Advancements in Super-High Frequency Al(Sc)N BAW Resonators for 5G and Beyond

Abstract

1. Introduction

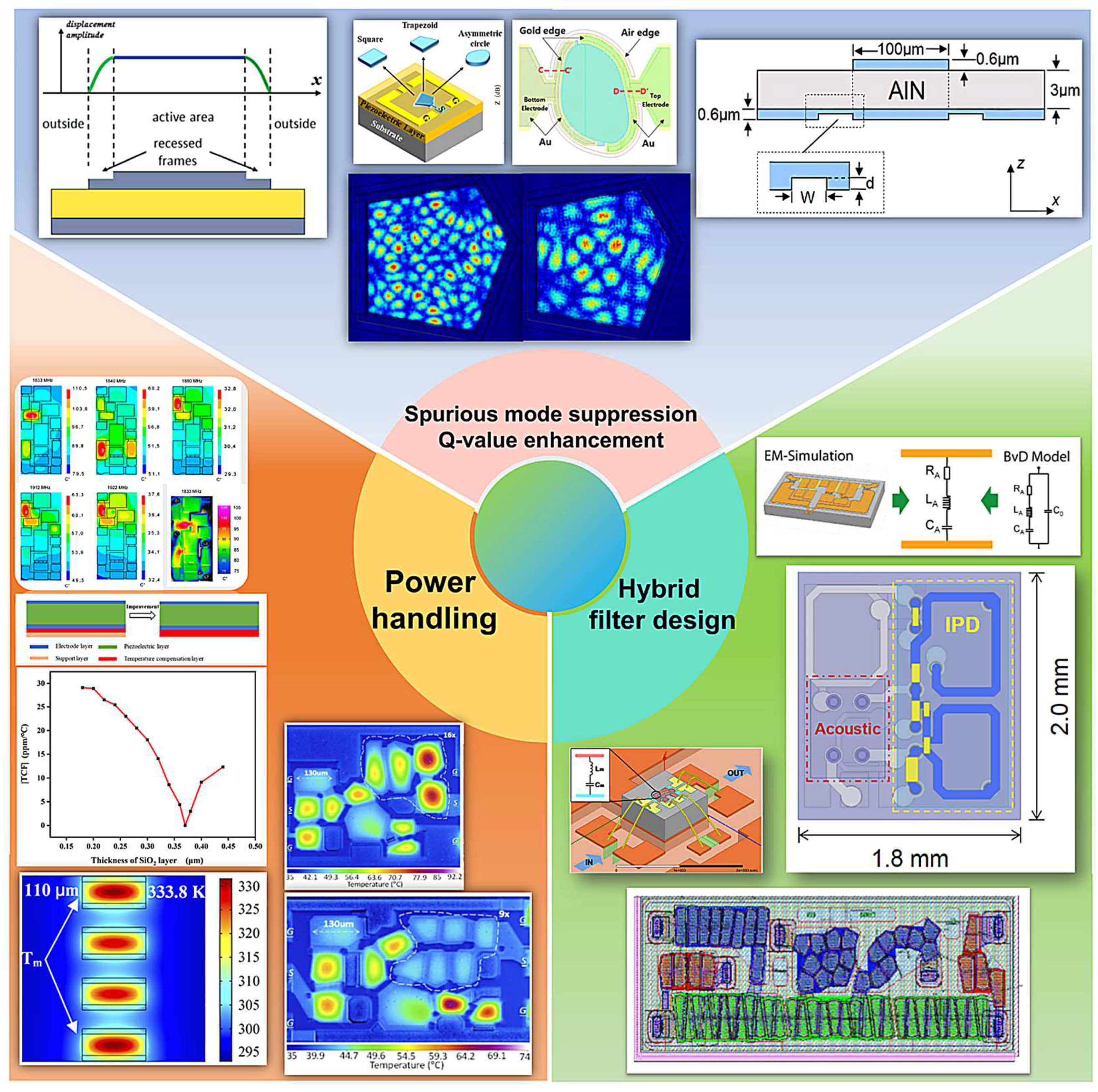

2. AlN-Based Bulk Acoustic Wave Resonators: Models, Technologies, and Frequency Advancement

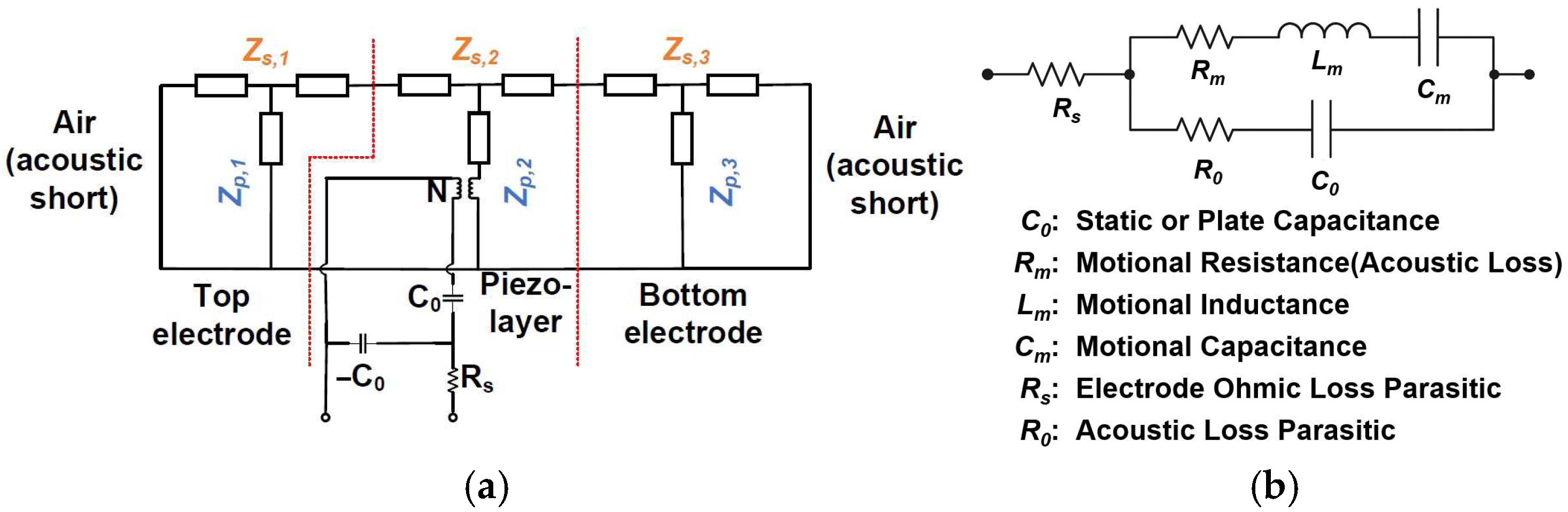

2.1. Mason and mBVD Modeling of AlN BAW Resonators

2.2. Finite-Element Analysis for Frequency Extraction and Thermal Effects

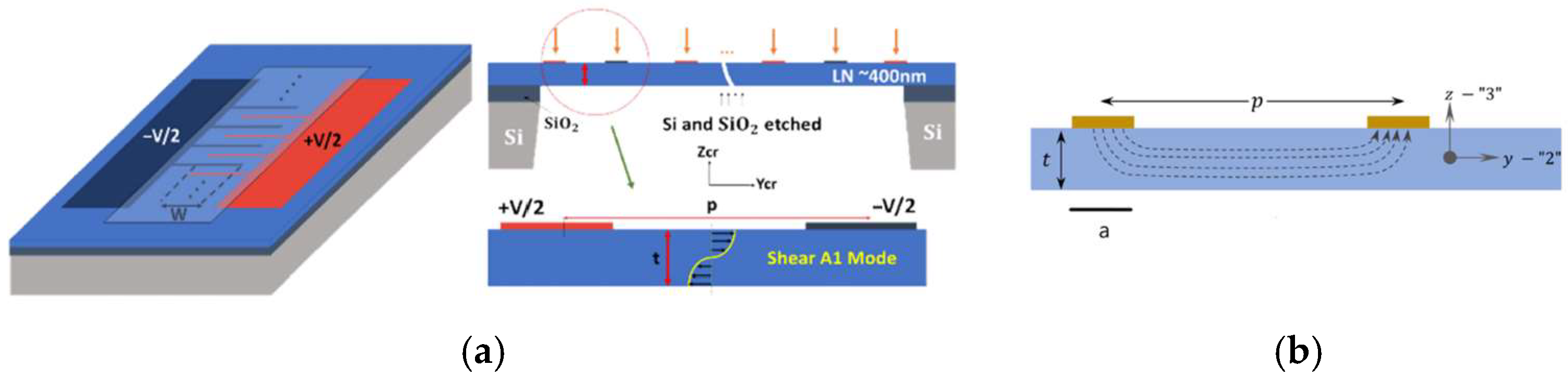

2.3. BAW Resonator Structures

2.4. Research Status and Development Bottlenecks of AlN BAW in the Super-High Frequency Band

3. Growth of AlN and AlScN Piezoelectric Films for Bulk Acoustic Wave Resonators

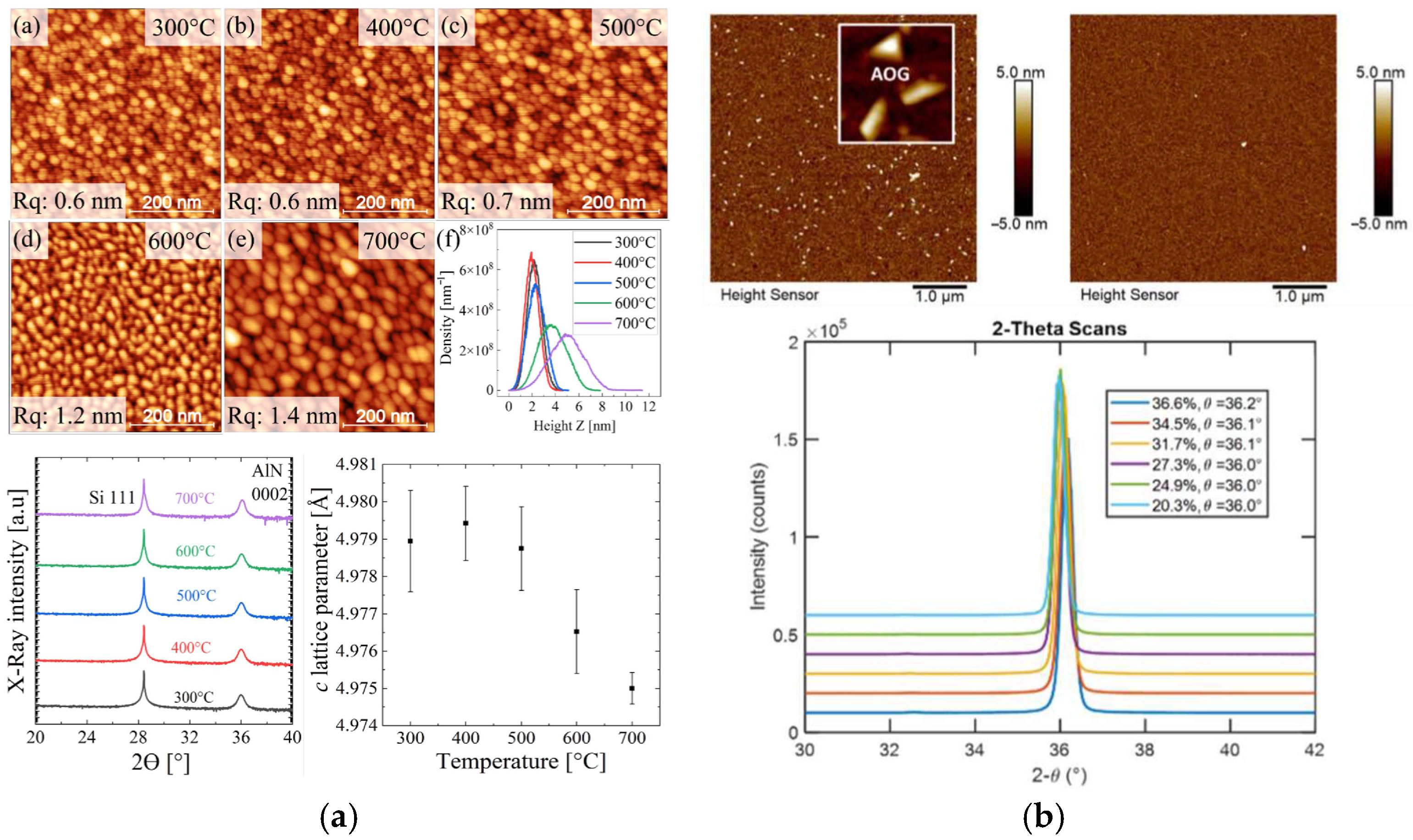

3.1. PVD Deposition of AlN and AlScN Films

3.2. MOCVD Deposition of AlN and AlScN Films

3.3. MBE Deposition of AlN and AlScN Films

3.4. Two-Step Method for AlN Piezoelectric Films Growth

4. Polarity Control and Inversion Mechanisms in AlN and AlScN Films

4.1. Mechanisms of Polarity Inversion in AlN and AlScN Materials

4.1.1. Interface Nucleation and Substrate Effect

4.1.2. Substrate Nitridation and Buffer Layers

4.1.3. Al Interlayer or Seed Layers

4.1.4. Interfacial Al-to-N Stoichiometry and Surface Reconstruction

4.1.5. Spontaneous Polarity Inversion

4.2. Polarity Control Approaches in AlN and AlScN Materials

5. Periodically Poled Al(Sc)N BAW Resonators for High-Frequency Applications

5.1. Multilayer P3F Stack Structure

5.2. BAW Resonators Fabricated Using P3F Stack

6. Discussion and Conclusions

- I.

- Polarity Characterization

- II.

- Material Innovation

- III.

- Device Design and Fabrication Optimization

- IV.

- Monolithic Integration and System-Level Demonstration

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mo, D.; Dabas, S.; Rassay, S.; Tabrizian, R. Complementary-Switchable Dual-Mode SHF Scandium Aluminum Nitride BAW Resonator. IEEE Trans. Electron Devices 2022, 69, 4624–4631. [Google Scholar] [CrossRef]

- Izhar; Fiagbenu, M.M.A.; Musavigharavi, P.; Du, X.; Leathersich, J.; Moe, C.; Kochhar, A.; Stach, E.A.; Vetury, R.; Olsson, R.H. A K-Band Bulk Acoustic Wave Resonator Using Periodically Poled Al0.72Sc0.28N. IEEE Electron Device Lett. 2023, 44, 1196–1199. [Google Scholar] [CrossRef]

- Izhar; Fiagbenu, M.M.A.; Du, X.; Musavigharavi, P.; Deng, Y.; Gunda, A.; Leathersich, J.; Moe, C.; Kochhar, A.; Stach, E.A.; et al. A High Quality Factor, 19-GHz Periodically Poled AlScN BAW Resonator Fabricated in a Commercial XBAW Process. IEEE Trans. Electron Devices 2024, 71, 5630–5637. [Google Scholar] [CrossRef]

- Hagelauer, A.; Ruby, R.; Inoue, S.; Plessky, V.; Hashimoto, K.-Y.; Nakagawa, R.; Verdu, J.; de Paco, P.; Mortazawi, A.; Piazza, G.; et al. From Microwave Acoustic Filters to Millimeter-Wave Operation and New Applications. IEEE J. Microw. 2023, 3, 484–508. [Google Scholar] [CrossRef]

- Gong, S.; Lu, R.; Yang, Y.; Gao, L.; Hassanien, A.E. Microwave Acoustic Devices: Recent Advances and Outlook. IEEE J. Microw. 2021, 1, 601–609. [Google Scholar] [CrossRef]

- Liu, Y.; Cai, Y.; Zhang, Y.; Tovstopyat, A.; Liu, S.; Sun, C. Materials, Design, and Characteristics of Bulk Acoustic Wave Resonator: A Review. Micromachines 2020, 11, 630. [Google Scholar] [CrossRef]

- Bi, F.Z.; Barber, B.P. Bulk Acoustic Wave RF Technology. IEEE Microw. Mag. 2008, 9, 65–80. [Google Scholar] [CrossRef]

- Lu, H.; Hao, X.; Yang, L.; Hou, B.; Zhang, M.; Wu, M.; Dong, J.; Ma, X. Recent Advances in AlN-Based Acoustic Wave Resonators. Micromachines 2025, 16, 205. [Google Scholar] [CrossRef]

- Lv, L.; Shuai, Y.; Huang, S.; Zhu, D.; Wang, Y.; Luo, W.; Pan, X.; Wu, C.; Zhang, W. Area Dependence of Effective Electromechanical Coupling Coefficient Induced by On-Chip Inductance in LiNbO3-Based BAW Resonators. Electronics 2022, 11, 4032. [Google Scholar] [CrossRef]

- Jamneala, T.; Bradley, P.; Koelle, U.B.; Chien, A. Modified Mason Model for Bulk Acoustic Wave Resonators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 2025–2029. [Google Scholar] [CrossRef] [PubMed]

- Neculoiu, D.; Bunea, A.-C.; Dinescu, A.M.; Farhat, L.A. Band Pass Filters Based on GaN/Si Lumped-Element SAW Resonators Operating at Frequencies Above 5 GHz. IEEE Access 2018, 6, 47587–47599. [Google Scholar] [CrossRef]

- Larson, J.D.; Bradley, P.D.; Wartenberg, S.; Ruby, R.C. Modified Butterworth-Van Dyke Circuit for FBAR Resonators and Automated Measurement System. In Proceedings of the 2000 IEEE Ultrasonics Symposium. Proceedings. An International Symposium (Cat. No.00CH37121), San Juan, PR, USA, 22–25 October 2000; Volume 1, pp. 863–868. [Google Scholar]

- Muller, C.; Dubois, M.-A. Effect of Size and Shape on the Performances of BAW Resonators: A Model and Its Applications. In Proceedings of the 2008 IEEE Ultrasonics Symposium, Beijing, China, 2–5 November 2008; pp. 1552–1556. [Google Scholar]

- Rosenbaum, J.F. Bulk Acoustic Wave Theory and Devices; Artech House Publishers: Norwood, MA, USA, 1988. [Google Scholar]

- Mason, W.P. Electromechanical Transducers and Wave Filters; D. Van Nostrand Company, Inc.: New York, NY, USA, 1942. [Google Scholar]

- Setter, N. (Ed.) Electroceramic-Based MEMS: Fabrication-Technology and Applications; Electronic Materials: Science and Technology; Springer: Boston, MA, USA, 2005; Volume 9, ISBN 978-0-387-23310-9. [Google Scholar]

- Tag, A.; Chauhan, V.; Huck, C.; Bader, B.; Karolewski, D.; Pitschi, F.M.; Weigel, R.; Hagelauer, A. A Method for Accurate Modeling of BAW Filters at High Power Levels. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 2207–2214. [Google Scholar] [CrossRef] [PubMed]

- Kumar, Y.; Singh, J.; Kumari, G.; Singh, R.; Akhtar, J. Effect of Shapes and Electrode Material on Figure of Merit (FOM) of BAW Resonator. AIP Conf. Proc. 2016, 1724, 020045. [Google Scholar] [CrossRef]

- Ennasar, S.; Ahyoud, S.; Asselman, A. Analysis of the Performance of A BAW Resonator According to Its Design Parameters. J. Mater. Sci. Metall. 2019, 1, 103. [Google Scholar]

- Liu, Y.; Sun, K.; Ma, J.; Yu, Z.; Lan, Z. Design and Fabrication of Temperature-Compensated Film Bulk Acoustic Resonator Filter Based on the Stress Compensation Effect. Coatings 2022, 12, 1126. [Google Scholar] [CrossRef]

- Wu, X.; Xu, L.; Shi, G.; Zhou, X.; Cai, J. Design and Modeling of Film Bulk Acoustic Resonator Considering Temperature Compensation for 5G Communication. Analog Integr. Circuits Signal Process. 2024, 118, 219–230. [Google Scholar] [CrossRef]

- Aigner, R.; Huynh, N.-H.; Handtmann, M.; Marksteiner, S. Behavior of BAW Devices at High Power Levels. In Proceedings of the IEEE MTT-S International Microwave Symposium Digest, 2005, Long Beach, CA, USA, 17 June 2005; pp. 429–432. [Google Scholar]

- Chauhan, V.; Huck, C.; Frank, A.; Akstaller, W.; Weigel, R.; Hagelauer, A. Enhancing RF Bulk Acoustic Wave Devices: Multiphysical Modeling and Performance. IEEE Microw. Mag. 2019, 20, 56–70. [Google Scholar] [CrossRef]

- Rocas, E.; Collado, C.; Mateu, J.; Orloff, N.D.; Booth, J.C.; Aigner, R. Electro-Thermo-Mechanical Model for Bulk Acoustic Wave Resonators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 2389–2403. [Google Scholar] [CrossRef]

- Zou, Y.; Gao, C.; Zhou, J.; Liu, Y.; Xu, Q.; Qu, Y.; Liu, W.; Soon, J.B.W.; Cai, Y.; Sun, C. Aluminum Scandium Nitride Thin-Film Bulk Acoustic Resonators for 5G Wideband Applications. Microsyst. Nanoeng. 2022, 8, 124. [Google Scholar] [CrossRef]

- Thalhammer, R.K.; Larson, J.D. Finite-Element Analysis of Bulk-Acoustic-Wave Devices: A Review of Model Setup and Applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 1624–1635. [Google Scholar] [CrossRef]

- Tong, Y.; Han, T. Anchor Loss Reduction of Lamb Wave Resonator by Pillar-Based Phononic Crystal. Micromachines 2021, 12, 62. [Google Scholar] [CrossRef]

- Lin, C.-M.; Hsu, J.-C.; Senesky, D.G.; Pisano, A.P. Anchor Loss Reduction in ALN Lamb Wave Resonators Using Phononic Crystal Strip Tethers. In Proceedings of the 2014 IEEE International Frequency Control Symposium (FCS), Taipei, Taiwan, 19–22 May 2014; pp. 1–5. [Google Scholar]

- Binci, L.; Tu, C.; Zhu, H.; Lee, J.E.-Y. Planar Ring-Shaped Phononic Crystal Anchoring Boundaries for Enhancing the Quality Factor of Lamb Mode Resonators. Appl. Phys. Lett. 2016, 109, 203501. [Google Scholar] [CrossRef]

- Yang, W.; Tam, W.-Y. Spurious Wave Suppression in BAW Resonators with Frame-like Airgap. In Proceedings of the 2010 IEEE International Frequency Control Symposium, Newport Beach, CA, USA, 1–4 June 2010; IEEE: Piscataway, NJ, USA; pp. 656–660. [Google Scholar]

- Nguyen, N.; Johannessen, A.; Rooth, S.; Hanke, U. The Impact of Area on BAW Resonator Performance and an Approach to Device Miniaturization. Ultrasonics 2019, 94, 92–101. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Song, S.; Zhang, J.; Chang, W.; Yang, H.; Tang, H.; Chen, S. Multi-Physics Coupling Modeling and Experimental Investigation of Vibration-Assisted Blisk Channel ECM. Micromachines 2021, 13, 50. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Xu, Z.; Meng, D.; Liu, L.; Fang, Z. Multi-Physical Field Coupling Simulation and Experiments with Pulse Electrochemical Machining of Large Size TiAl Intermetallic Blade. Metals 2023, 13, 985. [Google Scholar] [CrossRef]

- Shin, J.-S.; Song, I.; Kim, C.-S.; Lee, M.-C.; Son, S.U.; Kim, D.-H.; Park, H.-S.; Hwang, S.; Rieh, J.-S. Balanced RF Duplexer with Low Interference Using Hybrid BAW Resonators for LTE Application. ETRI J. 2014, 36, 317–320. [Google Scholar] [CrossRef]

- Dou, W.; Zhou, C.; Qin, R.; Yang, Y.; Guo, H.; Mu, Z.; Yu, W. Super-High-Frequency Bulk Acoustic Resonators Based on Aluminum Scandium Nitride for Wideband Applications. Nanomaterials 2023, 13, 2737. [Google Scholar] [CrossRef]

- Thalhammer, R.; Larson, J.D. Finite Element Analysis of BAW Devices: Principles and Perspectives. In Proceedings of the 2015 IEEE International Ultrasonics Symposium (IUS), Taipei, Taiwan, 21–24 October 2015; IEEE: Piscataway, NJ, USA; pp. 1–10. [Google Scholar]

- Lee, M.; Song, I.; Shin, J.-S.; Park, H.; Son, S.U.; Kim, C.-S.; Kim, D.-H.; Cui, J.; Ai, Y. Improved Bulk Acoustic Wave Resonator Using Edge Method for High Performance. In Proceedings of the 2012 Asia Pacific Microwave Conference Proceedings, Kaohsiung, Taiwan, 4–7 December 2012; IEEE: Piscataway, NJ, USA; pp. 520–522. [Google Scholar]

- Koohi, M.Z.; Lee, S.; Mortazawi, A. Design of BST-on-Si Composite FBARs for Switchable BAW Filter Application. In Proceedings of the 2016 46th European Microwave Conference (EuMC), London, UK, 4–6 October 2016; IEEE: Piscataway, NJ, USA; pp. 1003–1006. [Google Scholar]

- Kirkendall, C.; Yu, P.-L.; Shim, D.; Fouladi, S.; Liu, C. A 3D Finite Element Model of H2 Emissions in Apodized BAW Devices. In Proceedings of the 2022 IEEE MTT-S International Conference on Microwave Acoustics and Mechanics (IC-MAM), Munich, Germany, 18–20 July 2022; IEEE: Piscataway, NJ, USA; pp. 45–48. [Google Scholar]

- Zhao, L.; Yi, X.; Ouyang, P.; Li, G. A Theoretical Study of Thermal Management of FBAR Considering Thickness- and Temperature-Dependent Thermal Conductivity of AlN. AIP Adv. 2022, 12, 095018. [Google Scholar] [CrossRef]

- Fattinger, G.; Volatier, A.; Aigner, R.; Dumont, F. BAW PCS-Duplexer Chipset and Duplexer Applications. In Proceedings of the 2008 IEEE Ultrasonics Symposium, Beijing, China, 2–5 November 2008; IEEE: Piscataway, NJ, USA; pp. 602–606. [Google Scholar]

- Zuo, C.; He, C.; Cheng, W.; Wang, Z. Hybrid Filter Design for 5G Using IPD and Acoustic Technologies. In Proceedings of the 2019 IEEE International Ultrasonics Symposium (IUS), Glasgow, UK, 6–9 October 2019; IEEE: Piscataway, NJ, USA; pp. 269–272. [Google Scholar]

- Yang, Q.; Pang, W.; Zhang, D.; Zhang, H. A Modified Lattice Configuration Design for Compact Wideband Bulk Acoustic Wave Filter Applications. Micromachines 2016, 7, 133. [Google Scholar] [CrossRef]

- AlJoumayly, M.; Rothemund, R.; Schaefer, M.; Heeren, W. 5G BAW Technology: Challenges and Solutions. In Proceedings of the 2022 IEEE 22nd Annual Wireless and Microwave Technology Conference (WAMICON), Clearwater, FL, USA, 27 April 2022; IEEE: Piscataway, NJ, USA; pp. 1–3. [Google Scholar]

- Ruby, R.C.; Bradley, P.; Oshmyansky, Y.; Chien, A.; Larson, J.D. Thin Film Bulk Wave Acoustic Resonators (FBAR) for Wireless Applications. In Proceedings of the 2001 IEEE Ultrasonics Symposium. Proceedings, an International Symposium (Cat. No.01CH37263), Atlanta, GA, USA, 7–10 October 2001; Volume 1, pp. 813–821. [Google Scholar]

- Wingqvist, G. AlN-Based Sputter-Deposited Shear Mode Thin Film Bulk Acoustic Resonator (FBAR) for Biosensor Applications —A Review. Surf. Coat. Technol. 2010, 205, 1279–1286. [Google Scholar] [CrossRef]

- Ruby, R. 11E-2 Review and Comparison of Bulk Acoustic Wave FBAR, SMR Technology. In Proceedings of the 2007 IEEE Ultrasonics Symposium Proceedings, New York, NY, USA, 28–31 October 2007; pp. 1029–1040. [Google Scholar]

- Qu, Y.; Liu, Y.; Gu, X.; Wei, M.; Chen, X.; Huang, X.; Liu, Z.; Ding, J.; Wen, Z.; Cai, Y.; et al. Advanced Technologies of FBAR for Tuning Effective Electromechanical Coupling Coefficient. Appl. Phys. Lett. 2024, 124, 013501. [Google Scholar] [CrossRef]

- Yang, Y. Advancing Acoustic Filters for 5G Front-Ends: Lithium Niobate Piezoelectric MEMS Resonators and Filters. Available online: https://www.ideals.illinois.edu/items/113857 (accessed on 2 August 2025).

- Iqbal, A.; Mohd-Yasin, F. Reactive Sputtering of Aluminum Nitride (002) Thin Films for Piezoelectric Applications: A Review. Sensors 2018, 18, 1797. [Google Scholar] [CrossRef] [PubMed]

- Lakin, K.M.; McCarron, K.T.; Rose, R.E. Solidly Mounted Resonators and Filters. In Proceedings of the 1995 IEEE Ultrasonics Symposium. Proceedings. An International Symposium, Seattle, WA, USA, 7–10 November 1995; Volume 2, pp. 905–908. [Google Scholar]

- Villa-López, F.H.; Rughoobur, G.; Thomas, S.; Flewitt, A.J.; Cole, M.; Gardner, J.W. Design and Modelling of Solidly Mounted Resonators for Low-Cost Particle Sensing. Meas. Sci. Technol. 2016, 27, 025101. [Google Scholar] [CrossRef]

- Chung, C.-J.; Chen, Y.-C.; Cheng, C.-C.; Kao, K.-S. Fabrication and Frequency Response of Solidly Mounted Resonators with 1/4λ Mode Configuration. Thin Solid Films 2008, 516, 5277–5281. [Google Scholar] [CrossRef]

- Newell, W.E. Face-Mounted Piezoelectric Resonators. Proc. IEEE 1965, 53, 575–581. [Google Scholar] [CrossRef]

- Plessky, V.; Yandrapalli, S.; Turner, P.J.; Villanueva, L.G.; Koskela, J.; Hammond, R.B. 5 GHz Laterally-excited Bulk-wave Resonators (XBARs) Based on Thin Platelets of Lithium Niobate. Electron. Lett. 2019, 55, 98–100. [Google Scholar] [CrossRef]

- Wen, Z.; Liu, W.; Luo, T.; Tong, X.; Xie, Y.; Gu, X.; Liu, Y.; Cai, Y.; Guo, S.; Wang, J.; et al. A Laterally Excited Bulk Acoustic Resonator with Scattering Vias in Electrodes. Appl. Phys. Lett. 2023, 123, 093501. [Google Scholar] [CrossRef]

- Kumar, A.; Prajesh, R. Analytically Assisted FEM Approach for the Design and Optimization of Laterally Excited Bulk Acoustic Wave Resonators (XBARs) with a High Electromechanical Coupling. Appl. Phys. A 2024, 130, 276. [Google Scholar] [CrossRef]

- Wang, N.; Zhu, Y.; Chen, B.; Zhang, Y. Over 12% of Coupling Coefficient Demonstrated by 3GHz Sc0.12 Al0.88 N Based Laterally Coupled Alternating Thickness (LCAT) Mode Resonators. In Proceedings of the 2019 IEEE International Ultrasonics Symposium (IUS), Glasgow, UK, 6–9 October 2019; IEEE: Piscataway, NJ, USA; pp. 1971–1973. [Google Scholar]

- Chen, X.; Qu, Y.; Luo, T.; Gu, X.; Huang, X.; Cai, Y.; Guo, S.; Liu, Y.; Sun, C. A Lamb Wave Resonator with Trapezoidal Interdigitated Electrodes. In Proceedings of the 2024 IEEE MTT-S International Conference on Microwave Acoustics & Mechanics (IC-MAM), Chengdu, China, 13–15 May 2024; IEEE: Piscataway, NJ, USA; pp. 33–36. [Google Scholar]

- Zhu, Y.; Wang, N.; Sun, C.; Merugu, S.; Singh, N.; Gu, Y. A High Coupling Coefficient 2.3-GHz AlN Resonator for High Band LTE Filtering Application. IEEE Electron Device Lett. 2016, 37, 1344–1346. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, J.; Xie, Y.; Tang, C.; Zou, Y.; Tovstopyat, A.; Yu, H.; Sun, C. Dual-Mode Hybrid Quasi-SAW/BAW Resonators with High Effective Coupling Coefficient. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2020, 67, 1916–1921. [Google Scholar] [CrossRef]

- Chen, X.; Luo, T.; Qu, Y.; Wen, Z.; Ding, J.; Liu, Y.; Sun, C. 3.75 GHz AlN Lamb Wave Resonator with Hole-like Acoustic Reflection Structure. In Proceedings of the 2023 IEEE International Ultrasonics Symposium (IUS), Montreal, QC, Canada, 3–8 September 2023; IEEE: Piscataway, NJ, USA; pp. 1–3. [Google Scholar]

- Yang, T.; Gao, C.; Wang, Y.; Lin, B.; Zheng, Y.; Liu, Y.; Lei, C.; Sun, C.; Cai, Y. 5.5 GHz Film Bulk Acoustic Wave Filters Using Thin Film Transfer Process for WLAN Applications. Microsyst. Nanoeng. 2024, 10, 174. [Google Scholar] [CrossRef]

- Zhao, J.; Lv, S.; Sun, Z.; Cang, D.; Sun, H.; Shi, Q. High-Q Coupled Mode Resonator Based on Wafer-Level Transfer Technology. IEEE Trans. Electron Devices 2025, 72, 1977–1985. [Google Scholar] [CrossRef]

- Miller, J.; Wright, J.; Xing, H.G.; Jena, D. All-Epitaxial Bulk Acoustic Wave Resonators. Phys. Status Solidi A 2020, 217, 1900786. [Google Scholar] [CrossRef]

- Maribel, P. Bilayered Thin-Film Metal Electrode Development for Piezoelectric Devices. Master’s Thesis, Aalto University, Espoo, Finland, 2024. [Google Scholar]

- Tang, Z.; Esteves, G.; Yen, S.; Young, T.R.; Henry, M.D.; Gastian, L.; Nordquist, C.; Olsson, R.H. A Comprehensive Approach for Total Suppression of In-Band Spurious Modes in UHF Al0.72Sc0.28N Lamb Wave Resonators and Filters. J. Microelectromech. Syst. 2024, 33, 456–467. [Google Scholar] [CrossRef]

- Yu, J.; Chen, S.; Guo, X. Design and Simulation of a 2.4G Wi-Fi Band BAW Filter Chip Based on Frame Structure FBARs. In Proceedings of the 2024 IEEE International Conference on Computational Electromagnetics (ICCEM), Nanjing, China, 15–17 April 2024; pp. 1–3. [Google Scholar]

- Wu, T.; He, Y.; Wong, Y.-P.; Li, W.; Bao, J.; Hashimoto, K. 2D Scalar Wave Model for Fast Analysis of Apodized BAW Devices. In Proceedings of the 2022 IEEE International Ultrasonics Symposium (IUS), Venice, Italy, 10–13 October 2022; pp. 1–4. [Google Scholar]

- Sun, J.-H.; Wu, T.-T. Propagation of Surface Acoustic Waves through Sharply Bent Two-Dimensional Phononic Crystal Waveguides Using a Finite-Difference Time-Domain Method. Phys. Rev. B 2006, 74, 174305. [Google Scholar] [CrossRef]

- Cho, S.; Barrera, O.; Kramer, J.; Chulukhadze, V.; Hsu, T.-H.; Campbell, J.; Anderson, I.; Lu, R. 23.8-GHz Acoustic Filter in Periodically Poled Piezoelectric Film Lithium Niobate With 1.52-dB IL and 19.4% FBW. IEEE Microw. Wirel. Technol. Lett. 2024, 34, 391–394. [Google Scholar] [CrossRef]

- Vetury, R.; Kochhar, A.; Leathersich, J.; Moe, C.; Winters, M.; Shealy, J.; Olsson, R.H. A Manufacturable AlScN Periodically Polarized Piezoelectric Film Bulk Acoustic Wave Resonator (AlScN P3F BAW) Operating in Overtone Mode at X and Ku Band. In Proceedings of the 2023 IEEE/MTT-S International Microwave Symposium—IMS 2023, San Diego, CA, USA, 11–16 June 2023; pp. 891–894. [Google Scholar]

- Izhar; Fiagbenu, M.M.A.; Yao, S.; Du, X.; Musavigharavi, P.; Deng, Y.; Leathersich, J.; Moe, C.; Kochhar, A.; Stach, E.A.; et al. Periodically Poled Aluminum Scandium Nitride Bulk Acoustic Wave Resonators and Filters for Communications in the 6G Era. Microsyst. Nanoeng. 2025, 11, 19. [Google Scholar] [CrossRef]

- Park, M.; Wang, J.; Wang, D.; Mi, Z.; Ansari, A. A 19 GHz All-Epitaxial Al0.8Sc0.2N Cascaded FBAR for RF Filtering Applications. IEEE Electron Device Lett. 2024, 45, 1341–1344. [Google Scholar] [CrossRef]

- Assylbekova, M.; Chen, G.; Michetti, G.; Pirro, M.; Colombo, L.; Rinaldi, M. 11 GHz Lateral-Field-Excited Aluminum Nitride Cross-Sectional Lamé Mode Resonator. In Proceedings of the 2020 Joint Conference of the IEEE International Frequency Control Symposium and International Symposium on Applications of Ferroelectrics (IFCS-ISAF), Keystone, CO, USA, 19–23 July 2020; pp. 1–4. [Google Scholar]

- Yi, X.; Zhao, L.; Ouyang, P.; Liu, H.; Zhang, T.; Li, G. High-Quality Film Bulk Acoustic Resonators Fabricated on AlN Films Grown by a New Two-Step Method. IEEE Electron Device Lett. 2022, 43, 942–945. [Google Scholar] [CrossRef]

- Li, X.; Fang, Y.; Li, Y.; Wu, Z.; Huang, S.; Yang, Y.; Dong, B.; Chen, G.; Hao, Y.; Han, G. Advanced Growth Techniques and Challenges in Ferroelectric AlScN Thin Films for Next-Generation Electronic Devices. Moore More 2025, 2, 10. [Google Scholar] [CrossRef]

- Wang, W.; Yang, W.; Wang, H.; Zhu, Y.; Li, G. Quality-Enhanced AlN Epitaxial Films Grown on Al Substrates by Two-Step Growth. RSC Adv. 2015, 5, 97308–97313. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, K.; Luo, T.; Zhi, G.; Zhu, Y.; Ouyang, P.; Li, G. High-Performance Film Bulk Acoustic Resonator and Filter Based on an Al0.8Sc0.2N Film Prepared by a Low-Temperature Staged Deposition Method. IEEE Trans. Electron Devices 2025, 72, 383–389. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Luo, T.; Yi, X.; Li, G. X-Band Bulk Acoustic Wave Resonators with High Figure of Merit Based on Al0.8Sc0.2N. IEEE Electron Device Lett. 2024, 45, 2291–2294. [Google Scholar] [CrossRef]

- Zhi, G.; Xu, K.; Zhang, Y.; Zhu, Y.; Luo, T.; Tao, G.; Chen, Z.; Wang, J.; Yi, X.; Li, G. Substrate Loss Mechanism and Performance Enhancement via HR-Si of BAW Devices. IEEE Trans. Electron Devices 2025, 72, 3814–3819. [Google Scholar] [CrossRef]

- Ouyang, P.; Yi, X.; Li, G. Single-Crystalline Bulk Acoustic Wave Resonators Fabricated With AlN Film Grown by a Combination of PLD and MOCVD Methods. IEEE Electron Device Lett. 2024, 45, 538–541. [Google Scholar] [CrossRef]

- Yang, K.; Chen, J.; Lin, F.; Qiu, H.; Fang, J.; Zuo, C. SAW Resonators Based on High-Crystalline AlScN Film Grown by a Two-Step Method of MOCVD and PVD. In Proceedings of the 2024 IEEE Ultrasonics, Ferroelectrics, and Frequency Control Joint Symposium (UFFC-JS), Taipei, Taiwan, 22–26 September 2024; pp. 1–4. [Google Scholar]

- Qin, R.; Zhou, C.; Dou, W.; Lu, J.; Yang, Y.; Mu, Z.; Yu, W. 3.3 GHz BAW Resonators Fabricated on Single Crystal AlN Templates. In Proceedings of the 2023 IEEE International Ultrasonics Symposium (IUS), Montreal, QC, Canada, 3–8 September 2023; pp. 1–4. [Google Scholar]

- Sundarapandian, B.; Yassine, A.; Kirste, L.; Baeumler, M.; Straňák, P.; Fisslthaler, E.; Prescher, M.; Yassine, M.; Nair, A.; Raghuwanshi, M.; et al. Influence of Growth Temperature on the Properties of Aluminum Nitride Thin Films Prepared by Magnetron Sputter Epitaxy. J. Appl. Phys. 2023, 134, 185107. [Google Scholar] [CrossRef]

- Beaucejour, R.; Roebisch, V.; Kochhar, A.; Moe, C.G.; Hodge, M.D.; Olsson, R.H. Controlling Residual Stress and Suppression of Anomalous Grains in Aluminum Scandium Nitride Films Grown Directly on Silicon. J. Microelectromech. Syst. 2022, 31, 604–611. [Google Scholar] [CrossRef]

- Iborra, E.; Olivares, J.; Clement, M.; Vergara, L.; Sanz-Hervás, A.; Sangrador, J. Piezoelectric Properties and Residual Stress of Sputtered AlN Thin Films for MEMS Applications. Sens. Actuators Phys. 2004, 115, 501–507. [Google Scholar] [CrossRef]

- Su, J.; Fichtner, S.; Ghori, M.Z.; Wolff, N.; Islam, M.R.; Lotnyk, A.; Kaden, D.; Niekiel, F.; Kienle, L.; Wagner, B.; et al. Growth of Highly C-Axis Oriented AlScN Films on Commercial Substrates. Micromachines 2022, 13, 783. [Google Scholar] [CrossRef]

- Shealy, J.B.; Moe, C.; Leathersich, J.; Bi, F.; Kim, D.; Patel, P.; Cheema, K.; Kochhar, A.; Mehdizadeh, E.; Winters, M. Single Crystal AlScN-on-Silicon XBAW RF Filter Technology for Wide Bandwidth, High Frequency 5G and WiFi Applications. In Proceedings of the 2022 International Conference on Compound Semiconductor Manufacturing Technology, CS MANTECH, Monterey, CA, USA, 9–12 May 2022. [Google Scholar]

- Shen, Y.; Zhang, R.; Vetury, R.; Shealy, J. 40.6 Watt, High Power 3.55 GHz Single Crystal XBAW RF Filters for 5G Infrastructure Applications. In Proceedings of the 2020 IEEE International Ultrasonics Symposium (IUS), Las Vegas, NV, USA, 7–11 September 2020; pp. 1–3. [Google Scholar]

- Hodge, M.D.; Vetury, R.; Gibb, S.R.; Winters, M.; Patel, P.; McLain, M.A.; Shen, Y.; Kim, D.H.; Jech, J.; Fallon, K.; et al. High Rejection UNII 5.2GHz Wideband Bulk Acoustic Wave Filters Using Undoped Single Crystal AlN-on-SiC Resonators. In Proceedings of the 2017 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–6 December 2017; pp. 25.6.1–25.6.4. [Google Scholar]

- Shealy, J.B.; Vetury, R.; Gibb, S.R.; Hodge, M.D.; Patel, P.; McLain, M.A.; Feldman, A.Y.; Boomgarden, M.D.; Lewis, M.P.; Hosse, B.; et al. Low Loss, 3.7GHz Wideband BAW Filters, Using High Power Single Crystal AlN-on-SiC Resonators. In Proceedings of the 2017 IEEE MTT-S International Microwave Symposium (IMS), Honolulu, HI, USA, 4–9 June 2017; pp. 1476–1479. [Google Scholar]

- Zhao, W.; Asadi, M.J.; Li, L.; Chaudhuri, R.; Nomoto, K.; Xing, H.G.; Hwang, J.C.M.; Jena, D. 15-GHz Epitaxial AlN FBARs on SiC Substrates. IEEE Electron Device Lett. 2023, 44, 903–906. [Google Scholar] [CrossRef]

- Park, M.; Wang, J.; Dargis, R.; Clark, A.; Ansari, A. Super High-Frequency Scandium Aluminum Nitride Crystalline Film Bulk Acoustic Resonators. In Proceedings of the 2019 IEEE International Ultrasonics Symposium (IUS), Glasgow, UK, 6–9 October 2019; pp. 1689–1692. [Google Scholar]

- Lu, J.; Huo, C.; Fu, J.; Qin, R.; Mu, Z.; Yu, W. A Ku-Band 2nd Order Mode FBAR Based on Bilayer Polarity-Inverted Single Crystal AlN Films. In Proceedings of the 2024 IEEE Ultrasonics, Ferroelectrics, and Frequency Control Joint Symposium (UFFC-JS), Taipei, Taiwan, 22–26 September 2024; pp. 1–4. [Google Scholar]

- Yanagitani, T.; Takayanagi, S. Polarization Control of ScAlN, ZnO and PbTiO3 Piezoelectric Films: Application to Polarization-Inverted Multilayer Bulk Acoustic Wave and Surface Acoustic Wave Devices. Jpn. J. Appl. Phys. 2021, 60, SD0803. [Google Scholar] [CrossRef]

- Wang, H.; Adamski, N.; Mu, S.; Walle, C.G.V. de Piezoelectric Effect and Polarization Switching in Al1−xScxN. J. Appl. Phys. 2021, 130, 104101. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Xie, Y.P.; Guo, H.B.; Chen, Y.G. Thermodynamics of Inversion-Domain Boundaries in Aluminum Nitride: Interplay between Interface Energy and Electric Dipole Potential Energy. J. Appl. Phys. 2018, 123, 175301. [Google Scholar] [CrossRef]

- Krishnamoorthy, A.; Tiwari, S.C.; Nakano, A.; Kalia, R.K.; Vashishta, P. Electric-Field-Induced Crossover of Polarization Reversal Mechanisms in Al1−x Scx N Ferroelectrics. Nanotechnology 2021, 32, 49LT02. [Google Scholar] [CrossRef]

- Mohn, S.; Stolyarchuk, N.; Markurt, T.; Kirste, R.; Hoffmann, M.P.; Collazo, R.; Courville, A.; Di Felice, R.; Sitar, Z.; Vennéguès, P.; et al. Polarity Control in Group-III Nitrides beyond Pragmatism. Phys. Rev. Appl. 2016, 5, 054004. [Google Scholar] [CrossRef]

- Stolyarchuk, N.; Markurt, T.; Courville, A.; March, K.; Tottereau, O.; Vennéguès, P.; Albrecht, M. Impact of Sapphire Nitridation on Formation of Al-Polar Inversion Domains in N-Polar AlN Epitaxial Layers. J. Appl. Phys. 2017, 122, 155303. [Google Scholar] [CrossRef]

- Stolyarchuk, N.; Markurt, T.; Courville, A.; March, K.; Zúñiga-Pérez, J.; Vennéguès, P.; Albrecht, M. Intentional Polarity Conversion of AlN Epitaxial Layers by Oxygen. Sci. Rep. 2018, 8, 14111. [Google Scholar] [CrossRef]

- Tamano, T.; Shojiki, K.; Akiyama, T.; Akaike, R.; Nakamura, T.; Honda, H.; Sato, E.; Uemukai, M.; Tanikawa, T.; Katayama, R.; et al. Analysis of Inversion-Domain Boundaries in Four-Layer Polarity-Inverted AlN Structure. Appl. Phys. Lett. 2025, 126, 032108. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, B.; Ren, F.; Yin, Y.; Zhang, S.; Liang, M.; Dou, Z.; Liu, Z.; Yang, S.; Yan, J.; et al. Atomic-Scale Mechanism of Spontaneous Polarity Inversion in AlN on Nonpolar Sapphire Substrate Grown by MOCVD. Small 2022, 18, 2200057. [Google Scholar] [CrossRef]

- Kirste, R.; Mita, S.; Hussey, L.; Hoffmann, M.P.; Guo, W.; Bryan, I.; Bryan, Z.; Tweedie, J.; Xie, J.; Gerhold, M.; et al. Polarity Control and Growth of Lateral Polarity Structures in AlN. Appl. Phys. Lett. 2013, 102, 181913. [Google Scholar] [CrossRef]

- Alden, D.; Guo, W.; Kirste, R.; Kaess, F.; Bryan, I.; Troha, T.; Bagal, A.; Reddy, P.; Hernandez-Balderrama, L.H.; Franke, A.; et al. Fabrication and Structural Properties of AlN Submicron Periodic Lateral Polar Structures and Waveguides for UV-C Applications. Appl. Phys. Lett. 2016, 108, 261106. [Google Scholar] [CrossRef]

- Lee, S.-T.; Park, B.-G.; Kim, M.-D.; Oh, J.-E.; Kim, S.-G.; Kim, Y.-H.; Yang, W.-C. Control of Polarity and Defects in the Growth of AlN Films on Si (111) Surfaces by Inserting an Al Interlayer. Curr. Appl. Phys. 2012, 12, 385–388. [Google Scholar] [CrossRef]

- Milyutin, E.; Harada, S.; Martin, D.; Carlin, J.F.; Grandjean, N.; Savu, V.; Vaszquez-Mena, O.; Brugger, J.; Muralt, P. Sputtering of (001)AlN Thin Films: Control of Polarity by a Seed Layer. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2010, 28, L61–L63. [Google Scholar] [CrossRef]

- Brubaker, M.D.; Duff, S.M.; Harvey, T.E.; Blanchard, P.T.; Roshko, A.; Sanders, A.W.; Sanford, N.A.; Bertness, K.A. Polarity-Controlled GaN/AlN Nucleation Layers for Selective-Area Growth of GaN Nanowire Arrays on Si(111) Substrates by Molecular Beam Epitaxy. Cryst. Growth Des. 2016, 16, 596–604. [Google Scholar] [CrossRef]

- Fan, S.; Yin, Y.; Liu, R.; Zhao, H.; Liu, Z.; Sun, Q.; Yang, H. Polarity Control and Crystalline Quality Improvement of AlN Thin Films Grown on Si(111) Substrates by Molecular Beam Epitaxy. J. Appl. Phys. 2024, 136, 145301. [Google Scholar] [CrossRef]

- Yoshikawa, A.; Xu, K. In Situ Investigation for Polarity-Controlled Epitaxy Processes of GaN and AlN in MBE and MOVPE Growth. Opt. Mater. 2003, 23, 7–14. [Google Scholar] [CrossRef]

- Anggraini, S.A.; Uehara, M.; Hirata, K.; Yamada, H.; Akiyama, M. Polarity Inversion of Aluminum Nitride Thin Films by Using Si and MgSi Dopants. Sci. Rep. 2020, 10, 4369. [Google Scholar] [CrossRef]

- Calderon, S.; Hayden, J.; Baksa, S.M.; Tzou, W.; Trolier-McKinstry, S.; Dabo, I.; Maria, J.-P.; Dickey, E.C. Atomic-Scale Polarization Switching in Wurtzite Ferroelectrics. Science 2023, 380, 1034–1038. [Google Scholar] [CrossRef]

- Kirste, R.; Mita, S.; Hoffmann, M.P.; Hussey, L.; Guo, W.; Bryan, I.; Bryan, Z.; Tweedie, J.; Gerhold, M.; Hoffmann, A.; et al. Properties of AlN Based Lateral Polarity Structures. Phys. Status Solidi C 2014, 11, 261–264. [Google Scholar] [CrossRef]

- Sekimoto, J.; Suzuki, M.; Kakio, S. Polarity Control of (0001) Oriented AlN Films by Si Doping and Applications to Polarity Inverted SiAlN/AlN Film Bulk Acoustic Wave Resonators. In Proceedings of the 2021 IEEE International Ultrasonics Symposium (IUS), Virtual, 11–16 September 2021; pp. 1–3. [Google Scholar]

- Sekimoto, J.; Suzuki, M.; Kakio, S. High-Order Mode Bulk Acoustic Wave Resonators Based on Polarity-Inverted SiAlN/AlN Multilayered Films for High-Frequency Operation. Appl. Phys. Lett. 2022, 121, 141904. [Google Scholar] [CrossRef]

- Wright, J.; Moe, C.; Sampath, A.V.; Garrett, G.A.; Wraback, M. Fabrication of Periodically Poled AlN with Sub-micron Periods. Phys. Status Solidi C 2011, 8, 2331–2333. [Google Scholar] [CrossRef]

- Ishii, N.; Yanagitani, T. Polarization Inverted Two Layer ScAlN Thin Film Resonator Fabricated by Applying External Electric Field. In Proceedings of the 2022 IEEE International Ultrasonics Symposium (IUS), Venice, Italy, 10–13 October 2022; pp. 1–4. [Google Scholar]

- Eliseev, E.A.; Morozovska, A.N.; Maria, J.-P.; Chen, L.-Q.; Gopalan, V. A Thermodynamic Theory of Proximity Ferroelectricity. arXiv 2025, arXiv:2501.05219. [Google Scholar] [CrossRef]

- Kinoshita, T.; Yanagi, H.; Inoue, S. Polarity Control of AlN Layers Grown on Sapphire Substrates by Oxygen Doping during AlN Nucleation. J. Cryst. Growth 2014, 386, 76–79. [Google Scholar] [CrossRef]

- Uesugi, K.; Miyake, H. Fabrication of AlN Templates by High-Temperature Face-to-Face Annealing for Deep UV LEDs. Jpn. J. Appl. Phys. 2021, 60, 120502. [Google Scholar] [CrossRef]

- Tanigawa, S.; Sakoyama, T.; Kurai, S.; Okada, N.; Yamada, Y. Control of Polarity of AlN Grown on Sapphire Substrate and Growth with Both Al- and N-Polarities. Phys. Status Solidi B 2023, 260, 2200576. [Google Scholar] [CrossRef]

- Kochhar, A.; Vetury, R.; Leathersich, J.; Schaffer, Z.; Moe, C.; Kim, D.; Cheema, K.; Winters, M.; Shealy, J. X-Band Bulk Acoustic Wave Resonator (XBAW) Using Periodically Polarized Piezoelectric Films (P3F). In Proceedings of the 2023 IEEE International Ultrasonics Symposium (IUS), Montreal, QC, Canada, 3–8 September 2023; pp. 1–4. [Google Scholar]

- Naumenko, N.F. Enhancement of High-Frequency Harmonics in Resonators Using Multilayered Structures with Polarity-Inverted Layers. Results Phys. 2024, 65, 107998. [Google Scholar] [CrossRef]

- Hanai, A.; Shimano, Y.; Yanagitani, T. Polarization-Inverted Growth of ScAlN Thin Film by Si Doping. In Proceedings of the 2024 IEEE Ultrasonics, Ferroelectrics, and Frequency Control Joint Symposium (UFFC-JS), Taipei, Taiwan, 22–26 September 2024; pp. 1–3. [Google Scholar]

- Nam, S.; Peng, W.; Wang, P.; Wang, D.; Mi, Z.; Mortazawi, A. A mm-wave Trilayer AlN/ScAlN/AlN Higher Order Mode FBAR. IEEE Microw. Wirel. Technol. Lett. 2023, 33, 803–806. [Google Scholar] [CrossRef]

- Peng, W.; Nam, S.; Wang, D.; Mi, Z.; Mortazawi, A. A 56 GHz Trilayer AlN/ScAlN/AlN Periodically Poled FBAR. In Proceedings of the 2024 IEEE/MTT-S International Microwave Symposium—IMS 2024, Washington, DC, USA, 16 June 2024; IEEE: Piscataway, NJ, USA; pp. 150–153. [Google Scholar]

- Lu, J.; Huo, C.; Huang, X.; Li, W.; Mu, Z.; Yu, W. Switchable Bulk Acoustic Resonator Based on AlN/Al0.7 Sc0.3N Films. Electron. Lett. 2025, 61, e70241. [Google Scholar] [CrossRef]

- Zhu, P.; Huo, C.; Huang, X.; Ren, W.; Gao, Y.; Mu, Z.; Yu, W. High-K2eff High Frequency BAW Resonators Based on Single-Crystal Polarity-Inverted AlxSc1−xN Piezoelectric Films. In Proceedings of the 2024 IEEE Ultrasonics, Ferroelectrics, and Frequency Control Joint Symposium (UFFC-JS), Taipei, Taiwan, 22–26 September 2024; pp. 1–3. [Google Scholar]

- Larson, J.D.; Mishin, S.; Bader, S. Characterization of Reversed C-Axis AlN Thin Films. In Proceedings of the 2010 IEEE International Ultrasonics Symposium, San Diego, CA, USA, 11–14 October 2010; pp. 1054–1059. [Google Scholar]

| Method | Material | FWHM/° | RMS/nm | fs/GHz | K2eff/% | Qmax | Ref. |

|---|---|---|---|---|---|---|---|

| PVD | Al0.68Sc0.32N | 2.24 | 0.74 | 4.8 | 15.8 | 1180 | [86] |

| MOCVD | Al0.75Sc0.25N | 0.38 | - | 7.04 | 11.45 | 1087 | [89] |

| MOCVD | AlN | 0.027 | - | 5.2 | 6.32 | 1523 | [91] |

| MBE | AlN | 0.1 | 0.26 | 14.73 | 2.3 | 443 | [93] |

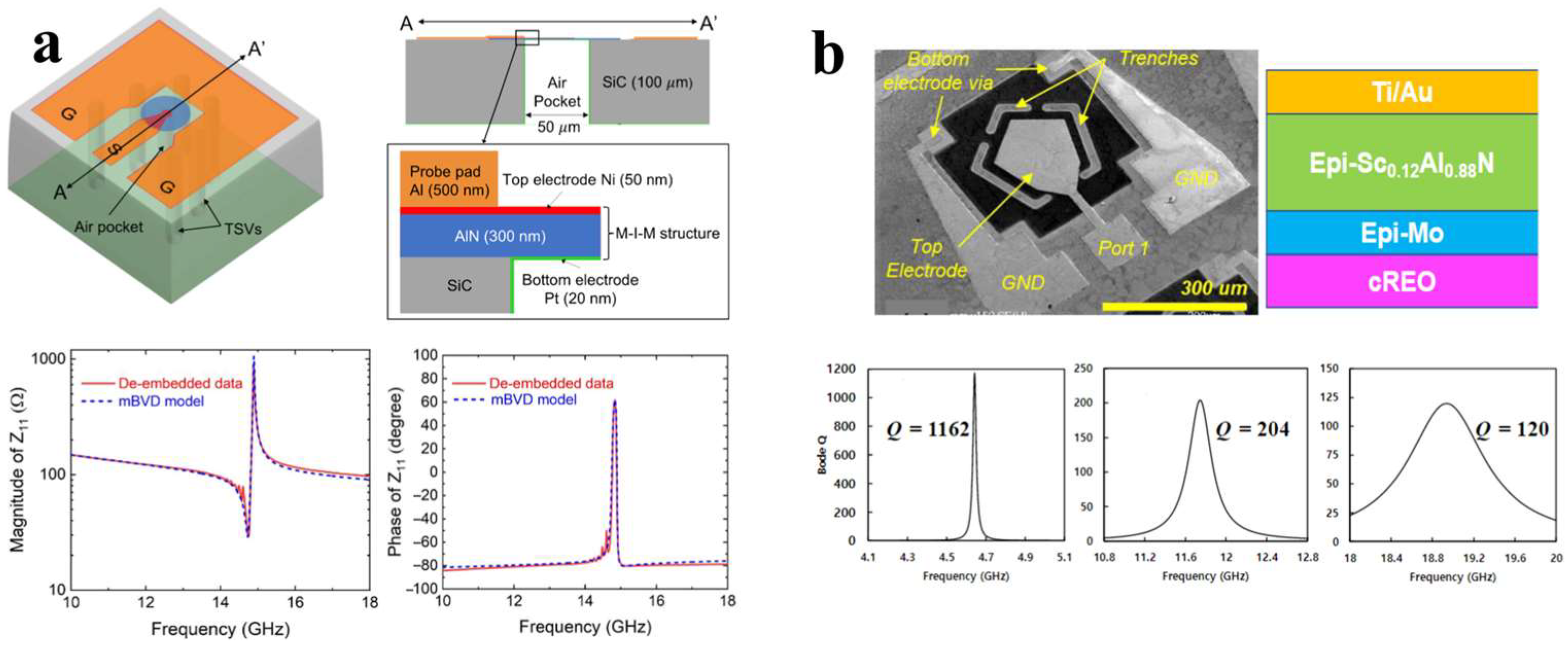

| MBE | Al0.88Sc0.12N | 0.8 | - | 4.6 | 1 | 1162 | [94] |

| MOCVD + PLD | AlN | 0.21 | 0.187 | 2.246 | 6.25 | 4097 | [82] |

| PLD + PVD | Al0.8Sc0.2N | 1 | 0.628 | 3.41 | 13.7 | 1362 | [79] |

| MOCVD + PVD | Al0.8Sc0.2N | 0.25 | 0.316 | 11.51 | 9.07 | 1244 | [80] |

| MOCVD + PVD | Al0.87Sc0.13N | 1.55 | 0.6 | 5.38 | 10.09 | 1451 | [81] |

| MOCVD + PVD | AlN | 0.46 | - | 14.57 | 5.13 | 551 | [95] |

| Material | Number of Layers | fs/GHz | K2eff (%) | Qs | Qp | Qmax | FOM (K2eff Q) | Ref. |

|---|---|---|---|---|---|---|---|---|

| AlScN | Single layer | 19.11 | 10.14 | - | - | 145 | 14.71 | [74] |

| AlScN (XBAR) | Single layer | 3.75 | 0.53 | - | 1137 | - | 6 | [62] |

| AlScN | 2-layer | 7.04 | 10.1 | 115 | - | - | 11.6 | [1] |

| 13.4 | 10.7 | 151 | - | - | 16.2 | |||

| AlScN | 3-layer | 20.7 | 8.23 | 92 | 160 | 217 | 18 | [2] |

| AlScN | 4-layer | 18.8 | 4.37 | 348 | 264 | 531 | 23.2 | [3] |

| AlScN | 2-layer | 18.4 | 7.55 | 180 | 260 | - | 19.6 | [72] |

| AlScN | 4-layer | 17.4 | 11.8 | 58.4 | 236.6 | - | 27.9 | [73] |

| AlN + AlScN + AlN | 3-layer | 9 | 5.1 | 183 | 169 | 395 | 20 | [126] |

| 31 | 5.5 | 61 | 61 | 61 | 3.4 | |||

| AlN + AlScN + AlN | 3-layer | 55.7 | 4.2 | 55 | 60 | 60 | 2.5 | [127] |

| AlN + AlScN | 2-layer | 14.18 | 9.7 | - | - | 439 | 42.6 | [129] |

| AlN + AlScN | 2-layer | 16.73 | 6.29 | 101 | 106 | - | 6.7 | [128] |

| AlN | 2-layer | 14.57 | 5.13 | 440 | 394 | 551 | 28.3 | [95] |

| AlN | 2-layer | 4.5 | 5~6 | - | - | - | - | [130] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Qin, R.; Dou, W.; Huo, C.; Huang, X.; Mu, Z.; Li, W.; Yu, W. Advancements in Super-High Frequency Al(Sc)N BAW Resonators for 5G and Beyond. Acoustics 2025, 7, 58. https://doi.org/10.3390/acoustics7030058

Li C, Qin R, Dou W, Huo C, Huang X, Mu Z, Li W, Yu W. Advancements in Super-High Frequency Al(Sc)N BAW Resonators for 5G and Beyond. Acoustics. 2025; 7(3):58. https://doi.org/10.3390/acoustics7030058

Chicago/Turabian StyleLi, Chen, Ruidong Qin, Wentong Dou, Chongyang Huo, Xuanqi Huang, Zhiqiang Mu, Weimin Li, and Wenjie Yu. 2025. "Advancements in Super-High Frequency Al(Sc)N BAW Resonators for 5G and Beyond" Acoustics 7, no. 3: 58. https://doi.org/10.3390/acoustics7030058

APA StyleLi, C., Qin, R., Dou, W., Huo, C., Huang, X., Mu, Z., Li, W., & Yu, W. (2025). Advancements in Super-High Frequency Al(Sc)N BAW Resonators for 5G and Beyond. Acoustics, 7(3), 58. https://doi.org/10.3390/acoustics7030058