of fertilizers for coffee in Brazil. Acta Hortic. 2009, 1, 261–266. [Google Scholar] [CrossRef]

- EMBRAPA SOLOS. Sistema Brasileiro de Classificação de Solos; EMBRAPA Produção de Informação: Brasília, Brazil, 1999; 412p. [Google Scholar]

- The R Development Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2009. [Google Scholar]

- Venables, W.N.; Ripley, B.D. Modern Applied Statistics with S, 4th ed.; Springer: New York, NY, USA, 2002; 498p. [Google Scholar]

- Ribeiro Junior, P.J.; Diggle, P.J. geoR: A package for geostatistical analysis. R News 2001, 1, 15–18. [Google Scholar]

- Cambardella, C.A.; Moorman, T.B.; Parkin, T.B.; Karlen, D.L.; Novak, J.M.; Turco, R.F.; Konopka, A.E. Field-scale variability of soil properties in central Iowa soils. Soil Sci. Soc. Am. J. Madison 1994, 58, 1501–1511. [Google Scholar] [CrossRef]

- Romanelli, T.L.; Milan, M. Material flow determination through agricultural machinery management. Sci. Agric. 2010, 67, 4. [Google Scholar] [CrossRef] [Green Version]

- Pellizzi, G. Use of energy and labor in Italian agriculture. J. Agric. Eng. Res. 1992, 52, 111–119. [Google Scholar] [CrossRef]

- Sartori, S.; Fava, J.F.M.; Domingues, E.L.; Ribeiro Filho, A.C.; Shiraisi, L.E. Mapping the Spatial Variability of Coffee Yield with Mechanical Harvester. In Proceedings of the World Congress of Computers in Agriculture and Natural Resources, Iguacu Falls, Brazil, 13–15 March 2002; pp. 196–205. [Google Scholar] [CrossRef]

- Franco, G. Tabela de Composição Química dos Alimentos, 9th ed.; Editora Atheneu: São Paulo, Brazil, 1999; 307p. [Google Scholar]

- QGIS v2.10—QGIS Development Team. QGIS Geographic Information System. Open Source Geospatial Foundation Project. 2019. Available online: http://www.qgis.org (accessed on 5 January 2021).

- Adrian, A.M.; Norwood, S.H.; Mask, P.L. Producers perceptions and attitudes toward precision agriculture technologies. Comput. Electron. Agric. 2005, 48, 256–271. [Google Scholar] [CrossRef]

- Camargo, A.P.; Camargo, M.B.P. Definição e esquematização das fases fenológicas do cafeeiro arábica nas condições tropicais do Brasil. Bragantia 2001, 60, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Harsono, S.S.; Wibowo, R.K.K.; Supriyanto, E. Energy Balance and Green House Gas Emission on Smallholder Java Coffee Production at Slopes Ijen Raung Plateau of Indonesia. J. Ecol. Eng. 2021, 22, 271–283. [Google Scholar] [CrossRef]

| Season | Treatment | Samples (1) | Mean | Min. | Max. | SD (2) | CV (3) (%) | W (4) |

|---|---|---|---|---|---|---|---|---|

| (leaf N, g kg−1) | ||||||||

| 07/08 | UR | 1 | 27.4 | - | - | - | - | - |

| VR | 8 | 26.9 | 26.3 | 27.6 | 0.47 | 1.74 | 0.942 * | |

| (soil P-resin, mg dm−3) | ||||||||

| 06/07 | UR | 1 | 18.0 | - | - | - | - | - |

| VR | 20 | 17.9 | 12.0 | 35.0 | 7.1 | 39.3 | 0.791 | |

| 07/08 | UR | 1 | 6.9 | - | - | - | - | - |

| VR | 14 | 6.0 | 5.0 | 7.0 | 0.8 | 13.1 | 0.912 * | |

| (soil K, mmolc dm−3) | ||||||||

| 06/07 | UR | 1 | 1.50 | - | - | - | - | - |

| VR | 20 | 1.49 | 1.1 | 3.5 | 0.53 | 35.7 | 0.642 | |

| 07/08 | UR | 1 | 4.50 | - | - | - | - | - |

| VR | 19 | 4.47 | 3.7 | 5.0 | 0.43 | 9.6 | 0.778 | |

| Season | Model | C0 (1) | C1 (2) | a (m) (3) | SC% (4) |

|---|---|---|---|---|---|

| Nitrogen (leaf sample) | |||||

| 07/08 | Spherical | 0.05 | 0.21 | 140.0 | 19 *** |

| Phosphorus (soil sample) | |||||

| 06/07 | Spherical | 0.53 | 0.91 | 109.1 | 37 ** |

| 07/08 | Spherical | 0.003 | 0.001 | 105.2 | 75 ** |

| Potassium (soil sample) | |||||

| 06/07 | Spherical | 0.002 | 0.01 | 124.7 | 17 *** |

| 07/08 | Spherical | 2680.92 | 20,777.16 | 105.2 | 11 *** |

| Yield | |||||

| 06/07 | Exponential | 7.9 × 103 | 4.7 × 103 | 69.1 | 62.4 ** |

| 07/08 | Exponential | 2.1 × 10−1 | 1.8 × 10−1 | 57.3 | 53.9 ** |

| Season | Treatment | N (kg ha−1) | P2O5 (kg ha−1) | K2O (kg ha−1) | Yield (kg ha−1) |

|---|---|---|---|---|---|

| 06/07 | VR | 340 | 13.7 ± 4.4 | 427.6 ± 25.6 | 2753 ± 507 |

| UR | 340 | 18.0 | 431.3 | 2835 ± 383 | |

| 07/08 | VR | 274 ± 56.4 | 7.1 ± 4.5 | 104.3 ± 45.5 | 702 ± 152 |

| UR | 278 | 8.6 | 262.3 | 655 ± 100 |

| Season | Treatment | N (MJ kg−1) | P2O5 (MJ kg−1) | K2O (MJ kg−1) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Max | Min | Mean ± s | Max | Min | Mean ± s | Max | Min | Mean ± s | ||

| 06/07 | VR | 14.14 | 6.7 | 9.09 ± 1.4 | 0.12 | 8.12 × 10−8 | 0.06 ± 0.02 | 1.84 | 0.71 | 1.08 ± 0.24 |

| UR | 14.14 | 6.7 | 9.05 ± 1.3 | 1.84 | 0.061 | 0.08 ± 0.012 | 1.62 | 0.78 | 1.03 ± 0.15 | |

| 07/08 | VR | 53.8 | 19.3 | 29.6 ± 5.1 | 0.5 | 2.32 × 10−7 | 0.12 ± 0.08 | 2.58 | 0.34 | 1.0 ± 0.4 |

| UR | 43.8 | 19.6 | 32.1 ± 4.4 | 0.23 | 0.1 | 0.16 ± 0.02 | 3.74 | 1.67 | 2.7 ± 0.4 | |

| Season | Treatment | Fertilizers (MJ kg−1) | Δ (MJ) | Δ (%) |

|---|---|---|---|---|

| 06/07 | VR | 10.7 ± 2.2 | −0.5 | −4.6 |

| UR | 10.2 ± 1.5 | |||

| 07/08 | VR | 30.7 ± 5.3 | 4.2 | 12 |

| UR | 34.9 ± 4.8 |

| Season | Treatment | EB | EROI | EI MJ kg−1 |

|---|---|---|---|---|

| 06/07 | VR | −0.98 | 0.90 | 10.7 |

| UR | −0.48 | 0.95 | 10.2 | |

| 07/08 | VR | −20.98 | 0.31 | 30.7 |

| UR | −25.18 | 0.28 | 34.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Angnes, G.; Martello, M.; Faulin, G.D.C.; Molin, J.P.; Romanelli, T.L. Energy Efficiency of Variable Rate Fertilizer Application in Coffee Production in Brazil. AgriEngineering 2021, 3, 815-826. https://doi.org/10.3390/agriengineering3040051

Angnes G, Martello M, Faulin GDC, Molin JP, Romanelli TL. Energy Efficiency of Variable Rate Fertilizer Application in Coffee Production in Brazil. AgriEngineering. 2021; 3(4):815-826. https://doi.org/10.3390/agriengineering3040051

Chicago/Turabian StyleAngnes, Graciele, Maurício Martello, Gustavo Di Chiacchio Faulin, José Paulo Molin, and Thiago Libório Romanelli. 2021. "Energy Efficiency of Variable Rate Fertilizer Application in Coffee Production in Brazil" AgriEngineering 3, no. 4: 815-826. https://doi.org/10.3390/agriengineering3040051

APA StyleAngnes, G., Martello, M., Faulin, G. D. C., Molin, J. P., & Romanelli, T. L. (2021). Energy Efficiency of Variable Rate Fertilizer Application in Coffee Production in Brazil. AgriEngineering, 3(4), 815-826. https://doi.org/10.3390/agriengineering3040051