1. Introduction

Nanocomposites with nano-scale reinforcements, such as carbon nanotubes (CNTs) or graphene nanoplatelets (GPLs), have gained significant attention in recent years due to their excellent properties and potential applications. These materials consist of a matrix phase reinforced with nanoscale fibres and/or particles, resulting in improved material qualities compared to macroscale composites [

1]. CNTs and graphene are two materials that possess superior mechanical properties, including high strength and strain to failure, making them suitable for lightweight structural and ballistic material applications [

2]. Additionally, CNTs and graphene exhibit special optical and electronic properties, which are adopted in various applications in photonics, optoelectronics, nanoelectronics, and sensors [

3].

Several researchers have conducted studies on the free vibration, buckling, and static bending behaviour of multi-layered composite structures reinforced with graphene nanoplatelets (GPL) [

4,

5]. Their findings revealed a significant enhancement in natural frequencies and buckling loads upon the incorporation of graphene. The study in [

6] focused on investigating the vibration-damping characteristics of GPL-reinforced NR/EPDM (Natural rubber/ethylene-propylene-diene rubber) composites through free vibration tests. The results demonstrated a notable increase in damping ratio values (up to

) with the addition of GPLs compared to the blend of NR/EPDM alone.

For many years, there has been growing scientific interest in the use of piezoelectric materials for active or passive vibration control [

7,

8]. Piezoelectricity refers to the capacity of a piezoelectric material to undergo a dual electro-mechanical transformation, achieved through either the direct effect (i.e., production of an electrical charge under pressure) or the inverse effect (i.e., mechanical strain induced when subjected to an electric field) [

9]. Many of those studies focus on the passive vibration control of structures by using shunted piezoelectric elements connected to electric circuits [

10,

11,

12].

In recent times, there has been increasing attention within the scientific community on the incorporation of piezoelectric layers into graphene nanoplatelets composite structures in order to actively control and reduce unexpected mechanical responses. Several studies have been conducted to investigate the mechanical behaviour of such structures. In [

13], the dynamic response and the active vibration control of functionally graded (FG) multilayer GPLs reinforced composite plates integrated with piezoelectric layer were studied. Dong et al. [

14] studied the active vibration control and vibration characteristics of a sandwich-thin cylindrical shell whose intermediate layer is made of graphene-reinforced composite that is bonded with integrated piezoelectric actuator and sensor layers at its outer and inner surfaces. Also, parameters like weight fractions, distribution patterns and geometrical sizes of graphene platelets, temperature variations, thicknesses of layers, the feedback control gain on the vibration characteristics, and the active vibration control of the novel sandwich cylindrical shell are discussed. The static and dynamic response of smart FG microplates reinforced by GPLs and integrated with piezoelectric layers under concurrently mechanical and electrical loads was studied in [

15]. Furthermore, active control of responses for an intelligent FG microplate, including the structural damping effect under simultaneous mechanical and electrical loads, was examined. The active control of vibrations of a nanocomposite microplate reinforced by graphene platelets as host layer bonded with two piezoelectric layers as sensor and actuator layers in the thermal environment was studied in [

16]. A closed-loop PD controller based on the velocity and the displacement feedback signals is developed for the active control of vibrations of the piezo-electric functionally graded (FG) GPL microplate. The effects of the control gain values, the material length scale parameter, the boundary condition type, the GPL distribution pattern, and the GPL weight fraction on the dynamic response of the piezoelectric GPL microplate are investigated. Zhang et al. [

17] studied the nonlinear vibration suppression of a piezoelectric functionally graded graphene-reinforced laminated composite cantilever using a positive position feedback control strategy.

To the authors’ best knowledge, even though numerous studies have been conducted about the active control of multilayered GPL reinforced composite structures, nonetheless, there is no paper relating the passive vibration control of such structures by utilising shunted piezoelectric elements.

On the other hand, in recent years, machine learning (ML), a sub-category of artificial intelligence, has provided researchers and engineers with novel methods for engaging with the data collected. In particular, ML techniques have shown great potential in material design. Transfer learning-based deep neural networks were developed by Pashmforoush [

18] to predict the mechanical properties of various graphene-reinforced nanocomposites, even with limited data samples. A machine-learning model is utilised to estimate the temperature-dependent moduli of neat, thermally reduced graphene and covalently functionalised graphene/epoxy nanocomposites [

19]. The governed mathematical expressions have been used to solve the buckling problem of beams fabricated from such nanocomposites in the presence of a thermal gradient.

Numerous authors have chosen to utilise ML techniques in addressing the vibration problems related to composite structures. Anitescu et al. [

20] introduced an appropriate approach for resolving partial differential equations through the employment of artificial neural networks and an adaptive collocation technique. Guo et al. [

21] proposed a novel deep collocation method for addressing Kirchhoff plate bending by first creating randomly distributed collocation points.

Very few papers have been reported on the vibration analysis of graphene-reinforced nanocomposite structures using a machine learning-based approach. An ML-assisted micromechanics model for the investigation of the buckling response of functionally graded hydrogen-functionalised graphene-reinforced beams at different temperatures has been developed in [

22]. A machine learning based probabilistic model is proposed in [

23] to perform the vibration analysis of functionally graded porous plates reinforced with graphene nanoplatelets with statistical variation in the elastic moduli of constituents, porosity index, and weight fraction of graphene nanoplatelets.

Based on the preceding literature, we found that the problem of vibrations of graphene/fibre reinforced (GPLFR) nanocomposite beams with shunted piezoelectric patches using machine learning based techniques has not been explored to the best of the authors’ knowledge. Therefore, the objective of the present study is to propose an efficient Artificial Neural Network (ANN) model in order to investigate the variation in the natural frequency as well as the vibration-damping performance of a GPLFR nanocomposite beam considering variation in material properties and electric circuit components. Emphasis is given to predicting the vibration suppression of the system. A key aspect of the investigation is to evaluate the level of accuracy that can be achieved. As will be shown, the accuracy of the trained ANN to predict the vibration response is quite high, indicating that the proposed approach can safely be adopted. Another goal of the study is to highlight the benefits of adopting machine learning in this field, to decrease the computational cost and effort. It is noted that within the traditional path, this problem would normally involve developing a finite element model, probably in a programming code environment, since not all commercial finite element packages can offer physics-oriented tools, like the shunted piezoelectric elements. Instead, calling a trained ANN to predict the response can be used to drastically reduce the effort to develop and solve the equivalent model.

2. Piezoelectric Graphene/Fibre-Reinforced Nanocomposite Beam

In this paper, a GPLFR nanocomposite beam with a shunted piezoelectric system is considered. The longitudinal cross-section of the laminated composite beam integrated with two piezoelectric patches on its top and bottom surfaces in a bimorph arrangement is illustrated in

Figure 1. The host beam consists of composite plies made of a polymer matrix reinforced with graphene nanoplatelets and fibres, which make a three-phase material. The length, thickness, and width of the beam are denoted by

, and

b, respectively, and the thickness of the PZT layer is denoted by

. The mid-plane of the composite beam is considered the reference plane. The origin of the laminate coordinate system (

x,y,z) is located on the mid-plane of the host GPLFR beam. The thickness coordinates (

z) of the bottom and top surfaces of any

k- th layer of the overall laminated GPLFR beam are represented by

and

, respectively. The fibre orientation angle of the

k-th layer is denoted by

. The piezoelectric patches have opposite poling directions along the

z-axis as indicated by the direction of the arrows in

Figure 1. In addition they are covered by continuous electrodes, which are assumed to be perfectly conductive with negligible thickness. The electrodes are connected in series to a passive electrical circuit composed of a resistor

R and an inductor

L.

2.1. Mathematical Description of the GPL-Reinforced Matrix

The Halpin–Tsai model is utilised to determine the material properties of the nanocomposite-reinforced polymeric matrix. Based on these principles, the effective material properties of the graphene-reinforced matrix can be computed as [

5]

where

The parameters

and

V in relations (

1) and (

2) express the Young modulus, Poisson’s ratio, shear modulus, density, and volume fraction of nano materials, respectively. The subscripts

, and

are used to denote the graphene nanoplatelets (

), the matrix (

M), and the graphene-reinforced matrix (

). Also,

and

denote the geometrical characteristics of the isolated GPLs.

The volume content

of graphene nanoplatelets is calculated in terms of its weight fraction

as:

2.2. Mixture of Fibres and GPL Reinforced Matrix

After specifying the mechanical characteristics of the GPL-reinforced matrix, it is necessary to achieve the mechanical specifications of the multi-phase material that consists of a mixture of fibres and the GPL-reinforced matrix. According to the Halpin–Tsai hypotheses, which serve as a micro-mechanic model, the orthotropic mechanical characteristics of the suggested mixture are provided as follows [

5]:

2.3. Constitutive Equations

In this paper, it is assumed that the top and bottom layers are made of the isotropic piezoelectric material and the host beam is made of the multi-phase GPL/fibre-reinforced polymer orthotropic composite material. Therefore, for the analysis of a (1D) beam problem, the constitutive equations can be rewritten in the following form:

for piezoelectric layers: for GPLFR layers:where the superscripts

p and

k are referred to as the piezoelectric and the elastic plies, respectively. In Equations (

11)–(

13),

denote the normal and shear stress, respectively, and

denote normal and shear strain, respectively. Also, the reduced stiffness coefficients are denoted as

. The transverse electric displacement is represented by

, and the electric field is represented by

. The piezoelectric constant is denoted by

and the electric permittivity constant by

. Lastly, the shear correction coefficient is represented by

and, in this work, is assumed to be equal to

. Notably, in this paper, the employed piezoelectric material is assumed to be of beam type in which only the electric field through the thickness direction of the piezoelectric patch is dominant. Furthermore, it is assumed that the electric potential varies linearly in the thickness direction. Therefore, the electric field of each piezoelectric layer can be expressed as follows:

where

are the thickness and the difference of electric potential between the electrodes covering the surface of each side of the piezoelectric layer.

Finally, for the case of cross-ply composite configuration, the parameters

and

can be expressed as:

with

and

where

are the longitudinal and transverse moduli,

are the Poisson’s ratios,

are the shear moduli of the

layer. For the case of isotropic material, two mater l constants are required, namely Young’s modulus

E and Poisson ratio

v. In addition

and

apply with

.

3. Governing Equations

The displacement fields are postulated in accordance with Timoshenko’s beam theory as follow:

where

t denotes the time,

and

denote the axial and transverse displacements of the beam mid–plane, respectively, and

is the rotation of the beam cross section about the positive

y-axis.

The composite beam in this study has been discretised through the use of a two-nodded superconvergent beam element. Each node of this element has three degrees of freedom. The interpolation of the generalised displacement vector is expressed as follows:

where

and

are the super convergence shape functions [

12]. Two further degrees of freedom (DOF) per element are incorporated to represent the electrical voltages of two distinct piezoelectric layers. For each additional piezoelectric layer, an extra voltage DOF is required per element.

By utilising the extended Hamilton’s variational principle, we can deduce the governing equations of motion of the piezoelectric composite beam in relation to the global coordinates by employing the standard procedure of the finite element (FE) method:

where

is the global vector of mechanical degrees of freedom,

is the global mass matrix,

is the global stiffness matrix and

is the global vector of mechanical forces. Also,

are the electromechanical coupling matrices,

and

are the capacitance and the electric charge output of the piezoelectric layer

i, respectively. Notice that the enforcement of equipotentiality in the electrodes is achieved by assigning a single electrical degree of freedom for each piezoelectric layer. Details regarding the development of this finite element model can be found in previous works from the authors [

12].

3.1. Free Vibrations Analysis

There exist two possible configurations for the patches, namely the short-circuit and open-circuit configurations. In the open-circuit configuration, which is often denoted as the sensor configuration, the two patch electrodes are disconnected. In the case where the piezoelectric layers are shorted, the difference of the electric potentials between their electrodes vanishes (

). Therefore, the Equation (

20) becomes

On the other hand, if the piezoelectric layers are open-circuited, then the electric potentials between their electrodes can be evaluated using the Equations (21) and (22), such that

Substituting Equation (

24) into (

20) the following condensed equation of motion is obtained

where

Once the global mass matrix

and stiffness matrix

have been generated, the natural frequencies and mode shape for the short-circuit and open-circuit configurations can be calculated by solving the following eigenvalue equations:

where

and

are the eigenfrequencies and eigenvectors for the short-circuit and open circuit configuration, respectively.

3.2. Inclusion of the Passive Shunt Circuit

In the event that a

circuit is connected to the piezoelectric patches (as depicted in

Figure 1), the total output charge is equivalent to the individual output charge produced by each piezoelectric layer, namely

. Similarly, the total output voltage is the aggregate of each output voltage, i.e.,

. Additionally, as the two piezoelectric layers are identical in terms of material and dimensions and are poled in opposite directions,

. Summing up the Equations (21) and (22), we obtain

By employing Kirchhoff’s voltage law, the electrical dynamics is represented by a second-order equation:

Solving the Equations (21) and (22) with respect to

and

, respectively, substituting into (

20) and using (

29) and (

30) we obtain the governing equations of the shunted piezoelectric damping structural system:

In order to derive the frequency response equation of the above system, a harmonic input

can be assumed. Therefore, solutions of the mechanical displacement and electric charge responses can be formulated as

and

, where

and

are the amplitudes of the displacement and the charge, respectively, and is the driving frequency. Substituting the assumed solutions in the system Equations (

31) and (32) and doing some mathematical manipulations, the frequency response equation is obtained as:

where the analytical frequency response matrix is given by

Open- and closed-loop behaviour of the laminated GPLFR beams is studied by the frequency response function (FRF) for the transverse displacement at the free end of the laminated GPLFR beam. Since the study focuses on the passive vibration damping of the second mode, a range of frequencies only around the second mode of vibrations is used. Thus, the performance of the shunt damping control for the laminated GPLFR beam can be evaluated as the percentage reduction between the maximum amplitudes of the FRF (resonance peak) for short-circuit and shunt-circuit conditions as

where

and

denote, respectively, the frequency response of the open-loop (short circuit) and closed-loop (shunt circuit) system at the tip (

i node) for excitation at the same point (

i node).

4. Machine Learning

During the last few years, increasing effort has been made to use accumulated data, either numerically or experimentally derived, in the investigation of the mechanical response of various structural systems. In this framework, several machine learning methodologies have been adopted, using tools such as artificial neural networks, decision trees, support vector machines, image recognition, and others [

24].

Artificial neural networks (ANNs) are machine learning algorithms which are developed by mimicking the human brain structure. Thus, neurons are interconnected to imitate thinking, recognition, and decision-making. Among various types of neural networks, the feedforward artificial neural network is probably the most widely used system due to its simplicity and robustness in solving engineering (among other) problems. A sketch providing the general layout of an ANN is provided in

Figure 2. Briefly, an ANN adopts a supervised training mode, where input and output parameters are used to determine optimal weight values that minimise the error between the prediction and the real (dataset) values. Different activation functions are also used, such as the nonlinear continuous sigmoid, the tangent sigmoid function, and others [

24].

In this work, two ANN models are developed in Matlab and used to predict the vibration response and attenuation of a shunted piezoelectric beam. Details for the architecture of the ANN models are presented in

Section 5 of the article. To train the ANNs, the Levenberg–Marquardt backpropagation algorithm is chosen in Matlab [

25].

6. Conclusions

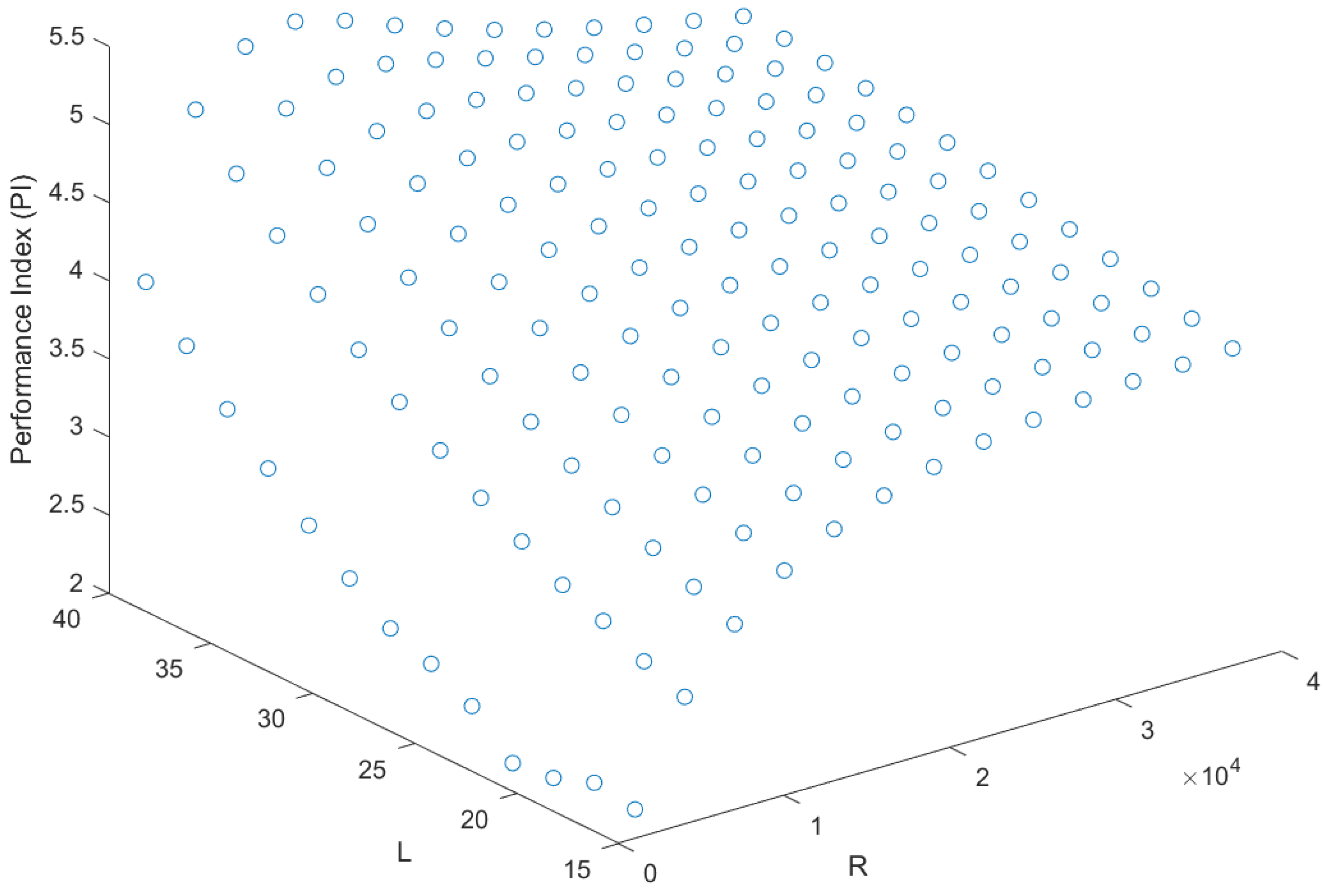

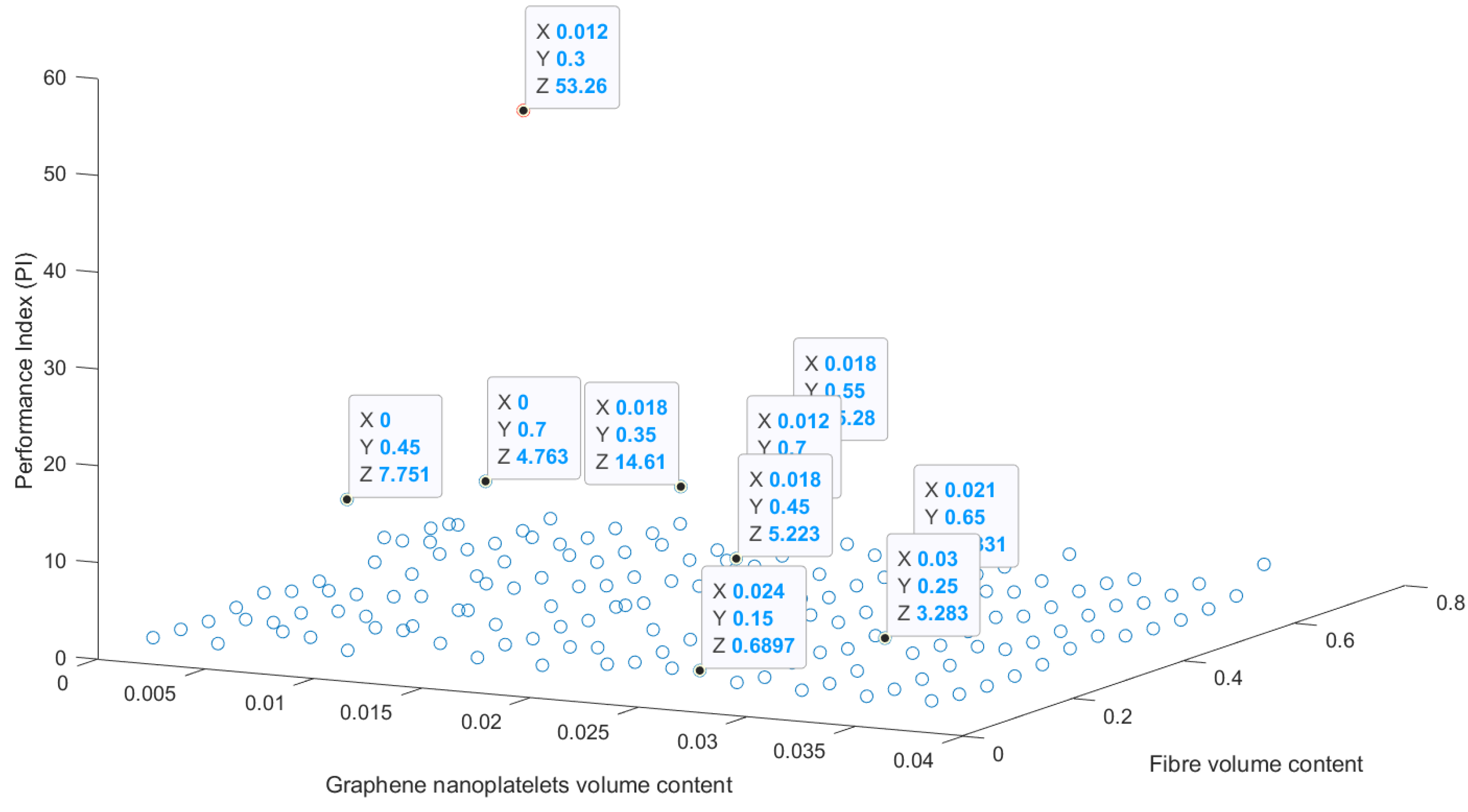

A data-driven machine learning methodology is adopted in this article, aiming to investigate the vibration response of a shunted piezoelectric composite beam. A dataset is first developed using parametric finite element simulations, considering various input and output parameters. Input parameters are the R and L properties of the shunted piezoelectric beam, the graphene nanoplatelets volume content , the fibre volume content , and the fibre angles . Output parameters are the vibration reduction achieved by the shunted piezoelectric beam (), as well as the first and second natural frequencies for the short-circuit and the first and second natural frequencies for the open-circuit conditions.

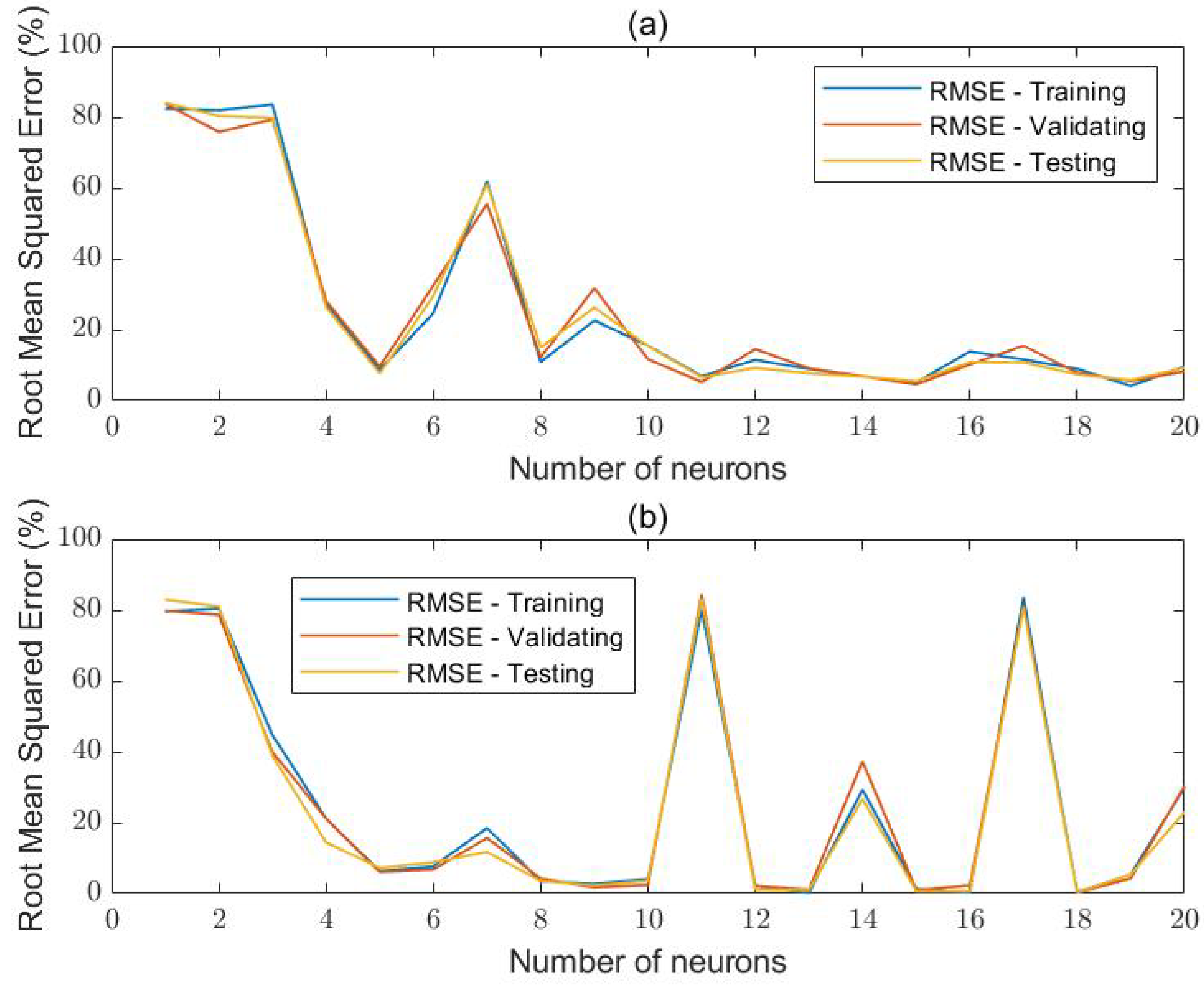

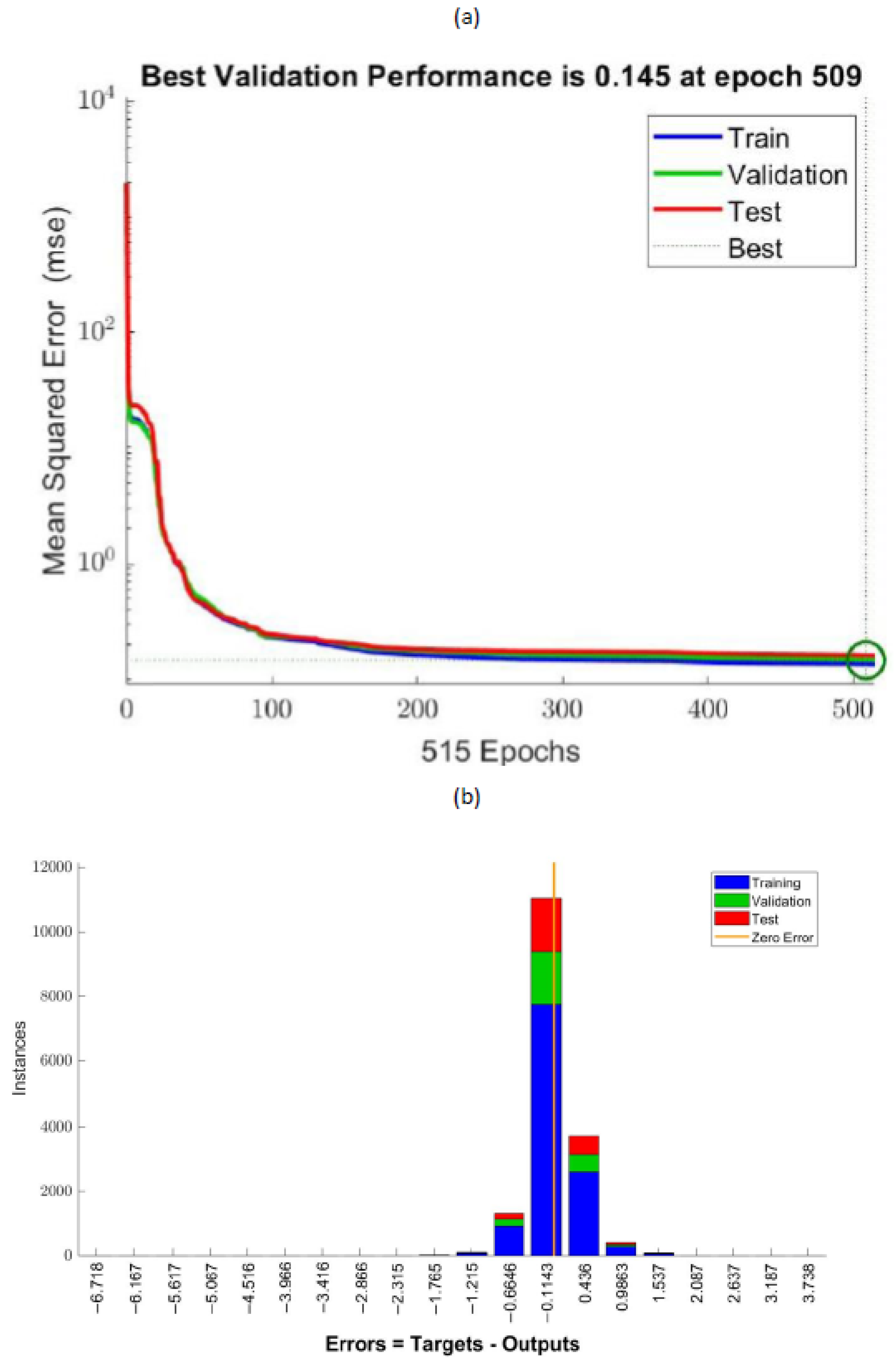

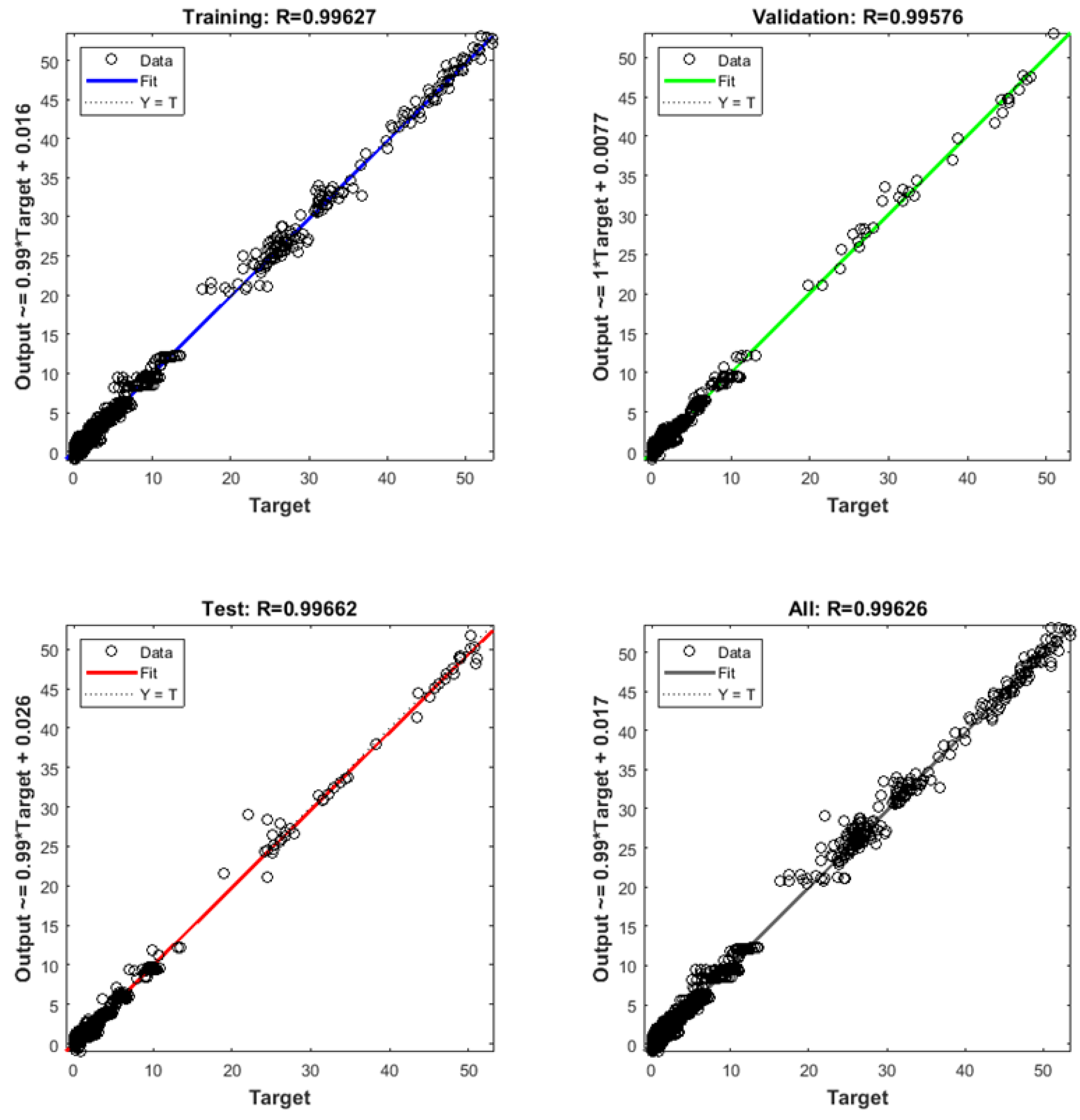

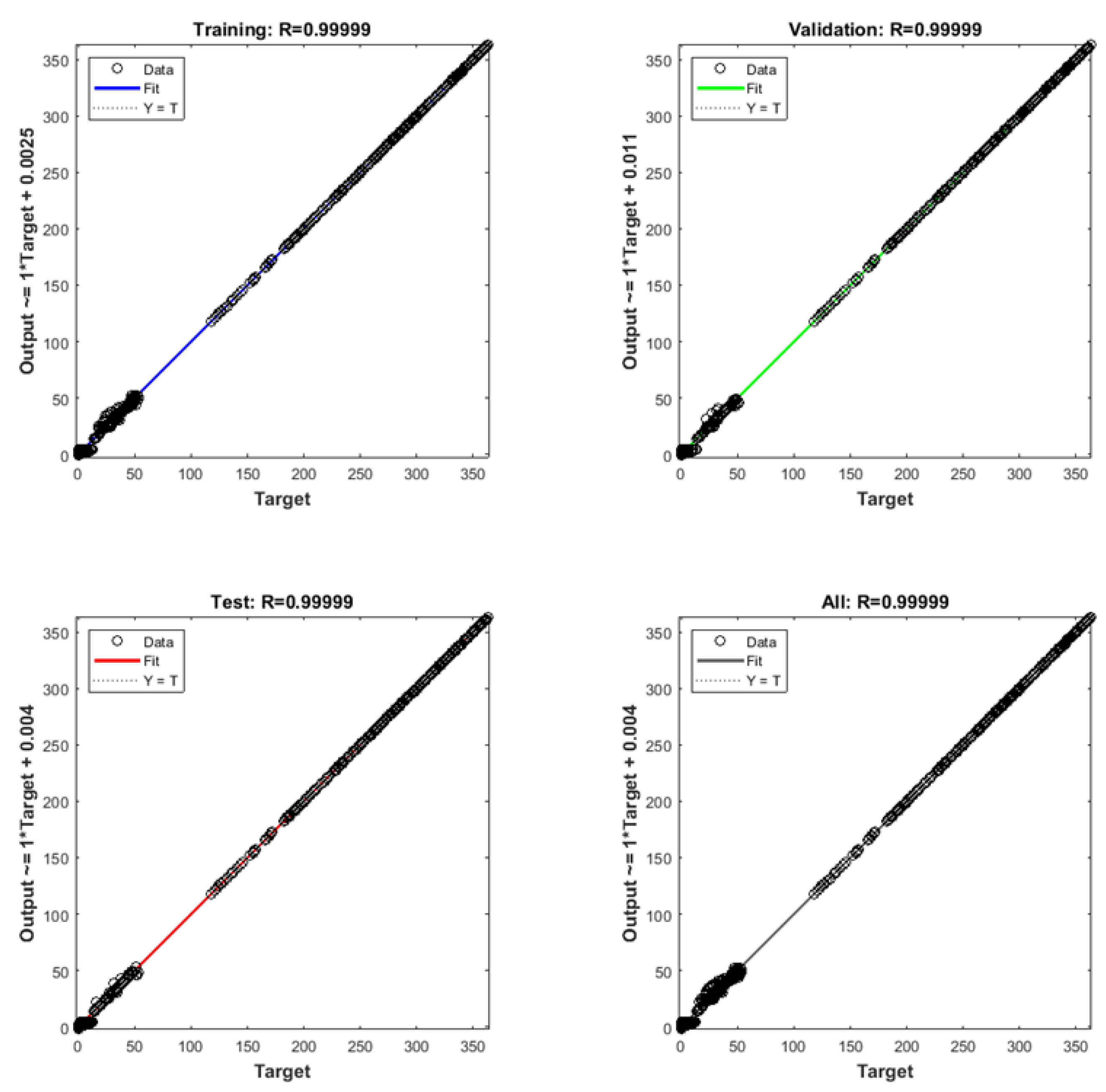

Those input and output parameters are used to train, validate, and test two artificial neural networks in Matlab. After a parametric investigation, an optimal architecture of two hidden layers and 13 neurons per hidden layer is chosen for this study.

Results of the investigation indicate that the accuracy of the trained ANNs to predict the vibration response of the composite beam is high. In addition, relevant regression diagrams provide high values for the correlation factor (close to 1), indicating a high correlation between the predicted parameters by the trained ANNs and the real dataset values.

The methodology offers the opportunity for a fast and accurate prediction of the mechanical response of composite beams under vibration analysis. It is noted, that though a single finite element simulation of this type has a relatively low computational cost, the effort, time, knowledge, and expertise needed to develop relevant numerical models in a programming code (like Matlab or Python) are pretty demanding. This further increases the impact of the proposed approach in evaluating the mechanical response of those systems.

Future studies can include the investigation of different beam geometries involving potentially varying numbers of input and output parameters, incorporating, for instance, the geometric parameters of the beam, the piezoelectric patch thickness, etc.