A Basic Study on the Absorption Properties and Their Prediction of Heterogeneous Micro-Perforated Panels: A Case Study of Micro-Perforated Panels with Heterogeneous Hole Size and Perforation Ratio

Abstract

:1. Introduction

2. Prototype of the Test Specimen and the Experimental Procedure

2.1. Specimens

- -

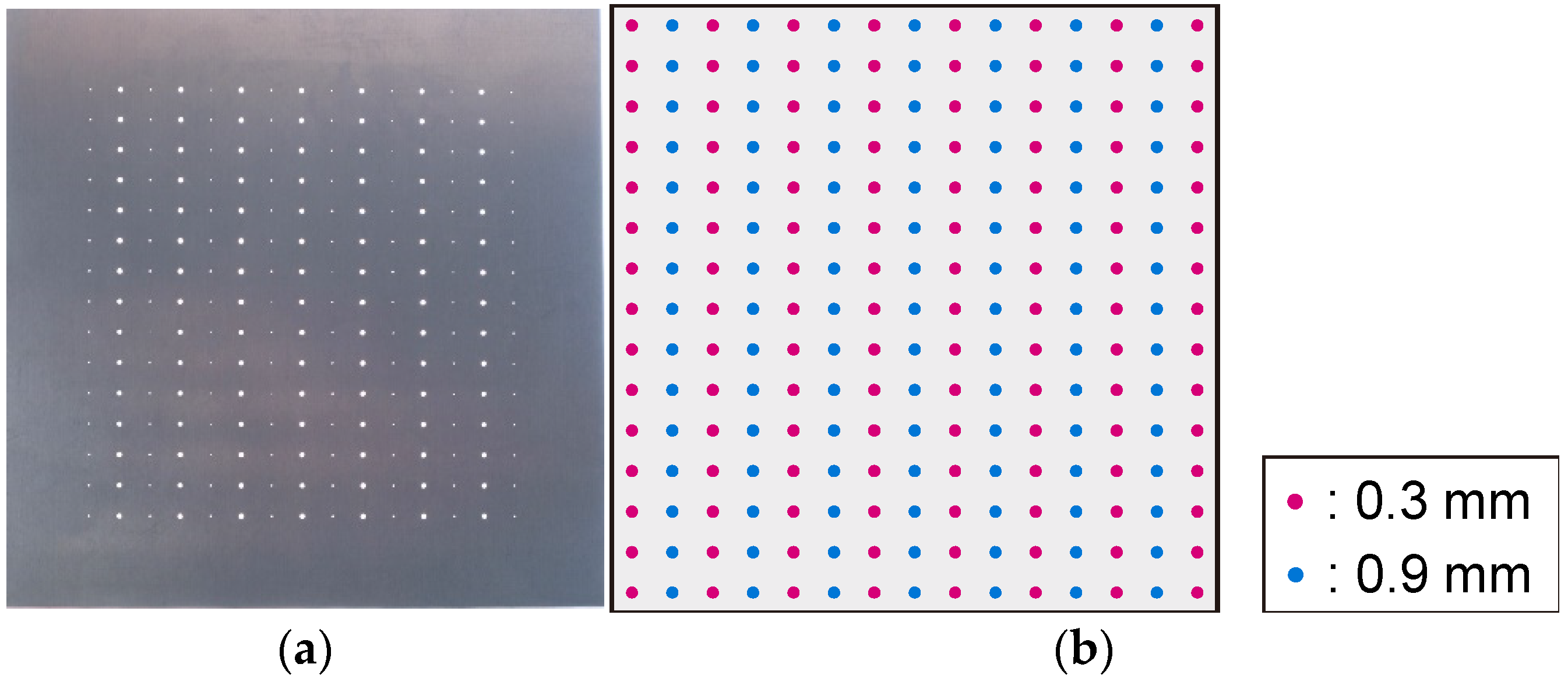

- Specimen (A): An MPP with holes of 0.3 and 0.9 mm in diameter (Figure 1). These two types of holes are placed in alternate rows. The holes are arranged in a row (15 holes per row), but the number of rows is not the same for each diameter. In this case, the number of rows for holes of 0.3 mm diameter was 8 and the number of holes was 120, while the number of rows for holes of 0.9 mm was 7 and the number of holes was 105.

- -

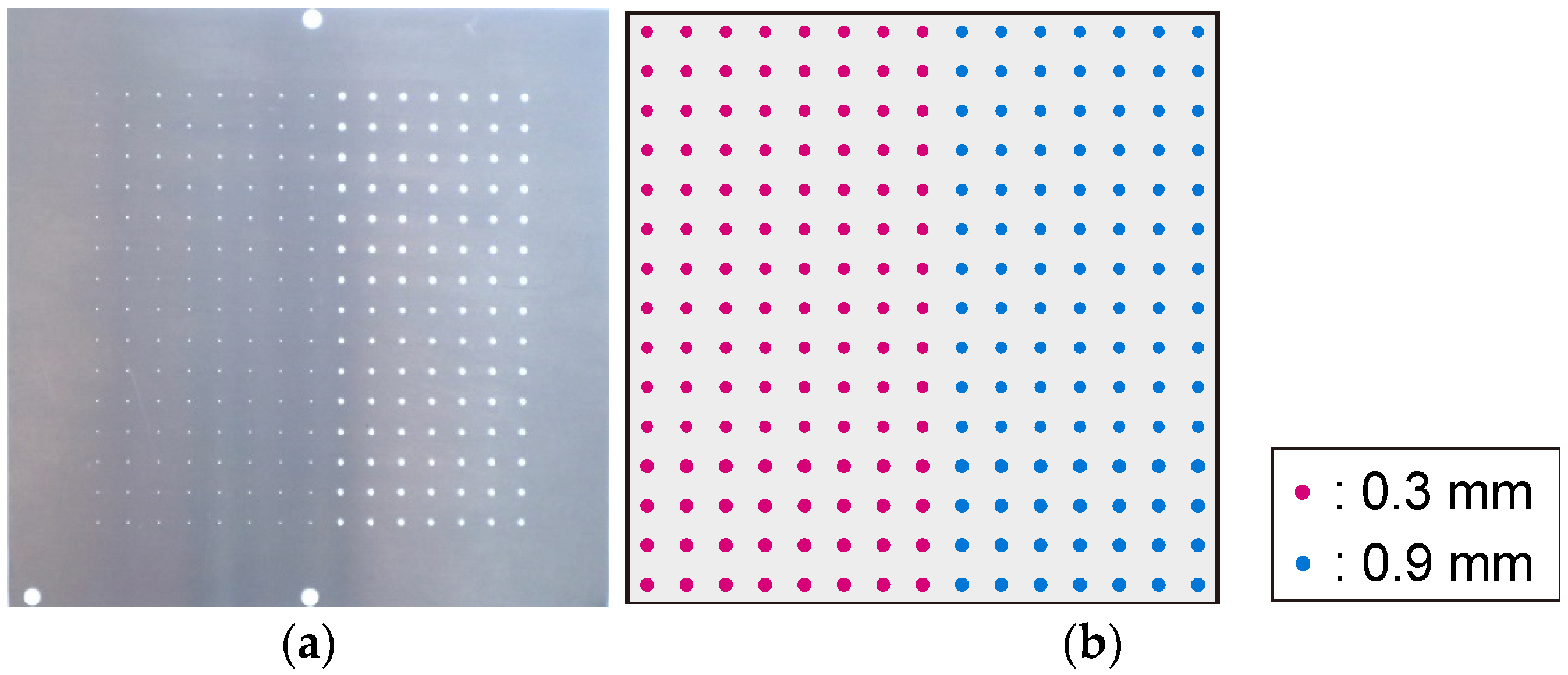

- Specimen (B): An MPP with a 0.3 mm diameter hole and a 0.9 mm diameter hole, arranged separately on the left and right sides (Figure 2). The number of holes for each diameter is the same as for specimen (A).

- -

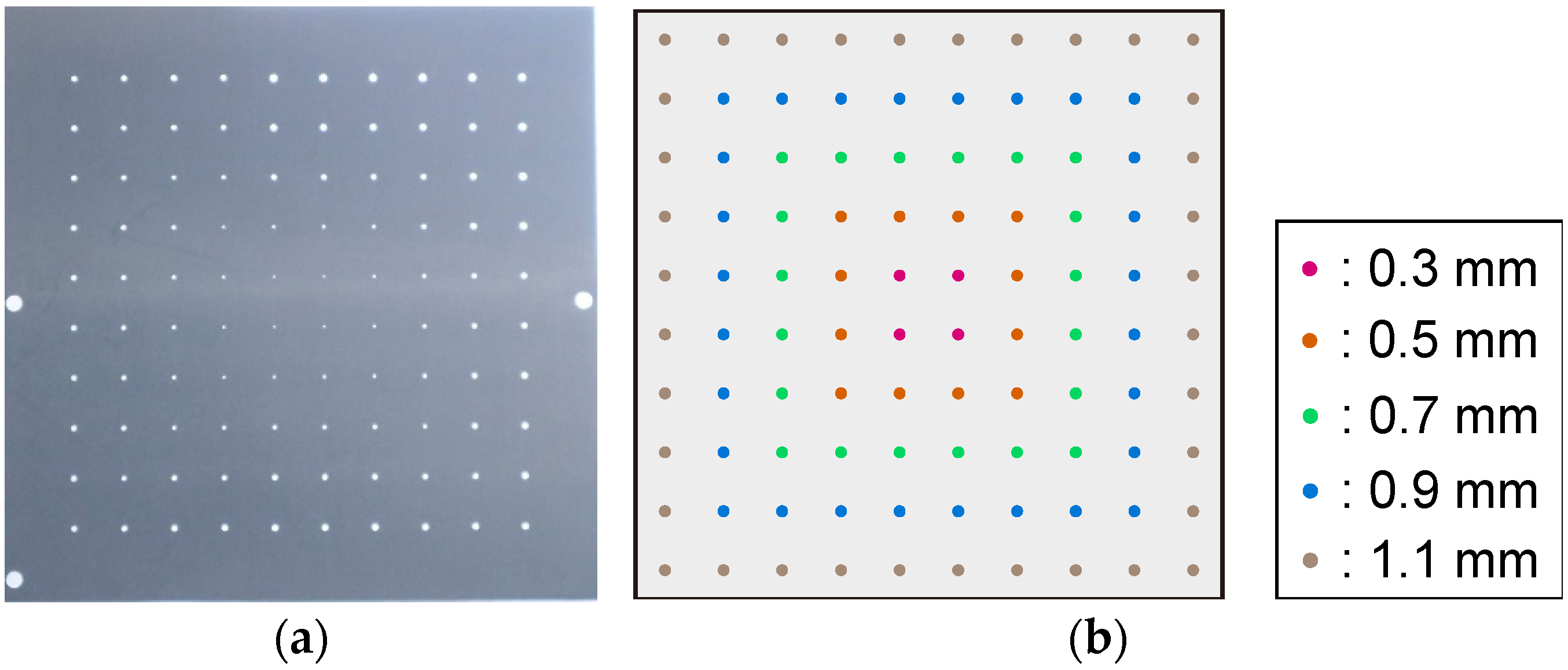

- Specimen (C): An MPP with holes of diameters 0.3, 0.5, 0.7, and 0.9 mm, arranged so as to increase from smallest to largest (Figure 3). The number of rows for each hole diameter is not constant: For the 0.9 mm diameter holes there are 3 rows, whereas for the other diameter holes there are 4. The numbers of the holes are: 60 (0.3, 0.5, 0.7 mm), and 45 (0.9 mm).

- -

- Specimen (D): As shown in Figure 4, specimen (D) consists of five different hole diameters, 0.3, 0.5, 0.7, 0.9, and 1.1 mm, arranged from the center to the periphery, with the diameter increasing as one moves towards the outside. The numbers of the holes are: 4 (0.3 mm), 12 (0.5 mm), 20 (0.7 mm), 28 (0.9 mm), and 36 (1.1 mm).

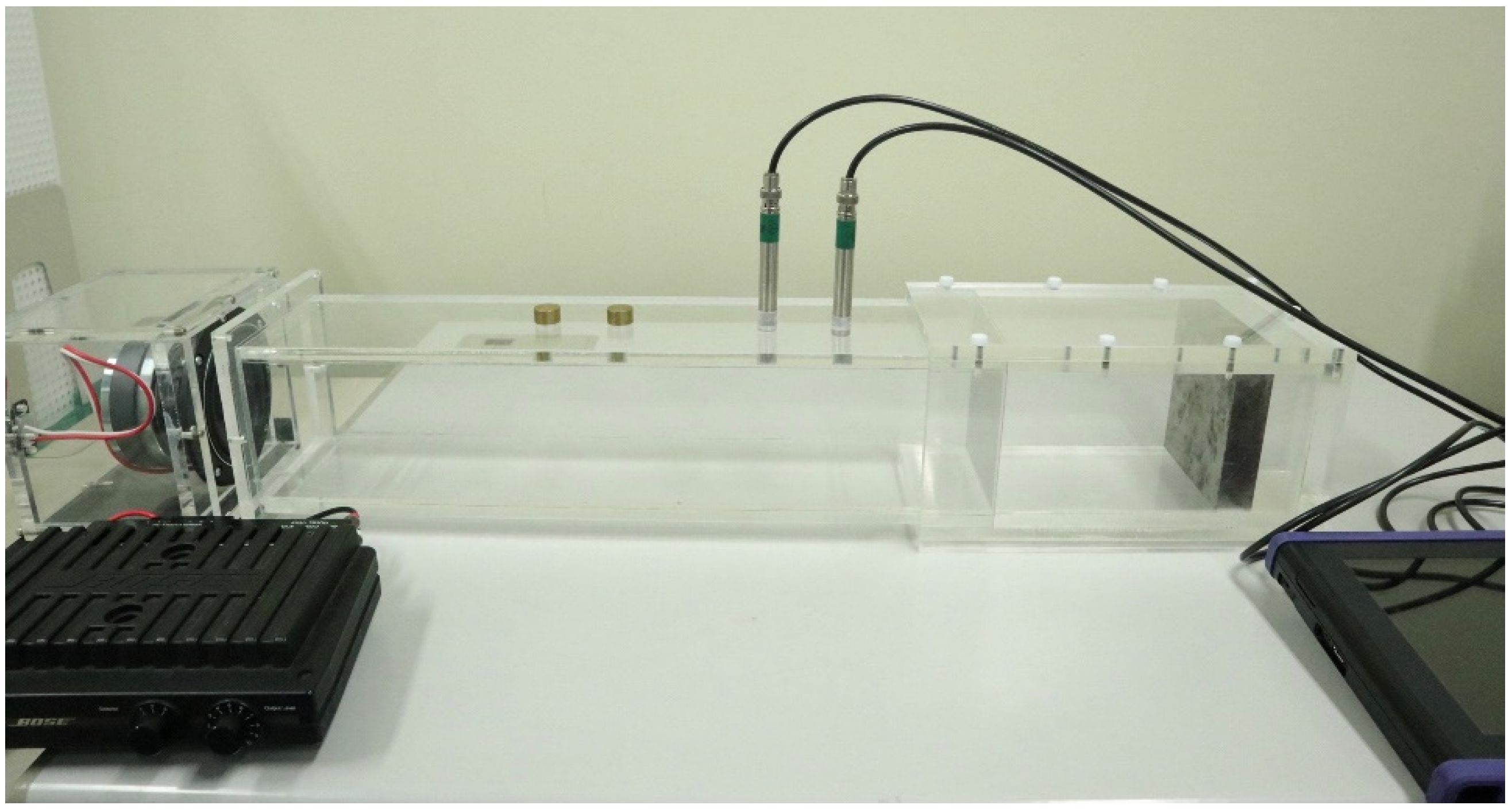

2.2. Measurement Setup

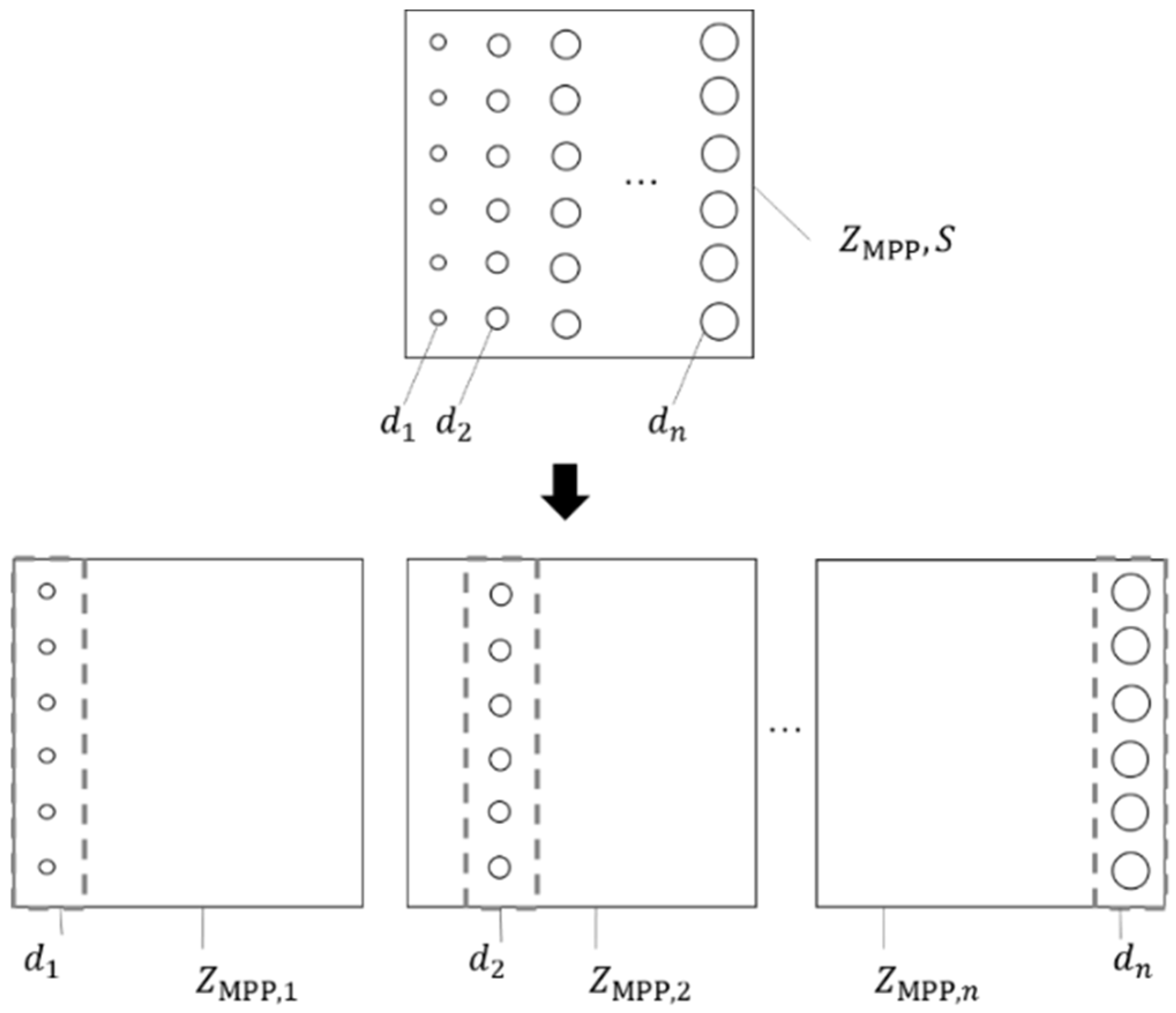

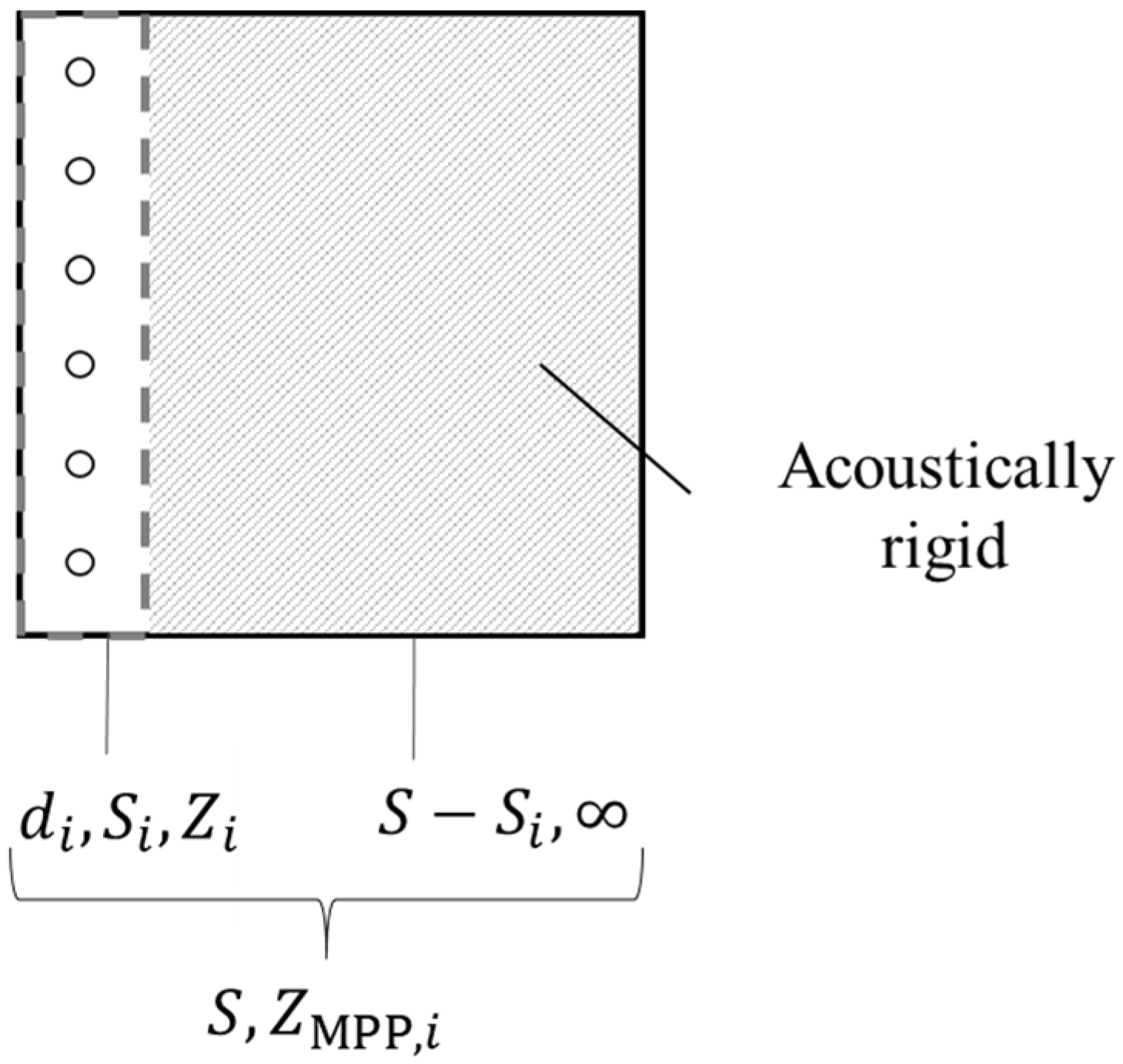

3. Prediction Method

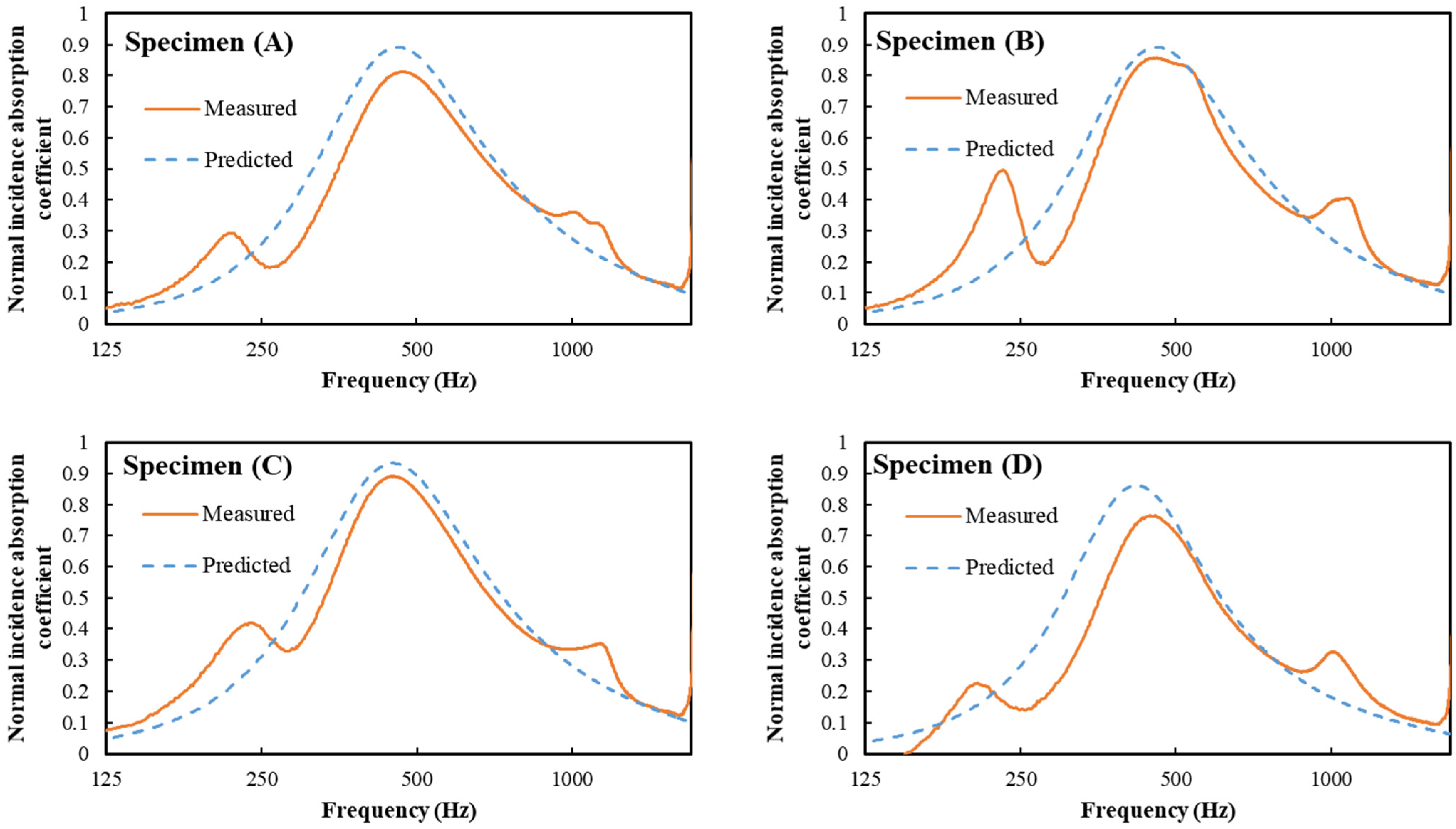

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Outline of Guo’s Theory

References

- Maa, D.Y. Theory and design of microperforated panel sound-absorbing constructions. Sci. Sin. 1975, 17, 55–71. [Google Scholar]

- Maa, D.Y. Microperforated-panel wideband absorbers. Noise Control Eng. J. 1987, 29, 77–84. [Google Scholar] [CrossRef]

- Maa, D.Y. Potential of microperforated panel absorber. J. Acoust. Soc. Am. 1998, 104, 2861–2866. [Google Scholar] [CrossRef]

- Kang, J.; Fuchs, H.V. Predicting absorption of open weave textiles and micro-perforated membranes backed by an air space. J. Sound. Vib. 1999, 220, 905–920. [Google Scholar] [CrossRef]

- Fuchs, H.V.; Zha, X.; Zhou, X.; Drotleff, H. Creating low-noise environments in communication rooms. Appl. Acoust. 2001, 62, 1375–1396. [Google Scholar] [CrossRef]

- Zha, X.; Fuchs, H.V.; Drotleff, H. Improving the acoustic working conditions for musicians in small spaces. Appl. Acoust. 2002, 63, 203–221. [Google Scholar] [CrossRef]

- Herrin, D.; Liu, J.; Seybert, A. Properties and applications of microperforated panel. Sound Vib. 2011, 45, 6–9. [Google Scholar]

- Herrin, D. A guide to the applications of microperforated panel absorbers. Sound Vib. 2017, 51, 12–18. [Google Scholar]

- Adams, T. Sound Materials: A Compendium of Sound Absorbing Materials for Architecture and Design; Frame Pub: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Guo, Y.; Allam, S.; Abom, M. Micro-perforated plates for vehicle applications. In Proceedings of the Inter-Noise 2008, Shanghai, China, 26–29 October 2008. [Google Scholar]

- Sakagami, K.; Nagayama, Y.; Morimoto, M.; Yairi, M. Pilot study on wideband sound absorber obtained by combination of two different microperforated panel (MPP) absorbers. Acoust. Sci. Technol. 2009, 30, 154–156. [Google Scholar] [CrossRef] [Green Version]

- Yairi, M.; Sakagami, K.; Takebayashi, K.; Morimoto, M. Excess sound absorption at normal incidence by two microperforated panel absorbers with different impedance. Acoust. Sci. Technol. 2011, 32, 194–200. [Google Scholar] [CrossRef] [Green Version]

- Mosa, A.I.; Putra, A.; Ramlan, R.; Esraa, A. Wideband sound absorption of a double-layer microperforated panel with in-homogeneous perforation. Appl. Acoust. 2020, 161, 107167. [Google Scholar] [CrossRef]

- Carbajo, J.; Ramis, l.; Godinho, L.; Amado-Mendes, P. Assessment of methods to study the acoustic properties of heterogene-ous perforated panel absorbers. Appl. Acoust. 2018, 133, 1–7. [Google Scholar] [CrossRef]

- Pan, L.; Martellotta, F. A parametric study of the acoustic performance of resonant absorbers made of micro-perforated membranes and perforated panels. Appl. Sci. 2020, 10, 1581. [Google Scholar] [CrossRef] [Green Version]

- Sakagami, K.; Kusaka, M.; Okuzono, T.; Nakanishi, S. The effect of deviation due to the manufacturing accuracy in the pa-rameters of an MPP on its acoustic properties: Trial production of MPPs of different hole shapes using 3D printing. Acoustics 2020, 2, 605–616. [Google Scholar] [CrossRef]

- Liu, Z.; Zhan, J.; Fard, M.; Davy, J.L. Acoustic properties of multilayer sound absorbers with a 3D printed micro-perforated panel. Appl. Acoust. 2017, 121, 25–32. [Google Scholar] [CrossRef]

- Boulvert, J.; Costa-Baptista, J.; Cavalier, T.; Perna, M.; Fosting, E.R.; Romero-Garcia, V.; Ross, A.; Mardjono, J.; Groby, J.-P. Acoustic modelling of micro-lattice obtained by additive manufacturing. Appl. Acoust. 2020, 164, 107244. [Google Scholar] [CrossRef] [Green Version]

- Nakanishi, S. Sound absorption of Helmholtz resonator included a winding built-in neck extension. In Proceedings of the Inter-Noise 2016, Hamburg, Germany, 21–24 August 2016. [Google Scholar]

- Sakagami, K.; Kusaka, M.; Okuzono, T.; Kido, S.; Yamaguchi, D. Application of Transparent Microperforated Panel to Acrylic Partitions for Desktop Use: A Case Study by Prototyping. 2021, 1. UCL Open: Environment Preprint. Available online: https://ucl.scienceopen.com/document?vid=42d011c5-c09b-41ac-a124-8c5a8803cc44 (accessed on 5 July 2021).

- JIS A 1405-2: 2007. Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method; JIS: Tokyo, Japan, 2007. [Google Scholar]

- ISO 10534-2:1998. Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method; ISO: Geneva, Switzerland, 1998. [Google Scholar]

- Bolton, J.S.; Kim, N. Use of CFD to calculate the dynamic resistive end correction for microperforated materials with tapered holes. Acoust. Aust. 2010, 38, 134–144. [Google Scholar]

- Herdtle, T.; Bolton, J.S.; Kim, N.; Alexander, J.H.; Gardes, R.W. Transfer impedance of microperforated materials with tapered holes. J. Acoust. Soc. Am. 2013, 134, 4752–4762. [Google Scholar] [CrossRef]

- Okuzono, T.; Nitta, T.; Sakagami, K. Note on microperforated panel model using equivalent-fluid-based absorption elements. Acoust. Sci. Technol. 2019, 40, 221–224. [Google Scholar] [CrossRef] [Green Version]

| Specimens | Parameters | ||

|---|---|---|---|

| Hole Diameters (mm) | Perforation Ratio (%) | Thickness (mm) | |

| Specimen (A) | 0.3/0.9 | 0.753 | 0.5 |

| Specimen (B) | 0.3/0.9 | 0.753 | 0.5 |

| Specimen (C) | 0.3/0.5/0.7/0.9 | 0.677 | 0.5 |

| Specimen (D) | 0.3/0.5/0.7/0.9/1.1 | 0.624 | 0.5 |

| Thickness of Air Cavity | MPP Specimens | ||||

|---|---|---|---|---|---|

| Specimen (A) | Specimen (B) | Specimen (C) | Specimen (D) | Homogeneous MPP | |

| 25 mm | 0.03996 | 0.07254 | 0.03492 | 0.13020 | 0.05439 |

| 50 mm | 0.02710 | 0.09156 | 0.02632 | 0.09570 | 0.04160 |

| 75 mm | 0.06945 | 0.08251 | 0.06705 | 0.09218 | 0.03386 |

| Parameters | |||

|---|---|---|---|

| Hole Diameter (mm) | Perforation Ratio (%) | Thickness (mm) | |

| Homogeneous MPP | 0.5 | 0.785 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kusaka, M.; Sakagami, K.; Okuzono, T. A Basic Study on the Absorption Properties and Their Prediction of Heterogeneous Micro-Perforated Panels: A Case Study of Micro-Perforated Panels with Heterogeneous Hole Size and Perforation Ratio. Acoustics 2021, 3, 473-484. https://doi.org/10.3390/acoustics3030031

Kusaka M, Sakagami K, Okuzono T. A Basic Study on the Absorption Properties and Their Prediction of Heterogeneous Micro-Perforated Panels: A Case Study of Micro-Perforated Panels with Heterogeneous Hole Size and Perforation Ratio. Acoustics. 2021; 3(3):473-484. https://doi.org/10.3390/acoustics3030031

Chicago/Turabian StyleKusaka, Midori, Kimihiro Sakagami, and Takeshi Okuzono. 2021. "A Basic Study on the Absorption Properties and Their Prediction of Heterogeneous Micro-Perforated Panels: A Case Study of Micro-Perforated Panels with Heterogeneous Hole Size and Perforation Ratio" Acoustics 3, no. 3: 473-484. https://doi.org/10.3390/acoustics3030031

APA StyleKusaka, M., Sakagami, K., & Okuzono, T. (2021). A Basic Study on the Absorption Properties and Their Prediction of Heterogeneous Micro-Perforated Panels: A Case Study of Micro-Perforated Panels with Heterogeneous Hole Size and Perforation Ratio. Acoustics, 3(3), 473-484. https://doi.org/10.3390/acoustics3030031