Man-Machine-Interface Software Design of a Cotton Harvester Yield Monitor Calibration System

Abstract

:1. Introduction and Overview of the Research and Results of System Performance That This Technical Note Is in Support of

2. Man-Machine-Interface Software Design

2.1. Background Development Tools

- Serial-port communication reception of bytes

- Asynchronous functions responding to events

- User clicking or pressing on form buttons or typing in text boxes

- QT Timers

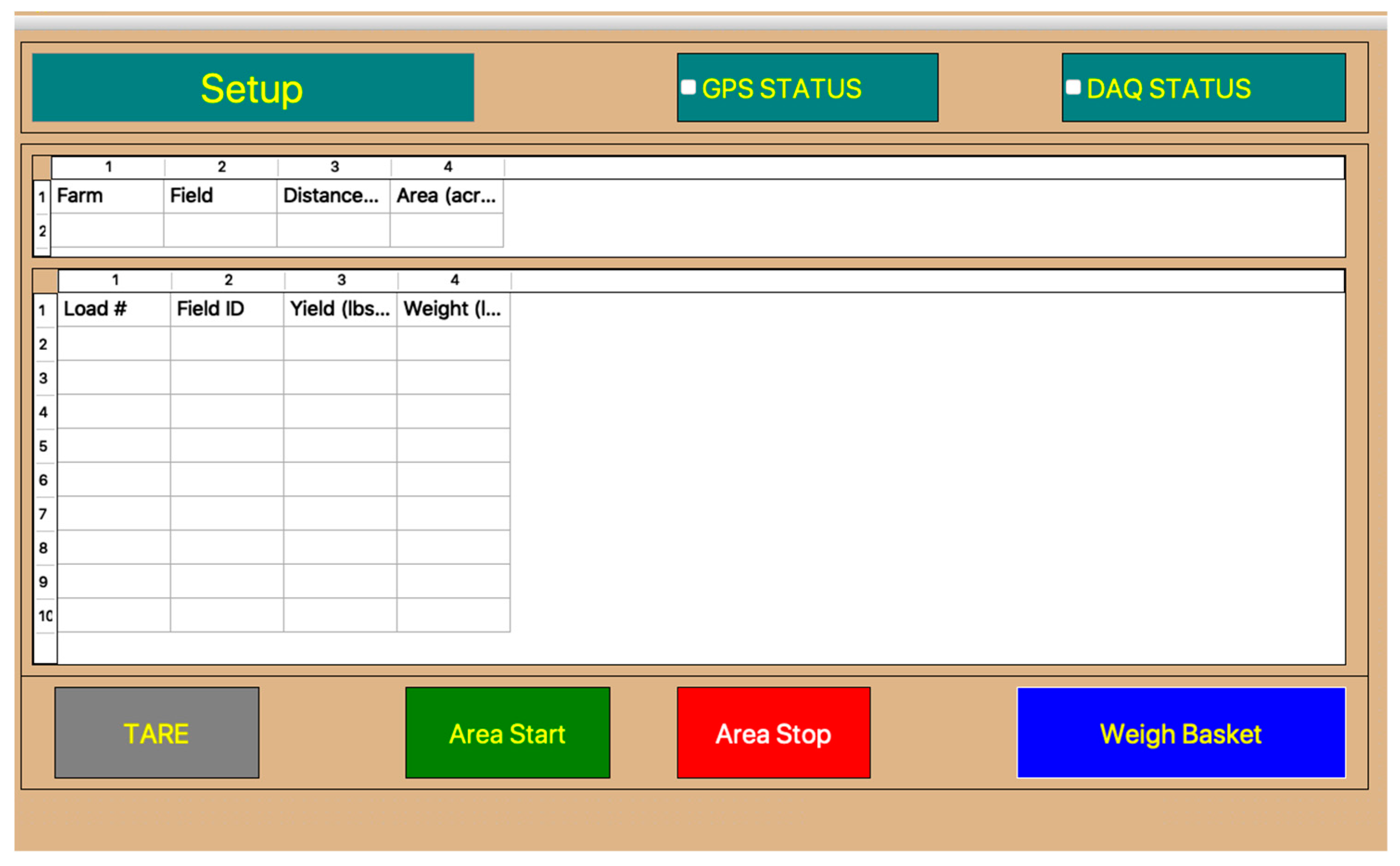

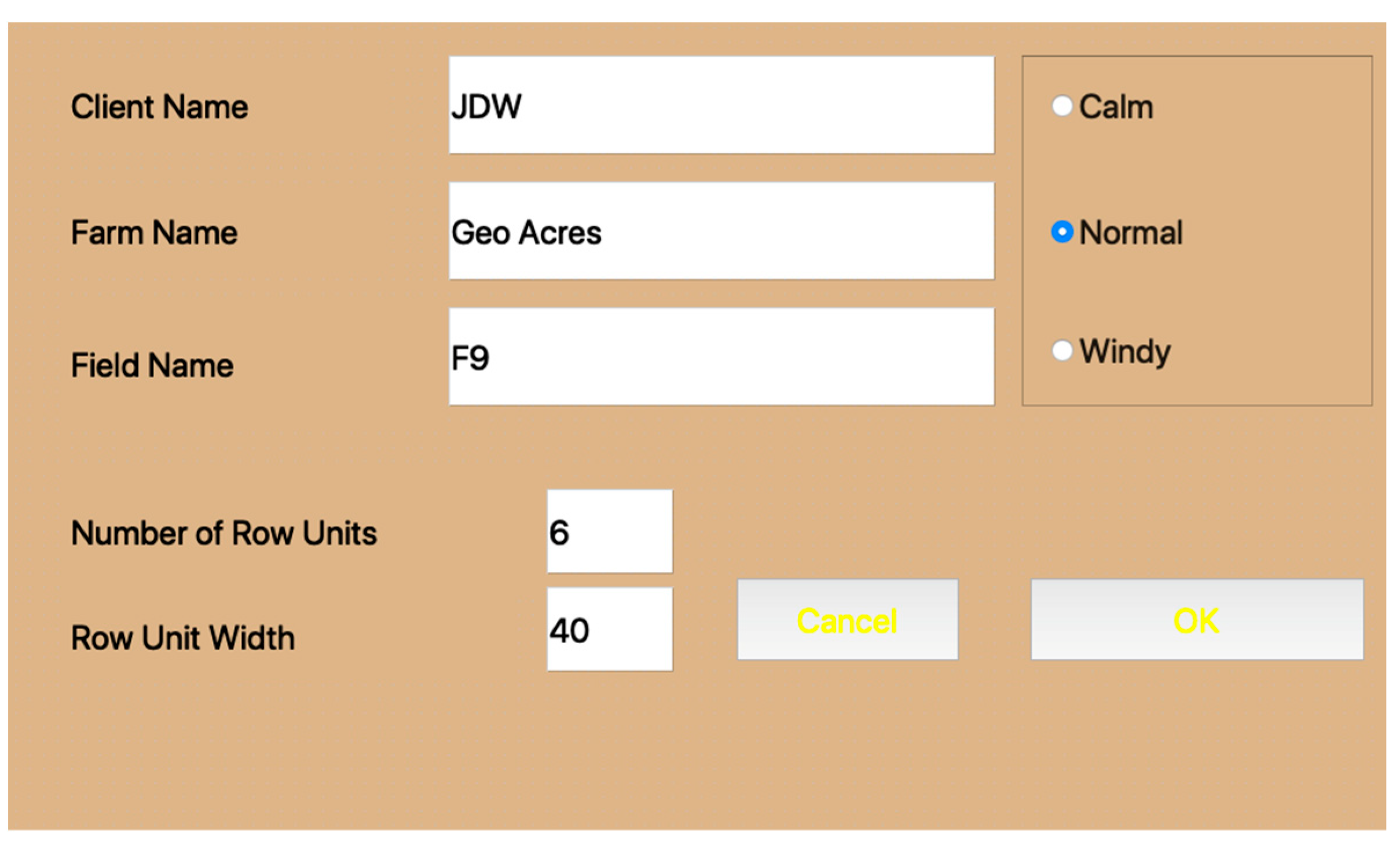

2.2. User Interface

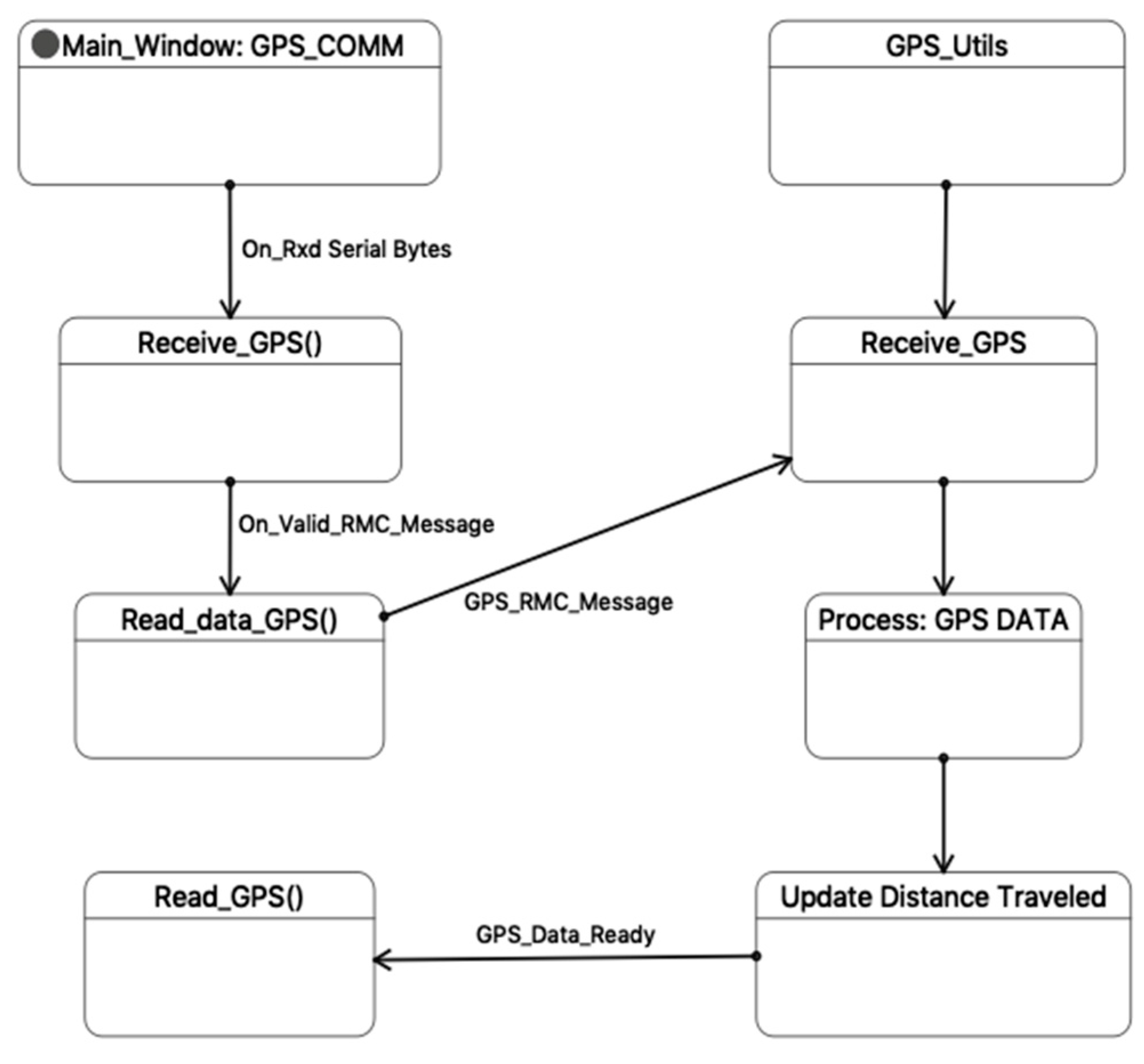

2.3. Software Design

- Instantiate all supporting utility classes,

- Configure QT event driven signal-slot connections for each of the serial ports for {global satellite positioning system (GPS), Data-Acquisition},

- Configure and verify serial communication to:

- ○

- GPS

- ○

- Data-Acquisition

- Load default standard saving locations, filenames, and data-base settings,

- Load farm-field setup screen and get user input as to specifics by which to tag all collected data,

- Delay using QT timer long enough to allow for GPS to establish connection and verify connection,

- Verify connection to the micro-controller that provides the data-acquisition and weigh controller functionality.

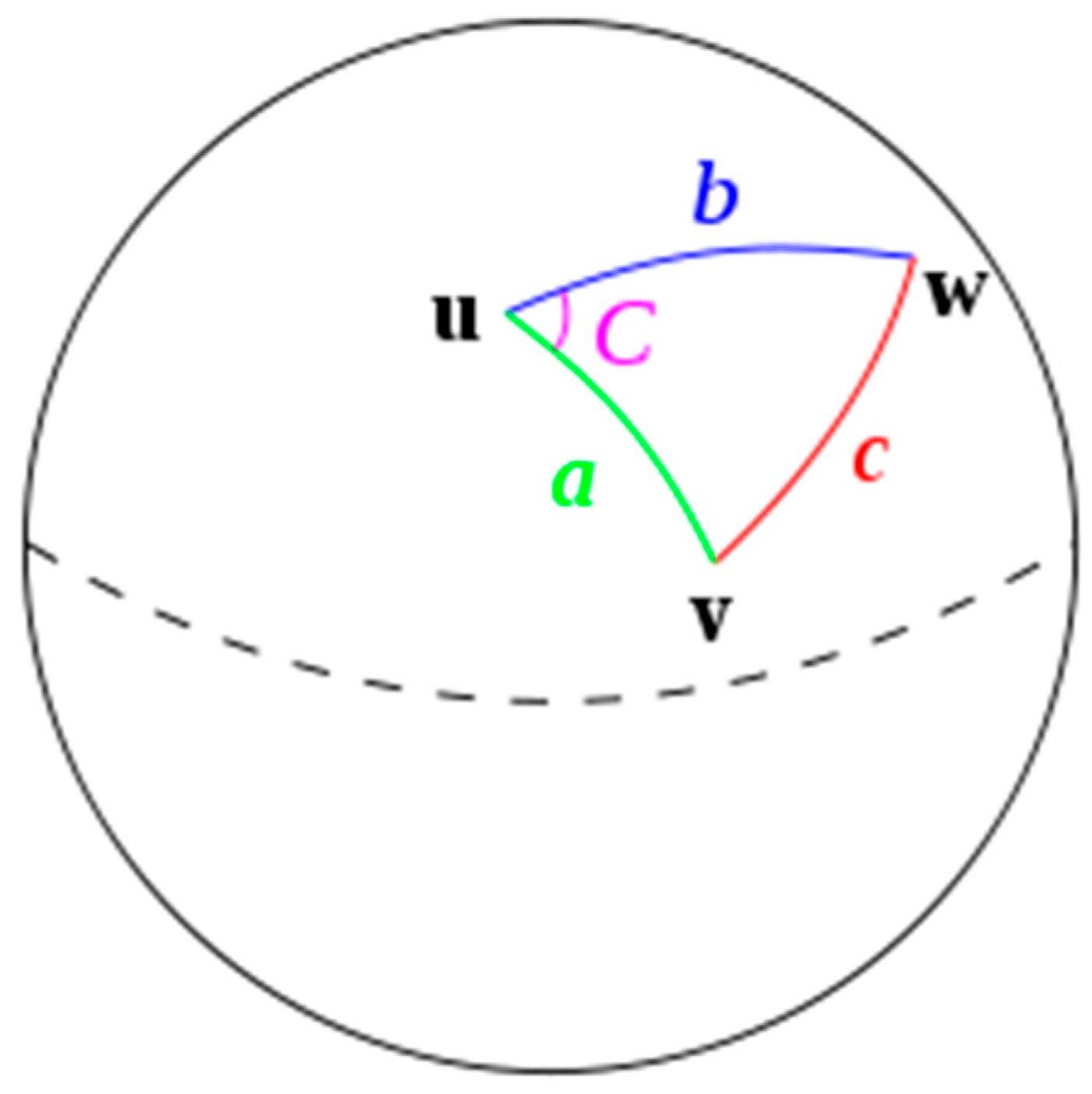

2.4. GPS Distance Computation

- φ1 is latitude of first location

- φ2 is latitude of second location

- λ1 is longitude of first location

- λ2 is longitude of second location

- Δφ is latitude difference between points 1, 2

- Δλ is longitude difference between points 1, 2

- R is earth’s radius (mean radius = 6371 km)

- atan2() is four quadrant function that computes tan−1()

- c is angular distance in radians

- a is the square of half the chord length between the points

- d is the distance between the two GPS points (m)

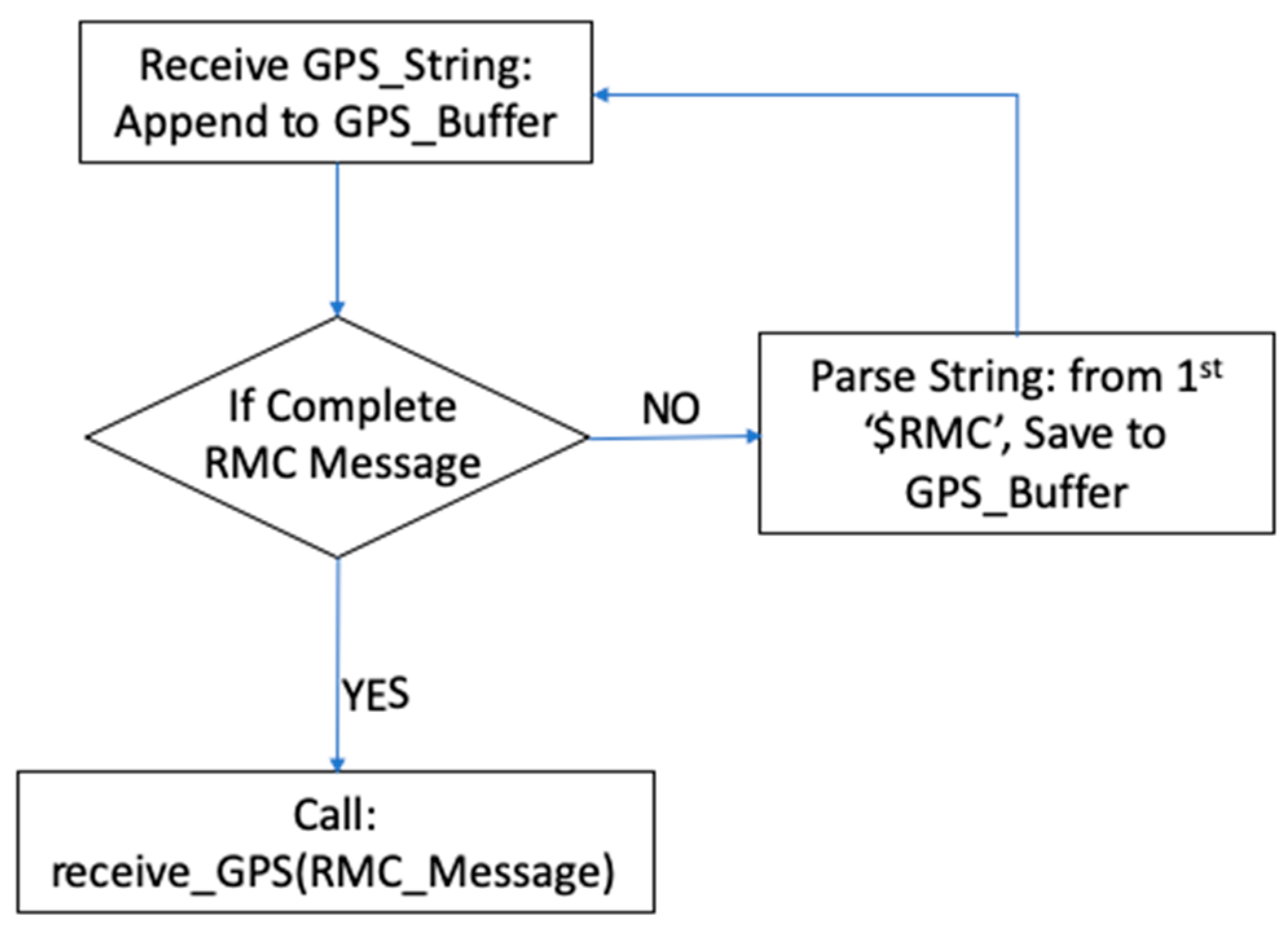

2.5. GPS Distance Integration

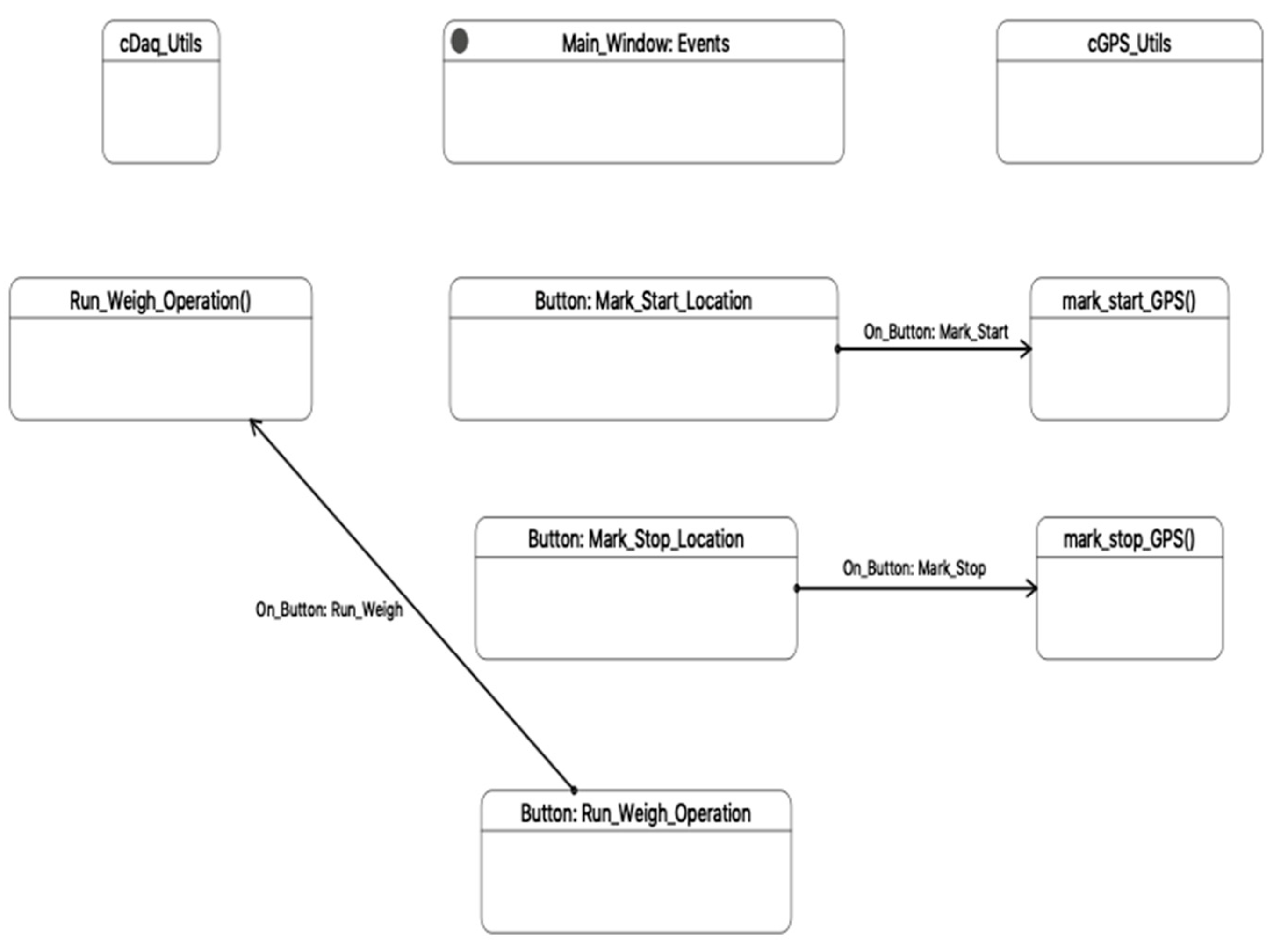

2.6. GPS Area Marking

2.7. Software Design Summary

3. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Rains, G.C.; Perry, C.D.; Vellidis, G.; Thomas, D.L.; Wells, N.; Kvien, C.K.; Dales, H.D. Cotton Yield Monitor Performance in Changing Varieties; ASAE Paper No. 021160; ASAE: St. Joseph, MI, USA, 2002. [Google Scholar]

- Wilkerson, J.B.; Moody, F.H.; Hart, W.E. Implementation and field evaluation of a cotton yield monitor. Appl. Eng. Agric. 2002, 18, 153–159. [Google Scholar] [CrossRef]

- Robertson, B.; Cordell, M.; Matthews, S.; Groves, F. Utility of Yield Monitors for On-farm Research. In Proceeding 2006 Beltwide Cotton Conferences; National Cotton Council: Memphis, TN, USA, 2006; pp. 1756–1758. [Google Scholar]

- Stewart, A.M.; Wright, I.R.; Deville, S.F.; Woolam, B.W. Comparison of On-Farm Cotton Variety Trial Results when Using Yield Monitors vs. Weigh Wagons. In Proceeding 2008 Beltwide Cotton Conferences; National Cotton Council: Memphis, TN, USA, 2008; pp. 69–71. [Google Scholar]

- Taylor, R.; Porter, W.; Boman, R.; Osborne, S.; Henderson, W.; Buschermohle, M.; Barnes, E. Using yield monitors to evaluate cotton variety tests. In Proceeding 2014 Beltwide Cotton Conferences; National Cotton Council: Memphis, TN, USA, 2014; pp. 494–498. [Google Scholar]

- Wanjura, J.D.; Kelley, M.S.; Taylor, R.K.; Porter, W.M.; Barnes, E.M.; Pelletier, M.G.; Holt, G.A. Evaluation of a cotton stripper yield monitor. In Proceeding 2014 Beltwide Cotton Conferences; National Cotton Council: Memphis, TN, USA, 2014; pp. 481–493. [Google Scholar]

- Vories, E.D.; Jones, A.S.; Meeks, C.D.; Stevens, W.E. Variety Effects on Cotton Yield Monitor Calibration. Appl. Eng. Agric. 2019, 35, 345–354. [Google Scholar] [CrossRef]

- Gvili, M. Cotton yield sensor produces yield maps. In Proceeding 1998 Beltwide Cotton Conferences; National Cotton Council: Memphis, TN, USA, 1998; pp. 1655–1657. [Google Scholar]

- Wilkerson, J.B.; Moody, F.H.; Hart, W.E.; Funk, P.A. Design and Evaluation of A Cotton Flow Rate Sensor. Trans. ASAE 2001, 44, 1415–1420. [Google Scholar] [CrossRef]

- Thomasson, J.A.; Sui, R. Advanced optical cotton yield monitor. In Proceeding 2000 Beltwide Cotton Conferences; National Cotton Council: Memphis, TN, USA, 2000; pp. 408–410. [Google Scholar]

- Deere & Company. Cotton Mass-Flow Sensor; Deere & Company: Moline, IL, USA, 2010; Available online: http://salesmanual.deere.com/sales/salesmanual/en_NA/cotton_harvesters/2011/feature/pickers/ams/cotton_mass_flow_sensor.html (accessed on 8 August 2019).

- Head, J.C.; Wilkerson, J.B.; Hart, W.E.; Allen, P.B. Identification and quantification of cotton yield monitor errors. In Proceeding 2009 Beltwide Cotton Conferences; National Cotton Council: Memphis, TN, USA, 2009; pp. 374–377. [Google Scholar]

- Walak, F.J.; Khalilian, A.; Dodd, R.B.; Han, Y.J.; Keshlkin, M.; Lippert, R.M.; Hair, W. Cotton yield monitor evaluation, South Carolina–Year 2. In Proceeding 1999 Beltwide Cotton Conferences; National Cotton Council: Memphis, TN, USA, 1999; pp. 361–364. [Google Scholar]

- Sassenrath–Cole, G.F.; Thomson, S.J.; Williford, J.R.; Hood, K.B.; Thomasson, J.A.; Williams, J.; Woodard, D. Field testing of cotton yield monitors. In Proceeding 1999 Beltwide Cotton Conferences; National Cotton Council: Memphis, TN, USA, 1999; pp. 364–366. [Google Scholar]

- Sui, R.; Thomasson, J.A. Test of temperature and stray-light effects on mass-flow sensor for cotton yield monitor. Appl. Eng. Agric. 2002, 18, 429–434. [Google Scholar]

- Thomasson, J.A.; Sui, R. Mississippi cotton yield monitor: Three years of field-test results. Appl. Eng. Agric. 2003, 19, 631–636. [Google Scholar] [CrossRef]

- Wanjura, J.D.; Pelletier, M.G.; Holt, G.A.; Kelley, M.S. A harvester-based calibration system for cotton yield monitors. In Proceeding 2015 Beltwide Cotton Conferences; National Cotton Council: Memphis, TN, USA, 2015; pp. 635–647. [Google Scholar]

- Wanjura, J.; Pelletier, M.; Holt, G.; Kelley, M. Reliability testing of an on-harvester cotton weight measurement system. In Proceeding 2016 Beltwide Cotton Conferences; National Cotton Council: Memphis, TN, USA, 2016; pp. 658–670. [Google Scholar]

- Pelletier, M.G.; Wanjura, J.D.; Holt, G.A. Electronic Design of a Cotton Harvester Yield Monitor Calibration System. AgriEngineering 2019. forthcoming. [Google Scholar]

- Pelletier, M.G.; Wanjura, J.D.; Holt, G.A. Embedded Micro-controller Software Design of a Cotton Harvester Yield Monitor Calibration System. AgriEngineering 2019, 1, 485–495. [Google Scholar] [CrossRef]

- Pelletier, M.G.; Wanjura, J.D.; Holt, G.A.; Funk, P.A. Methods for Protecting a Personal Computer and Data Acquisition Electronics Installed on Mobile Equipment. AgriEngineering 2019, 1, 4–16. [Google Scholar] [CrossRef]

- QT Company. QT Version 5.5; QT Group Plc: Helsinki, Finland, 2014; Available online: https://www.qt.io (accessed on 6 August 2019).

- National Marine Electronics Association. NEMA 0183 V4.0 Stand; National Marine Electronics Association: Severna Park, MD, USA, 2008. [Google Scholar]

- Goodwin, H.G. The haversine in nautical astronomy. Nav. Inst. Proc. 1910, 36, 735–746. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pelletier, M.G.; Wanjura, J.D.; Holt, G.A. Man-Machine-Interface Software Design of a Cotton Harvester Yield Monitor Calibration System. AgriEngineering 2019, 1, 511-522. https://doi.org/10.3390/agriengineering1040037

Pelletier MG, Wanjura JD, Holt GA. Man-Machine-Interface Software Design of a Cotton Harvester Yield Monitor Calibration System. AgriEngineering. 2019; 1(4):511-522. https://doi.org/10.3390/agriengineering1040037

Chicago/Turabian StylePelletier, Mathew G., John D. Wanjura, and Greg A. Holt. 2019. "Man-Machine-Interface Software Design of a Cotton Harvester Yield Monitor Calibration System" AgriEngineering 1, no. 4: 511-522. https://doi.org/10.3390/agriengineering1040037

APA StylePelletier, M. G., Wanjura, J. D., & Holt, G. A. (2019). Man-Machine-Interface Software Design of a Cotton Harvester Yield Monitor Calibration System. AgriEngineering, 1(4), 511-522. https://doi.org/10.3390/agriengineering1040037