1. Introduction

The multistate flow network (MFN) is a popular and generic construction of an intelligent wireless sensing system. The MFN is a network composed of a plurality of nodes and edges, and the network satisfies the following assumptions: the nodes must satisfy the flow conservation law, and the flow of the edge must satisfy the following conditions, i.e.,

The reliability of an MFN, which is the probability that the specified flow will be delivered from the source of the network to the sink, has been widely studied and applied in various fields of practice under numerous conditions, such as two-terminal networks [

4], the proposed quickest path approach [

5], constant delivery characteristics [

6], a used recursive algorithm [

7], binary element states [

8], a novel direct approach [

9], a proposed adjacent-first-based branch-and-bound approach [

10], a used artificial neural network [

11], a considered time constraint [

12], a studied vehicle routing problem [

13], a production network [

14], priority components based on considered cost [

15], a power system [

16], an adopted cut vectors approach [

17], the quickest method studied considering deterioration [

18] and a studied angle network [

19].

Several scholars continue to contribute to the study of new algorithms to assess MFN reliability. In addition to the traditional flow capacity constraints, several scholars added other conditions, such as a delivery lead time limit [

12]. Several scholars applied MFN reliability to practical environments, such as logistics distribution systems [

12], factory production systems [

14], and power distribution systems [

16].

The construction of intelligent logistics with intelligent wireless sensing is a global trend. Though several scholars have contributed to the relevant research on MFN reliability over the years, fewer works on the type of roads, that is, the type of the edges of the network, have been produced. Intelligent logistics require an investment in sensor devices. In order to effectively increase the effective value of this investment, and therefore of intelligent logistics, it is necessary to have a good driving plan for the choice of road types in advance to effectively improve the reliability of delivery and ensure and enhance the value of this investment in intelligent logistics. In each country’s domestic transportation, most of the goods are carried by trucks, and trucks can choose different road types to complete the delivery of goods. Therefore, this study proposes two different types of roads, namely highways and slow roads. Here, the speed limit of the road is used as the basis for distinguishing the road types. The study of the types of roads in this study not only can contribute to the effective planning of intelligent logistics and enhance the investment value of sensors but also can be applied to general logistics.

This study further explores the limitations of the proposed different road types. Trucks travel at different speeds on two types of roads; the speed of the highway is higher than that of the slow road, so the truck is limited by the turning angle due to the fast speed on the highway. If the speed is fast, and the turning angle is too large, it is easy to cause the risk of a truck rollover. In addition, the weight of trucks carrying goods includes a lower capacity on highways than that of slow roads, so it is necessary to include constraints. Moreover, today’s logistics delivery is time-sensitive to enhance the competitiveness of the company, so the completion of delivery time should also be included in the constraints.

Therefore, this work studied the reliability of goods delivery on trucks in two types of roads, i.e., highways and slow roads, which is subject to constraints including the turning angle of a truck, weight capacity of a truck, and delivery completion time. The d-MP (d-minimal path), which is a system state for a specified transmission d value, is a well-known algorithm for assessing MFN reliability [

4]. In this study, the MFN reliability of the cargo distribution is evaluated based on the famous d-MP algorithm [

4].

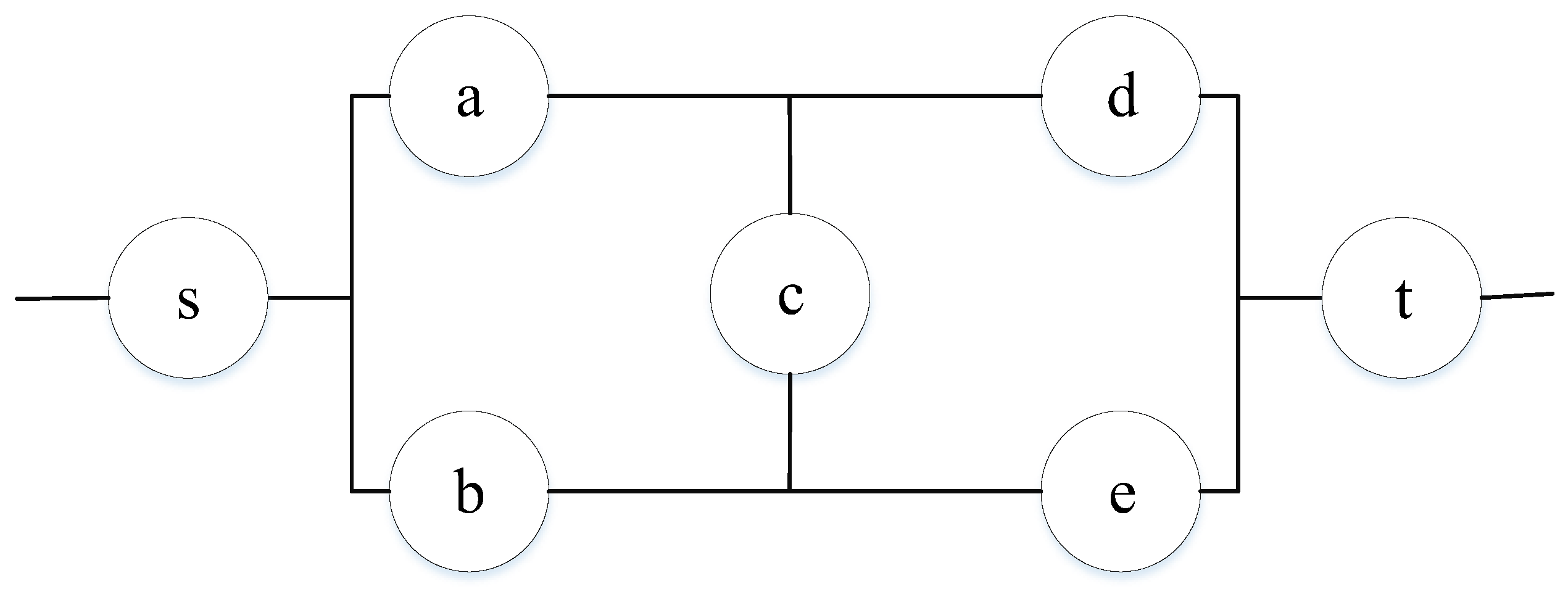

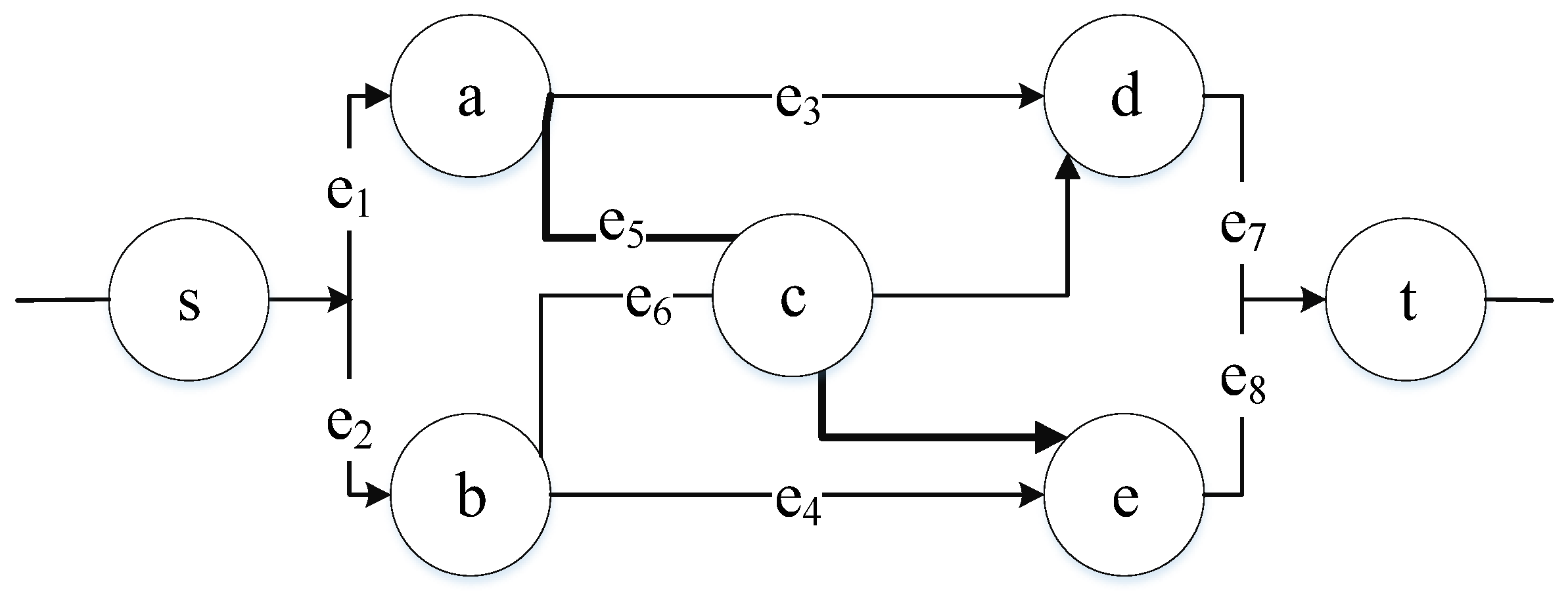

Moreover, considering that the current research on MFN reliability has been less applied to a bridge network (as shown in

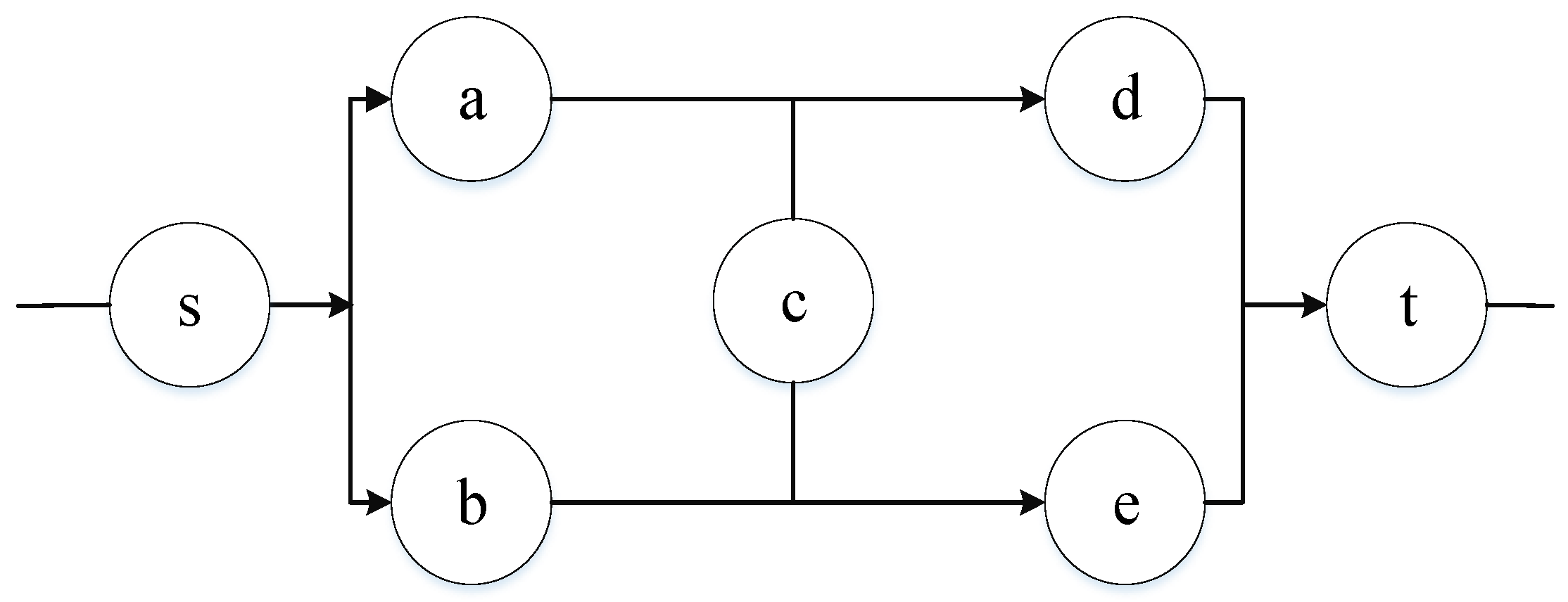

Figure 1), in which the symbols a, b, c, d, and e represent five nodes that are connected by edges, this study is based on a bridge network and expands it to add a source node and a sink node (as shown in

Figure 2), in which the symbols s and t represent the source node and the sink node, respectively. The multi-stage traffic network map used in this study is an innovative network diagram. This study-extended bridge network is shown in

Figure 2 as an example, where it has been applied to logistics distribution from north to south in Taiwan to evaluate MFN reliability considering road conditions with different speed limits.

The remaining sections of the manuscript are structured as follows:

Section 2 presents a literature review. A description of the studied problem is stated in

Section 3. The proposed method is based on the basic d-MP algorithm that is introduced in

Section 4. The proposed algorithm is shown in

Section 5.

Section 6 presents a numerical example. Finally, the conclusions are discussed in

Section 7.

4. The Basic d-MP Algorithm

The proposed method is based on the basic d-MP algorithm, introduced in

Section 4.

The d-MP flow can find by the d-MP algorithm [

4], as shown in Theorem 1.

Theorem 1. Any state vector of system X = (3.5x1, x2, …, xn) is a d-MP candidate, i.e., the maximum flow of the system M(X) = d, if and only if the flow vector (f1, f2, …, fp) satisfies the following terms, i.e., Equations (5)–(7).

where

F is the maximum capacity of the flow, and

M(

ei) is the maximum flow of the edge

ei.

In Theorem 1, Equation (5) is the total flow of each MP, and Equations (6) and (7) are the constraints of the flow of each MP and each edge, respectively.

5. The Algorithm

As stated in

Section 2, one of the major research gaps between the existing approaches and the novel approach proposed in this manuscript is that this study proposes two different types of roads. Therefore, the distinction between the existing d-MP algorithm and the improvements proposed in this manuscript is arranged in the following two points:

For a truck driving on a highway (Rd

h), the (

d;

θ,

W,

T)-MP algorithm, which is limited by the turning angle (

θ), vehicle loading capacity (

W), and transportation lead time (

T), can be found by extension of the d-MP algorithm and is shown in Theorem 3 [

19], which was clearly introduced in

Section 5.2.

For a truck driving on a slow road (Rd

g), the (

d;

W,

T)-MP algorithm, which is limited by the vehicle loading capacity (

W) and transportation lead time (

T), can be found by extension of the d-MP algorithm and is shown in Theorem 5 [

19], which was clearly introduced in

Section 5.3.

The MFN reliability of the cargo distribution is evaluated based on the famous d-MP algorithm [

4] first to find all feasible minimum paths (MPs), as described in

Section 4. The turning angle is limited for driving on Rd

h; thus, the d-MP algorithm is expanded to the (

d; A)-MP algorithm, which is limited by the turning angle and is described in detail in

Section 5.1. Trucks driving on slow roads and highways are subject to different constraints, as explained in

Section 5.2 and

Section 5.3, respectively. Finally,

Section 5.4 describes the calculation of MFN reliability.

5.1. d-MP with Angle Constraint

The (

d;

θ)-MP algorithm, which is limited by the turning angle denoted as

θ, can be found by extension of the d-MP algorithm and is shown in Theorem 2 [

19].

Theorem 2. Any state vector of a system considering the angle window X∠θ = (x1, x2, …, xn) is a (d;θ)-MP candidate, i.e., the maximum flow of the system M(X∠θ) = d, if and only if the flow vector (f1, f2, …, fp) satisfies the following terms, i.e., Equations (5) and (7)–(9).

where ∠

θ is denoted as the angle

θ;

F∠θ is the maximum capacity of the flow considering the angle window;

M(

ei) is the maximum flow of the edge

ei; and

M∠θ is the maximum flow of

ei, limited by the angle window of ∠

θ.

In Theorem 2, Equation (5) is the total flow of each MP with the angle θ, and Equations (6)–(9) are the constraints of the flow of each MP with the angle θ, each edge, and each angle.

5.2. (d;θ,W,T)-MP

For a truck driving on the highway (Rd

h), the (

d;

θ,

W,

T)-MP algorithm, which is limited by the turning angle (

θ), vehicle loading capacity (

W), and transportation lead time (

T), can be found by extension of the d-MP algorithm and is shown in Theorem 3 [

19].

Theorem 3. Any state vector of a system considering the constraints of the turning angle, vehicle loading capacity, and transportation lead time X∠θ,W,T = (x1, x2, …, xn) is a (d;θ,W,T)-MP candidate, i.e., the maximum flow of the system M(X∠θ,W,T) = d, if and only if the flow vector (f1, f2, …, fp) satisfies the following terms, as shown in Equations (5) and (7)–(11).

where

wi is the weight limit of the edge

ei, which was used to present the maximum vehicle loading capacity;

t(

ei) is time spent driving on the edge

ei;

W and

T are the upper limitations of the maximum vehicle loading capacity and the total transportation lead time, respectively.

In Theorem 3, Equation (5) is the total flow of each MP, and Equations (7)–(11) are the constraints of the flow of each MP with the angle θ, each edge, each angle, the vehicle loading capacity, and the total transportation lead time.

Next, we check whether the state vector candidates are real state vectors in the MFN according to Theorem 4 [

19].

Theorem 4. The state vector candidate is a real state vector if and only if the cyclic direction does not exist in the system of the network.

5.3. (d;W,T)-MP

For the truck driving on the slow road (Rd

g), the (

d;

W,

T)-MP algorithm, which is limited by the vehicle loading capacity (

W) and transportation lead time (

T), can be found by extension of the d-MP algorithm and is shown in Theorem 5 [

19].

Theorem 5. Any state vector of a system considering the constraints of the vehicle loading capacity and transportation lead time X = (x1, x2, …, xn) is a (d;W,T)-MP candidate, i.e., the maximum flow of the system M(X) = d, if and only if the flow vector (f1, f2, …, fp) satisfies the following terms, as shown in Equations (5)–(7), (10) and (11).

In Theorem 5, Equation (5) is the total flow of each MP, and Equations (6), (7), (10) and (11) are the constraints of the flow of each MP, each edge, the vehicle loading capacity, and the total transportation lead time.

Next, we also check whether the state vector candidates are real state vectors in the MFN according to Theorem 4 [

19].

5.4. MFN Reliability

The MFN reliability, denoted as R, is calculated by the inclusion–exclusion method [

19], as shown in Equation (12):

where

x1,

x2, …,

xv are the real (

d;

θ,

W,

T)-MP or the real (

d;

W,

T)-MP.

7. Conclusions

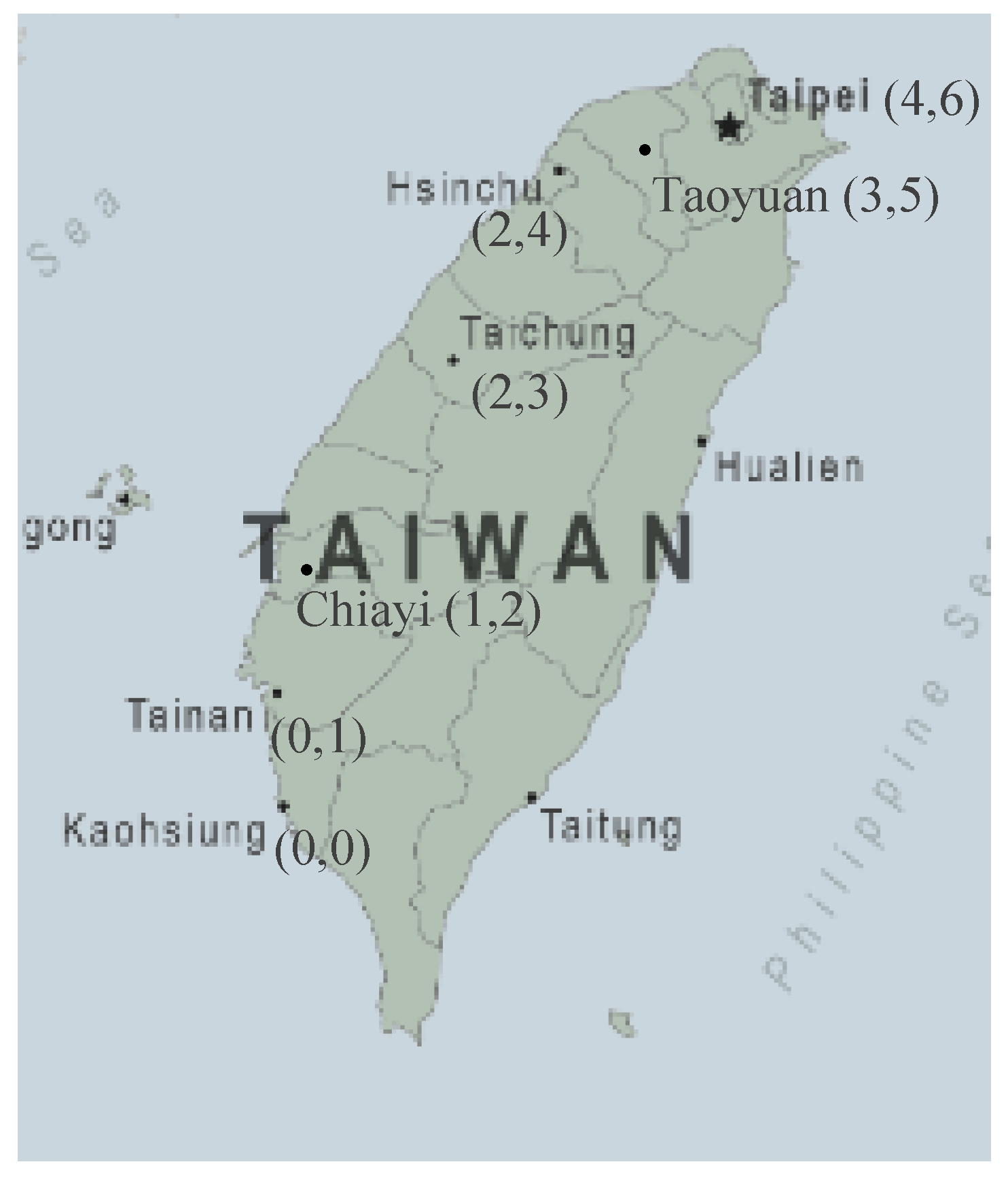

The contribution of this study is to propose a new multistate flow network diagram with the complexity of the actual transportation road network to help enhance the construction of intelligent wireless sensing in intelligent logistics. The complex multistate flow network proposed in this study can be used to simulate the logistics distribution network from north to south in Taiwan.

Road type (type of edge) has rarely been discussed in the existing reliability research on the multistate flow network, so that is proposed by this study for discussion. The reliability of the multistate flow network is evaluated by studying trucks traveling on highways and slow-speed roads, two road types with different speeds and different constraints. These are applied to the delivery of goods on the multistate flow network from north to south in Taiwan as an actual case to discuss. The results of this study show that trucks traveling on highways and slow-speed roads have similar logistics reliability for the same unit of goods distributed. This also echoes the actual situation. In the transportation of goods in Taiwan, it is not difficult to find that there are trucks of various companies driving through both types of roads for the distribution of goods.

In today’s business environment, the competition has become increasingly fierce, and the reliability of the logistics distribution is also one of the factors for the success of each enterprise. Therefore, the research planning and research results of this study can be effectively provided for academic and practical reference.

For continuation in further research, automated data acquisition of intelligent logistics is being considered for study in future work.

In the future study, weight restrictions for trucks and heavy goods vehicles on all public roads can be considered to ensure public safety and to relocate heavy road transport to main roads and highways that link main logistic centers and bypass cities and heavily populated areas. Furthermore, in future work, the assumption that “The turning angle is limited by less than 90 degrees when the truck is driving in highways” can be considered for deletion because there are fewer curves or junctions on major roads and highways than on local roads.

The model for analyzing and optimizing the delivery of goods by trucks can be planned to be more universal, and certain restrictions and parameters of individual routes can be included as weights, or certain attributes can be assigned to the edges between nodes in a future study. More than two types of roads (national highways, provincial highways, expressways, non-urban roads, urban roads, etc.) can be studied based on this work in the future. Moreover, various patterns of vehicle movement can be considered in future work. In addition, in this work in the future, the edges of the network in the model can take into account the real length of the route instead of the length between the nodes calculated from the coordinates as the distance between two points using Formula (2).